Patents

Literature

232results about How to "Easy to inhale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

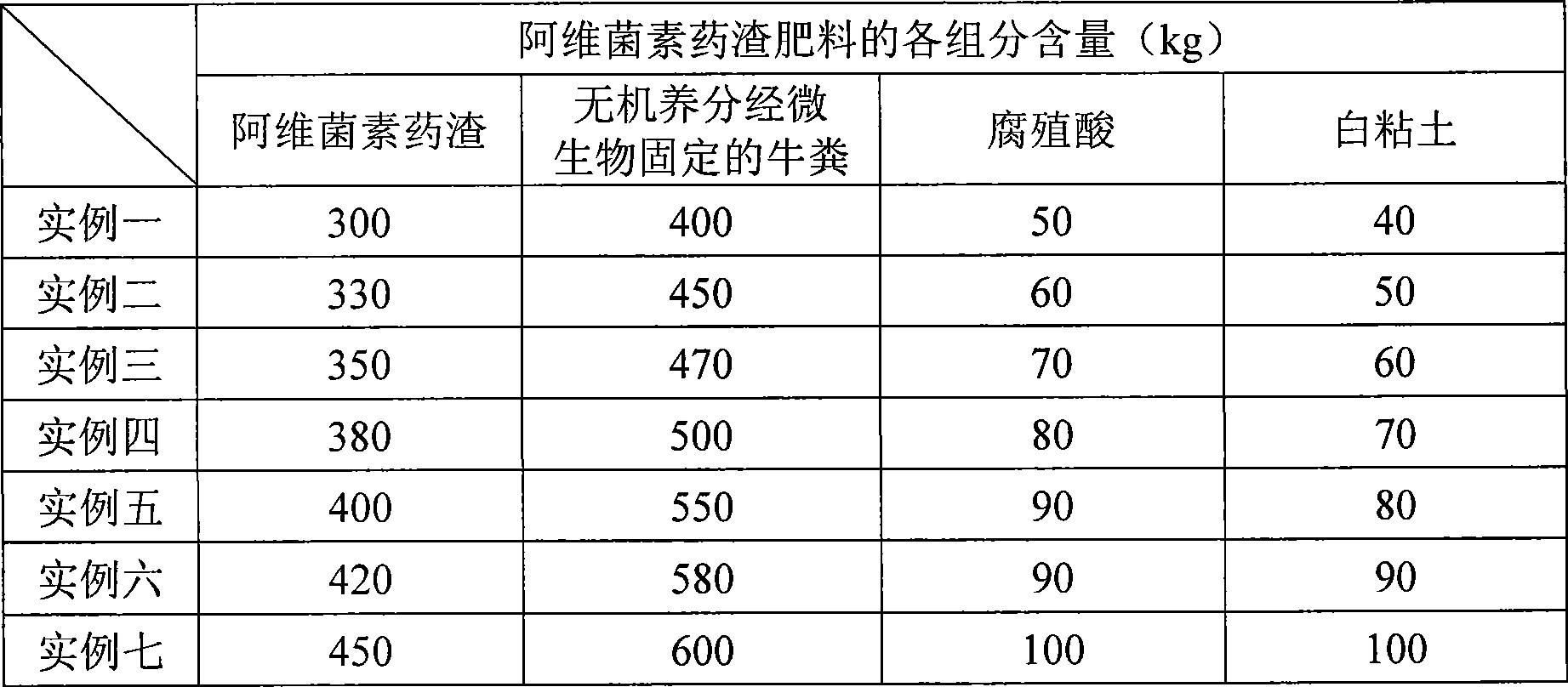

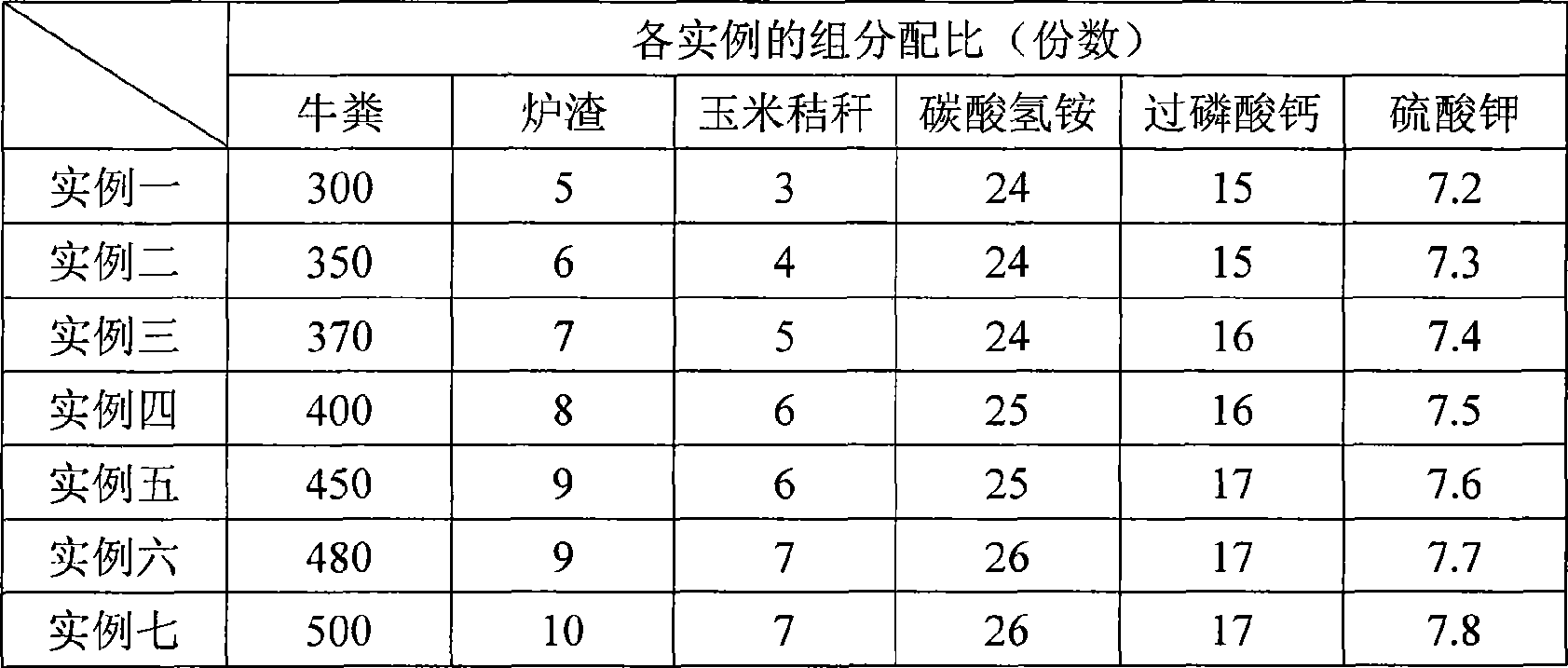

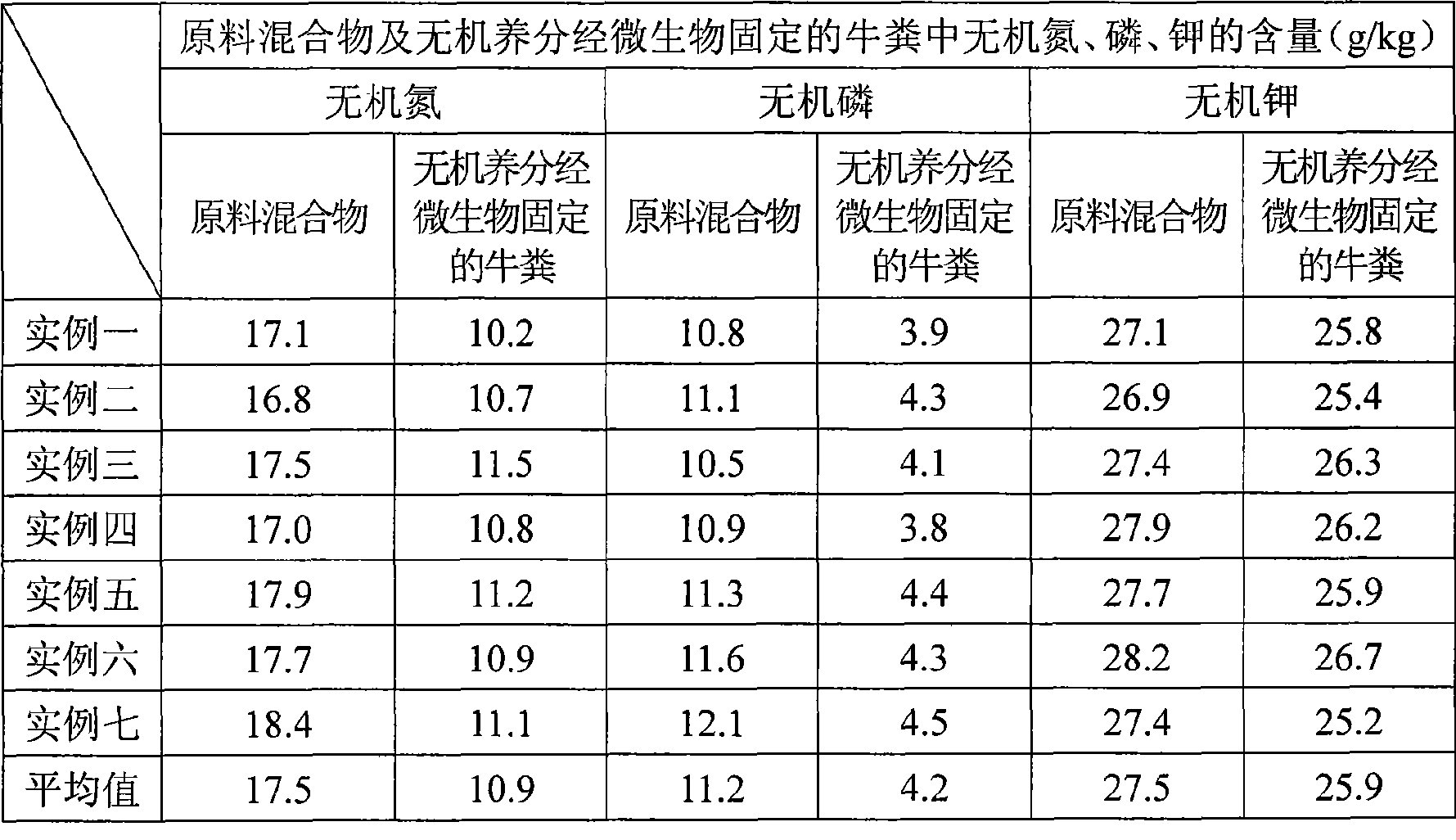

Preparation of avermectin slag fertilizer

InactiveCN101462909AIncrease contentReduce contentBio-organic fraction processingOrganic fertiliser preparationSlagPotassium

The invention relates to a preparation method of abamectin dreg fertilizer; the method solves the problem that: the existing preparation method of the organic fertilizer affects the content of total nitrogen, total phosphorus and total potassium when reducing the content of inorganic nitrogen, phosphorus and potassium in the fertilizer. The preparation method is characterized in that: the preparation method comprises the following steps: (1) dairy manure, slag, maize straw, ammonium hydrogen carbonate and potassium sulphate are uniformly mixed, composted and fermented; after the fermentation is finished, the dairy manure, the inorganic nutrients of which are fixed by microorganisms is obtained; (2) the abamectin dreg is dried to have 40-55% of the water content; (3) the dairy manure, the inorganic nutrients of which are fixed by microorganisms, the abamectin dreg, humic acid and argil are uniformly mixed and are made into particles, thus obtaining the abamectin dreg fertilizer. The method not only can improve the content of total nitrogen, total phosphorus and total potassium in the organic fertilizer, but also can effectively reduce the content of inorganic nitrogen, phosphorus and potassium in the fertilizer simultaneously; therefore, the produced fertilizer has high content of the total nitrogen, the total phosphorus, the total potassium and organic matters.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

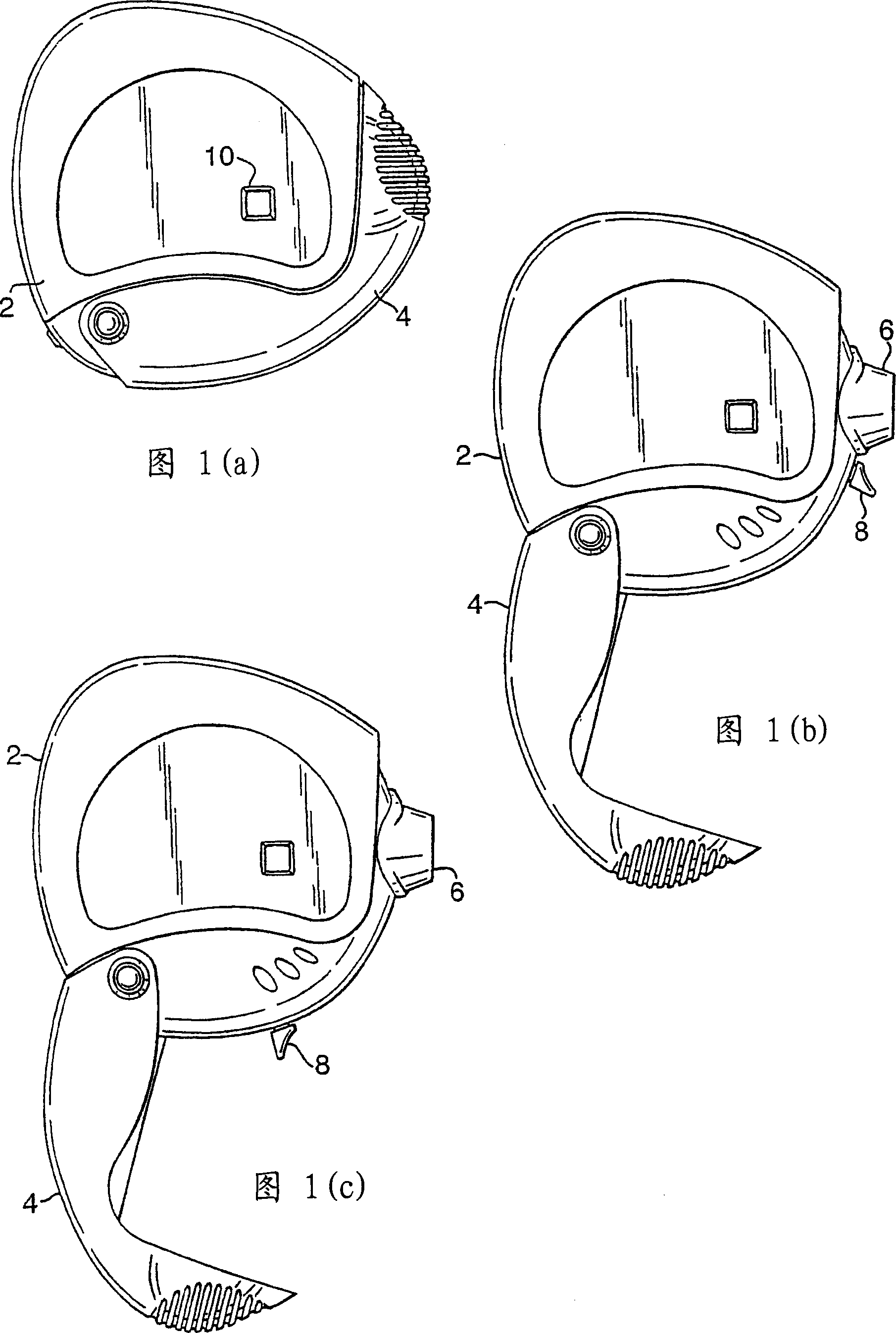

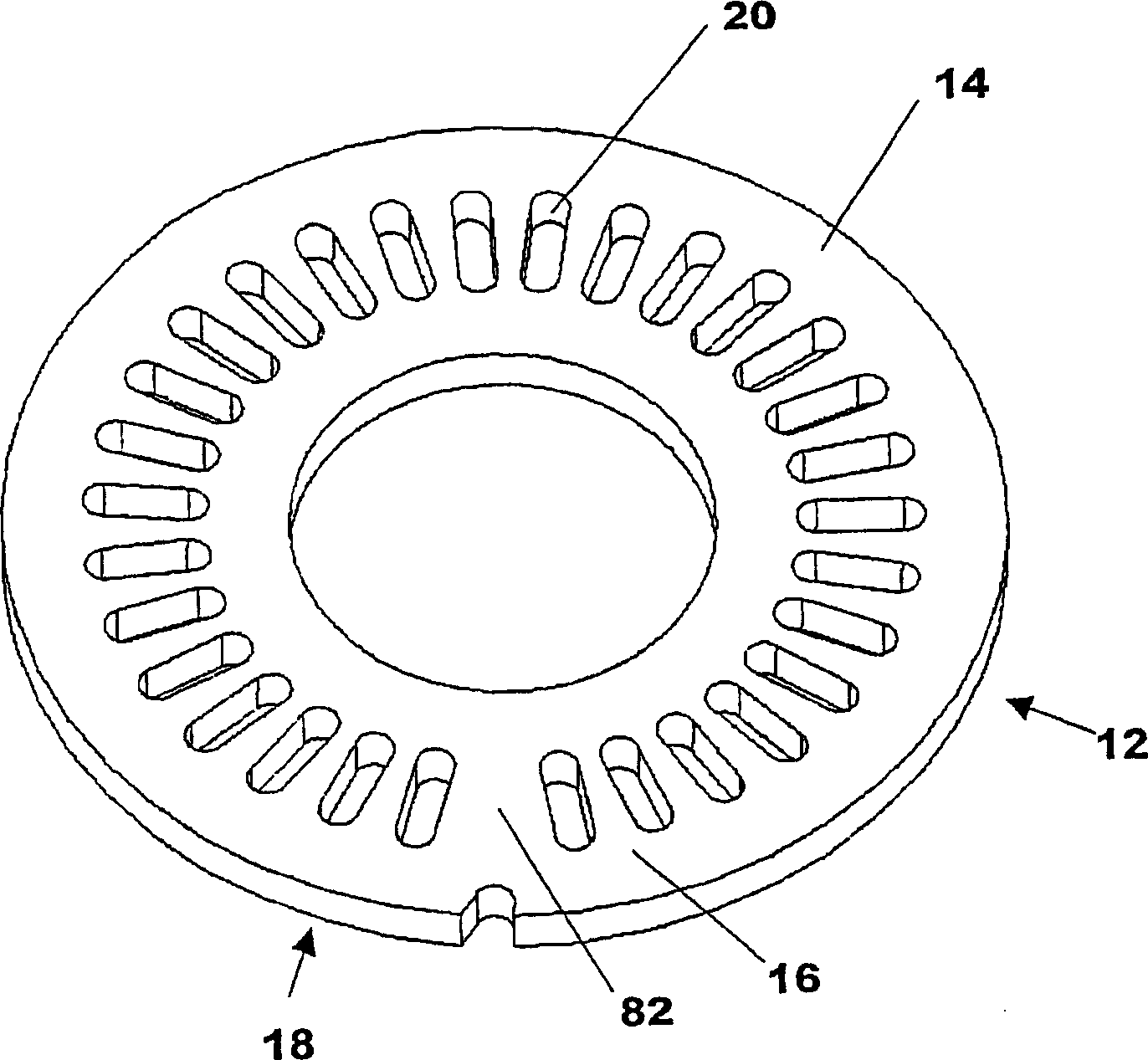

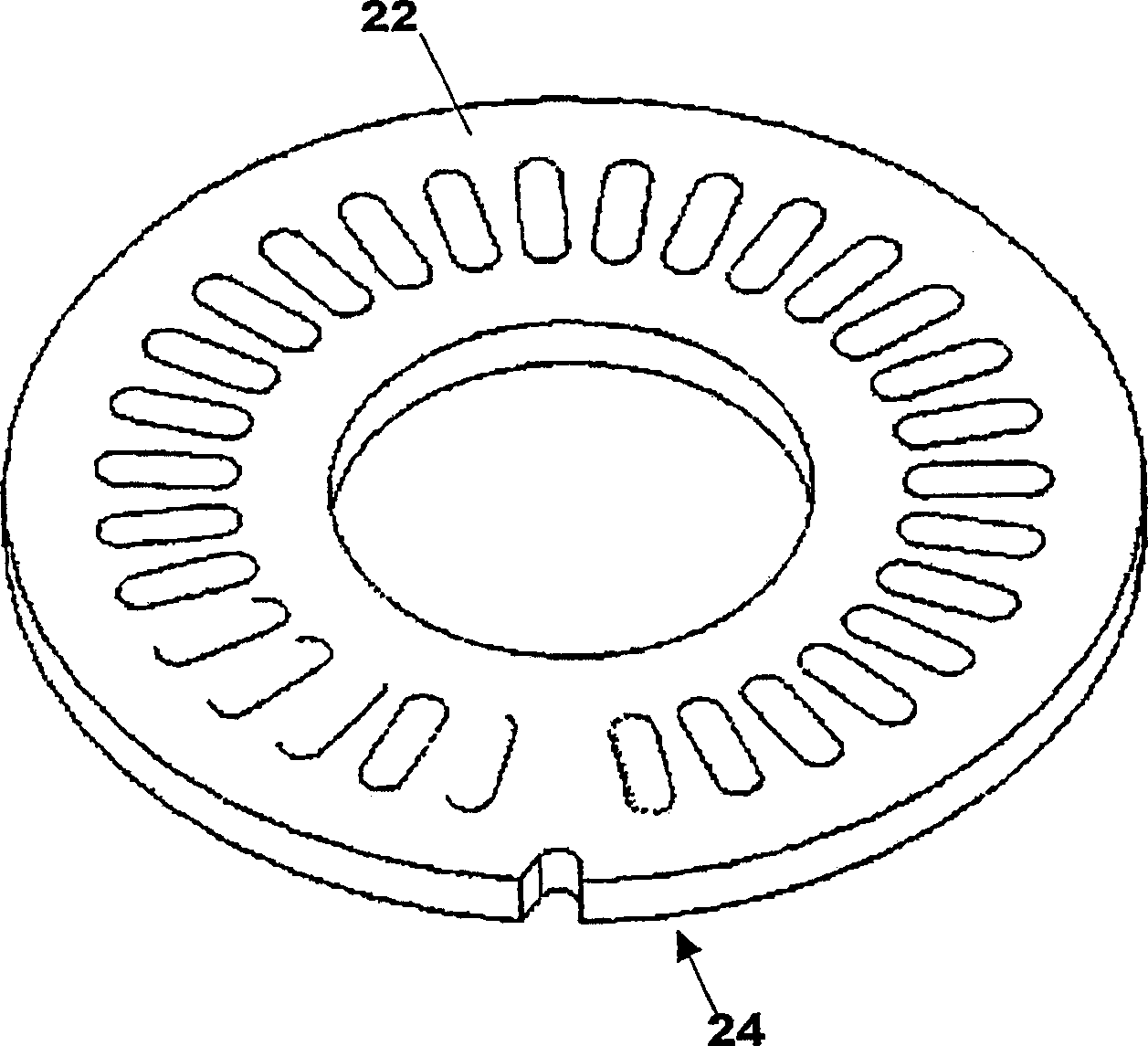

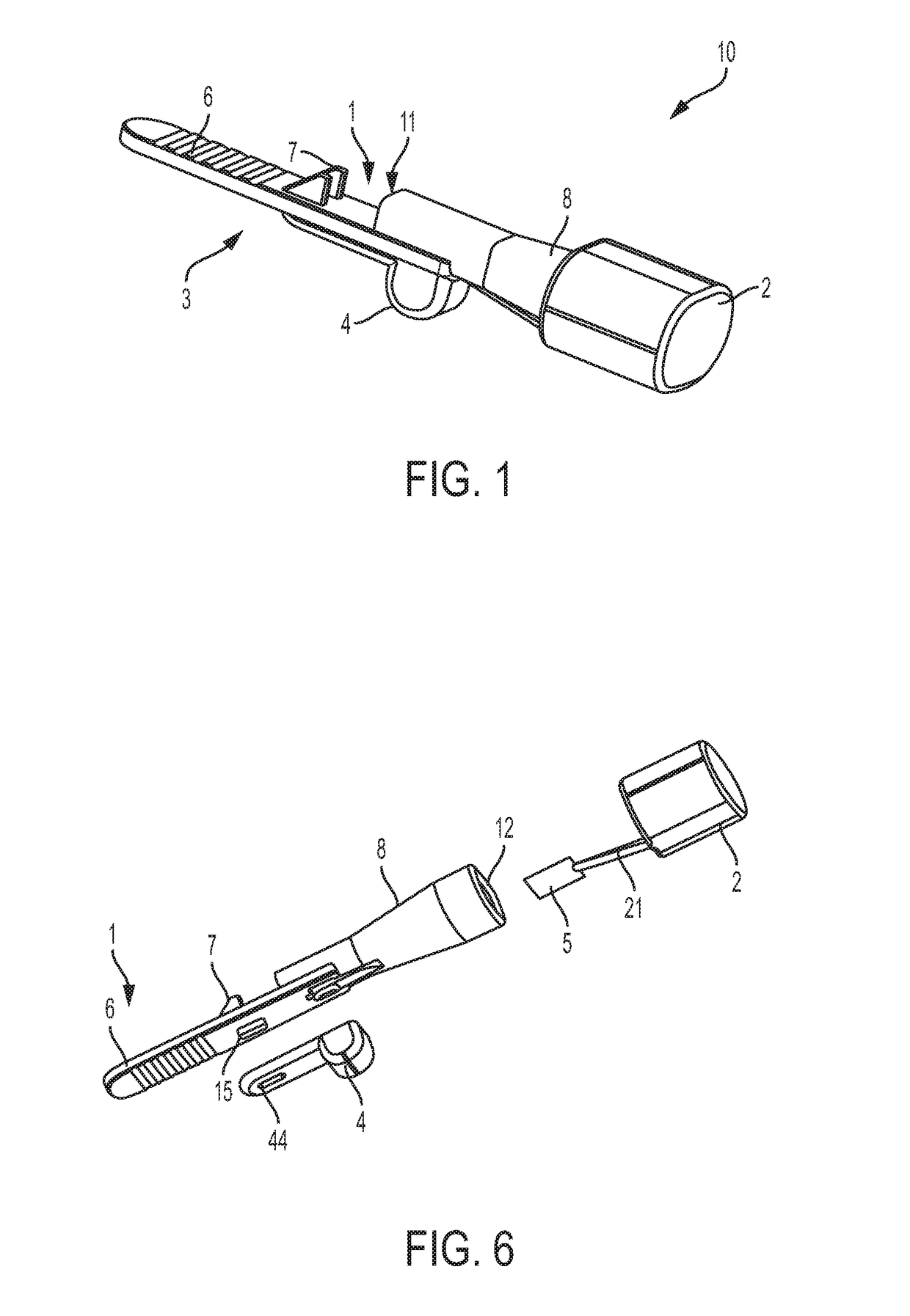

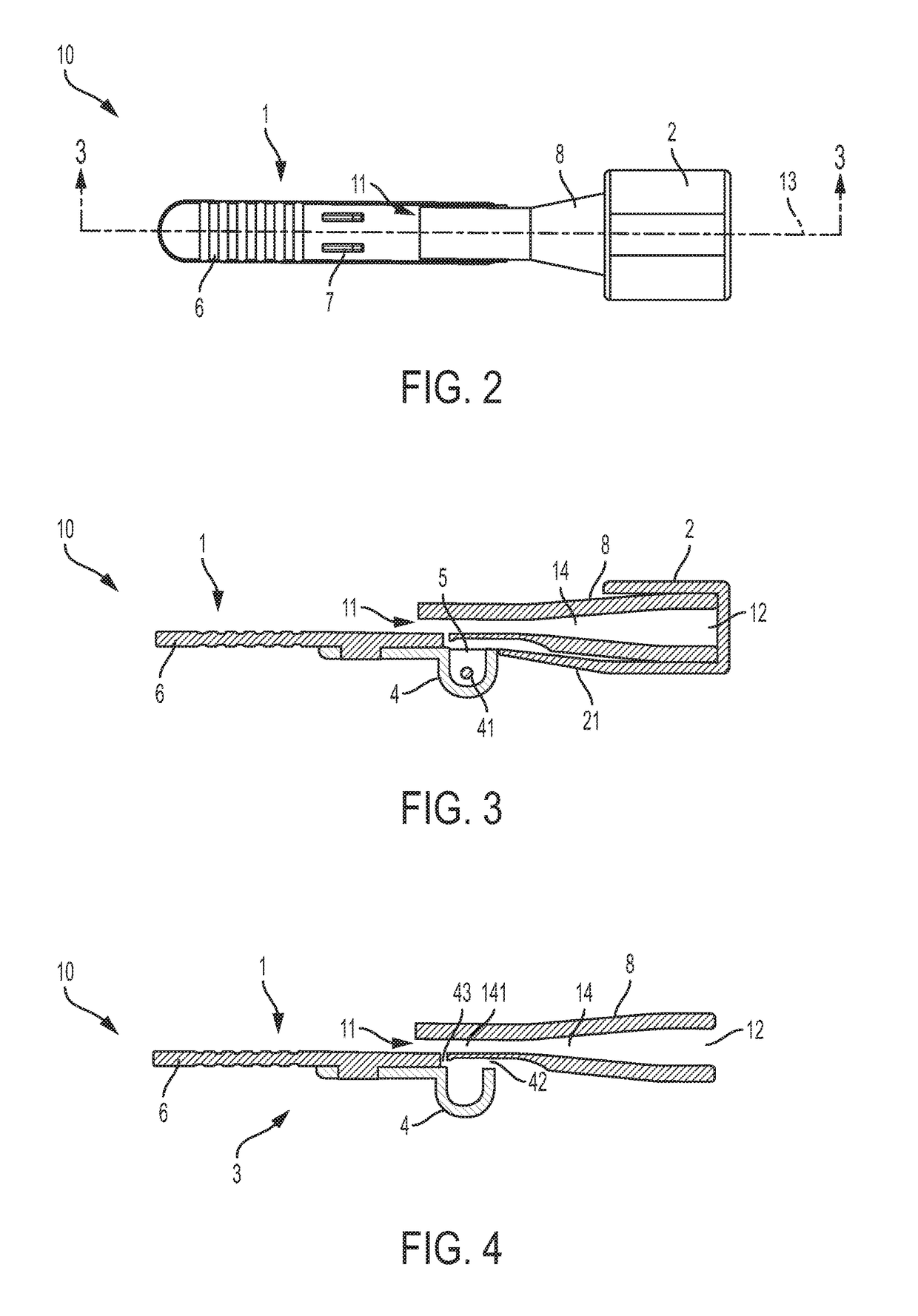

Dispensing device

ActiveCN1871044AReduce hindranceAvoid smallPowdered material dispensingMedical devicesIndividual doseEngineering

A device for dispensing individual doses of powder from respective pockets of a disc-shaped carrier by outwardly rupturing a lidding foil by means of pressure on an opposite side surface, the device providing individual respective deaggregation flow paths for each pocket, split airstreams allowing improved entrainment of powder, a cam mechanism for outwardly rupturing the pockets, an indexing mechanism linked to the cam mechanism and a dose counter.

