Polysiloxane-modified cationic polysaccharide compound as well as preparation method and application thereof

A technology of cationic polysaccharides and polysiloxanes, applied in cosmetic preparations, cosmetics, pharmaceutical formulations, etc., can solve problems such as insufficient softness and gloss, improve dispersibility, facilitate packaging and transportation, and improve application effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

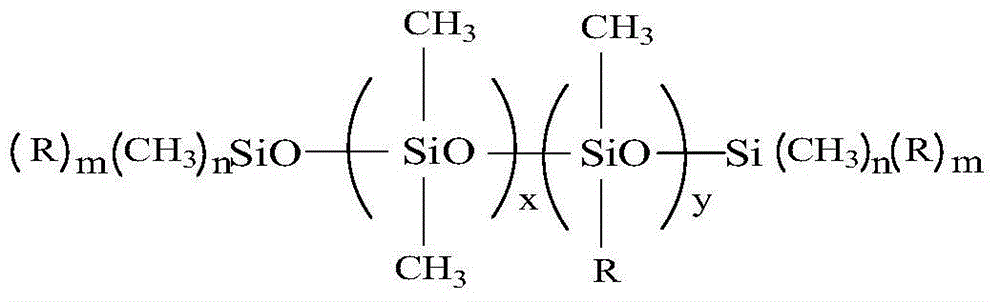

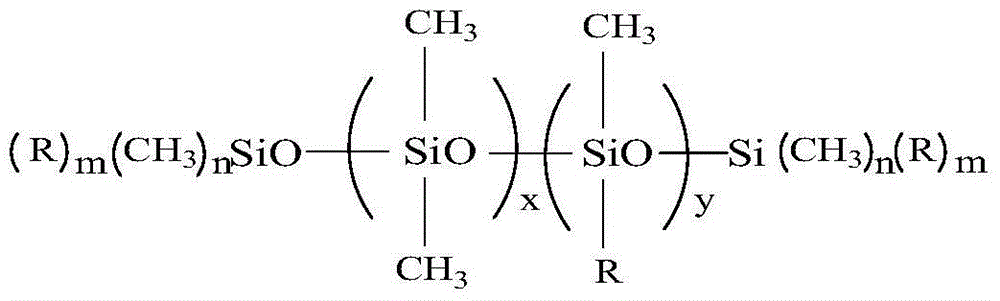

Method used

Image

Examples

Embodiment 1

[0038] Prepare 300g of ethanol aqueous solution with a mass fraction of 80% in the reactor, add 100g of starch, stir and disperse evenly, heat the material to a temperature of 50°C, then slowly add 6g of a 32% NaOH aqueous solution, and add 20g of it after reacting for 30min 70% aqueous solution of 2,3-epoxypropyltrimethylammonium chloride was stirred evenly, then the temperature was raised to 60°C for cationization reaction for 5 hours, and then aminopropanol with an average molecular weight of 35,000 and an amino group content of 0.6% was added Modification reaction was carried out with 5 g of base polydimethylsiloxane, and the reaction was completed by maintaining the temperature of the material at 60° C. to 70° C. for 2 hours.

[0039] Add 2.9g of glacial acetic acid for neutralization, measure pH=6.9 to stop the reaction, then filter the reaction material, and vacuum-dry the powder solid phase at 90°C to obtain 108g of polysiloxane-modified cationic starch.

Embodiment 2

[0041] Prepare 250g of ethanol aqueous solution with a mass fraction of 75% in a reaction flask, add 120g of cellulose, stir and disperse evenly, heat up to a material temperature of 55°C, then slowly add 6.5g of a 32% NaOH aqueous solution, react for 15min, then add 20g The aqueous solution of 2,3-epoxypropyltrimethylammonium chloride with a mass fraction of 70% was stirred evenly, then heated to 60°C for cationization reaction for 5 hours, and then added with an average relative molecular mass of 35,000 and an amino group content of 0.6%. 5g of aminopropyl polydimethylsiloxane was used for the modification reaction, and the temperature of the material was maintained at 60°C to 70°C for 2h to complete the reaction.

[0042] Add 3.1g of glacial acetic acid for neutralization, the measured pH=7.2 to stop the reaction, then filter the reaction material, and vacuum-dry the powder solid phase at 85°C to obtain 125g of polysiloxane-modified cationic cellulose.

Embodiment 3

[0044] Prepare 300g of isopropanol aqueous solution with a mass fraction of 75% in a reaction flask, add 100g of guar gum, stir and disperse evenly, heat up to a material temperature of 50°C, then slowly add 6g of a 32% KOH aqueous solution with a mass fraction, and react for 30 minutes Add 20 g of 2,3-epoxypropyltrimethylammonium chloride aqueous solution with a mass fraction of 70% and stir evenly, then raise the temperature to 55°C for cationization reaction for 5 hours, and then add 7.5 g of aminoethylaminopropyl polysiloxane was used for the modification reaction, and the reaction was completed for 1.5 hours while maintaining the temperature of the material at 60° C. to 70° C.

[0045] Add 2.9g of glacial acetic acid for neutralization, measure PH=7.1 to stop the reaction, then centrifuge the reaction material, take the powdered solid phase and carry out vacuum drying at 90°C to obtain 106g of polysiloxane-modified cationic guar gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com