Patents

Literature

170results about How to "Enough thickness" patented technology

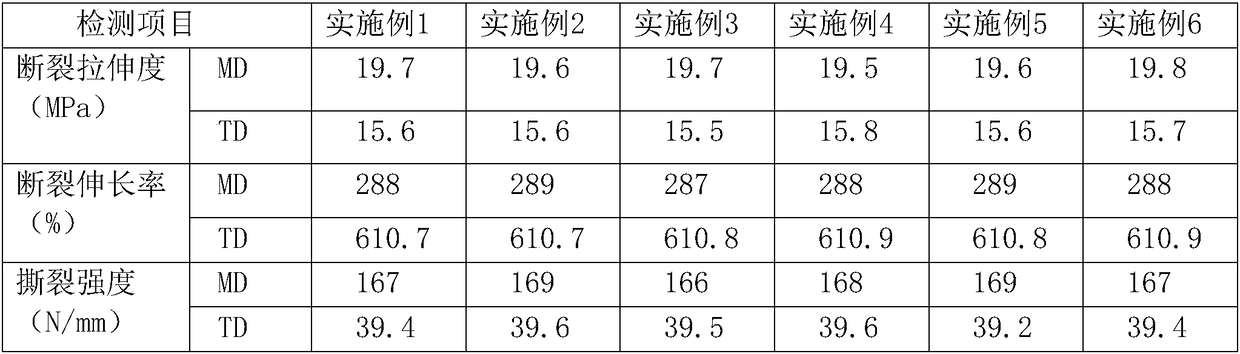

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

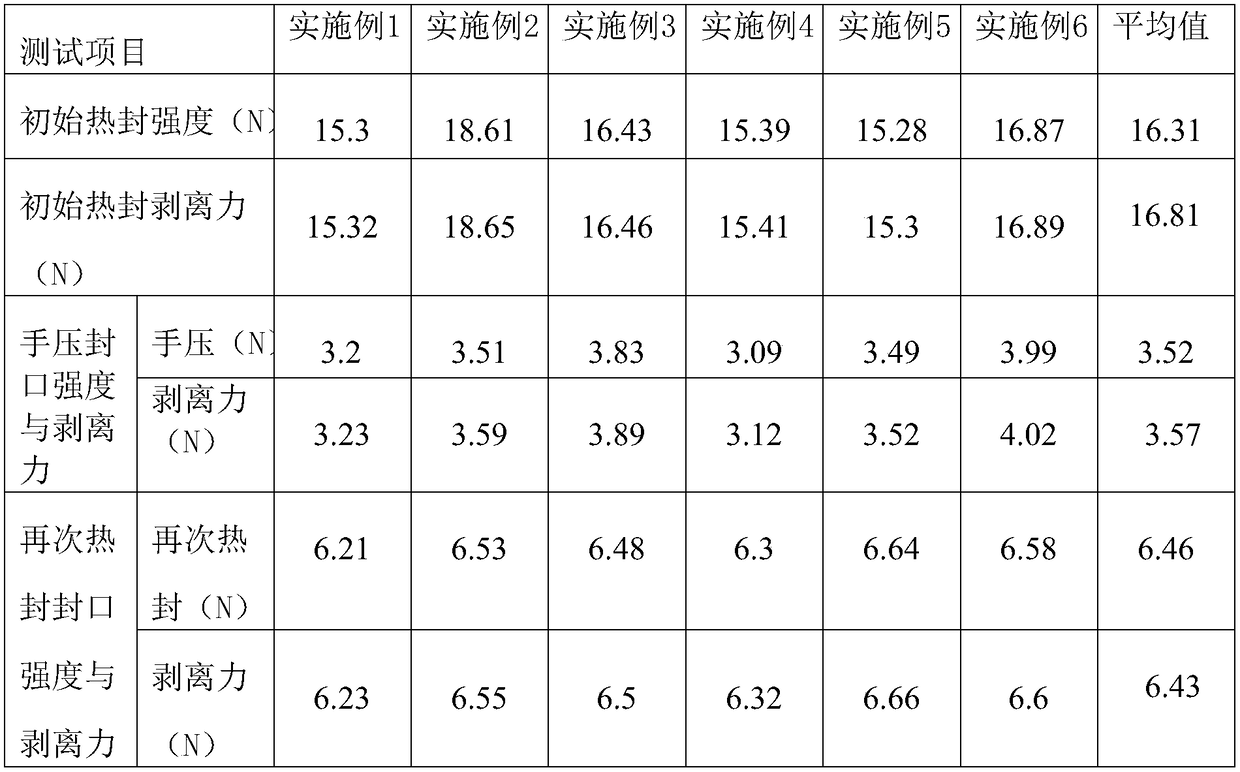

Multilayer chip capacitor

ActiveCN1808649AEnough thicknessAvoid damageFixed capacitor dielectricStacked capacitorsEngineeringEquivalent series inductance

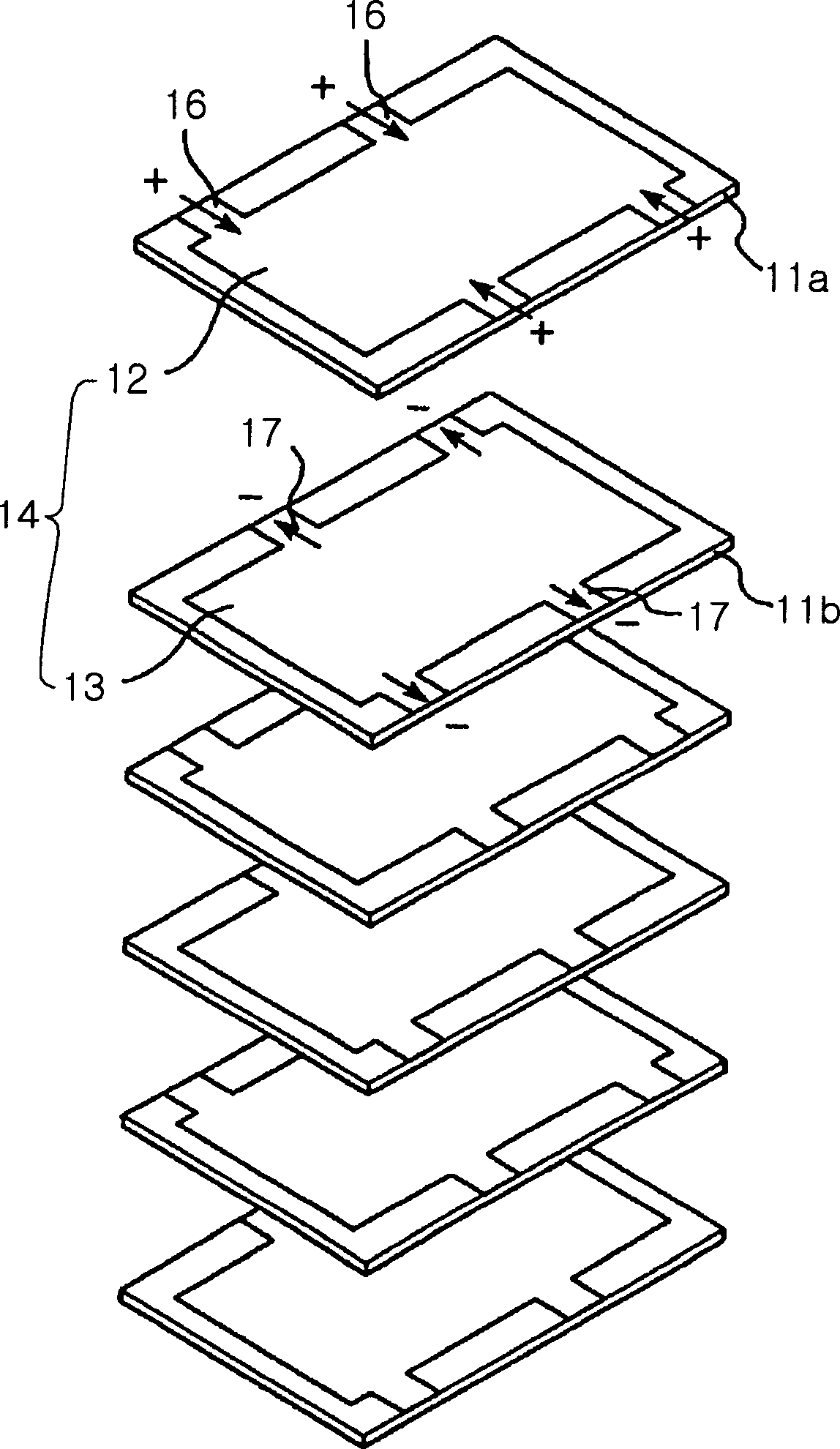

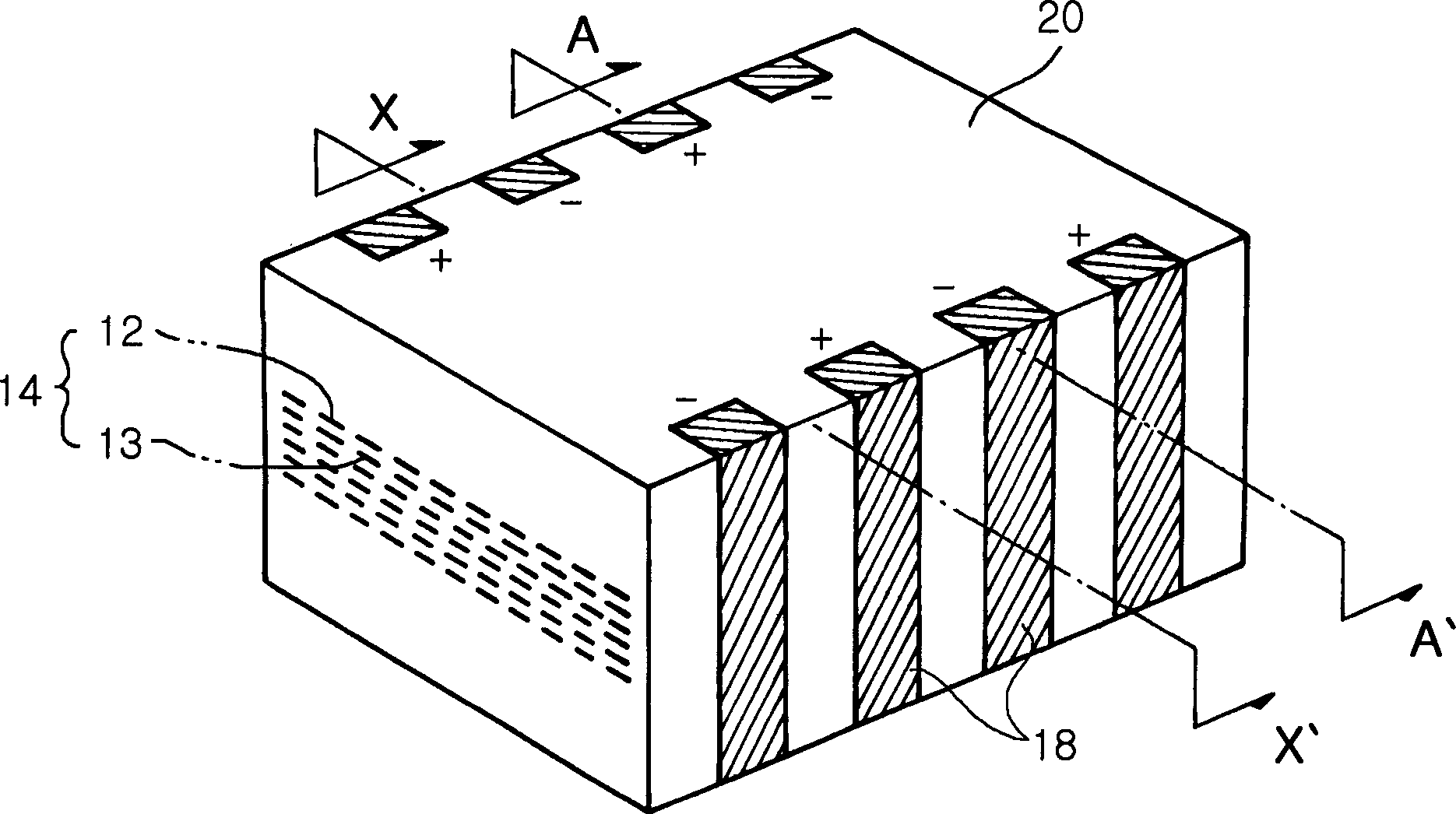

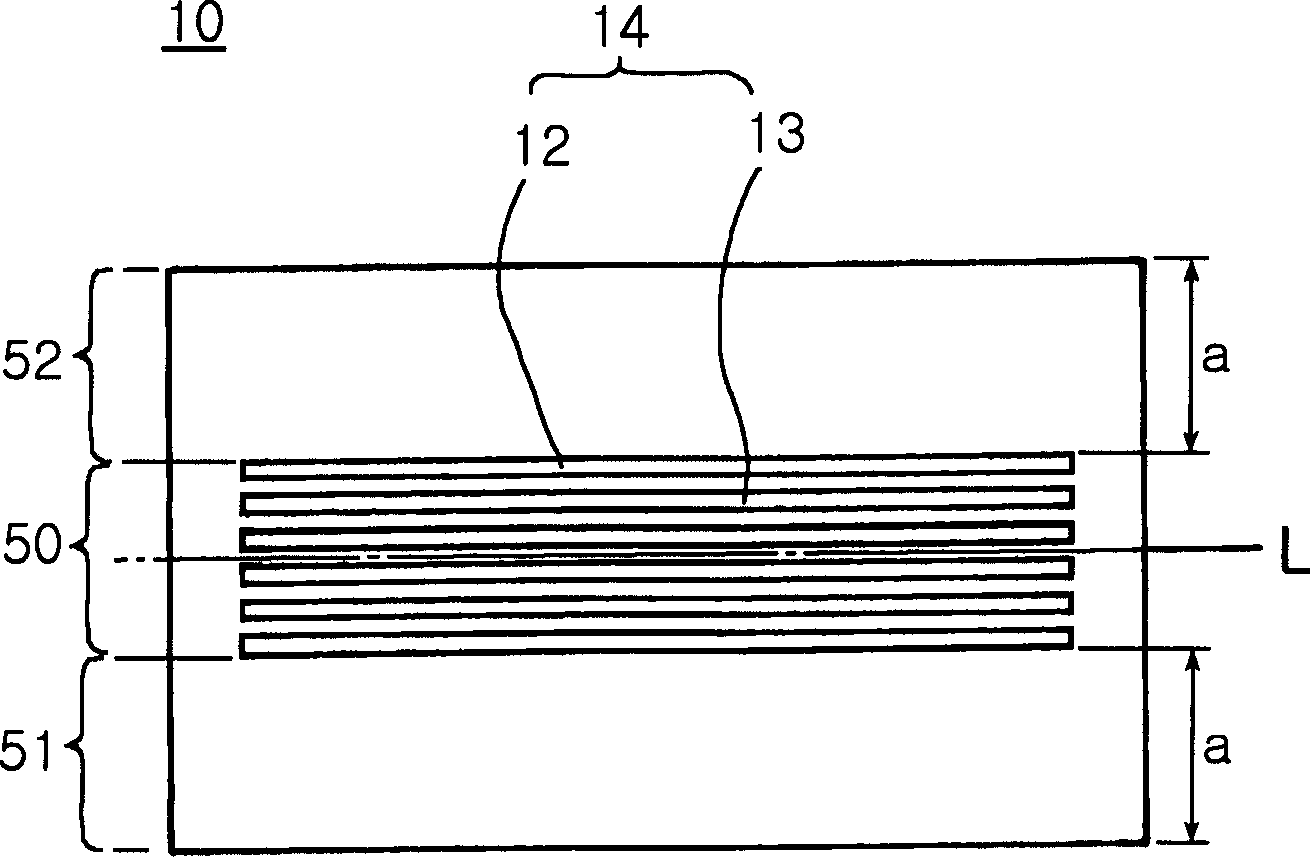

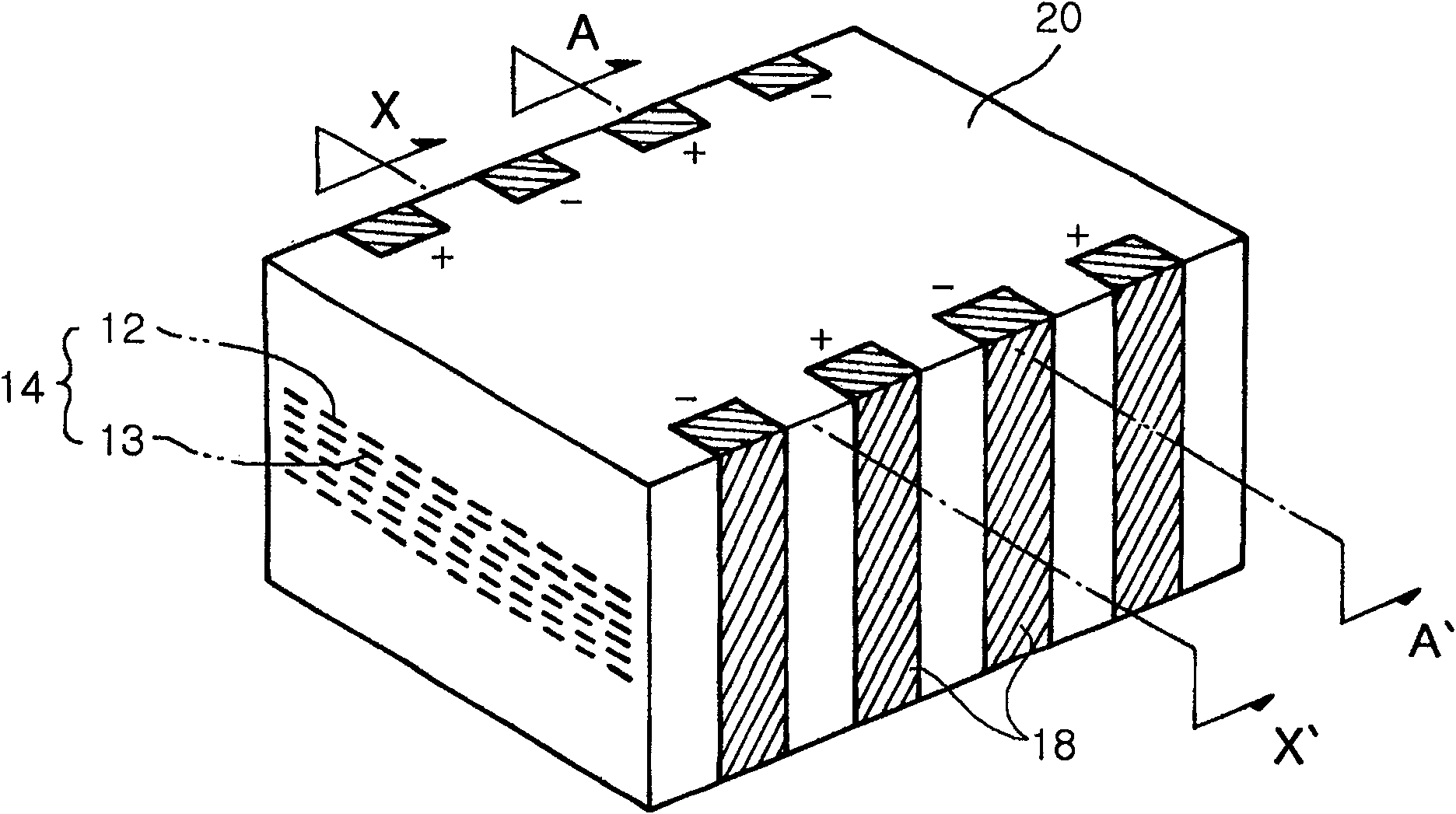

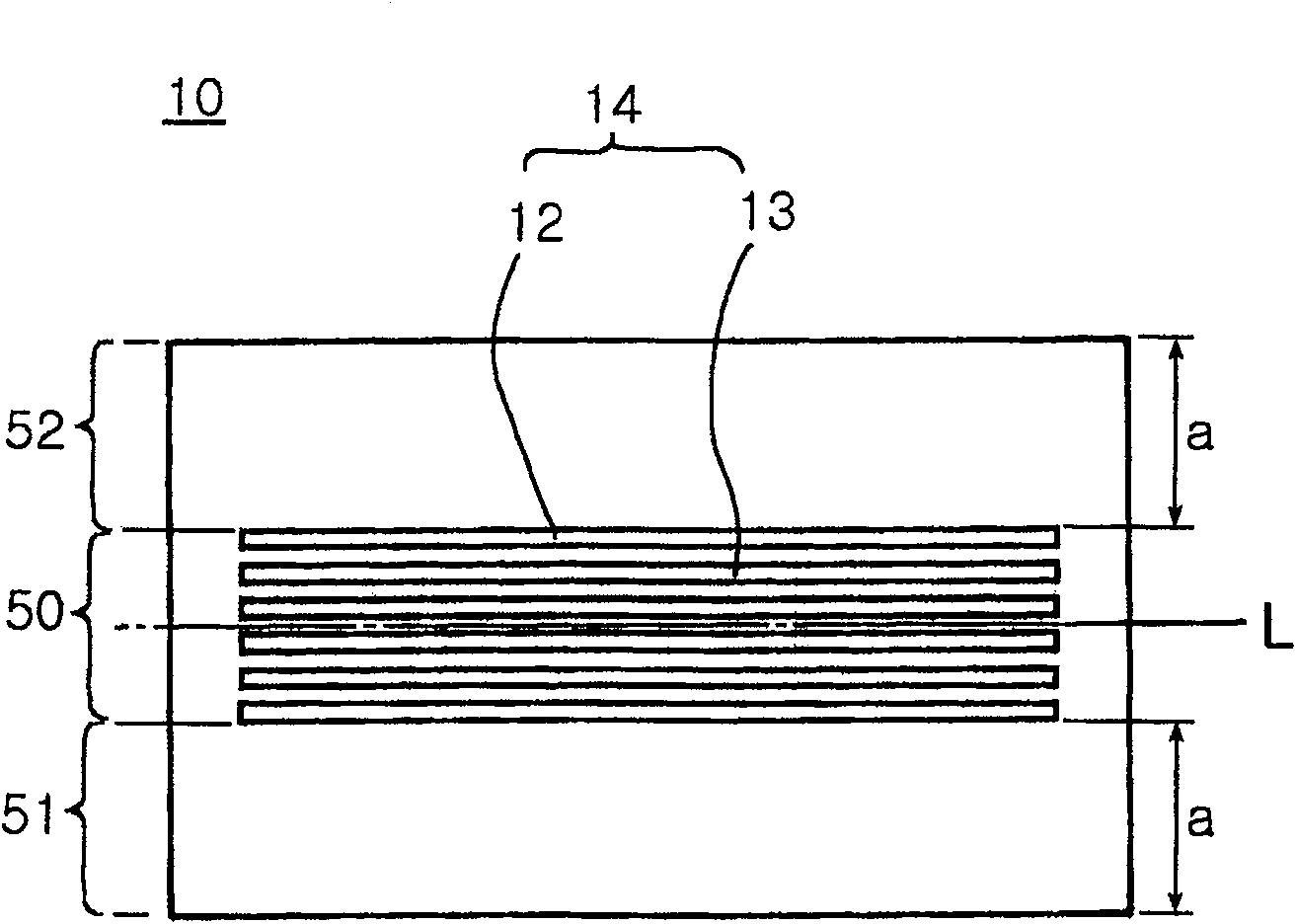

A multilayer chip capacitor, which reduces ESL generated due to current flowing through external electrodes and assures an improved mechanical strength. The multilayer chip capacitor includes an upper dummy layer and a lower dummy layer; a plurality of internal electrodes interposed between the upper and lower dummy layers; and external electrodes connected to the internal electrodes, wherein the thickness of the lower dummy layer is smaller than the thickness of the upper dummy layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

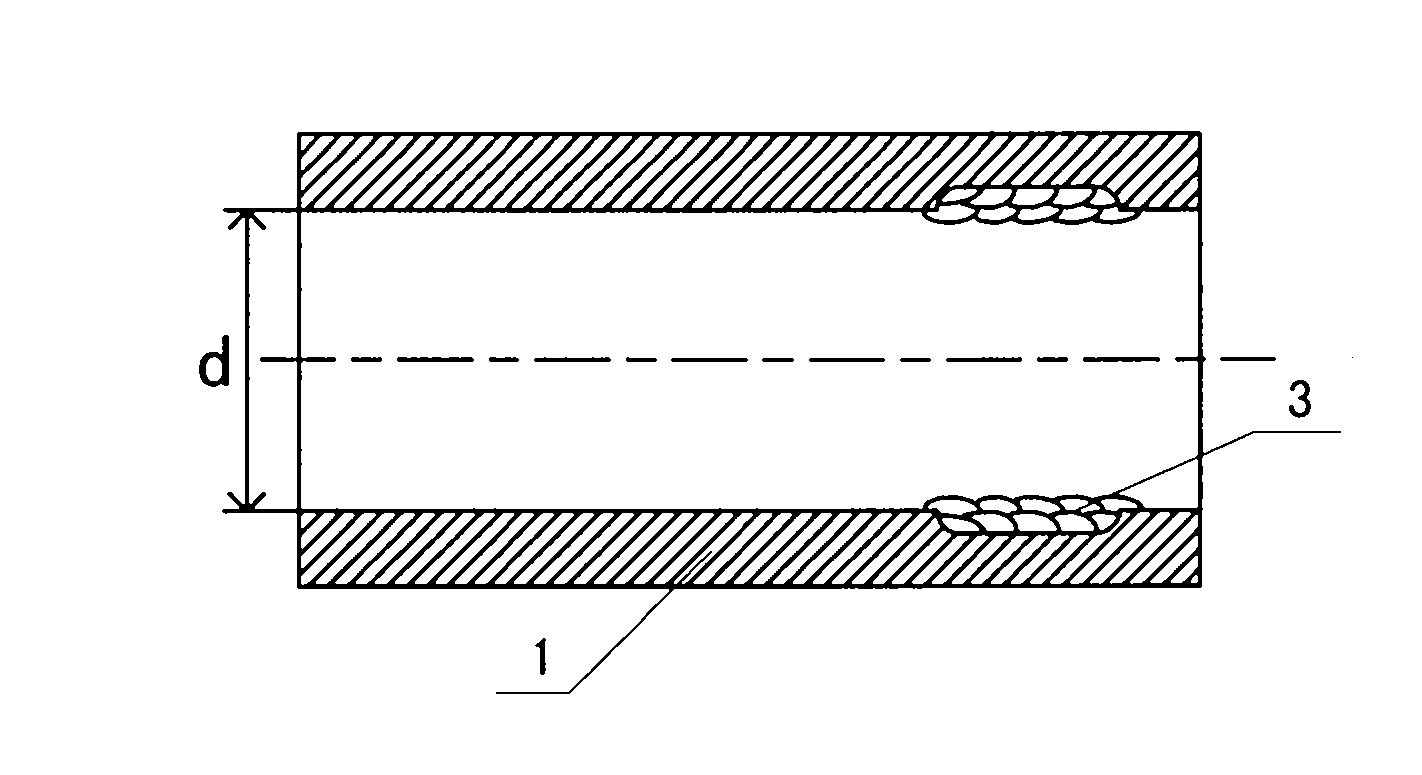

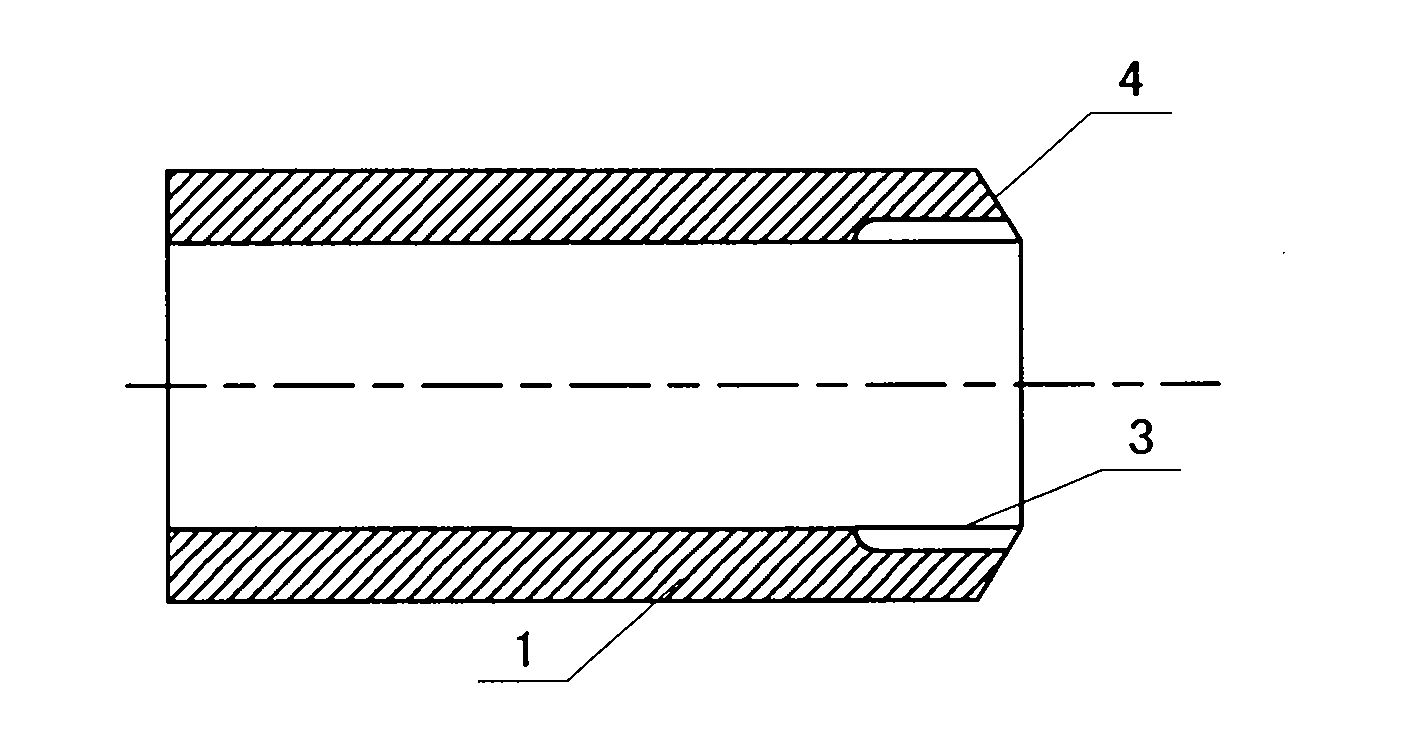

Method for welding anticorrosion steel pipeline with no internal repaired mouth

InactiveCN103008988AReduce the chance of welding defectsRigid enoughArc welding apparatusChemical industryAlloy

The invention provides a method for welding an anticorrosion steel pipeline with no internal repaired mouth, which is applicable to the anticorrosion treatment of a steel pipeline welding connector with an anticorrosion coating in the petroleum industry and the chemical industry. The method is characterized in that a groove with a certain length and depth is machined on a position which is at a certain distance from the end part of the steel pipe, an anticorrosion alloy material is surfaced on the groove, the end part of the surfaced steel pipe is machined into a V-shaped groove, an anticorrosion coating with sufficient thickness is coated on the inner wall of the steel pipe, the anticorrosion coating covers sufficient length of the anticorrosion alloy surfacing layer, then two steel pipes are in butt connection with each other, layering welding is carried out after the two steel pipes are fixed on one point, an argon tungsten-arc welding method is adopted, the anticorrosion alloy material which is identical to that of the surfacing is selected as the filling material, and argon is filled into the pipe to protect the pipe in the welding process. Due to the adoption of the novel technology for welding the anticorrosion steel pipeline with no internal repaired mouth, the corrosion resistance of the inner wall and a weld mouth of the pipeline can be guaranteed, the internal mouth repairing technology on the spot after the welding can be avoided, characteristics such as simplicity in construction and reliability in performance can be realized, and the method is suitable for the real engineering application of the petroleum and chemical industry fields.