Owner:PFIZER INC

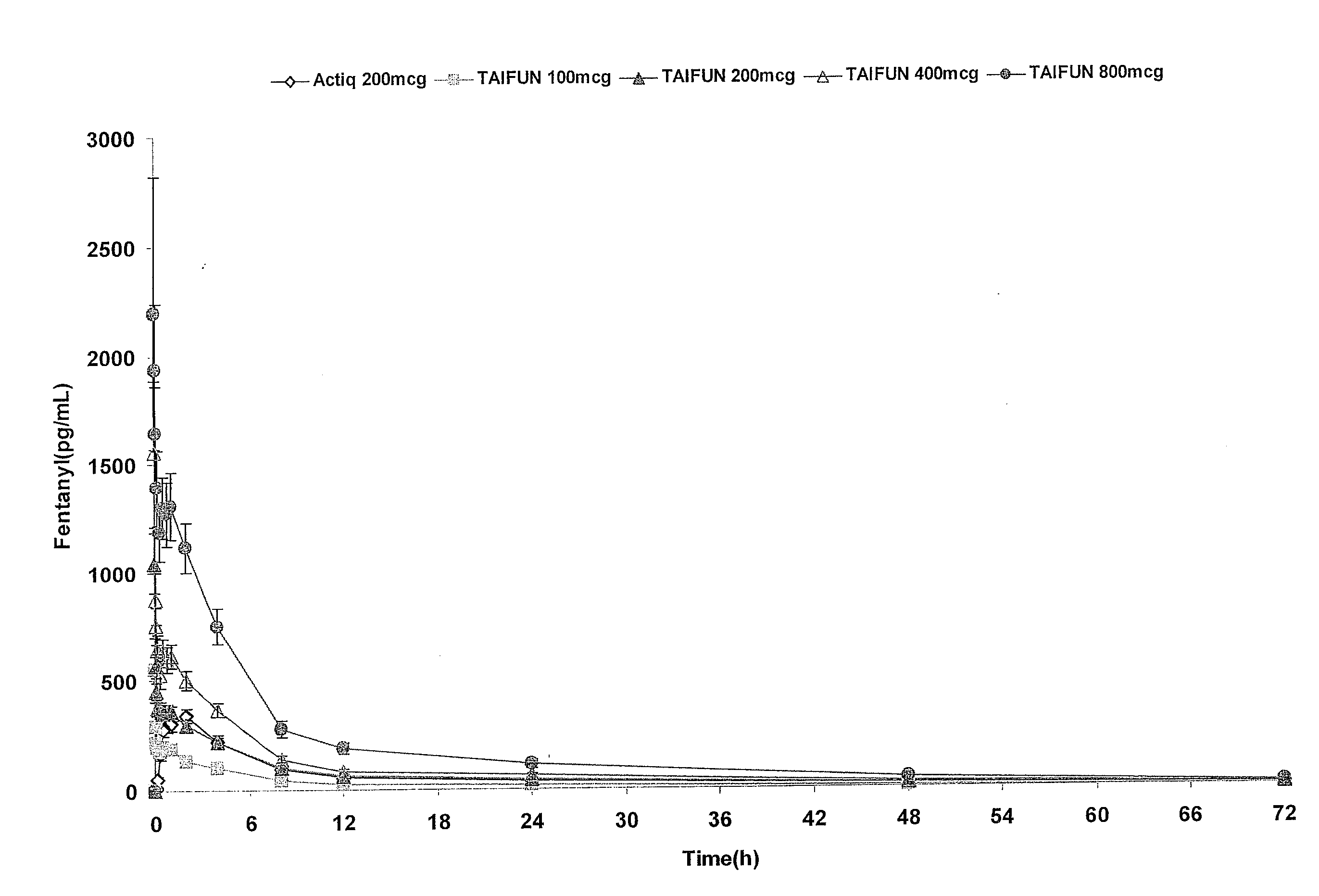

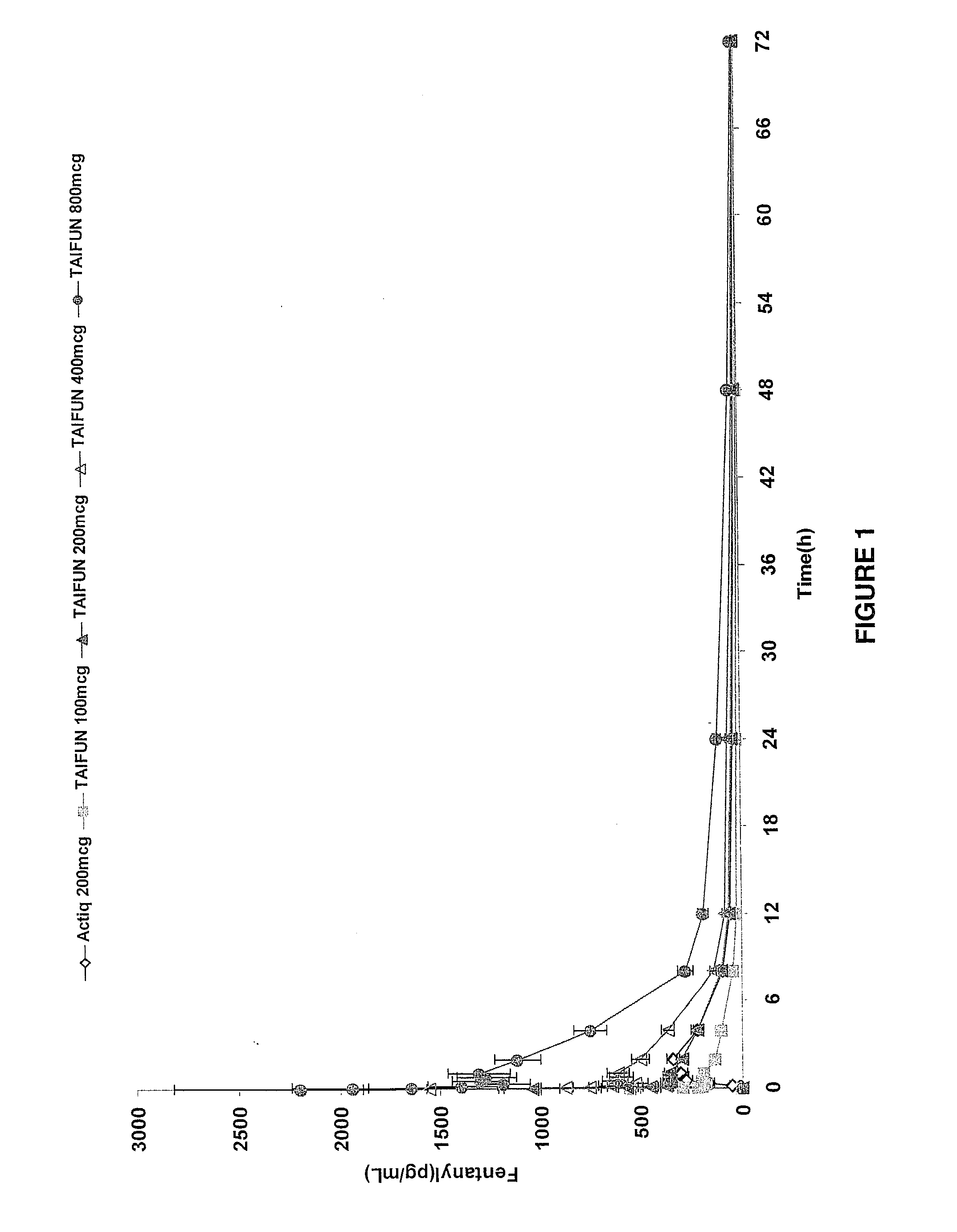

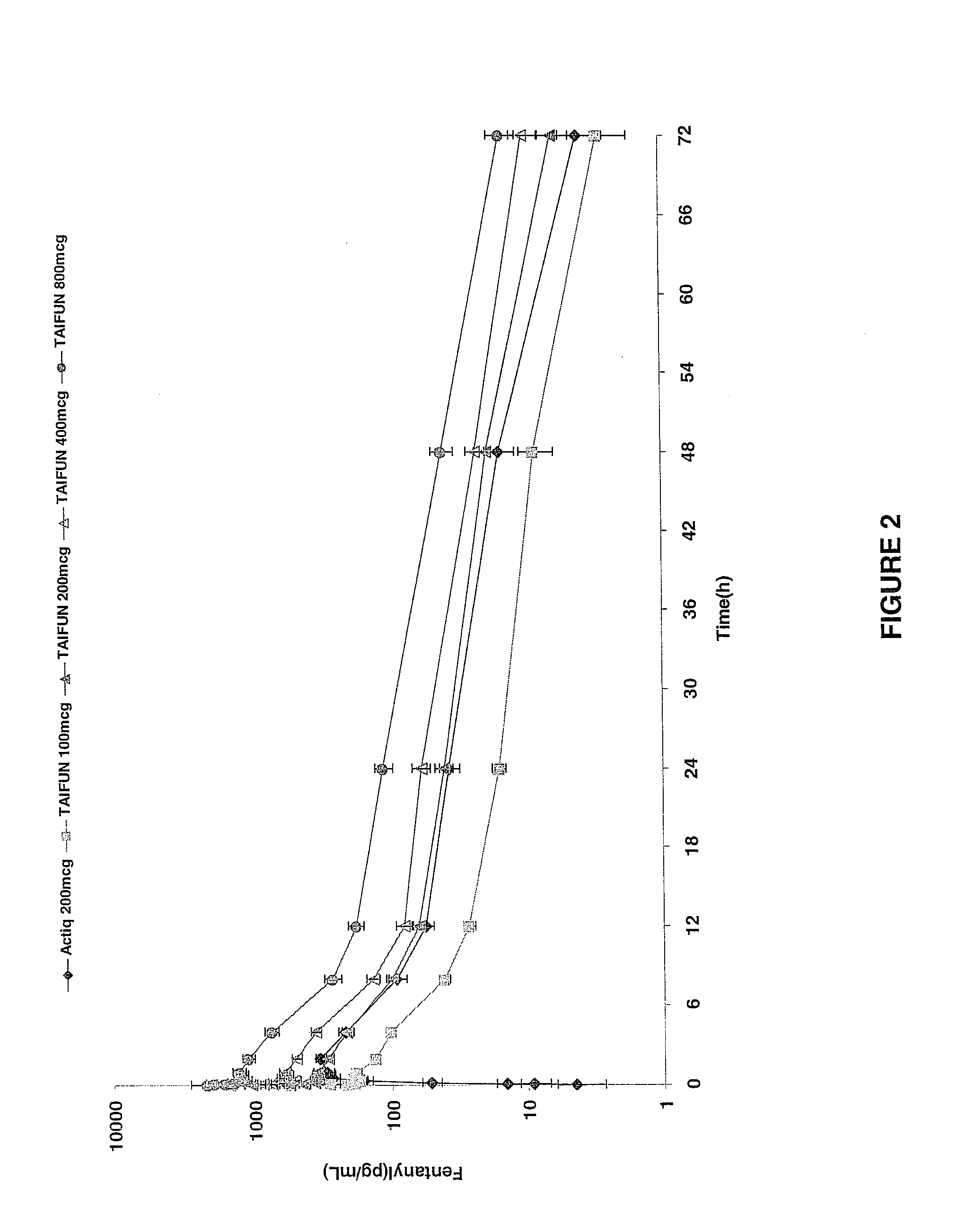

Breakthrough pain management

InactiveUS20090011030A1Treatment and alleviation of painAct quicklyBiocidePowder deliveryPulmonary inhalationFentanyl

The present invention is directed to a powdered formulation comprising an analgesic, preferably fentanyl, for use in pulmonary inhalation administration for the rapid analgesic titration of pain, in particular breakthrough pain. Upon administration, the powdered formulation is able to provide a narrower titration range in patients suffering from pain, as well as effective analgesic amounts of fentanyl in a shorter time and at lower dose levels of administered fentanyl when compared to fentanyl administered by an oral transmucosal route.

Owner:LAB INT

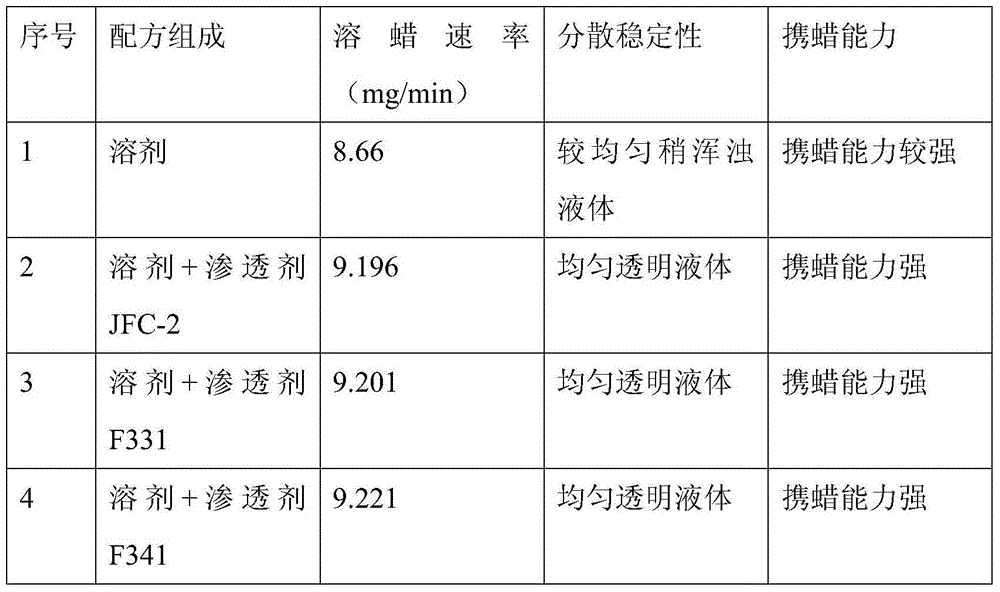

Oil-base paraffin remover for oil wells

The invention provides an oil-base paraffin remover for oil wells, which is composed of aromatic hydrocarbon, saturated alkane, a penetrant and a solubilizer. The paraffin remover is composed of the following components in percentage by volume: 30-45% of aromatic hydrocarbon, 45-65% of saturated alkane, 0.1-1% of penetrant and 1.0-11.0% of solubilizer. The components are mixed by volume and stirred uniformly to obtain the paraffin remover. The density is 0.8-0.9 g / cm<3>; the paraffin dissolution rate is greater than 20mg / minute; the paraffin remover is free of sulfur and chlorine; the open flash point is greater than 40 DEG C; and the solidifying point is lower than -60 DEG C. The paraffin remover has the advantages of high flash point, high paraffin dissolution rate, environment friendliness and low toxicity, and well solves the problem of balance between the paraffin removal product rate and the environment friendliness and safety.

