Patents

Literature

285results about How to "Improve convective heat transfer coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Near-wall air device for preventing high-temperature corrosion of water-cooled wall of power station boiler

InactiveCN101706110AReduce resistanceOvercome the shortcoming of fast wind speed attenuationCasings/liningsAir volumeCombustor

The invention discloses a near-wall air device for preventing the high-temperature corrosion of the water-cooled wall of a power station boiler, which comprises an air duct, a regulating valve, a near-wall air box, near-wall air unit nozzles, a fuel component on-line monitor and a speed measuring device, wherein the direction of the near-wall air is parallel to the axis of a pipe of the water-cooled wall, the resistance along the course is small and the air speed reduction is slow; only one layer of near-wall air nozzles is required to be arranged in a burner area and the system structure is simple; and the nozzles are flexibly arranged, the nozzle cooling condition is good, the operational air volume is small and the stability is high. Thus, the device is suitable to be promoted for preventing the high-pressure corrosion of the water-cooled walls of power station boilers.

Owner:XI AN JIAOTONG UNIV +1

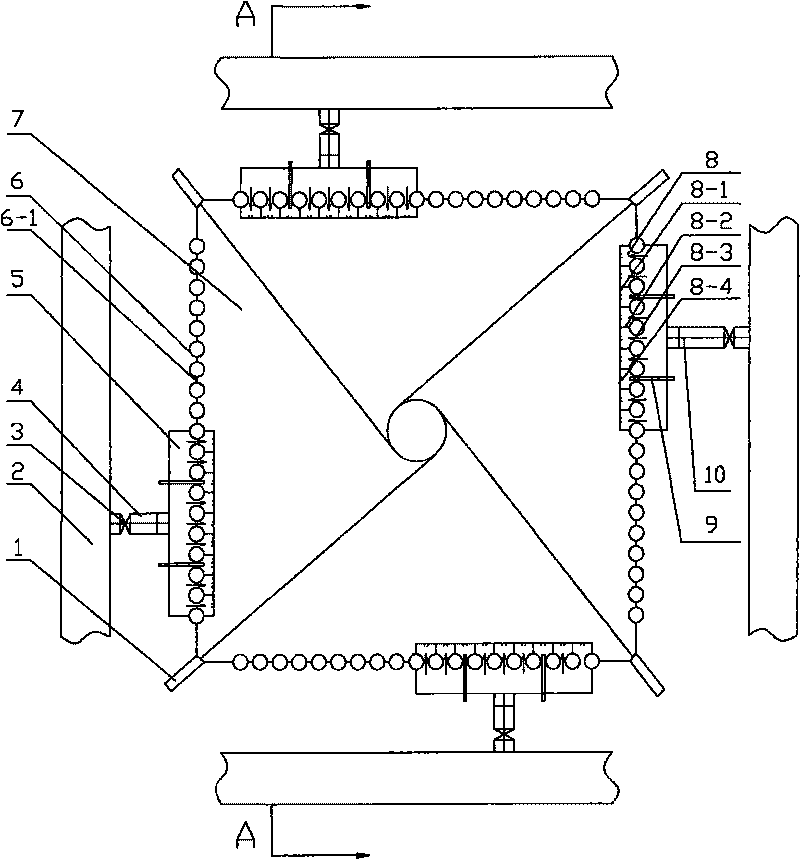

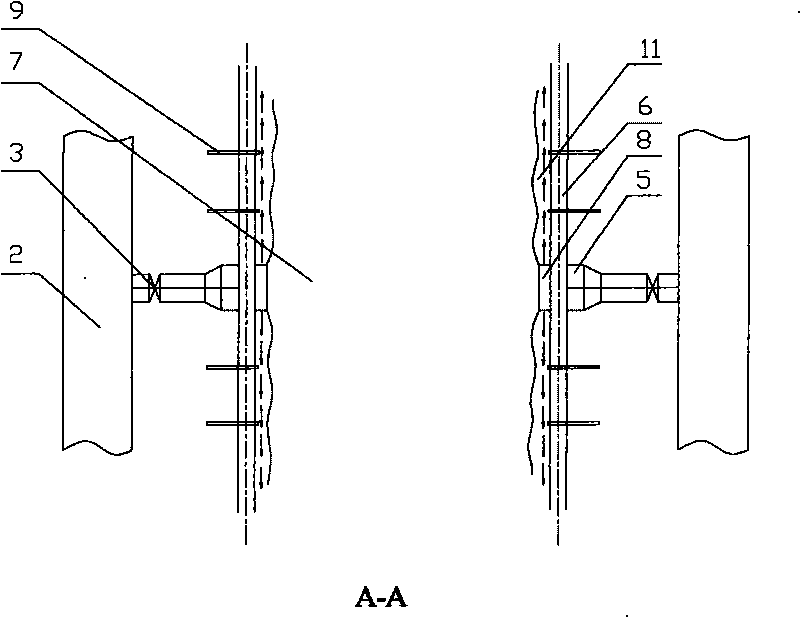

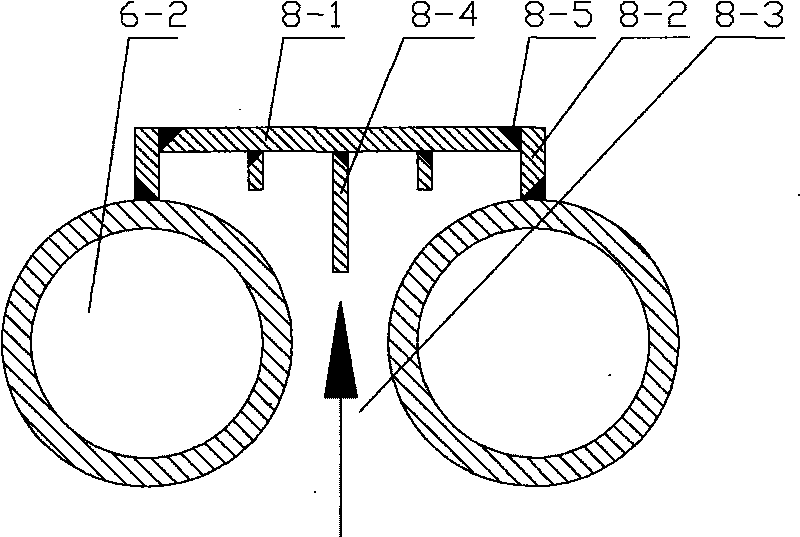

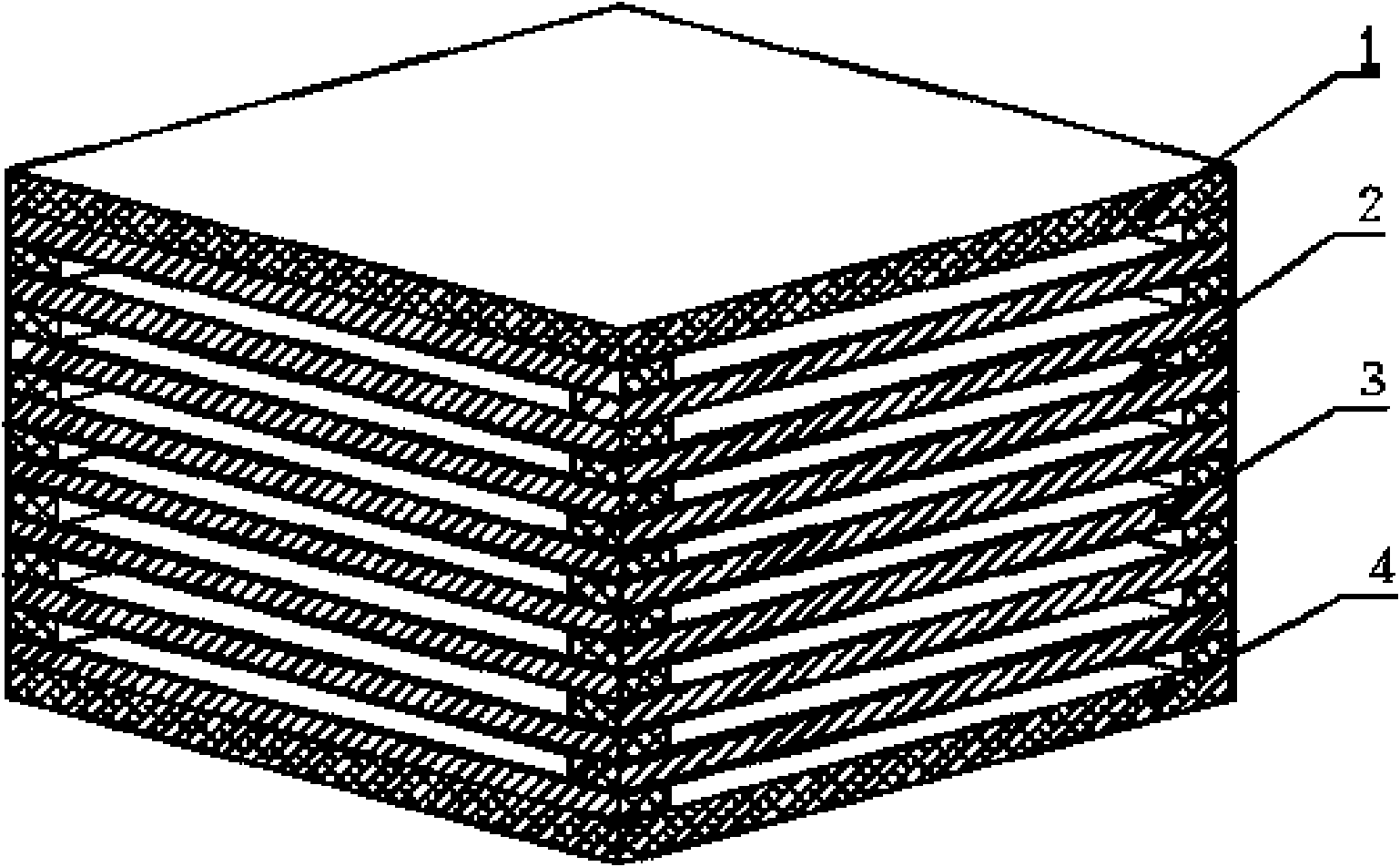

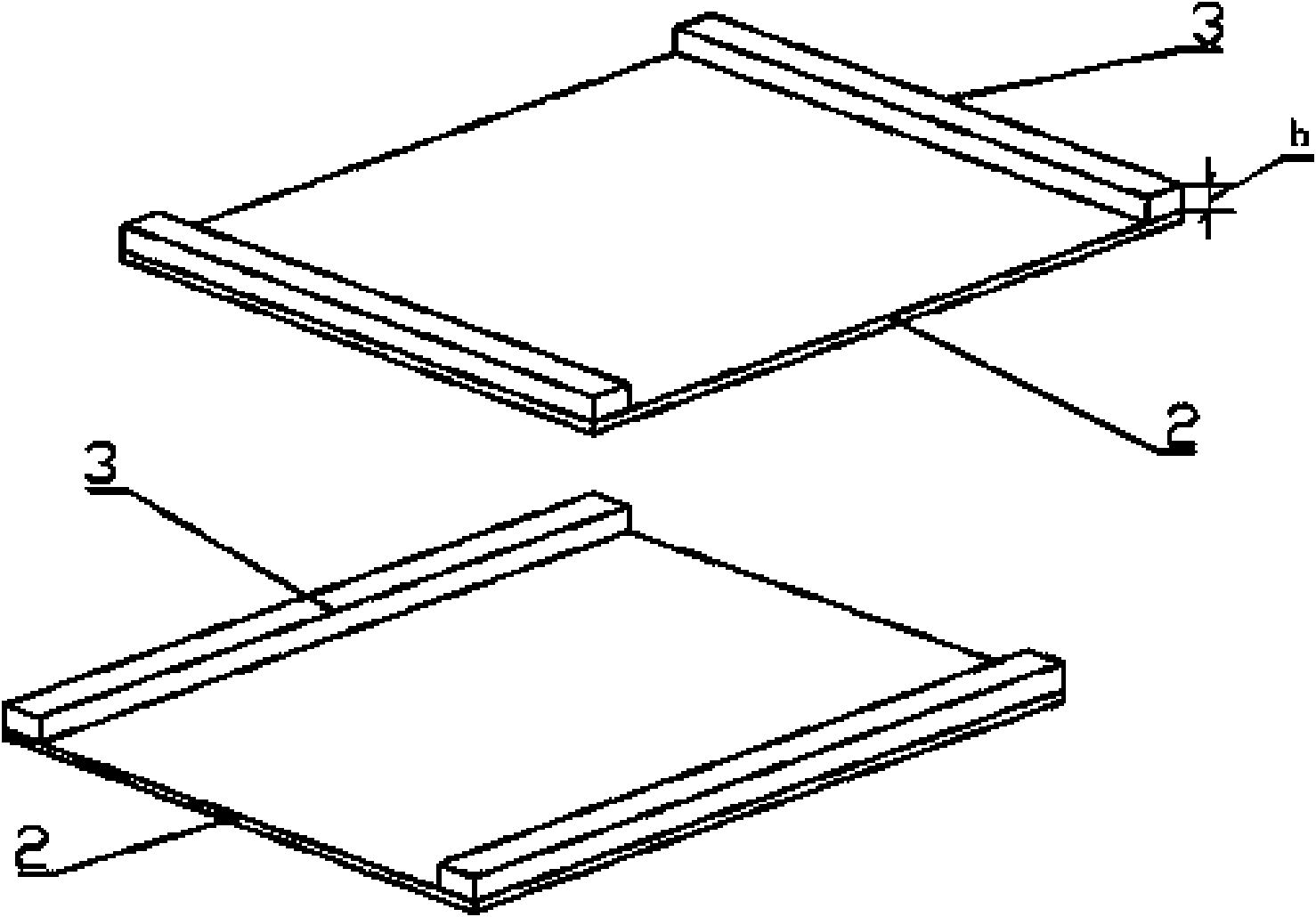

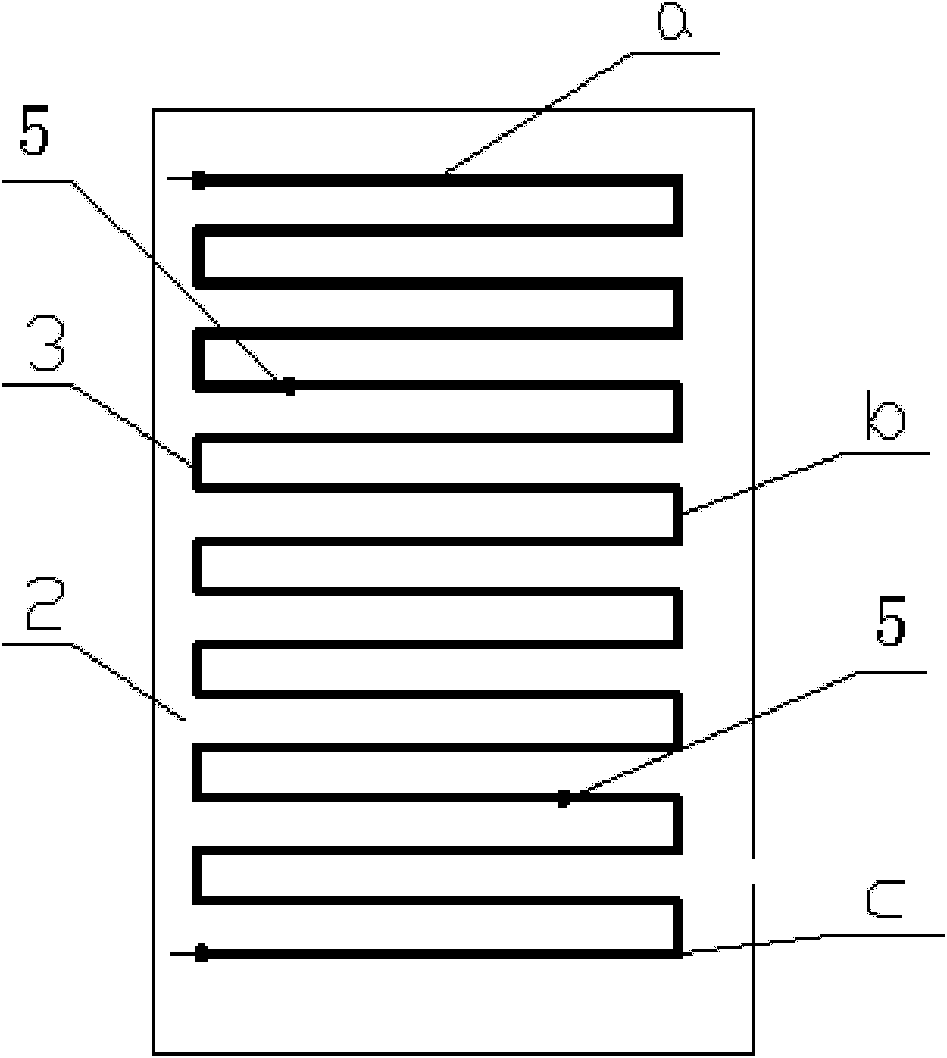

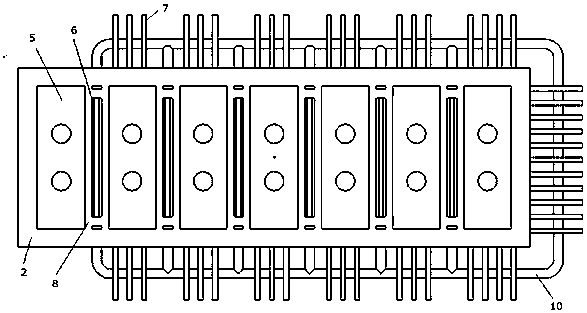

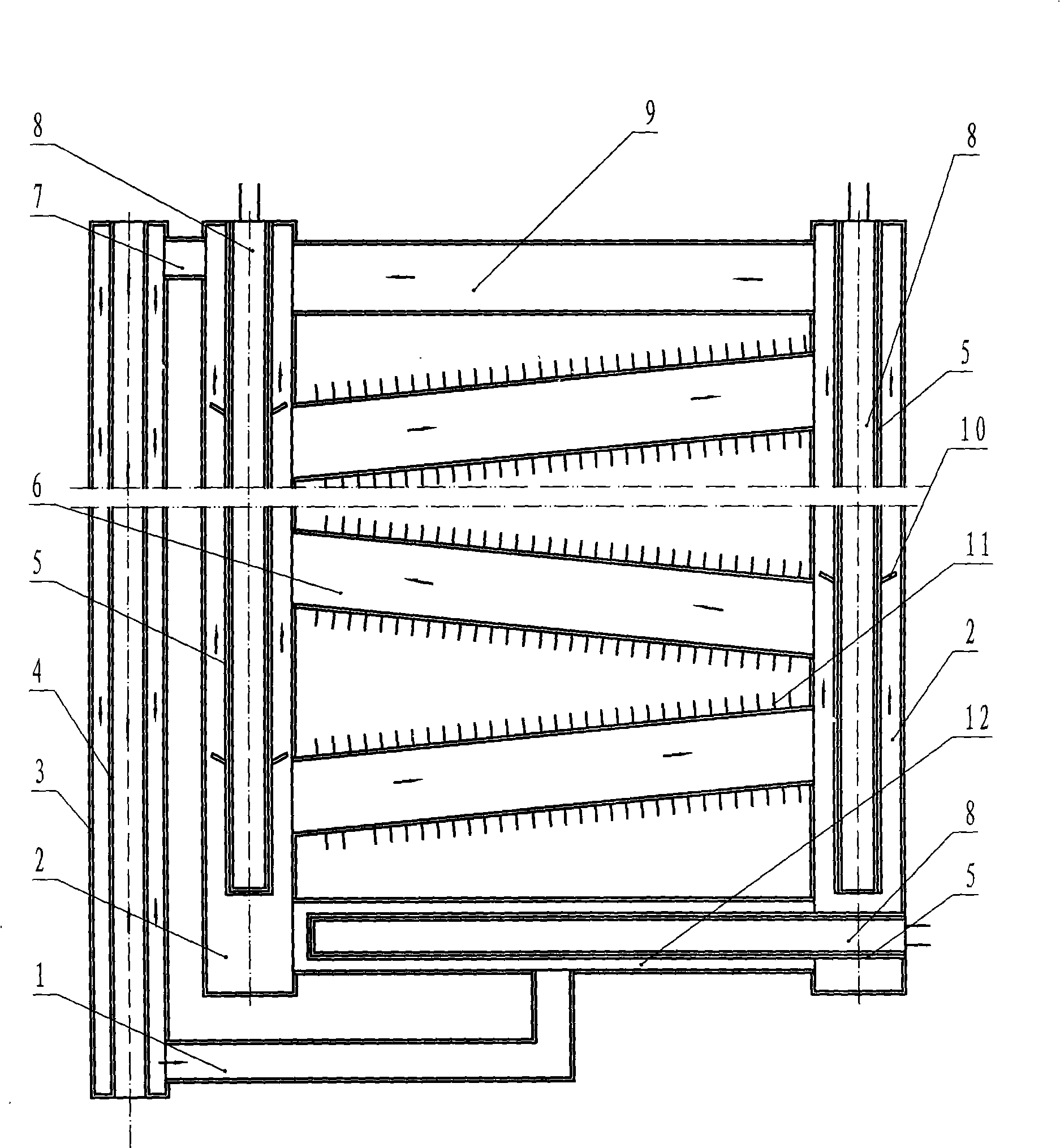

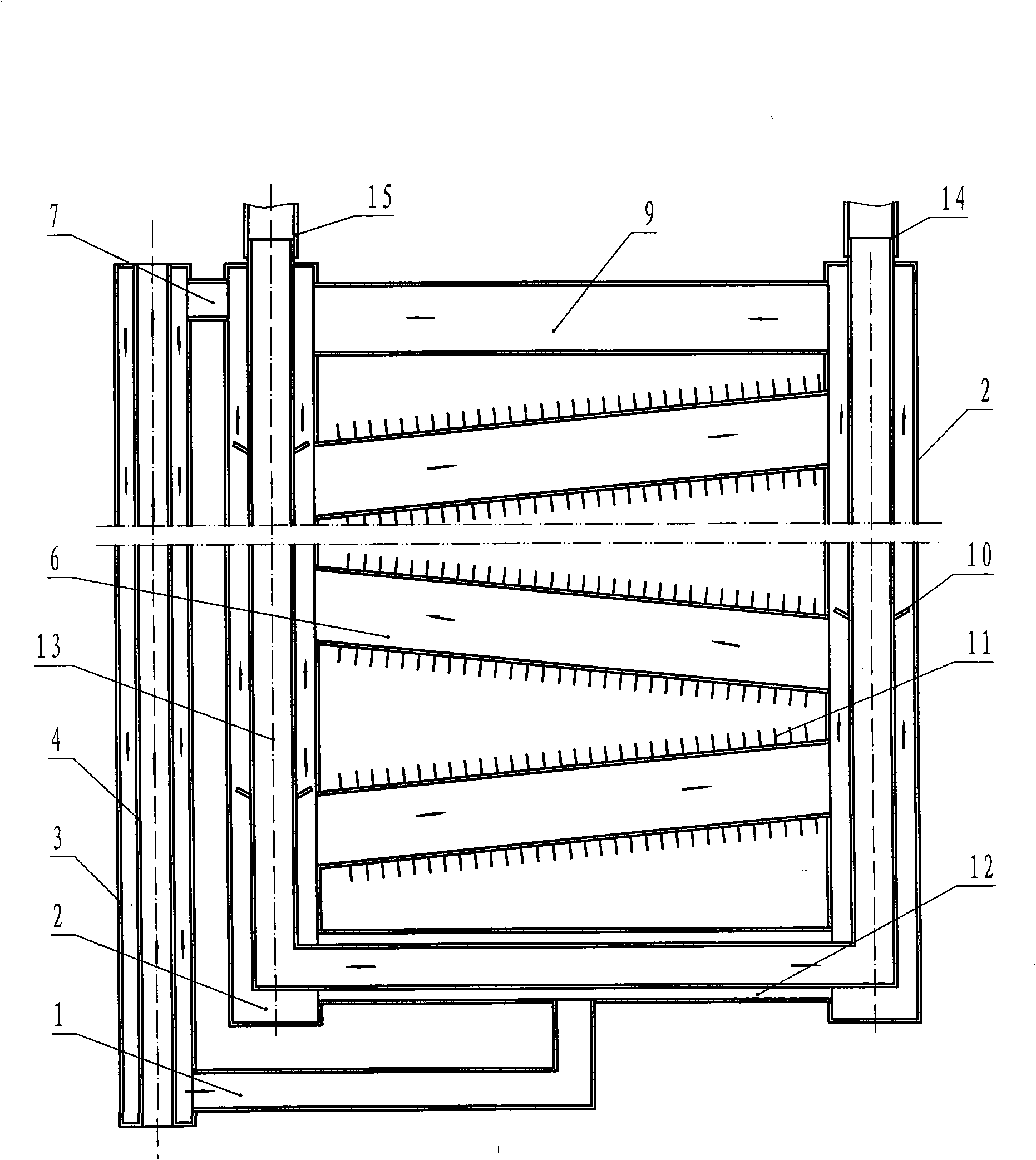

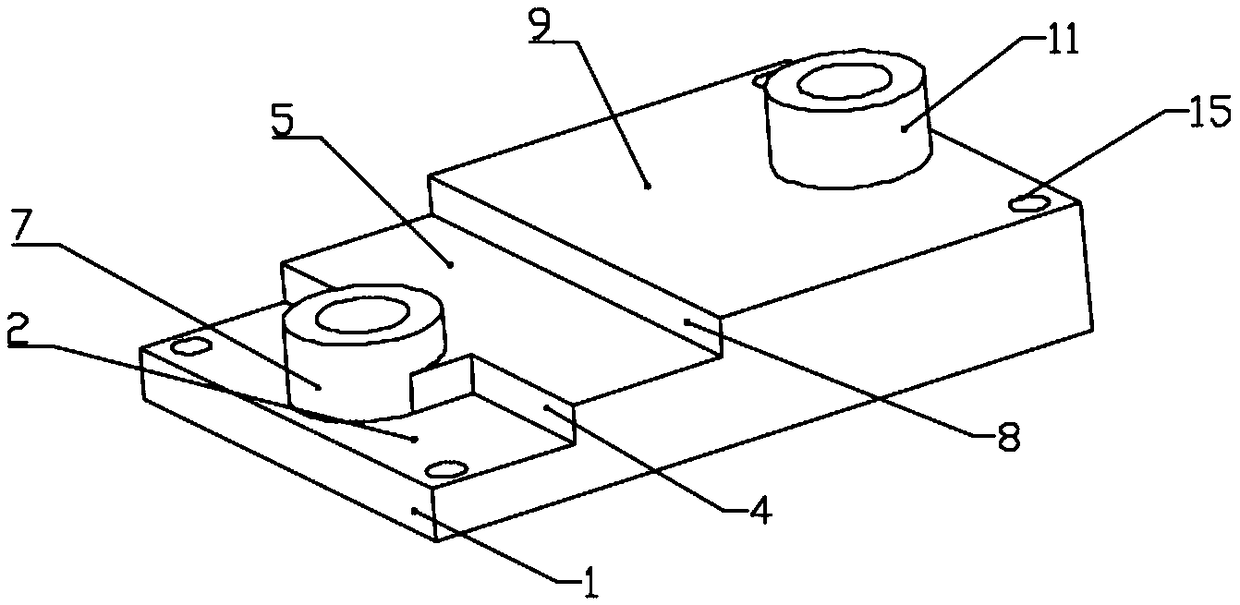

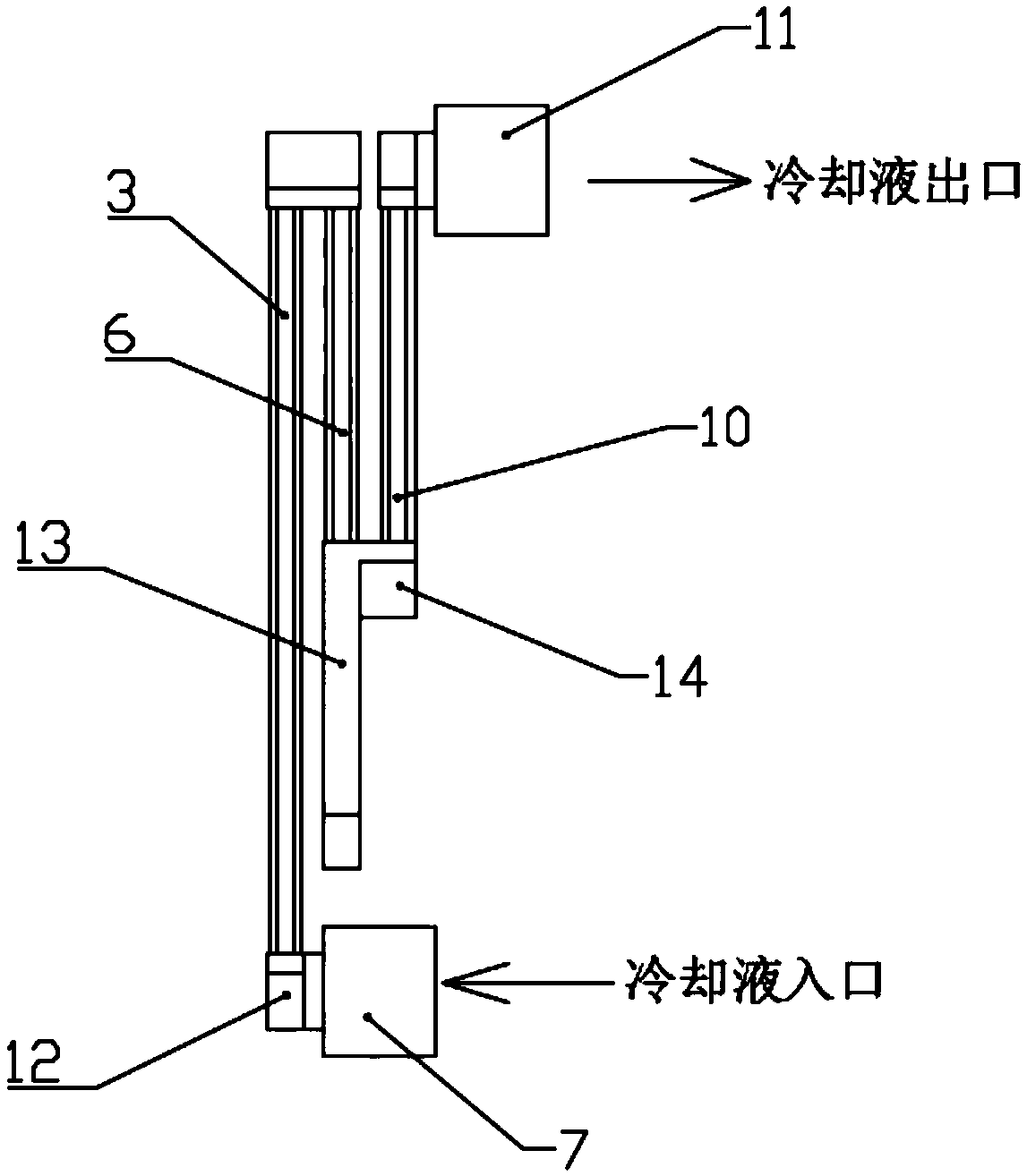

