Prestressed reinforced concrete special-shaped precast pile

A technology of prestressed steel bars and concrete prefabricated piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, and can solve the problems of low lateral bearing capacity of soft soil foundations and restrictions on the use of high-rise building foundations, so as to improve vertical bearing capacity , increase the bending resistance, increase the effect of the outer surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

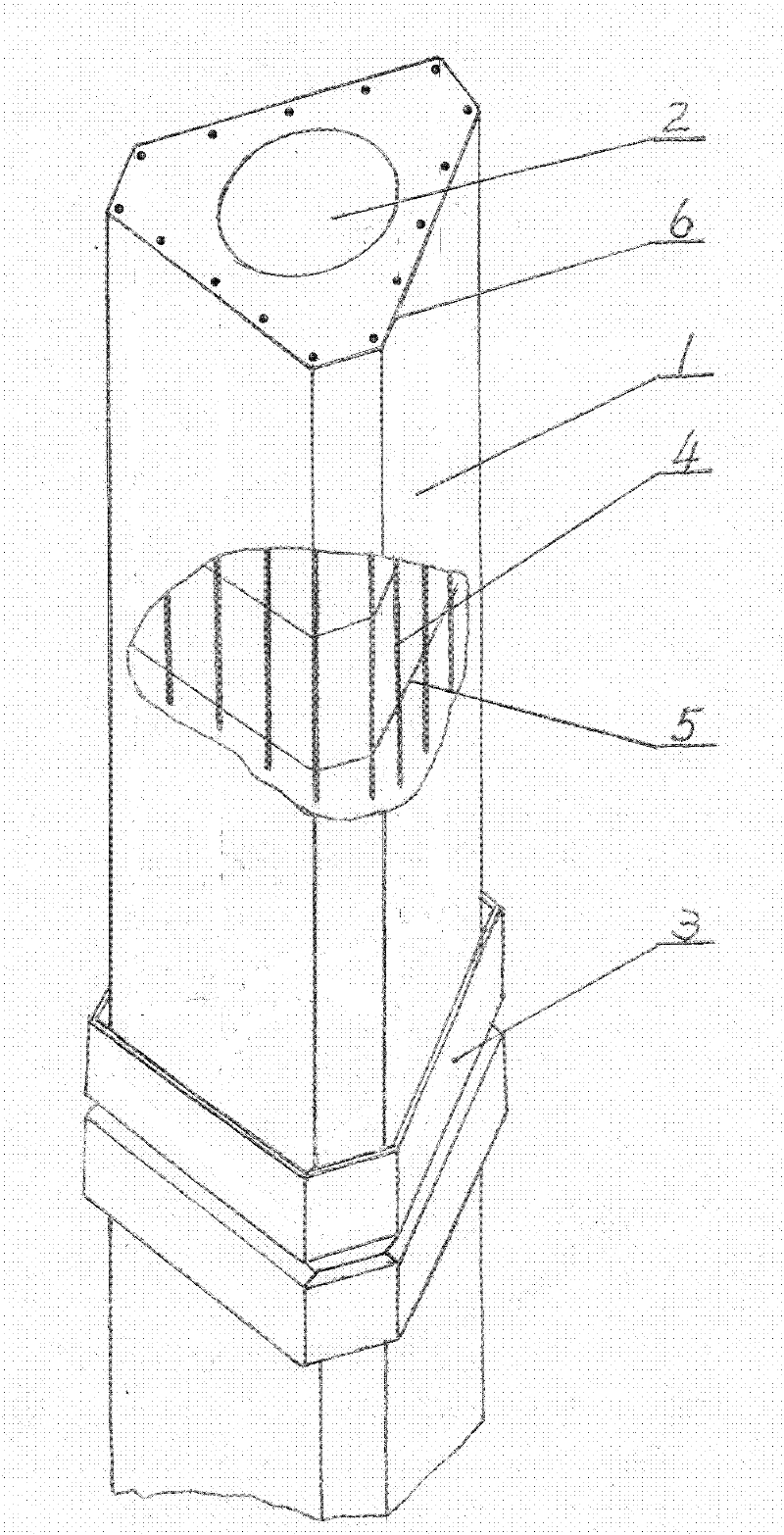

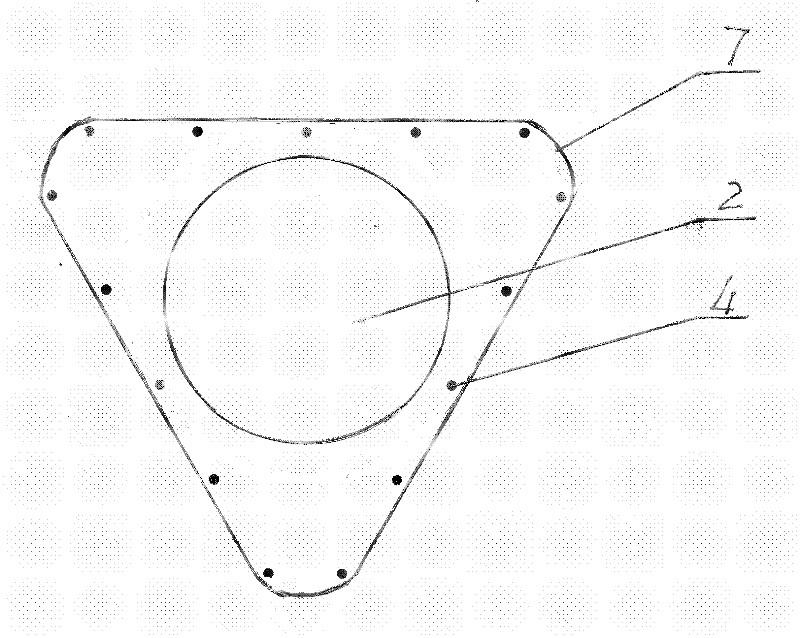

[0015] Embodiment 1: Take the hexagonal concrete prefabricated pile 1 of three long sides and three short sides by cutting off three vertices of an equilateral triangle as an example to illustrate,

[0016] like figure 1 As shown: the pile type of the prefabricated concrete pile 1 is a special shape, and the center of the prefabricated concrete pile 1 has a central hole 2. Because the concrete bearing capacity of the central part is small, the diameter of the central hole 2 is about 1 / 3 of the length of the long side. 1 / 5 cylinder; in order to facilitate transportation, each concrete prefabricated pile 1 is about 15 meters long. In practical applications, 15 meters cannot meet the load-bearing requirements, and most of them are more than two