Novel rapid-insertion self-locking connection mechanism

A connection mechanism and self-locking technology, which is applied to the connection, parts of the connection device, coupling device, etc., can solve the problems of cost increase, insufficient holding force, high structural cost, etc., and achieve high mechanism reliability, high degree of freedom of use, The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] In this embodiment, the SMA type radio frequency coaxial connector is used as a model to describe in detail.

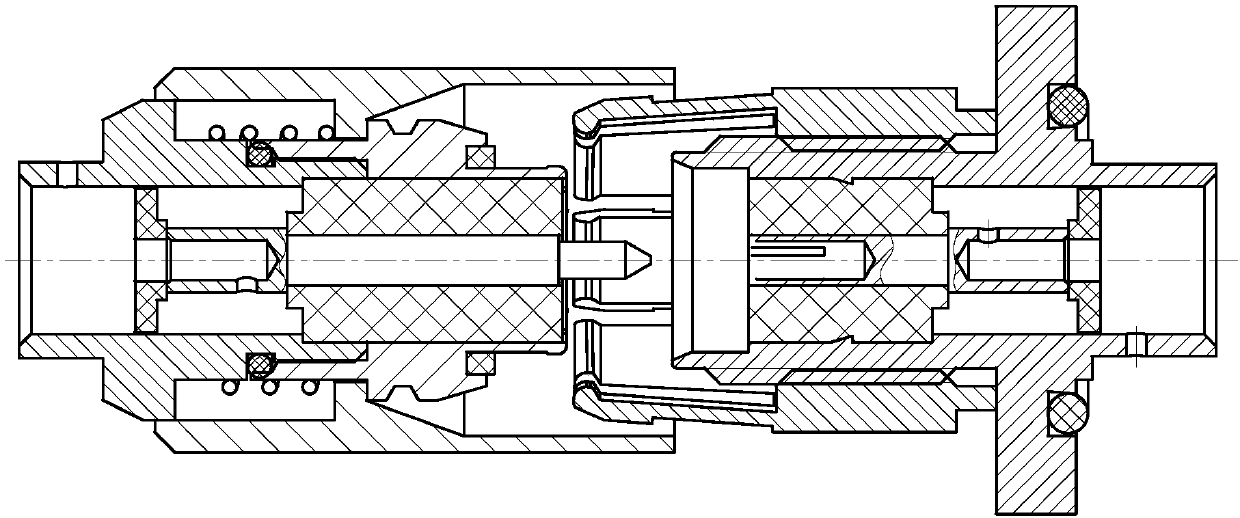

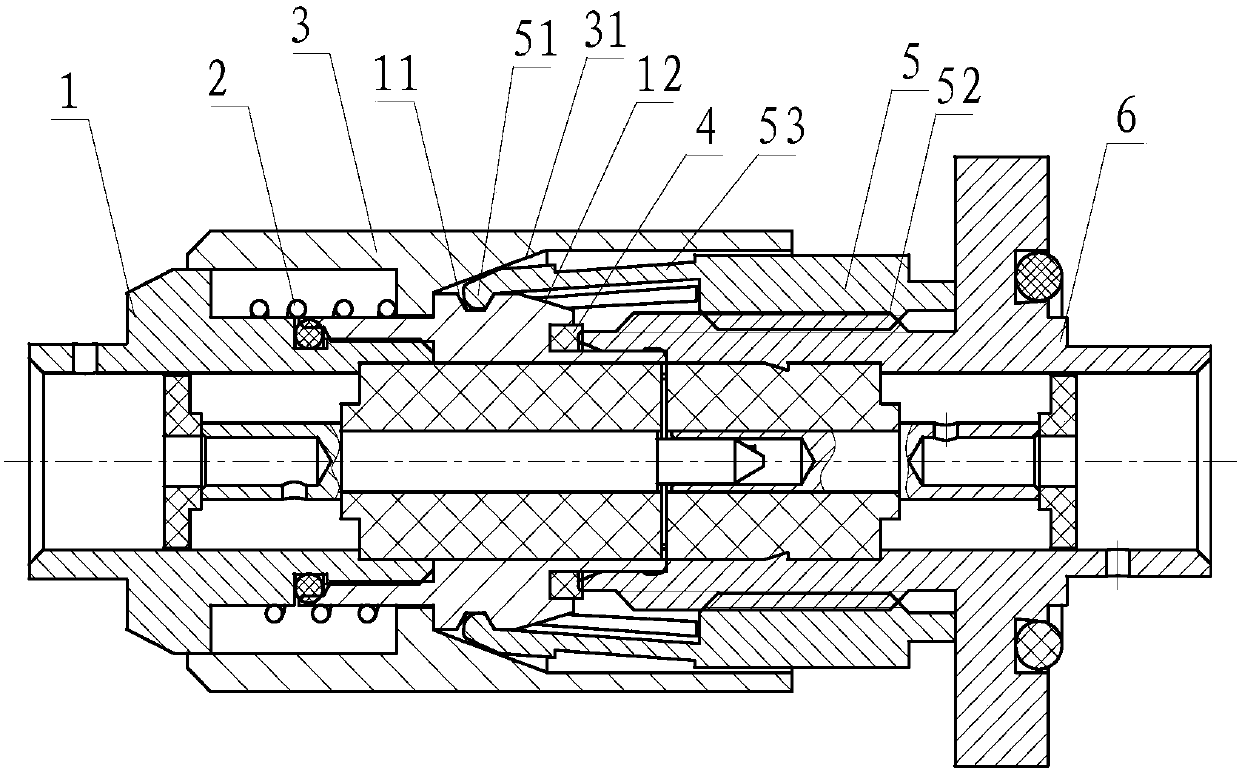

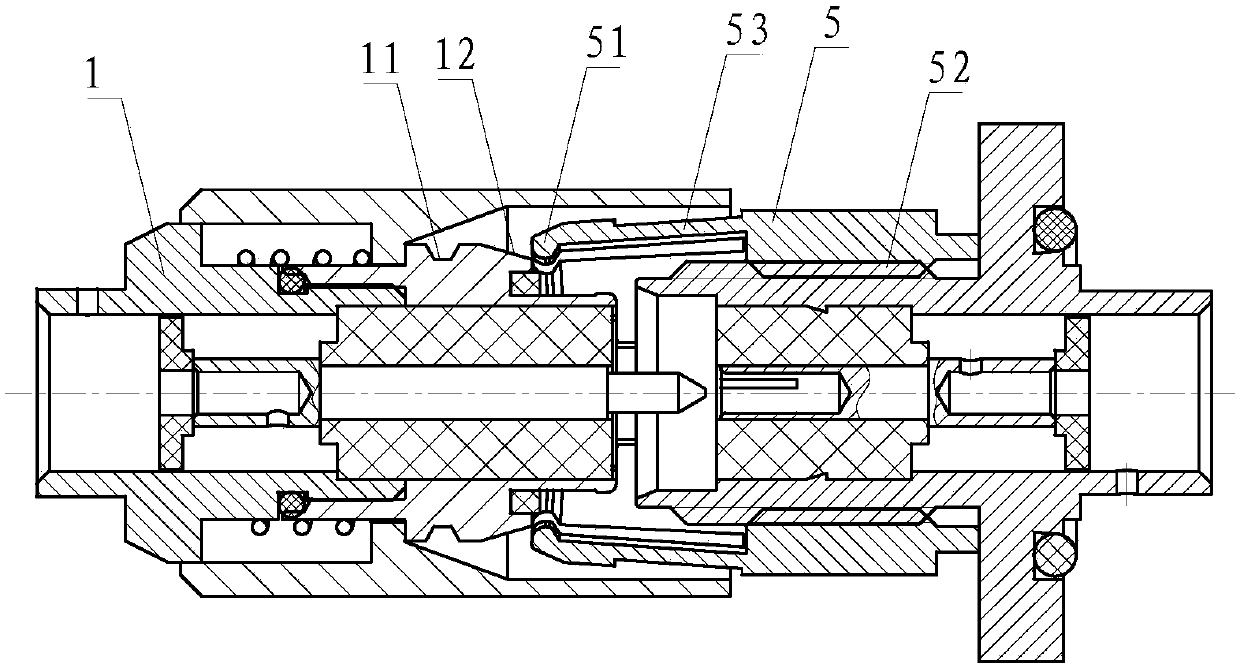

[0029] A new type of quick-plug self-locking connection mechanism shown in this embodiment is roughly composed of 6 parts, mainly divided into, plug body 1, spring 2, unlocking sleeve 3, elastic seal 4, elastic claw 5, socket body 6.

[0030] Same as the conventional quick lock mechanism, the unlocking mechanism is arranged at the plug end, and the unlocking sleeve 3 is assembled and interconnected with the plug main body 1 to form a whole. A trapezoidal groove 11 is provided at an appropriate position at the front end of the plug body 1 as a locking point of the quick lock mechanism. The unlocking sleeve 3 ensures that it can slide relative to the plug body and lock the stroke through the elasticity of the spring 2. The slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com