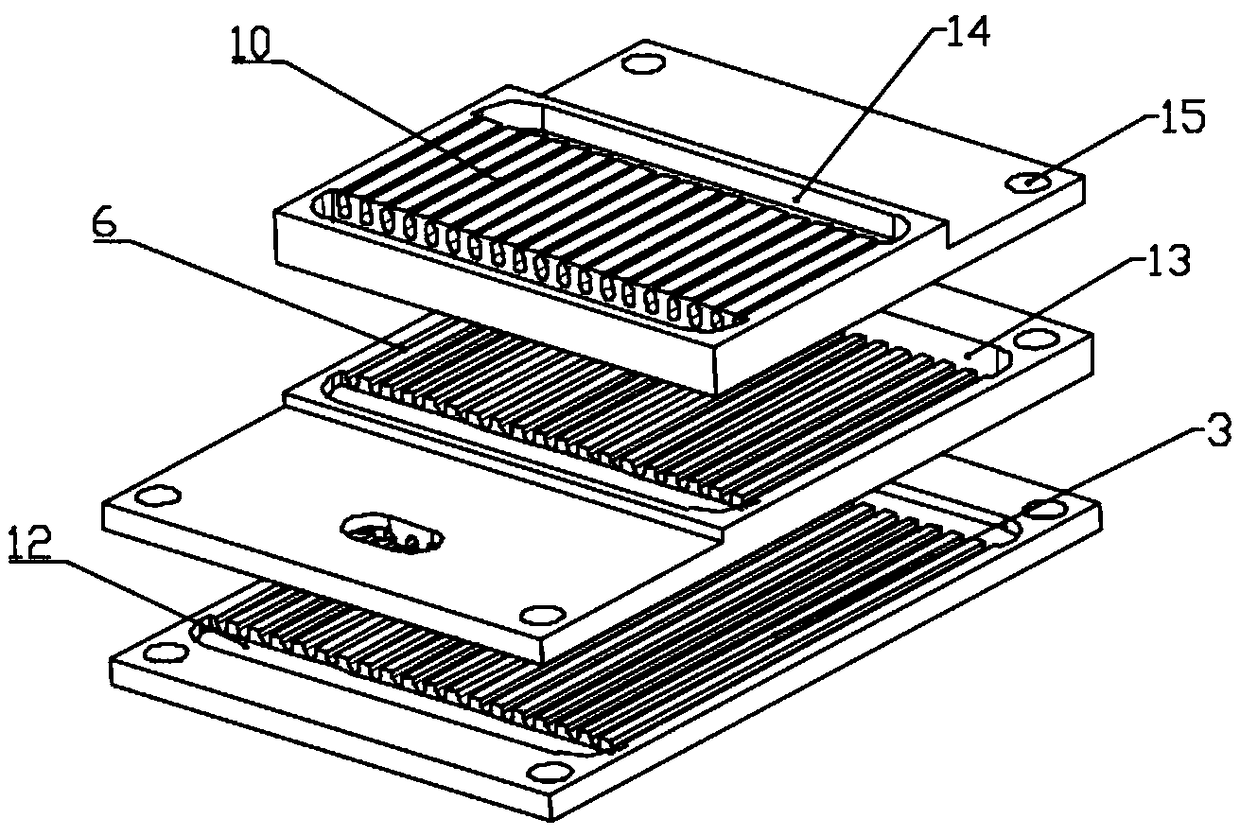

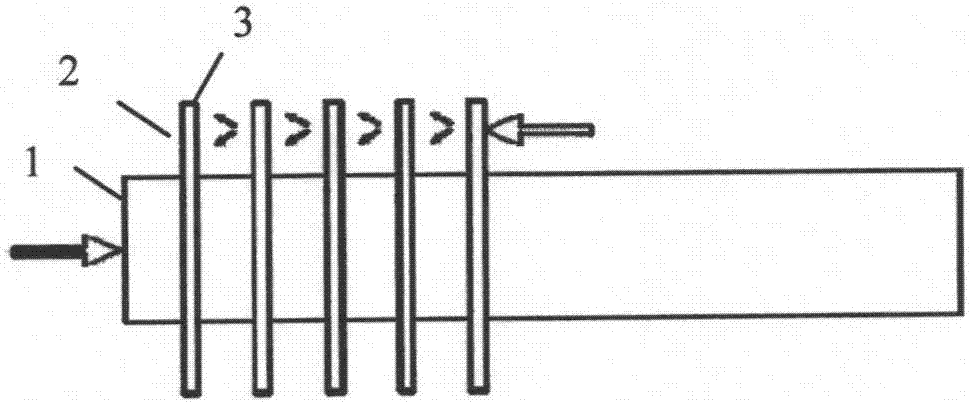

Core body of flat-plate heat exchanger for fresh air ventilator

InactiveCN101650141AAchieve low speed turbulent flowReduce thermal resistanceLaminated elementsStationary plate conduit assembliesFresh airEngineering

The present invention discloses a core body of a flat-plate heat exchanger for a fresh air ventilator, which comprises quadrangular plastic heat exchanging membranes, a top plate in the same shape asthat of the plastic heat exchanging membranes, a bottom plate and sealing strips. The upper surfaces on the near edges of two opposite edges of the plastic heat exchanging membranes with odd number are fixedly connected with the lower surfaces on the near edges of two opposite edges of the plastic heat exchanging membranes with even number through the sealing strips to form first airflow channels,the upper surface on the near edges of another two opposite edges of the plastic heat exchanging membranes with even number are fixedly connected with the lower surfaces on the near edges of two opposite edges of the other plastic heat exchanging membranes with odd number through the sealing strips to form second airflow channels crisscrossed with the adjacent first airflow channels, the top plate is fixedly connected with the uppermost plastic heat exchanging membranes through the sealing strips, and the bottom plate is fixedly connected with the lowermost plastic heat exchanging membranes through the sealing strip. The present invention has the advantages of favorable heat transfer performance, high heat exchanging efficiency, low weight and cost, simple structure, low production and running cost, convenient installation and easy integration with constructions.

