Novel pre-stressed concrete pipe pile

A concrete pipe pile and prestressing technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of complex formwork making and pipe piles not being considered, so as to increase the compression and pullout resistance and improve the friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

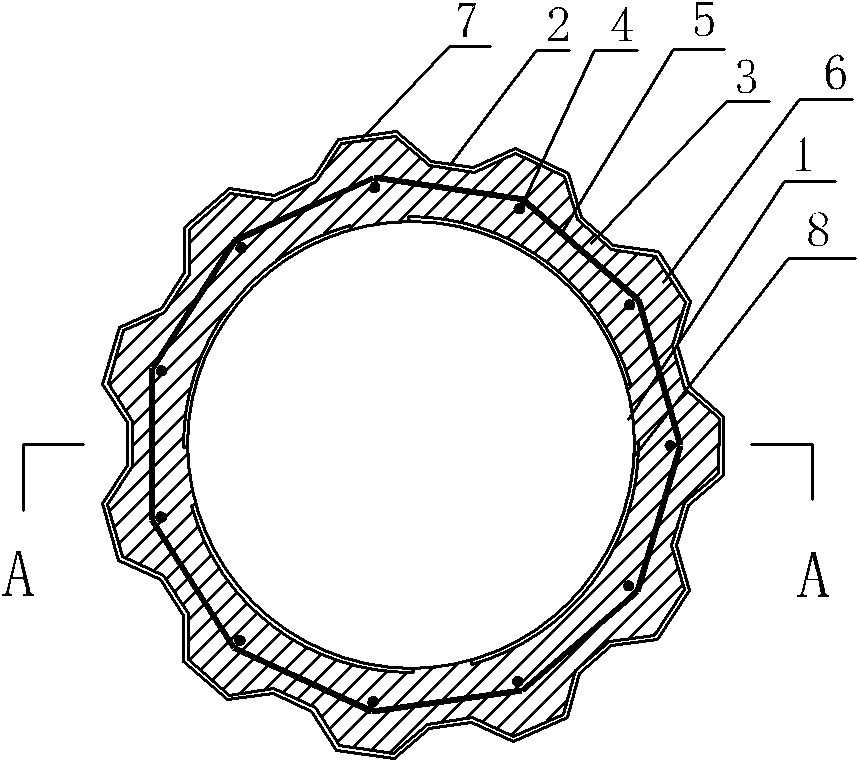

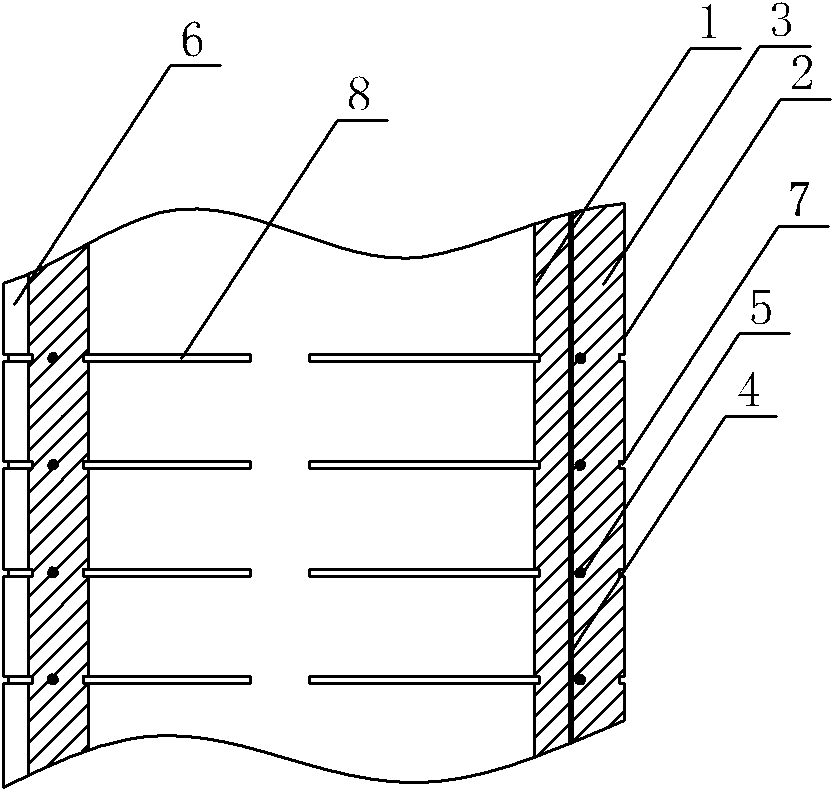

[0022] Embodiment 1: A new type of prestressed concrete pipe pile, the pipe pile has an equivalent diameter of 500 mm, including a pipe wall 3 surrounded by an inner surface 1 and an outer surface 2, the inner surface 1 is circular, and the outer surface 2 is evenly surrounded Eleven axially extending radial protruding teeth 6 are distributed, and the pipe wall 3 is provided with a reinforcement skeleton composed of eleven axial reinforcement bars 4 and eleven transverse stirrup bars 5 arranged side by side along the axial reinforcement bars 4 , the axial steel bar 4 is set on the radial center line of the radial convex teeth 6, the surface between the radial convex teeth 6 is a plane, viewed from the cross section, the radial convex teeth 6 are isosceles trapezoidal, the radial convex teeth The plane between the teeth 6 is a straight line, the outer surface 2 is uniformly provided with a continuous outer annular groove 7 along the axial direction, and the inner surface 1 is pr...