Owner:HARBIN INST OF TECH

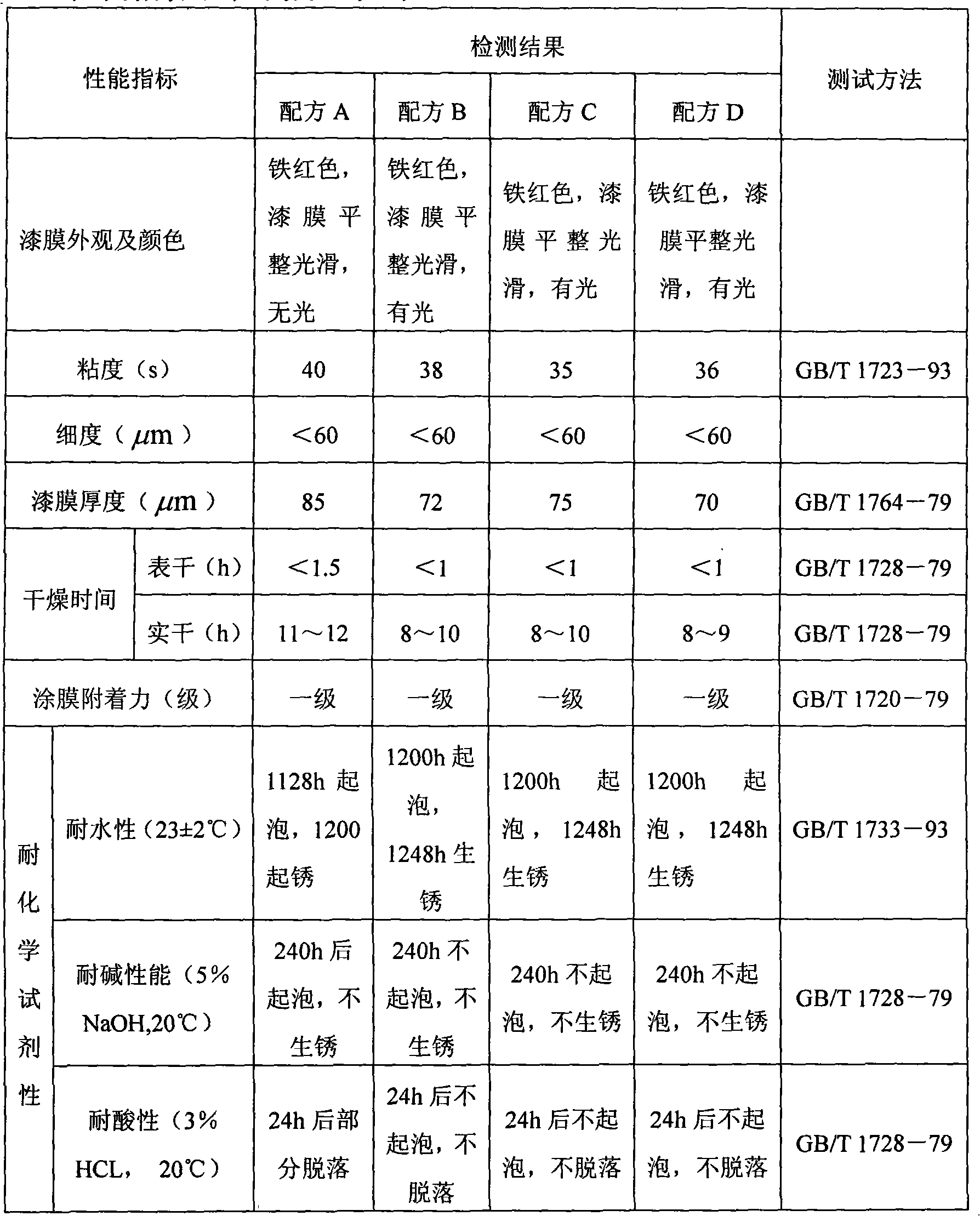

Steel structure aqueous corrosion resisting paint without need of cleaning rust and preparation thereof

InactiveCN101323726AGood acid and alkali resistanceImprove the painting environmentLiquid surface applicatorsAnti-corrosive paintsAqueous corrosionWater based

The invention relates to a water-base rusting anti-corrosion paint of a steel structure, and a manufacturing technology thereof. The water-base rusting paint comprises styrene-acrylic latex, ferric oxide, talcum powder, phosphoric acid, tannin, aluminum hydroxide, zinc oxide, zinc dihydric phosphate, potassium dichromate, a film-forming auxiliary agent, sodium hexametaphosphate, dibutyl phthalate, an antifoam agent and water which is added till 100 percent (mass). The preparation method of the paint of the invention is that a pigment filler is added into a ball mill to prepare pigment filler slurry according to a mixing ratio, the phosphoric acid, the tannin, the zinc oxide and the aluminum hydroxide are mixed and heated till the solution is clear so as to prepare transformation liquid, then the pigment filler slurry and the transformation liquid and other components are mixed and stirred, and finally a finished product is obtained after filtration. The paint of the invention is characterized by good performance and low cost, etc., can be used for hull painting with rust directly, and can be used not only as a base paint, but also as a surface paint.

Owner:HUNAN UNIV

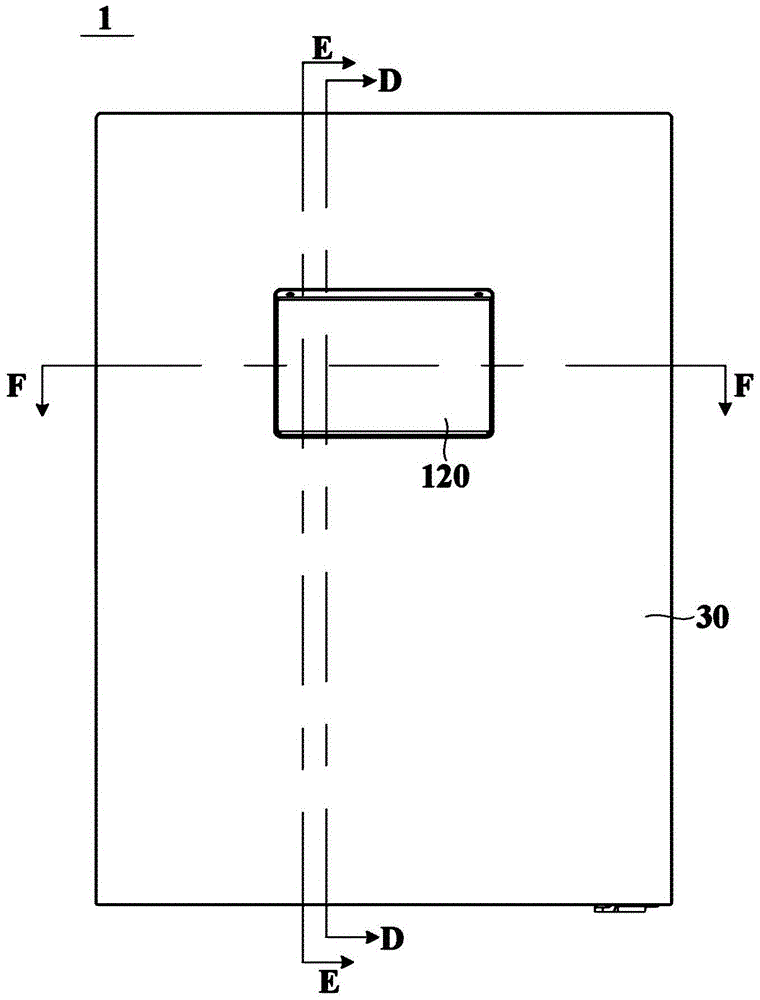

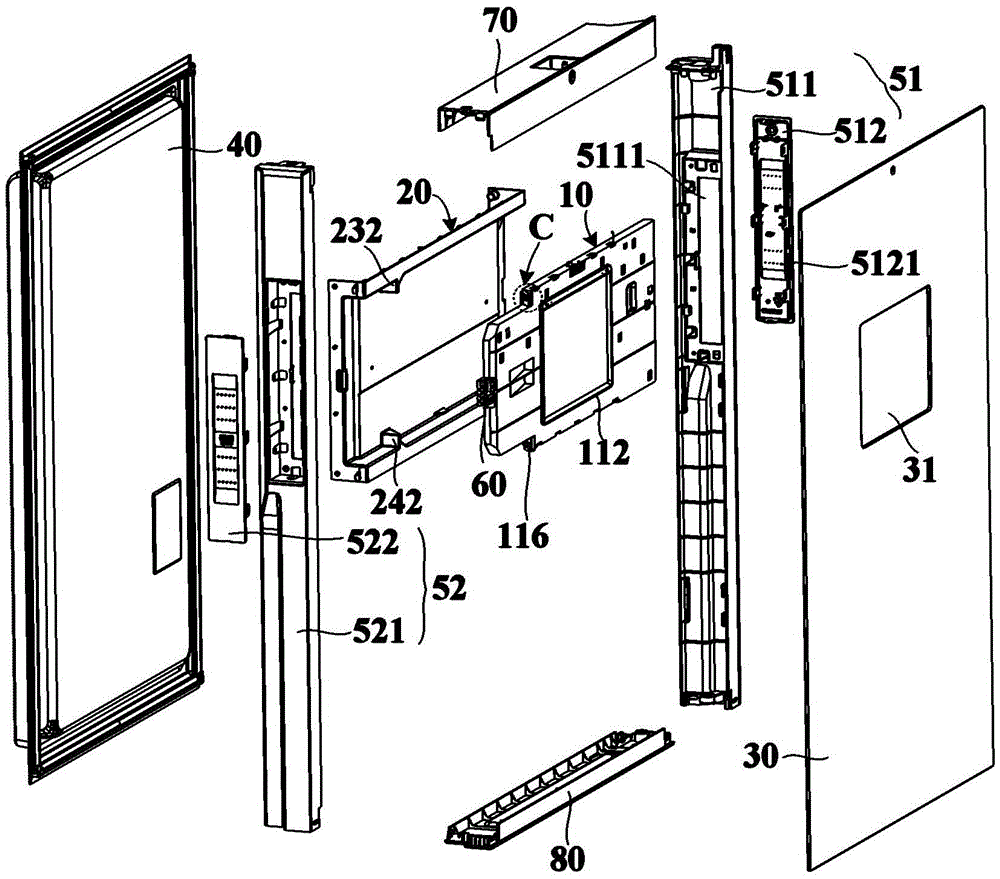

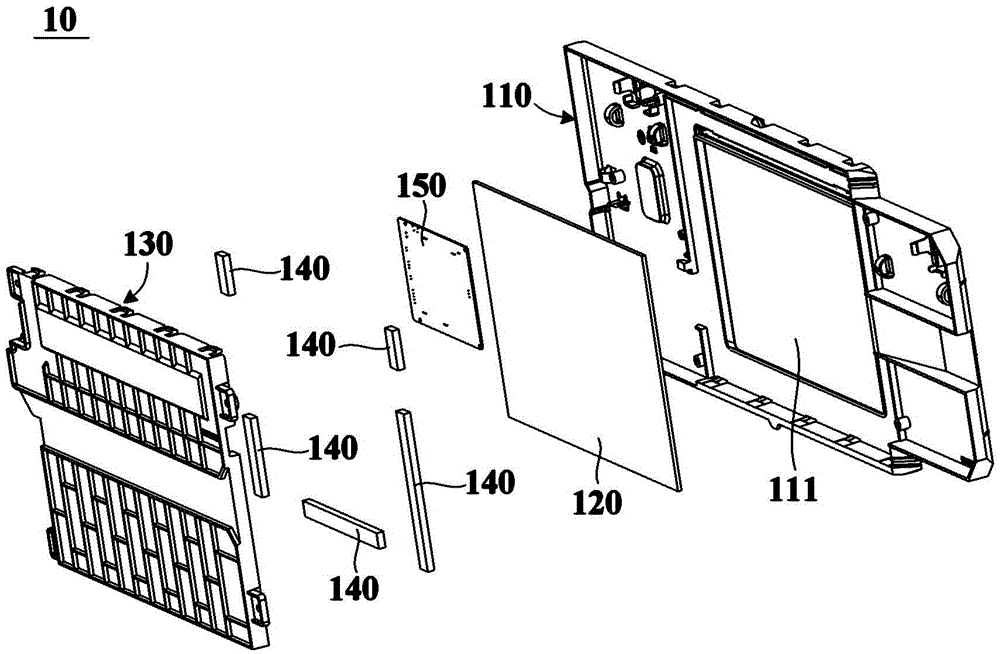

Door body used for cold storage and refrigeration device and cold storage and refrigeration device

InactiveCN105526766AGuaranteed cooling efficiencyGuaranteed cooling effectDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention relates to a door body used for a cold storage and refrigeration device and the cold storage and refrigeration device. Particularly, the door body used for the cold storage and refrigeration device comprises a panel used for forming the front portion of the door body, a door liner used for forming the rear portion of the door body, two side frames used for forming the two side portions of the door body, a rear cover and a display control assembly. The rear cover is arranged between the panel and the door liner, and a containing cavity is defined by the rear cover and the panel. The display control assembly is arranged in the containing cavity. The two side frames are provided with through holes communicating with the containing cavity so as to form a heat dissipation channel transversely penetrating through the door body, air convective circulation is facilitated, heat is dissipated out in time conveniently, and accordingly the heat dissipation efficiency and effect of the display control assembly are ensured. The invention further provides the cold storage and refrigeration device. The cold storage and refrigeration device comprises a refrigerator body with a defined storage space and the door body, and the door body is directly or indirectly connected to the refrigerator body so as to open and / or close at least part of the storage space.

Owner:HAIER SMART HOME CO LTD

Light-weight foamed magnesia wall slab

InactiveCN1396140ASolve the technical problems applied to the wallImprove surface hydrophobicityCeramicwarePolymer scienceFoaming agent

A light-weight foamed wall slab is prepared from magnesium oxide (1070 wt. portions), magnesium chluride (60-70), water (20-50), stabilizer (5-26), short fibres (2-15), modifier (1.65-9), foaming agent (0.8-8), and water-resisting agent (0.15-1) through mixing while stirring, foaming and solidifying. Its advantages are high effect, low cost of modifier, light dead weight, high strength, and low cost.

Owner:龚德馨 +2

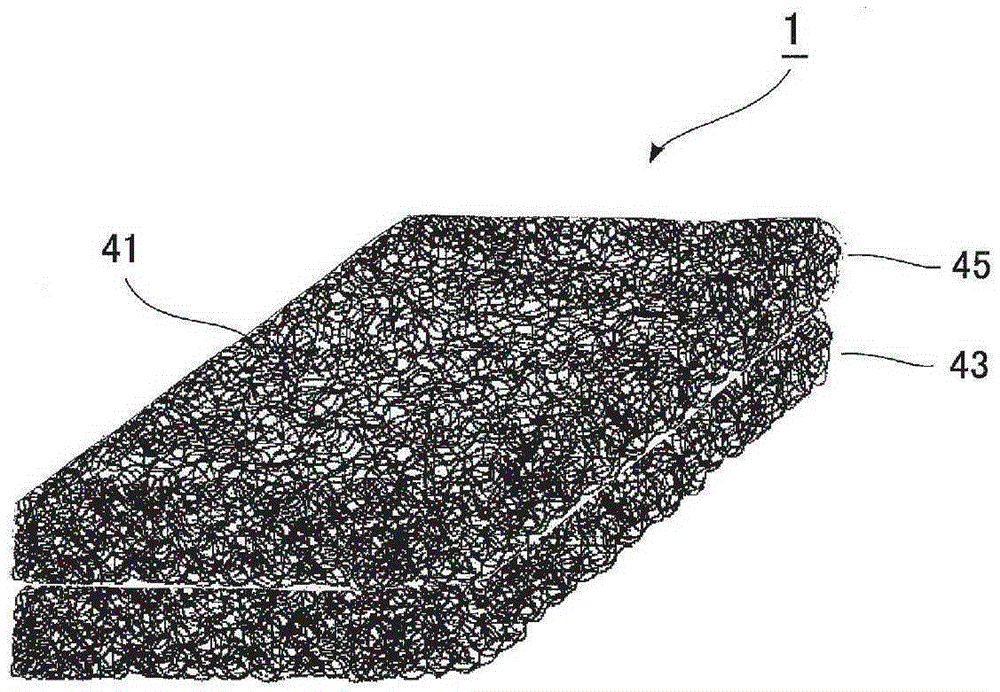

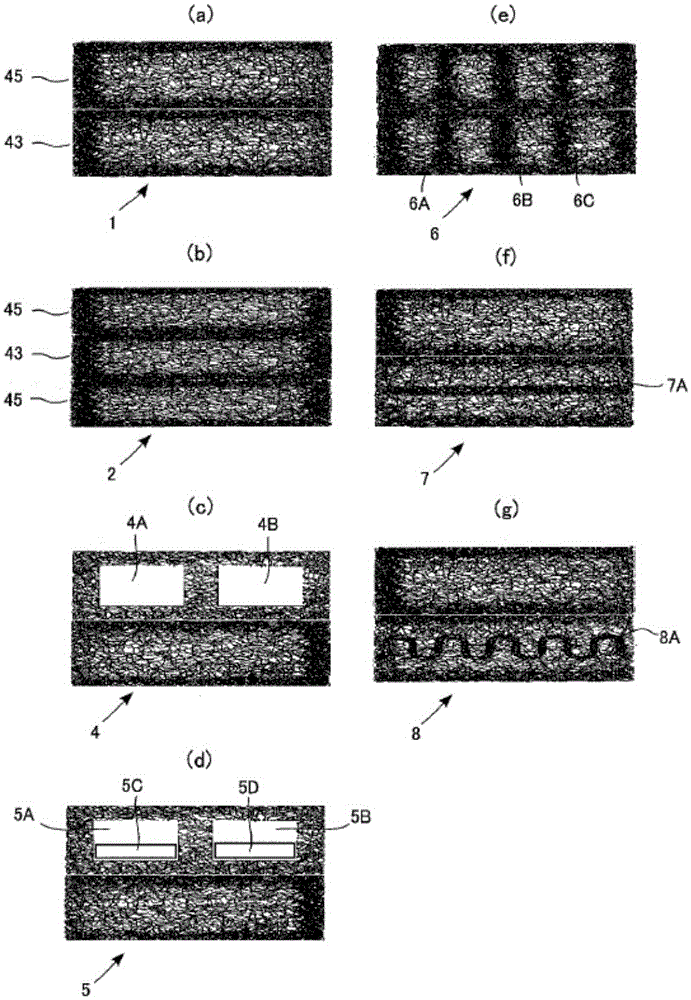

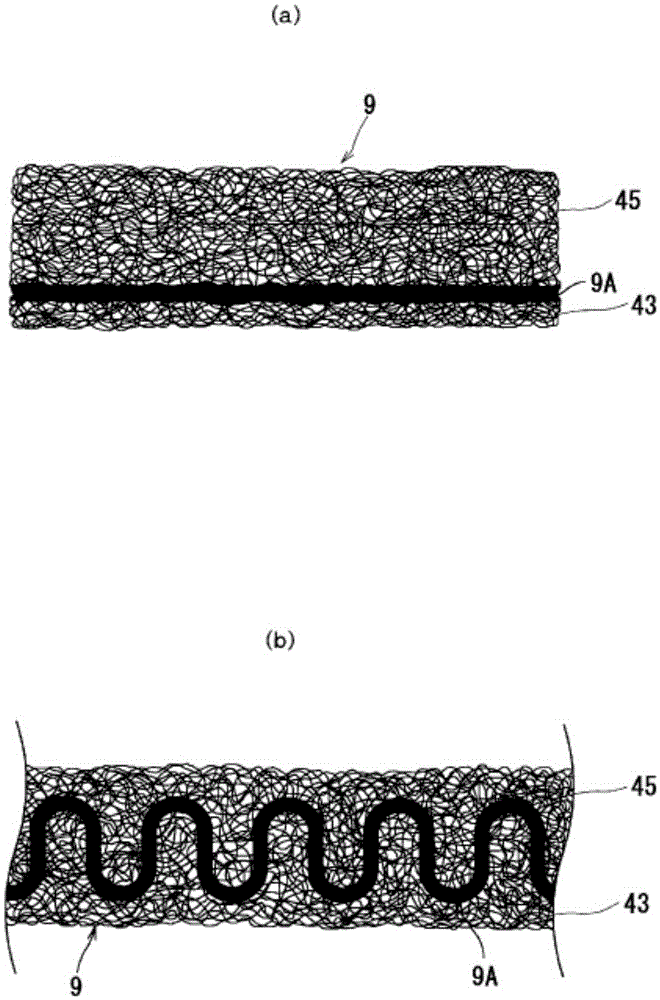

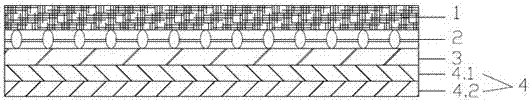

Core material for cushion, and cushion

ActiveCN105377083AInhibition of contractionHigh Thermal Expansion PropertiesStuffed mattressesDomestic upholsteryHysteresisPolyester

The present invention provides a hygienic cushion which can be washed in water, exhibits excellent air permeability, and is light while exhibiting body-shape retention and exerting a resiliency force no less than a given standard at an appropriate thickness. A core material (1) for a cushion, wherein: one surface or both surfaces of a first layer in a three-dimensional mesh structure, said first layer being formed from a polyethylene-based thermoplastic resin, a polyester-based thermoplastic elastomer, or a mixture of a polyethylene-based thermoplastic resin and a polyethylene-based thermoplastic elastomer, is / are laminated with a second layer containing a thermoplastic resin that is different from that of the first layer; the three-dimensional mesh structure has an impact resilience of 13cm or greater and a hysteresis loss of 13-34%; and the thermal elongation rate of the three-dimensional mesh structure in the lengthwise direction before and after a hot-air drying test is 0-8% after 30 minutes at 90 DEG C in the case of a polyethylene-based thermoplastic resin, after 30 minutes at 130 DEG C in the case of a polyester-based thermoplastic elastomer, or after 30 minutes at 90 DEG C in the case of a mixture of a polyethylene-based thermoplastic resin and a polyethylene-based thermoplastic elastomer.