Owner:CHINA PETROLEUM & CHEM CORP +2

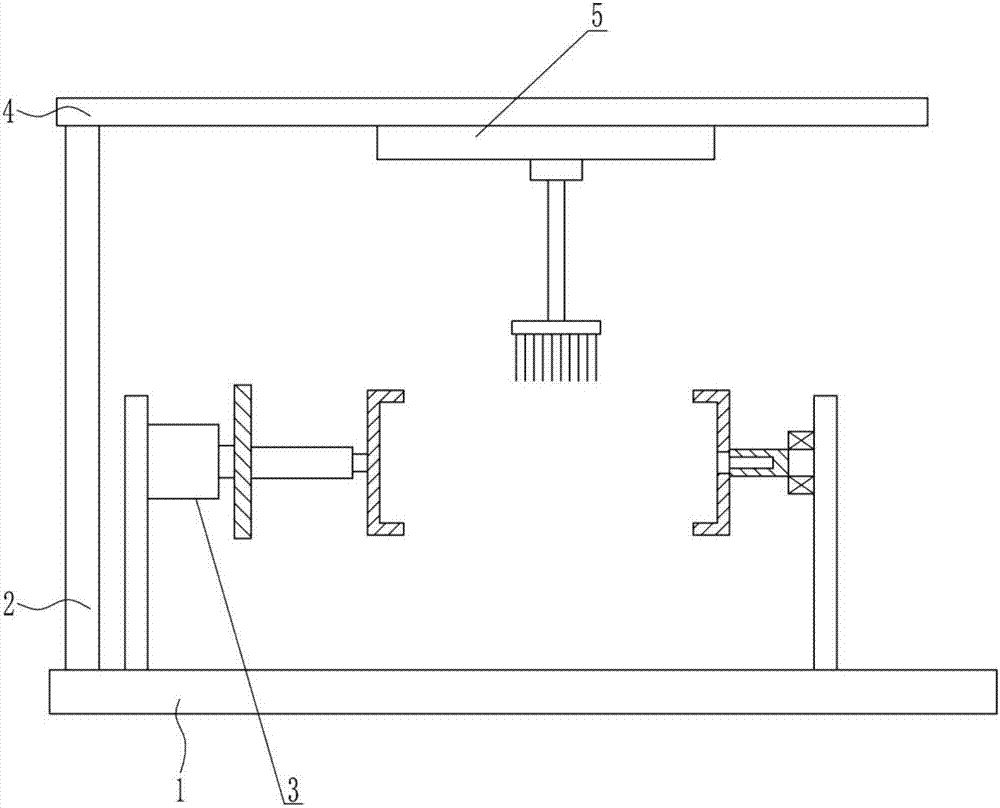

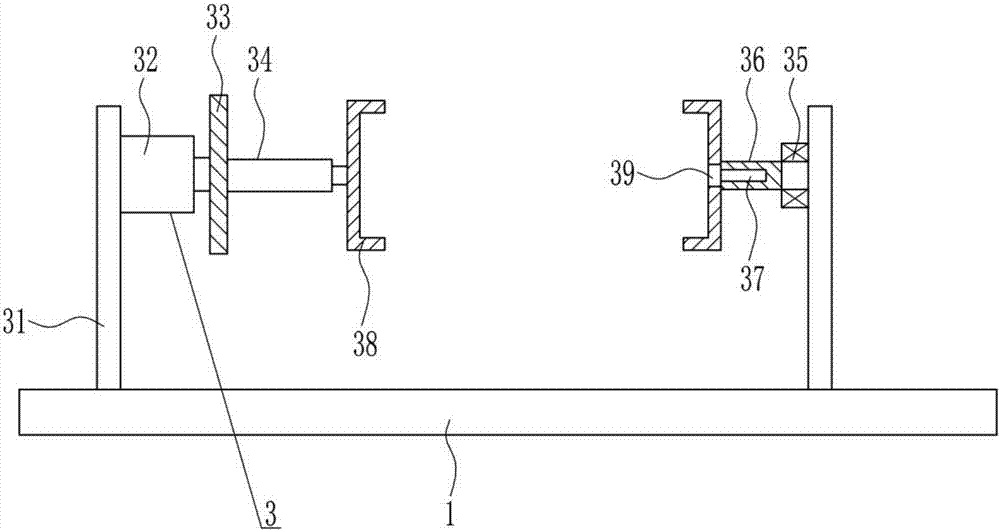

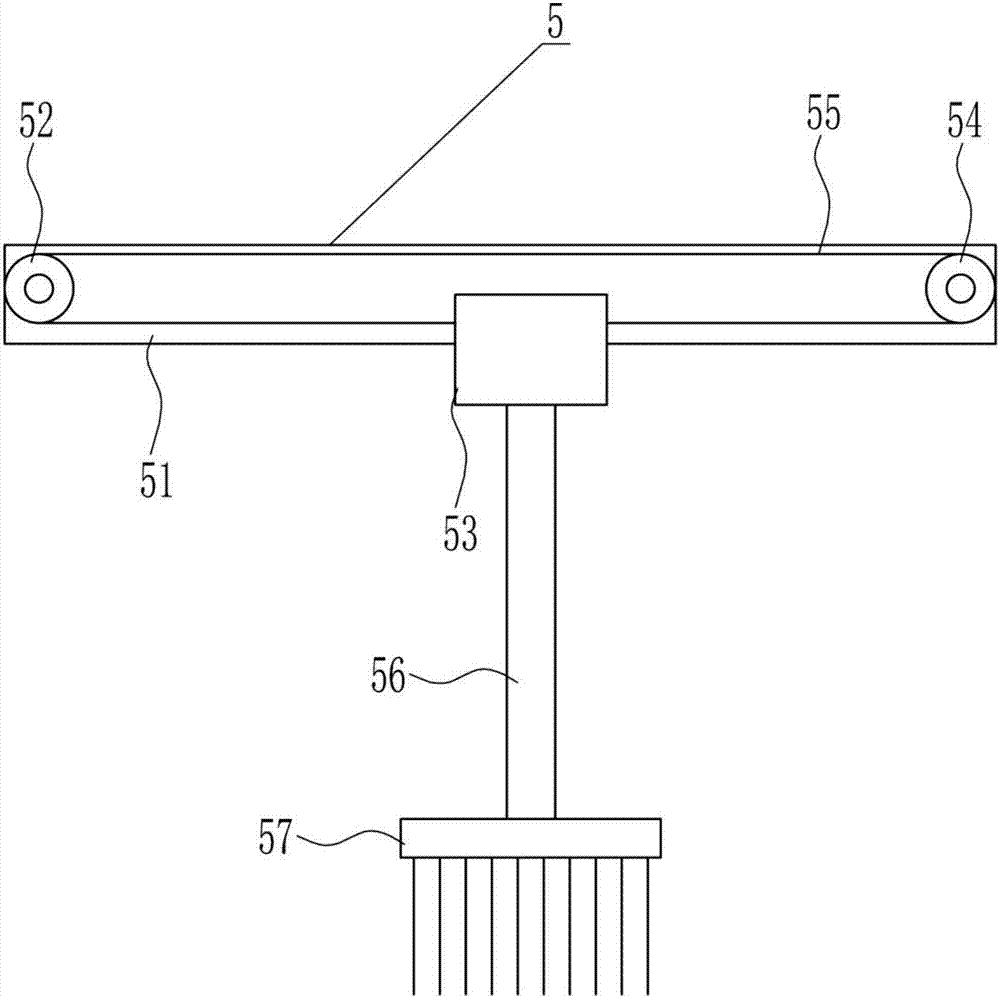

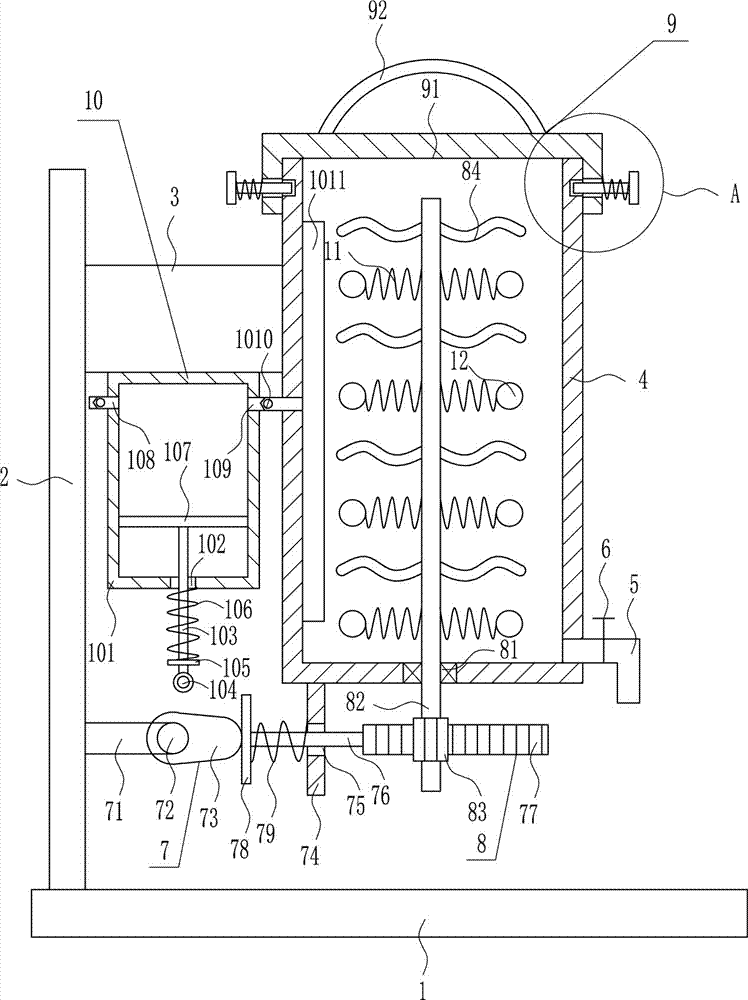

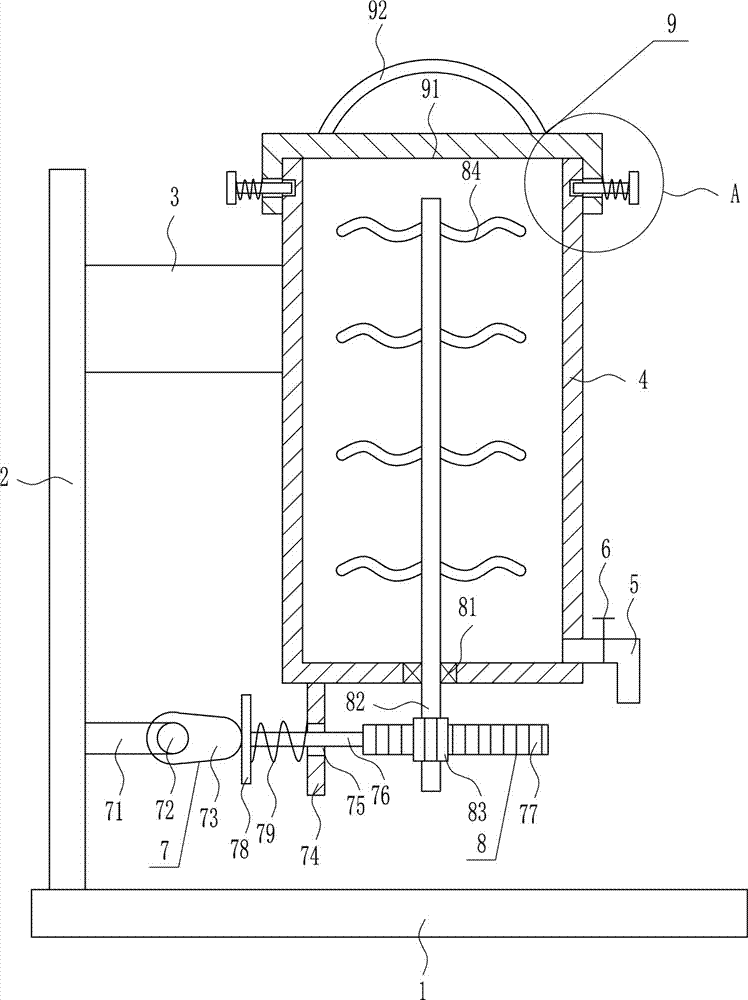

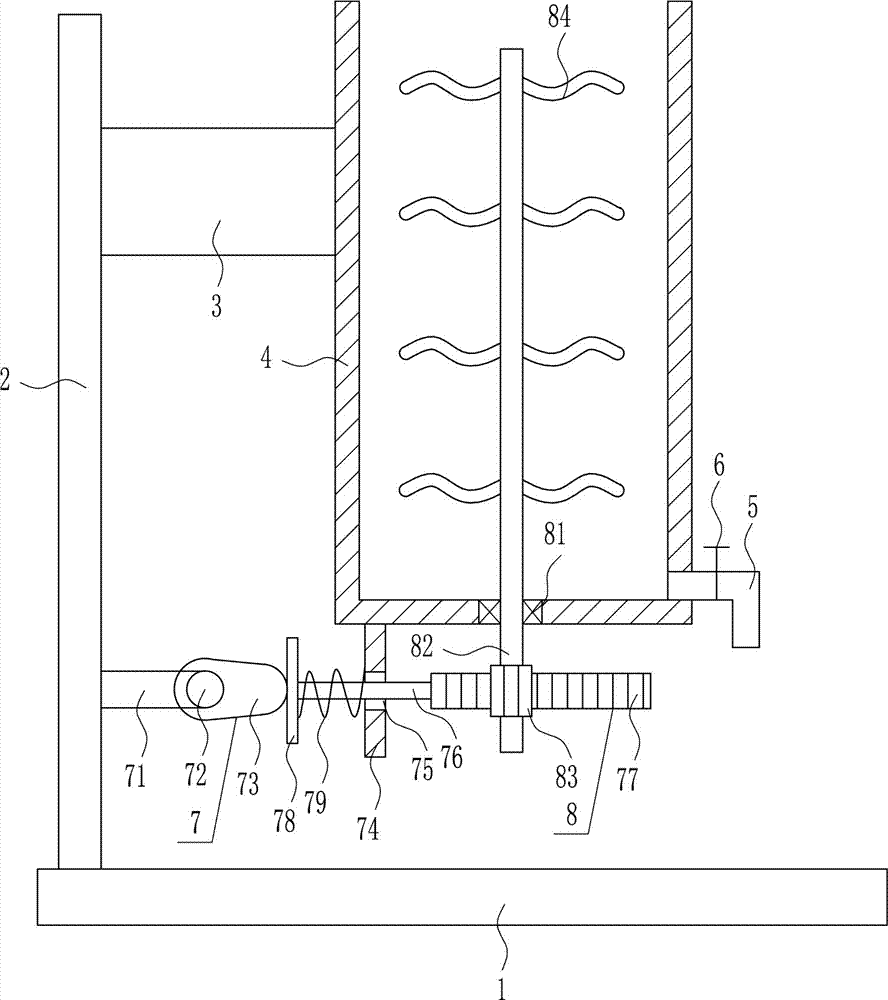

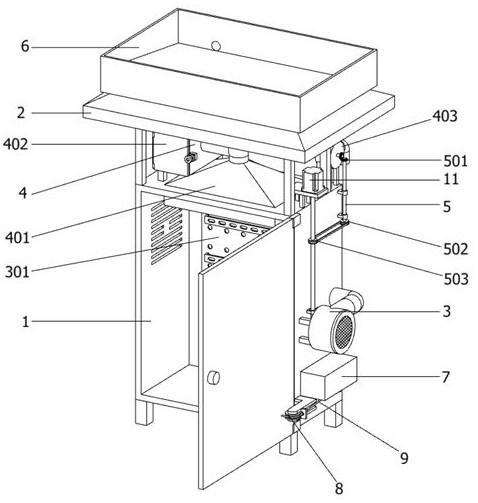

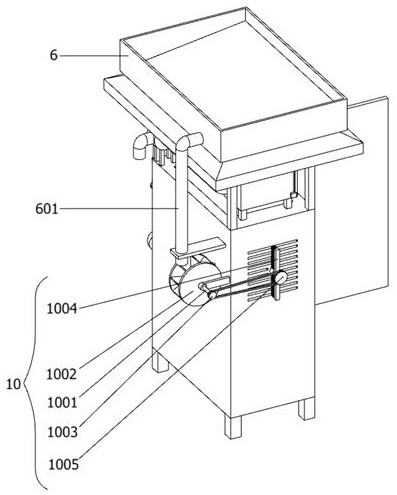

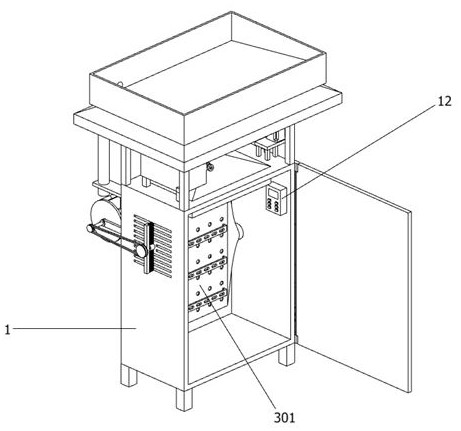

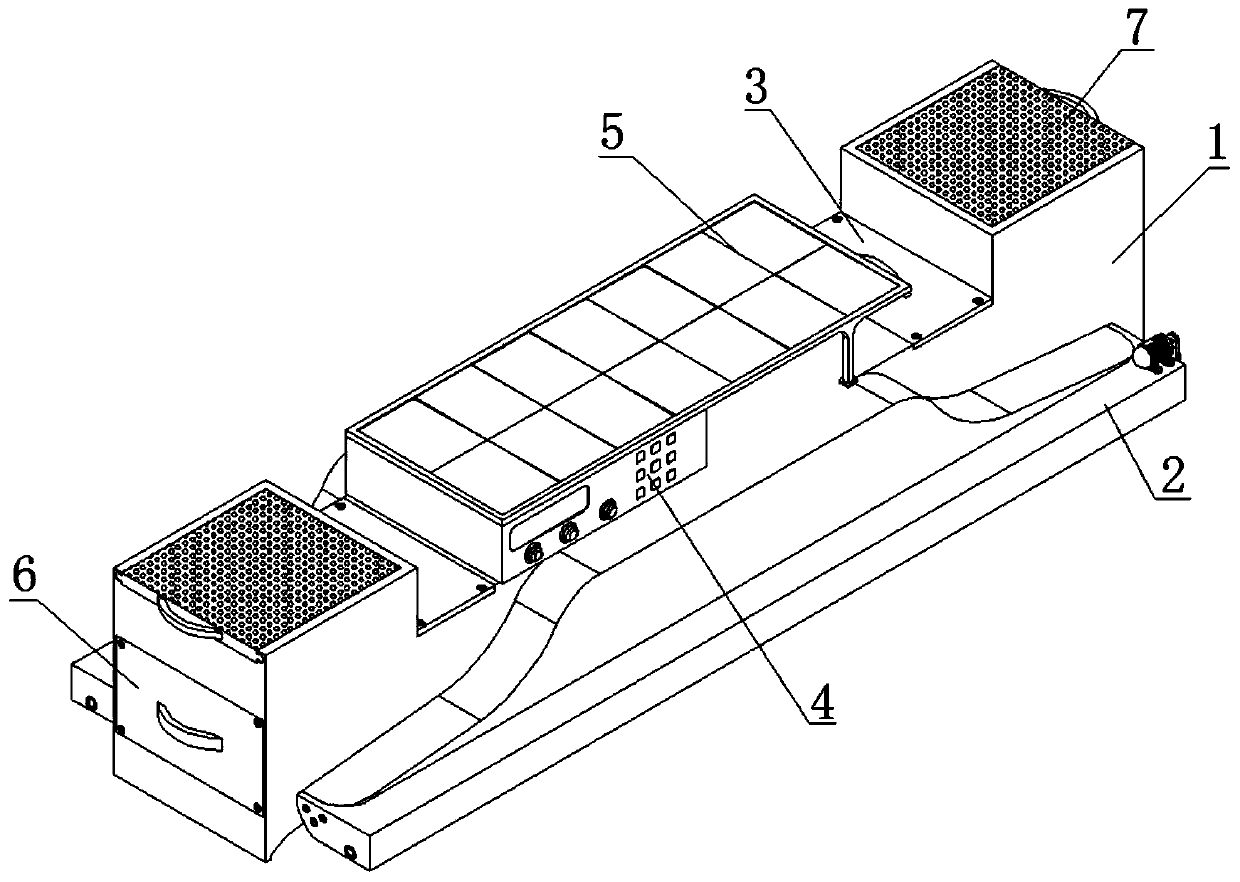

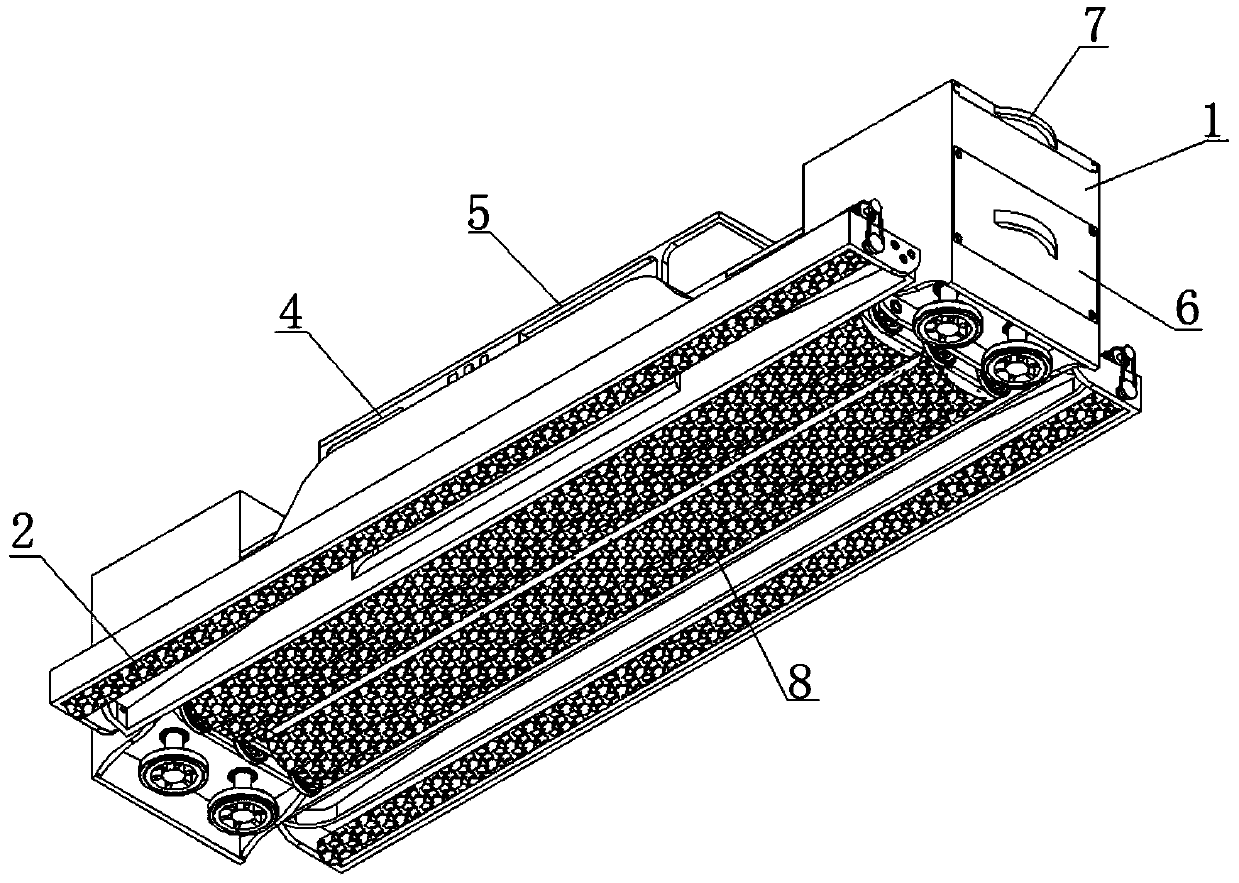

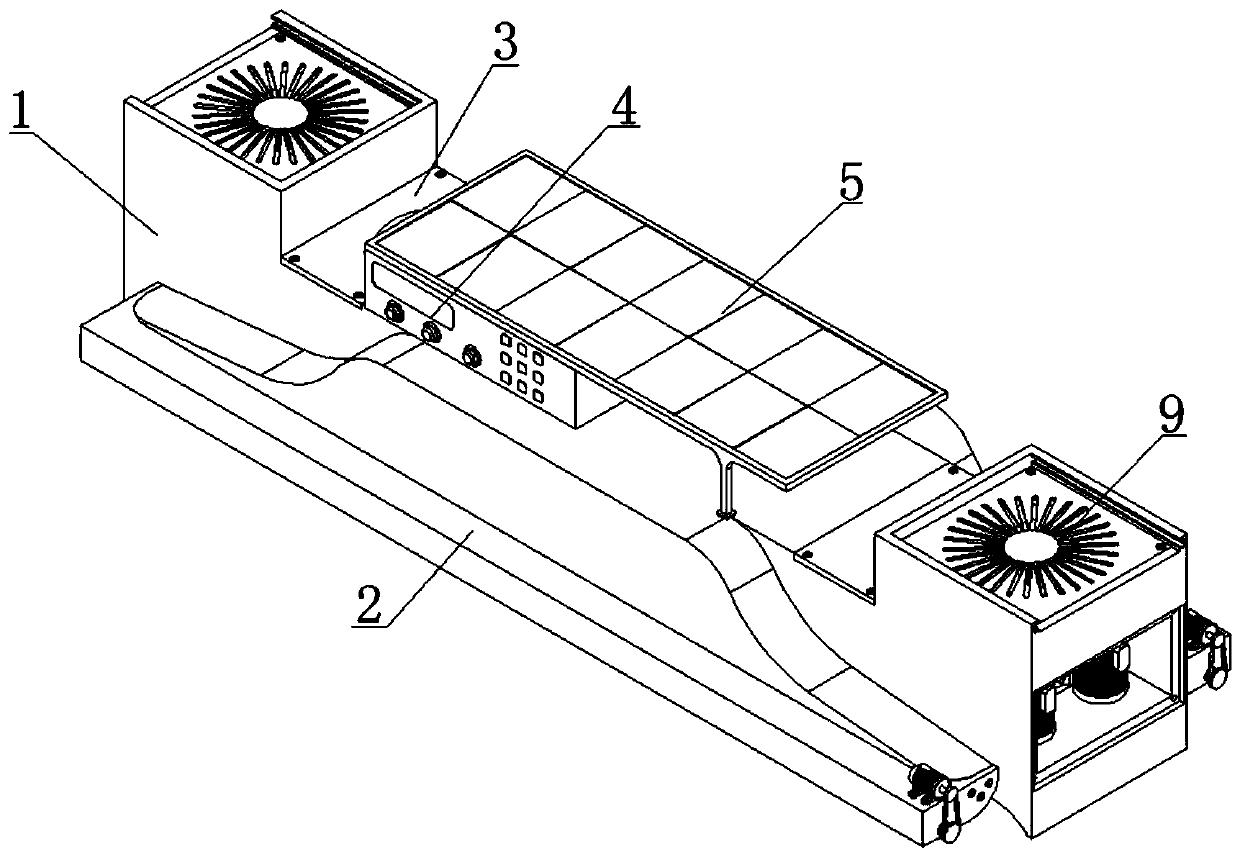

Motor surface dust comprehensive sweeping equipment for motor maintenance

InactiveCN107262407ANot easy to damageNo manual manipulationUsing liquid separation agentCleaning using toolsPhysical healthSurface dust

The invention relates to motor maintenance equipment, in particular to motor surface dust comprehensive sweeping equipment for motor maintenance. The technical effects that the motor surface dust comprehensive sweeping equipment for motor maintenance is capable of saving manpower and time and low in labor intensity, dust is not liable to be inhaled by workers, and the motor surface dust comprehensive sweeping equipment does not influence physical health are achieved. In order to achieve the technical effects, the provided motor surface dust comprehensive sweeping equipment for motor maintenance comprises a bottom plate and the like. A support is vertically mounted on the left side of the bottom plate in a bolt connection mode. A rotary fixing device is arranged in the position, on the right side of the support, of the top of the bottom plate. Dust on the surface of a motor can be cleaned up rapidly, and the effects that manpower and time are saved, the labor intensity is low, dust is not liable to be inhaled by workers, and the motor surface dust comprehensive sweeping equipment does not influence physical health are achieved.

Owner:闫梦蝶

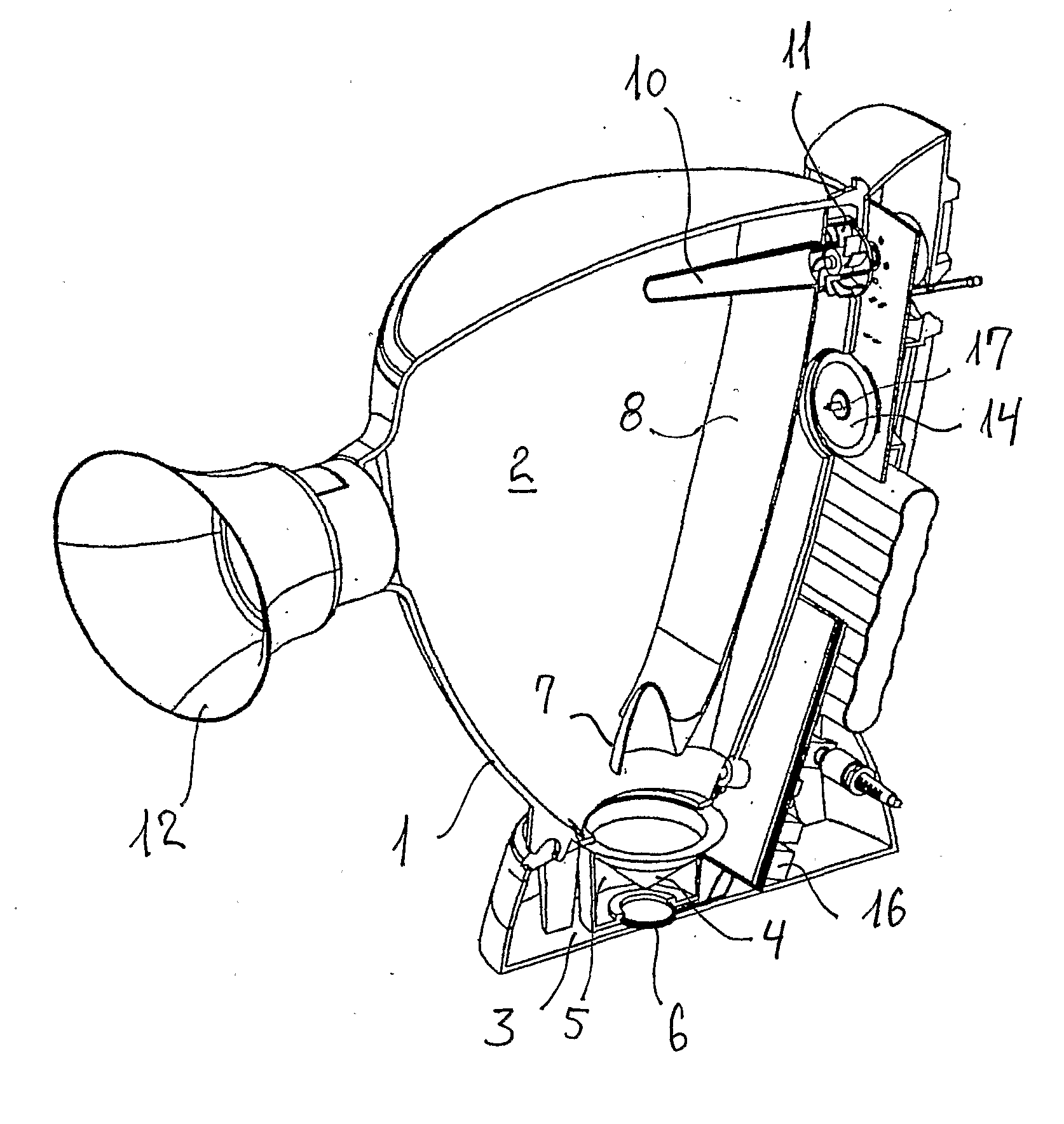

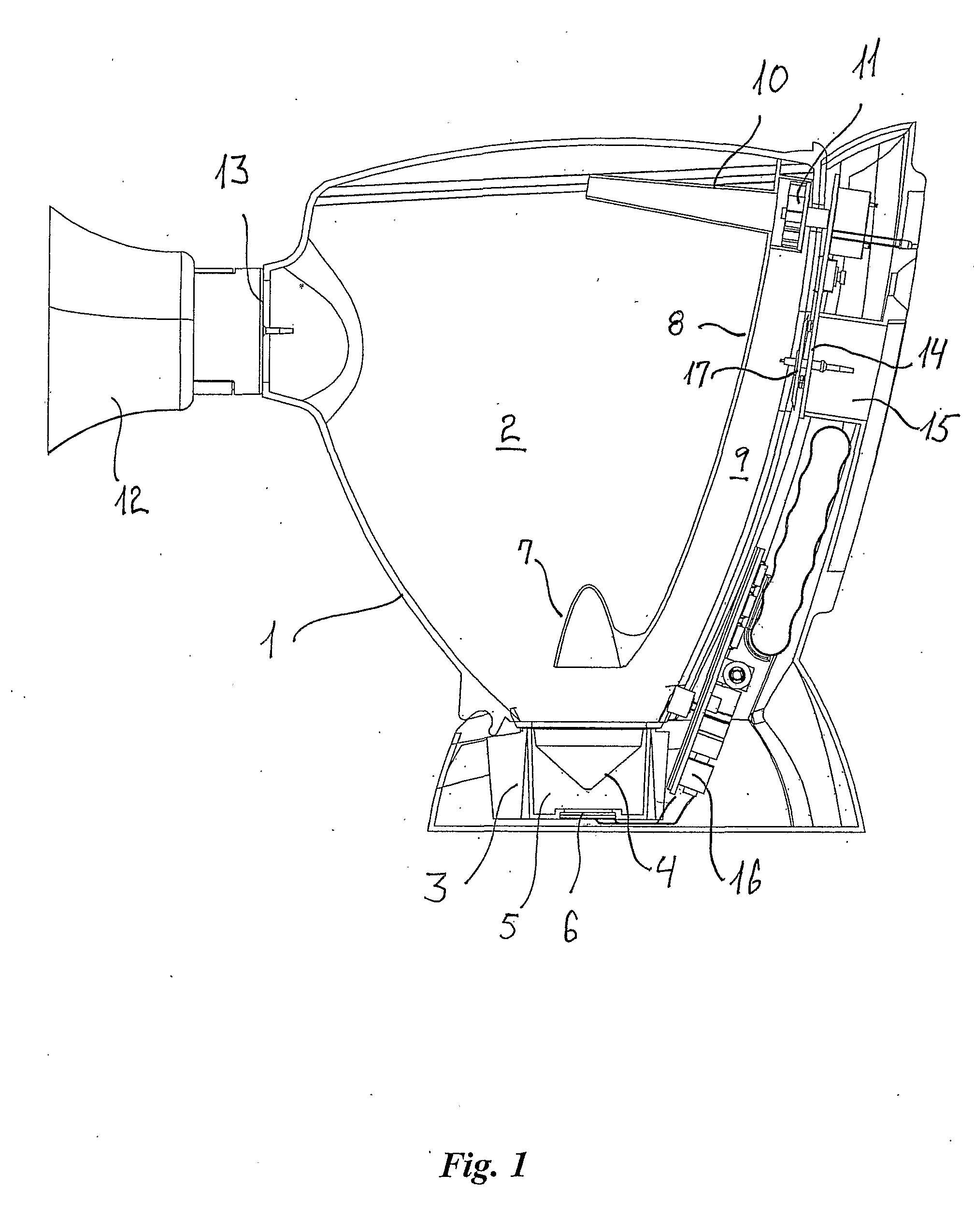

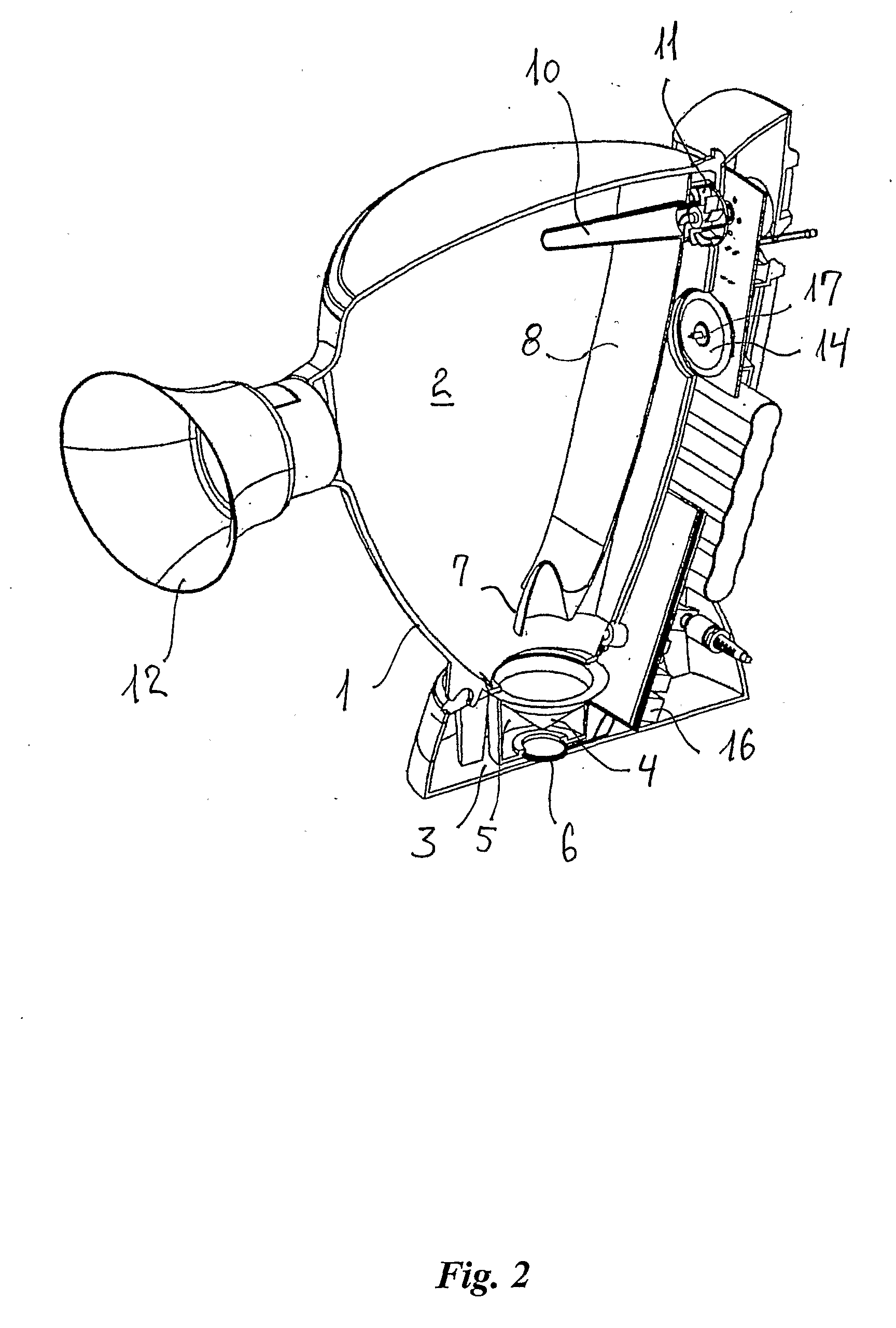

Inhalation device for providing a mist of nebulised liquid medical solution to a user

InactiveUS20090038610A1Waste of liquid is reduced and eliminatedReduce in quantityRespiratorsLiquid spraying apparatusDiseaseInhalation

A device is disclosed including ultrasonic nebulising means for providing a mist of a liquid medical solution for the treatment of diseases in the lungs, such as asthma or the like, to a human or animal user, such as a horse, the device including a mist reservoir enclosure for receiving the mist produced by the nebulising means, whereby a mist may be produced to fill the enclosure prior to inhalation thereof. The mist is therefore kept ready for inhalation for a longer period of time instead of being produced only in connection with the actual inhalation, and a more efficient and precise inhalation with finer droplets and less waste of the medical solution is obtained.

