A kind of beneficiation method of magnetite concentrate to increase iron and reduce silicon

A technology of magnetite concentrate and beneficiation method, which is applied in the fields of iron-lifting and silicon-reducing of high-silicon magnetite concentrate, and iron-lifting and silicon-reducing field of high-silicon magnetite concentrate, can solve the problem of large water consumption, unfavorable mineral processing process, stable production, The problem of difficult operation, etc., can achieve the effect of realizing particle size classification, reducing the amount of regrinding and the number of flotation operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the present invention, a beneficiation method for increasing iron and reducing silicon from magnetite concentrate of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

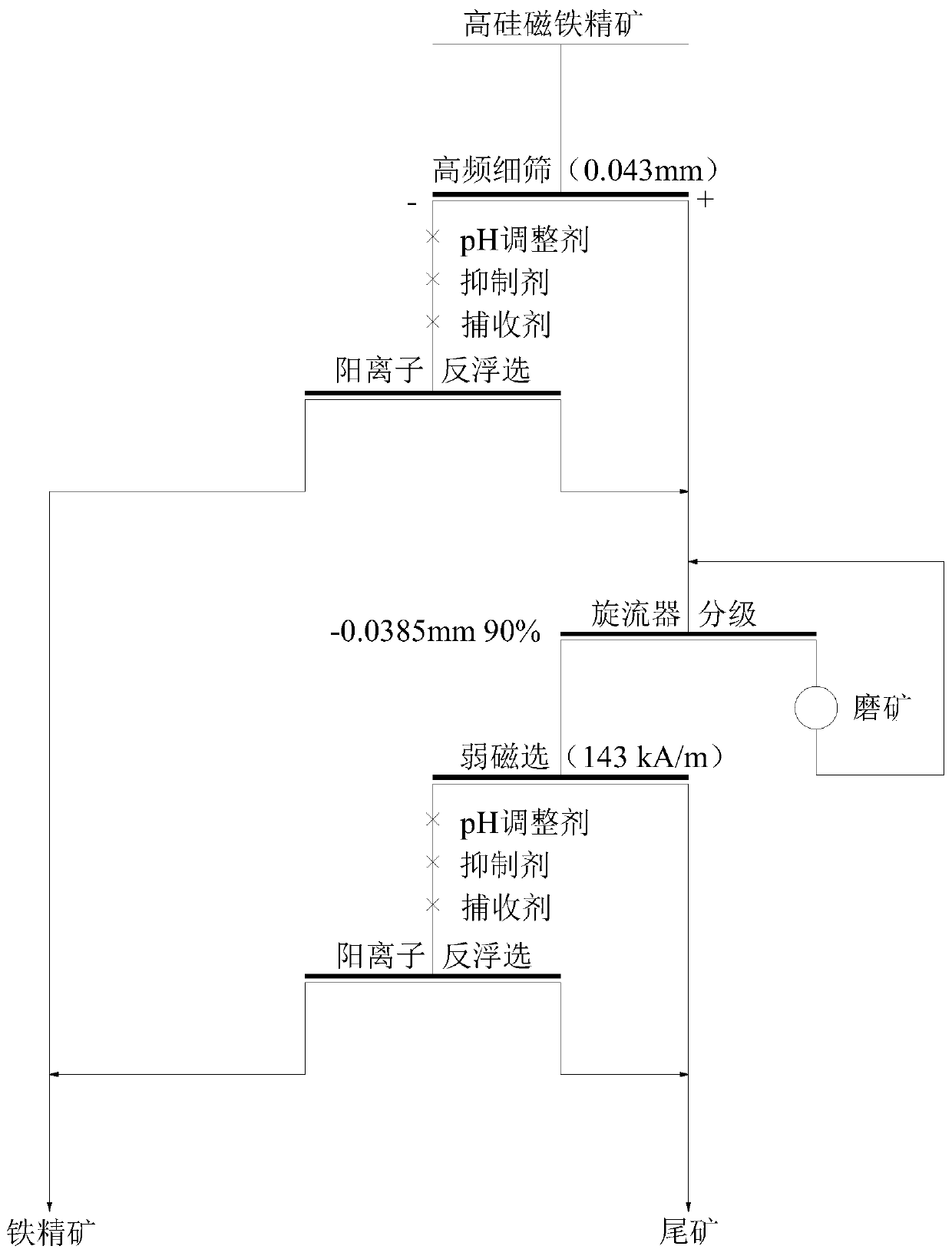

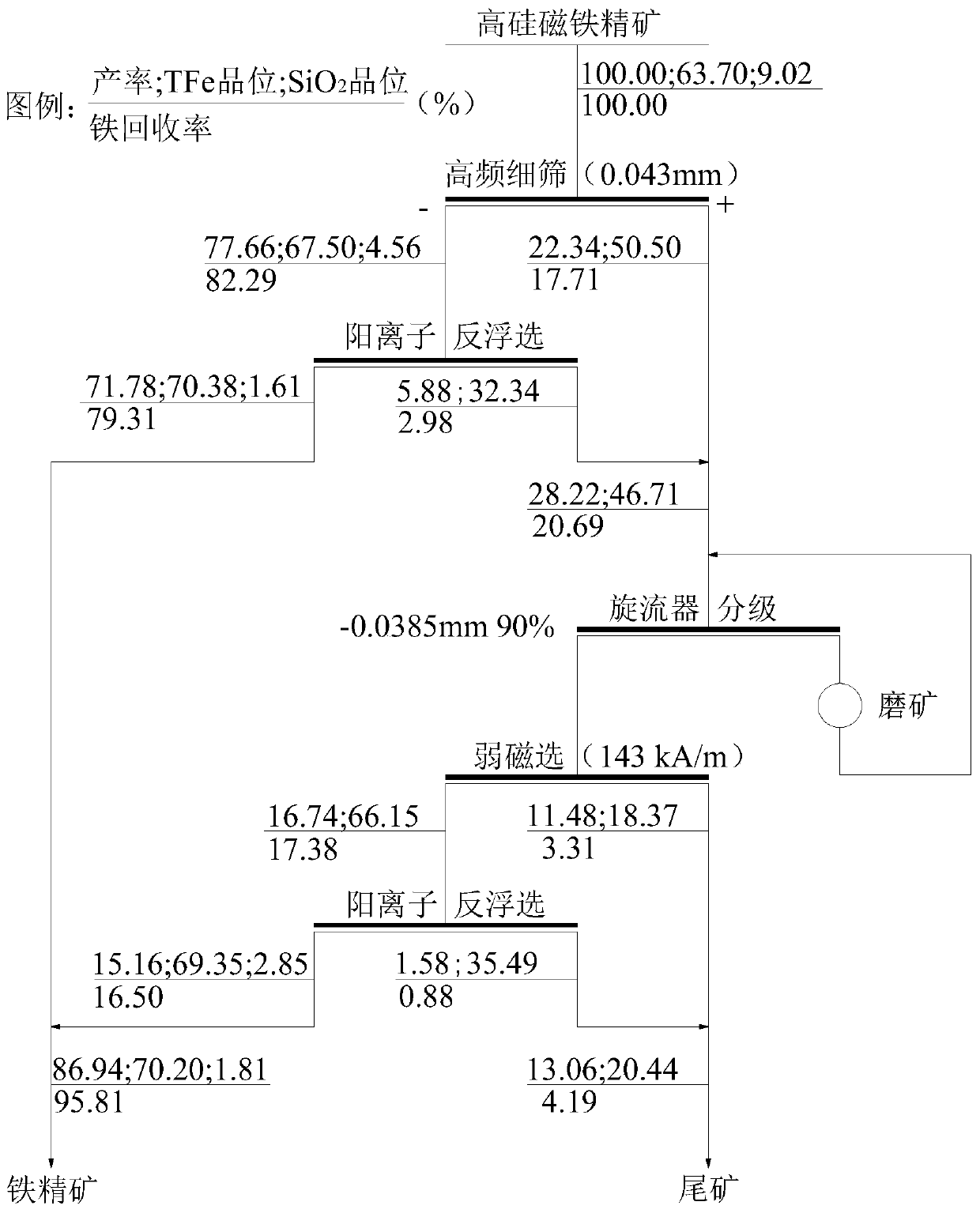

[0027] Depend on figure 1 The principle process flow diagram of the ore dressing method of a kind of magnetite concentrate of the present invention raising iron and reducing silicon as shown finds out that a kind of magnetite concentrate of the present invention raises iron and reduces silicon ore dressing method comprises following technology, step:

[0028] 1) High-frequency fine sieve screening of high-silicon magnetite concentrate.

[0029] Iron grade 62.0%-65.0% (SiO 2 The high-silicon magnetite concentrate with a content of 10.5%-6.5%) is sieved by a high-frequency fine sieve to obtain two products under the sieve (TFe 67.50%) and on the sieve.

[0030] The high-frequency fine sieve adopts Derek high-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com