Owner:TIANJIN UNIV

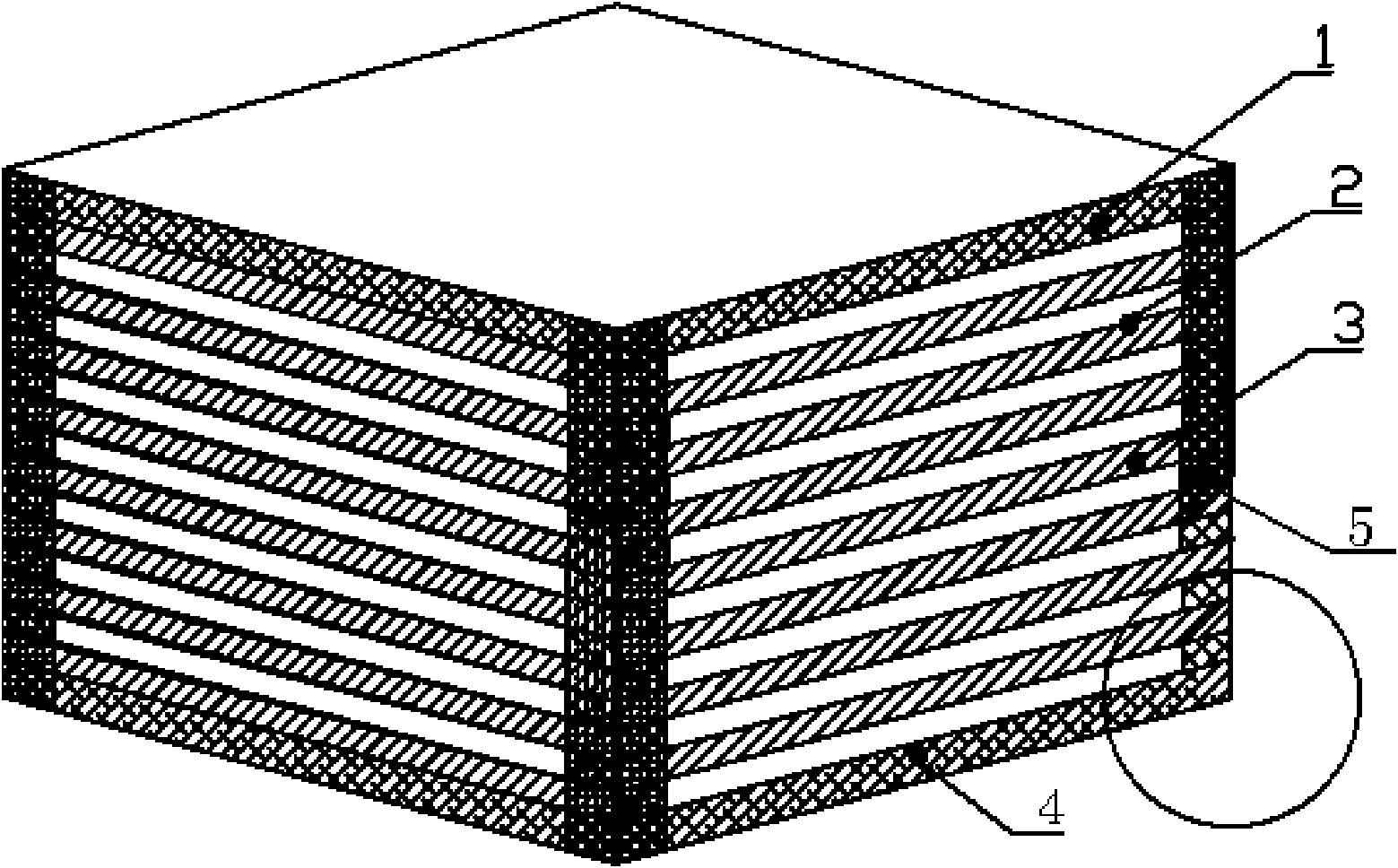

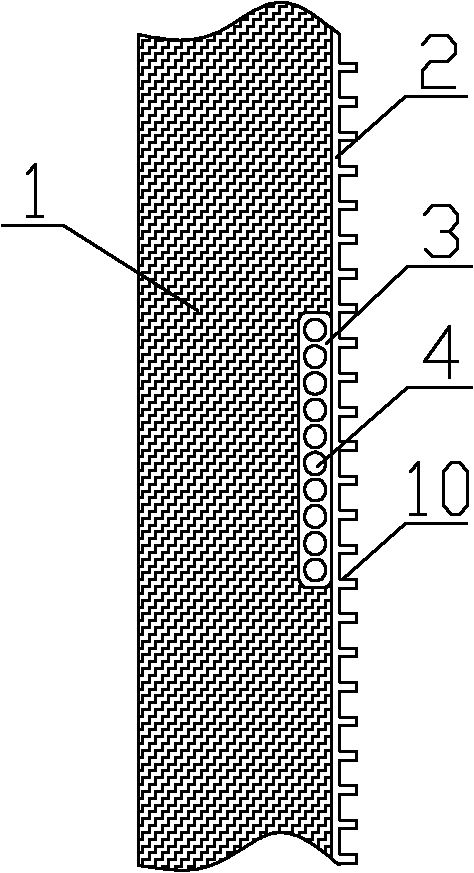

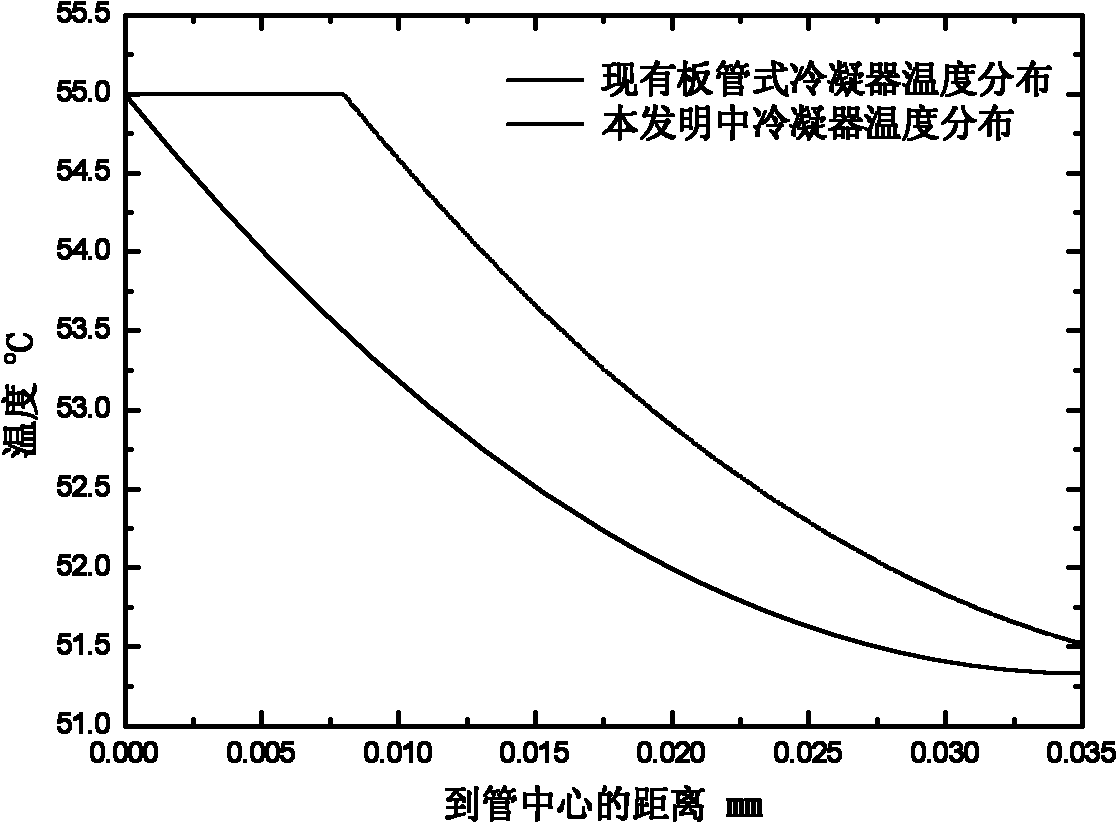

Condenser

InactiveCN102052807AIncrease temperatureImprove the overall heat transfer coefficientThermal insulationEvaporators/condensersFlow resistivityMaterial consumption

The invention discloses a condenser which is composed of a porous micro through heat exchange flat tube, a corresponding connecting header and a heat dissipation back plate arranged at one side of the heat exchange flat tube. In the invention, the structure is compact, the heat exchange efficiency is high, the aluminum flat tube is adopted, thus the condenser is more advantageous than the existing copper heat exchange tube in the aspect of economical efficiency, and the condenser is suitable for the fields such as refrigeration, chemical engineering, energy source, heat exchange and the like. The condenser is characterized in that on the one hand, since the porous micro channel flat tube structure is adopted, the coefficient of heat transfer in the tube is improved, and simultaneously the flow resistance of a refrigerant in the tube is reduced; and on the other hand, the contact type of the condenser and the side wall of the heat dissipation back plate is surface contact, so that contact thermal resistance is reduced, the average temperature of the side wall of the heat dissipation back plate is improved, and the heat exchange between the side wall of the back plate and the ambient air is strengthened, namely the condensing effect is strengthened, thus, when the lengths of pipes are the same, the quantity of the condenser can be increased, or when the heat exchange quantities are the same, the length of the pipes can be reduced, therefore the condenser is more compact, simultaneously the material consumption is reduced, and the condenser has a certain advantage in the aspect of economical efficiency.

Owner:XI AN JIAOTONG UNIV

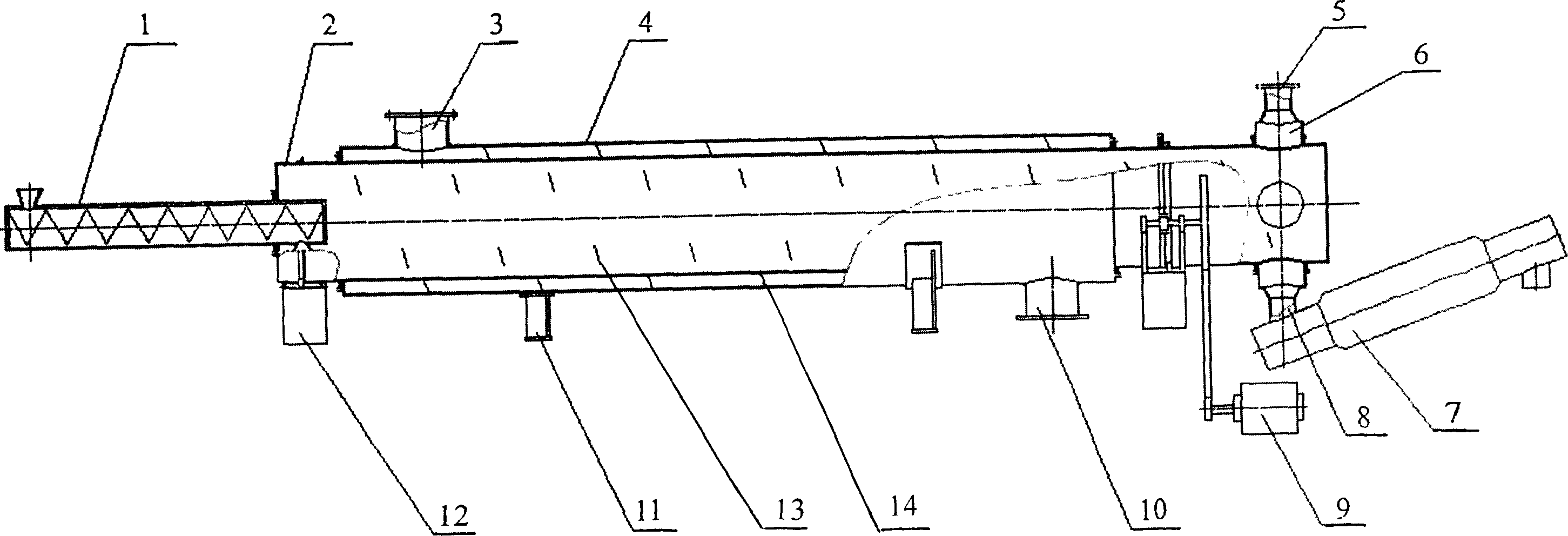

Horizontal type slew cylinder structure cracking furnace for waste steel wire blank continuous thermal cracking

InactiveCN1952045AAchieve self-sufficiencyThe cleavage reaction is fast and sufficientPigmenting treatmentLiquid hydrocarbon mixture productionEngineeringFlue

The invention disclosed a lying posture turnover cylinder cracking furnace which is used in the successive thermal cracking of a waste steel-wire tyre material. There's a below stack gas inlet and a top stack gas outlets on the outside tube of the cylinder; inside being positioned inner turning-over tube drived by transmission system; one side of the inner tube connects the tyre spiral feeder which can change the pitch, and the other side connects the static split product gathering trunk; on the top of the gathering trunk is the outlet of the gas hydrocracking product, while below the gathering trunk is outlet of the solid hydrocracking product, the gathering trunk also connects the spiral discharging device. The waste tyre material which is transferred by the spiral feeder is repeatedly grabbed by the grabbing plank located on the inner wall and pushed to the outlet. The high temperature stack gas counterflows in the passage between the outside and the inside tubes, during the process of the material's axial direction translation and circular direction rotation, the material absorbs the conducted calory from the tube wall to finish the splitting process. The gas product is pulped away by the blower while the solid product is discharged by the spiral discharging device through the bottom canal orifice.

Owner:ZHEJIANG UNIV

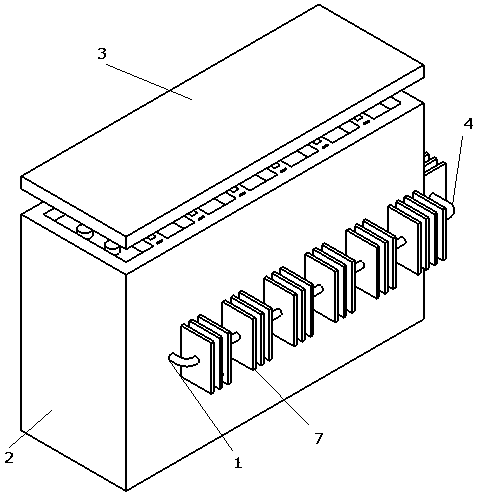

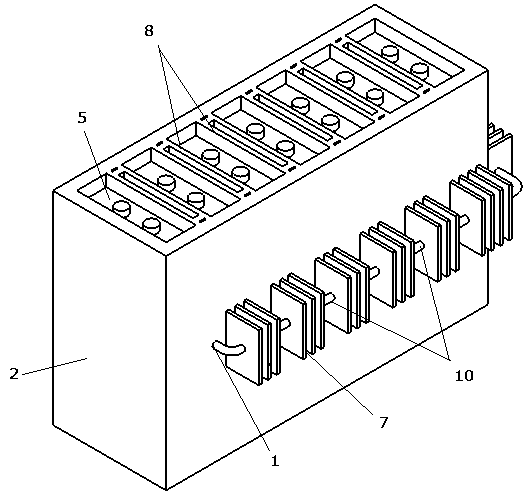

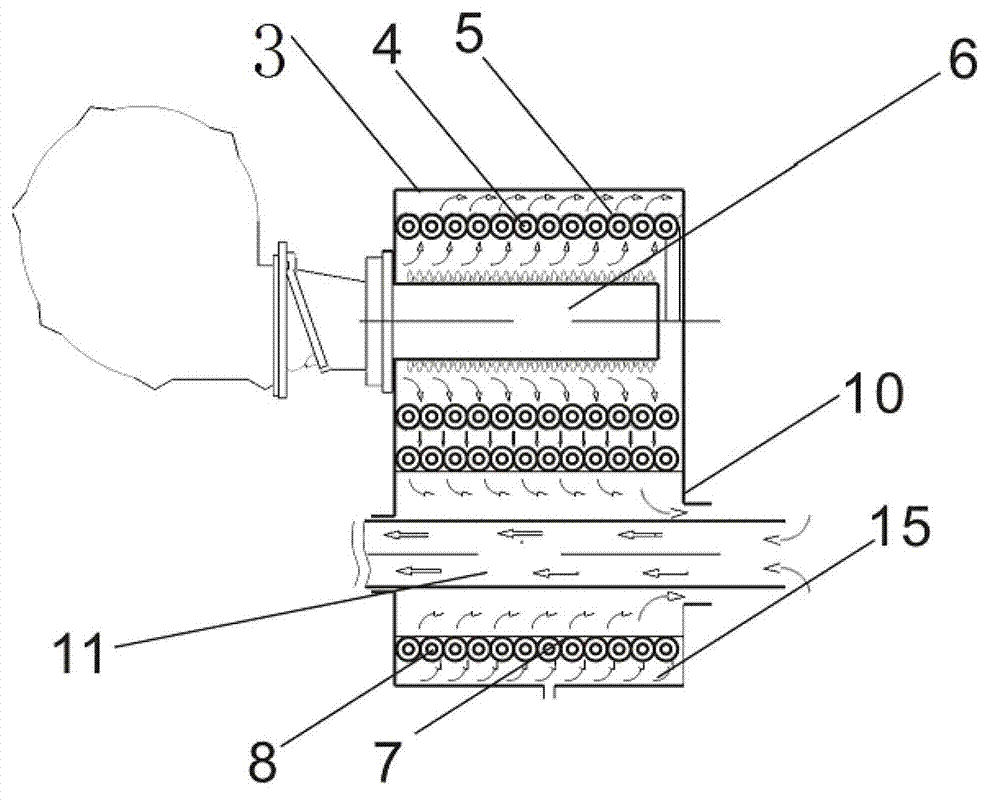

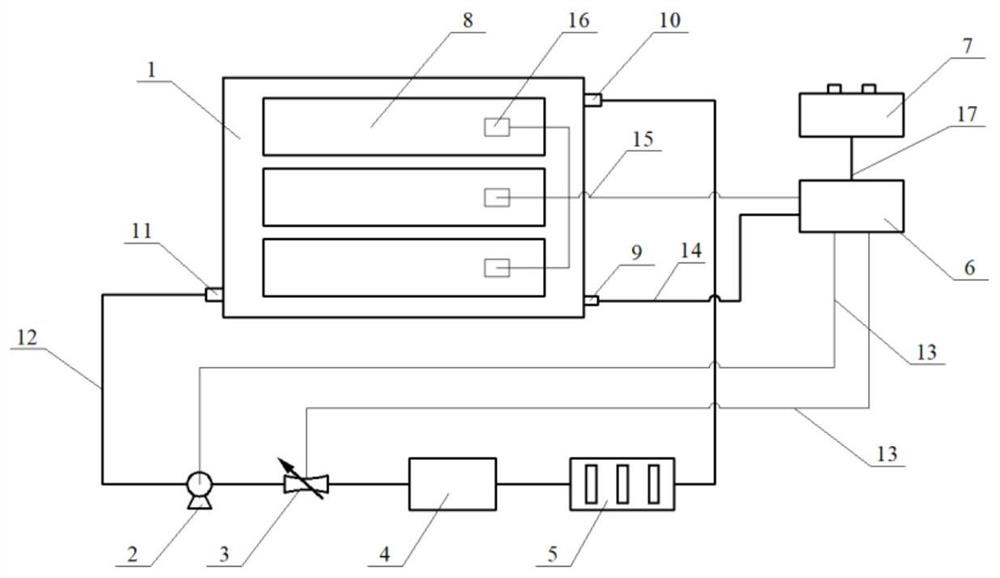

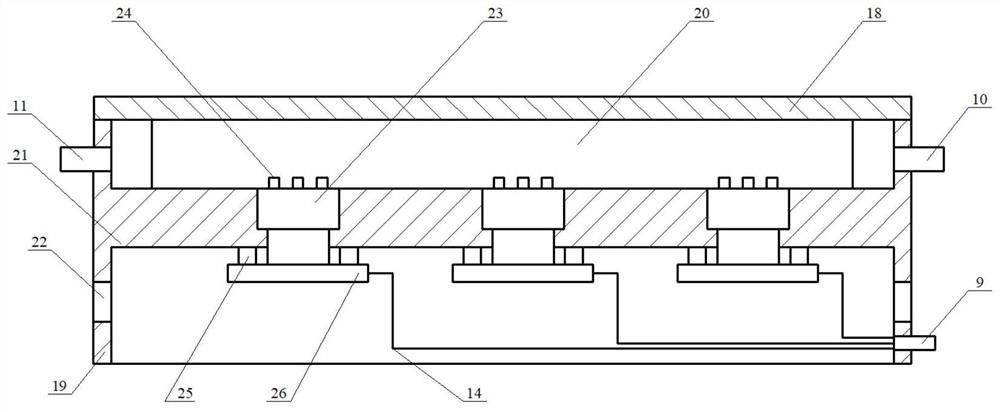

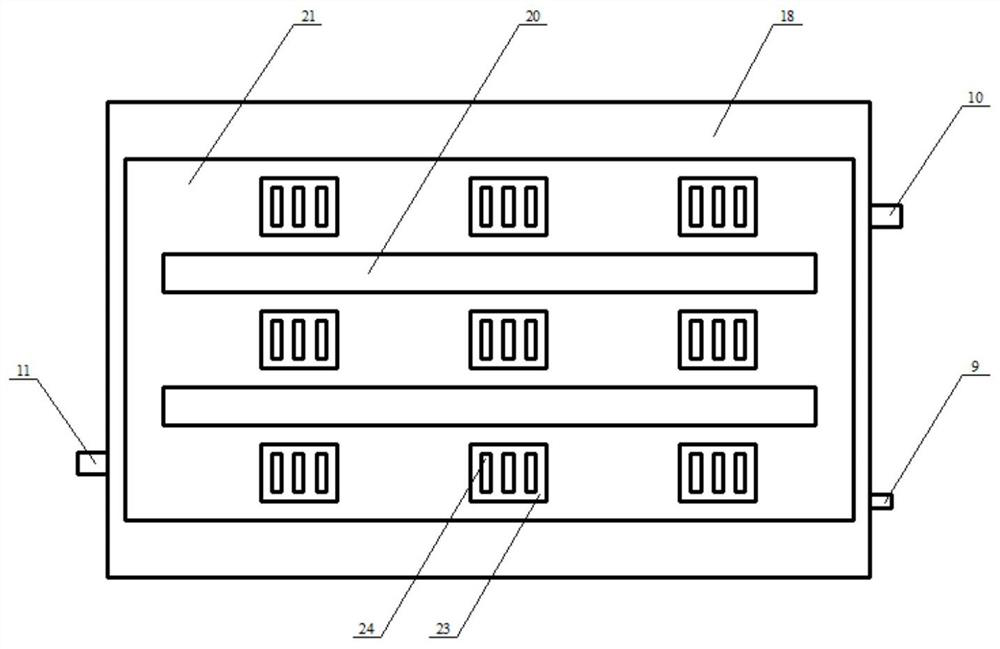

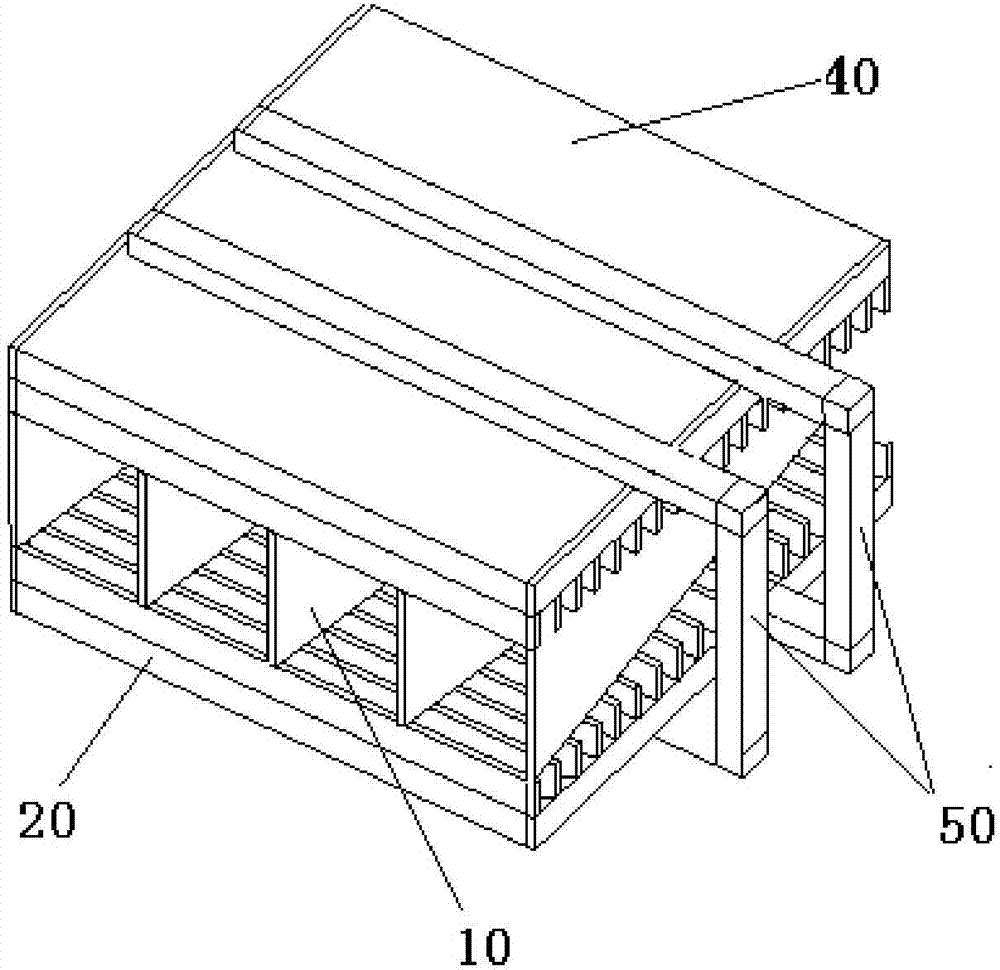

Power battery thermal management system based on combination of microchannel heat pipe and phase change material