Owner:EQUINE NEBULIZER

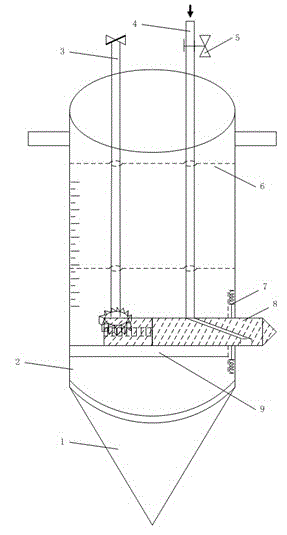

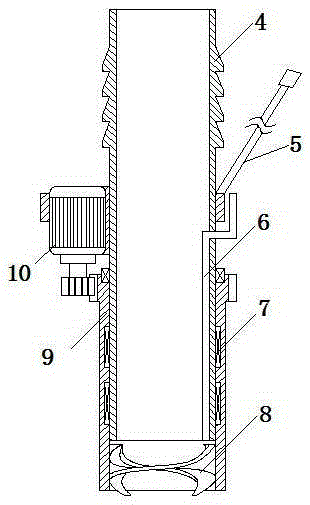

Underground micro-irrigation device

InactiveCN102907298AMeet water requirementsIncrease productionWatering devicesCultivating equipmentsWater savingSubsurface irrigation

The invention relates to an underground micro-irrigation device, and belongs to the technical field of agricultural water-saving irrigation. The underground micro-irrigation device disclosed by the invention comprises a groundbreaking cone and an outer tube, wherein the groundbreaking cone is arranged at the lower end of the outer tube, an advance-retreat rotating rod, a water inlet pipe, a fixator, a soil scraper and an emitter are arranged in the outer tube, the fixator is arranged in the middle of the outer tube, the advance-retreat rotating rod and the water inlet pipe are fixed in the outer tube through the fixator, the soil scraper is arranged on the lower side inside the outer tube, a sliding rail is arranged at the lower part of the outer tube, and the emitter is arranged on the sliding rail. The underground micro-irrigation device disclosed by the invention can satisfy the water demands of crops; due to adoption of underground irrigation, water can be saved, so that the root system of a crop can achieve the best water uptake effect, and the utilization efficiency of water can be improved; the device can be inserted and drawn out randomly as required, and does not need to be pre-buried underground, the position and depth of irrigation can be adjusted, and the emitter has small possibility of being jammed; and the device is convenient to carry, easy to install, good in water-saving effect, and easy to popularize and apply.

Owner:KUNMING UNIV OF SCI & TECH

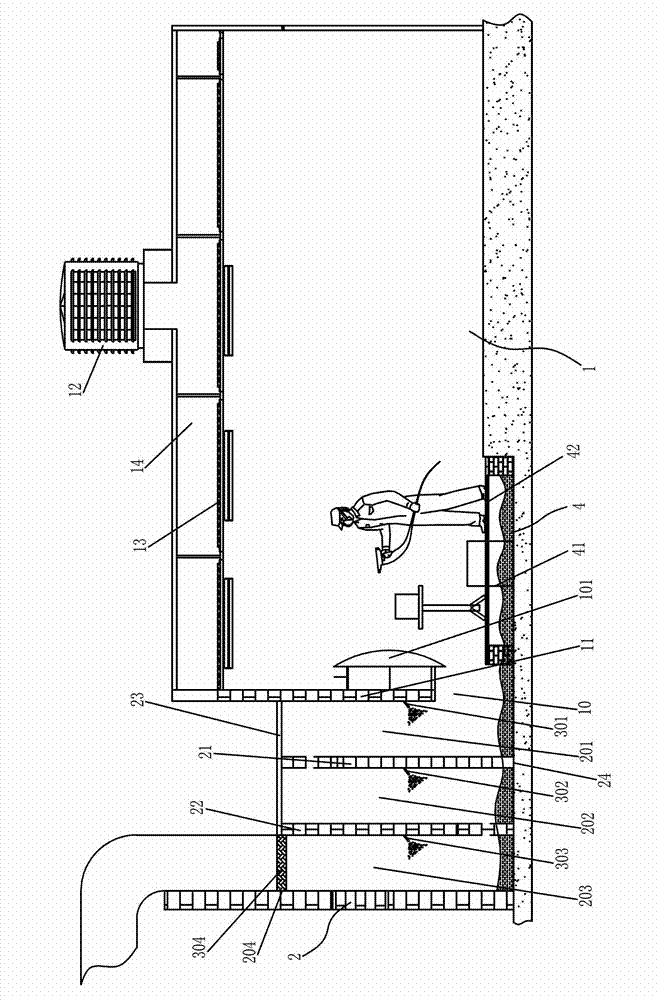

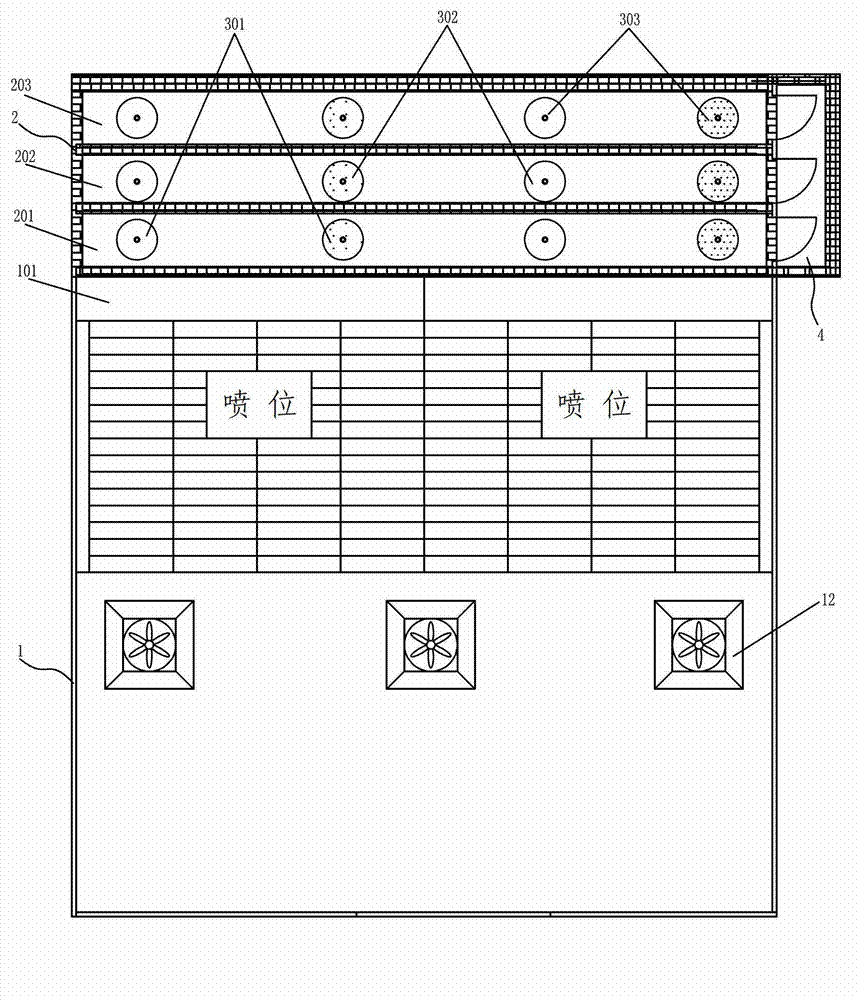

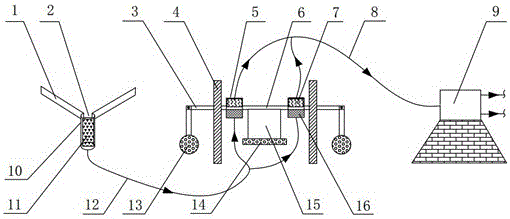

Paint room with paint production waste gas treatment system, and paint production waste gas treatment method

InactiveCN103041945AAvoid liquidityAvoid rising paint mistCombination devicesLiquid surface applicatorsActivated carbon filtrationHuman health

The invention relates to a paint room with a paint production waste gas treatment system, and a paint production waste gas treatment method. The paint production waste gas treatment system comprises a waste gas treatment chamber communicated with a paint room body. A first longitudinal channel communicated with a waste gas outlet at the bottom of the paint room obey, a second longitudinal channel communicated with the top of the first longitudinal channel, a third longitudinal channel communicated with the bottom of the second longitudinal channel, and an exhaust hole arranged at the top of the third longitudinal channel are arranged in the waste gas treatment chamber. A first spray unit is disposed in the first longitudinal channel. A second spray unit is disposed in the second longitudinal channel. A third spray unit is disposed in the third longitudinal channel. Activated carbon filter cotton is disposed at the exhaust hole. three spray treatment procedures and one activated carbon filtering procedure are added to treat the paint production waste gas, so that paint mist and peculiar odors in the paint production waste gas are removed completely, no paint mist or peculiar odors are present in the exhausted gas and pollution of atmospheric environment and threat on human health are avoided.

Owner:东莞市四友机械设备有限公司

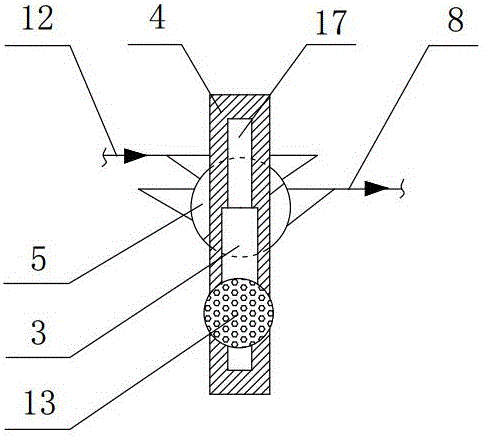

Stirring equipment of plant protecting unmanned aerial vehicle for spraying pesticide

InactiveCN107469681AImprove distributionReduce wasteAircraft componentsRotary stirring mixersToxic gasPulp and paper industry

The invention relates to pesticide stirring equipment and particularly relates to stirring equipment of a plant protecting unmanned aerial vehicle for spraying a pesticide, which has time- and labor-saving effects, stirs the pesticide sufficiently and thoroughly, and prevents people from inhaling toxic gas in the stirring process. In order to solve the technical problems, the stirring equipment comprises a bottom plate, a bracket, a connecting plate, a stirring box and the like; the left side of the top of the bottom plate is connected to the bracket by way of bolt connection, and the right side of the upper portion of the bracket is connected to the connecting plate by way of bolt connection. A first stirring device is driven by the driving device to stir the pesticide and clean water. The stirring equipment is also provided with an air stirring device, so that the pesticide and clean water stirring effect is further improved, and the effects that the stirring equipment has time- and labor-saving effects and stirs the pesticide sufficiently and thoroughly, and people are unlikely to inhale toxic gas in the stirring process are achieved.

Owner:陈建福

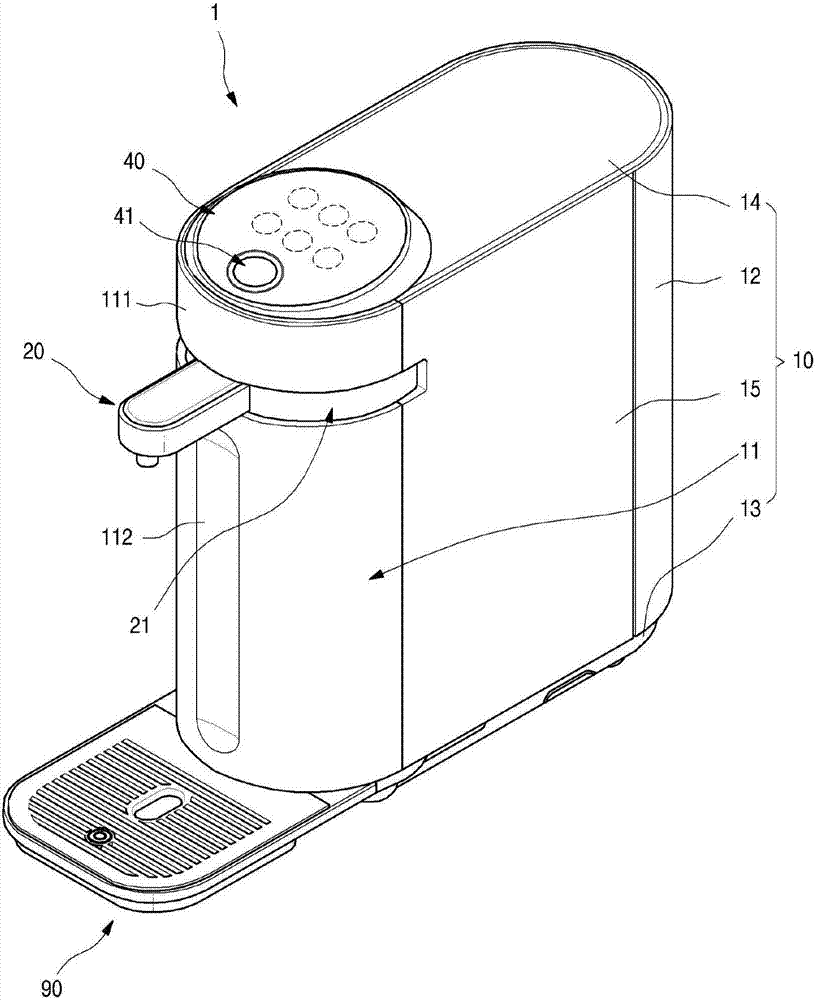

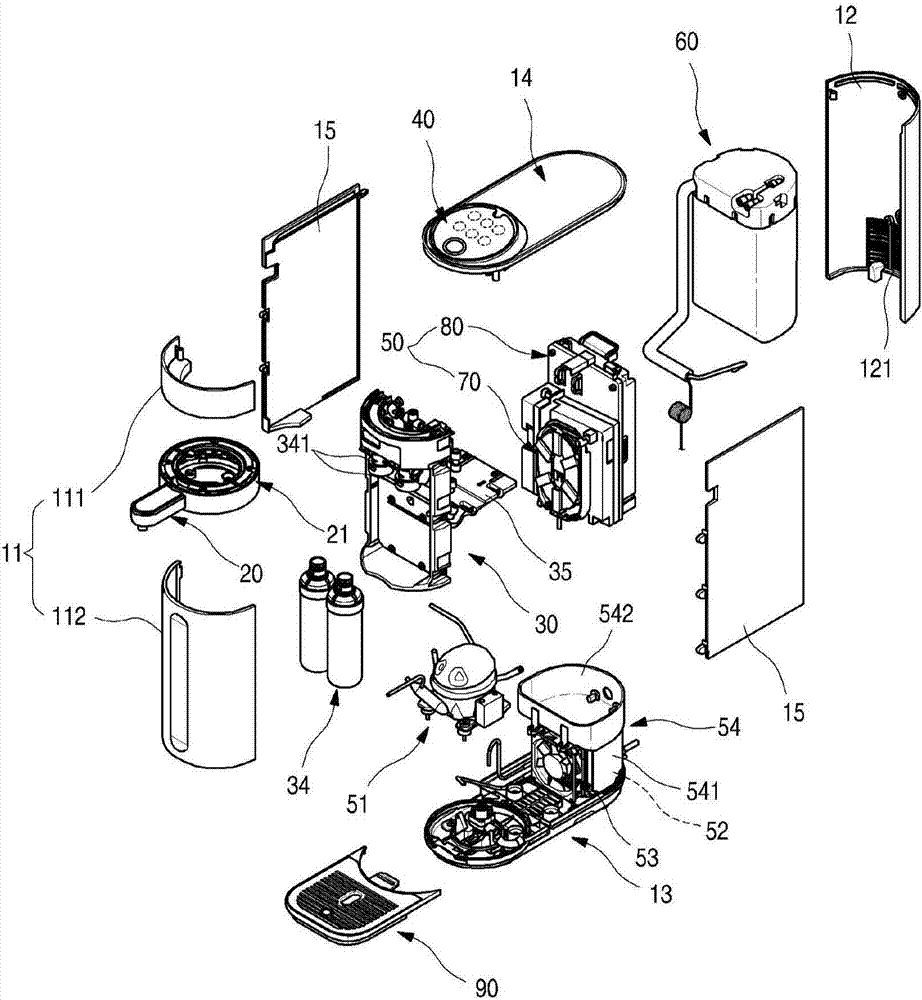

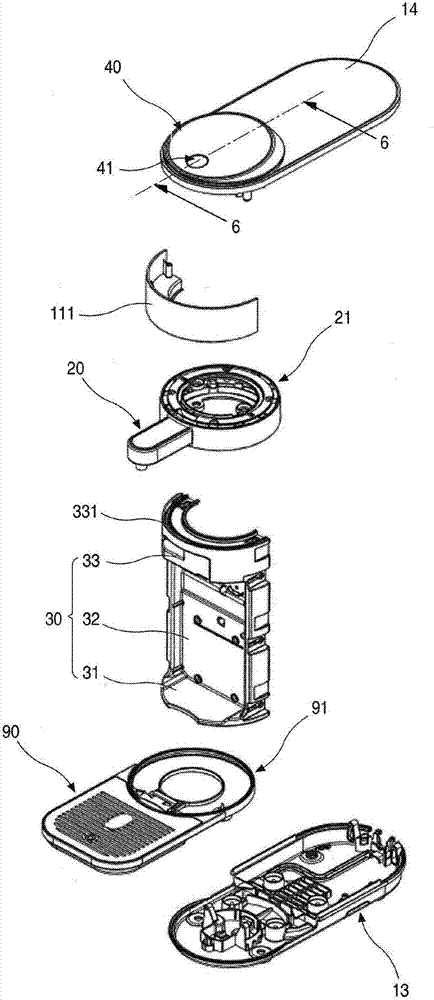

Water purifier

ActiveCN106963241AImprove efficiencyIncrease productivityWater treatment parameter controlLighting and heating apparatusWater filterFilter holder

The invention provides a water purifier. The water purifier according to the embodiment of the invention includes a shell used for forming a shape; a filter support arranged inside the shell and equipped with a filter and a valve; a condenser support arranged inside the shell and separated from the filter support, a condenser being accommodated on the condenser support; a cooling box placed at the upper end of the condenser support and used for cooling water purified by the filter; a support plate connecting the filter support and the cooling box and dividing space between the filter support and the cooling box vertically; a compressor arranged under the support plate; and a control assembly mounted on the support plate.

Owner:LG ELECTRONICS INC

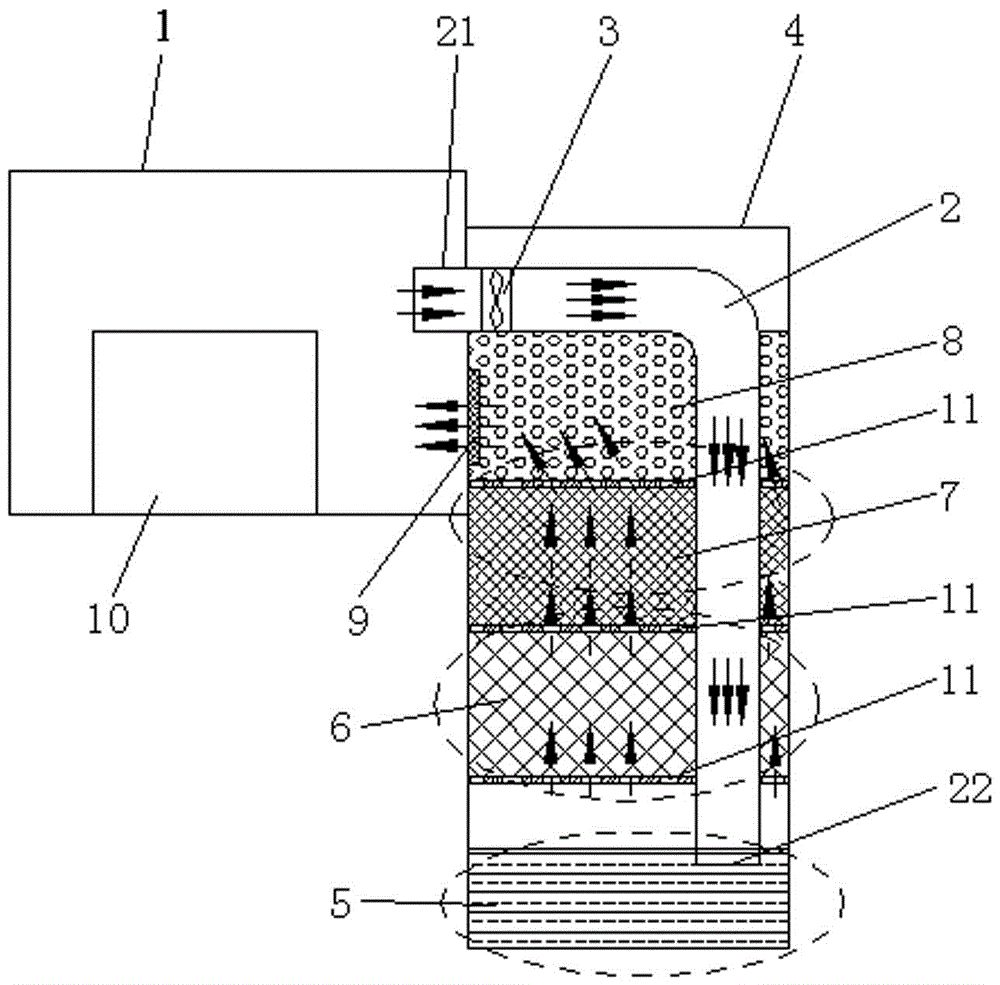

Dust filtering device used for 3D printing of selective laser melting and use method

The invention relates to a dust filtering device used for 3D printing of selective laser melting and a use method. All parts of the filtering device are integrated in a gas purification box; a liquid filtering medium layer, a rough filtering medium layer, a fine filtering medium layer and a dryer layer which are spaced by porous partitions are arranged in the gas purification box in sequence from bottom to top; a gas suction pipeline is arranged between the layers in a penetrating manner; a gas suction pipeline inlet of the gas suction pipeline penetrates through the dryer layer to enter a forming chamber and is formed in the oblique upper part of a forming platform; a gas suction pipeline outlet of the gas suction pipeline is positioned in the liquid filtering medium layer and inserted in the liquid surface for about 0.2-8mm; and a gas suction fan is arranged in the gas suction pipeline, so that dust in the forming chamber can be sucked in the gas suction pipeline, then the gas is filtered by the liquid filtering medium layer, the rough filtering medium layer and the fine filtering medium layer in sequence and dried by the dryer layer, and then returns to the forming chamber. The dust filtering device has numerous advantages the technical means is simple, convenient and feasible, the cost is low, and the device is convenient to use and maintain, small in volume and the like.

Owner:苏州科弗曼机械有限公司

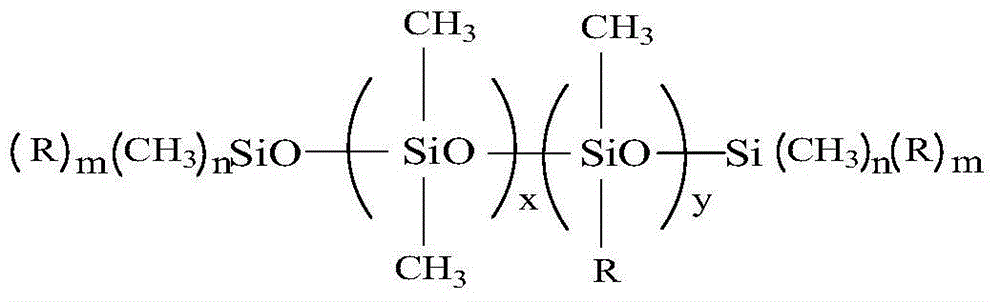

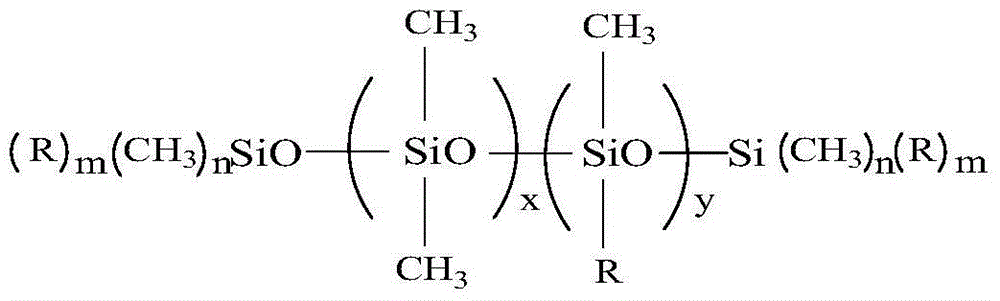

Polysiloxane-modified cationic polysaccharide compound as well as preparation method and application thereof

ActiveCN104086780ALarge particle sizeReduce harmCosmetic preparationsHair cosmeticsWater dispersiblePolysaccharide

The invention belongs to the technical field of modification of natural high polymer compounds and discloses a polysiloxane-modified cationic polysaccharide compound as well as a preparation method and application thereof. The preparation method comprises the following steps: carrying out a cationic modification reaction between a polysaccharide compound and a cationization agent, performing polysiloxane modification with active polysiloxane, or simultaneously performing cationic modifier polysiloxane modification on the polysaccharide compound, neutralizing and drying, thereby obtaining the polysiloxane-modified cationic polysaccharide compound. The product has the advantages of high water dispersibility and drifting difficulty of powder. In addition, due to the introduced polysiloxane, the application performances, such as softness and smoothness, of the cationic polysaccharide compound can be improved to a certain degree, and the polysaccharide compound can be applied to daily care products.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