sections, so that the bending resistance of the entire pile body is concentrated on the two piles. The connection part, so the two ends of the prefabricated concrete pile 1 are respectively equipped with pile caps 3 made of steel plates. T...

Embodiment 2

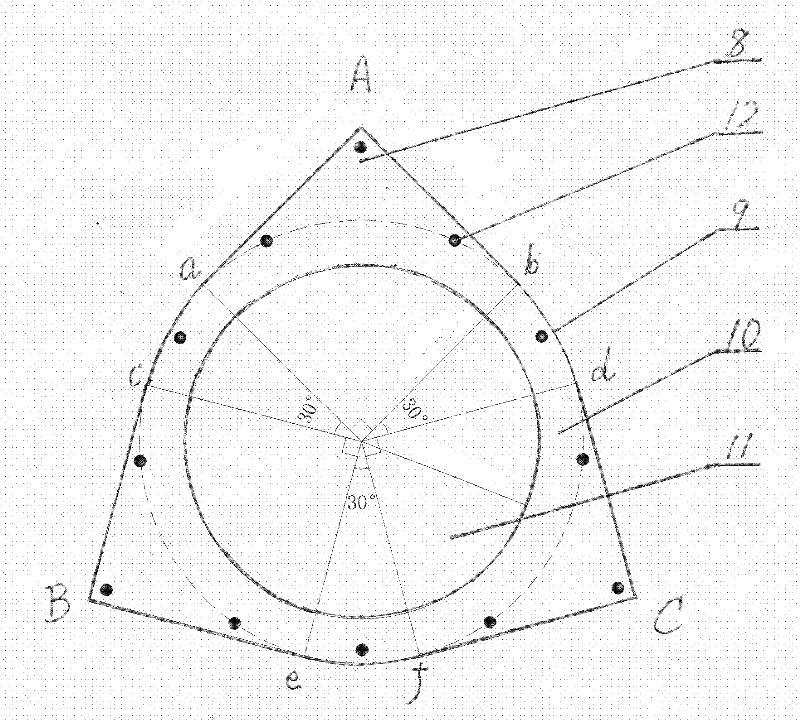

[0018] Example 2: Taking the tangent line of a round pile to form three 90° external angle concrete prefabricated piles as an example to illustrate

[0019] like image 3 As shown: the tangent line of the round pile forms three outer corners. The cross section of the prefabricated concrete pile is formed based on the round pile as the intersection point a and b of the center line and the round pile with an angle of 90° on the basis of the round pile, and a circle is made from the intersection point a and b outward Tangent, the intersection of the two tangents forms a 90° external angle A, and the intersection points of the two centerlines and the round pile after turning 30° are c and d, then the line segment ac and bd is arc-shaped, and the intersection point of the two centerlines and the round pile after turning 90° For e and f, draw tangents to the circle from points c, e, b, and f respectively, and the intersection of the two tangents generates another two external angles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com