Filter device with a partition

A filter device and spacer technology, which is applied in the directions of dispersed particle filtration, separation method, charging system, etc., can solve problems such as engine combustion interference, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

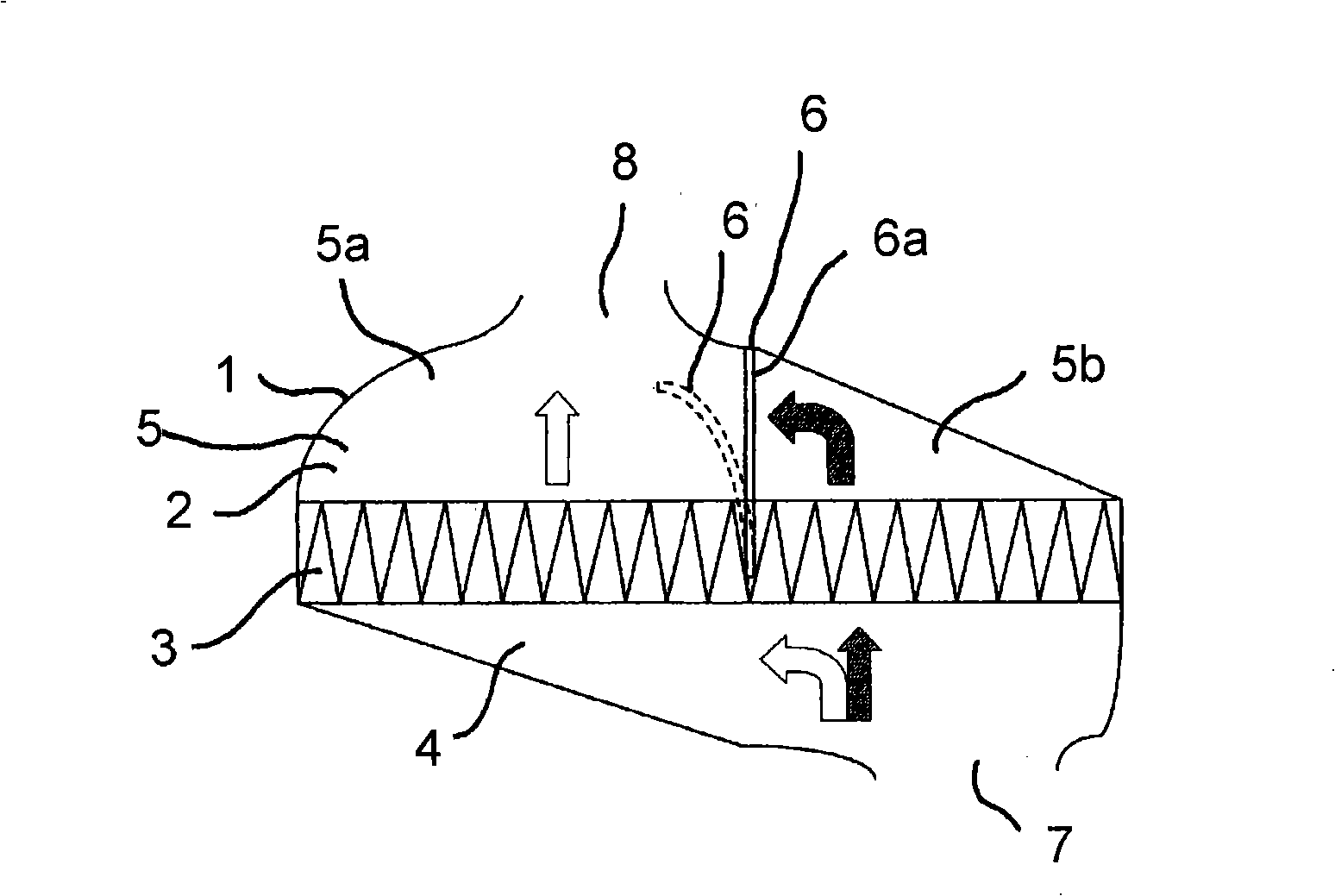

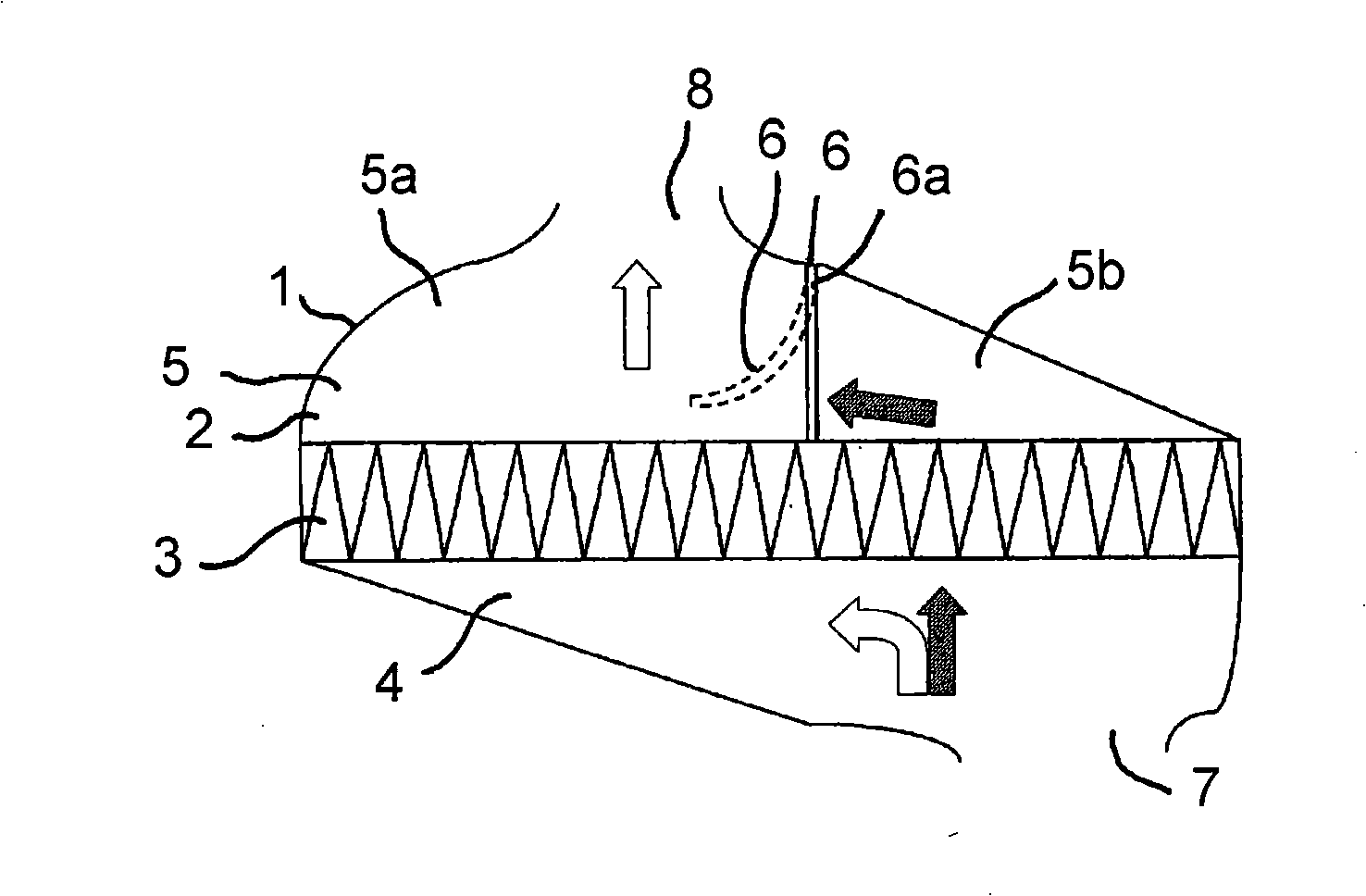

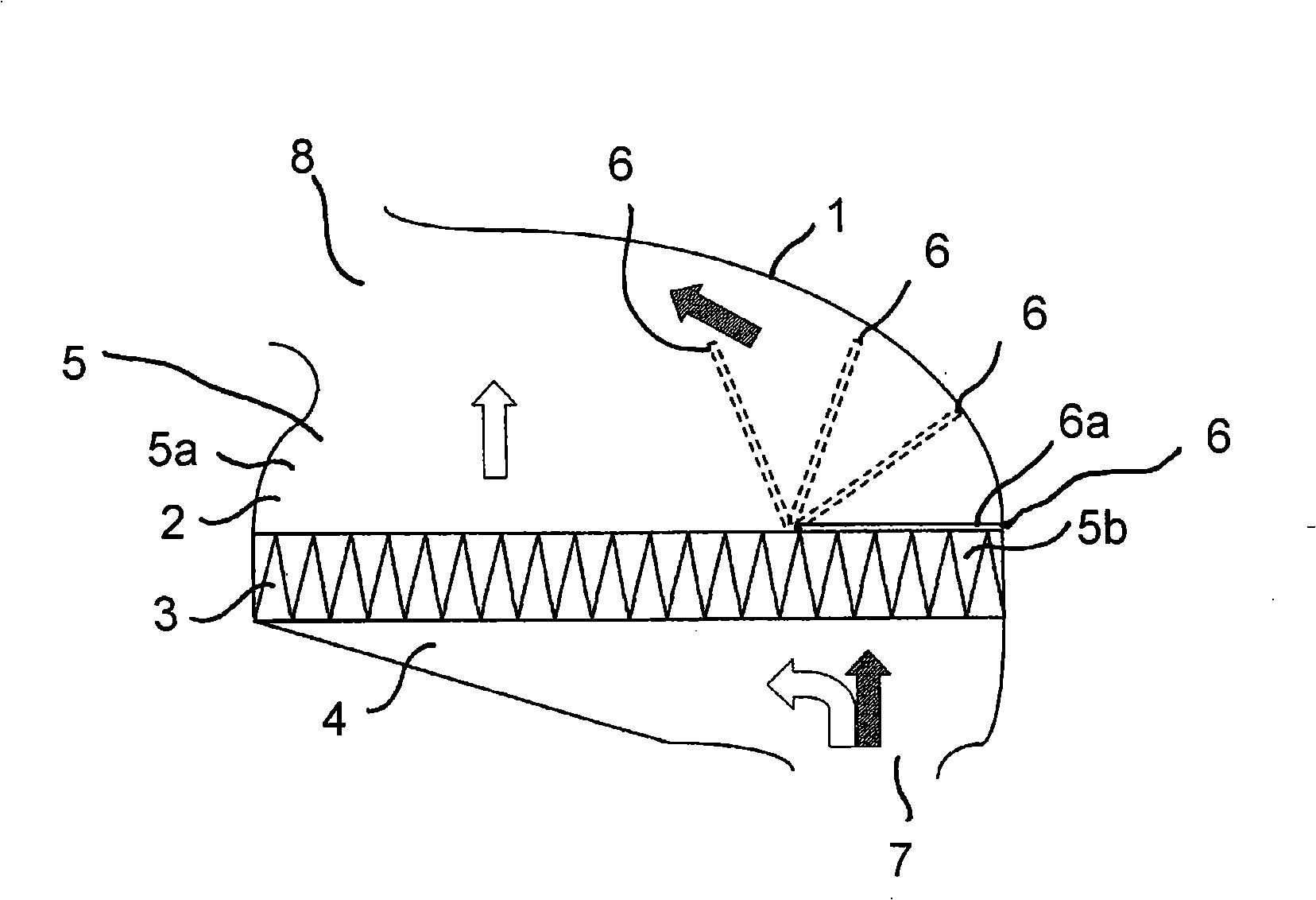

[0028] figure 1 A filter device for filtering a fluid medium, ie air for a car engine, is shown. The filter device comprises a housing 1 which accommodates a filter element 3 in a receiving chamber 2 . The filter element 3 divides the receiving chamber 2 into an inflow chamber 4 and an outflow chamber 5 . The receiving chamber 2 is divided in such a way that dirt particles separate the inflow chamber 4 from the outflow chamber 5 in a sealed manner. The filter element 3 can be glued or welded on the inner wall of the housing 1 . The outflow chamber 5 is divided by an at least partially movable partition 6 into a main chamber 5a and a secondary chamber 5b. When the partition 6 moves, the primary chamber 5a and the secondary chamber 5b are fluidly connected.

[0029] The spacer 6 has a working surface 6a on which the force generated by the pressure difference existing between the inflow chamber 4 and the outflow chamber 5 can act in such a way that the main chamber 5a and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com