Owner:C ENG CO LTD

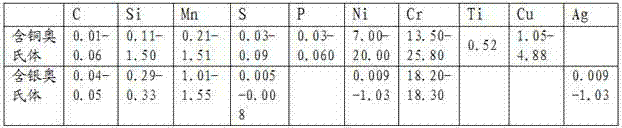

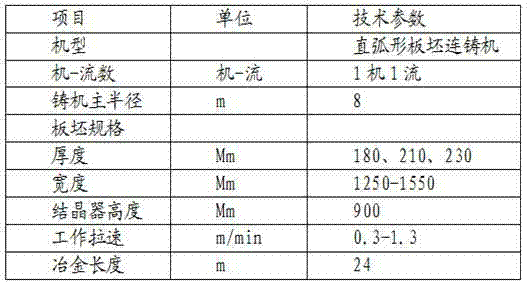

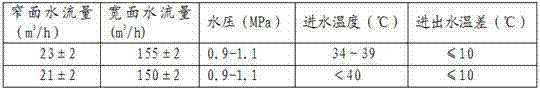

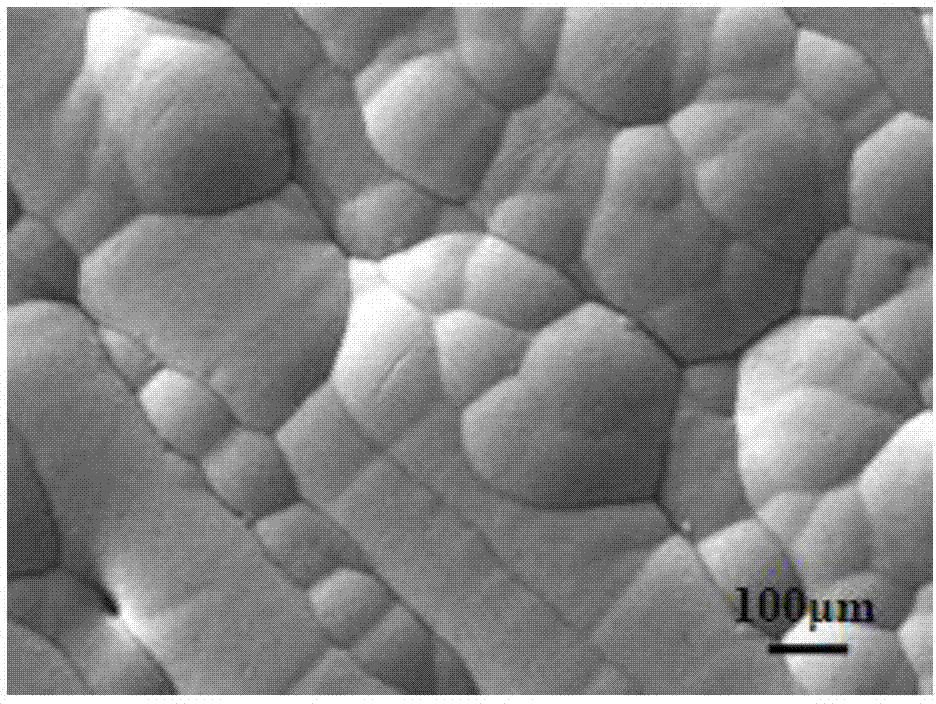

Crystallizer casting powder for austenite antibacterial stainless steel

ActiveCN103785808AMeet the needs of shrinkage characteristicsGood control of heat transferHeat resistanceField tests

The invention discloses continuous casting crystallizer casting powder for austenite antibacterial stainless steel. The alkalinity of the continuous casting crystallizer casting powder ranges from 1.0 to 1.1, and the continuous casting crystallizer casting powder can achieve a very good heat transfer control effect and meet the requirement for shrinkage characters of the austenite antibacterial stainless steel. The viscosity is set as 0.10 Pa*s-0.18 Pa*s at the temperature of 1300 DEG C, so that the casting powder flows in gaps between blank shells and a crystallizer copper plate more evenly, casting blanks are lubricated, the requirement for the consumption of the crystallizer casting powder is met, and the viscosity is mainly controlled Al2O3, MgO and F-. The melting point ranges from 1130 DEGC to 1190 DEG C, heat resistance of the casting powder is increased, the heat transfer uniformity index of the crystallizer casting powder is increased, and cracks are difficult to produce. Raw materials of the continuous casting crystallizer casting powder are easy to obtain, and cost is relatively low. By means of field tests, the casting powder is melt uniformly and stably, the indentation rate of the edges of the casting blanks is decreased by about 9.5%-19%, quality of the casting blanks is improved, and smooth operation of processes of a steel mill is guaranteed.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

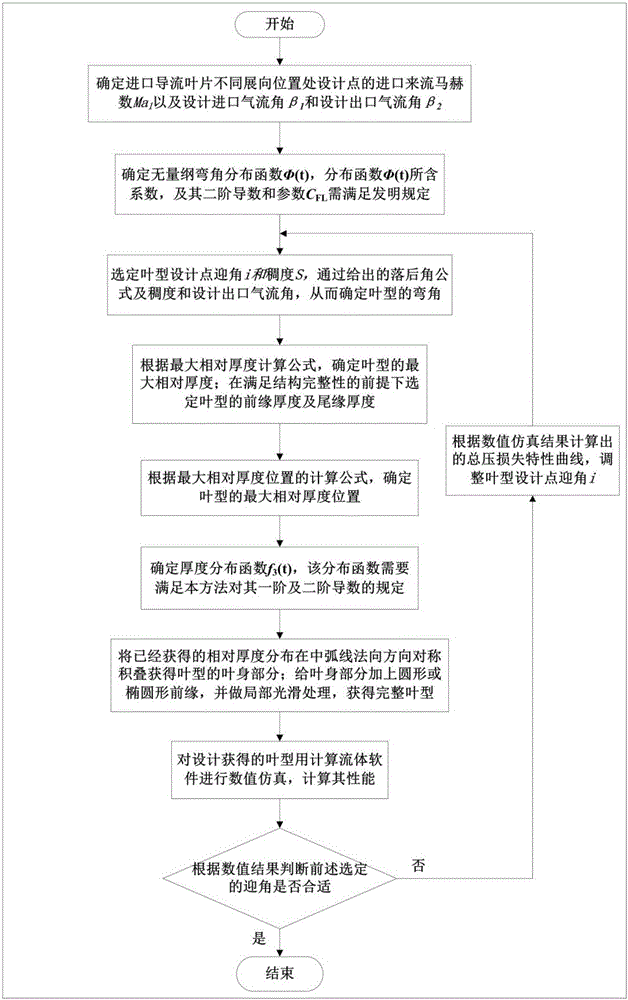

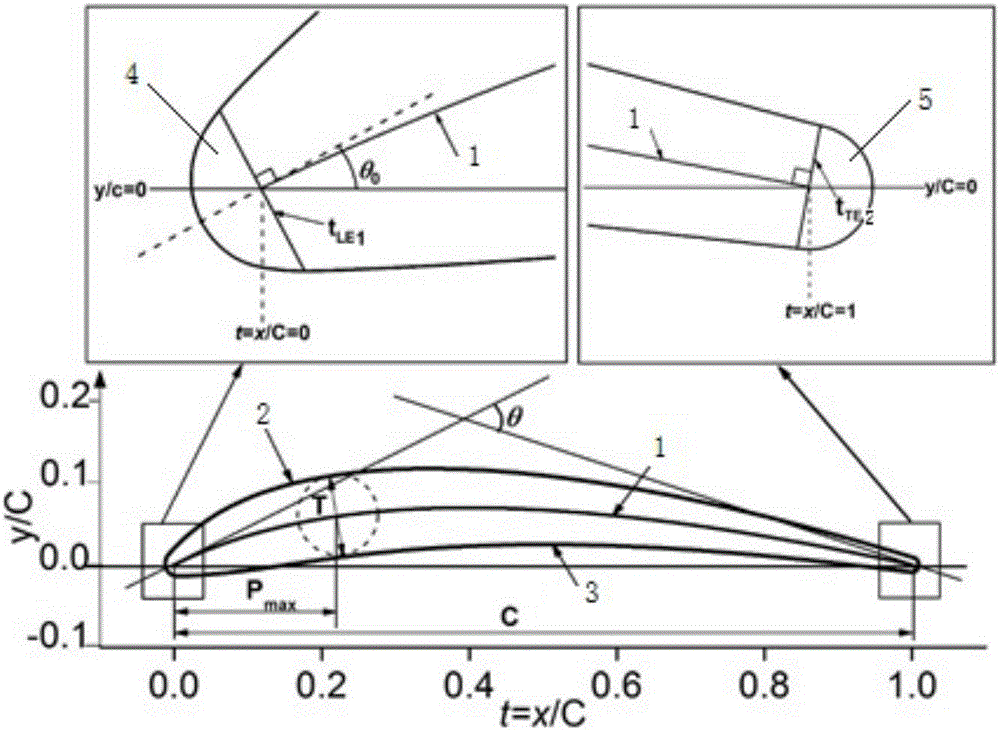

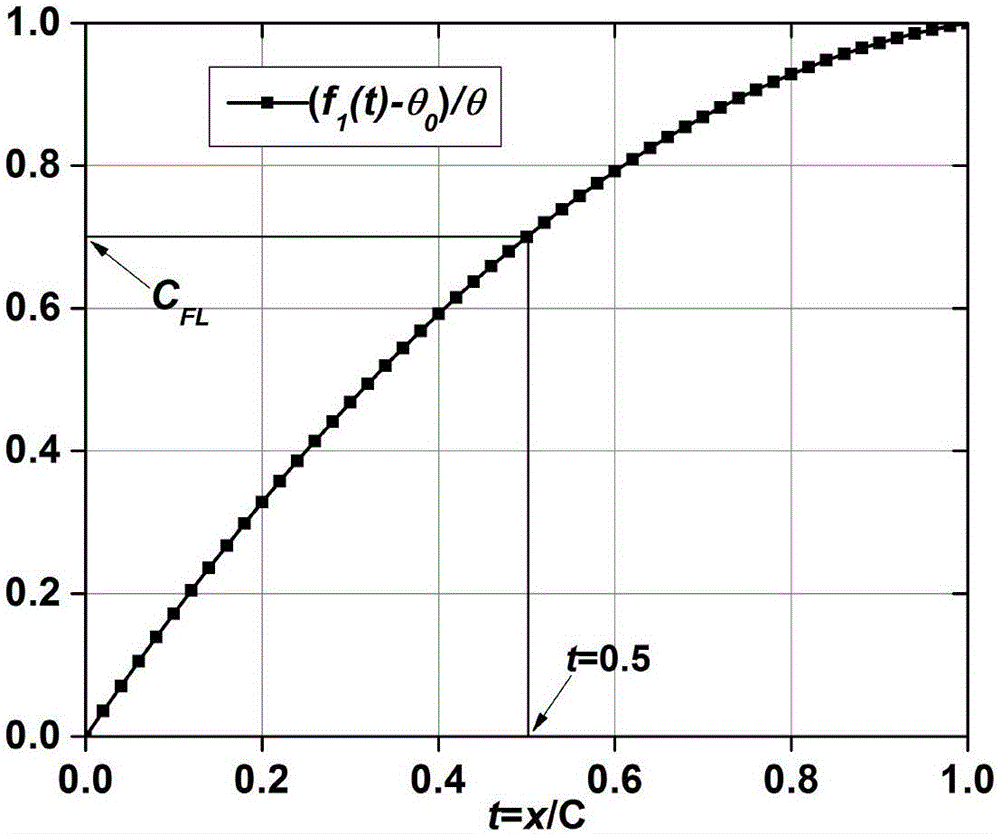

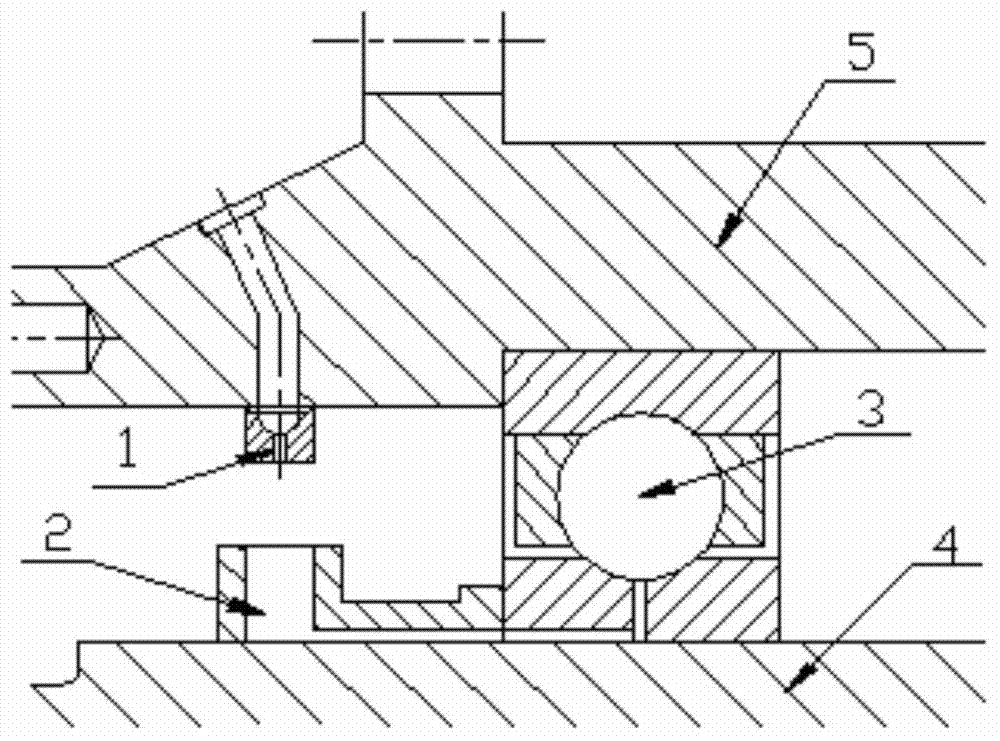

Design method of variable inlet guide vane, and blade and compressor

ActiveCN106570213AReduce the average total pressure loss coefficientMeet Structural Integrity RequirementsGeometric CADDesign optimisation/simulationLeading edgeEngineering

Owner:BEIHANG UNIV

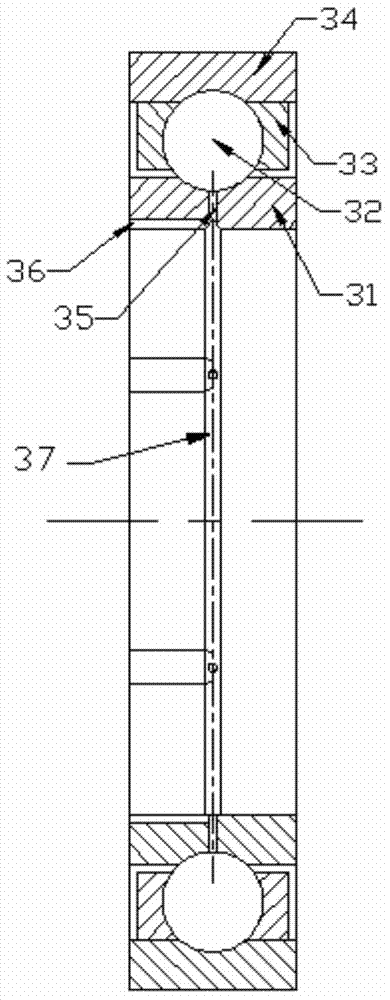

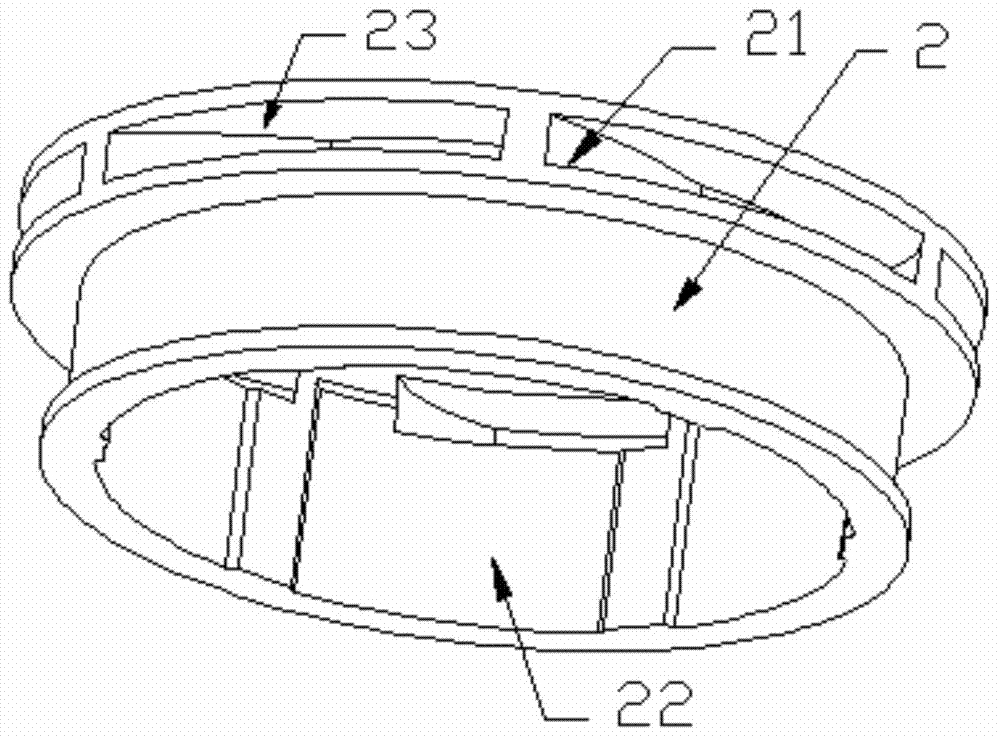

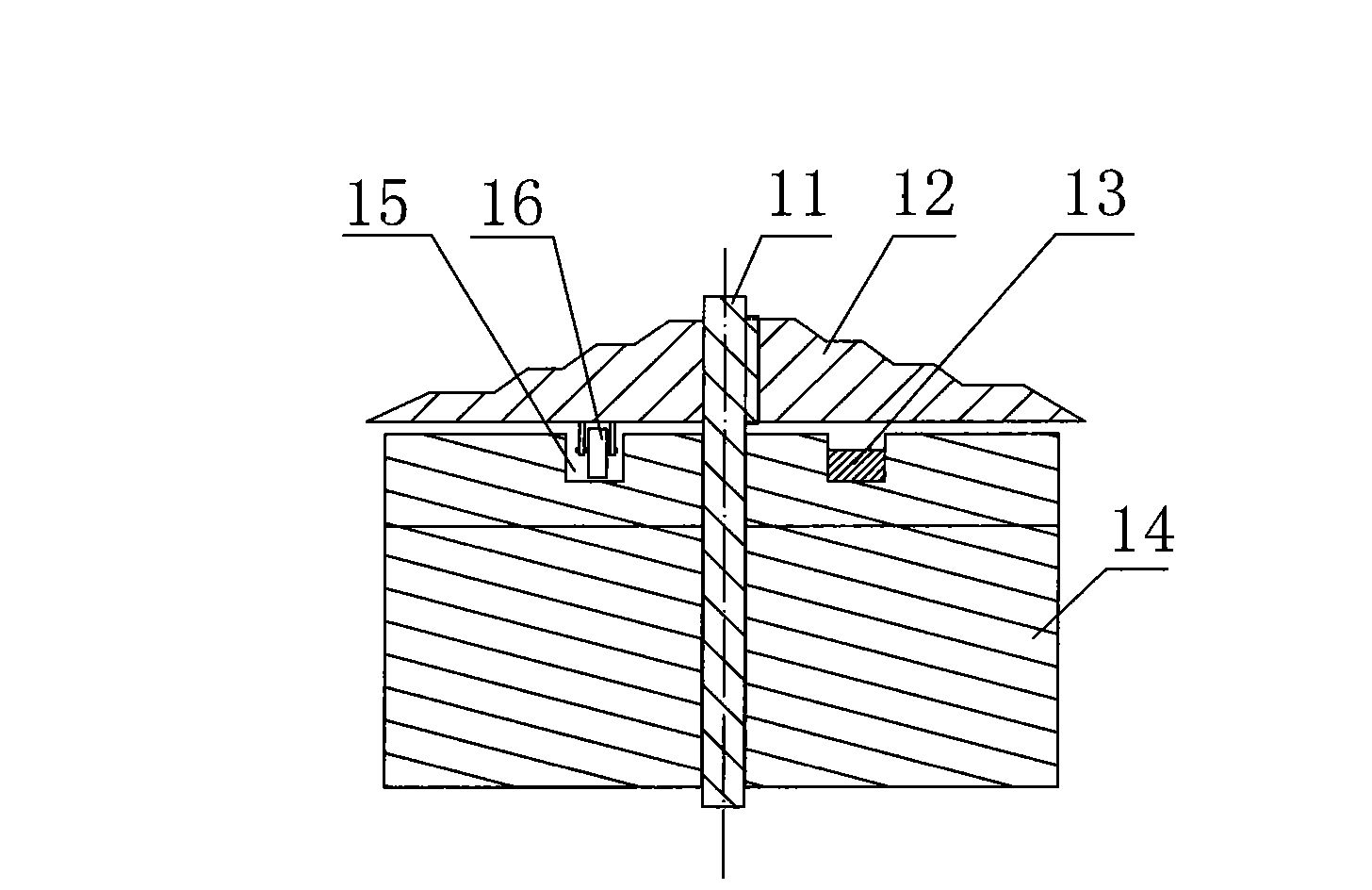

High-speed lower lubricating device for bearing ring

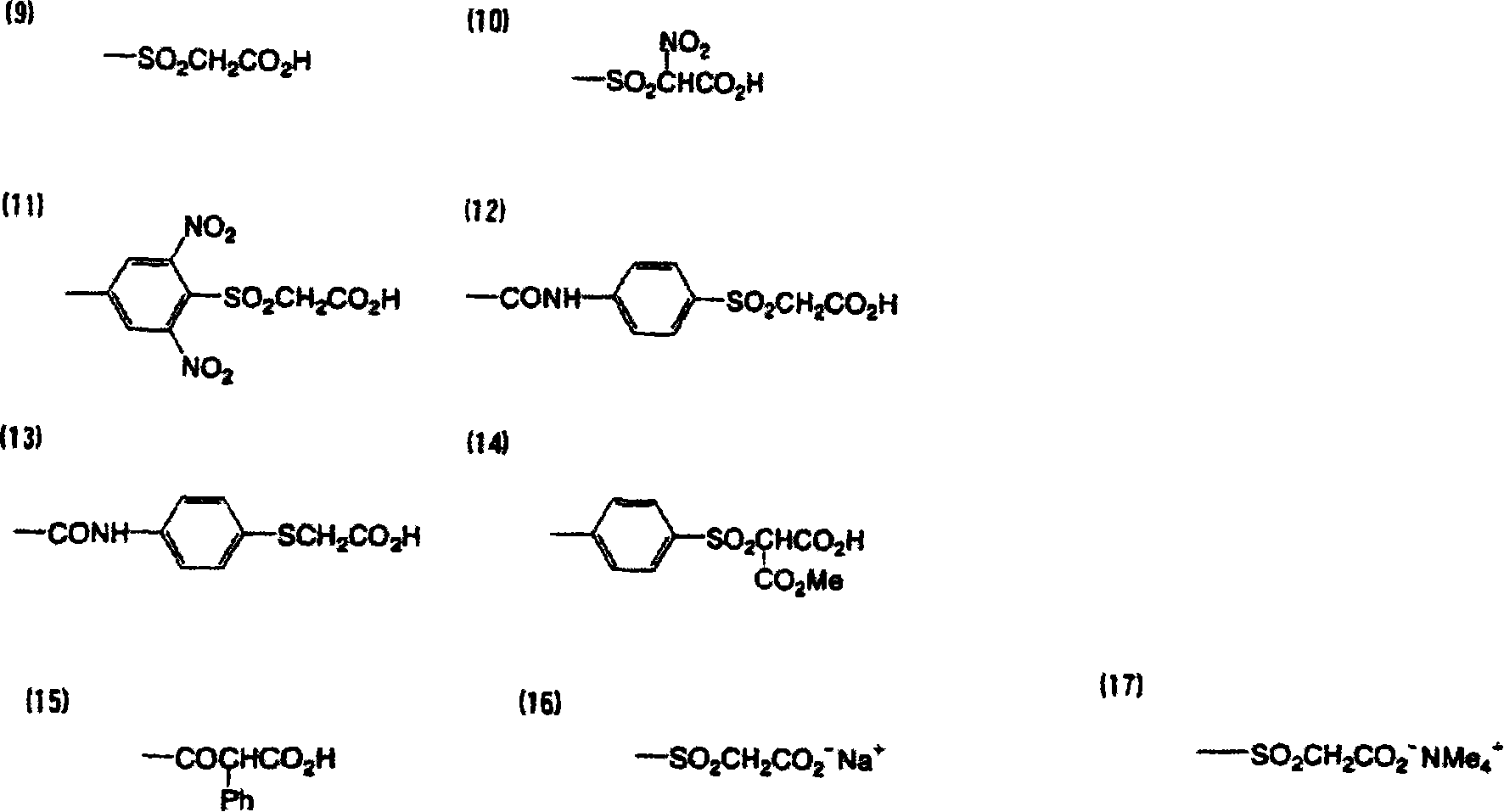

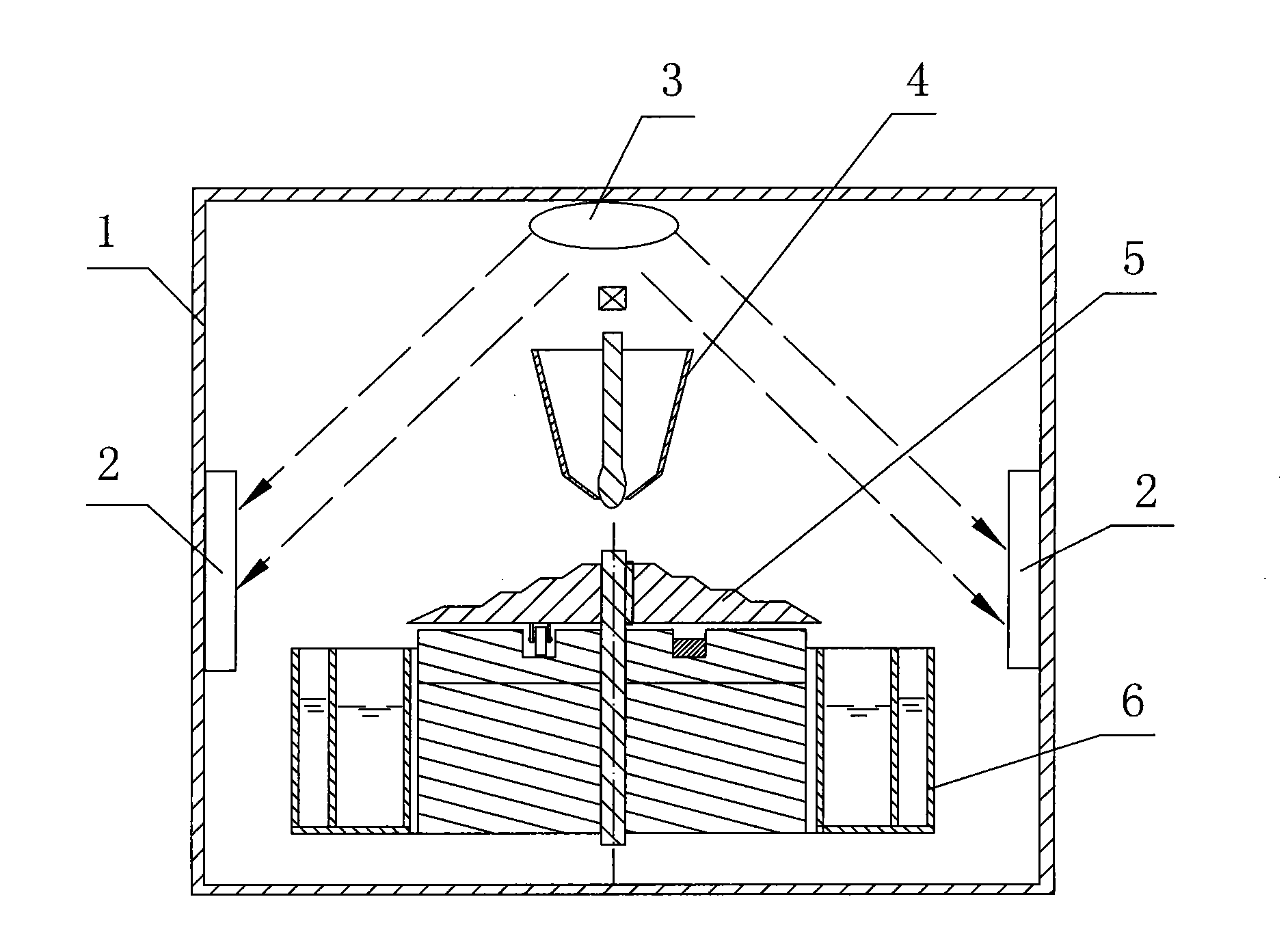

InactiveCN104747602ACause delay in deliveryEfficient collectionBearing componentsEngineeringPetroleum engineering

The invention discloses a high-speed lower lubricating device for a bearing ring. The high-speed lower lubricating device comprises an oil gathering sleeve, wherein an inner ring of a bearing and the oil gathering sleeve rotate synchronously; the inner wall of the inner ring of the bearing is respectively provided with a lubricating oil groove in an axial direction and a radial oil hole in a radial direction; one end of the radial oil hole is communicated with the lubricating oil groove, and the other end of the radial oil hole is communicated with a raceway of the inner ring of the bearing; the oil gathering sleeve and the inner ring of the bearing coaxially and fixedly sleeve a main shaft; the oil gathering sleeve is divided into two parts along the axial direction, the inner part of one part is provided with axial oil grooves butted with the lubricating oil groove, and the other part is radially provided with oil gathering passages which are in one-to-one butt joint with the axial oil grooves; the oil gathering passages are separated by a plurality of oil gathering blades distributed in the radial direction; an outer ring of the bearing is fixedly arranged on a shaft shell; the parts, which correspond to the oil gathering passages, of the shaft shell are provided with nozzles connected with a lubricating oil system. The high-speed lower lubricating device is capable of improving the bearing lubricating efficiency, reducing the lubricating oil quantity, further reducing the internal friction heat of the bearing and ensuring that sufficient oil film thickness exists in the raceway during high-speed rotation of the bearing.