InactiveCN107634164APromote exchangeAdequate heat dissipationSecondary cellsCell component detailsPower batteryEvaporation

The invention discloses a power battery thermal management system based on the combination of a microchannel heat pipe and a phase change material. The power battery thermal management system comprises multiple battery cells, a microchannel heat pipe, a box with through holes, a box cover, fins welded to the side walls of the box and clamping plates. The microchannel heat pipe comprises multiple evaporation ends and condensation ends. The evaporation ends and the battery cells are arranged at intervals. The evaporation ends are connected in parallel and form a loop with the condensation ends.The battery cells are separated from the evaporation ends through the clamping plates. The gap between the two clamping plates is filled with a phase-change material. The condensation ends stretch outof the box through the through holes and are installed on the fins. The power battery thermal management system has the advantages of large heat dissipation amount, high heat dissipation efficiency,fast heat dissipation rate, low cost, high safety, energy saving, environmental friendliness and simple structure.

Owner:XIANGTAN UNIV

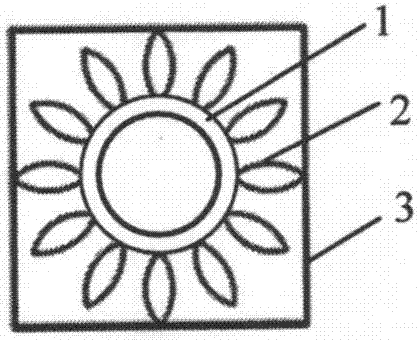

Forced finned straight pipe condensation heat-supply heat exchanger

ActiveCN102901221AImprove heat transfer efficiencyImprove heat transfer effectEnergy efficient heating/coolingAir heatersPlate heat exchangerCombustor

The invention discloses a forced finned straight pipe condensation heat-supply heat exchanger, which comprises a shell, a combustor and a plurality of finned straight pipes, wherein the combustor is positioned on the upper part of the shell; the periphery of the combustor is provided with a group of finned straight pipe bundles consisting of a plurality of finned straight pipes which are tightly and uniformly distributed along the circumference; a smoke exhaust pipeline which consists of the shell and a plurality of tightly arranged finned straight pipes is arranged below the combustor; the smoke exhaust pipeline is emptied through a smoke outlet; two ends of the finned straight pipes are respectively front water main pipes and rear water main pipes; clapboards are arranged in the rear water main pipes; the rear water main pipes are separated into a water inlet area and a water outlet area through the clapboards; and water flow enters part of the finned straight pipes through the water inlet area, reaches the front water main pipes and enters the water outlet area of the rear water main pipes through the other part of the finned straight pipes. The inwards folded finned straight pipes serve as basic elements of the forced finned straight pipe condensation heat-supply heat exchanger, and the heat exchange efficiency is obviously improved.

Owner:SUZHOU CQ HEAT EXCHANGER

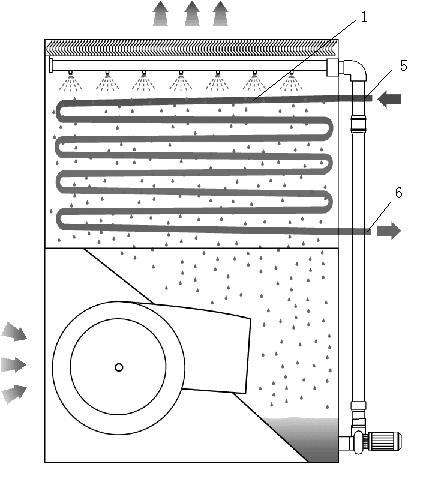

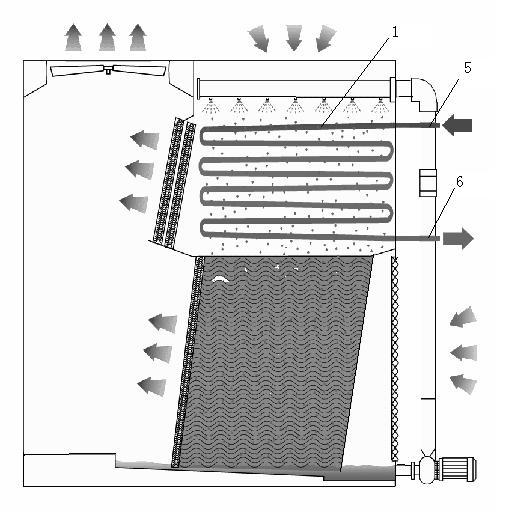

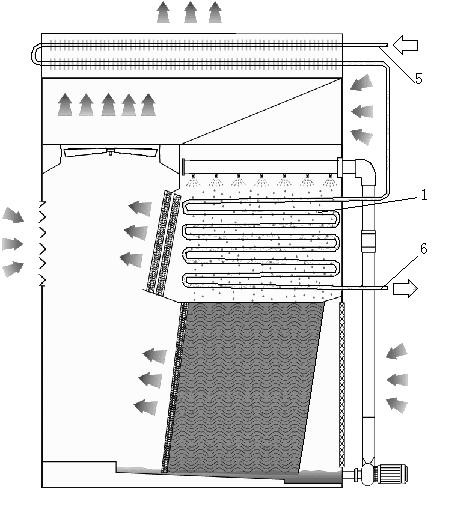

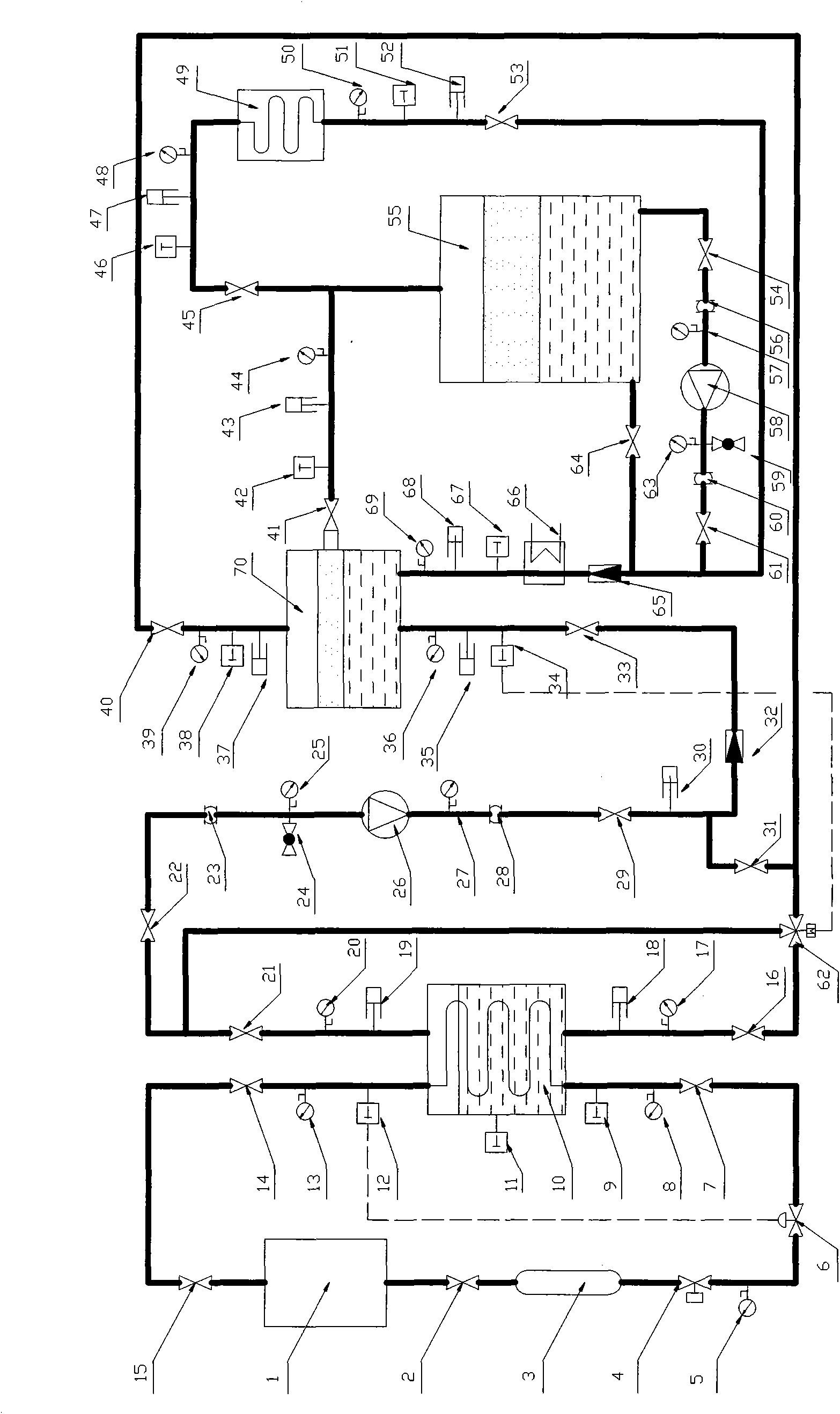

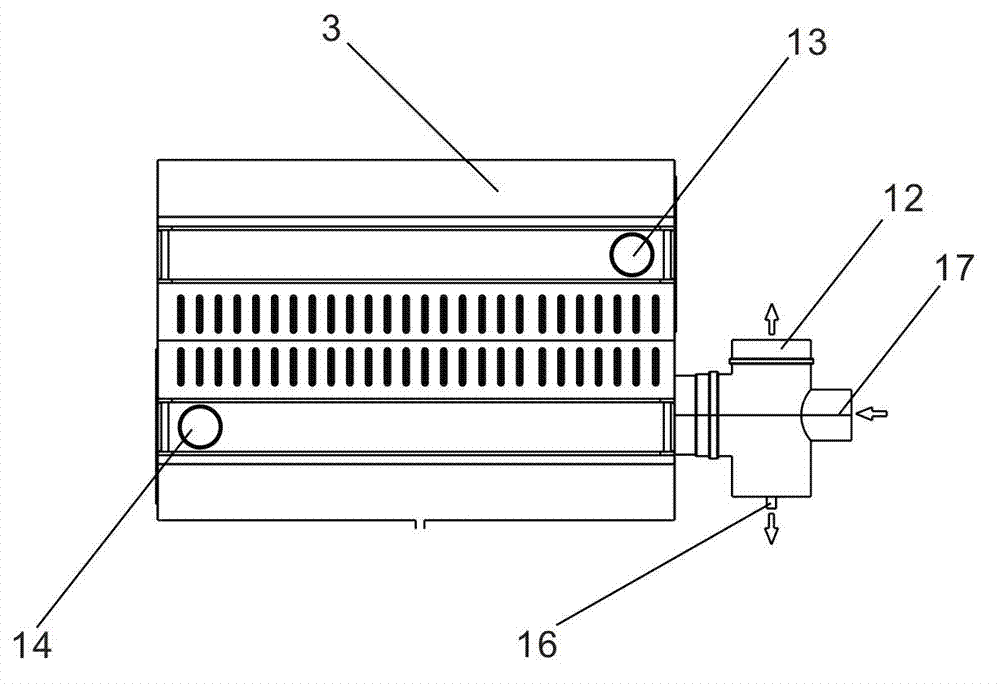

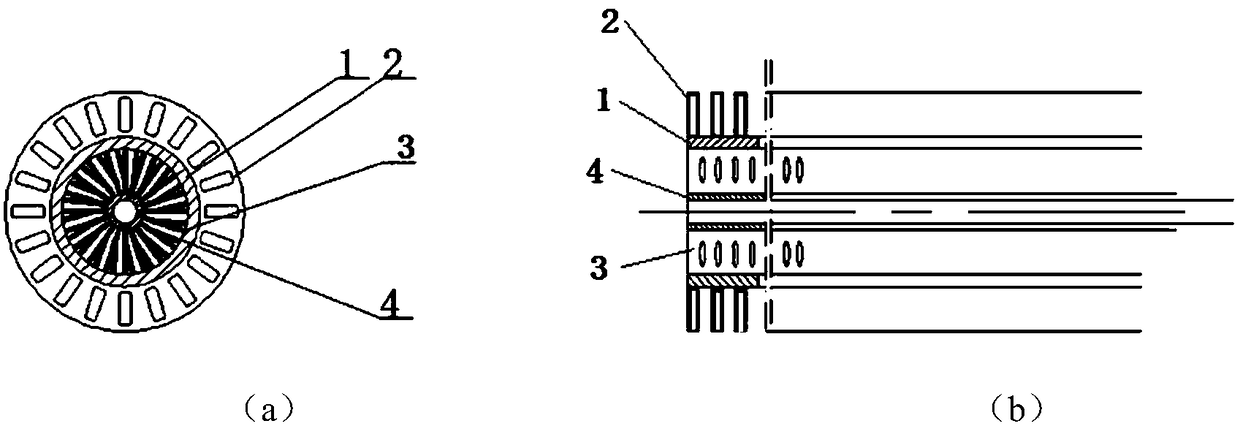

Reinforcing heat transfer method and heat exchange coil tube component for evaporative heat exchanger

InactiveCN101846477ASmall convective heat transfer coefficientImprove convective heat transfer coefficientTubular elementsEnhanced heat transferEngineering

The invention belongs to the field of evaporative heat exchange equipment, and relates to a reinforcing heat transfer method for an evaporative heat exchanger. Gaseous working media which are subjected to heat exchange by a coil tube flow into an upper connector of the coil tube, condensed and cooled working media outflow from a lower connector, and a reinforcing heat transfer component is additionally arranged in tube bundles of the coil tube of part or all of tube passes to improve the heat transfer efficiency. In the coil tube component of the invention, the coil tube is subjected to the processing of an integrally-finned expansion heat exchange surface partially or completely according to the properties of the condensed or cooled working media and the requirement of tube resistance; fins are machined by made-to-measure dies independently, and structures and shapes of the fins can be adjusted; the fins are arranged in a direct-insert mode, are convenient, flexible and have low manufacturing cost; the support action supplied by a core tube can ensure the contact area between the fins and an outer tube fully, and reduce the contact heat resistance of the internal fins furthest. The coil tube component adopting the integrally-finned reinforcing heat transfer component has the advantages of occupied space saving, large heat exchange rate of unit volume, high heat exchange efficiency and small appearance dimensions of a complete machine.

Owner:BAC DALIAN

Gas direct contact type ice slurry preparation system

InactiveCN101629771AFacilitated DiffusionReduce usageLighting and heating apparatusIce productionEngineeringSlurry

The invention discloses a gas direct contact type ice slurry preparation system. The system comprises three parts of refrigerant circulation, gas circulation and ice-making solution circulation, wherein a refrigerating medium adopts an environmental-friendly gas, such as air, nitrogen, and the like. Compared with a liquid refrigerating medium, the gas with same mass can generate more air bubbles in an ice slurry generator so as to increase the heat exchange area; the gas is easier to realize higher gas inlet speed so as to promote the diffusion of the air bubbles; the temperature distribution in the ice slurry generator is more even, the local supercooling is prevented, and the probability of generating an ice blockage is reduced. In addition, a first-class heat exchanger is adopted in the system. A refrigeration system evaporator is arranged in the first-class heat exchanger, and a refrigerating medium gas directly contacts with solution (ethanediol solution) in the first-class heat exchanger to exchange heat. Because of the intensive disturbance function of the gas, the convection heat exchanging factor of the refrigerating medium and the evaporator is greatly increased, and the problem of larger heat resistance caused by direct convection heat exchange of the gas and the refrigerating system evaporator is solved. Accordingly, the gas with higher temperature passes through refrigerating medium solution with lower temperature, thereby achieving the aim for removing water in the gas and further reducing the probability of the ice blockage of the system.

Owner:ZHEJIANG UNIV

Gravity type hot pipe trapezoid combined warming heat radiator

InactiveCN101408387AIncrease the heating areaImprove heat transfer coefficientIndirect heat exchangersSuperheaterEngineering

A gravity-style heat pipe trapezoid-combined heating radiator solves the problems of existing heat pipe radiators that the height is limited; the radiation area is small; and the heat transmission coefficient is low and the application range is narrow. The gravity-style heat pipe trapezoid-combined heating radiator comprises a liquid medium collecting pipe, a heat exchanger, a fin radiation pipe, a waste-steam collecting pipe and a condensation returning pipe. The heating radiator is characterized in that a superheater is respectively connected with two ends of the liquid medium collecting pipe and the heat exchanger is positioned in the liquid medium collecting pipe and the superheater to form a U-shaped heat-exchanger assembly; two ends of the fin radiation pipe are connected with the superheater and the fin radiation pipe is arranged in an inclined manner and the head is adjacent to the tail; the waste-steam collecting pipe is arranged on the top of the superheater and connected with the superheater; and the upper end and the lower end of the condensation returning pipe are respectively connected with the top of the superheater and the liquid medium collecting pipe and the upper end of the condensation returning pipe is communicated with the waste-steam collecting pipe. The heating radiator has the advantages that the problems that the heat-transmission medium is condensed in the radiation pipe and the height of the radiator is limited are solved; the specification of the product achieves the big, intermediate and small series; and the application range is wider; and the different requirements of people can be satisfied.

