Forced spiral finned coil pipe condensation heat-supply heat exchanger

A spiral fin, coil condensation technology, applied in indirect heat exchangers, heat exchanger types, water heaters, etc., can solve the problems of small volume, insufficient heat exchange in the flue gas flow path, etc., to enhance heat transfer , The effect of reducing the volume and improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention are described in detail below, examples of which are shown in the accompanying drawings, which are only used to explain the present invention and are not to be construed as limiting the present invention.

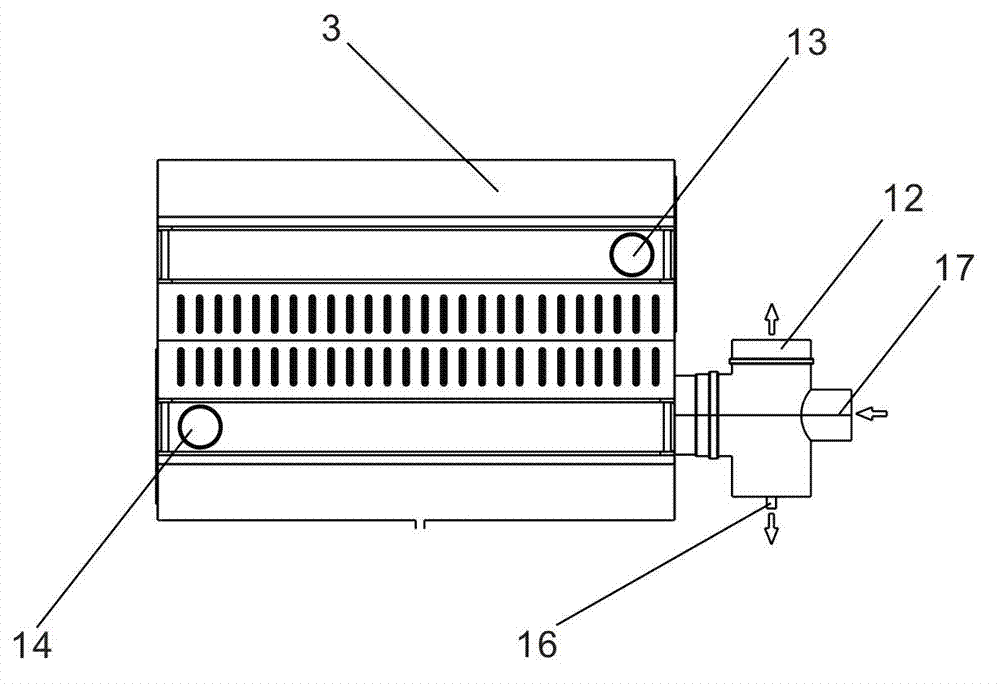

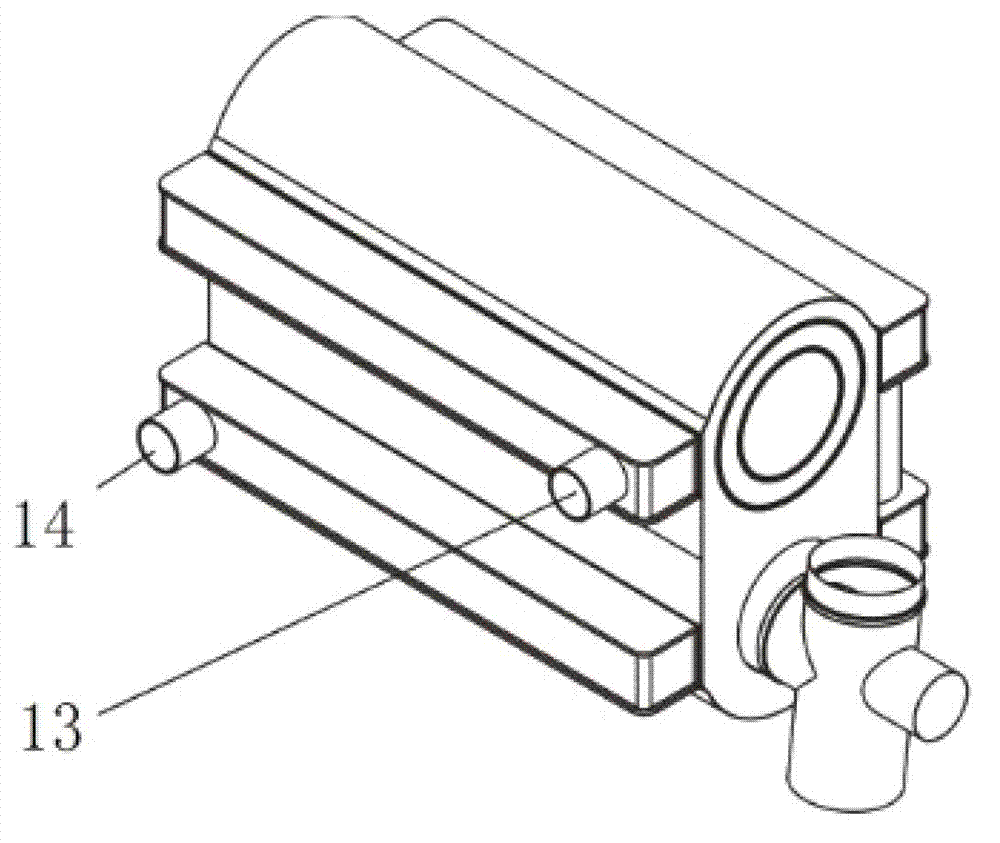

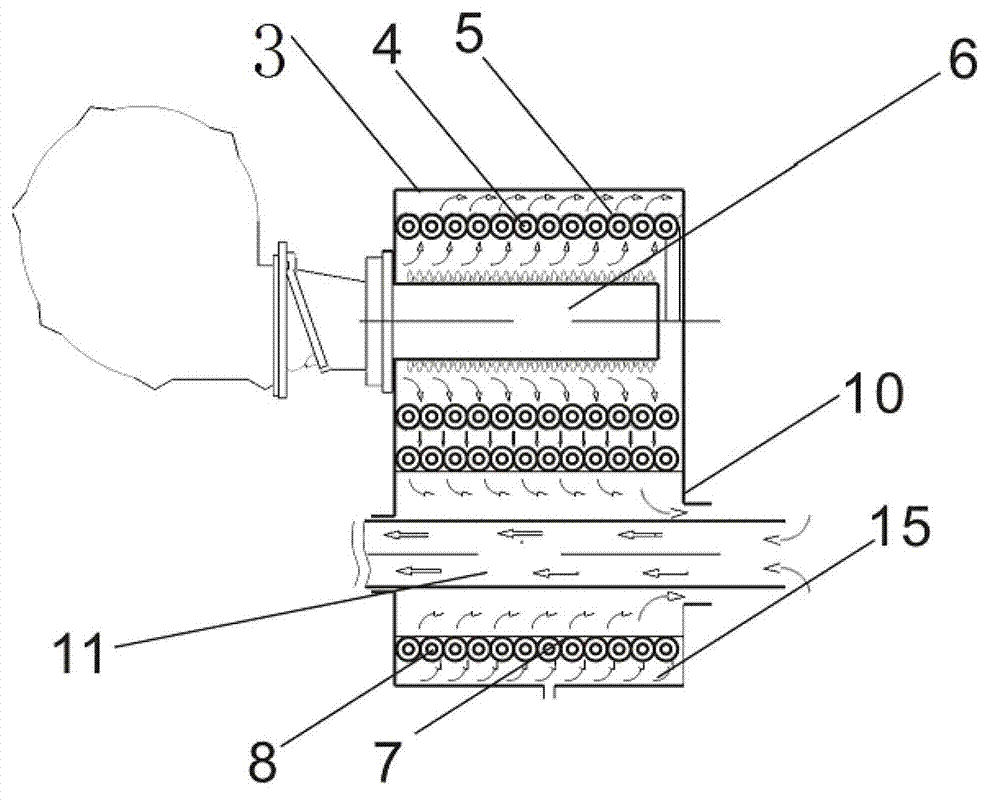

[0042] like Figure 1~Figure 12 As shown, it includes: upper jellyfish tube 1, front baffle plate 2, shell 3, spiral fin coil tube bundle 4, outer deflector 5, burner 6, inner deflector 7, a plurality of closely arranged spiral fins Sheet coil pipe 8, lower jellyfish pipe 9, tailgate 10, air preheater 11, smoke exhaust port 12, water outlet 13, water inlet 14, smoke exhaust pipe 15, condensate water outlet 16, air inlet 17.

[0043] refer to Figure 1~Figure 4 A forced spiral fin coil condensing heat supply heat exchanger according to one embodiment of the present invention is described. like figure 1 , figure 2 , image 3 and Figure 4 As shown, a forced spiral fin coil condensing heat exchanger includes a shell 3, a burne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com