Owner:CENT SOUTH UNIV

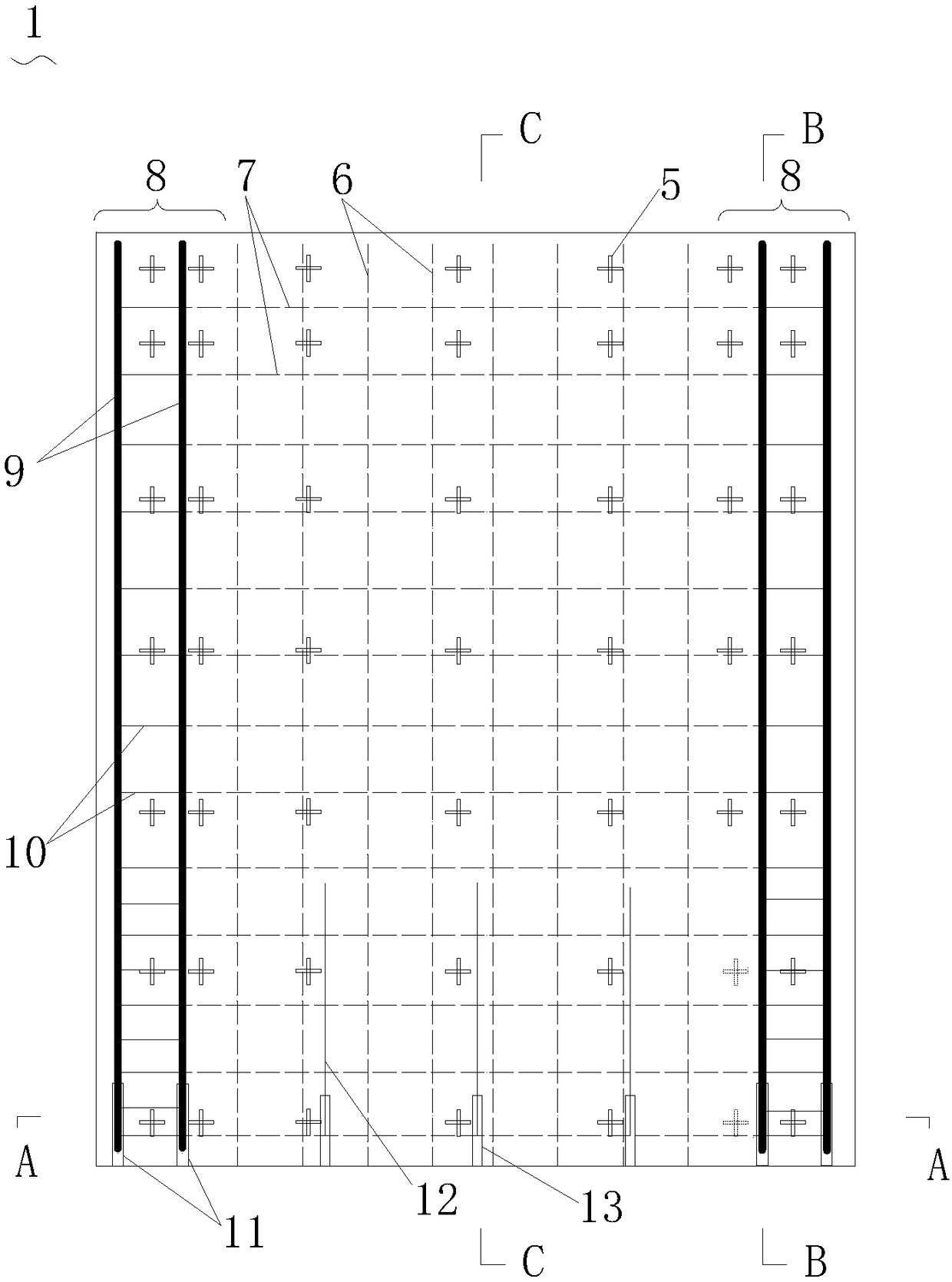

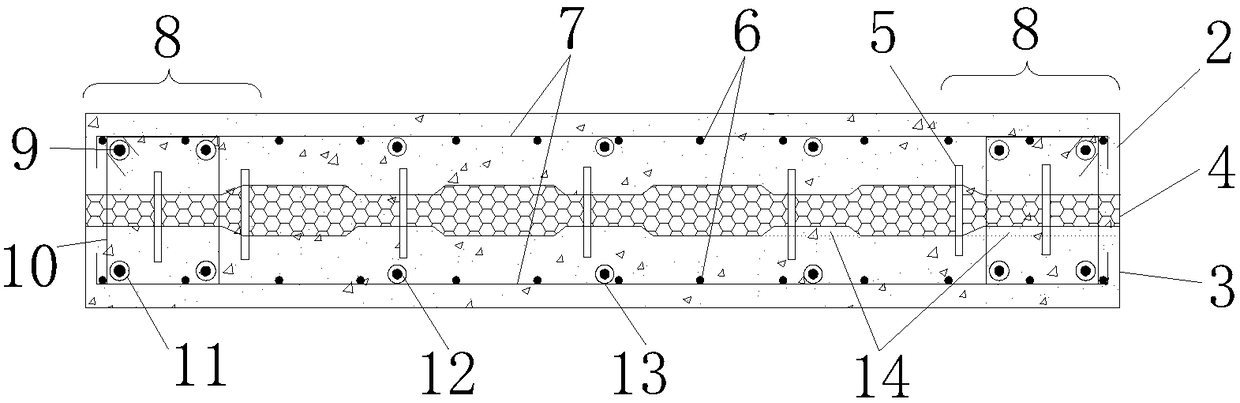

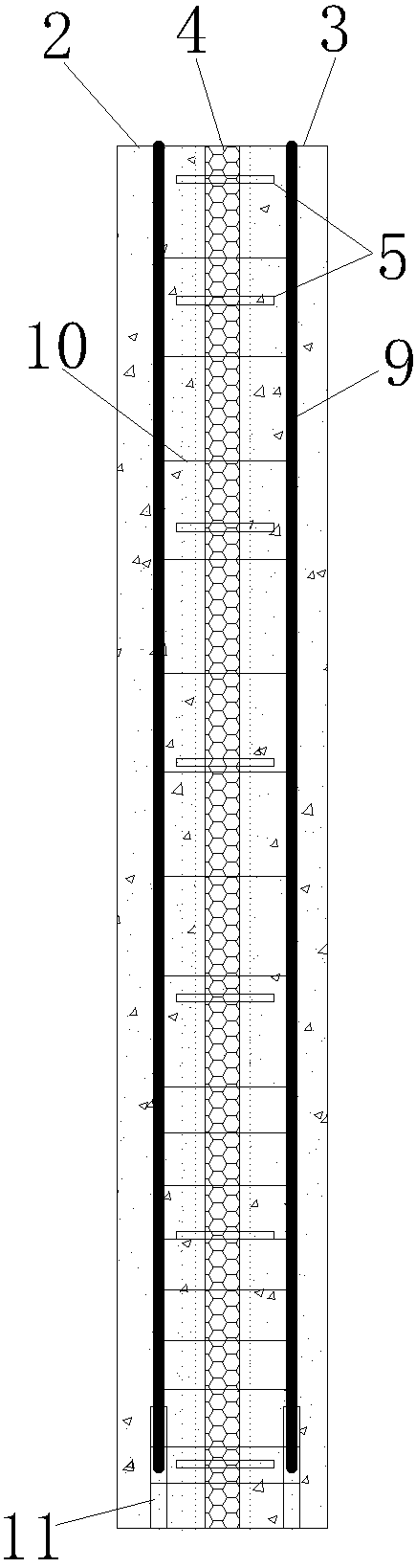

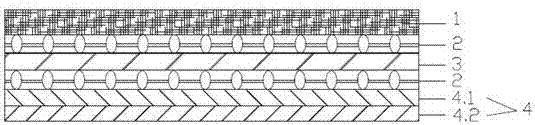

Novel load-bearing and heat-insulation integrated prefabricated fabricated-type shear wall and construction method

InactiveCN108149814AStable mechanical propertiesWith load-bearing functionWallsHeat proofingFiberBlade plate

The invention relates to a novel load-bearing and heat-insulation integrated prefabricated fabricated-type shear wall and a construction method, and belongs to the technical field of fabricated-type building construction. The novel prefabricated fabricated-type shear wall comprises an inner blade plate, an outer blade plate, a heat-insulation structure layer and a plurality of connecting pieces made of fiber reinforced plastic, wherein both the inner blade plate and the outer blade plate are provided with vertically-distributed steel bars and transversely-distributed steel bars. A restrained edge member area is provided with longitudinal stress steel bars, stirrups and first steel sleeves. According to the novel prefabricated fabricated-type shear wall, the thickness of a wall body is reduced, so that the effective usable area of a building is increased, the structures of the inner blade plate and the outer blade plate are optimized, so that the two sides of the heat-insulation structure layer are effectively protected, and the connecting pieces and the stirrups adopt the fiber reinforced plastic, so that heat-insulation performance of the heat-insulation structure layer is improved; and meanwhile, the wall body has excellent mechanical properties. The construction method has the advantages of being simple in operation, high in construction efficiency and the like.

Owner:SHANGHAI CONSTRUCTION GROUP

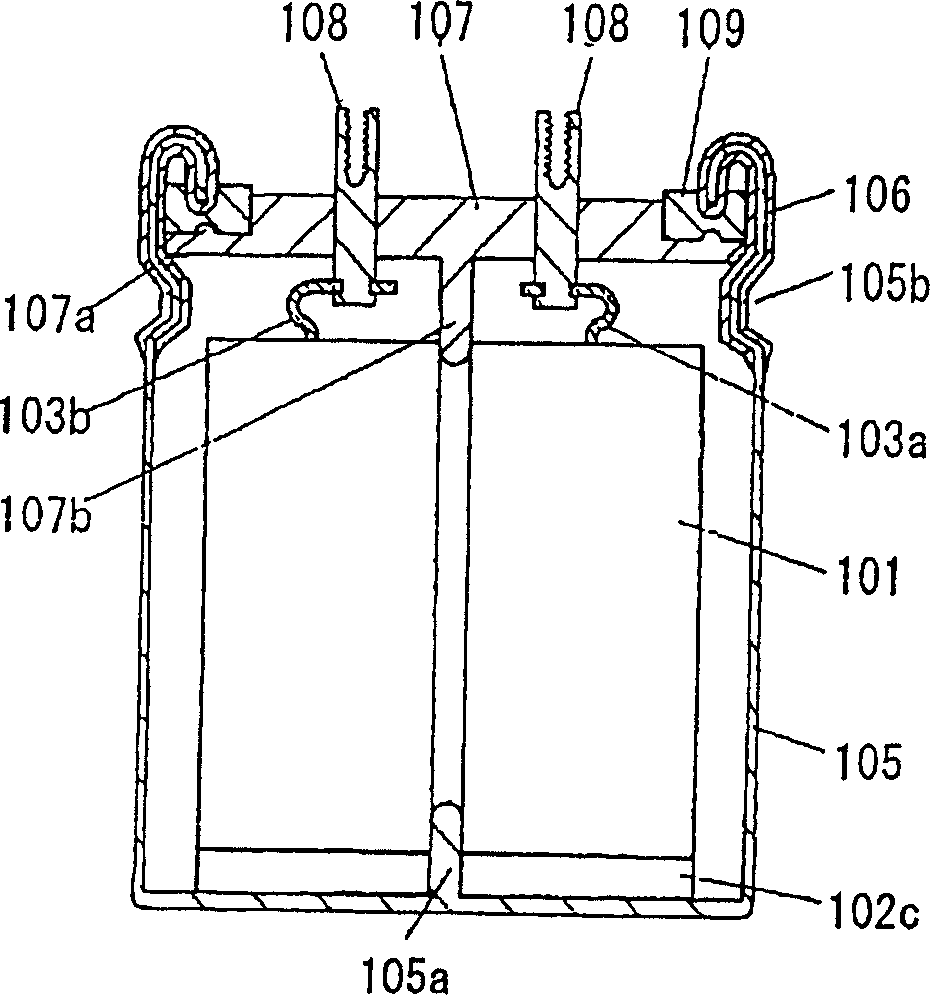

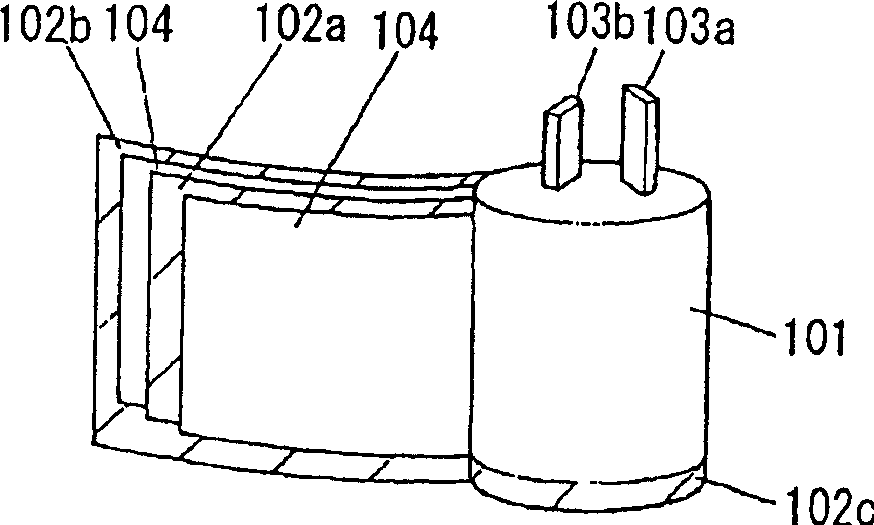

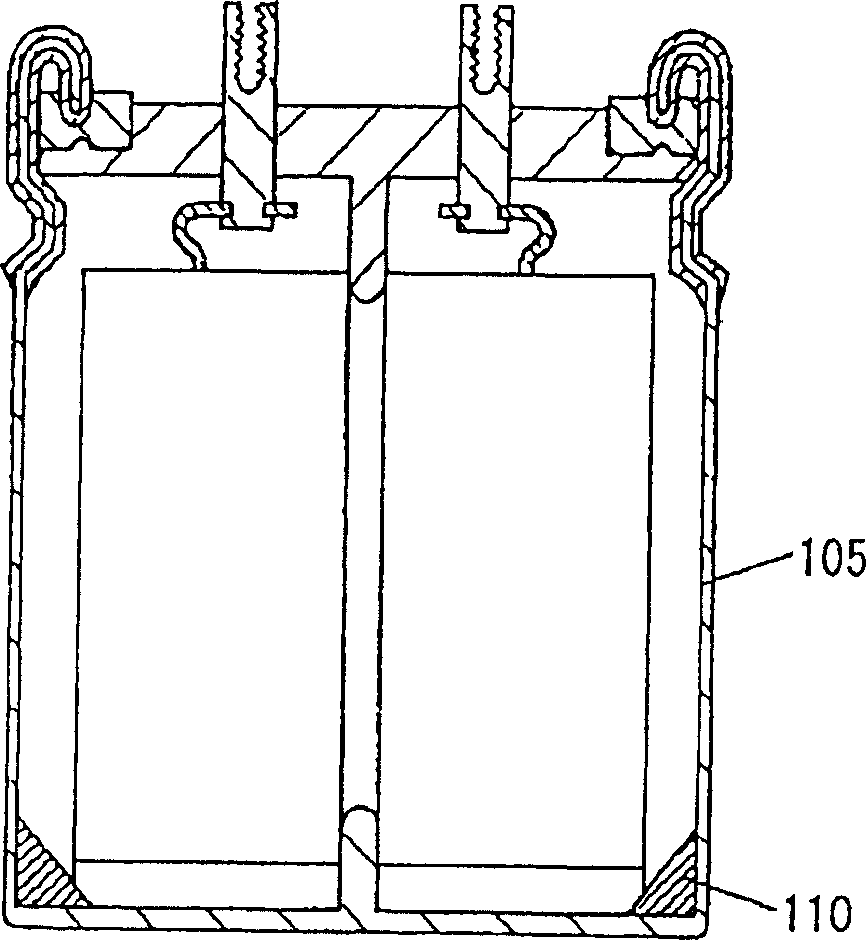

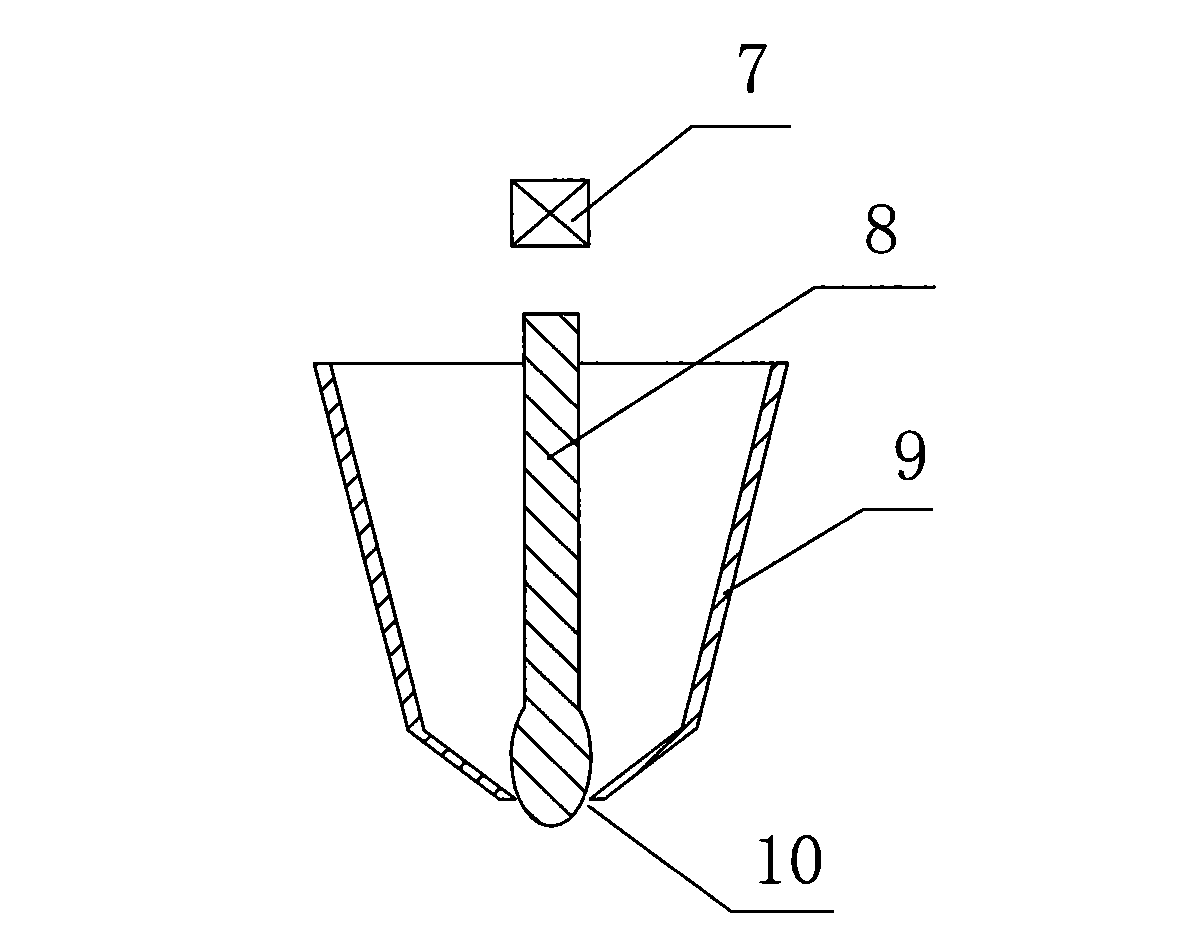

Capacitor and method of connecting the same

InactiveCN1701402AReduce contact resistanceImprove distributionCapacitor terminalsCapacitor housing/encapsulation

A large capacity capacitor of which driving electrolyte does not leak to the outside even when used in high-temperature, high-humidity conditions. A capacitor has a hollow capacitor element (1) constructed by rolling a pair of flat plate-like electrodes (2a, 2b) with a separator (4) in between, a bottomed tubular metallic case (5) for receiving the capacitor element (1) together with a driving electrolyte, and a sealing plate (7), with external connection terminals (8), for sealing the opening of the metallic case (5). A rubber-like elastic body (9) is provided on the peripheral edge of a surface of the sealing plate (7), an electric insulation layer (6) covering at least portion from an opening edge of the metallic case (5) to a recess (5b) for fixing the sealing plate (7) is provided, and the elastic body (9) is pressed at the opening edge portion of the metallic case (5).

Owner:PANASONIC CORP

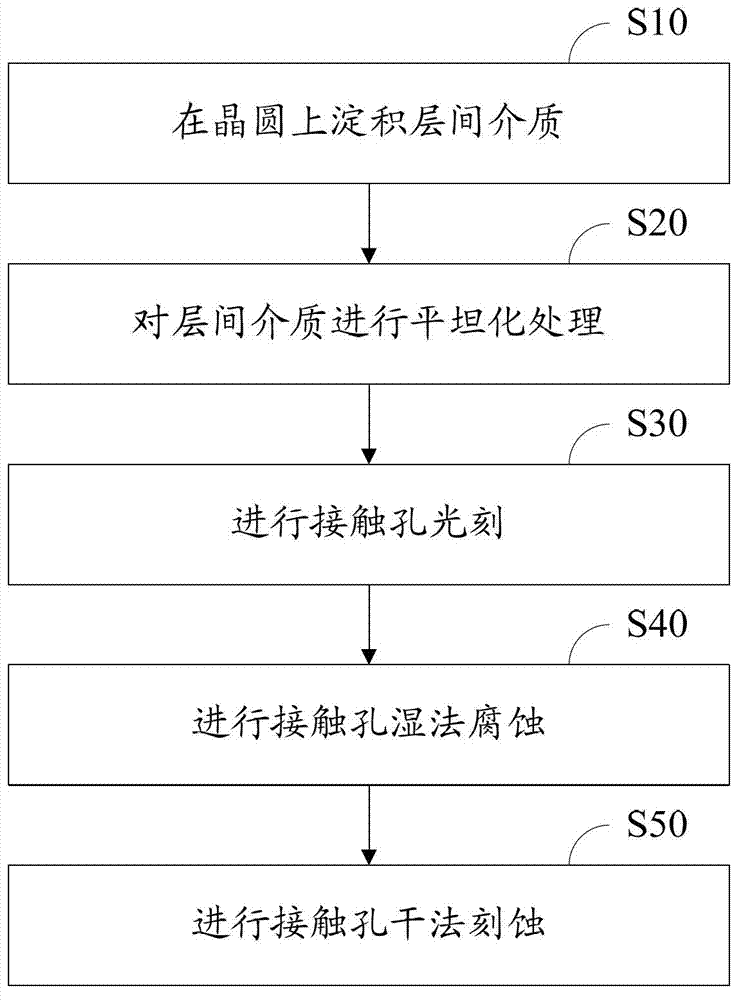

Etching method of contact hole

ActiveCN103050438AEnough thicknessAvoid it happening againSemiconductor/solid-state device manufacturingDielectricTwo step

The invention relates to an etching method of a contact hole. The method comprises the following steps of: depositing an interlayer dielectric on a wafer; flattening the interlayer dielectric; etching the contact hole; performing contact hole wet etching, and etching 30%-70% thickness of the interlayer dielectric; and performing contact hole dry etching. Through two steps of etching technologies, the wet etching uses the isotropic characteristics of the etching, so that the interlayer dielectric is in bowl-like appearance at the steps of the contact hole; and the dry etching uses the anisotropic of the dry etching, so that the appearance of the steps is approximate to a right angle. Through the combination of the wet etching and the drying etching, the steps at the contact hole are smooth without large closed angle; a metal layer can be avoided from generating cavities at the closed angle at the edge of the contact hole; the interlayer dielectric can be ensured to have enough thickness at the steps of polysilicon gates; and enough BVDSS (drain-source breakdown voltage) can be guaranteed.

Owner:深圳深爱半导体股份有限公司

Method of forming metallic pattern, metallic pattern and printed wiring board using it and tft wiring circuit

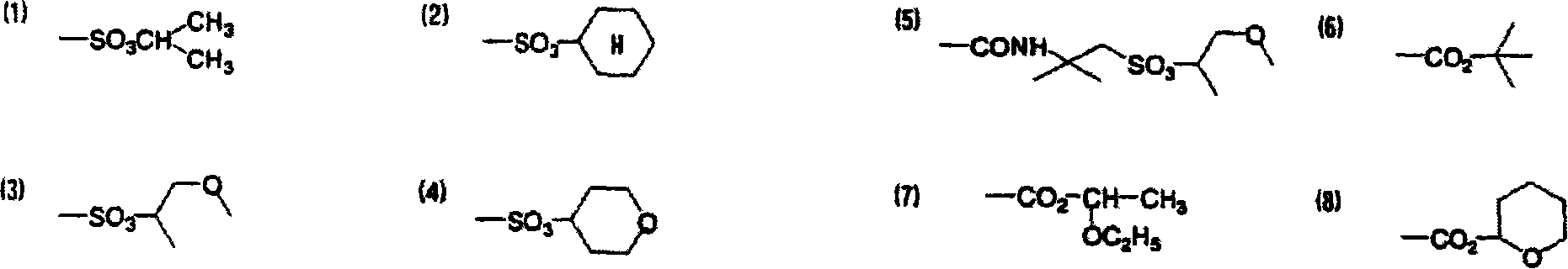

InactiveCN101120621AHigh precisionImprove adhesionLiquid/solution decomposition chemical coatingPrinted circuit manufactureSurface chargesElectroless plating

The invention provides a method of forming a metallic pattern including: (a) forming, in a pattern form on a substrate, a polymer layer which contains a polymer that has a functional group that interacts with an electroless plating catalyst or a precursor thereof; (b) imparting the electroless plating catalyst or precursor thereof onto the polymer layer; and (c) forming a metallic film in the pattern form by subjecting the substrate having the polymer layer to electroless plating using an electroless plating solution, wherein the substrate is treated using a solution comprising a surface charge modifier or 1*10<-10> to 1*10<-4> mmol / l of a plating catalyst poison before or during the (c) forming of the metallic film. The invention further provides a metallic pattern obtained thereby. Furthermore, the invention provides a printed wiring board and a TFT wiring board, each of which uses the metallic pattern as a conductive layer.

Owner:FUJIFILM CORP

Preparation method of aluminum-cladding boron composite powder

InactiveCN101787515ACoating time is shortDispersedVacuum evaporation coatingSputtering coatingPre treatmentBoron

The invention relates to a preparation method of an aluminum-cladding boron composite powder, which is characterized by comprising the following steps: (1) pretreating boron powder; (2) carrying out multi-arc aluminizing treatment on the surface of the pretreated boron powder in a multi-arc ion-plating machine by adopting a multi-arc ion-plating technology to obtain the aluminum-cladding boron composite powder; parameters of the multi-arc ion-plating technology comprise the following: selecting an aluminum target as a target; firstly, vacuumizing to 2.0*10<-2>Pa; secondly, introducing argon gas to (2.5-3.3)*10<-1>Pa; ensuring the current of an argon transmitting source is 55-70A and the film-plating temperature is 170-200DEG C; thirdly, feeding pretreated boron powder into a bearing platform positioned in a vacuum furnace body at the feeding speed of 5-20g / min; enabling powder particles to jump or roll from one step to another step of the bearing platform by rotating and vibrating; and finally enabling the powder particles to fall into a powder collection device. The invention has the advantages of short membrane-plating time, uniform cladding, simple process and suitability for large-scale production.

Owner:WUHAN UNIV OF TECH

Arc-protective garment

ActiveCN107415385AImprove insulation performanceImprove the protective effectSynthetic resin layered productsCellulosic plastic layered productsSocial benefitsSurface layer

The invention discloses an arc-protective garment. The arc-protective garment comprises an arc-protective surface layer and is characterized by comprising a plurality of comfortable layers located on the inner side of the arc-protective surface layer, and a supporting layer with bulges on two surfaces of at least one layer of fabric is arranged between the arc-protective surface layer and one comfortable layer. According to the arc-protective garment, the interlayer configuration structure comprising the arc-protective surface layer, the supporting layer and the comfortable layers is ingenious, air layers under the garment are ensured to be enough thick, the impact resistance of the fabric can be improved at the moment of arc explosion, the high-temperature harm of arc can be greatly reduced, escape time is won, burns are avoided or the burn degree is reduced, the wearing comfort of the arc-protective garment is greatly improved due to the adoption of multiple air layers, the practicability is extremely high, and the arc-protective garment has good social benefits and is worth popularization.