Owner:姚新安

Three-dimensional micro channel and a pulsating flow heat dissipation device

ActiveCN109275311ARealize the printing functionAvoid tightnessModifications using liquid coolingEngineeringMicrochannel heat sink

The invention discloses a three-dimensional microchannel and pulsating flow heat dissipation device, which relates to the technical field of radiators, in particular to a novel three-dimensional microchannel heat dissipation device using pulsating or intermittent fluid and a 3D printing manufacturing method thereof. The heat dissipation device comprises a radiator, a pulse pump, a cooler and a connecting pipe; The heat sink is closely attached to the heat source, Connect the radiator by connecting the pipes, pulsating pump, cooler in series, The heat sink comprises a liquid injection port, a bottom layer heat dissipation structure, an intermediate layer heat dissipation structure, a top layer heat dissipation structure, a liquid outlet, the bottom layer heat dissipation structure, the intermediate layer heat dissipation structure and the top layer heat dissipation structure, which are stacked in turn, and have good heat dissipation effect, and the heat dissipation effect is further improved after the device is made into an organic whole by adopting the 3D printing method.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

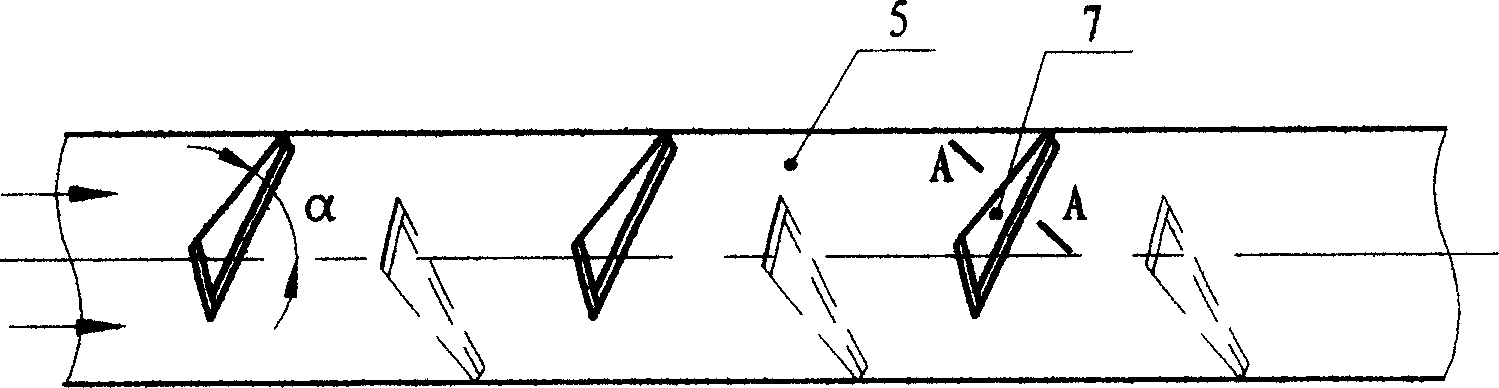

Method and device for preventing thermal-power boiler from quick coking and ash deposition

The invention discloses a method for preventing a thermal-power boiler from quick coking and ash deposition. The method is characterized by including that flowing gas with certain momentum is blown in along a heated face of the boiler in a wall-adhering manner to flow on the heated face of the boiler in a wall-adhering manner to form a gas boundary layer adhered to the heated face, so that speed and composition of an original gas boundary layer are changed, molten mineral substances are avoided from contacting with the heated face, the molten mineral substances are enabled to be less prone to attaching on the heated face, and inhibition on coking and ash deposition of the heated face of the thermal-power boiler is realized; a gas protection layer can ba additionally arranged outside the gas boundary layer according to needs; gas flowing direction can be vertical, horizontal, obliquely downward or obliquely upward. The invention further discloses a boundary layer gas generating device for preventing the heated face of the boiler from coking and ash deposition. By the method and the device, the formed gas boundary layer can be ensured to play an effective role in protection, purified smoke containing a lot of CO2 can be led back into a hearth, NOx generation can be inhibited, heat exchange coefficient of the convective heated face can be increased, and corrosion of the heated face can be controlled.

Owner:HUAZHONG UNIV OF SCI & TECH

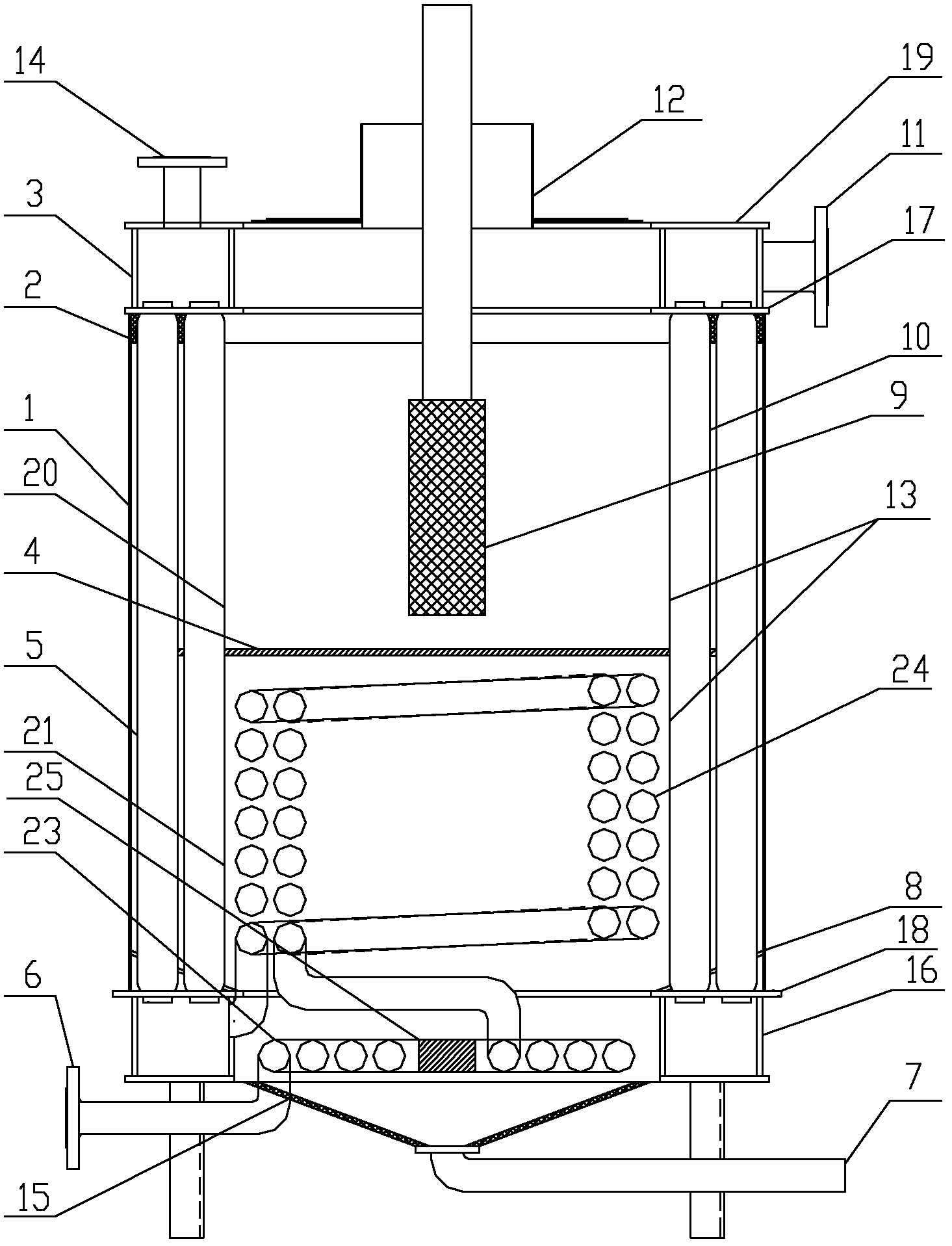

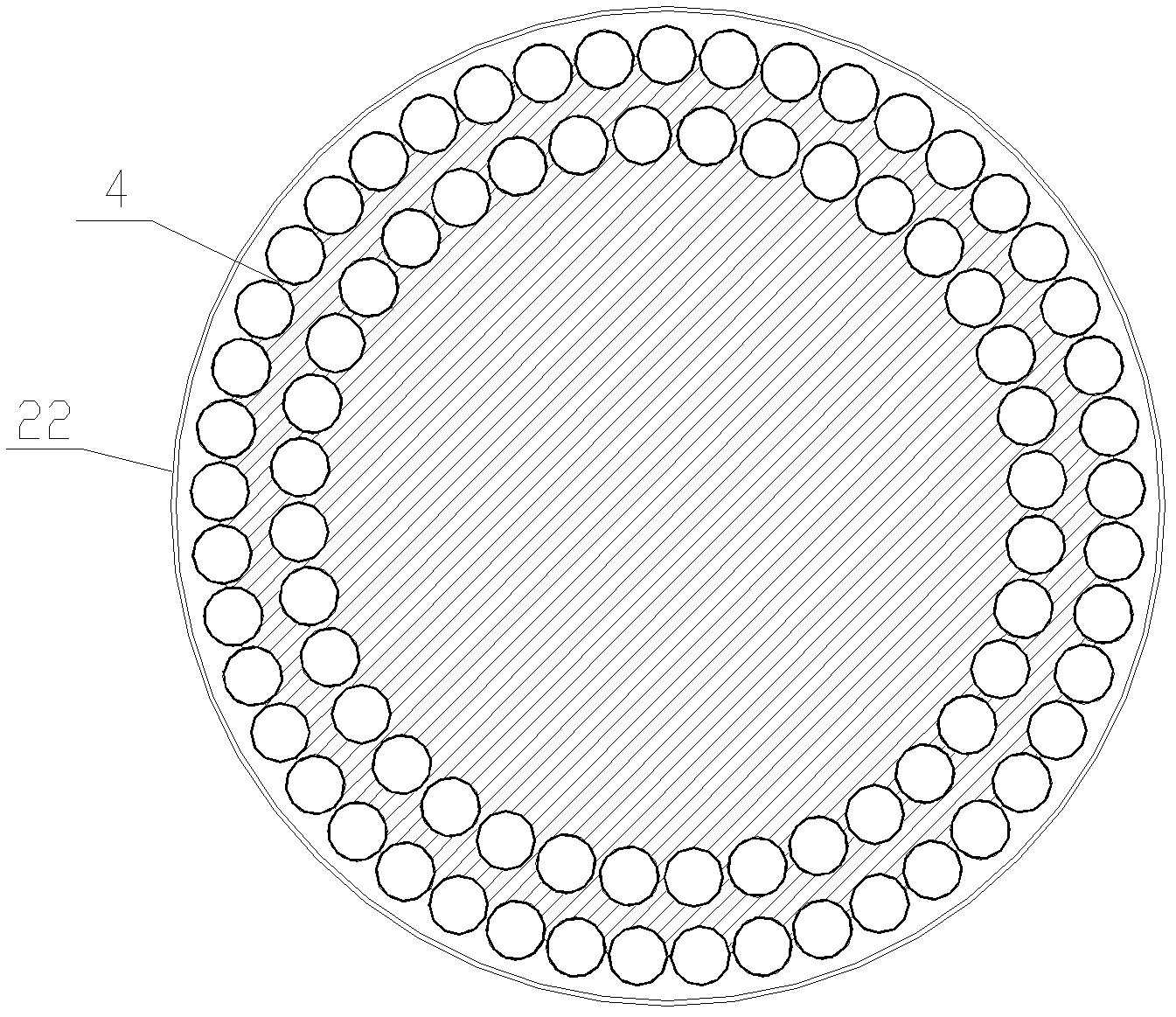

Through-flow type narrow-clearance integral condensation hot-water boiler

InactiveCN102635945ALow investment costAvoid uneven temperature distributionAir heatersSustainable buildingsCombustorEngineering

A through-flow type narrow-clearance integral condensation hot-water boiler comprises a shell. An annular water outlet header is arranged on the upper portion of the shell, an annular water feeding header is arranged on the lower portion of the shell, a deep condensation heat exchange tube bundle and a V-shaped condensation collecting device with a condensate neutralizing treatment device are arranged below the annular water feeding header, an all-premixing metal fiber combustor is arranged on a top plate of a boiler, a metal fiber head of the all-premixing metal fiber combustor penetrates into a radiation heat exchange space so as to realize the characteristic of high radiation heat exchange capacity of the metal fiber head, the annular water outlet header is communicated with the annular water feeding header via inner and outer circles of annular water cooling walls consisting of a plurality of vertical water tubes, a clearance with the size of 1-2mm is reserved between each two adjacent vertical water tubes and is used as a smoke circulation channel, smoke realizes convection heat exchange and condensation heat exchange when flowing among the vertical water tubes, heat is transmitted to working medium water in the vertical water tubes, the deep condensation heat exchange tube bundle deeply cools the smoke, and efficiency of the boiler is improved. In addition, the through-flow type narrow-clearance integral condensation hot-water boiler is simple in structure and convenient in manufacture, and can effectively avoid the harm that tubes are easy to be exploded due to uneven heat load distribution of a traditional through-flow boiler.

Owner:XI AN JIAOTONG UNIV

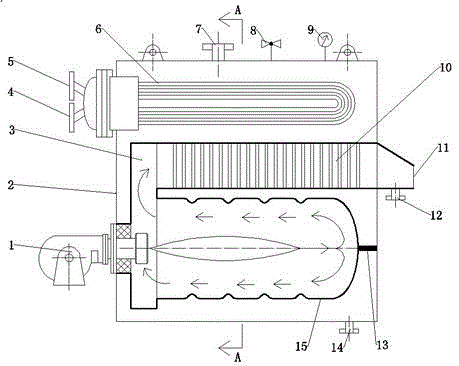

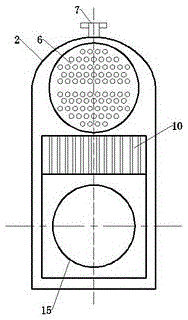

Water tube type vacuum boiler with central reverse flames

The invention discloses a water tube type vacuum boiler with central reverse flames. The vacuum boiler mainly comprises a combustor, a casing, a flue gas transfer chamber, a container, a water tube type heat exchanger and a U-shaped tube heat exchanger. The vacuum boiler is characterized in that the boiler casing is formed by butt-jointing an upper arc-shaped barrel and a lower cuboid casing, the U-shaped tube heat exchanger is located at the upper part of the casing, and the container, the flue gas transfer chamber and the water tube type heat exchanger are located at the lower part of the casing; the container is waved, the front end of the container is welded on the flue gas transfer chamber, and the back end is welded on an ellipsoidal gland; a central reverse flame combustion manner is adopted; a plurality of vertical heat exchange tubes are arranged in the water tube type heat exchanger, flue gas inlets of the heat exchange tubes are welded on the flue gas transfer chamber, and flue gas outlets are connected with an exhaust tube. The boiler keeps a certain vacuum degree inside during running, boiler water boils at the temperature lower than 100 DEG C after being heated, steam rises and condenses outside the U-shaped tube heat exchanger to release heat to heat return water in the tube, and condensate water flows back into the boiler. The boiler is compact in structure and higher in heat efficiency and occupies small area, and no external heat exchanger is required.

Owner:ZHENGZHOU UNIV

Outer fin heat exchange tube and application method thereof

ActiveCN107976101ARealize complete countercurrent heat exchangeRealize small temperature difference heat transferChemical industryHeat exhanger finsPlate heat exchangerEngineering

The invention provides an outer fin heat exchange tube, which comprises a heat transfer tube, outer fin groups, and an outer fin group frame. Each outer fin group is used for extending an outside heatexchange surface of the heat transfer tube, forming a micro-channel, restraining an adverse current of an outside tube fluid along an axial direction of the heat transfer tube, and producing a turbulent flow action at the same time; the outer fin group frame is used for reducing transverse flow of the outside tube fluid of the heat transfer tube; an outer wall of the heat transfer tube is connected with the multiple outer fin groups; the outer fin groups are arrayed along an axial direction of the heat transfer tube; holes are formed in the outer fin groups; the holes of the multiple outer fin groups form the micro-channel parallel to the axial direction of the heat transfer tube; and the peripheries of the outer fin groups are connected with the outer fin group frame. The invention further provides an application method of the outer fin heat exchange tube. According to the outer fin heat exchange tube provided by the invention, complete countercurrent flow heat exchange is realized between fluids inside and outside the tube, so that small temperature-difference heat transfer can be realized; when the outside tube fluid passes through the micro-channel structure of the outer fin groups, fins have the sufficient turbulent flow action, so that a convective heat-transfer coefficient is improved; and the outer fin heat exchange tube can be used for manufacturing a high-efficient and compact heat exchanger, and is particularly applicable to a gas-gas heat exchange working condition.

