Coating machine for plate group of lead acid battery

A technology of extremely group coating machine and lead-acid battery, which is applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., and can solve the problem of easy inhalation of dust, side-to-side displacement of diaphragm or plate, and high labor intensity and other problems, to achieve the effect of increasing the scope of use, avoiding film damage, and improving the quality of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

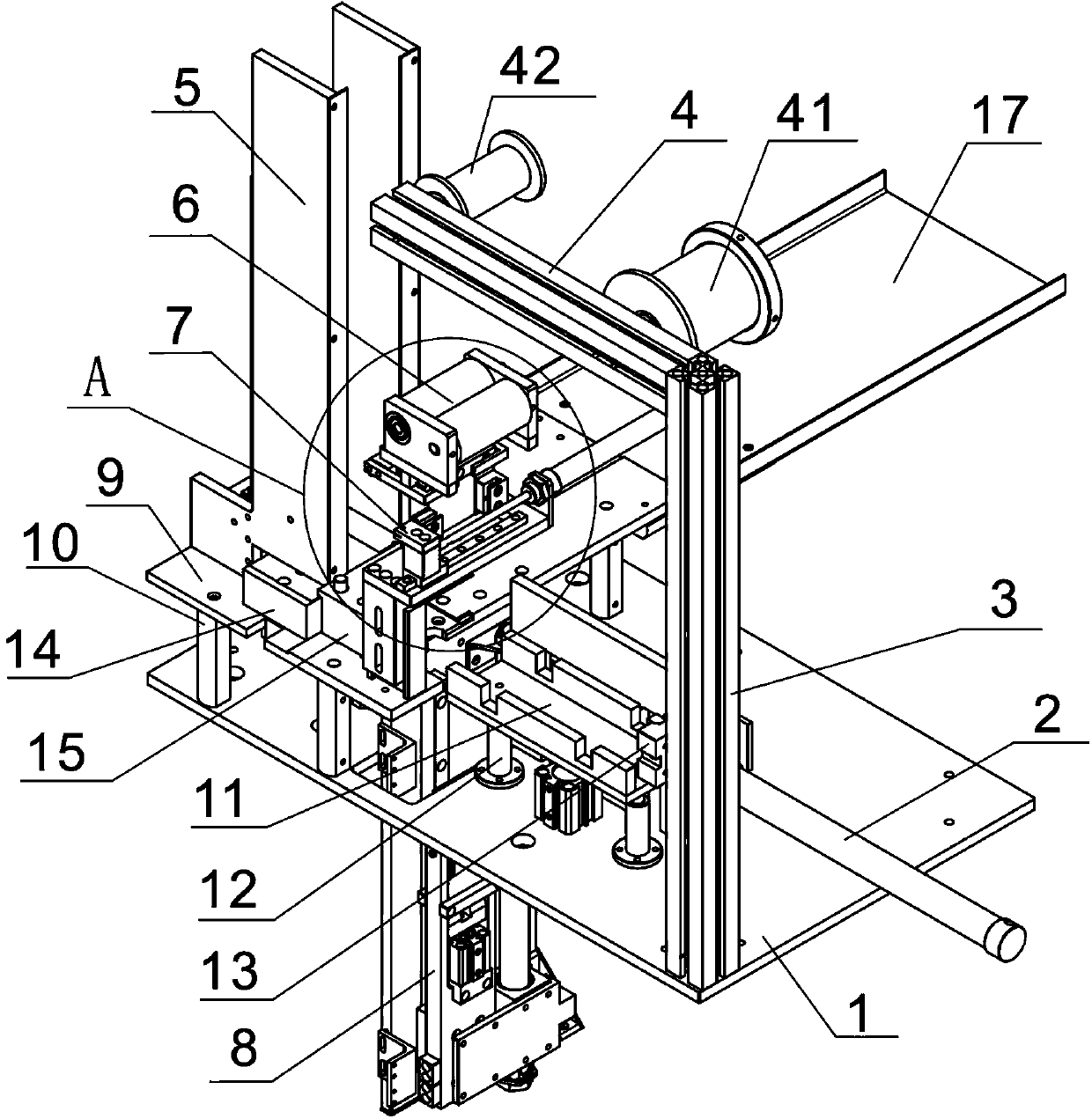

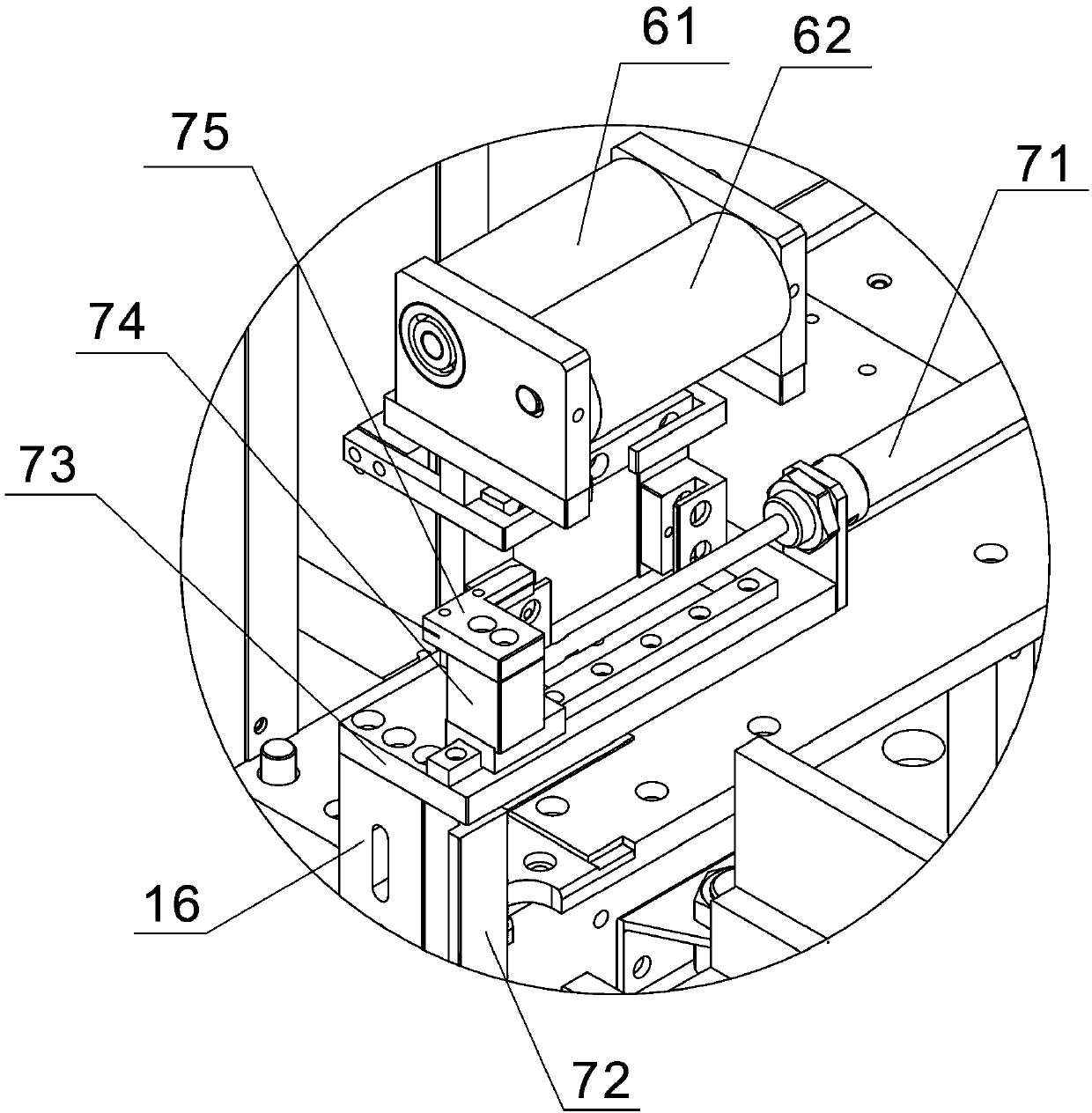

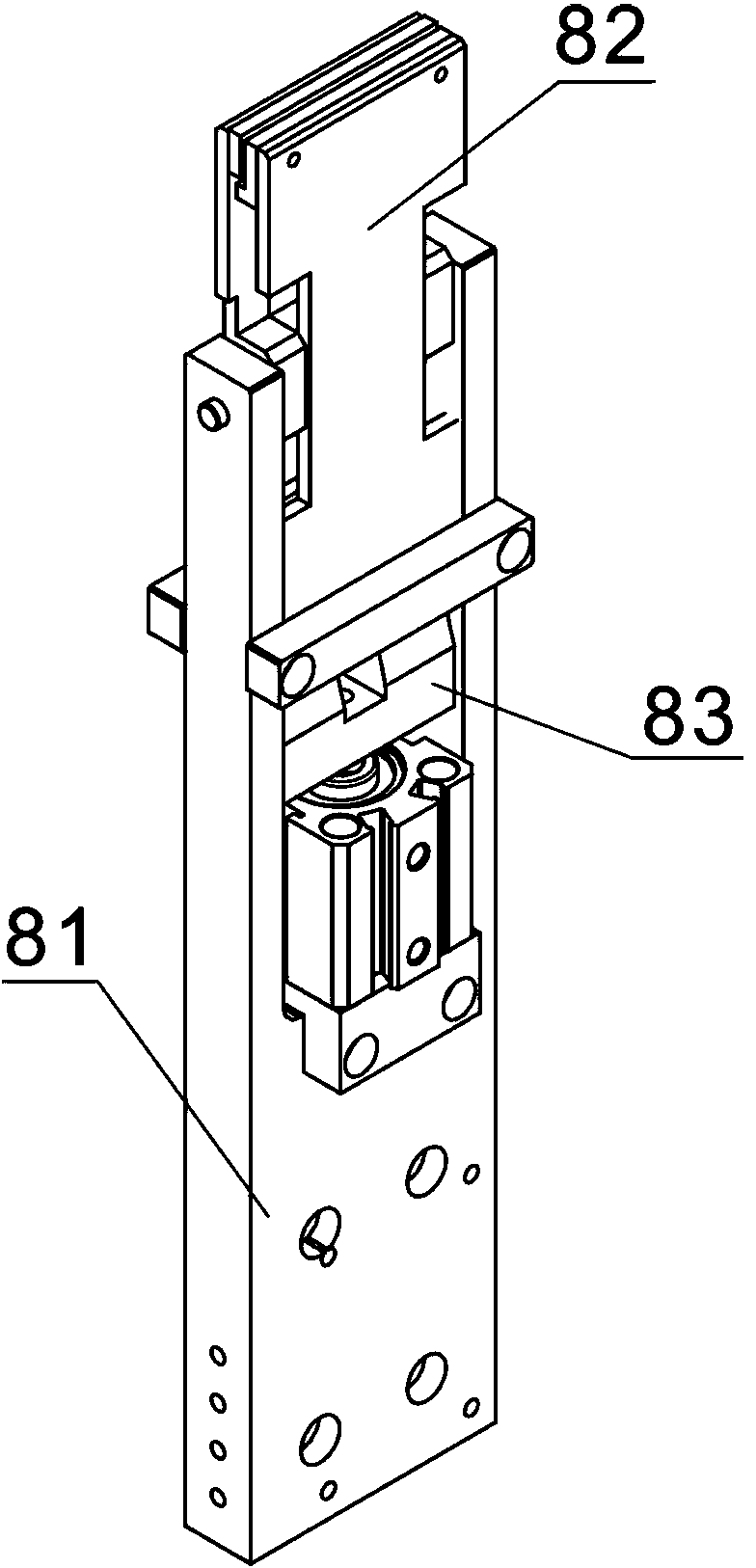

[0023] Such as Figure 1 to Figure 4 As shown, a lead-acid battery electrode group coating machine according to the present invention includes a base plate 1 and a film traction device and a film guide device 6 installed on the base plate 1, and the film guide device 6 is located below the film traction device. A film cutting mechanism 7 is arranged below the film guiding device 6, and a film pulling device 8 is also arranged directly below the film guiding device 6, and a feeding device and a box-input device are respectively provided on both sides of the film pulling device 8, and The box device is installed on the base plate 1 through the work table 9 and the table support 10 placed below it.

[0024] Described film traction device comprises film vertical support 3 and film transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com