Owner:SWOTO PROTECTION & TECH CO LTD

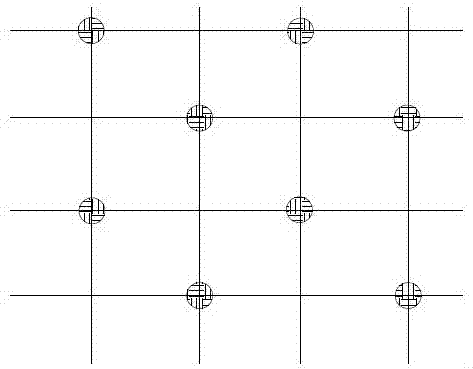

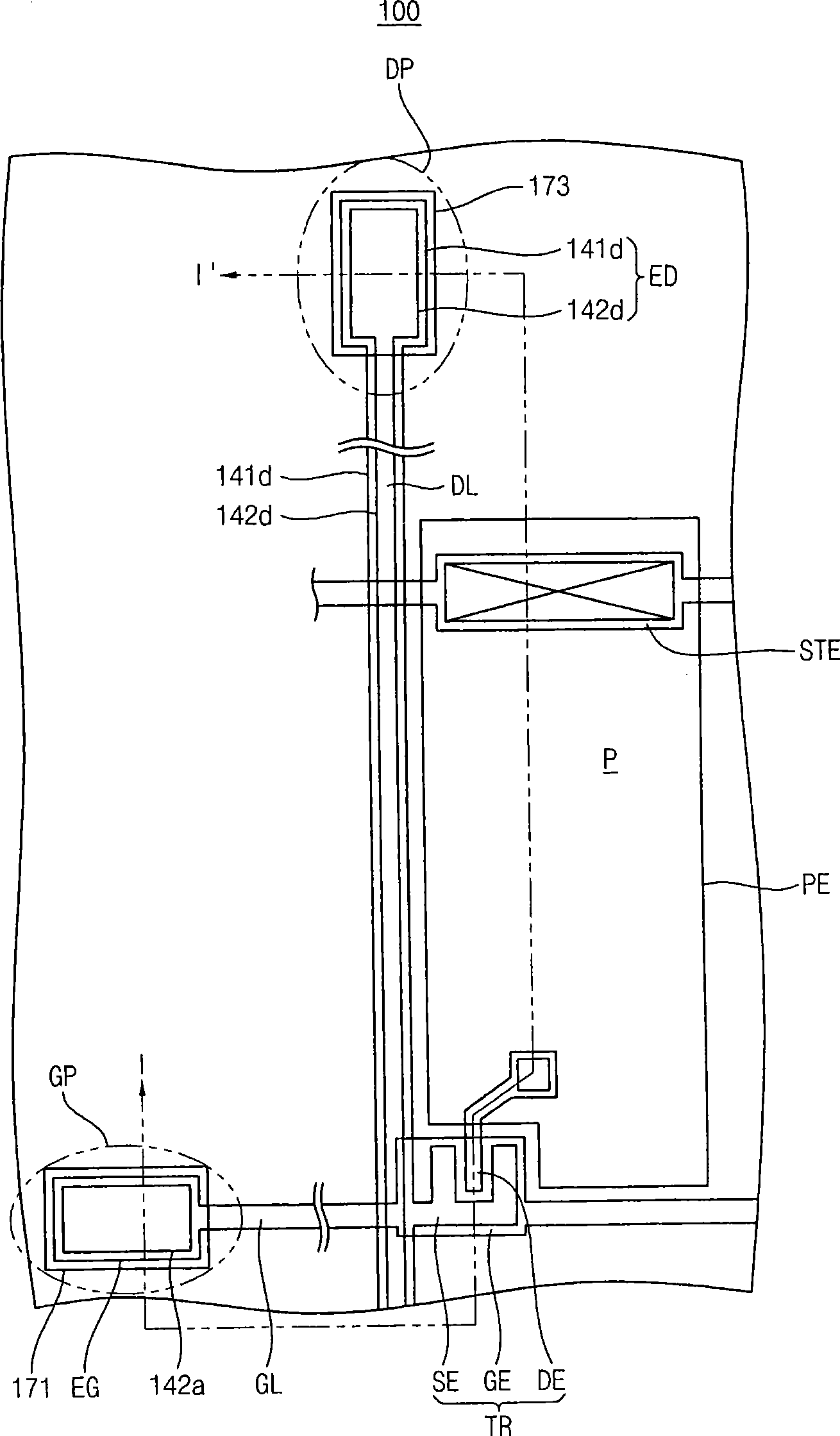

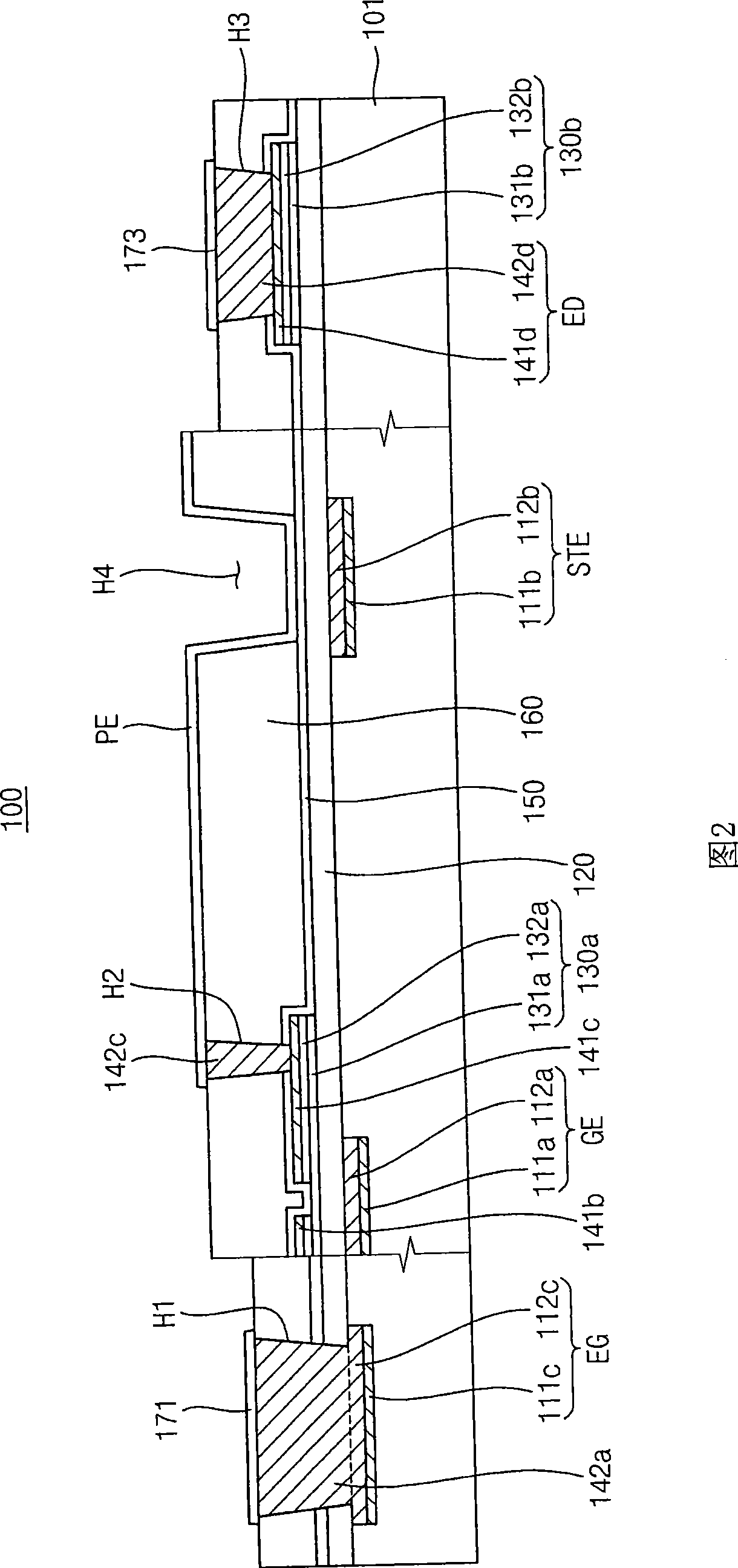

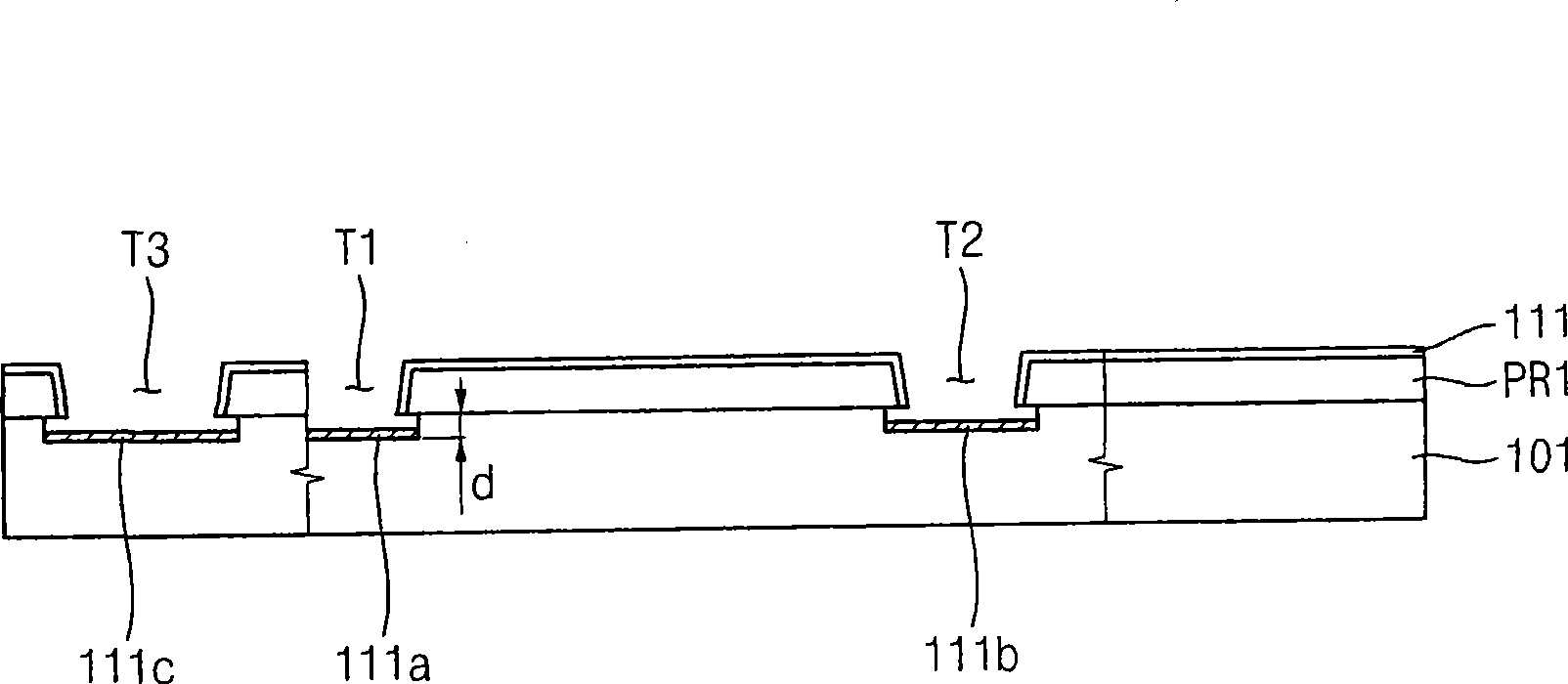

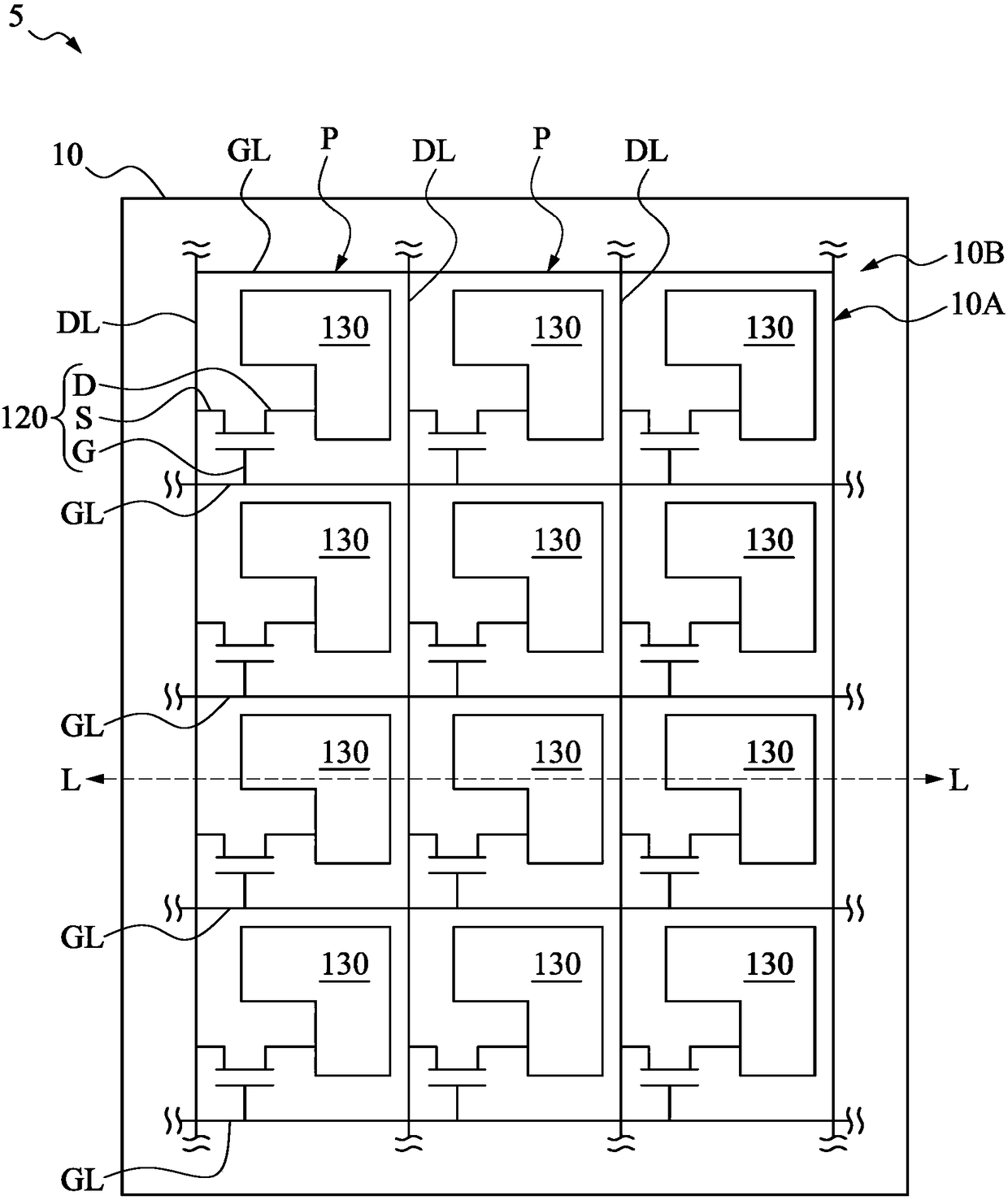

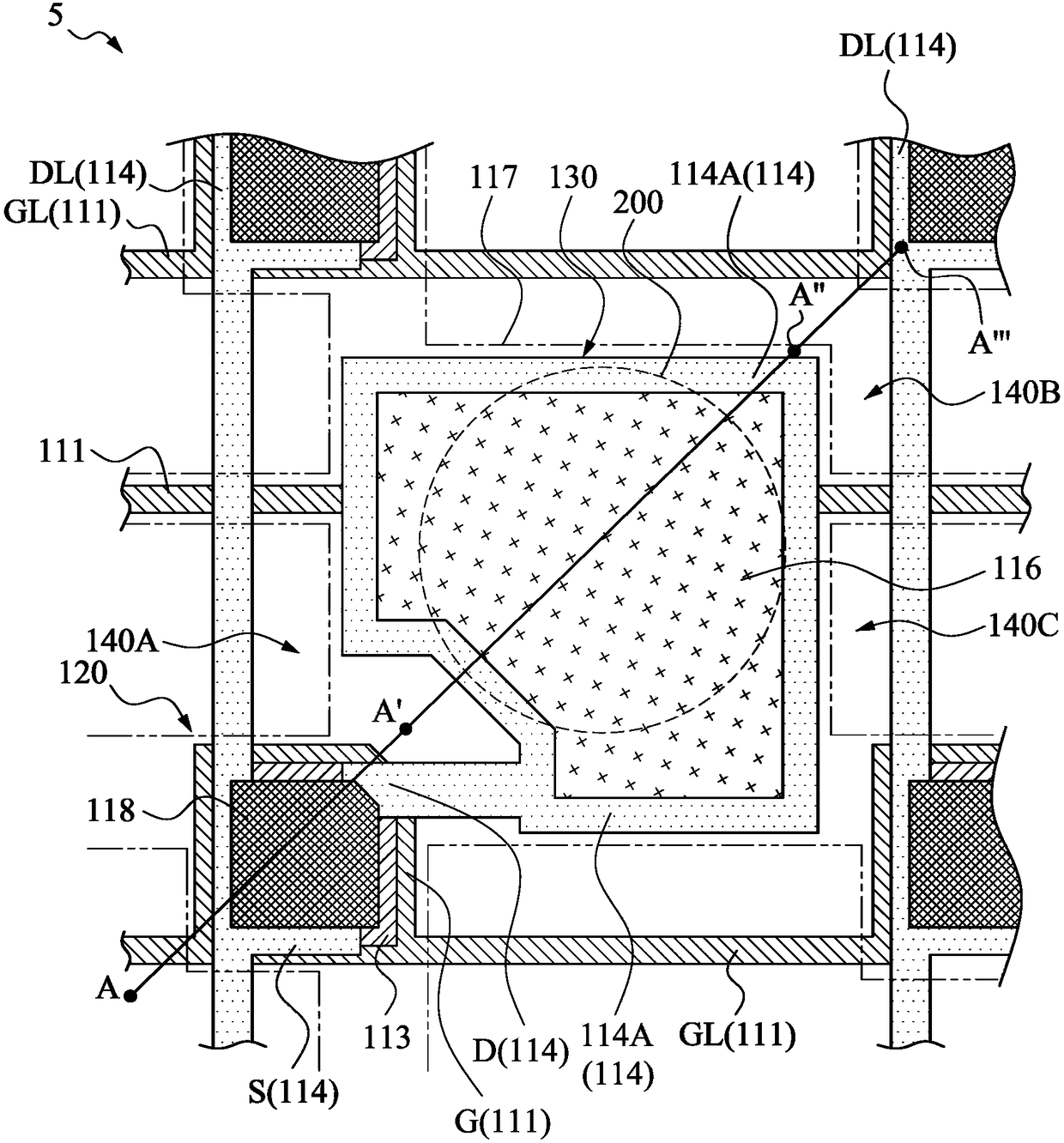

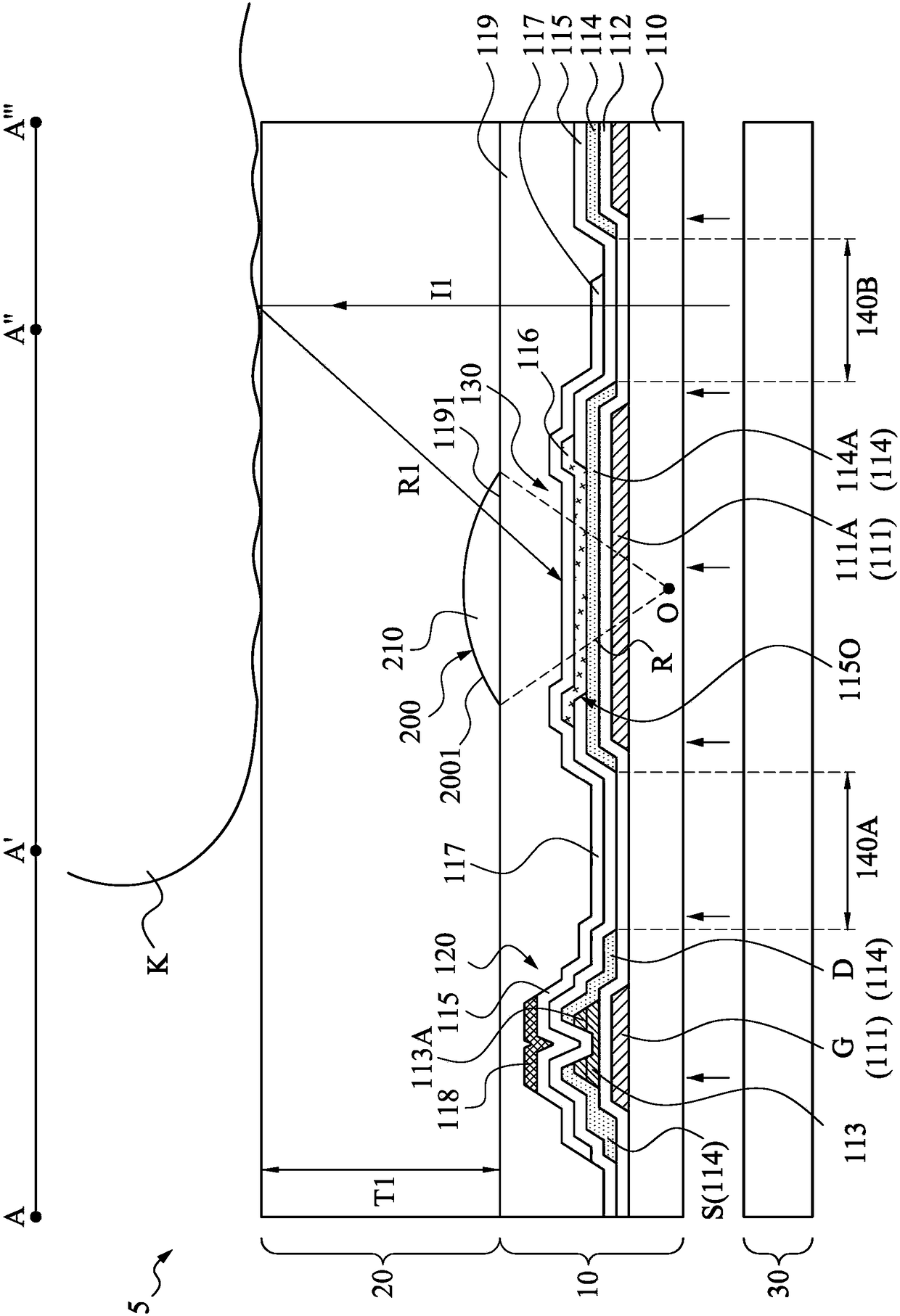

Array substrate and method for manufacturing the same

ActiveCN101447490AEnough thicknessLower resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringData lines

The invention provides a array substrate, wherein a gate line includes a first seed layer formed on a base substrate and a first metal layer formed on the first seed layer. A first insulation layer is formed on the base substrate. A second insulation layer is formed on the base substrate. Here, a line trench is formed through the second insulation layer in a direction crossing the gate line. A data line includes a second seed layer formed below the line trench and a second metal layer formed in the line trench. A pixel electrode is formed in a pixel area of the base substrate. Therefore, a trench of a predetermined depth is formed using an insulation layer and a metal layer is formed through a plating method, so that a metal line having a sufficient thickness may be formed. The invention also provides a method for manufacturing the array substrate.

Owner:SAMSUNG DISPLAY CO LTD

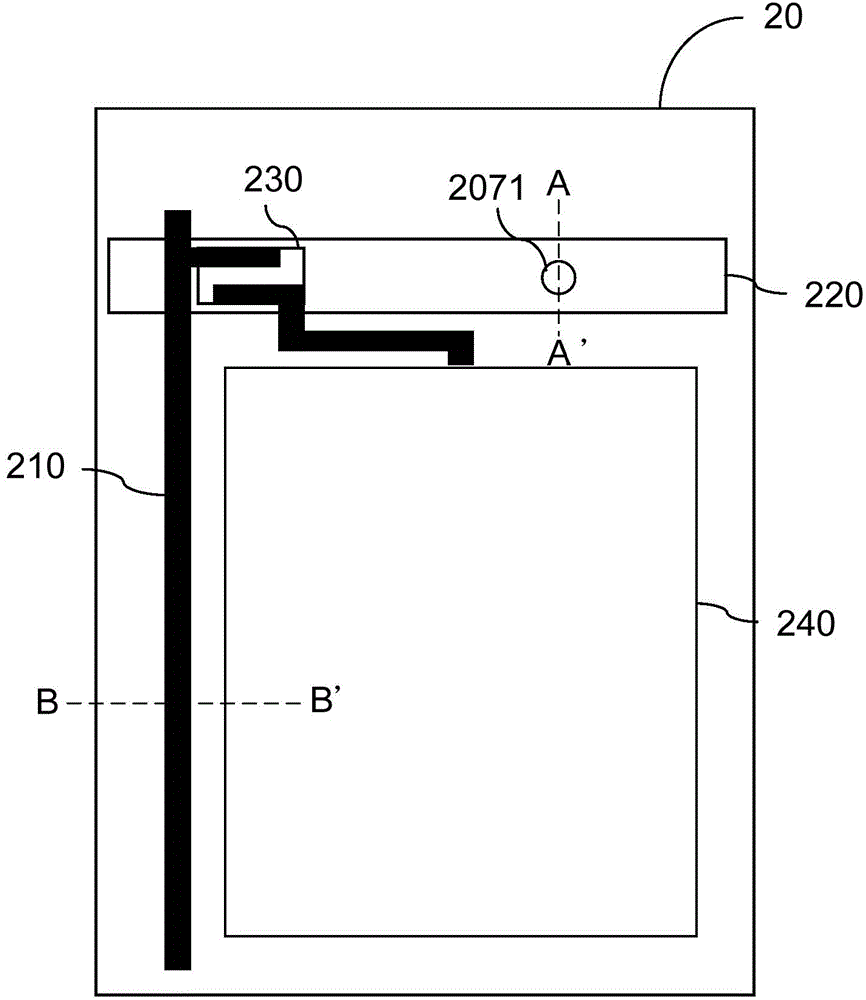

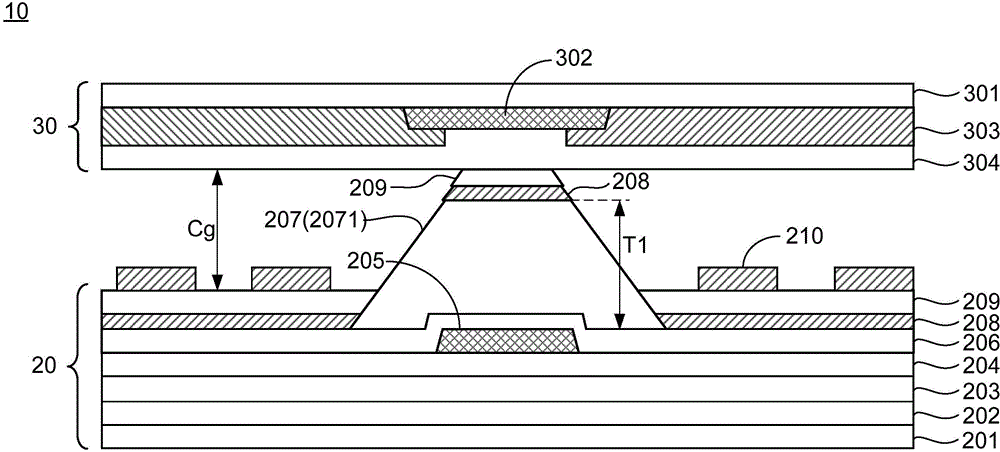

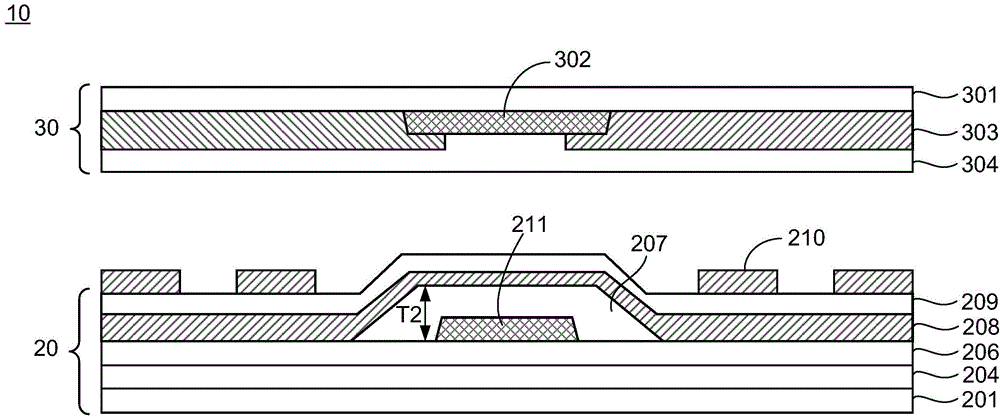

Liquid crystal display panel and manufacturing method thereof

ActiveCN104932152AEnough thicknessReduce processSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayColor film

