A kind of method for removing heavy metal in fly ash

A technology for fly ash and heavy metals, applied in the field of coal chemical industry, can solve the problems of poor economic benefit, secondary pollution and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

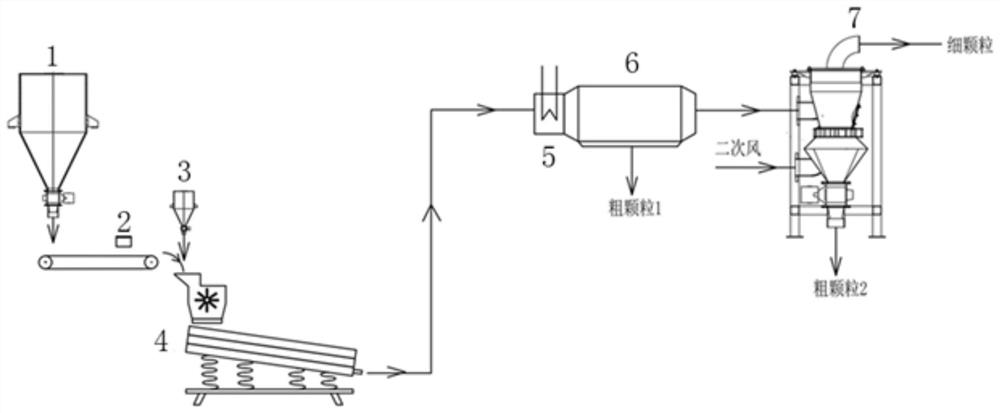

[0052] The fly ash is firstly removed from the iron element by the iron remover, and then 0.02% triethanolamine is added and stirred for 15 minutes, and then the powder is dispersed by vibration. The dispersed powder is heated to 150°C in a heater, and then conveyed to an electrostatic separator by pneumatic force to maintain a flow rate of 1m / s and a flue gas concentration of 90g / Nm 3 . In the electrostatic separator, under the action of 7500V high voltage, the coarse particles in the fly ash are enriched on the electrode plate, and the rapping force is 200g every 60min. The two poles of the electrodes were ripped in turn, and the rapping time was 2 min each time.

[0053] The fly ash in the flue gas enters the centrifugal separator. At this time, the intake air velocity is 1.5m / s, the turbine speed in the primary separation chamber is 1000rpm, and the secondary air component is 1500m 3 / h. After passing through the two-stage separation system, the fine particles leave the...

Embodiment 2

[0056] The fly ash is firstly removed from the iron element through the iron remover, and then 0.05% glycerol is added and stirred for 12 minutes, and then the powder is dispersed by vibration. The dispersed powder is heated to 150°C in a heater, and then transported to an electrostatic separator by pneumatic force to maintain a flow rate of 1.2m / s and a flue gas concentration of 110g / Nm 3 . In the electrostatic separator, under the action of 8500V high voltage, the coarse particles in the fly ash are enriched on the electrode plate, and the rapping force is 360g every 75min. The two poles of the electrode were ripped in turn, and the rapping time was 3.5 min each time.

[0057] The fly ash in the flue gas enters the centrifugal separator. At this time, the intake air velocity is 1.5m / s, the turbine speed in the primary separation chamber is 3200rpm, and the secondary air component is 2000m 3 / h. After passing through the two-stage separation system, the fine particles leav...

Embodiment 3

[0060] The fly ash was firstly removed from the iron element by the iron remover, and then 0.01% stearic acid was added and stirred for 15 minutes, and then the powder was dispersed by vibration. The dispersed powder is heated to 120°C in a heater, and then conveyed to an electrostatic separator by pneumatic force to maintain a flow rate of 1.3m / s and a flue gas concentration of 130g / Nm 3 . In the electrostatic separator, under the action of 8000V high voltage, the coarse particles in the fly ash are enriched on the electrode plate, and the rapping force is 440g every 90min. The two poles of the electrodes were ripped in turn, and the rapping time was 5 min each time.

[0061]The fly ash in the flue gas enters the centrifugal separator. At this time, the intake air velocity is 1.8m / s, the turbine speed in the primary separation chamber is 3200rpm, and the secondary air component is 3500m 3 / h. After passing through the two-stage separation system, the fine particles leave t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com