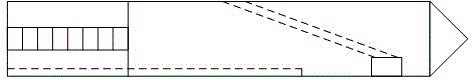

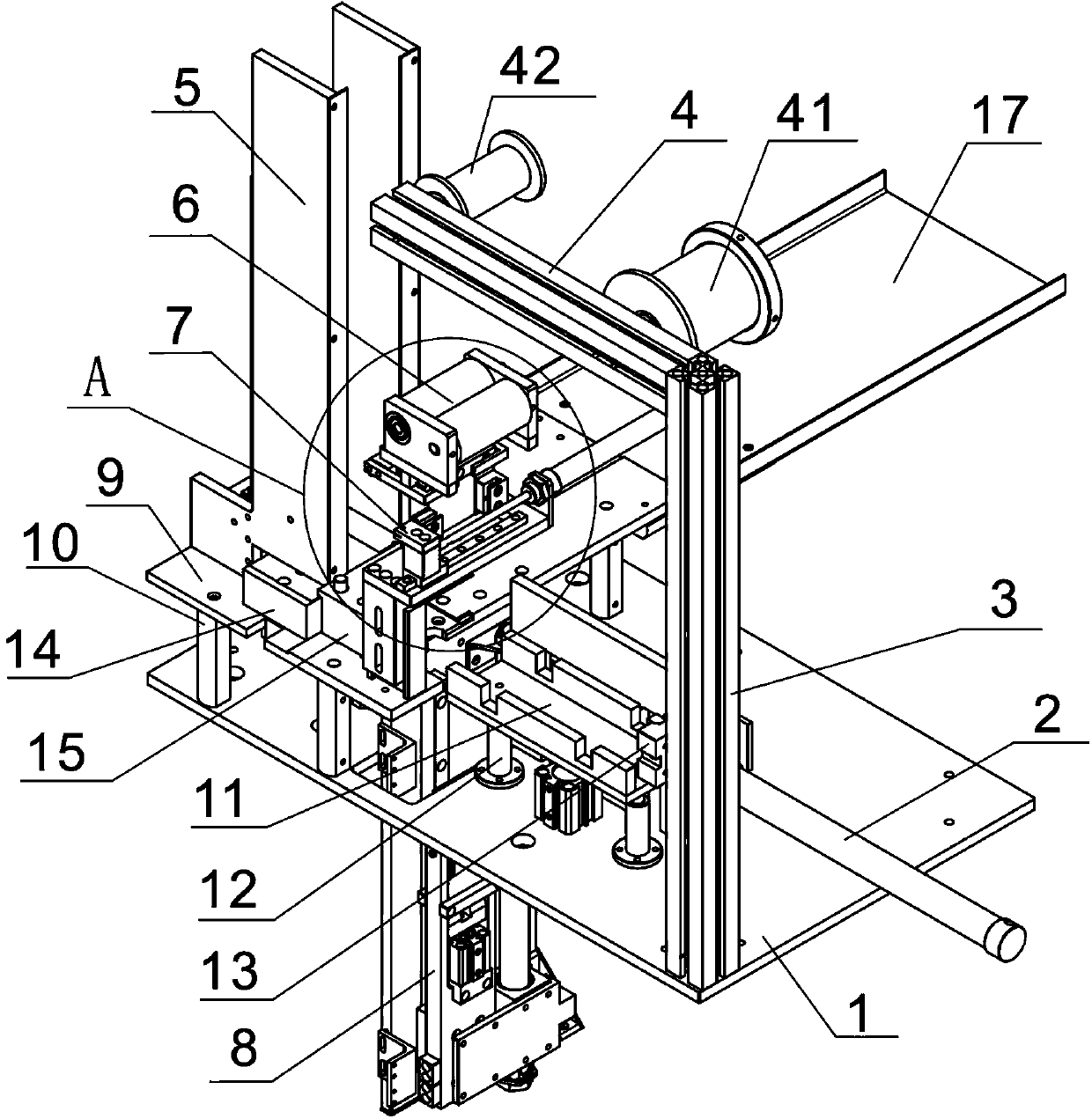

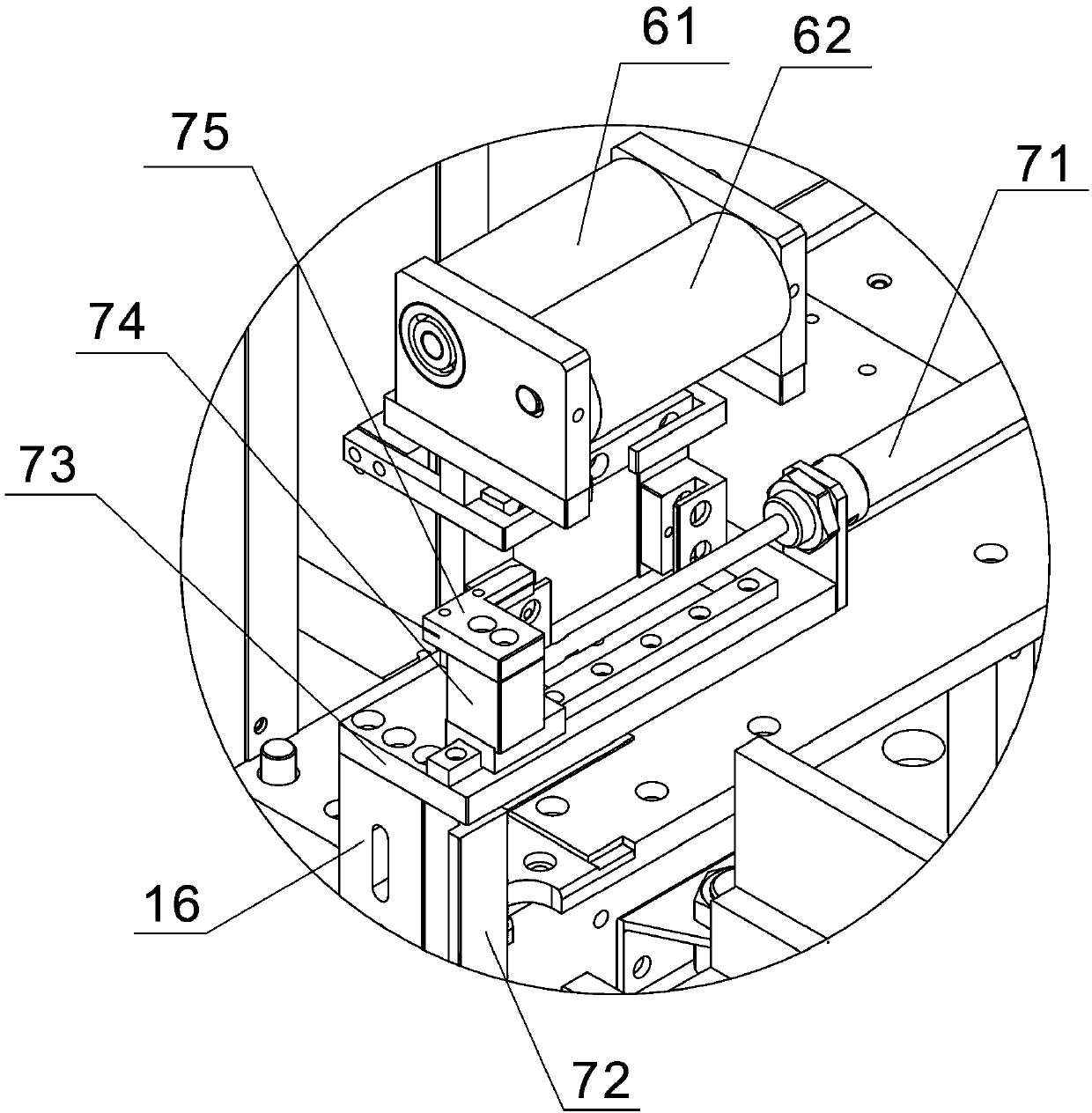

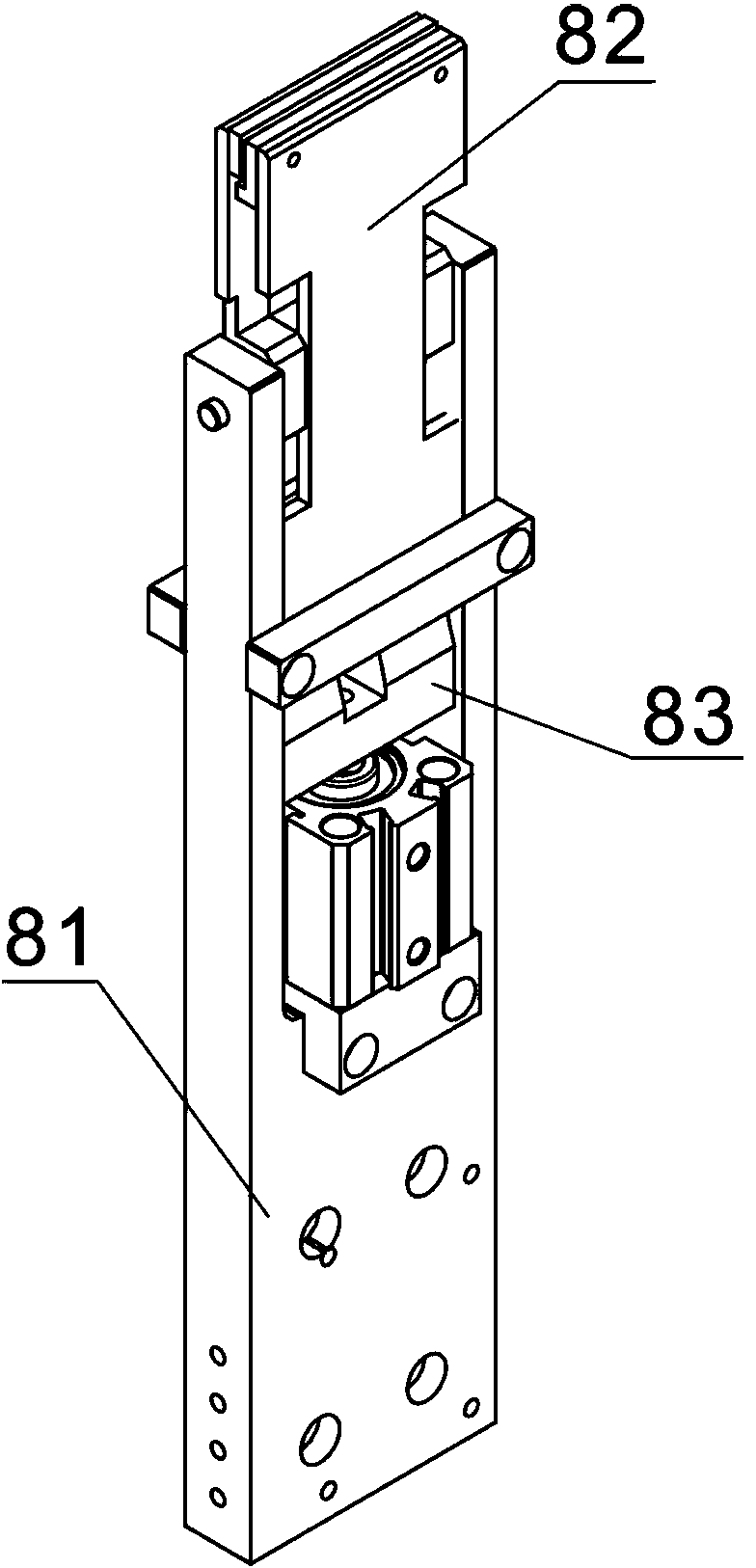

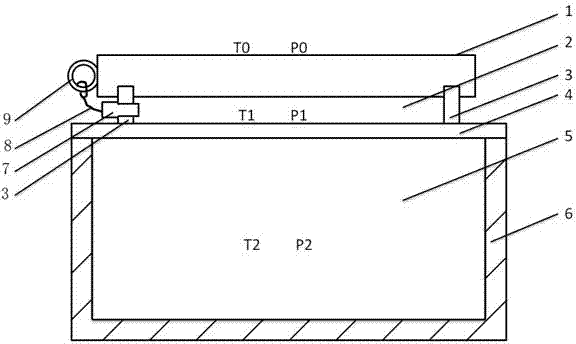

Coating machine for plate group of lead acid battery

InactiveCN103390773AAdjustable lengthImprove envelope qualityFinal product manufactureLead-acid accumulators constructionUltimate tensile strengthBiomedical engineering

The invention discloses a coating machine for a plate group of a lead acid battery. The coating machine comprises a base plate as well as a membrane draft gear and a membrane guide device which are arranged on the base plate, wherein the membrane guide device is arranged below the membrane draft gear, a membrane cutting mechanism is arranged below the membrane guide device, a membrane pulling device is also arranged under the membrane guide device, a feed device and a boxing device are respectively arranged at two sides of the membrane pulling device, and the boxing device is installed on the base plate through a work platen and a platen support arranged below the boxing device. The coating machine can complete automatic coating of the plate group of the lead acid battery by integrating the membrane draft gear, the membrane guide device, the membrane cutting mechanism and the membrane pulling device and combining the feed device and the boxing device, thus having high degree of automation, low labor intensity, high production efficiency, and convenience in use, and operators do not inhale dust easily. The coating machine has low cost and simple structure, is easy to process, and can be widely popularized and applied in the technical field of storage battery production.