Owner:SHANGHAI POWER EQUIP RES INST

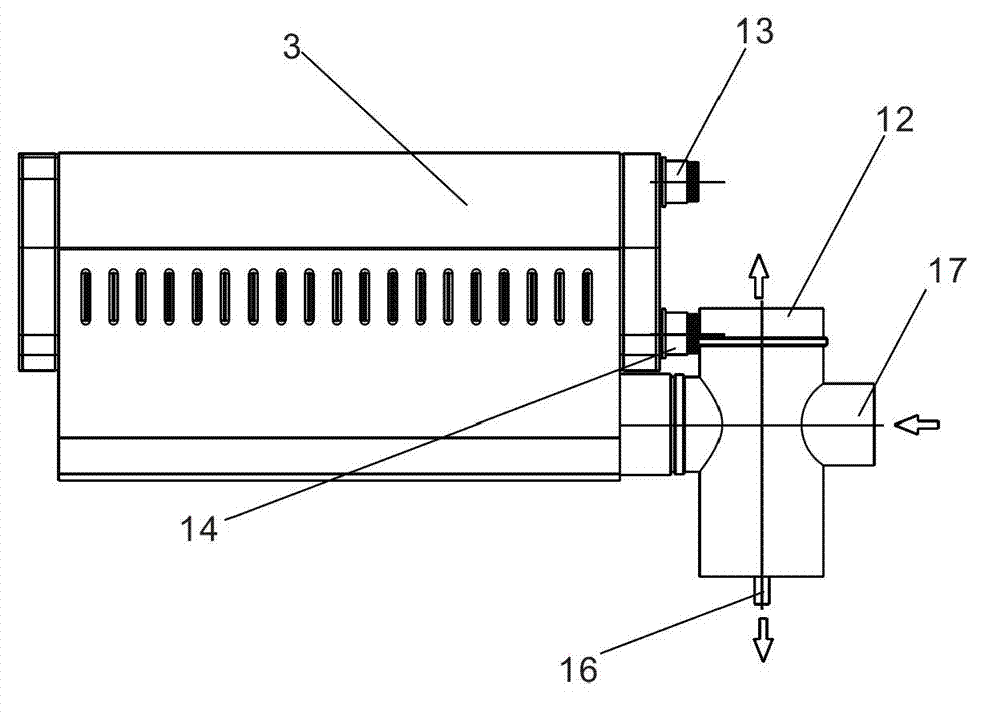

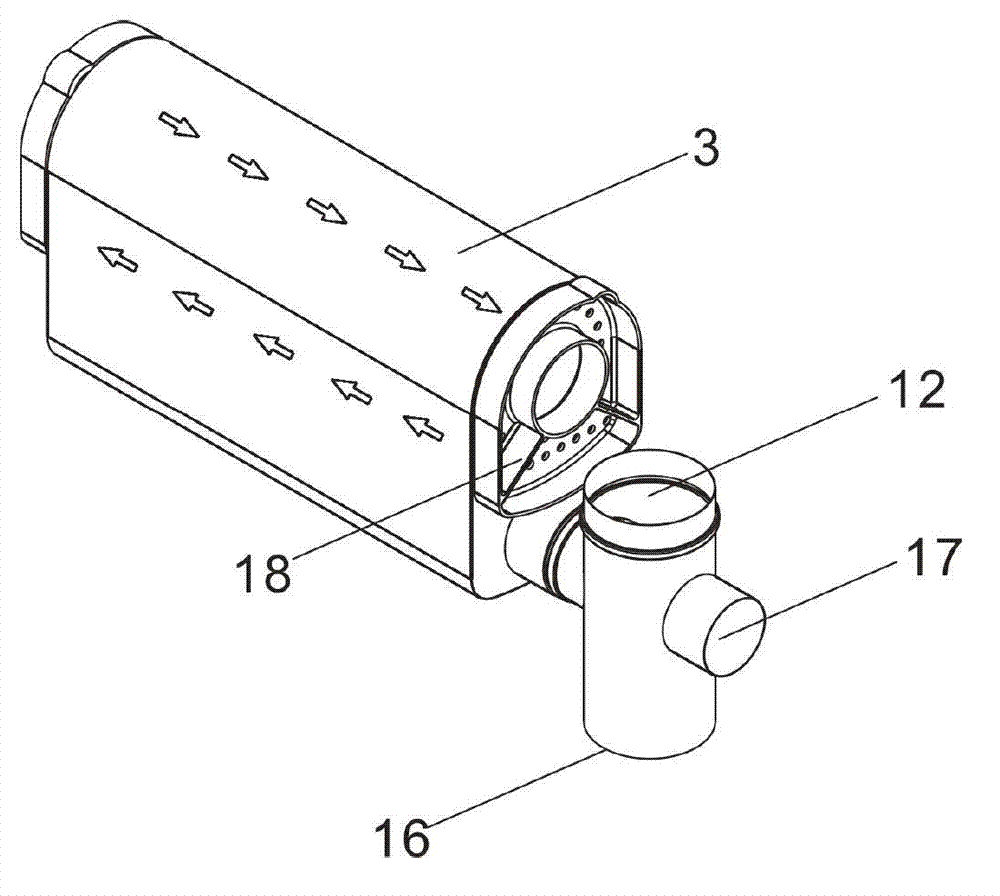

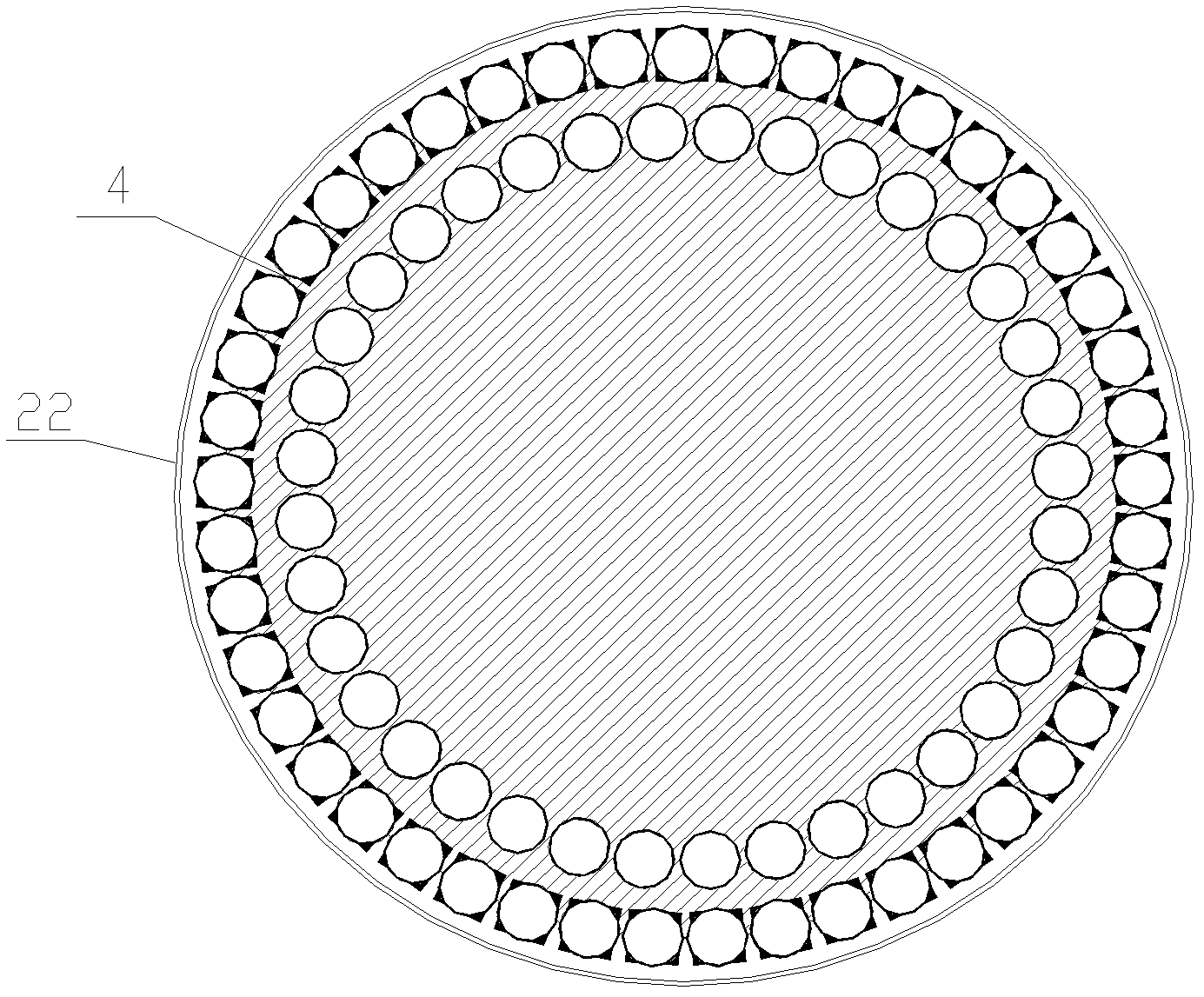

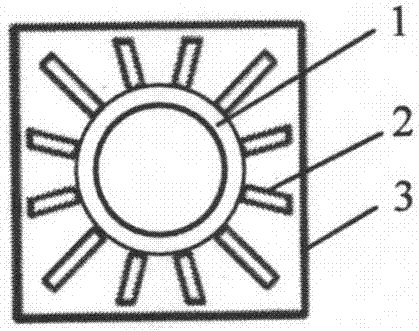

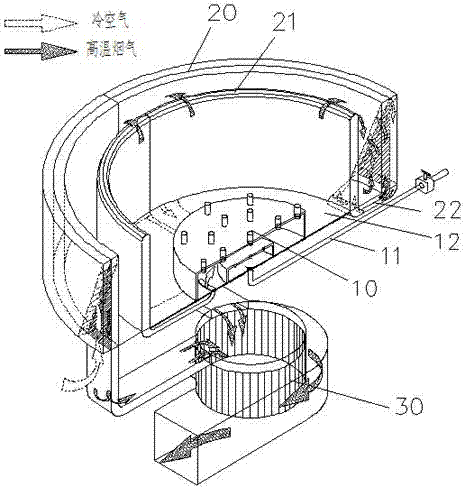

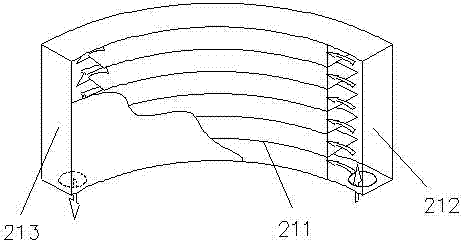

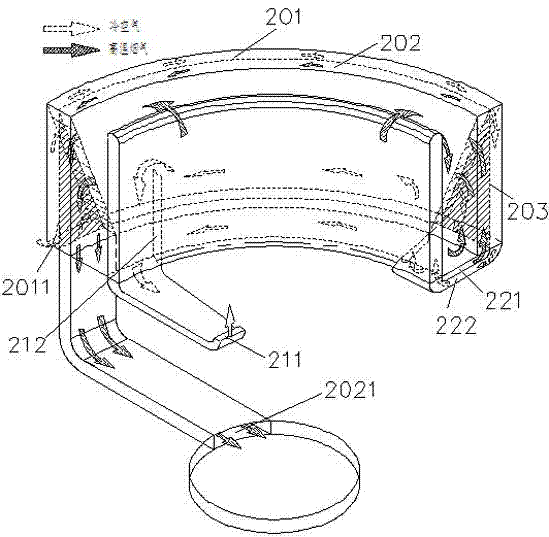

Forced spiral finned coil pipe condensation heat-supply heat exchanger

ActiveCN102901225AImprove heat transfer efficiencyImprove heat transfer effectEnergy efficient heating/coolingAir heatersCombustorPlate heat exchanger

The invention discloses a forced spiral finned coil pipe condensation heat-supply heat exchanger, which comprises a shell, a combustor arranged in the shell and a plurality of spiral finned coil pipes, wherein a water inlet, a water outlet and a smoke outlet are formed on the shell; the combustor is connected with an air and gas inlet device; the combustor is positioned on the upper part of the shell; the periphery of the combustor is coaxially provided with a group of pipe bundles consisting of a plurality of spiral finned coil pipes; a smoke exhaust pipeline which consists of a plurality of tightly arranged spiral finned coil pipes is arranged below the combustor; the smoke exhaust pipeline is emptied through a smoke outlet; the water inlet is communicated with the spiral finned coil pipes which are tightly arranged below the combustor; the spiral finned coil pipes which are tightly arranged below the combustor are communicated with the spiral finned coil pipes at the periphery of the combustor; and the spiral finned coil pipes at the periphery of the combustor are communicated with the water outlet. The inwards folded finned straight pipes serve as basic elements of the heat exchanger, the heat exchange on the smoke side is intensified, and the size of the whole heat exchanger is further reduced.

Owner:SUZHOU CQ HEAT EXCHANGER

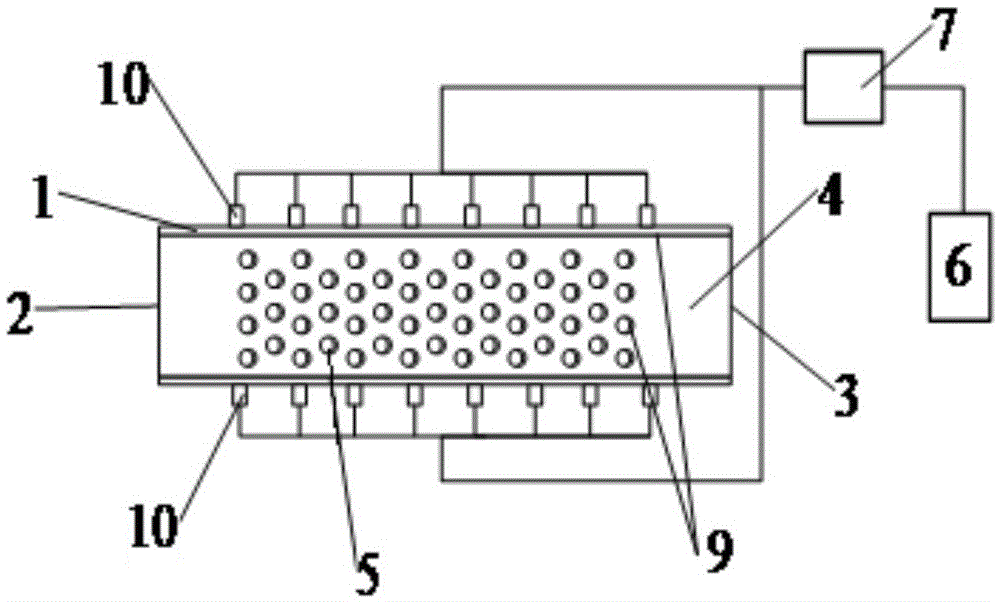

Ultrasonic reinforced micro-channel heat exchanger

InactiveCN105609475AImprove heat transfer effectSlow down the flow of waterSemiconductor/solid-state device detailsSolid-state devicesUltrasonic cavitationPlate heat exchanger

The invention provides an ultrasonic reinforced micro-channel heat exchanger. The heat exchanger comprises a shell, a water-cooling system, micro pin fins, an ultrasonic generator and an ultrasonic transducer, wherein the water-cooling system comprises a cooling water channel, a water inlet and a water outlet; the cooling water channel is arranged in the shell; the water inlet and the water outlet are connected with the cooling water channel to form the water-cooling system; the shell comprises a channel main body and an upper sealing cover; the channel main body and the upper sealing cover are connected in a sealing manner; the micro pin fins and the cooling water channel are arranged in the channel main body; the micro pin fins are arranged along the axial direction of the channel main body; the cooling water channel is formed in the spaces among the micro pin fins, and the spaces between the micro pin fins and the inner wall of the channel main body; ultrasonic transducer oscillators are distributed on the two sides of the channel main body; and the ultrasonic generator is connected with the transducer through a wire. According to the ultrasonic reinforced micro-channel heat exchanger, the ultrasonic generator is adopted to give out high-frequency signals to enable the transducer to generate ultrasonic vibration; an ultrasonic cavitation effect generated by the cooling water is changed into an ultra-turbulent flow state, so that the cooling effect is reinforced; and in addition, dirt in the channel can be cleaned at any time, and the heat transfer resistance is lowered.