Embodiment 2

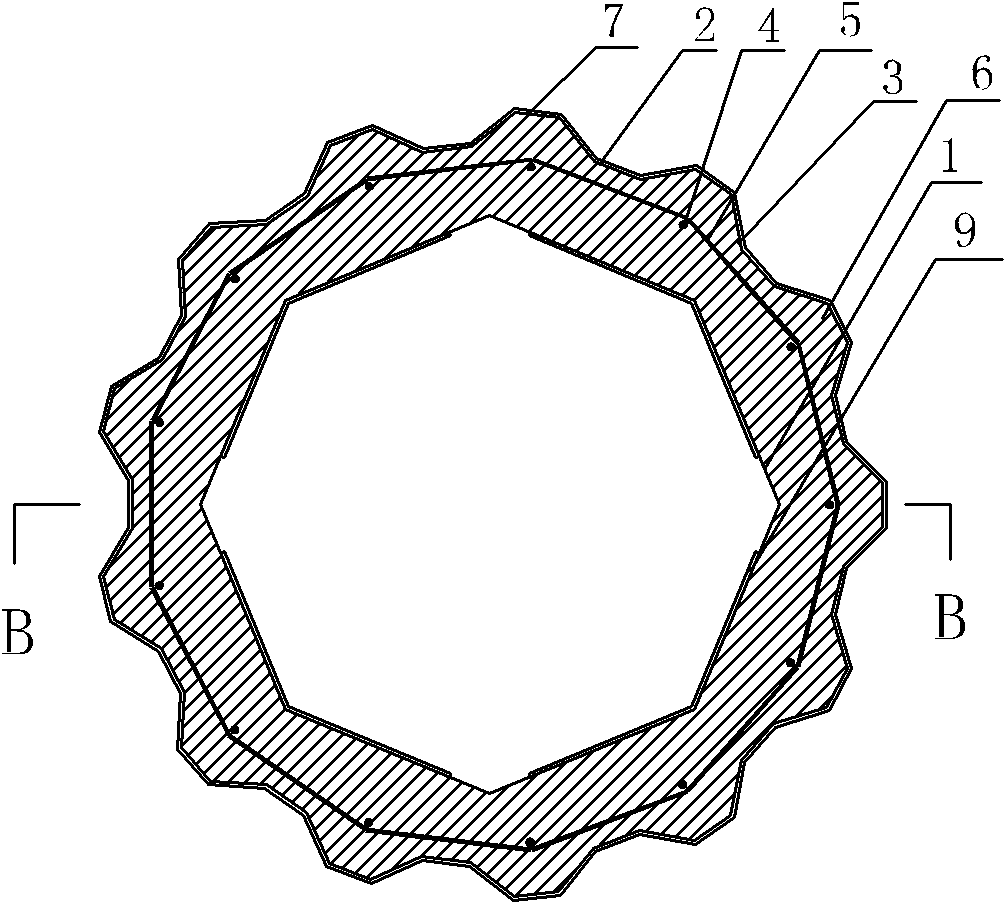

[0023] Embodiment 2: A new type of prestressed concrete pipe pile, the equivalent diameter of the pipe pile is 600mm, including the pipe wall 3 surrounded by the inner surface 1 and the outer surface 2, the inner surface 1 is a regular octagon, and the outer surface 2 is uniform Thirteen axially extending radial protruding teeth 6 are arranged in a surrounding distribution, and the steel bar composed of thirteen axial steel bars 4 and thirteen transverse stirrups 5 arranged side by side along the axial steel bar 4 is arranged in the pipe wall 3 Skeleton, the axial reinforcement 4 is set on the radial center line of the radial convex teeth 6, the surface between the radial convex teeth 6 is a plane, viewed from the cross section, the radial convex teeth 6 are isosceles trapezoidal, the radial The plane between the protruding teeth 6 is a straight line, the outer surface 2 is uniformly provided with a continuous outer annular groove 7 along the axial direction, and the inner surf...

Embodiment 3

[0024] Embodiment 3: A new type of prestressed concrete pipe pile, the equivalent diameter of the pipe pile is 800mm, including the pipe wall 3 surrounded by the inner surface 1 and the outer surface 2, the inner surface 1 is a regular hexagon, and the outer surface 2 Fifteen axially extending radial protruding teeth 6 are evenly distributed around, and the pipe wall 3 is provided with fifteen axial steel bars 4 and fifteen transverse stirrups 5 arranged side by side along the axial steel bars 4 The steel bar skeleton, the axial steel bars 4 are arranged on the radial center line of the radial convex teeth 6, the surface between the radial convex teeth 6 is a plane, and viewed from the cross section, the radial convex teeth 6 are isosceles trapezoidal, The plane between the radial protruding teeth 6 is a straight line, the outer surface 2 is uniformly provided with continuous outer annular ribs 10 along the axial direction, and the inner surface 1 is provided with intermittent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com