The invention provides a liquid crystal display panel and a manufacturing method thereof. The liquid crystal display panel comprises an array substrate and a color film substrate. The array substrate comprises a data line, a scanning line, a thin film transistor and an open region. The array substrate further comprises a patterned flat layer formed on the data line, the scanning line and the thin film transistor and exposed out of the open region. A columnar protrusion is formed at the portion, located on the scanning line, of the patterned flat layer, the columnar protrusion is supported between the array substrate and the color film substrate, no spacer needs to be additionally manufactured, and therefore the procedure of manufacturing photosensitive spacers on the color film substrate is omitted.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

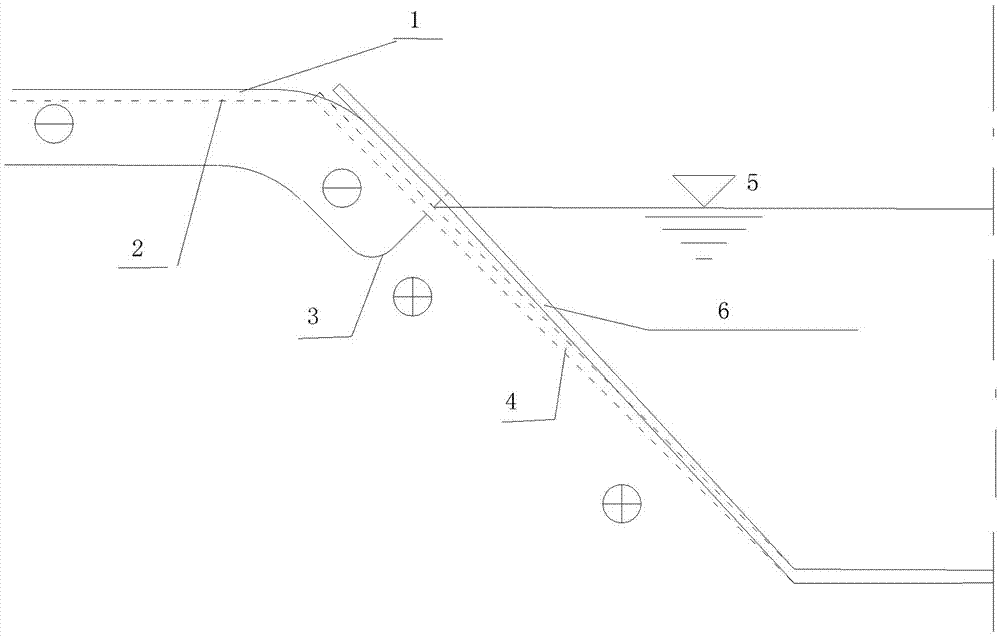

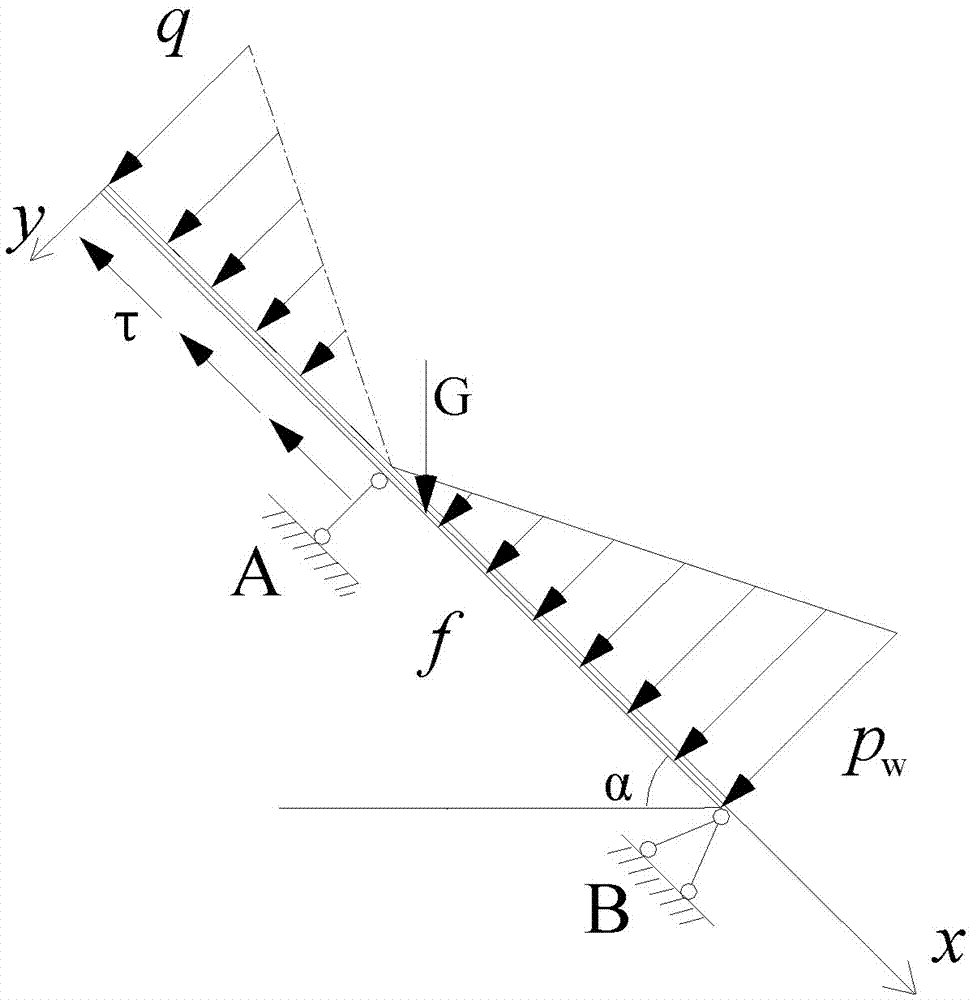

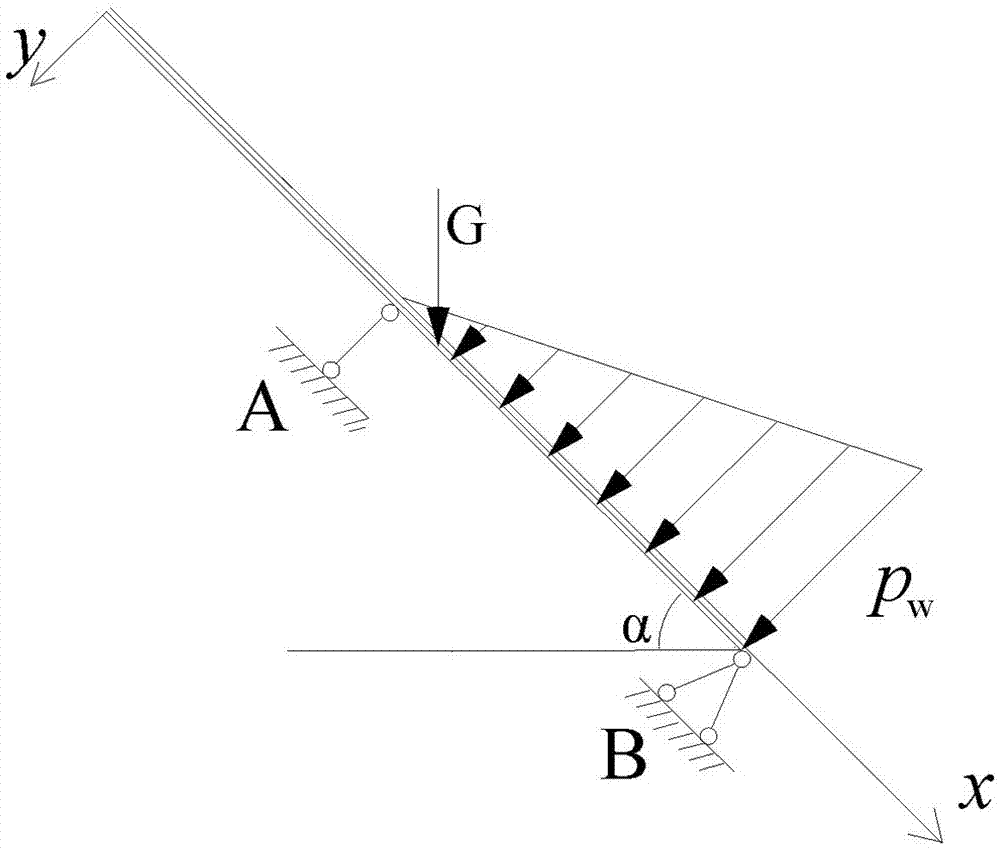

Method for checking anti-frost heaving damage of slope concrete lining layer of water conveyance canal in winter

ActiveCN105447229AEnough thicknessGuaranteed uptimeGeometric CADDesign optimisation/simulationMechanical modelsForce analysis

The present invention relates to a method for checking anti-frost heaving damage of a slope concrete lining layer of a water conveyance canal in winter. The method is applied to the design of an open channel water conveyance canal and to perform a force analysis on a slope concrete lining layer under an 5 of canal base soil frost heaving. The method comprises: by using a canal slope concrete lining layer as a member with a slope foot as a fixed hinge support and a water level surface as a movable hinge support, establishing a mechanical model of checking the anti-frost heaving damage of a canal slope concrete lining layer; and determining, according to a stress generated by a transverse bending effect or / and a stretch-bending combination effect of the member and axial tensile strength of concrete, whether the slope concrete lining layer can resist the damage generated by a frost heaving effect. According to the method for checking anti-frost heaving damage provided by the present invention, influence of interaction between canal slope bidirectional freezing as well as a concrete lining layer and canal base soil deformation is considered; and a deficiency of a checking method of anti-frost heaving damage capacity of a slope concrete lining layer under the circumstance of water conveyance by a concrete canal in a permafrost region is made up.

Owner:SHIHEZI UNIVERSITY

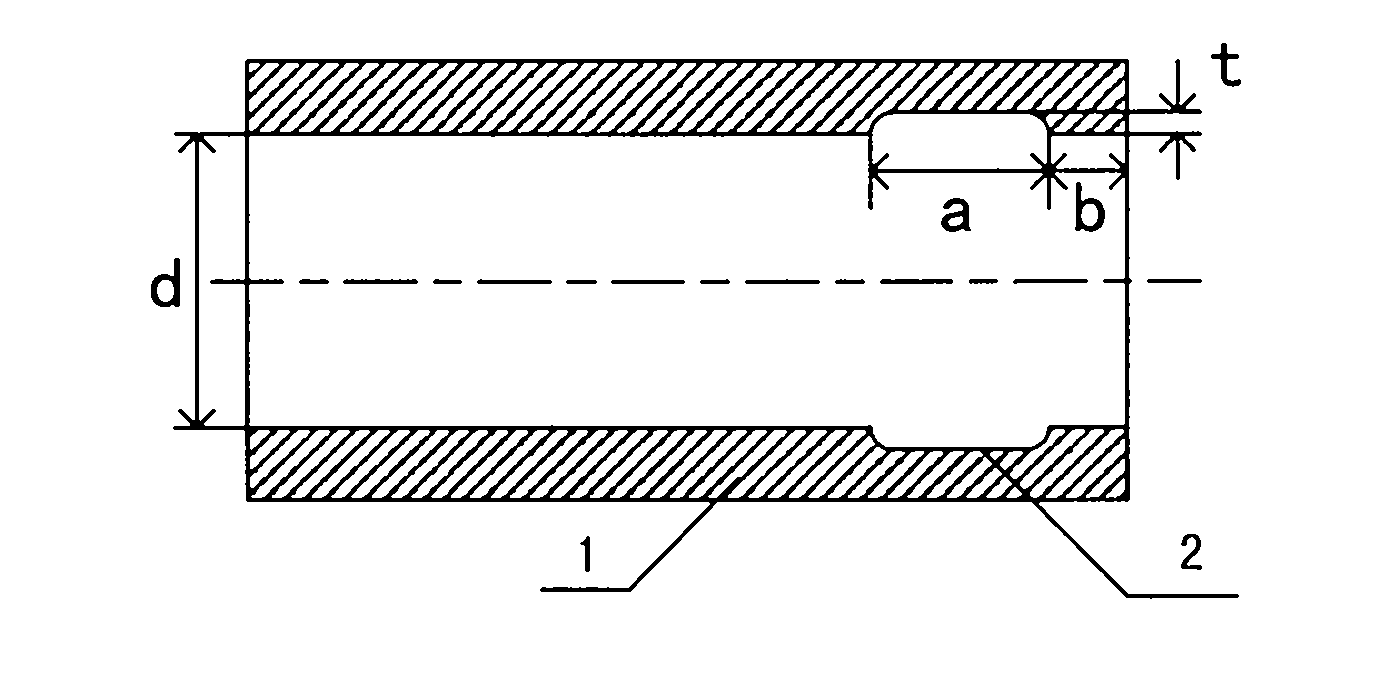

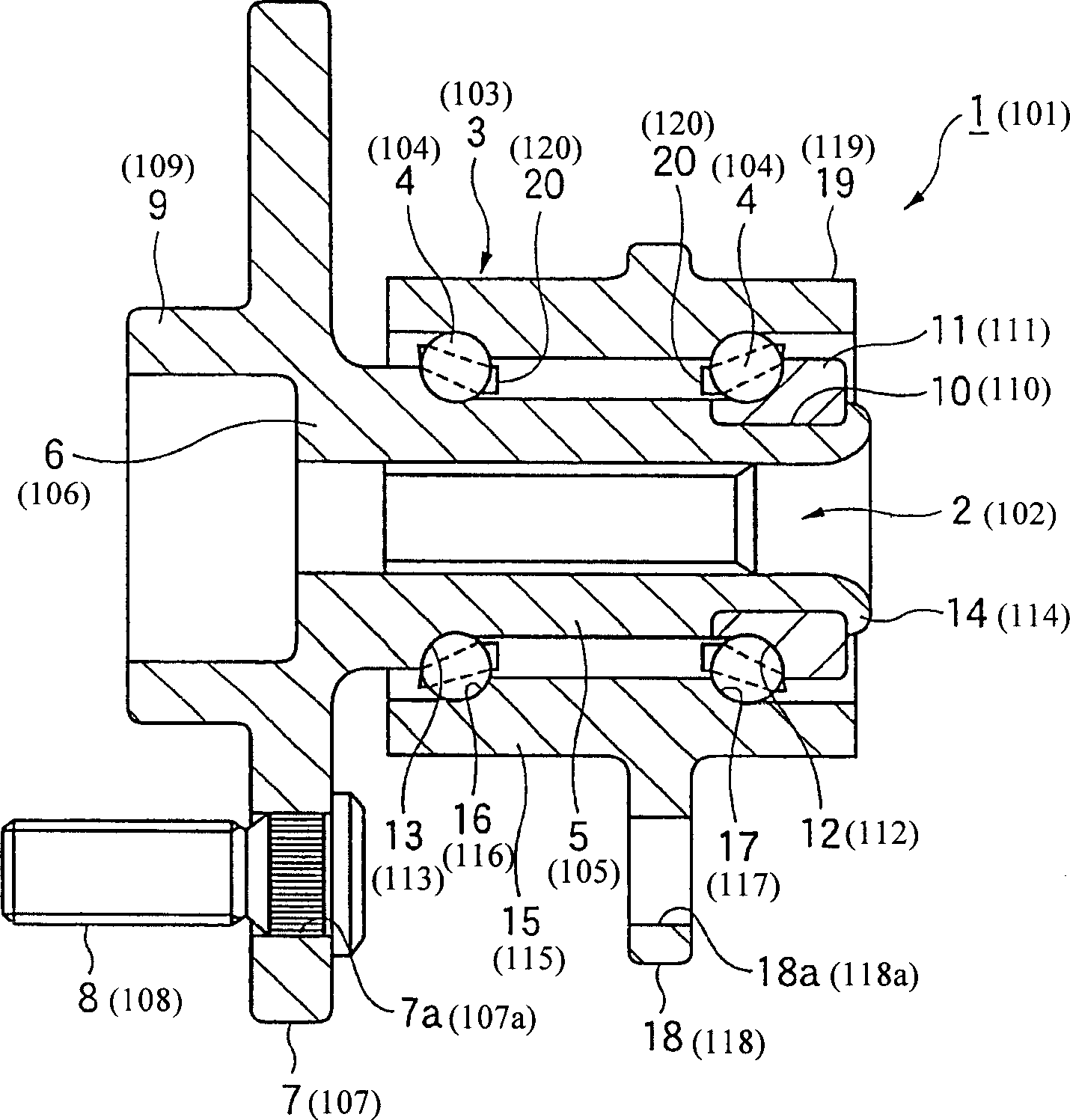

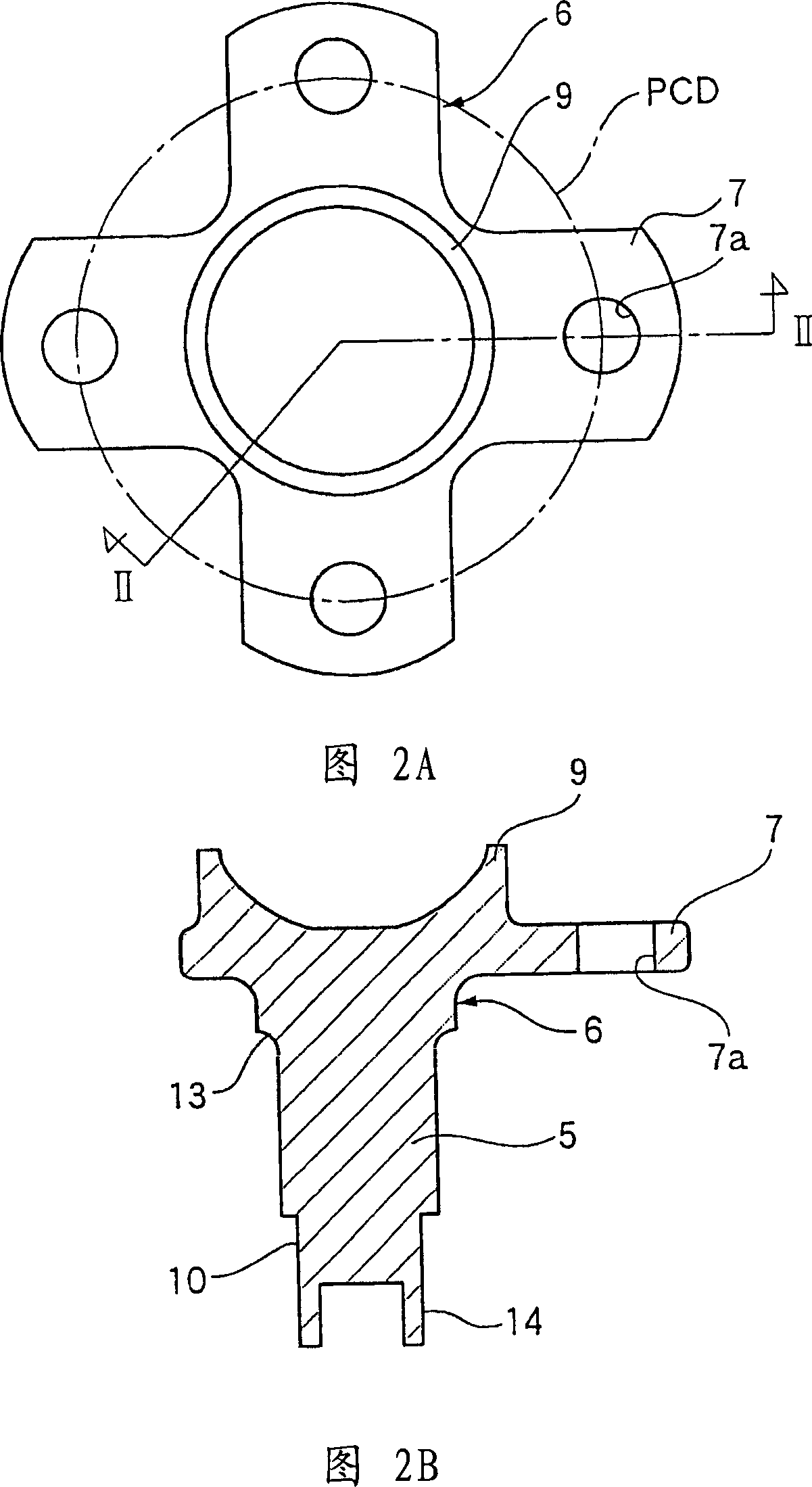

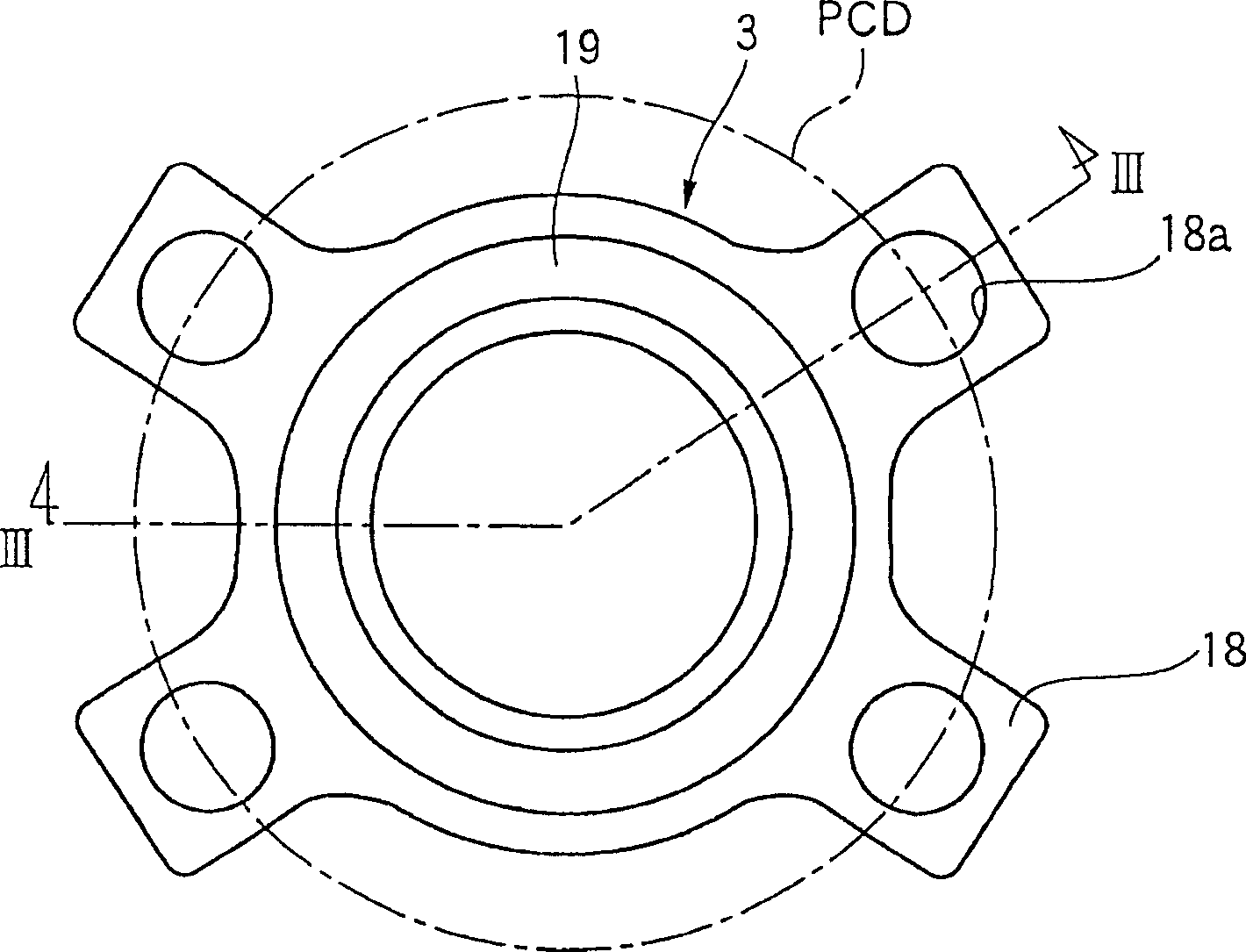

Hub unit with wheel support and bearing ring, and method of manufacturing the hub unit

A raceway member 6 of a wheel support hub unit, having wheel or vehicle body fixing portions 7 extending radially outward from a solid or hollow shaft portion, and a wheel or vehicle body positioning cylindrical portion 9 extending concentrically with the shaft portion, the fixing portion 7 being formed by the cold side extrusion so that the fixing portion is integral with the shaft portion 5.