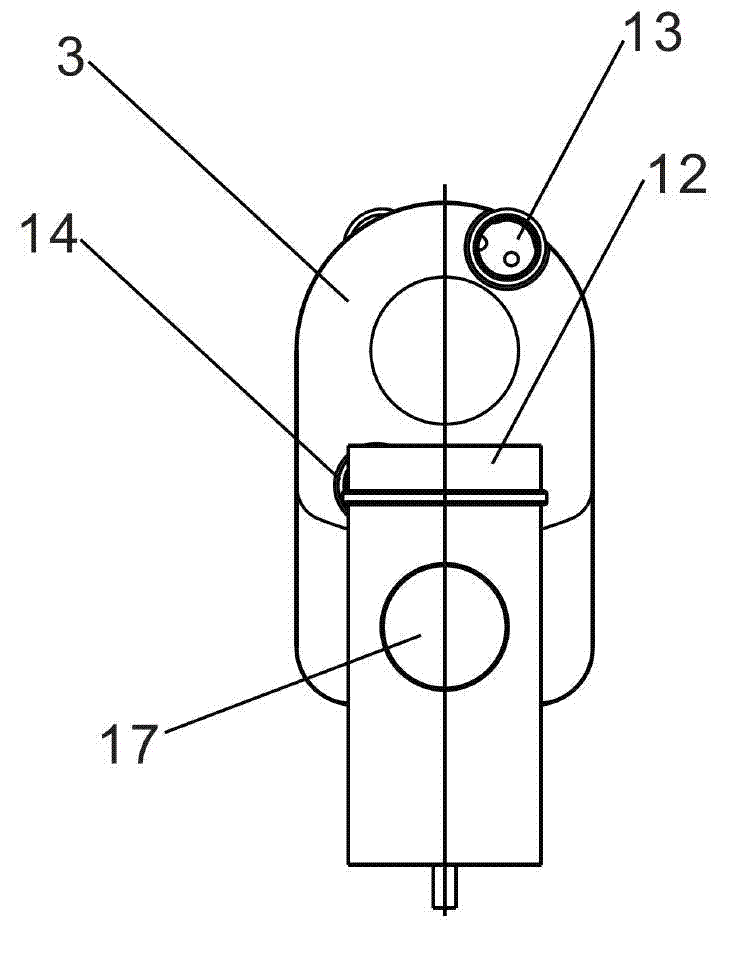

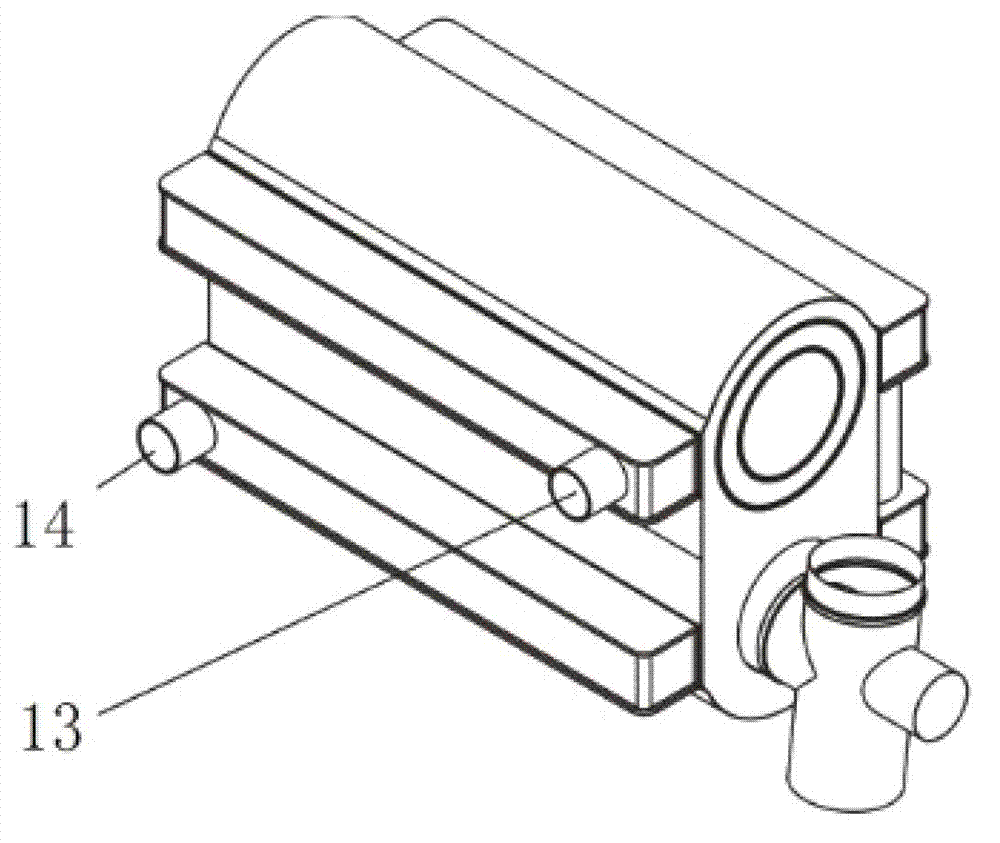

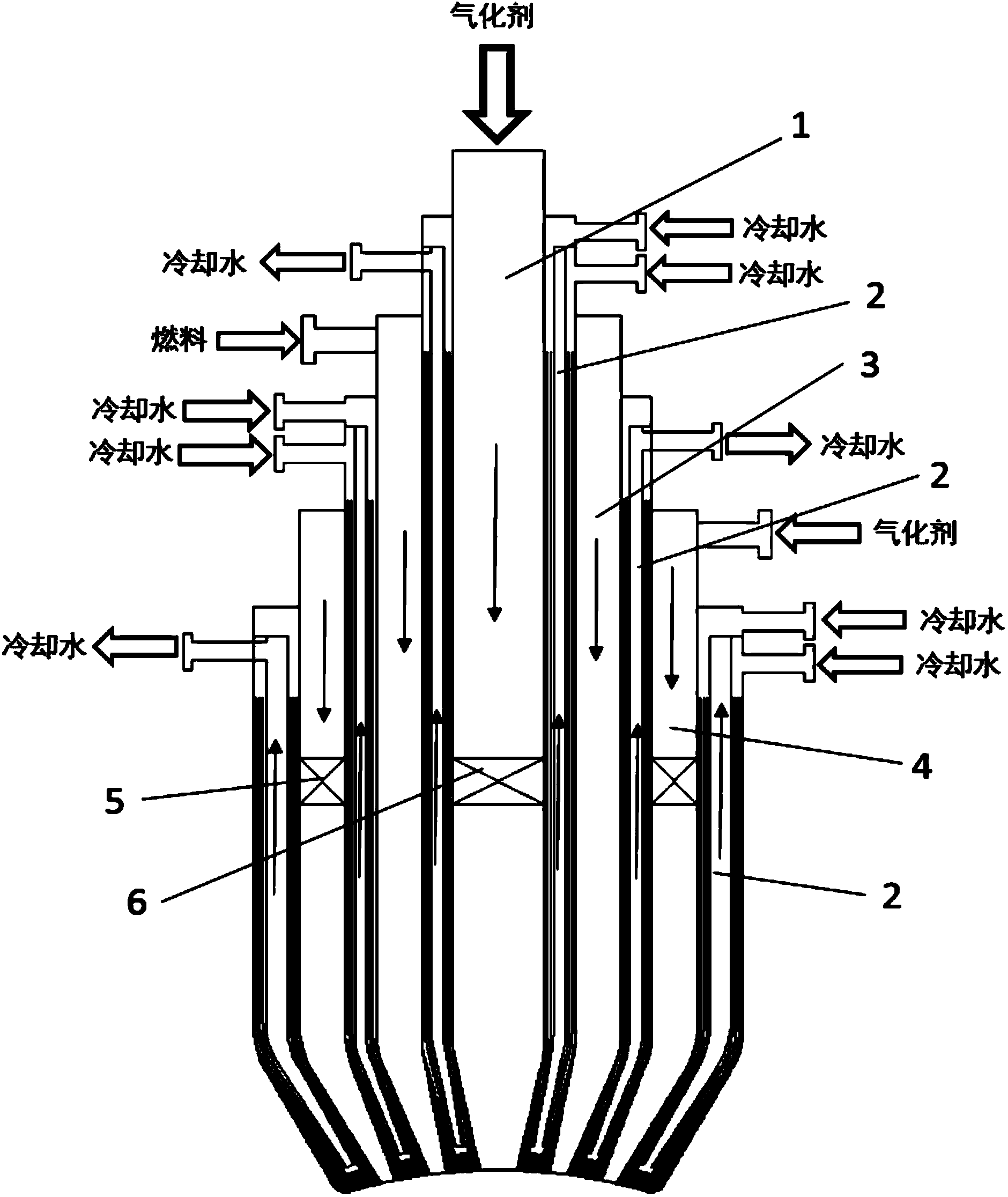

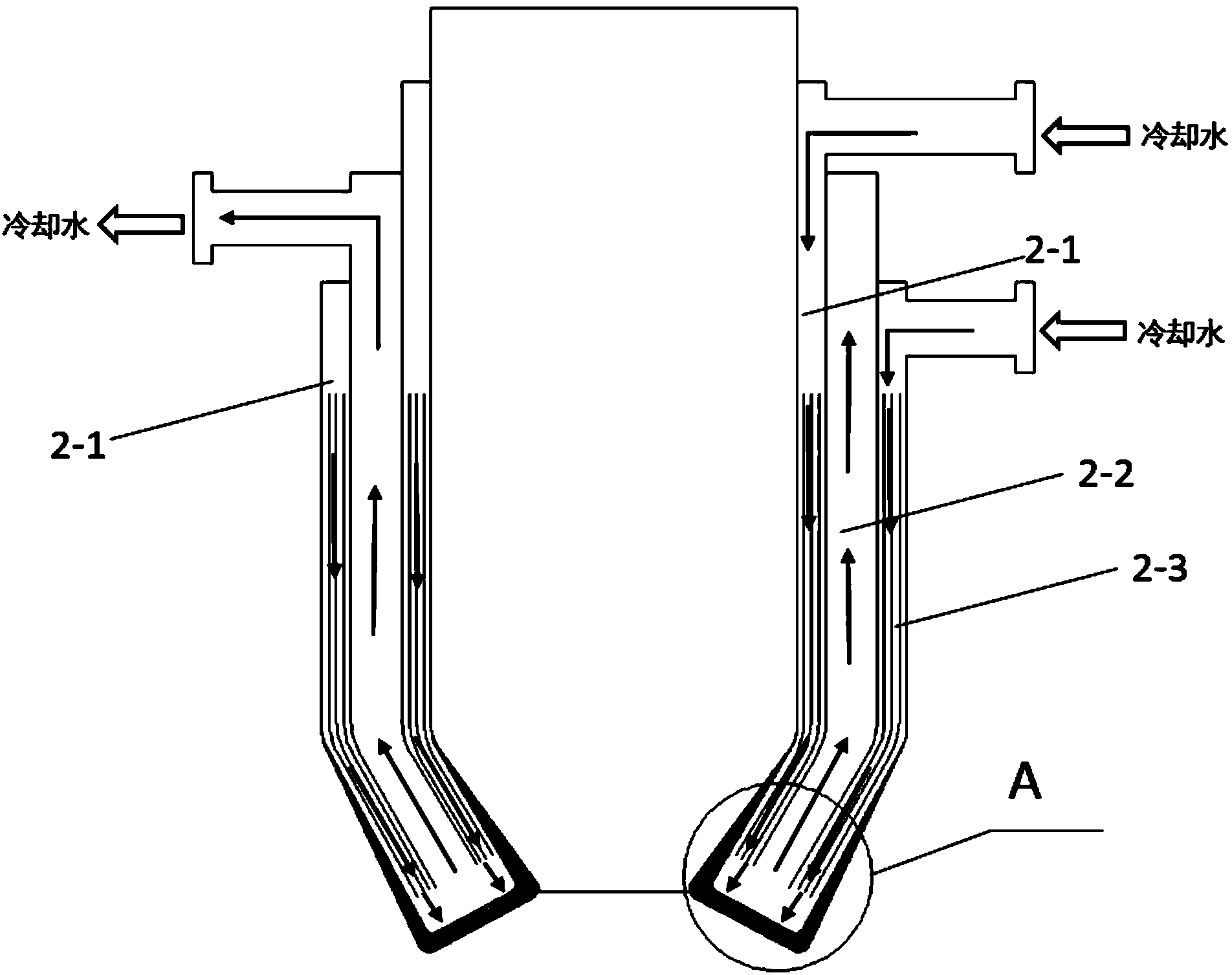

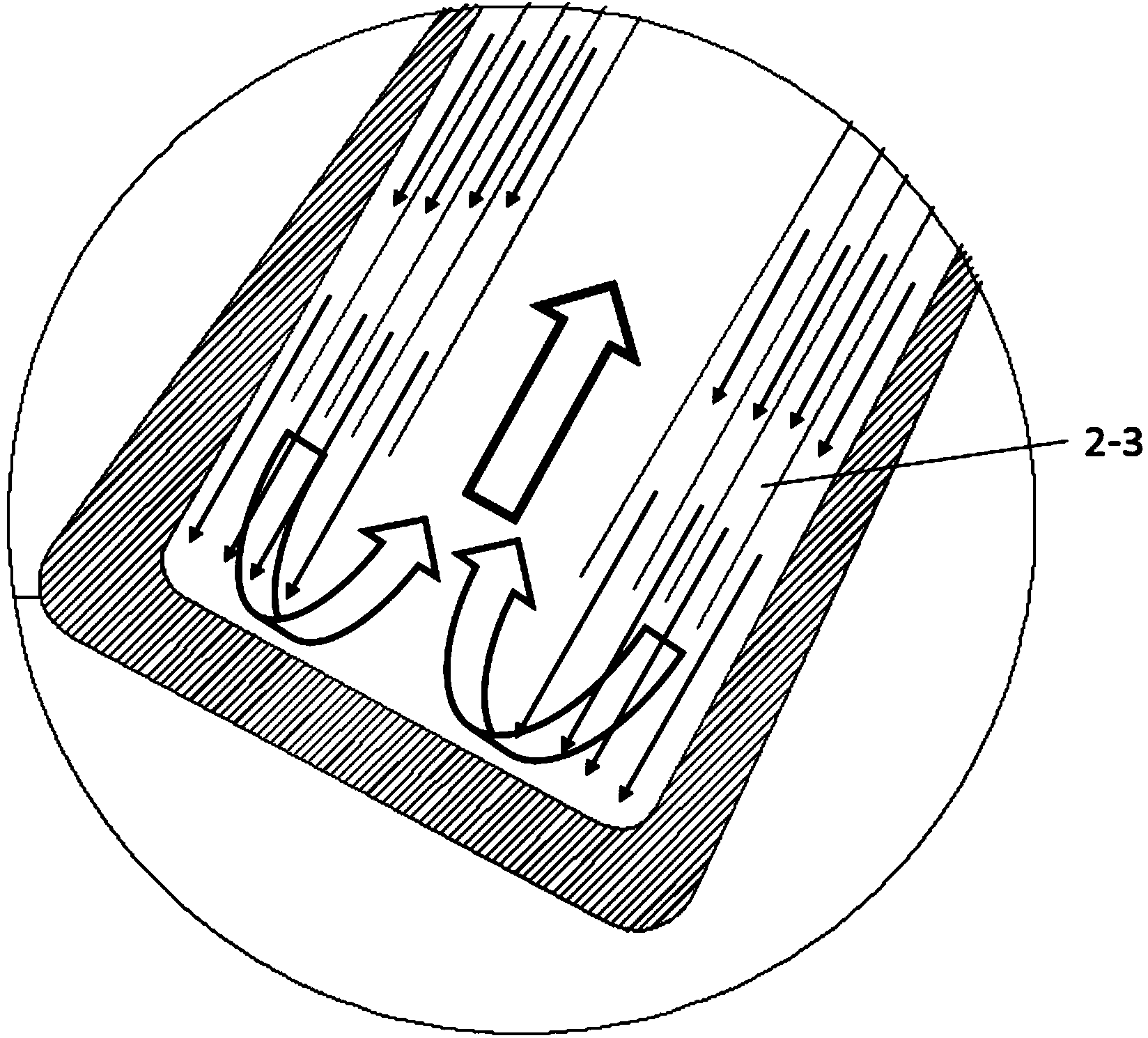

Novel micro-channel circularly cooling gasification process nozzle

ActiveCN103881760AGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationWater channelWater flow

The invention provides a novel micro-channel circularly cooling gasification process nozzle. The nozzle comprises a center gasifying agent channel, a fuel channel, an outer gasifying agent channel and cooling water channels which are distributed between the center gasifying agent channel and the fuel channel, between the fuel channel and the outer gasifying agent channel and outside the gasifying agent channel, wherein the fuel channel and the outer gasifying agent are coaxial with and sequentially sleeved on the center gasifying agent channel; the water intake channels of the cooling water channels are composed of a plurality of micro-channels; the flowing speed of high-pressure cooling water increases in the micro-channels, and the center gasifying agent channel, the fuel channel, the outer gasifying agent channel and metal wall surfaces of the cooling water channels are efficiently cooled in heat conduction and forced-convection heat transfer modes; cooling water is sprayed from the micro-channel outlets in a high-speed jet manner, and the bottom metal wall surfaces of the cooling water channels are effectively cooled in a forced impact jet convection heat transfer manner, and then the cooling water flows back to the water outlets of the cooling water channels from a return channel. The novel micro-channel circularly cooling gasification process nozzle can be used for overcoming the defect of the gasified nozzle technology in the prior artthe nozzle is poor in cooling effect and has a short service life.

Owner:XI AN JIAOTONG UNIV

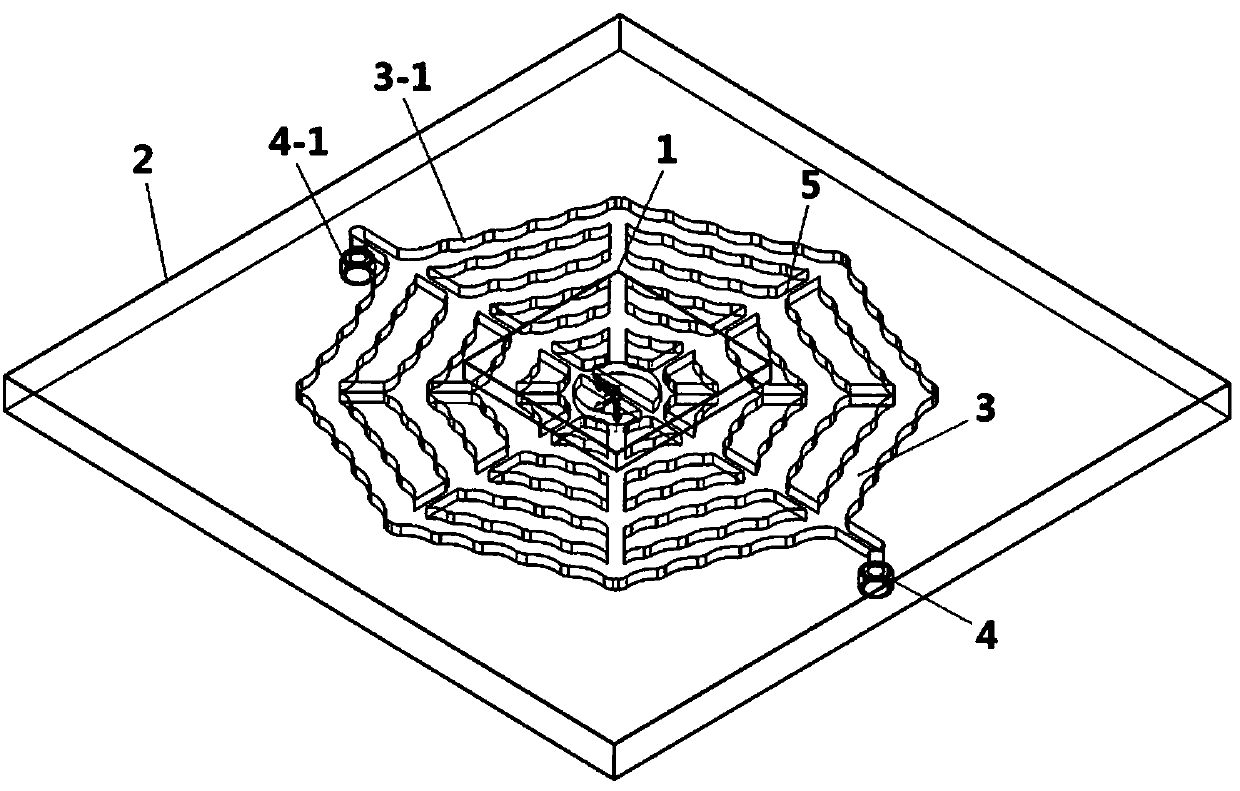

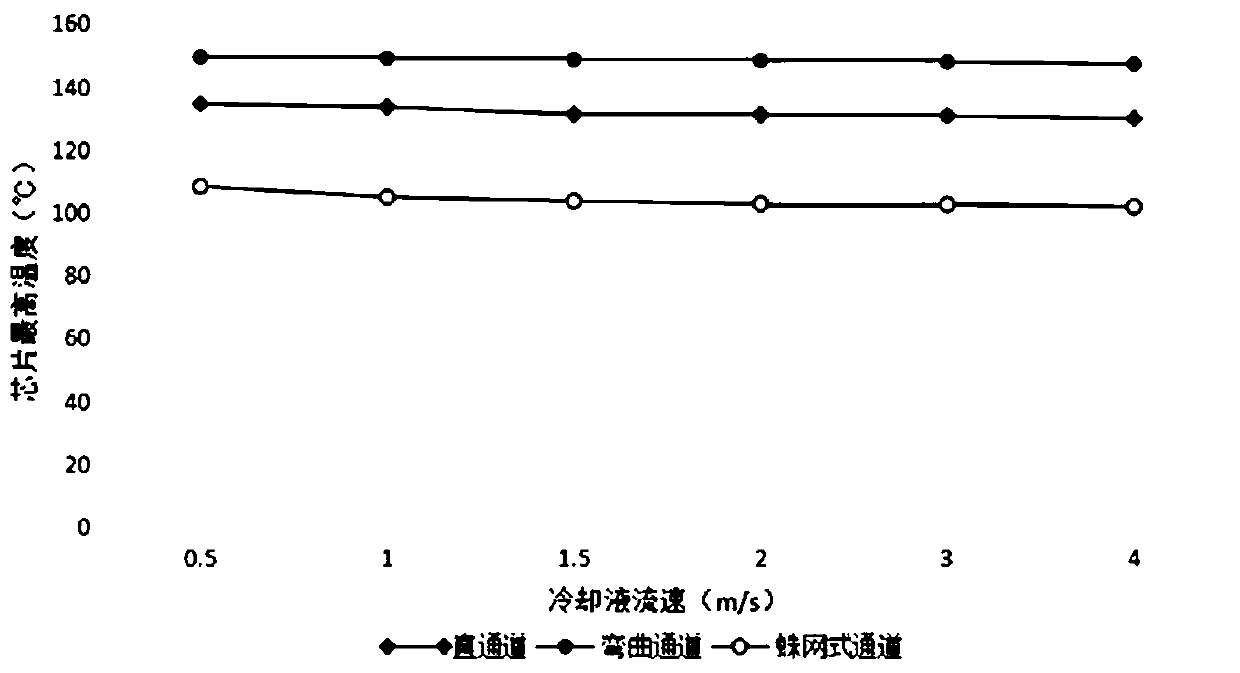

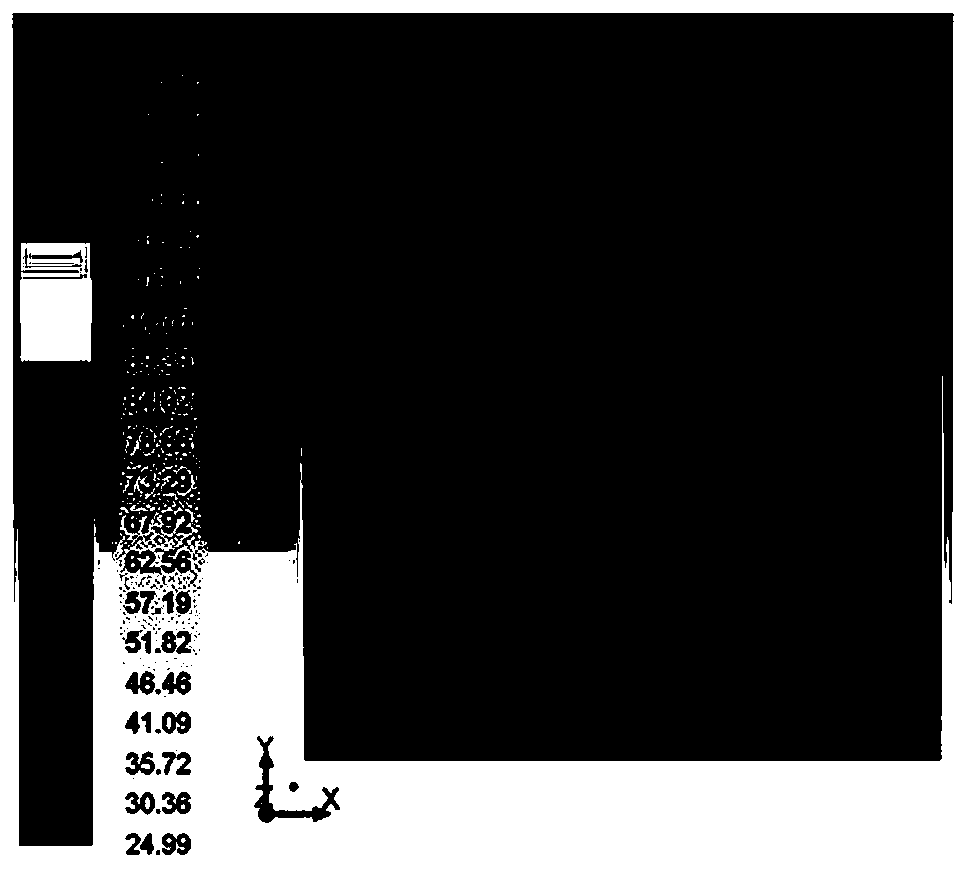

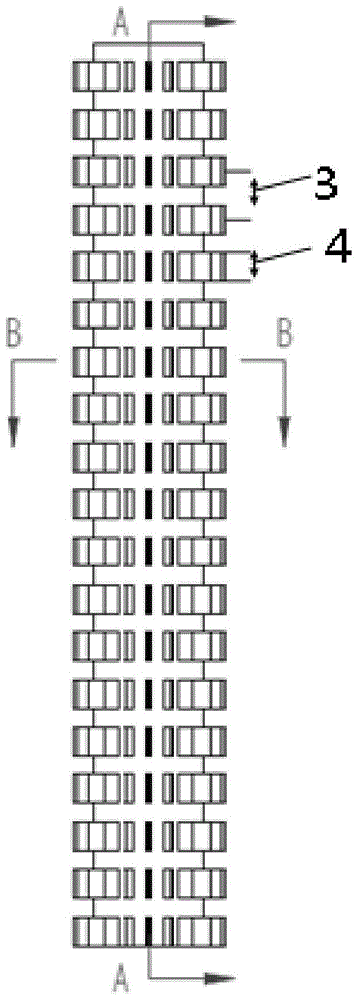

Cobweb type micro channel heat radiation apparatus

PendingCN108172557ALower coefficient of frictional resistanceImprove heat transfer effectSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsWave shape

The invention discloses a cobweb type micro channel heat radiation apparatus. The cobweb type micro channel heat radiation apparatus includes a substrate, and is characterized in that the bottom of the substrate is provided with a fluid micro channel which is distributed uniformly in a cobweb shape; the center of the substrate is the central position of the fluid micro channel; the fluid micro channel radiates outward from the central position, and is displayed in the shape of circles with different diameter; the fluid micro channel takes the central position as the base to set *-shaped fluidmicro straight channels; the *-shaped fluid micro straight channels divide the fluid micro channel into 8 equal symmetrically distributed sectors; two ends of one of the *-shaped fluid micro straightchannels are respectively connected with cooling working medium inlet and outlet at the bottom of the substrate; and the inner wall of the fluid micro channel is wave-shaped, and a heat source is arranged at the central position of the substrate. The cobweb type micro channel heat radiation apparatus has the advantages of being simple in structure, being more uniform in overall heat radiation, andbeing able to improve heat radiation performance of a radiator.