Owner:贵阳市江山自动化设备有限公司

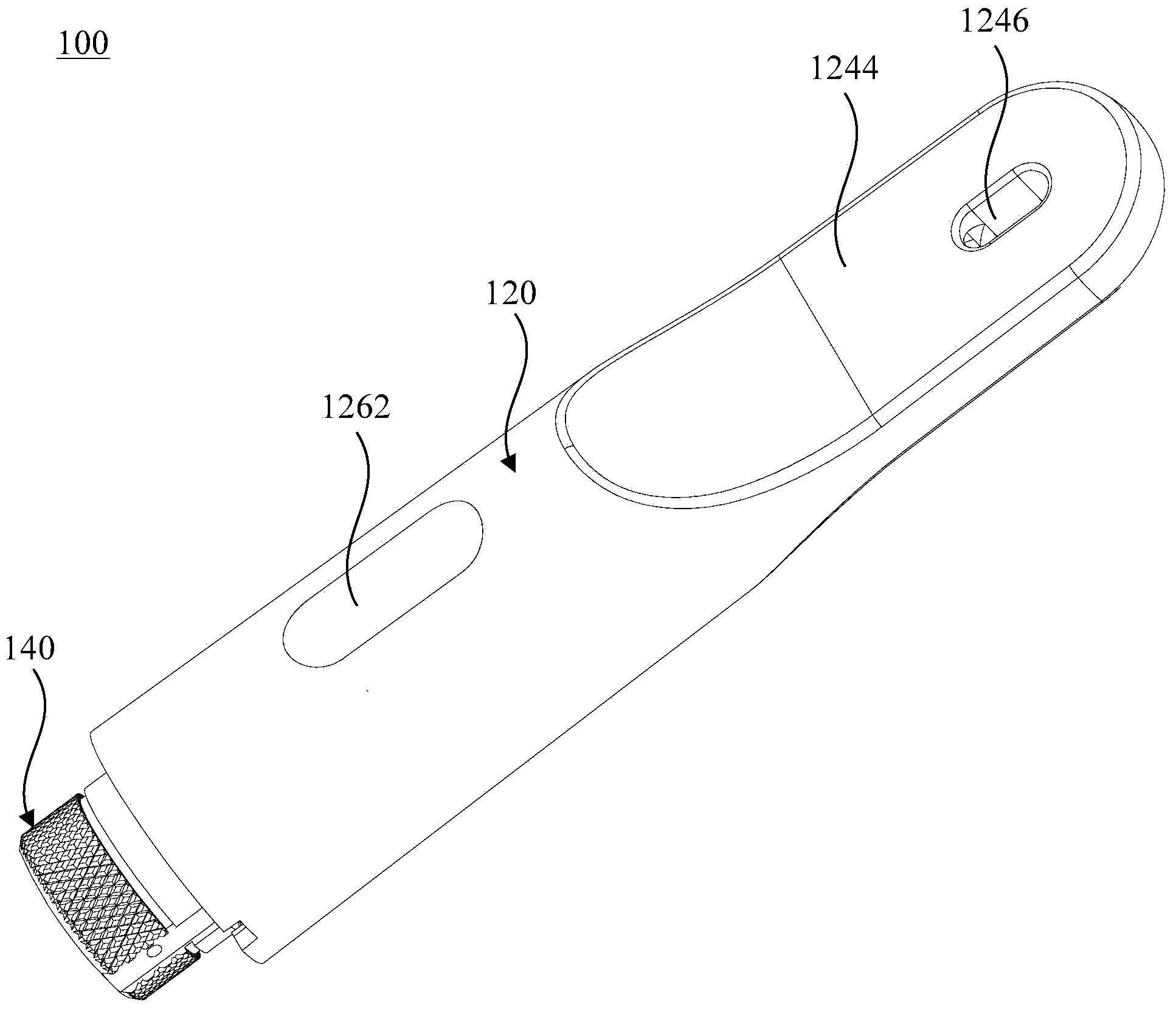

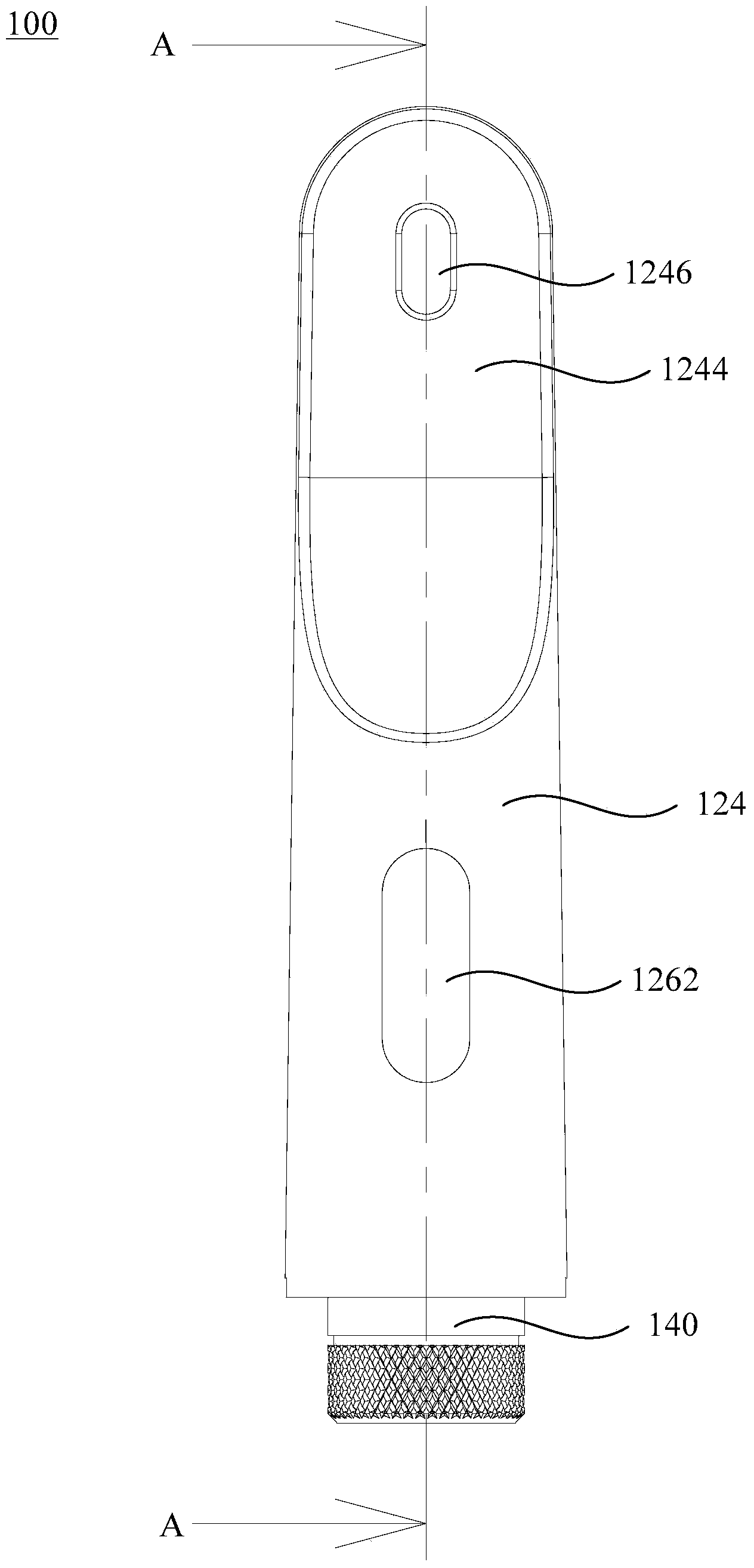

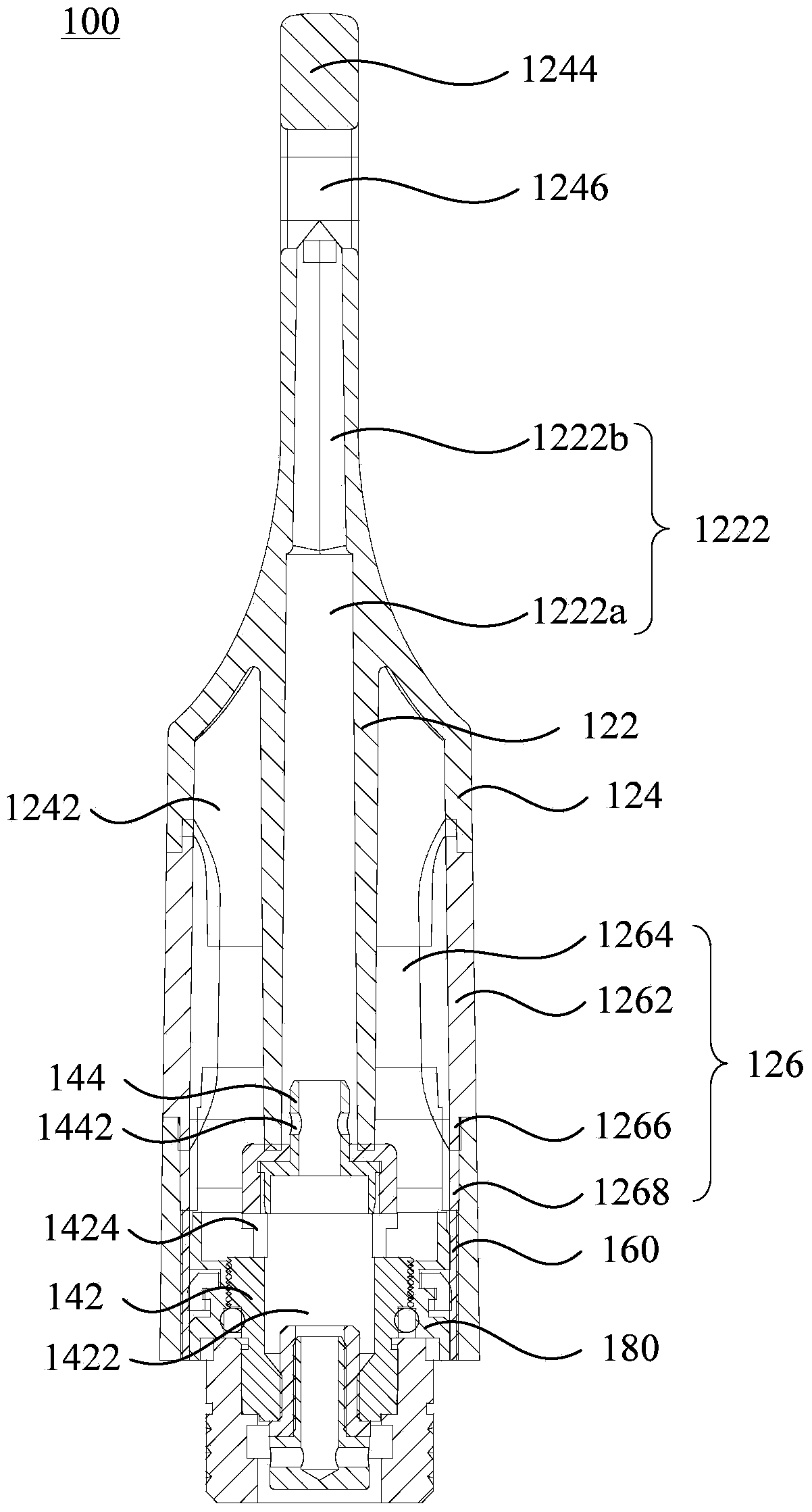

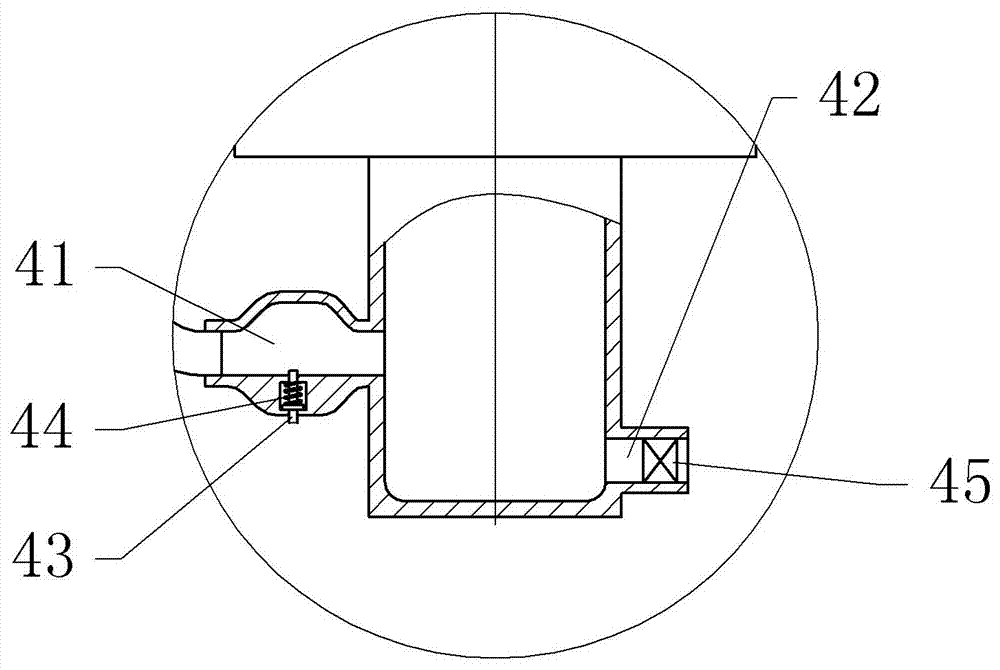

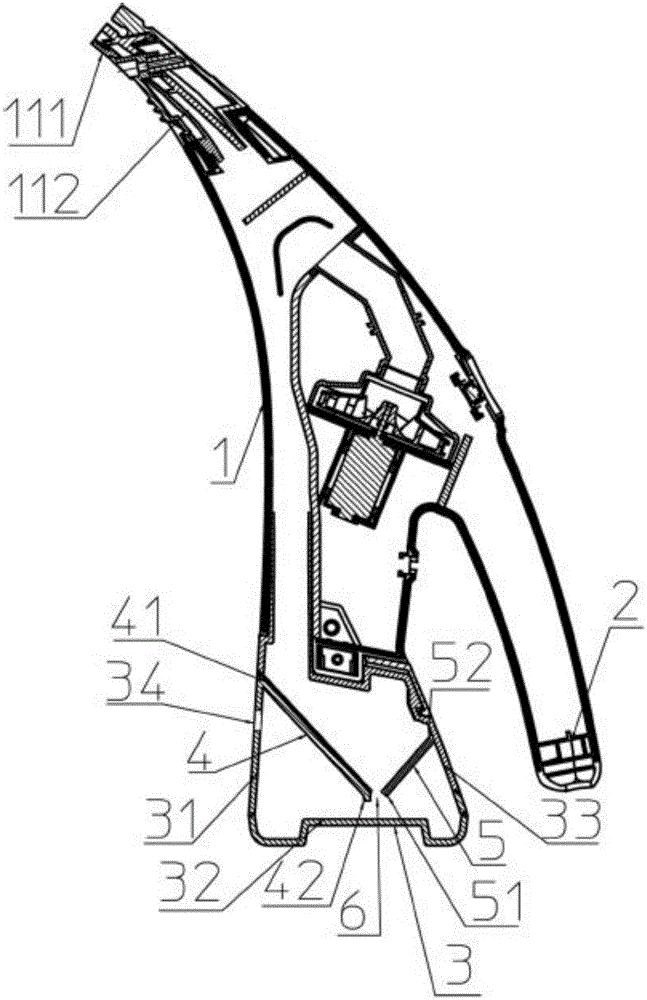

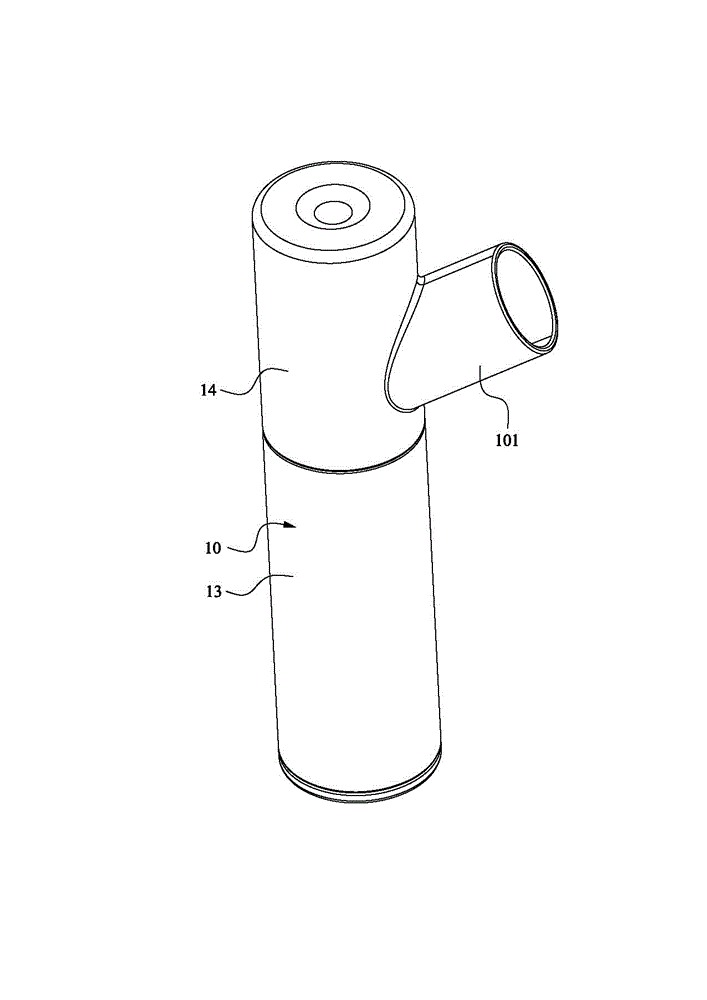

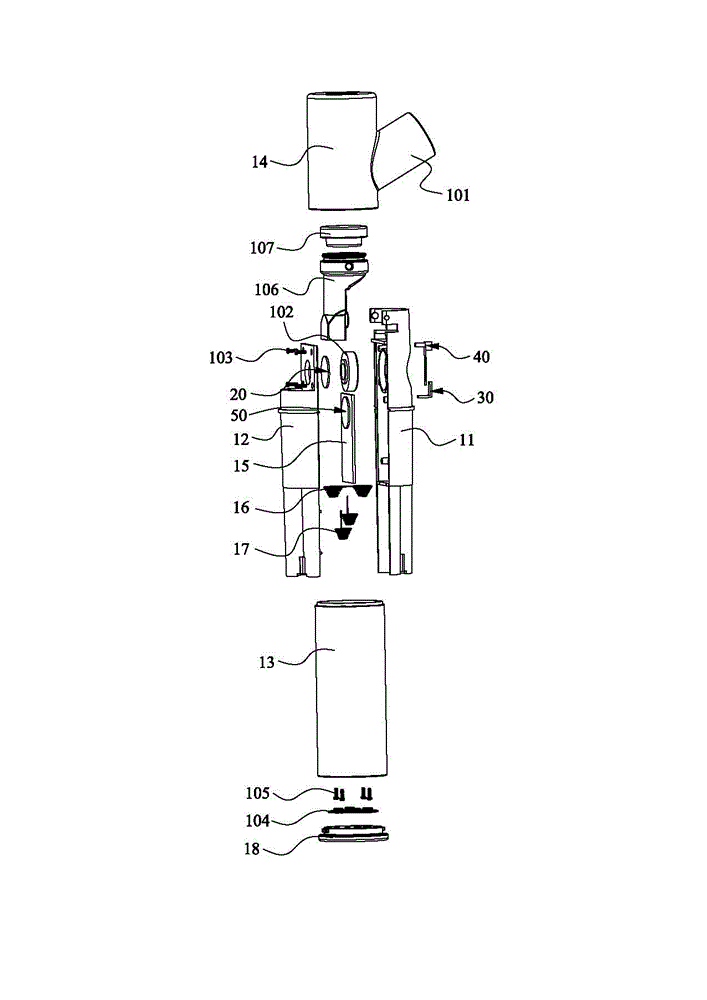

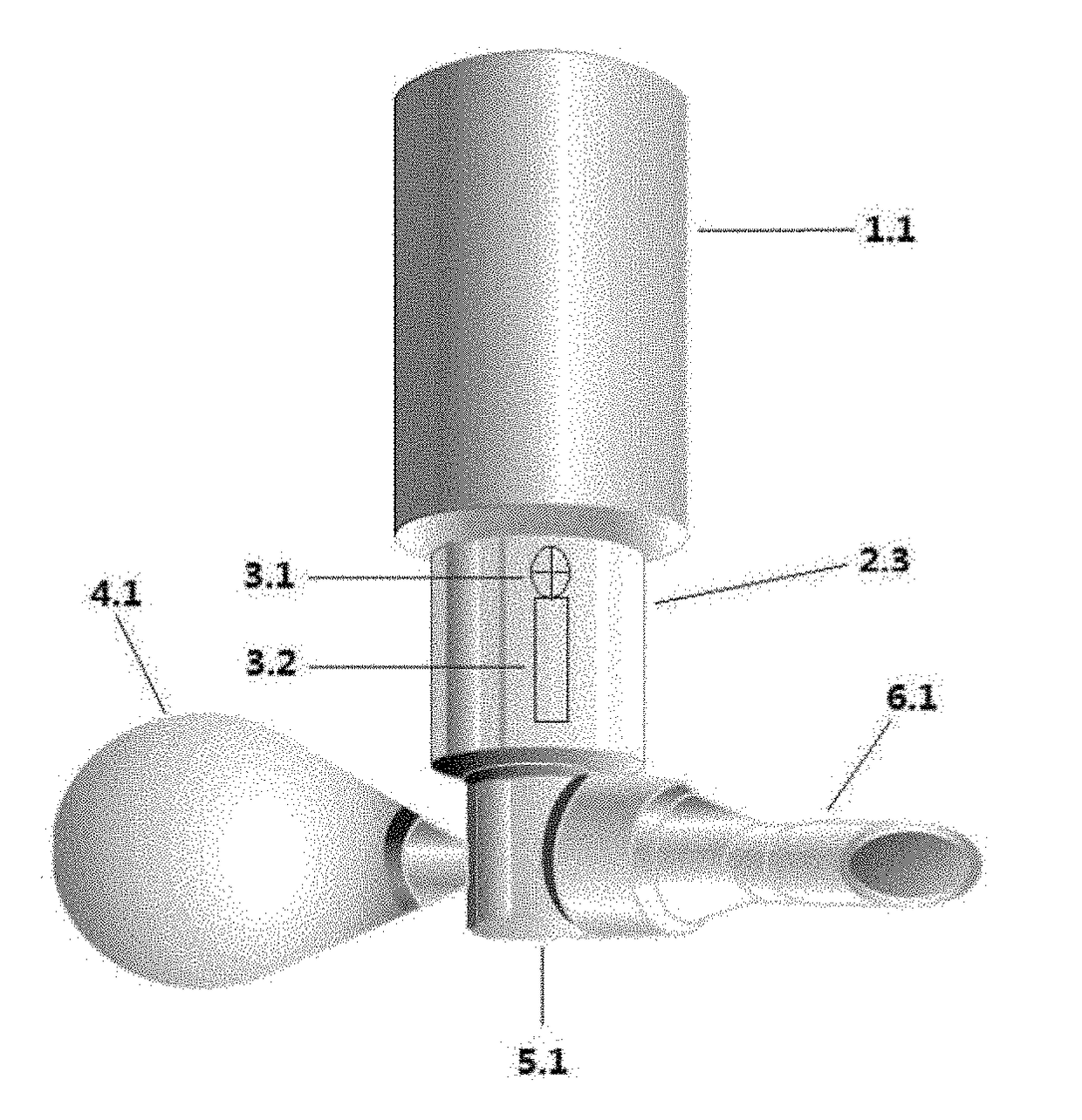

Inhaler and atomization assembly thereof

The invention relates to an inhaler and an atomization assembly of the inhaler. The atomization assembly of the inhaler comprises a shell and an atomization core arranged to be combined with the shell. The shell comprises an outer shell and a breather pipe, a liquid storing cavity used for storing liquid is formed in the outer shell, a flat suction nozzle is formed at one end of the outer shell, and an inhaling hole is formed in the suction nozzle; an airflow channel is formed in the breather pipe, the breather pipe is located in the liquid storing cavity, one end of the breather pipe is connected with the atomization core, the other end of the breather pipe is connected with the outer shell, and the airflow channel is communicated with the inhaling hole. The cross section of at least part of the airflow channel is flat, the part, with the flat cross section, of the airflow channel is close to the inhaling hole, and the shape of the airflow channel is matched with that of the suction nozzle. The cross section of the at least part of the airflow channel is flat to be matched with the flat suction nozzle, it is ensured that the outer shell and the breather pipe are thick enough, the product qualified rate is increased, the area of the cross section of the airflow channel is ensured, and therefore a user can suck the atomized liquid into the mouth easily.

Owner:SHENZHEN SMOORE TECH LTD

Drinking water bucket cleaning device

ActiveCN107363049AComprehensive cleaningImprove cleaning efficiencyHollow article cleaningEngineeringCentrifugal force

The invention discloses a drinking water bucket cleaning device, and relates to the field of drinking water processing. The drinking water bucket cleaning device comprises a base, a motor and a rotary disc rotationally connected to the base. A casing pipe is arranged at the center of the rotary disc. A suction cup capable of being matched with the water bucket is fixed to the upper surface of the rotary disc. A water sprayer is arranged below the casing pipe and comprises a Venturi tube, a water spraying pipe with one end communicating with the throat part of the Venturi tube, and a particle spraying pipe with one end communicating with the throat part of the Venturi tube, a water tank and a particle storage box. The other end of the water spraying pipe stretches into the water tank, the other end of the particle spraying pipe stretches into the particle storage box, and the upper end of the Venturi tube is connected with a flow guiding pipe penetrating from the interior of the casing pipe, and the outer diameter of the flow guiding pipe ranges from 2 cm to 2.5 cm. The lower end of the Venturi tube is connected with an air pump, the exhaust end of the air pump communicates with the Venturi tube, a pump wheel is arranged in the air pump, and the motor can drive the rotary disc and the pump wheel to rotate. The water bucket rotates, water is distributed to the inner wall of the water bucket under the action of centrifugal force, water and the inner wall of the water bucket moves relatively, and compared with flushing directly conducted through a sprayer, the water bucket is cleaned more comprehensively.

Owner:贵州天壶泉饮品有限责任公司

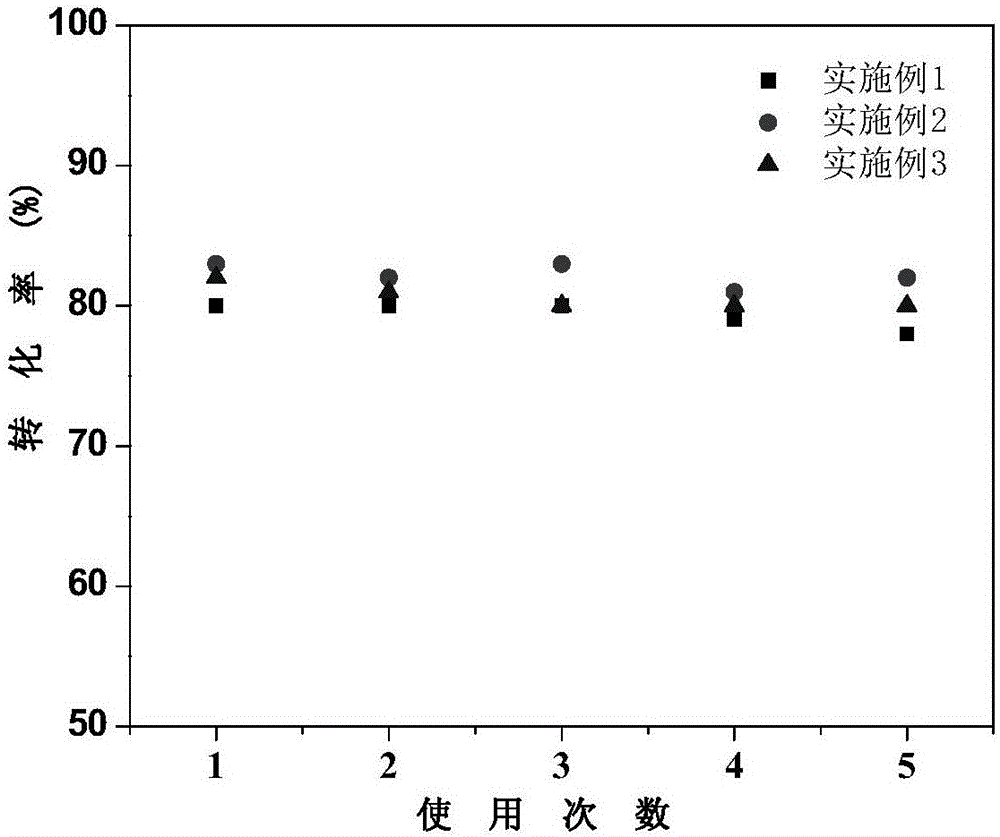

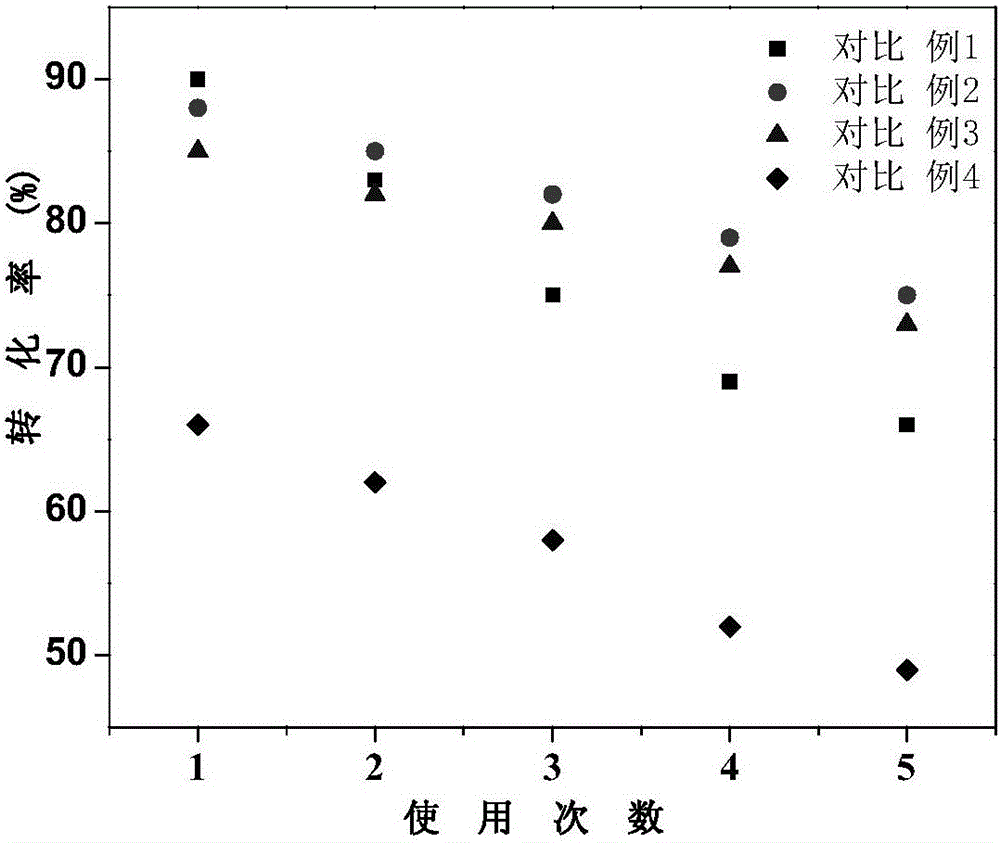

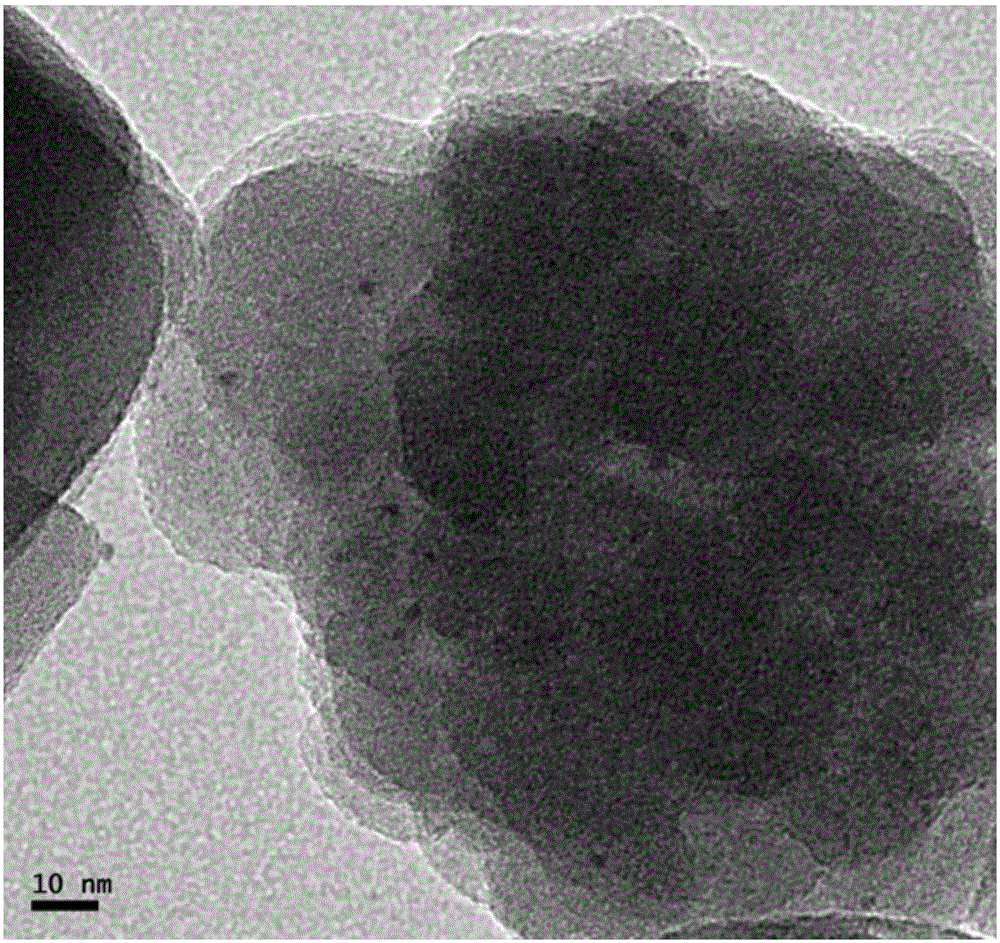

Method for preparing catalyst used for modulating distribution of metal on molecular sieve

ActiveCN105709856AEasy to inhaleRealize precise regulationMolecular sieve catalystsCatalyst activation/preparationDeposition precipitationMolecular sieve

Provided is a method for preparing a catalyst used for modulating distribution of metal on a molecular sieve.By control over the blockage of molecular sieve ducts and the pH of solution, or by selection of metal complexes of appropriate sizes and adjustment of deposition-precipitation process parameters and the pH of solution, catalytic activity metal elements can be selectively deposited on specific loci of the outer surface of the molecular sieve or deposited on specific loci of the inner surface of the molecular sieve as a priority.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Electric distribution box for 5G signal tower

InactiveCN112234471AImprove convenienceEfficient collectionSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringMechanical engineering

The invention provides an electric distribution box for a 5G signal tower, belongs to the technical field of electric distribution boxes, and aims to solve problems that when the interior of an existing electric distribution box is cleaned, dust blown up from the interior of the electric distribution box is extremely easily inhaled into a body by a cleaner, the health of the cleaner is affected, and the dust in the cleaning process cannot be effectively collected. The electric distribution box comprises a box body. A rain shade is arranged at the top of the box body, and an air blowing mechanism is installed on the lower portion of the right end surface of the box body. Through cooperation of the air blowing mechanism and an air suction mechanism, air blowing operation is performed on theinterior of the electric distribution box through the air blowing mechanism, meanwhile, the dust blown by the air blowing mechanism is rapidly and effectively collected through the air suction mechanism, and therefore the dust blown by the interior of the electric distribution box is not prone to being inhaled into the body of the cleaner in the cleaning process; and furthermore, the health of thecleaner is not influenced, the dust in the cleaning process can be effectively collected so that the convenience of cleaning the interior of the electric distribution box is improved.

Owner:夏喜明

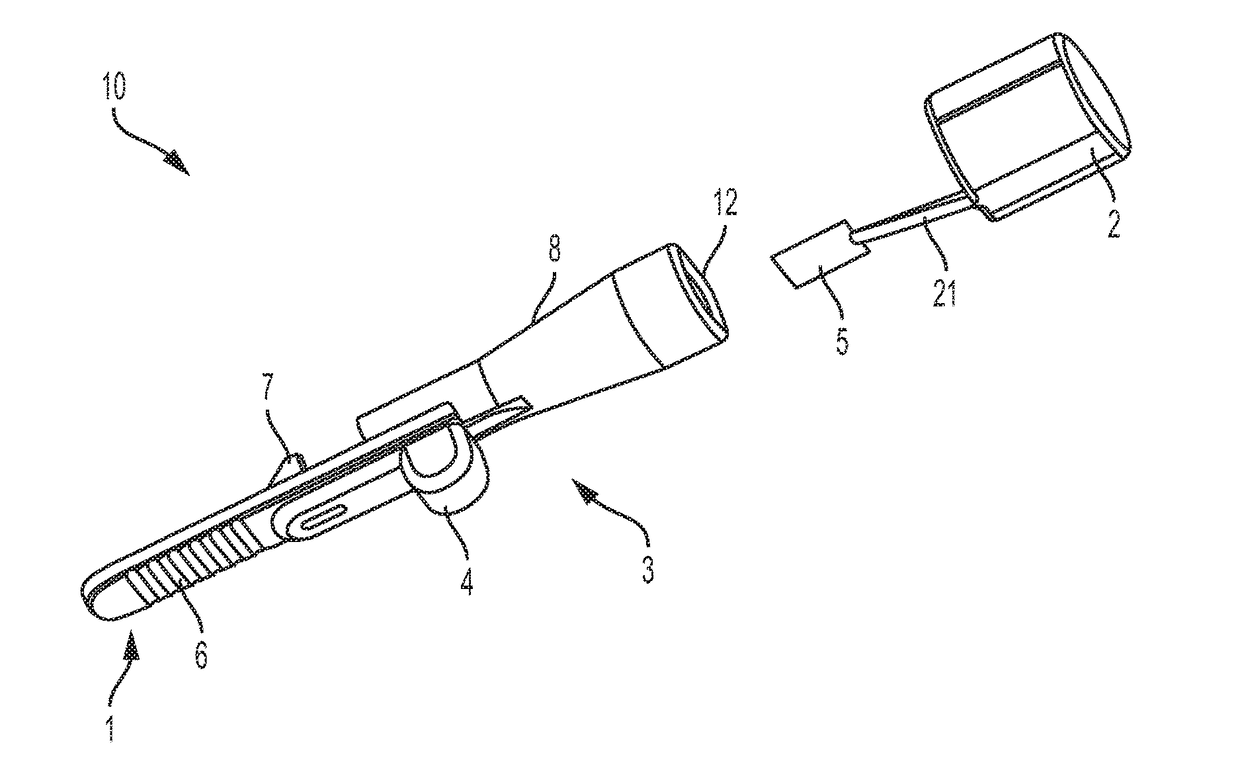

Delivery device and related methods

ActiveUS20170119982A1Minimize stepMinimizes stepMedical devicesMedical atomisersControlling environmentDose delivery

Dose delivery device with partially or fully surrounding cover may be removed to open fluid communication with a dose chamber. The cover may allow an inhaler to be stored in sterile or otherwise in a controlled environment prior to use, and removal of the cover may automatically prepare the inhaler for use.

Owner:MANTA DEVICES

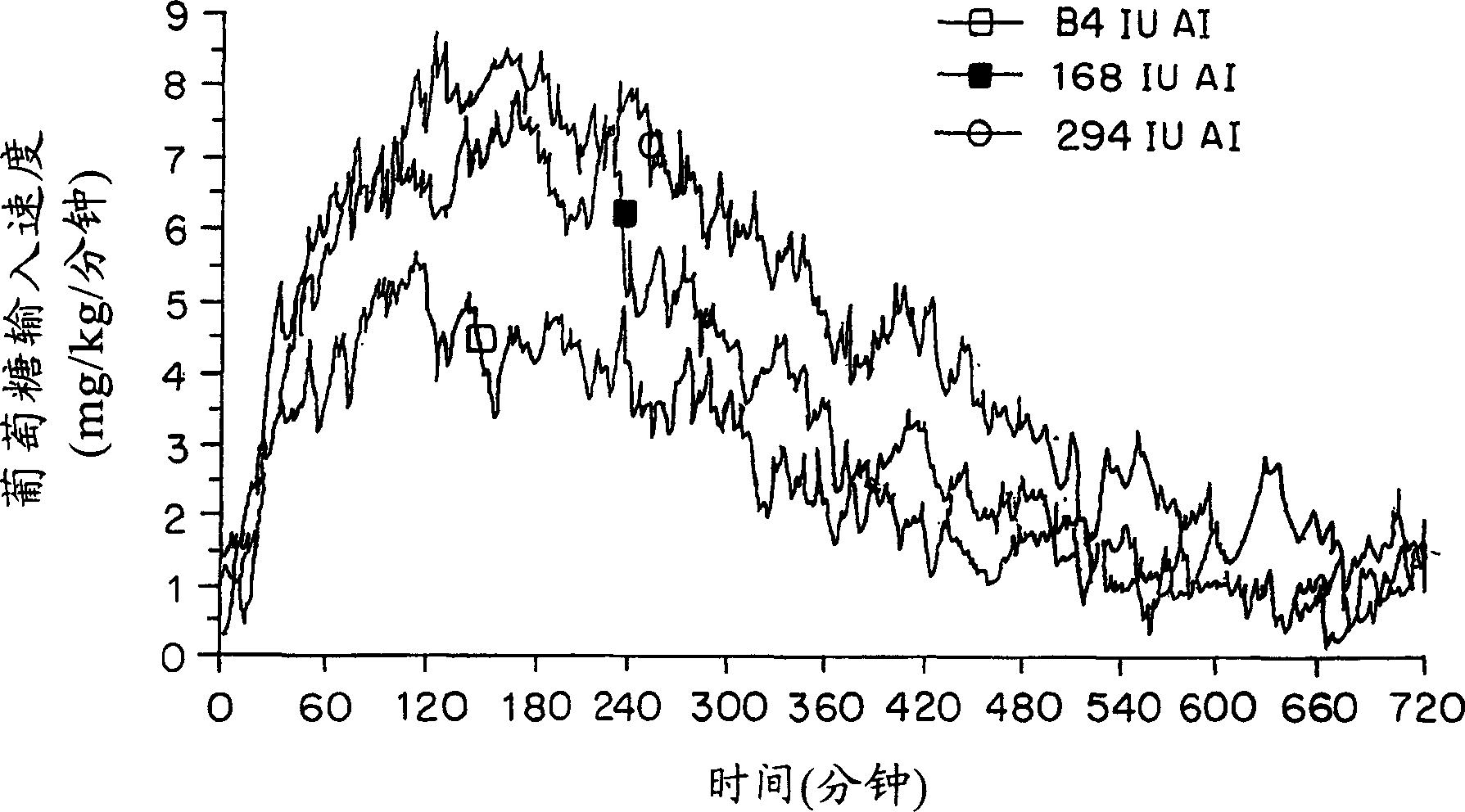

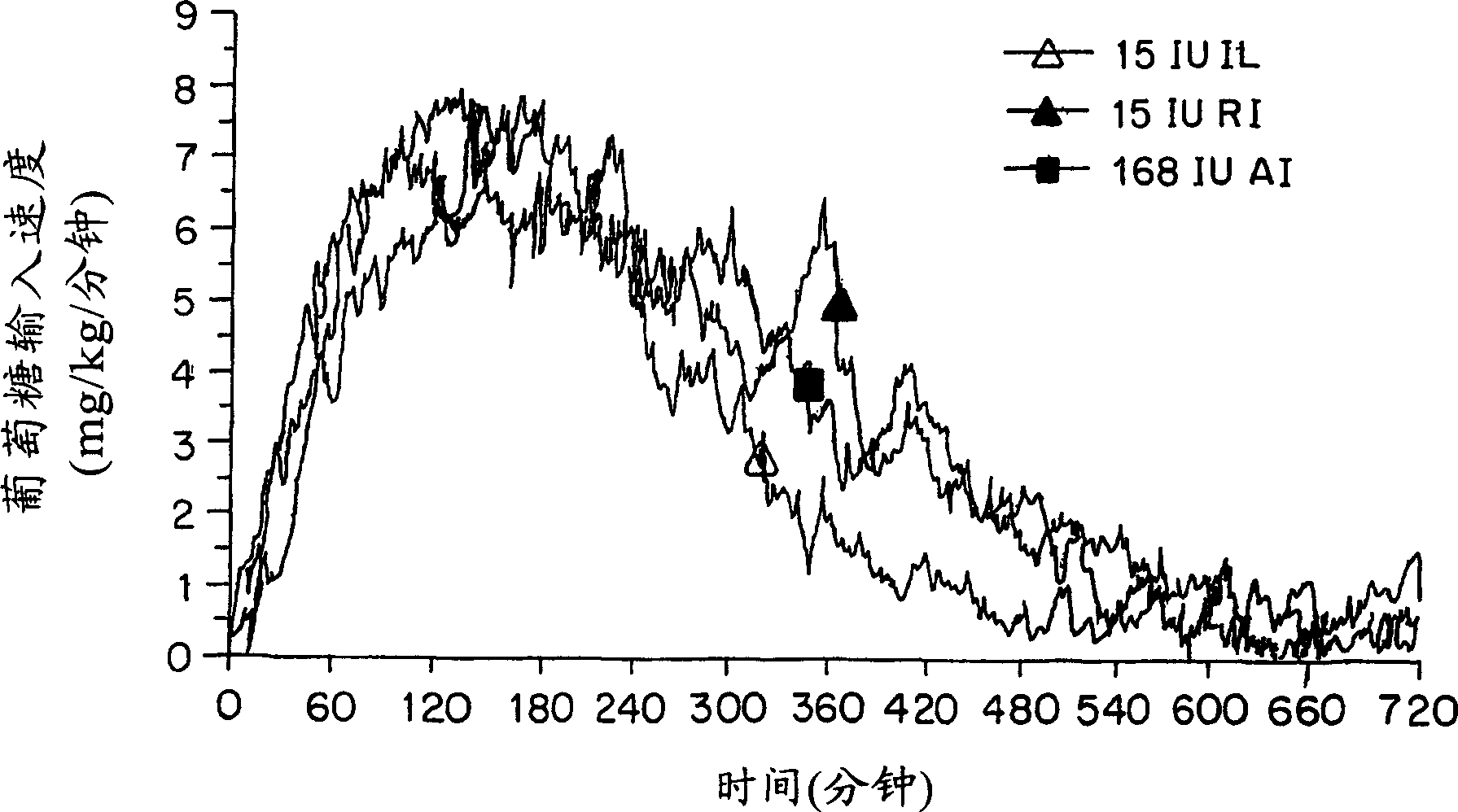

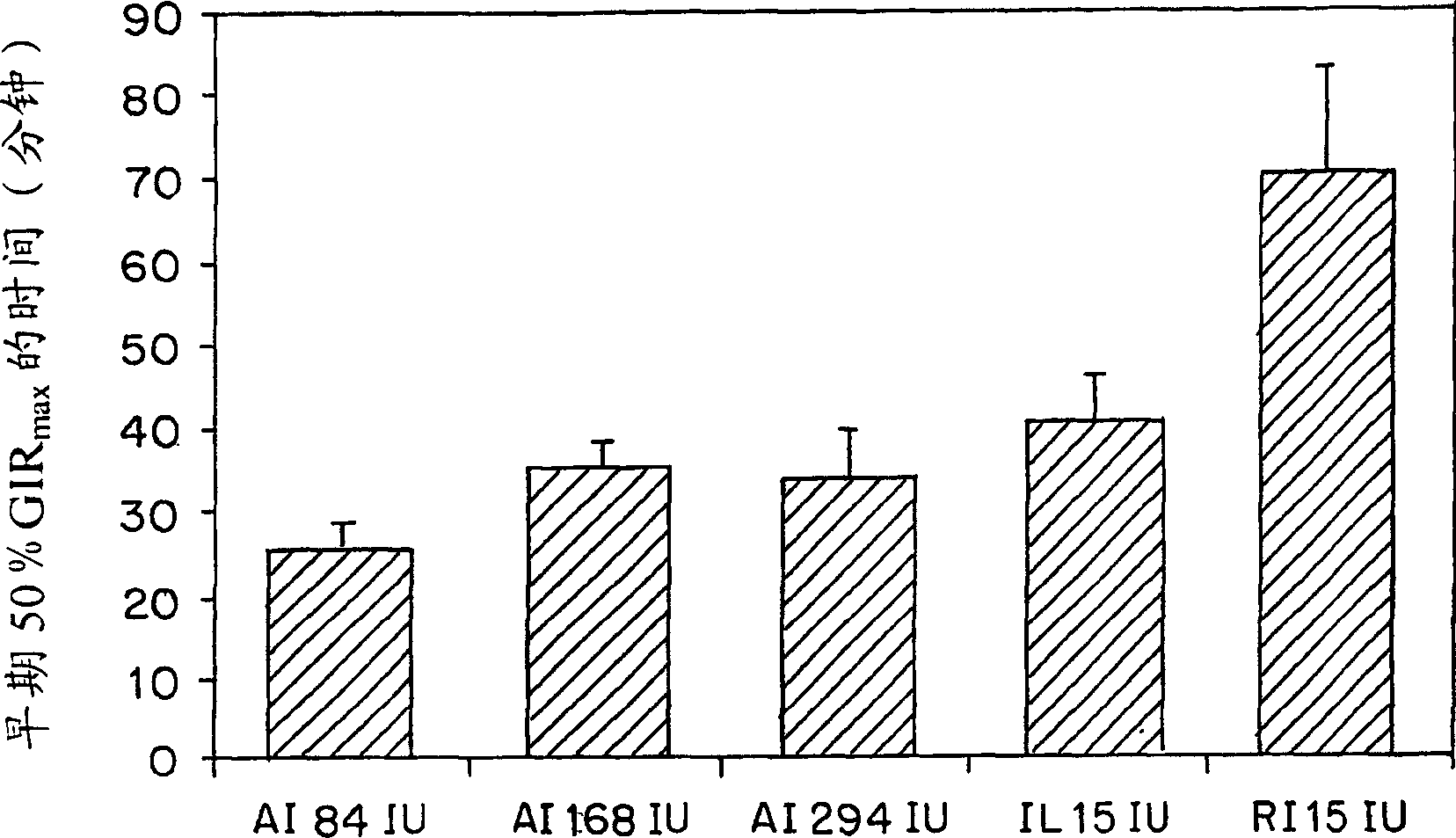

Particles for inhalation having rapid release properties

InactiveCN1518441AShorten the timeShortened stayPowder deliveryOrganic active ingredientsActive agentPhospholipid

The invention generally relates to formulations having particles comprising phospholipids, bioactive agent and excipients and the pulmonary delivery thereof. Dry powder inhaled insulin formulations are disclosed. Formulations comprising DPPC, insulin and sodium citrate which are useful in the treatment of diabetes are disclosed. Also, the invention relates to a method of for the pulmonary delivery of a bioactive agent comprising administering to the respiratory tract of a patient in need of treatment, or diagnosis an effective amount of particles comprising a bioactive agent or any combination thereof in association, wherein release of the agent from the administered particles occurs in a rapid fashion.