Owner:NSK LTD

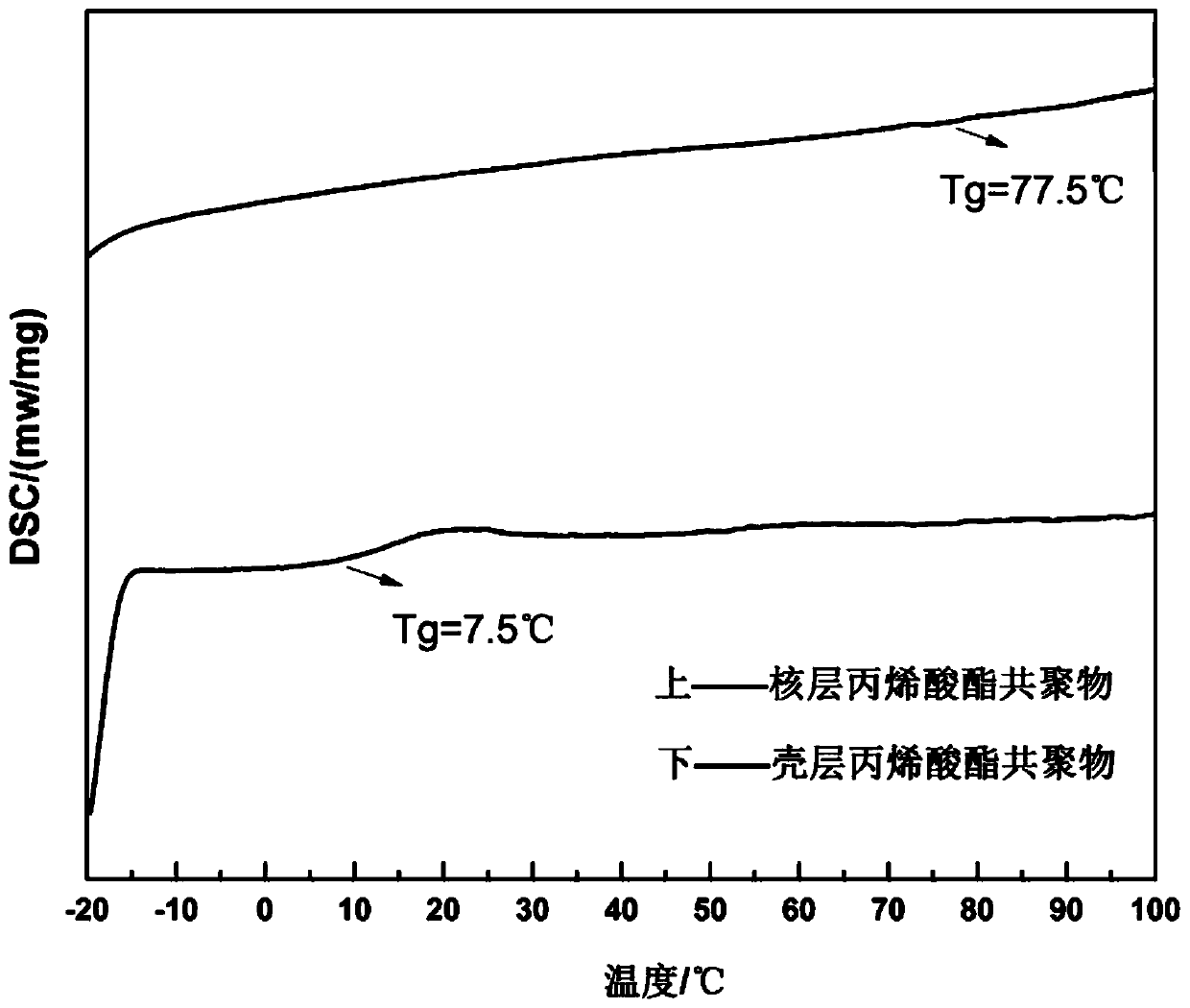

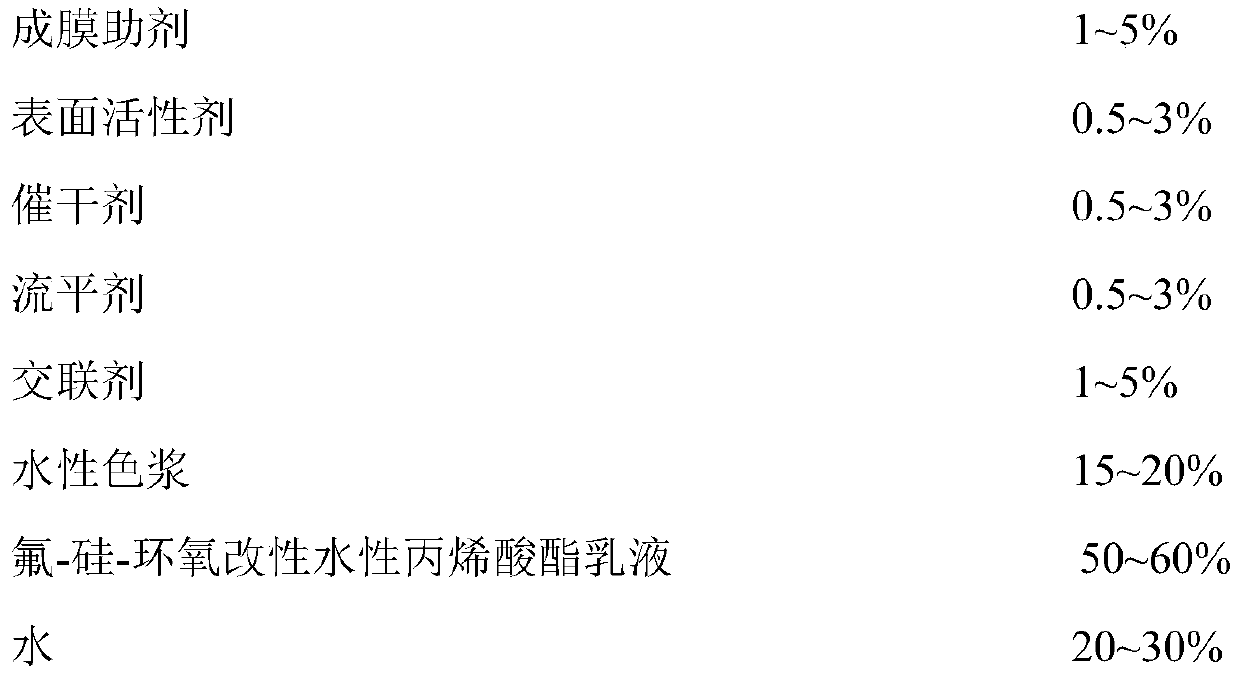

Fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink special for PVC film and preparation method of ink

The invention discloses fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink special for a PVC film and a preparation method of the ink. The ink consists of the following raw materials in parts by weight: 1-5% of a film forming additive, 0.5-3% of a surfactant, 0.5-3% of a drier, 0.5-3% of a leveling agent, 1-5% of a crosslinking agent, 15-20% of aqueous color paste, 50-60% of a fluorine-silicon-epoxy-modified aqueous acrylate emulsion and 20-30% of water. The fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink takes the water as a solvent, so that the ink has no volatile odor; when the ink is applied to the PVC film, the wettability is good; an ink coating film with the thickness of 50 um can reach a surface drying state within 6 seconds at 50 DEG C, and the adhesion fastness reaches 99%; the ink can be scrubbed by 70% of an ethanol aqueous solution more than 100 times after curing completely, and the adhesion resistance reaches 95%; and the preparation process is simple, the production cost is low, and the ink is favorable for universal popularization and application.

Owner:SOUTH CHINA UNIV OF TECH

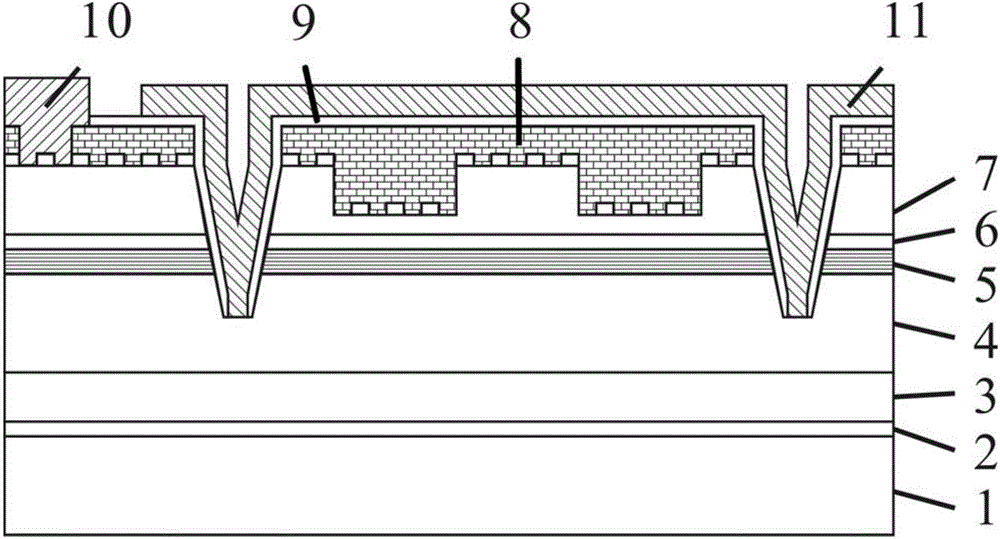

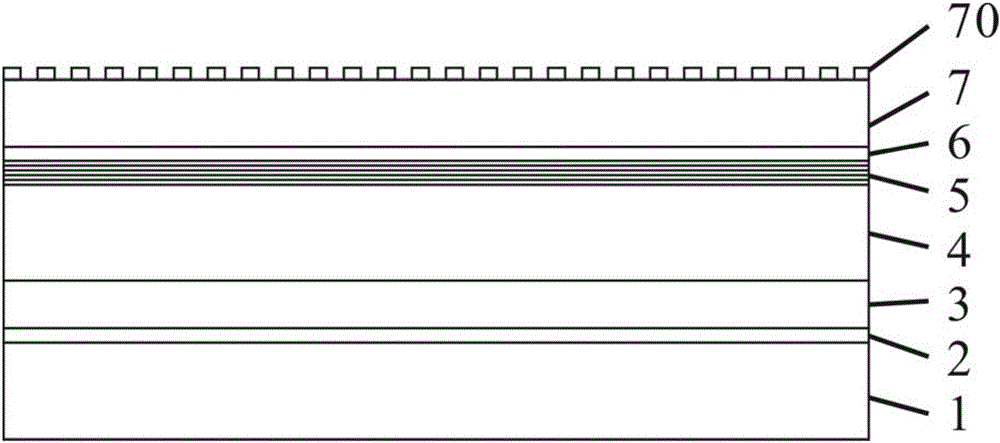

Broadband efficient GaN-based LED chip based on surface plasma effect and preparation method thereof

ActiveCN106784221AIncrease current densityEnough thicknessNanotechnologySemiconductor devicesQuantum wellCoupling

The invention discloses a broadband efficient GaN-based LED chip based on surface plasma effect and a preparation method thereof. The broadband efficient GaN-based LED chip is an inversion structure, and successively comprises a substrate, a buffer layer, an unintentional doping GaN layer, a n-GaN layer, a quantum well layer, an electronic barrier layer, a p-GaN layer, a metal reflector layer, a passivation layer, a p-electrode layer, a n-electrode layer, a p-electrode hole and a n-electrode hole from bottom to top. The bottom face, connected with the surface of the p-GaN layer, of the metal reflector layer is provided with a micron-nano compound metal structure. The micron metal structure comprises alternately installed bulge part and groove part. The bulge part is extended to the adjacent place of the quantum well, and the efficient SP-MQW coupling is realized. The p-GaN surface is covered by the groove part, so the p-GaN layer has enough thickness for injecting the hole. The nano-metal structure is distributed on the division surface of the micron-metal structure and the p-GaN.

Owner:SOUTH CHINA UNIV OF TECH

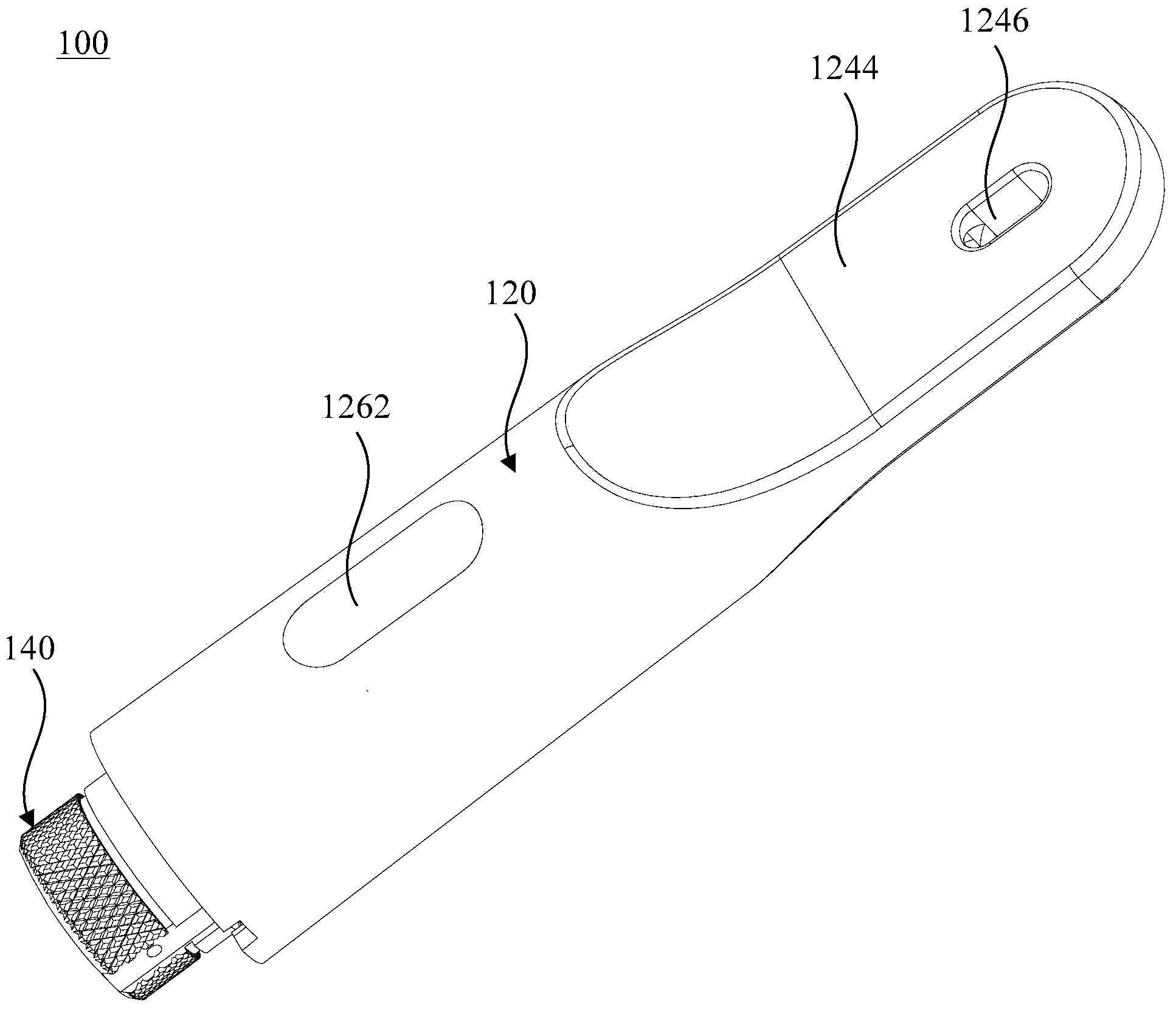

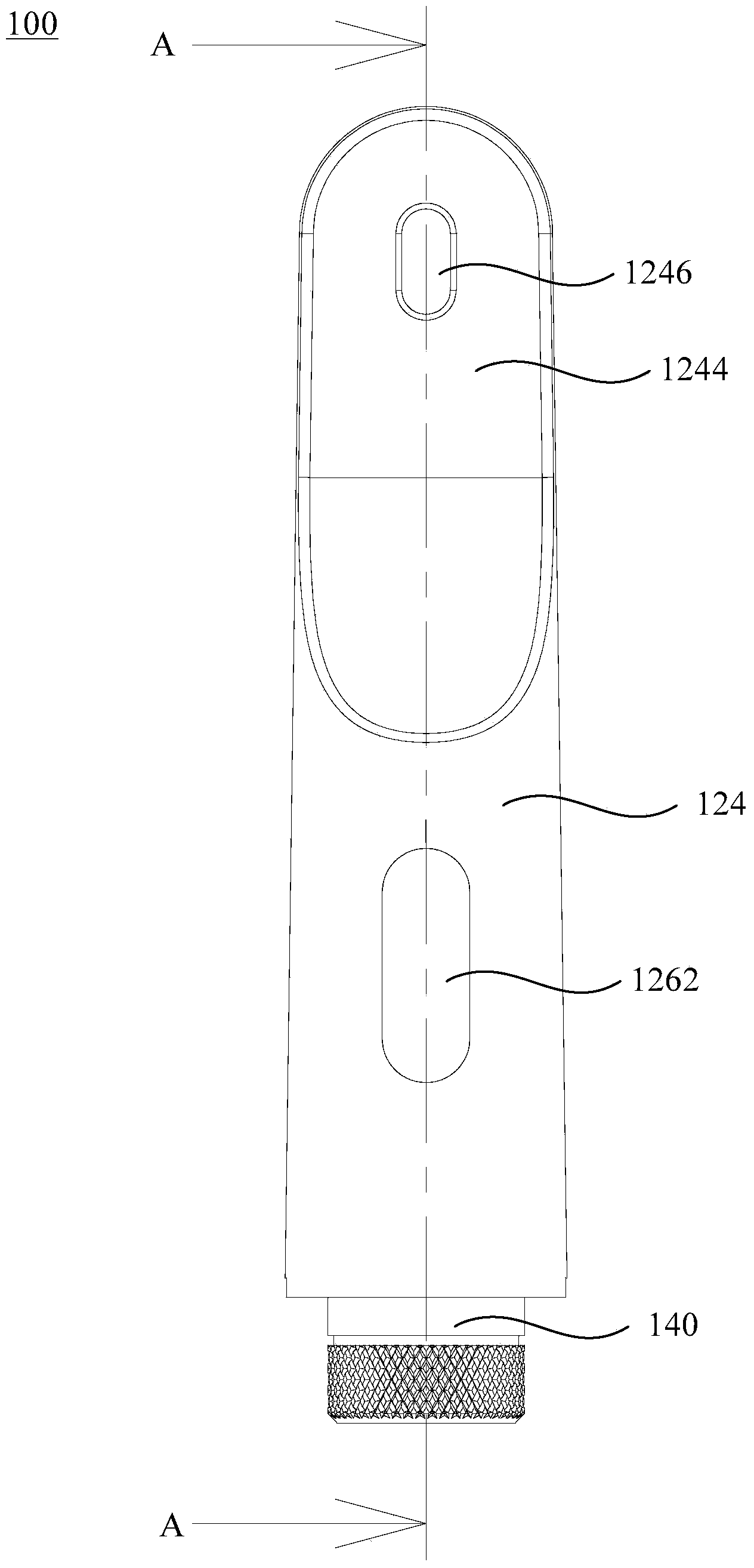

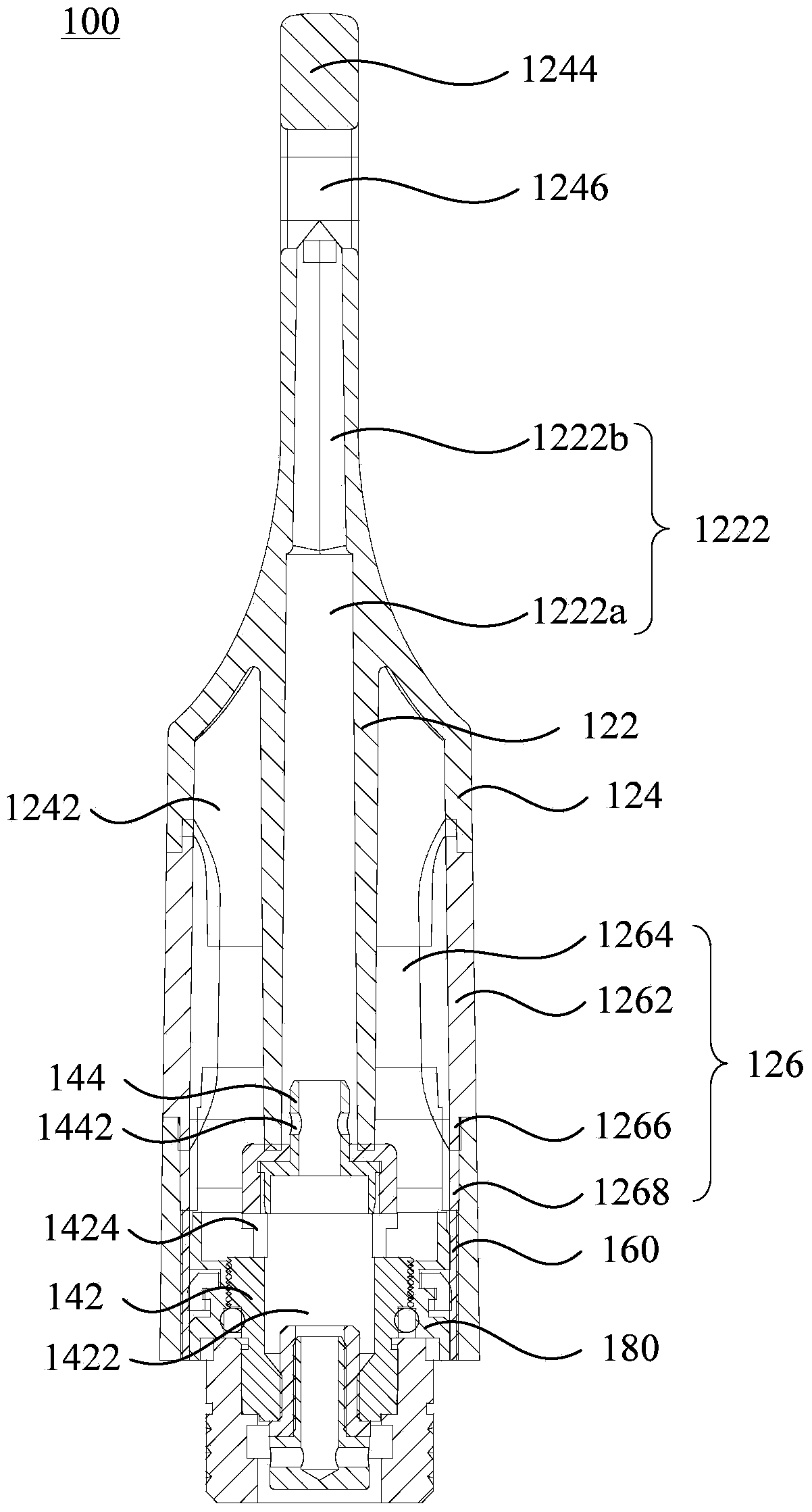

Inhaler and atomization assembly thereof

The invention relates to an inhaler and an atomization assembly of the inhaler. The atomization assembly of the inhaler comprises a shell and an atomization core arranged to be combined with the shell. The shell comprises an outer shell and a breather pipe, a liquid storing cavity used for storing liquid is formed in the outer shell, a flat suction nozzle is formed at one end of the outer shell, and an inhaling hole is formed in the suction nozzle; an airflow channel is formed in the breather pipe, the breather pipe is located in the liquid storing cavity, one end of the breather pipe is connected with the atomization core, the other end of the breather pipe is connected with the outer shell, and the airflow channel is communicated with the inhaling hole. The cross section of at least part of the airflow channel is flat, the part, with the flat cross section, of the airflow channel is close to the inhaling hole, and the shape of the airflow channel is matched with that of the suction nozzle. The cross section of the at least part of the airflow channel is flat to be matched with the flat suction nozzle, it is ensured that the outer shell and the breather pipe are thick enough, the product qualified rate is increased, the area of the cross section of the airflow channel is ensured, and therefore a user can suck the atomized liquid into the mouth easily.

Owner:SHENZHEN SMOORE TECH LTD

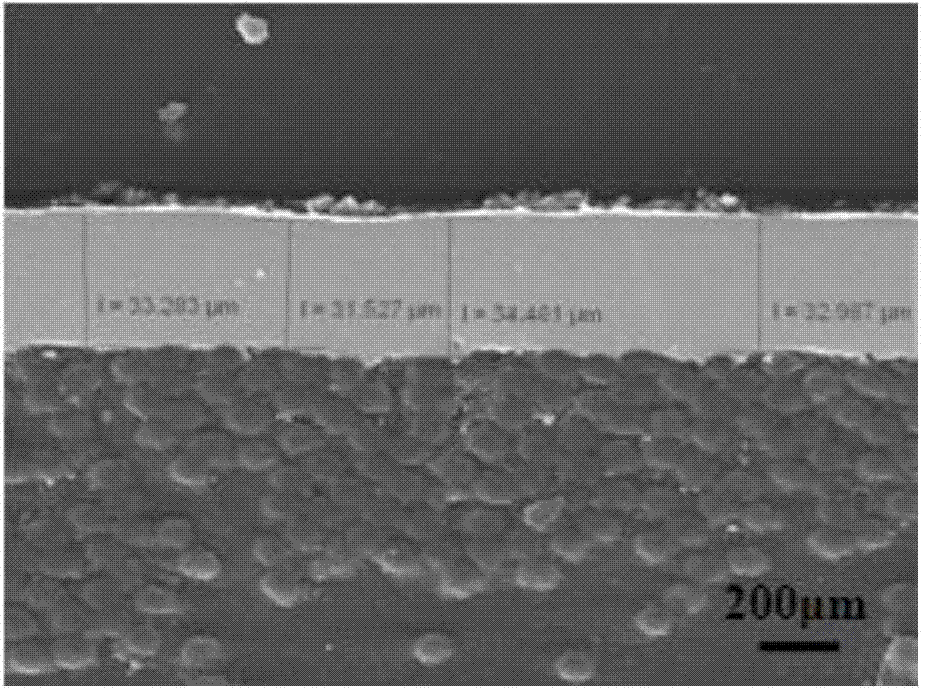

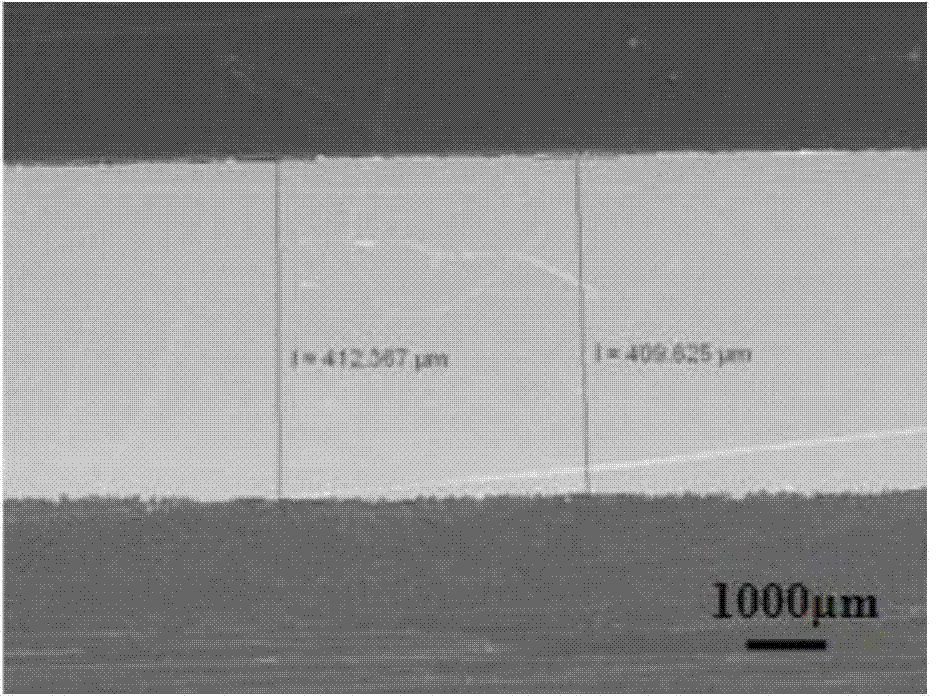

Method for nickeling carbon fiber/cyanate ester resin composite material

InactiveCN103668199AEnough thicknessReduce manufacturing costLiquid/solution decomposition chemical coatingSuperimposed coating processFiberChemical plating

The invention discloses a method for nickeling a carbon fiber / cyanate ester resin composite material. The method comprises the following steps: pre-nickeling the surface of a pretreated carbon fiber / cyanate ester resin composite material through a chemical plating method, and then, nickeling by using an electroplating method. According to the method, chemical plating is combined with electroplating, the pre-nickeling procedure is carried out by the chemical plating method firstly to form a uniform conductive layer on the material surface, and then, the nickel layer is thickened by the electroplating method to both ensure the uniformity of the nickeling layer and ensure enough thickness for the nickeling layer, the problems of plating leakage and too thin plating layer when nickeling the surface of the carbon fiber / cyanate ester resin composite material in the prior art are solved, uniform and thick enough plating layer is obtained, the plating layer is uniform, integral, free of plating leakage phenomenon, good in binding force with a base material, free of gap and capable of meeting the application conditions of a space optical mirror, and the electroplating and chemical plating production costs are low, so that volume production can be realized.

Owner:XIAN UNIV OF TECH

Sensing device

ActiveCN108346671AEnough thicknessImprove qualitySolid-state devicesPrint image acquisitionActive componentComputer module

A sensing device includes an array substrate, a protective layer, and a backlight module. The array substrate includes a substrate and has a plurality of sensing units, wherein each sensing unit includes an active element, a photosensitive element, and at least one light transmitting area. The active components are disposed on the substrate. The photosensitive elements are disposed on the substrate and electrically connected to the active elements. The light transmitting areas are located around the photosensitive elements. The protective layer is disposed on the array substrate, wherein the protective layer has a plurality of grooves, and the grooves are disposed adjacent to the array substrate, and the grooves respectively overlap the photosensitive elements of the sensing units in a normal direction of the substrate. The backlight module is disposed on the other side of the array substrate opposite to the protective layer.