Owner:ADVANCED INHALATION RES

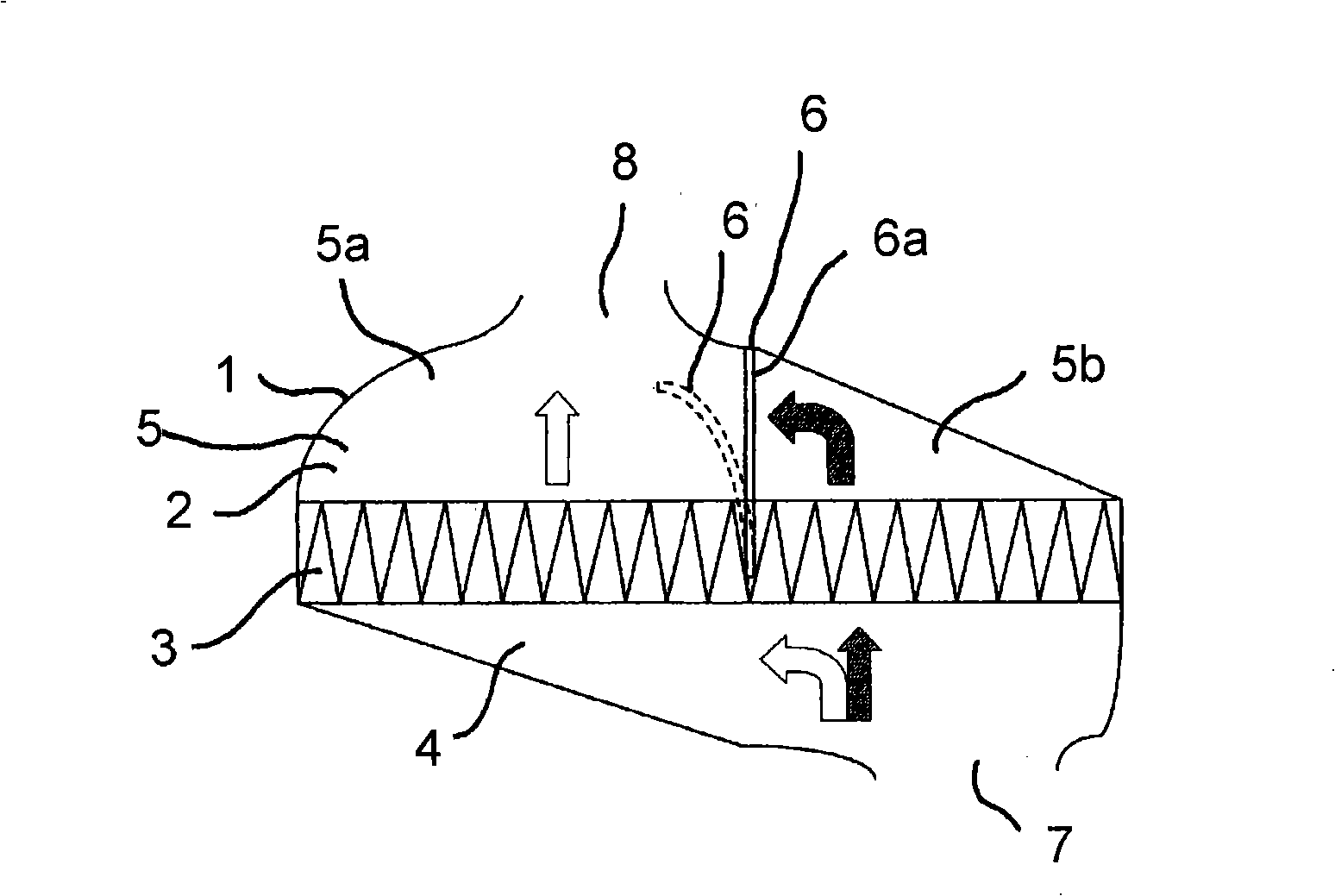

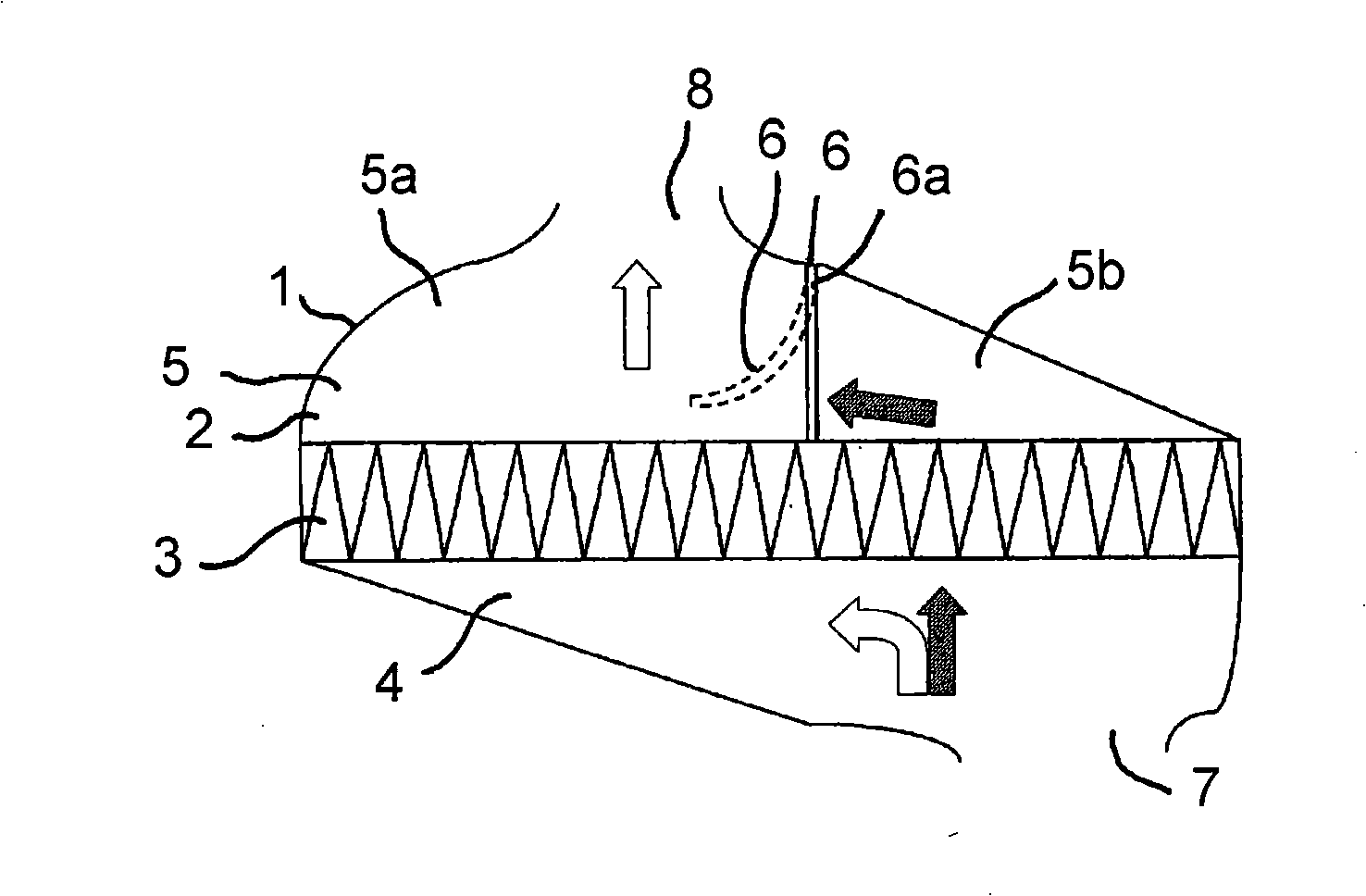

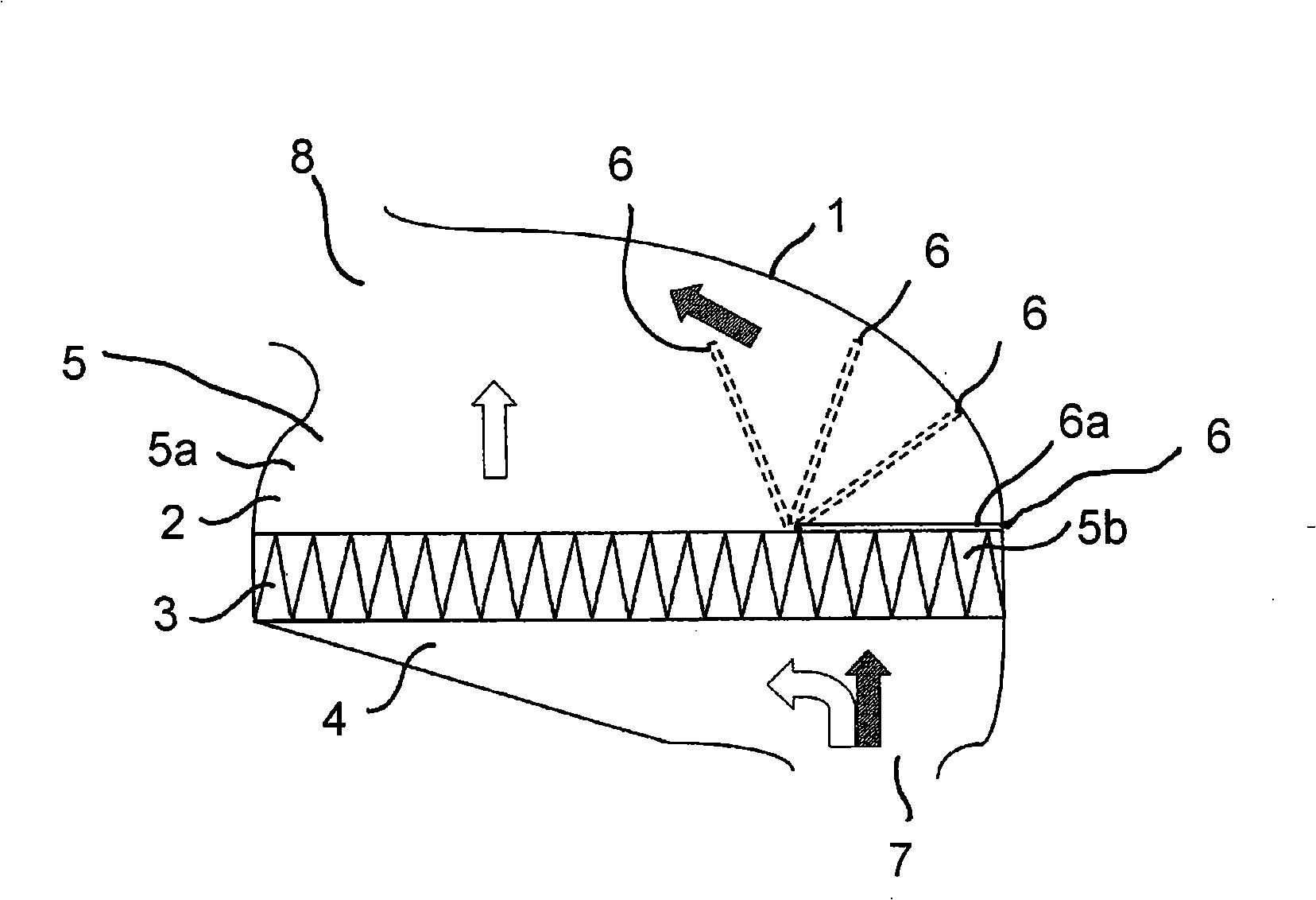

Filter device with a partition

InactiveCN101254384ALow costAvoid feesDispersed particle filtrationTransportation and packagingPhysicsInternal combustion engine

The invention relates to a filter device for filtering fluid media, comprising a housing (1) for accommodating a filter element (3) in an accommodation cavity (2), the filter element (3) divides the accommodation cavity (2) into an inflow cavity (4) and an outflow cavity (5) divided into a master cavity (5a) and a slavery cavity (5b) by a partition (6) at least partially movable, and the master cavity (5a) and the slavery cavity (5b) are flowably connected. The invention aims to provide a filter device capable of optimizing the air supply of an internal combustion engine after long running time at low cost, characterized in that the partition (6) has a working surface (6a), a force generated by a pressure difference between the inflow cavity (4) and the outflow cavity (5) can be applied to the working surface, such that the flowable connection between the master cavity (4) and the slavery cavity (5) can be formed directly by the force.

Owner:CARL FREUDENBERG KG

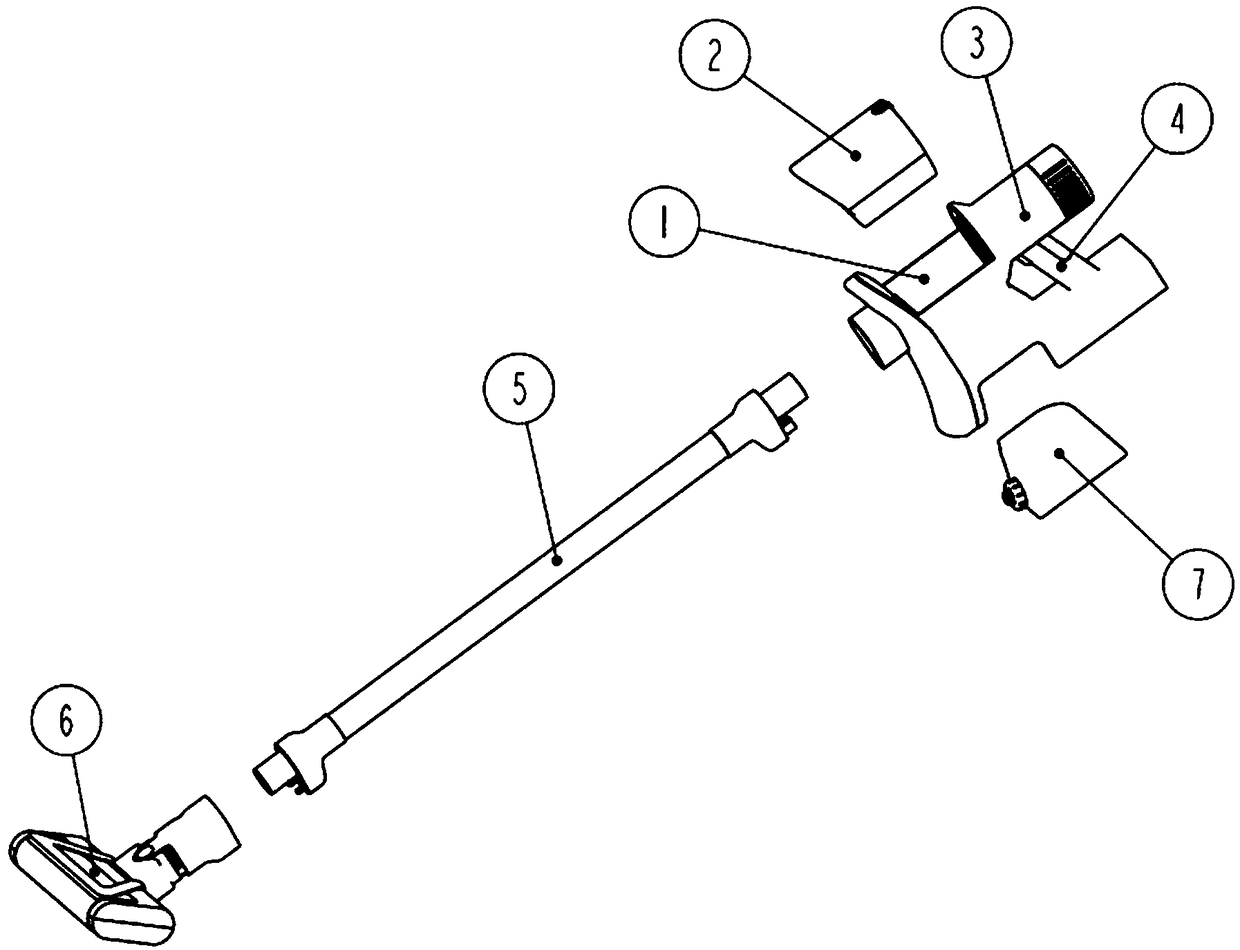

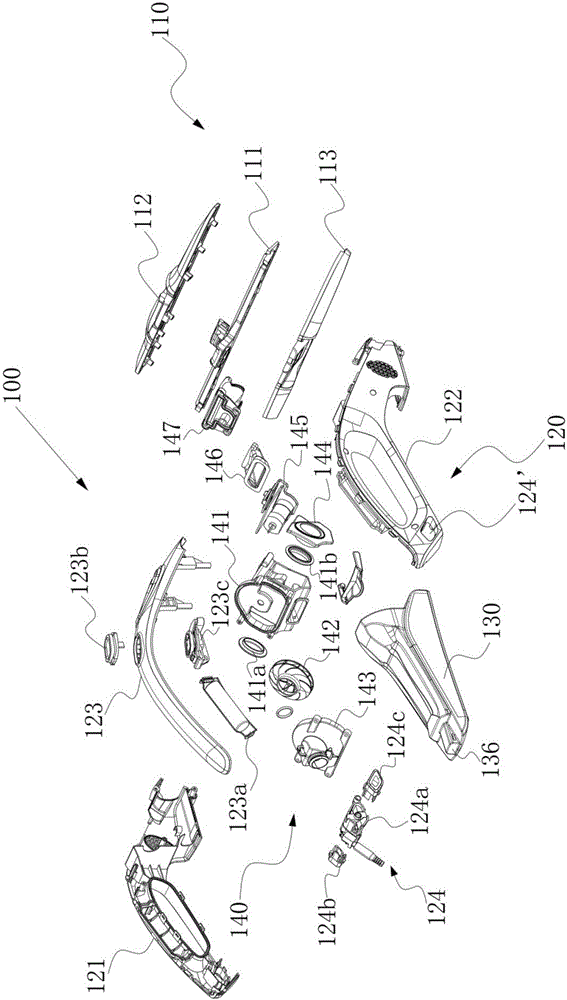

Connecting rod dust collection equipment

The invention provides connecting rod dust collection equipment. The equipment comprises dust collection main machine, a long pipe and a floor brush, wherein the dust collection main machine comprisesa casing, a dust collection motor provided with the casing, a water pump, a clear water tank for containing clear water, and a waste water tank for containing waste water; the inlet of the water pumpis connected with the clear water tank; the long pipe is mounted to the dust connection main machine and is provided with a water pipe connected with the outlet of the water pump; the floor brush ismounted at the tail end of the long pipe and is provided with a water injection nozzle; the water injection nozzle is connected with the water pipe; the dust collection motor is communicated with thelong pipe and the floor brush through the waste water tank. In the technical scheme, water in the clear water tank is led into the water injection nozzle in the floor brush through the water pipe of the water pump, the water injection nozzle directly wets a floor to be cleaned, so as to achieve the effect of scrubbing the floor with a wet body or a cleaning solution, and improves the floor cleaning effect. Dust is sucked into the floor brush, enters the connector of the dust collection main machine via the long pipe, enters the waste water tank, and is separated through the waste water tank, waste water is stored in the waste water tank, clean air is discharged out of the waste water tank, an air duct can be smoother, and the dust can be more easily sucked into the waste water tank.

Owner:GREE ELECTRIC APPLIANCES INC

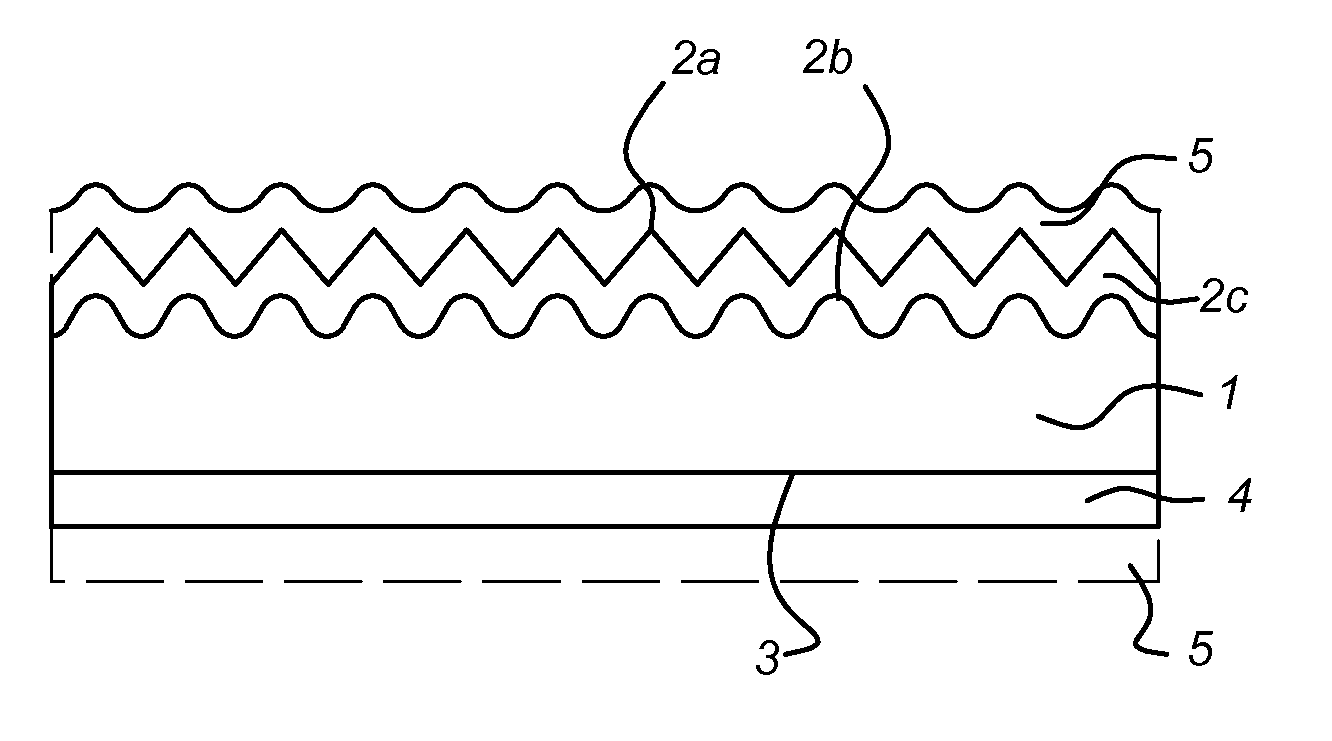

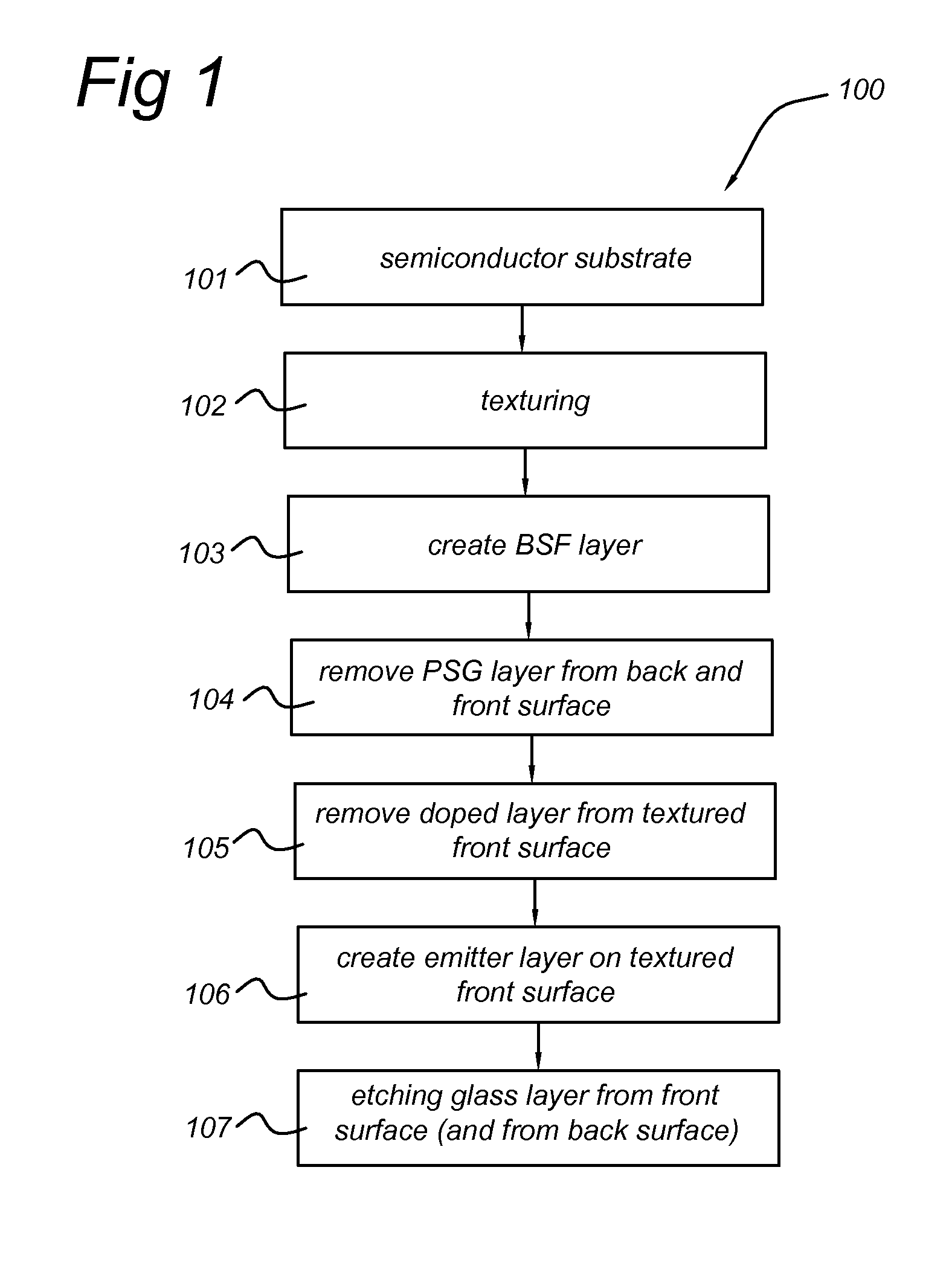

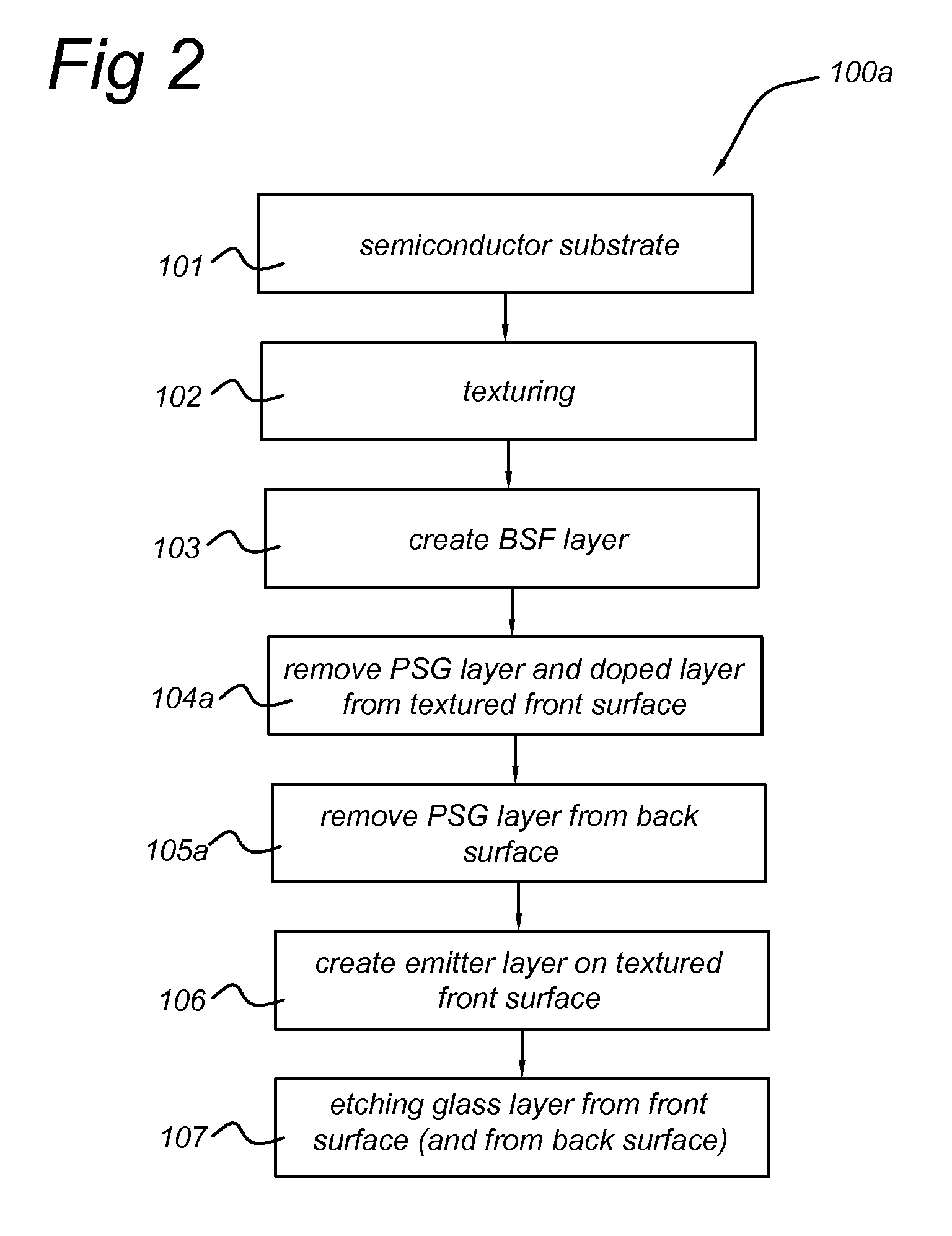

Solar cell and method for manufacturing such a solar cell

ActiveUS20120204948A1Easy to inhaleEasy to manufactureSemiconductor/solid-state device manufacturingPhotovoltaic energy generationDopantBack surface field

Owner:NEDERLANDSE ORG VOOR TOEGEPAST NATUURWETENSCHAPPELIJK ONDERZOEK TNO

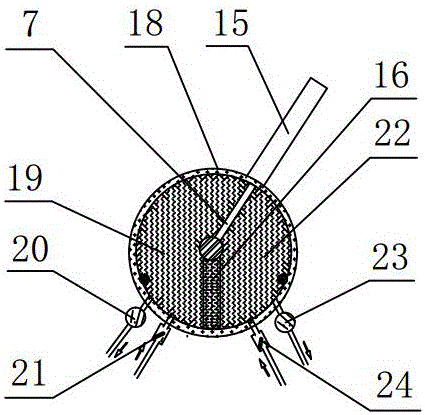

Centrifugal water and gas separation window-cleaning machine

The invention discloses a centrifugal water and gas separation window-cleaning machine, which comprises a shell component having a certain internal space; a suction component which is connected to the front end of the shell component in a pluggable mode; a water tank component for collecting sewage; and a water and gas separating component for separating the sewage from air, wherein a groove which sinks inwards is formed in the lower part of the shell component; an accommodating room is formed in the front of the groove; the water tank component is embedded in the groove in a pluggable mode; the water and gas separating component is arranged inside the accommodating room; and the water and gas separating component comprises a water and gas separating main body, a motor hood cover plate and an auxiliary water tank cover. The window-cleaning machine disclosed by the invention, when improving the cleaning efficiency thereof, can be used for solving a problem of water jet of the window-cleaning machine, so as to increase the water and gas separation efficiency of the window-cleaning machine and to improve the beneficial effect of user experience.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

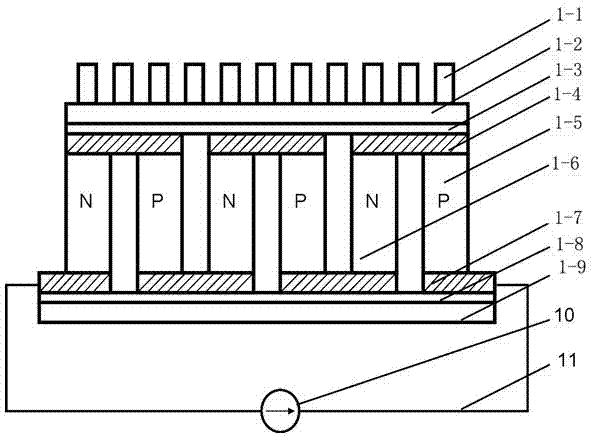

Adsorption device for semiconductor refrigeration

ActiveCN102901265AReduce the difficulty of operationImprove adsorption capacityMachines using electric/magnetic effectsClosed chamberEngineering

The invention discloses an adsorption device for semiconductor refrigeration. The adsorption device comprises a refrigeration mechanism and a closed chamber to be cooled, wherein the refrigeration mechanism comprises a semiconductor refrigeration sheet, first sealing rings, a sealing plug, a connecting line and a circular ring; the semiconductor refrigeration sheet has a mosaic structure; part of each first sealing ring is embedded in the semiconductor refrigeration sheet; the circular ring is fixed on the side surface of the semiconductor refrigeration sheet by welding, and is connected with the sealing plug through the connecting line; a vent hole is formed in one of the first sealing rings, and the sealing plug is inserted in the vent hole and is closely matched with the first sealing ring; the closed chamber to be cooled comprises a smooth flat plate, a cavity and a heat insulating layer; and the cavity is surrounded by the heat insulating layer and the smooth flat plate together, and exchanges heat with the outside through the smooth flat plate. According to the adsorption device, the semiconductor refrigeration sheet does not need to be closely attached to a plane to be refrigerated, so that the operation difficulty of a attaching technique is reduced, air induction and air admission are convenient, and the adsorptive power is high in controllability.

Owner:HANGZHOU DIANZI UNIV

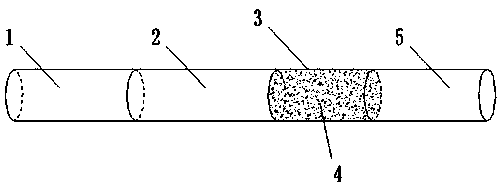

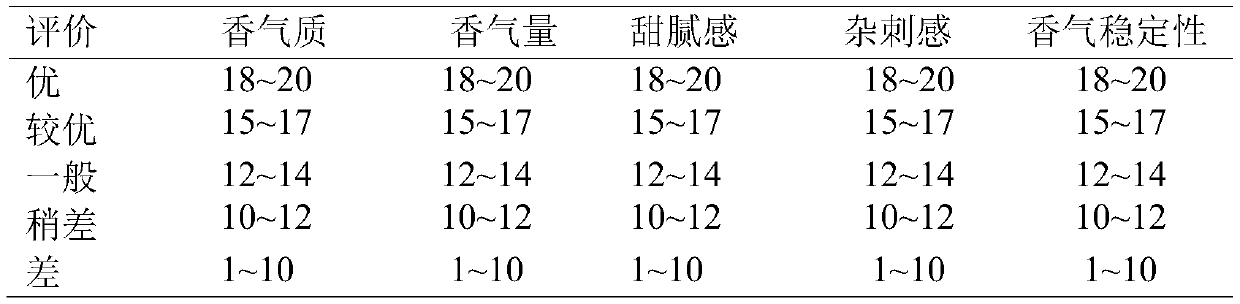

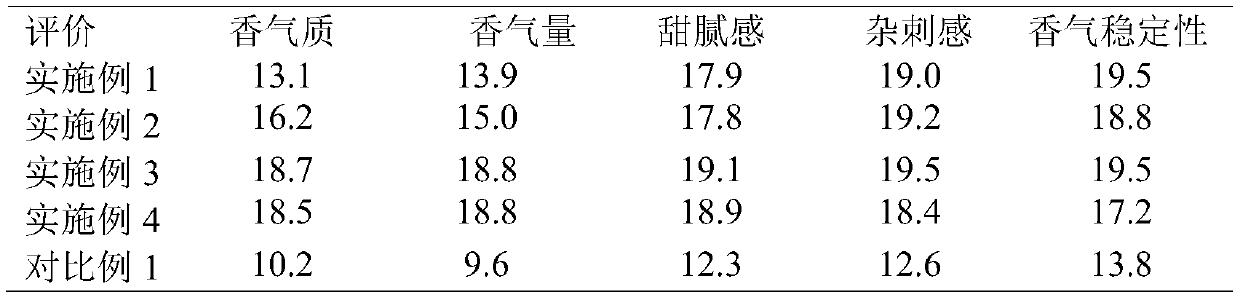

Perfumed tow rod added into heating non-combustible cigarette filter rod and preparation method thereof

InactiveCN110226775ASimple preparation processImprove pass rateCigar manufactureTobacco smoke filtersFlavorBoiling point

The invention relates to a perfuming tow rod added into a heated non-combustible tobacco filter rod. The method is characterized in that a tow rod is designed at the end close to tobacco; the tow rodis positioned between the tobacco section and the cooling section; the specific surface area of the pelelith is large; the porous adsorbability is good; adsorbing tobacco flavors and fragrances and loading the tobacco flavors and fragrances into the tow rod; according to the technical scheme, essence can be continuously released in the smoking process, the bad smoking smell of smoke is improved, essence and spice with the high boiling point can be added, the low-temperature tobacco smoke is more sweet and mellow in brewing, rich in saturation and durable in fragrance, and the perfumed tow rodis simple in preparation process, high in percent of pass, low in production cost and good in stability.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Solar power generation photovoltaic panel surface ash deposition cleaning device

ActiveCN111359924AAffectAvoid re-floating issuesDispersed particle filtrationTransportation and packagingEngineeringSolar power

The invention discloses a solar power generation photovoltaic panel surface ash deposition cleaning device which comprises a machine body, two cleaning heads, two filtering heads, a control box, an electricity generating panel, access doors, filtering plates, a scraper and a dust collecting fan, wherein the two cleaning heads are symmetrically arranged on the two sides of the machine body; the twofiltering heads are symmetrically arranged on the upper surface, close to the two ends, of the cleaning device; the control box is arranged on the upper surface, close to one end of the machine body,of the machine body; the access door is arranged at the front and back ends of the machine body; and the filtering plates are symmetrically arranged at the front and rear ends of the upper surface ofthe machine body. The solar power generation photovoltaic panel surface ash deposition cleaning device can solve the problem that most existing photovoltaic panel cleaning devices adopt rolling brushes to clean ash, as a result, plenty of dust is raised to the air once more, and dust is gradually accumulated on the photovoltaic panel once more; and through improving and optimizing the photovoltaic panel cleaning device, the photovoltaic panel cleaning device can clean ash deposition on the photovoltaic panel and also can adsorb cleaned ash deposition.

Owner:吴翰

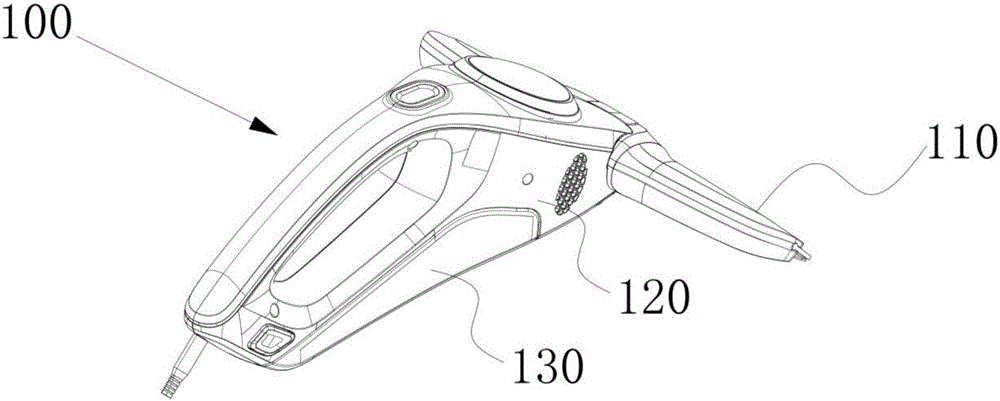

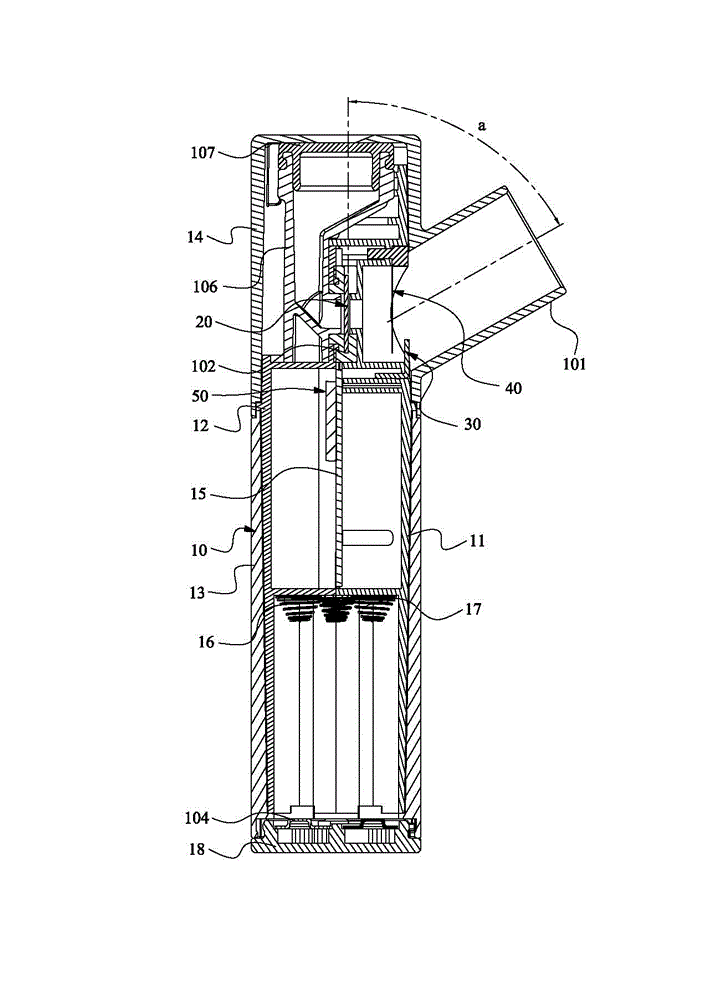

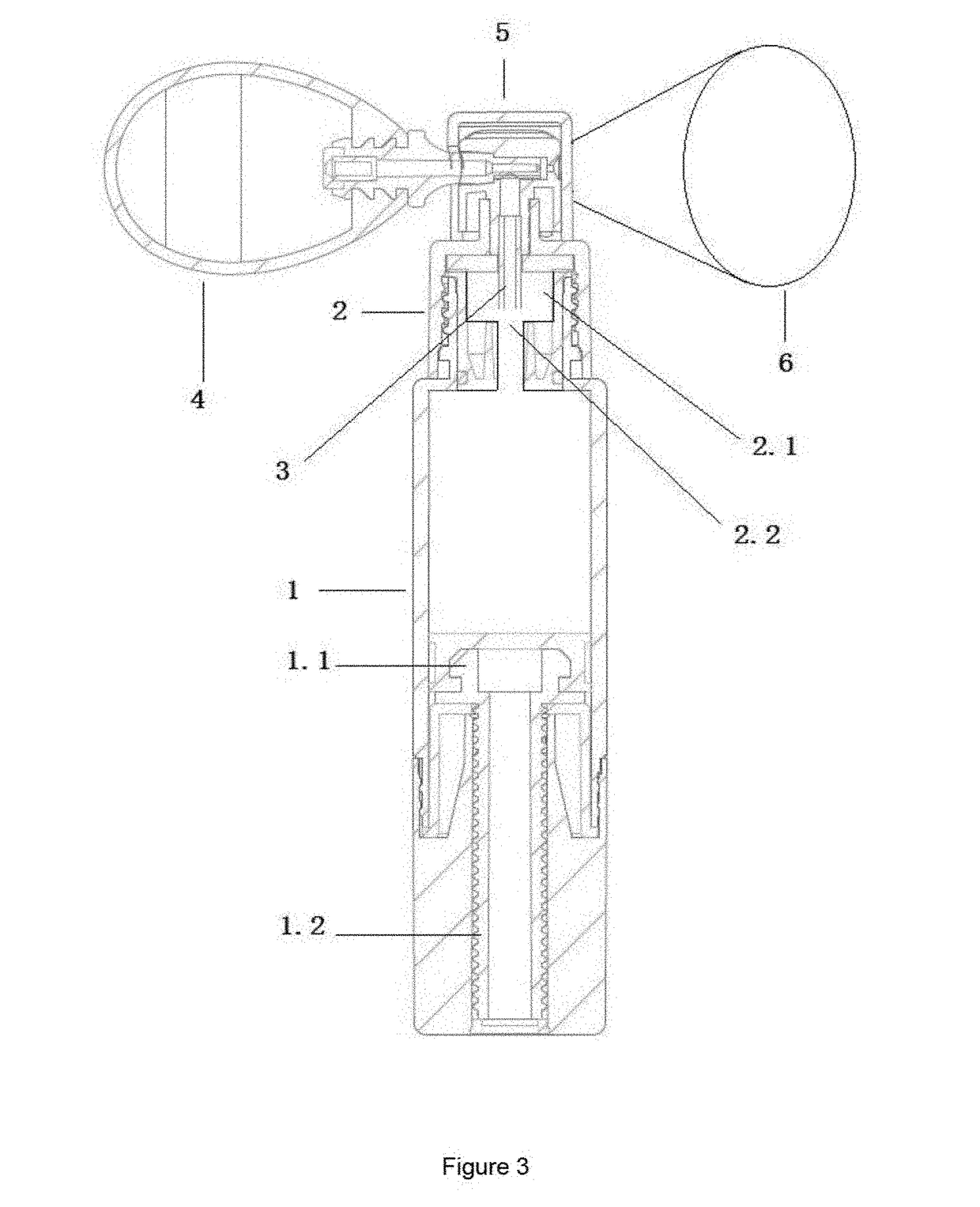

Micro handheld atomizer capable of quantitatively atomizing during air suction

The invention discloses a micro handheld atomizer capable of quantitatively atomizing during air suction. The micro handheld atomizer comprises a main body and an atomizing sheet arranged in the main body, wherein a guide spray pipe extends obliquely and upwardly out of the side face of the main body; the atomizing sheet is arranged vertically in the main body, and faces the input port of the guide spray pipe; an included angle is formed between the atomized air output plane of the atomizing sheet and the extending direction of the guide spray pipe; the included angle is smaller than 90 degrees; a quantifying device and a touch sheet assembly which are used for controlling the atomizing sheet to work in a matching way are arranged in the input port of the guide spray pipe; and the quantifying device is provided with a touch switch, and a controller for presetting and controlling the atomizing time. When a user sucks air through the guide spray pipe, the touch sheet assembly is pressed against the touch switch to start the atomizing sheet, and the touch sheet assembly and the touch switch can be automatically separated from each other to finish the work of the atomizing sheet after the control time preset by using the controller is reached; and the controller can be used for presetting different atomizing time according to different users, and automatically controlling each atomizing time, so that each atomizing amount is kept fixed.

Owner:VINCENT MEDICAL (DONG GUAN) MFG CO LTD

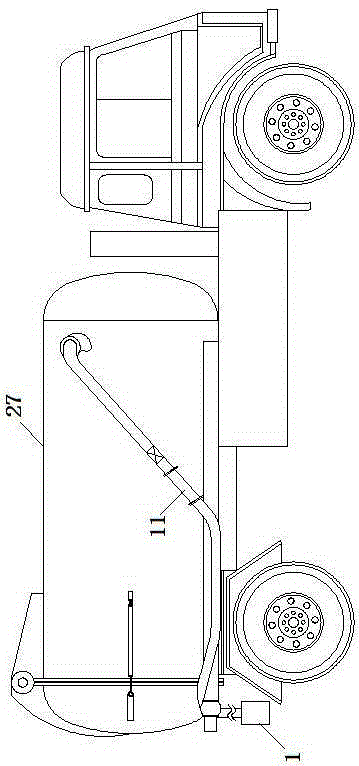

Suction sewage truck

The invention discloses a suction sewage truck. The suction sewage truck comprises a transport vehicle and further comprises a sludge suction system and a carriage. The sludge suction system and the carriage are arranged on a frame of the transport vehicle. The sludge suction system comprises a suction device, a connecting device for the suction device, and a gas exhaust device for tail gas of an engine of the transport vehicle. The suction device comprises a suction pipe, a transmission sleeve, a motor, a crushing cutter and a ventilation pipe. The connecting device comprises a connecting pipe made of transparent materials. The gas exhaust device comprises a main gas exhaust pipe and an auxiliary gas exhaust pipe. The carriage comprises a carriage body, a first-level separation device, a feeding device and a second-level separation device. The first-level separation device comprises a first-level auger and a first-level separation cavity. The feeding device comprises a feeding cavity and a feeding opening. The second-level separation device comprises a second-level auger and a second-level separation cavity. The second-level auger is arranged in the second-level separation cavity and fixedly connected with the outer cavity wall of the first-level separation cavity.

Owner:HUNAN JINSONG AUTOMOBILE CO LTD

Marine floating type garbage recycling device driven by wave energy

ActiveCN106400757AAchieving Active AbsorptionEasy to inhaleWater cleaningGeneral water supply conservationOil separationEngineering

The invention specifically relates to a marine floating type garbage recycling device driven by wave energy. The marine floating type garbage recycling device driven by the wave energy comprises a floating type overwater garbage can and a pair of floating type fences, wherein the pair of floating type fences are connected with the floating type overwater garbage can, the floating type overwater garbage can is connected with a wave energy water pump by virtue of a pumping pipe arranged at the bottom of the floating type overwater garbage can, and the wave energy water pump is arranged on a wave energy capture device and is connected with an oil separation pool by virtue of a water outlet pipe. By using the pair of floating type fences, floating garbage and spilling oil near a harbor frontage are intercepted to enter the floating type overwater garbage can by the floating type fences, and the wave energy water pump is driven to continuously pump water in the floating type overwater garbage can to the oil separation pool by the wave energy capture device so as to separate. The device has the advantages of high efficiency in cleaning and no pollution and can be applied to inner harbors and adjacent seas, and offshore floating garbage and sea oil of the inner harbors can be simultaneously recycled.

Owner:ZHEJIANG UNIV

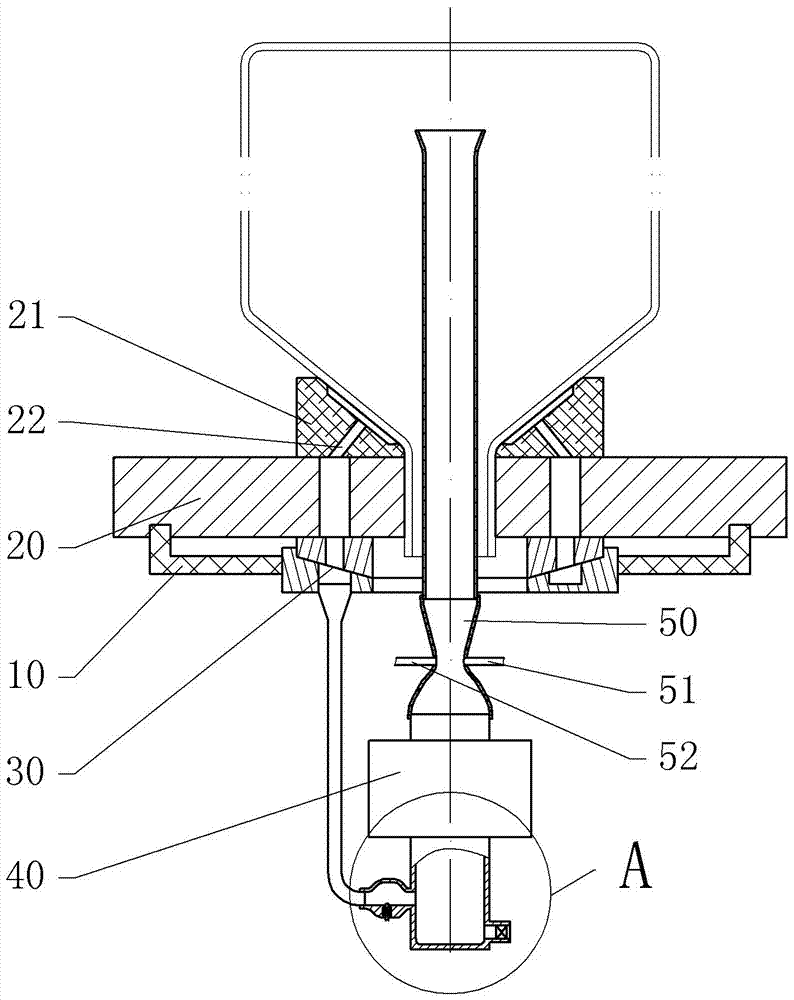

Hand-actuated aerosol generator and its use

InactiveUS20180126100A1Safe and effective useImprove practicalityMedical devicesSingle-unit apparatusNebulizerMedicine

Disclosed herein are hand-actuated aerosol generators, having an adjustable two-compartment medicament container (20) that holds a medicament in a liquid or a fine dry powder form, and connects to a fluid passage; a cap of said container with a jet-sprayer capacity; a mouthpiece (6) through which a medicament released from said jet-sprayer (2) can be inhaled into the respiratory tract by a patient without leakage; a hand-actuated positive air pressure supplier connected to the cap of said medicament container, and an optional spacer that increases inhalation efficiency.

Owner:LIU JAMES ZHOU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com