Owner:AU OPTRONICS CORP

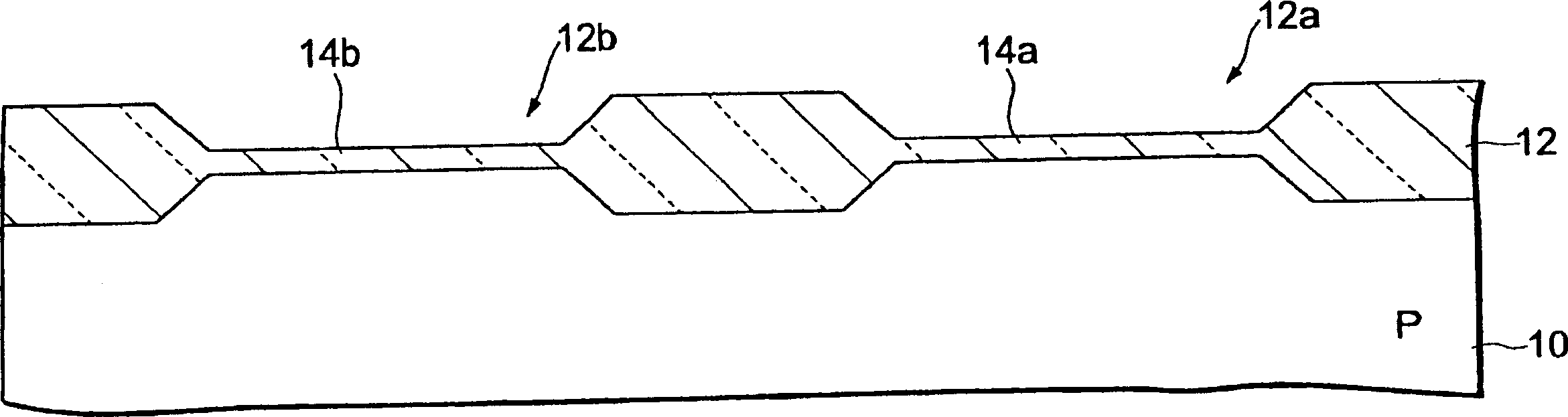

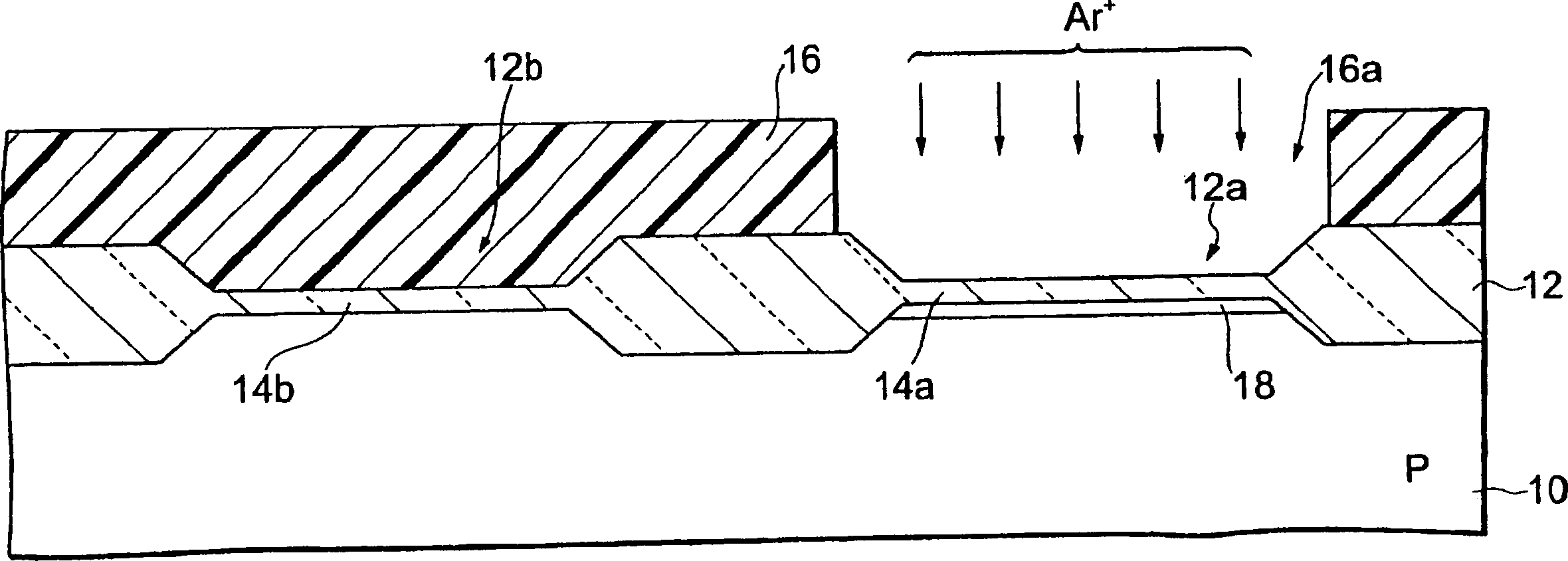

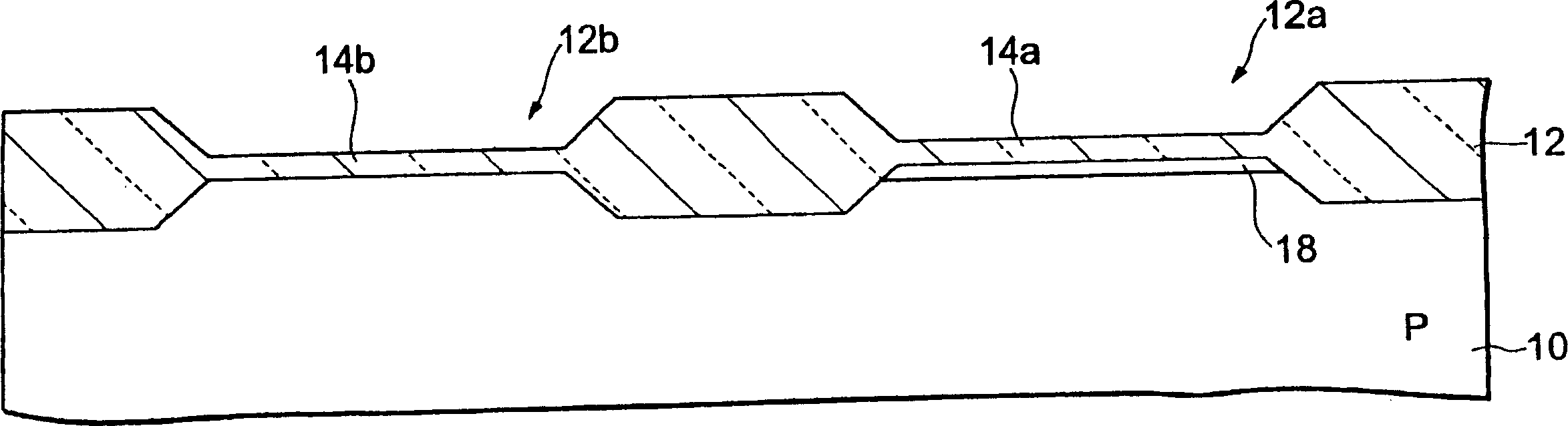

Manufacturing method of grating oxide film

InactiveCN1722408APromote oxidation efficiencyEnough thicknessSemiconductor/solid-state device manufacturingResistFluoride

After forming a field insulating film 12 on a substrate, sacrificing or gate oxidation films are formed as oxidation films 14 a and 14 b. An ion implantation layer 18 is formed by one or plurality of implantation process of argon (or fluoride) ion in an element hole 12 a using a resist layer 16 as a mask via the oxidation film 14 a. When the oxidation films 14 a and 14 b are used as sacrificing oxidation films, gate oxidation films are formed in the element holes 12 a and 12 b after removing the resist film 16 and the oxidation films 14 a and 14 b. When the oxidation films 14 a and 14 b are used as gate oxidation films, the oxidation films are once thinned by etching and then thickened after removing the resist layer 16. The gate oxidation film 14 a is thicker than the gate oxidation film 14 b by forming the ion implantation layer 18.

Owner:YAMAHA CORP

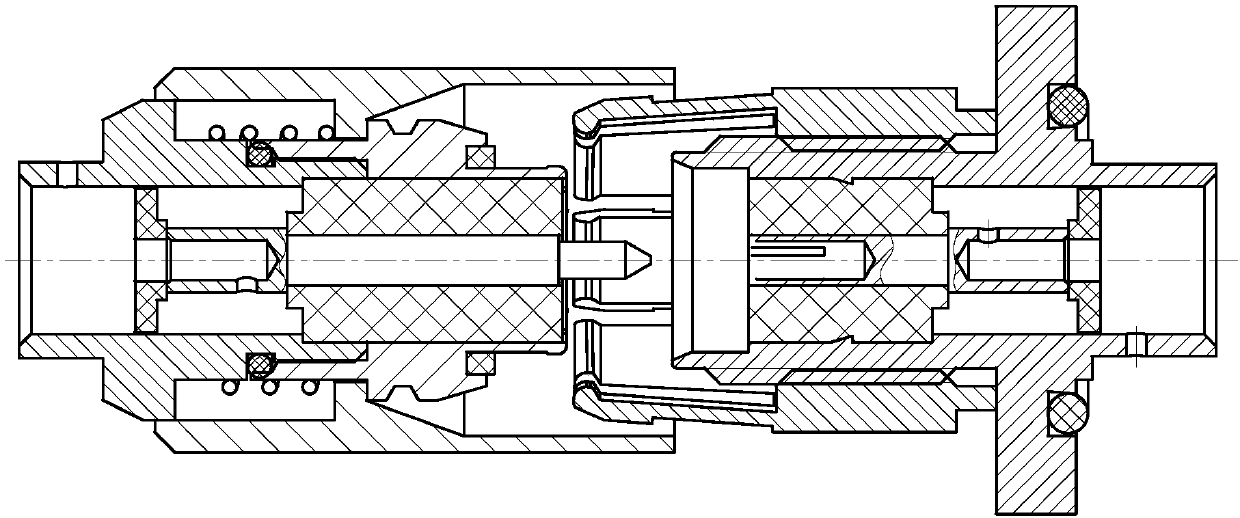

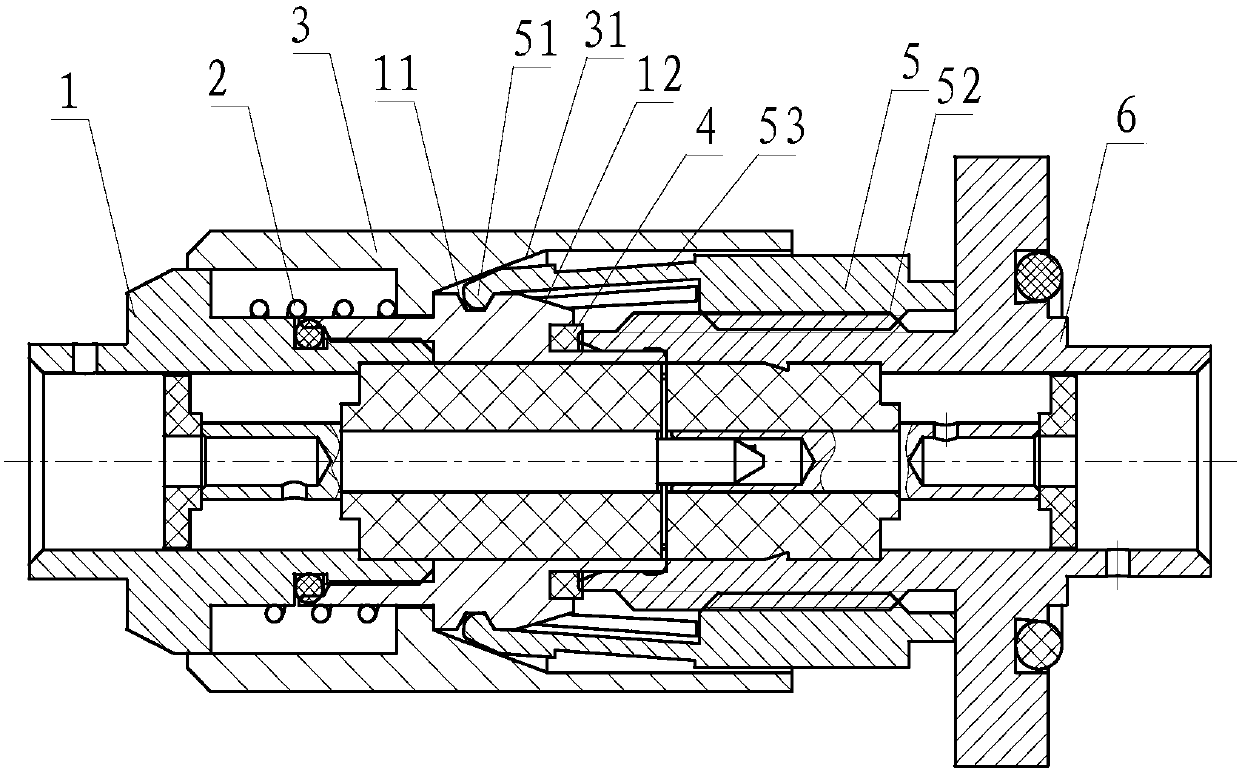

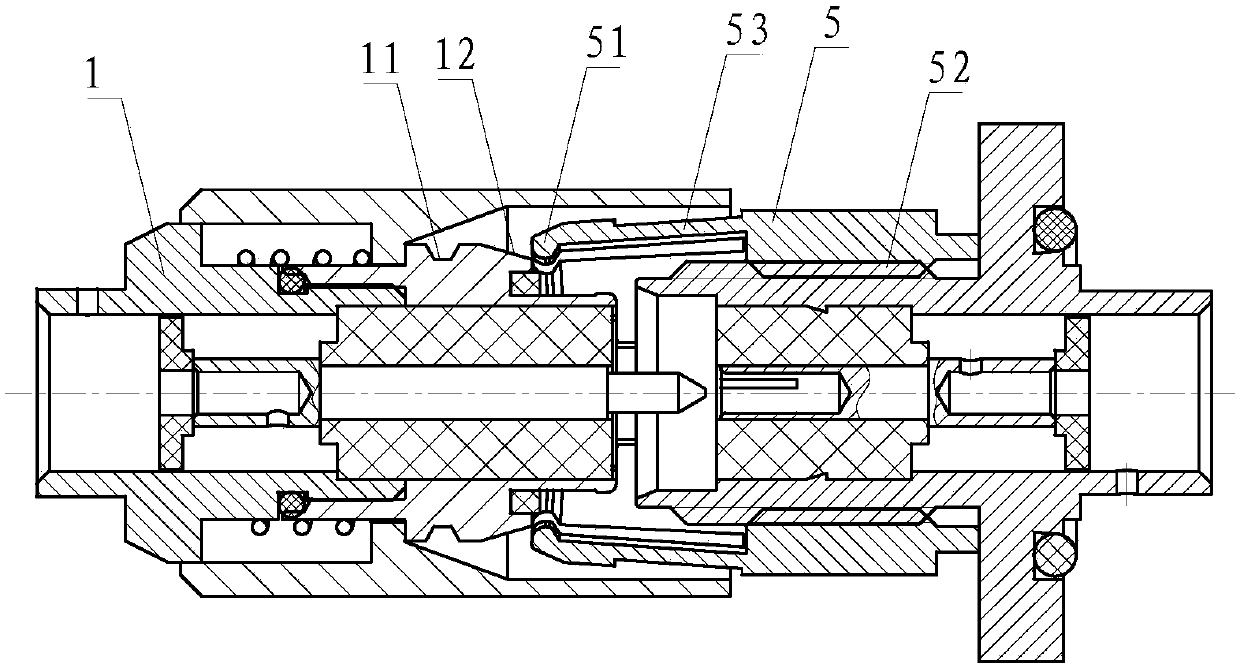

Novel rapid-insertion self-locking connection mechanism

InactiveCN109755814AImprove retentionImprove shear resistanceCoupling device detailsEngineeringSelf locking

The invention discloses a novel rapid-insertion self-locking connection mechanism. The novel rapid-insertion self-locking connection mechanism comprises a plug main body (1), a spring (2), an unlocking sleeve (3), an elastic claw (5) and a socket main body (6), wherein the elastic claw (5) is arranged at an interface of the socket main body (6), a hook claw (51) is arranged at the bottom of the elastic claw (5), a trapezoid groove (11) is formed in an outer side of the plug main body (1), the spring (2) is arranged between the plug main body (1) and the unlocking sleeve (3) and is used for providing an axial elastic force for the plug main body (1) and the unlocking sleeve (3), a sliding rail (31) is formed in the unlocking sleeve (3) and is sued for the elastic claw to slide, an inclinedsurface is arranged at the bottom of the sliding rail (31), and the bottom of the sliding rail (31) is in closely contact with the hook claw (51) during the locking process so that the hook claw (51)is locked in the trapezoid groove (11). Rapid insertion and self locking are achieved by matching of the trapezoid groove and the unlocking sleeve in a sliding rail surface way.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

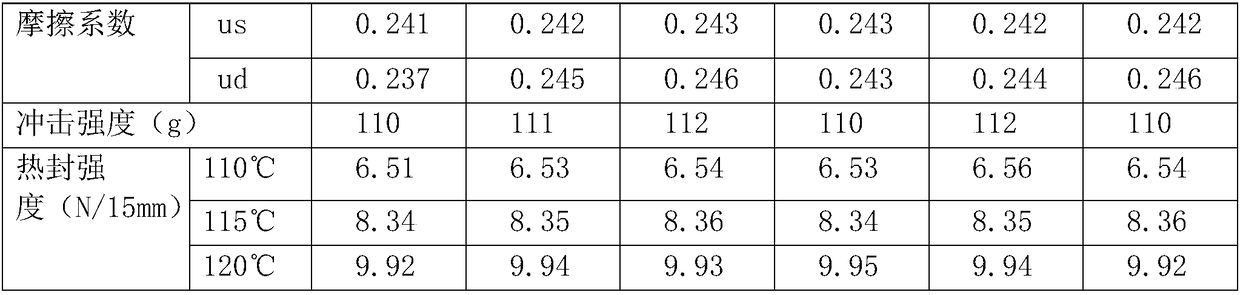

Heat-sealing easy-to-repeatedly tear PE film and preparation method thereof

ActiveCN108189506AGood impact strengthIncrease softnessSynthetic resin layered productsMacromolecular adhesive additivesRosinMelt flow index

The invention discloses a heat-sealing easy-to-repeatedly tear PE film which comprises an inner layer, middle layer and surface layer which are sequentially stacked, wherein the inner layer is prepared from LDPE with melt flow index of 2g / 10min and density of 0.926g / cm<3>, 3-6 parts of LLDPE with melt flow index of 2g / 10min and density of 0.926g / cm<3>, 3-6 parts of metallocene LLPDE with melt flowindex of 2g / 10min and density of 0.905g / cm<3> and 0.08 part of PPA masterbatch; the material No.1 of the middle layer is prepared from 10 weight parts of LDPE with melt flow index of 4g / 10min and density of 0.920g / cm<3>; the material No.2 of the middle layer is prepared from 10 weight parts of hot melt adhesive; the hot melt adhesive is prepared from 3-6 parts of styrene-ethylene-styrene block copolymer, 1.5-3 parts of rosin resin and 1.5-3 parts of acrylonitrile-butadiene-styrene copolymer; the surface layer is prepared from 1.5-3 parts of LDPE with melt flow index of 2g / 10min and density of0.926g / cm<3>, 3.5-7 parts of LLDPE with melt flow index of 2g / 10min and density of 0.921g / cm<3> and 0.08 part of PPA masterbatch. The invention solves the problems that when a PE film composite bag is torn, the remaining product is not easily sealed for storage and refreshment.

Owner:青岛东海包装产业有限公司

Intermediate-frequency electric furnace liner patching material and method of use thereof

The invention provides a patching material for intermediate frequency electric furnace lining and a use method thereof. The invention is characterized in that the patching material is prepared by mixing the following raw materials according to percentage by weight: 1%-7% of waste glass powder, 25%-55% of electroquartz, 15%-35% of electroquartz micro powder, 17.5%-27.5% of chromic oxide micro powder, 5%-10% of zirconium oxide micro powder, and 0.5%-1.5% of boric anhydride. The use method is spraying on the furnace wall with a conventional spray gun at a temperature between 1000 DEG C and 1200 DEG C in the furnace to patch the furnace lining. The material of the invention can realize fast spraying and fast sintering, and can extensively prolong the service life of the furnace lining.

Owner:ZIBO ZHUYOU FIREPROOF FURNACE MATERIAL

Multilayer chip capacitor

ActiveCN100568426CEnough thicknessAvoid damageFixed capacitor dielectricStacked capacitorsEquivalent series inductanceLayer thickness

The present invention discloses a multilayer chip capacitor which can reduce low equivalent series inductance due to current flowing through external electrodes and can ensure improved mechanical strength. A multilayer chip capacitor includes an upper dummy layer and a lower dummy layer; a plurality of internal electrodes interposed between the upper dummy layer and the lower dummy layer; and external electrodes connected to the internal electrodes, wherein the thickness of the lower dummy layer is smaller than that of the upper dummy layer thickness of.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

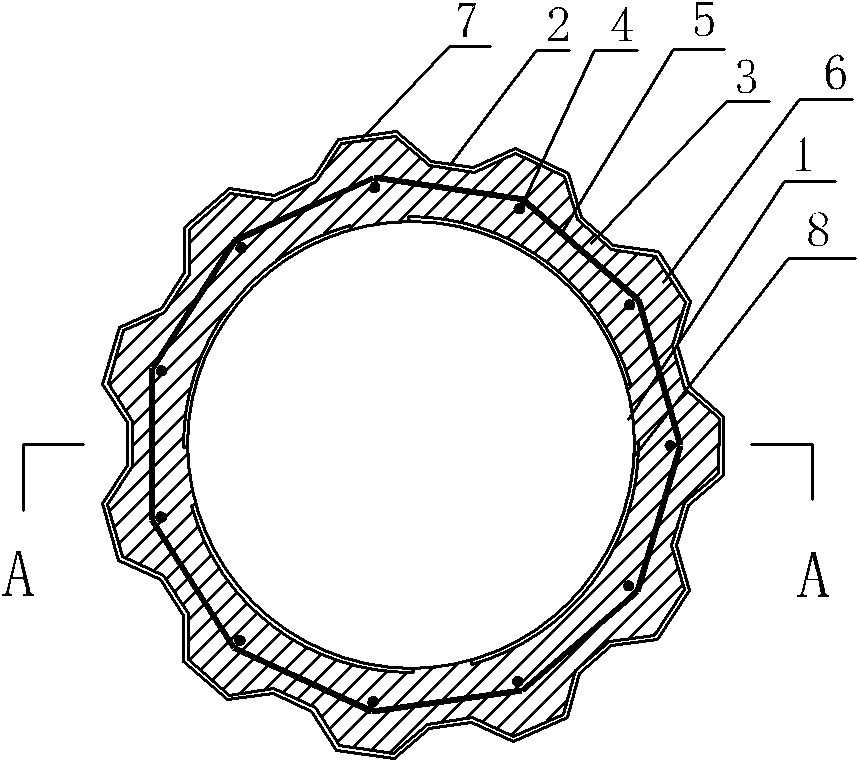

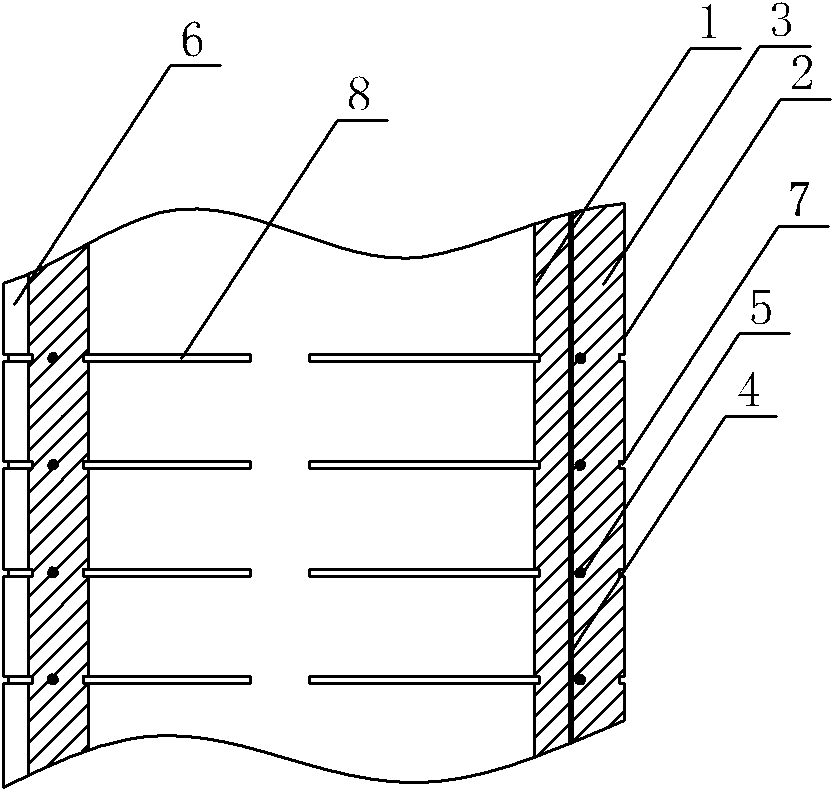

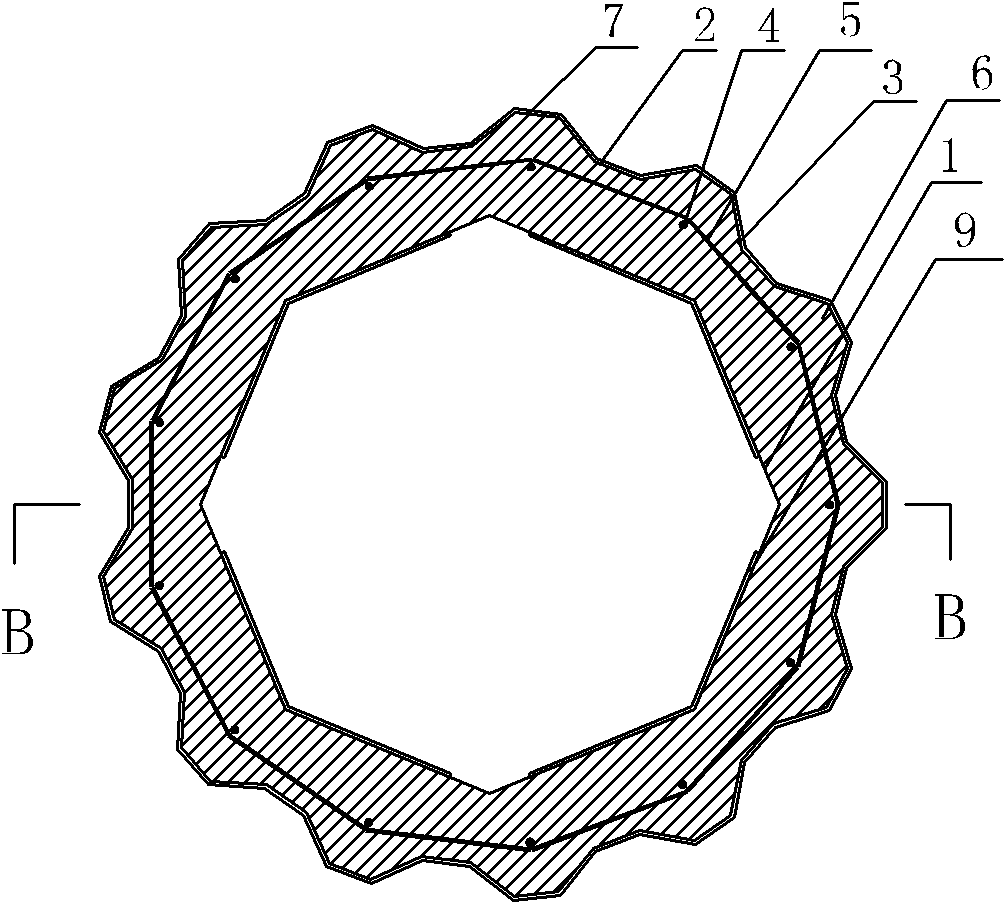

Novel pre-stressed concrete pipe pile

InactiveCN102080375AIncrease the outer surface areaIncrease frictionBulkheads/pilesIsosceles trapezoidPre stress

The invention discloses a novel pre-stressed concrete pipe pile. The novel pre-stressed concrete pipe pile comprises a pipe wall enclosed by an inner surface and an outer surface, wherein a framework of steel reinforcement formed by axial reinforcing steel bars and a plurality of transverse stirrups which are arranged in parallel along the axial reinforcing steel bars is arranged in the pipe wall. The novel pre-stressed concrete pipe pile is characterized in that: at least six convex teeth which are axially extended are regularly distributed around the outer surface; the surfaces among the convex teeth are planes; the quantity of the axial reinforcing steel bars is equal to that of the convex teeth; and the convex teeth are of isosceles trapezoids and connecting lines among the convex teeth are straight lines when the convex teeth are observed from the cross-section. The novel pre-stressed concrete pipe pile has the advantages that: all surfaces on the outer surface are planes; and the pipe pile can be conveniently manufactured by utilizing a plane template when the area of the outer surface of the pipe pile is improved.

Owner:杨红旵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com