Owner:GUILIN UNIV OF ELECTRONIC TECH

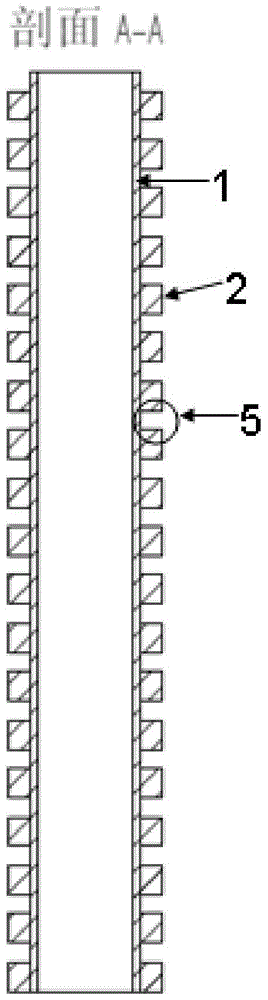

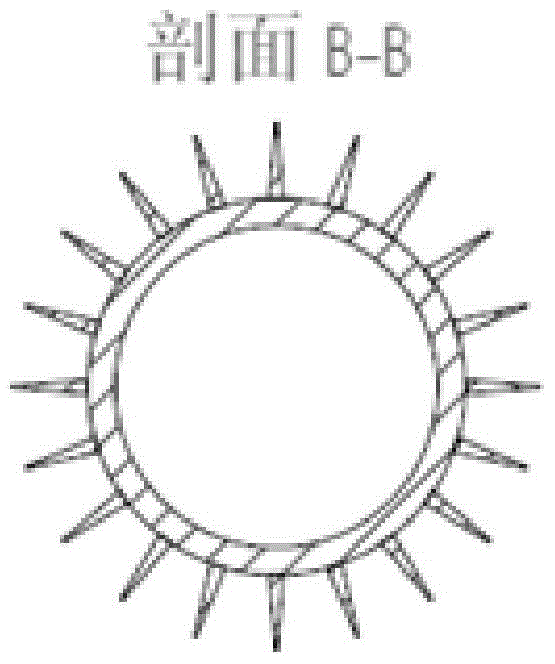

Non-continuous outer trapezoid longitudinal rib tube

PendingCN105758245AIncrease disturbanceIncrease the heat exchange areaHeat transfer modificationTubular elementsMaterial consumptionMetallic materials

The invention discloses a non-continuous trapezoid longitudinal rib tube.The longitudinal rib tube is formed by integrating a base tube (1) and non-continuous longitudinal ribs (2) with the trapezoid cross sections, a plurality of fins (2) are evenly arranged on the peripheral direction of the base tube (1) in an aligned or staggered mode in the longitudinal direction, and the longitudinal ribs and the base tube are mechanically formed.Compared with a common continuous longitudinal rib tube, the non-continuous trapezoid longitudinal rib tube has the advantages that metal material consumption is low, and the cost is saved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

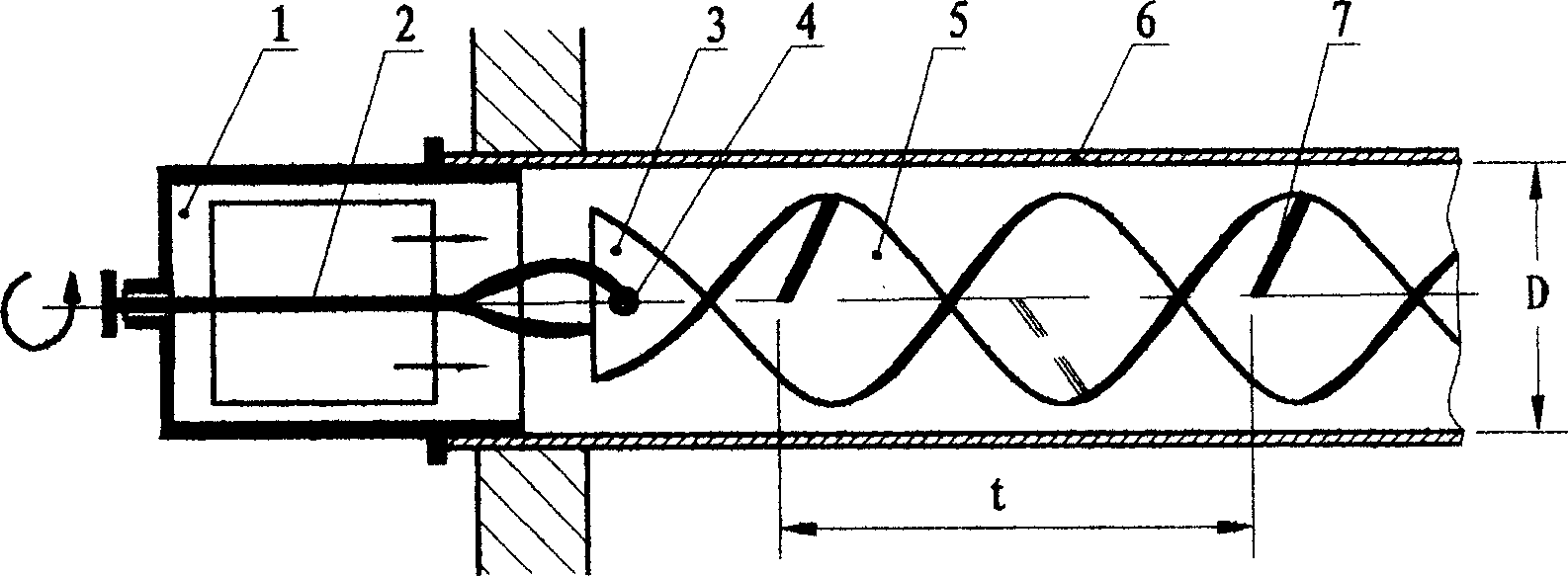

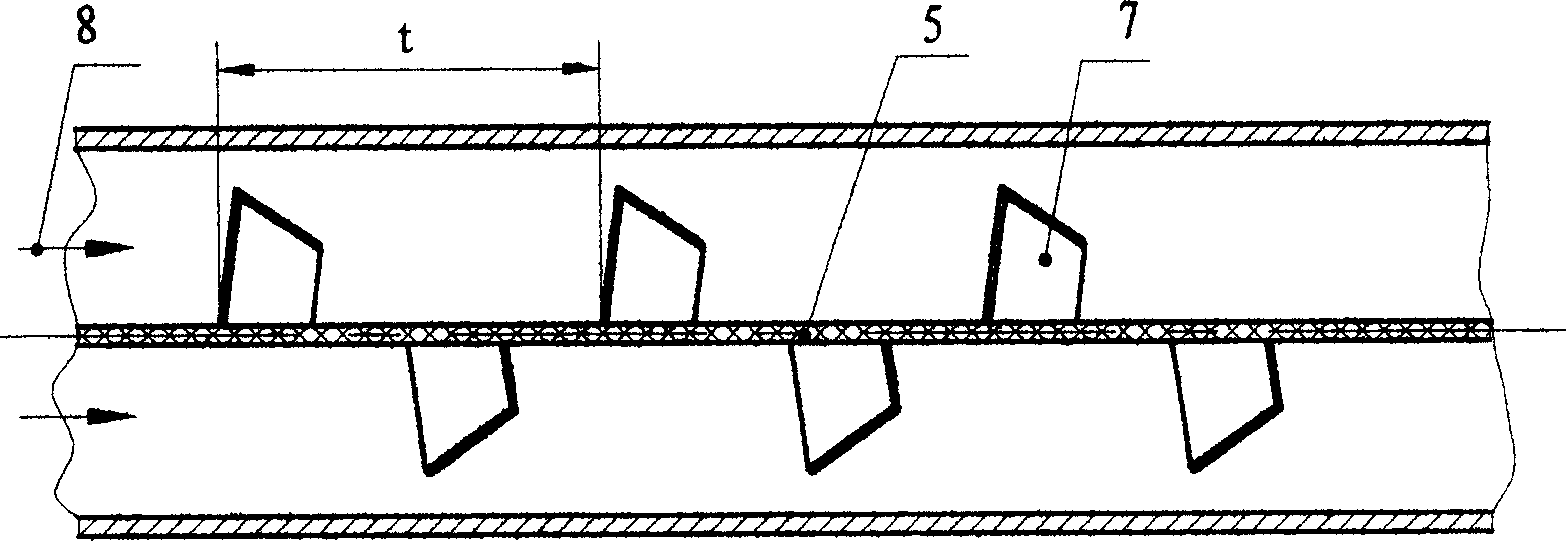

An inner tube spinning type purification and thermal conduction reinforced tooth shape twisting belt

InactiveCN1485596AImprove convective heat transfer coefficientRotary device cleaningHeat transmissionEngineering

A inner tube rotating type purification and heat transfer reinforcement notched belt, having the double functions of automatic purification and scale prevention and heat transmission reinforcement inthe heat transmission pipes, wherein reinforcement teeth are arranged on both sides of the spiral band at a finite distance, the counteracting force resulted by the guided liquid of the reinforcementteeth can increase the rotation cleaning torque by 277%. The invention can be widely used in the automatic purification and scale prevention for various type of low flow rate column tubes type heat transfer equipment.

Owner:株洲工学院帅科机械清洗研究所

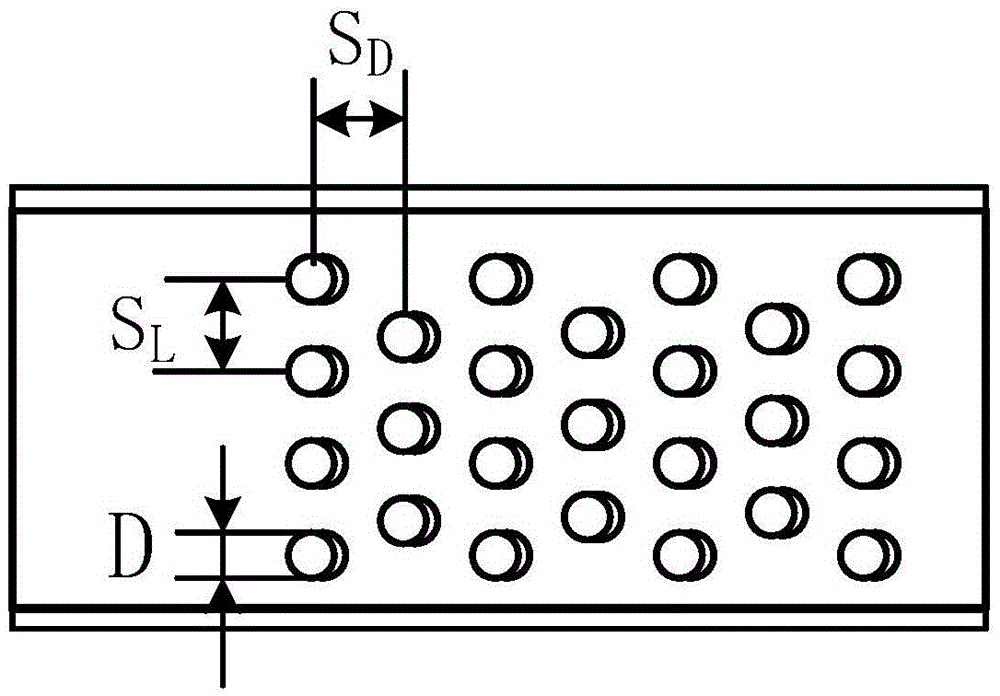

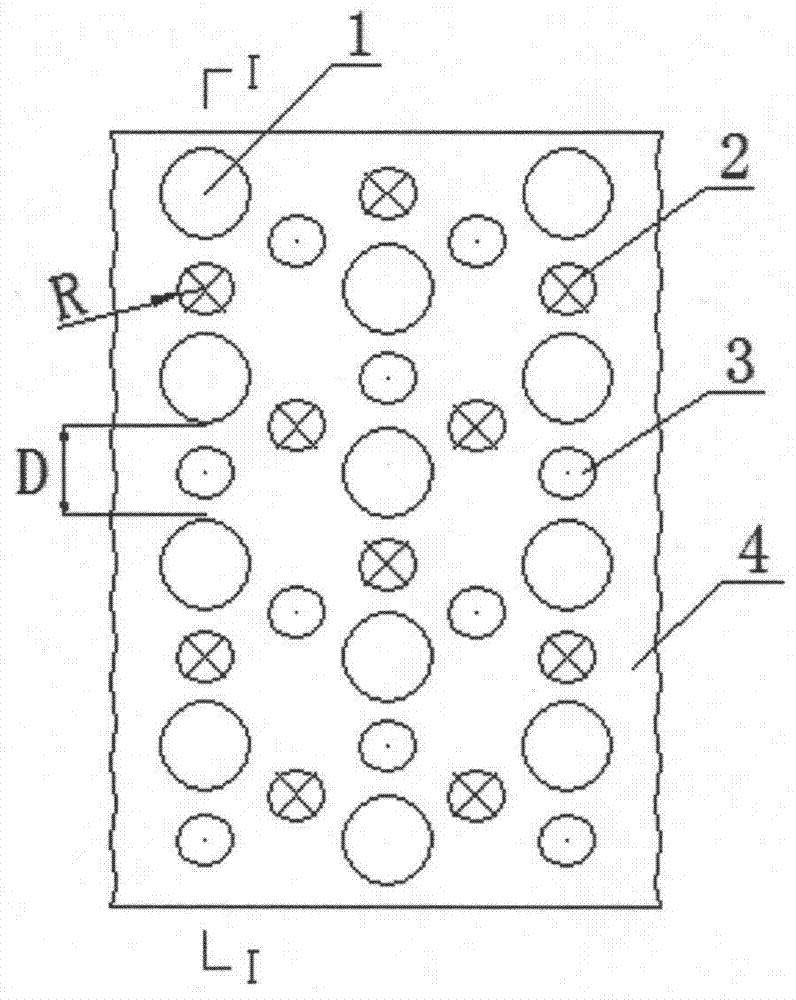

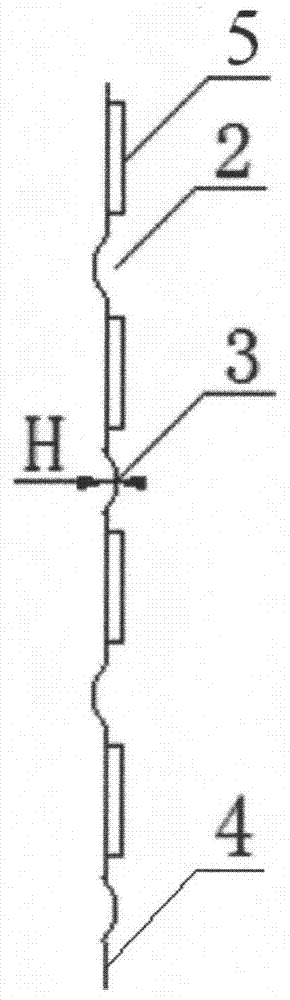

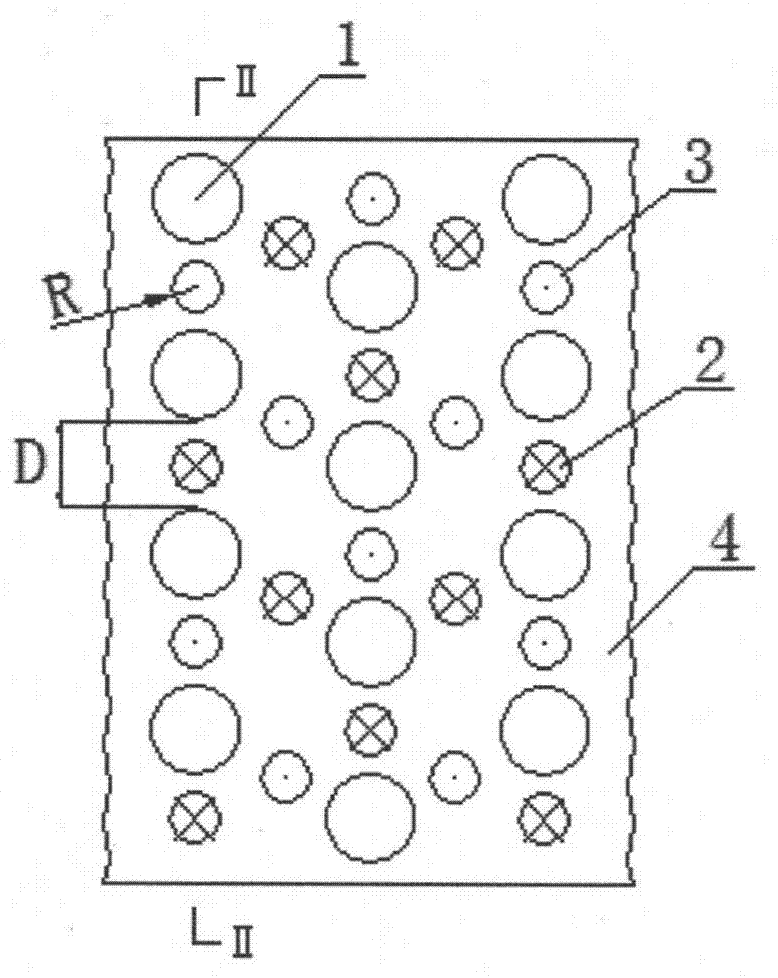

Radiating fin with spherical protrusions

InactiveCN103925828AIncreased turbulenceImprove convective heat transfer coefficientTubular elementsEngineeringHeat exchanger

The invention discloses a radiating fin with spherical protrusions. The radiating fin comprises a plate. A plurality of rows of pipe holes which are uniformly distributed are formed in the plate, each two adjacent rows of pipe holes are arranged in a staggered manner, and an outward step which is perpendicular to the fin is arranged at the edge of each pipe hole. The radiating fin is characterized in that the spherical protrusions which are uniformly distributed are further arranged on the plate, the pipe holes in each row and the corresponding spherical protrusions are arranged at intervals, and a row of corresponding spherical protrusions is arranged between each two corresponding rows of pipe holes. The radiating fin has the advantages that the structure and the shape of the fin are modified on the basis that the overall structure and raw materials of a heat exchanger are not changed, accordingly, a heat exchange coefficient can be increased, and influence of air layers which are formed at second defrosting stages on the defrosting efficiency can be reduced.

Owner:DONGHUA UNIV

Balanced heat dissipation liquid cooling system for power battery based on thermal shrinkage material and control method thereof

InactiveCN111864299ASmall temperature differenceSolve temperature buildupSecondary cells testingPower batteryThermal dilatation

The invention discloses a balanced heat dissipation liquid cooling system for a power battery based on a thermal shrinkage material and a control method of the balanced heat dissipation liquid coolingsystem. The thermal shrinkage material is mounted on the surface of the liquid cooling plate runner; the turbulence degree of cooling liquid flowing is increased; the lower part is in contact with aheat conduction block prepared from a high-heat-conduction silicon material; the heating sheet transmits heat to the thermal shrinkage material through the heat conduction block; the invention discloses a liquid cooling system. The controller controls the circulating flow of the cooling liquid and the power output of the heating sheet in real time according to the temperature information of the battery module; the heating sheet generates high temperature during working; through the thermal conduction of the thermal conduction block, the thermal shrinkable material above the thermal conductionblock is heated to expand and deform; the rapid reduction of the maximum temperature and the maximum temperature difference between the modules and in a single module is realized; meanwhile, the controller can adjust the output power of each heating piece in real time according to the temperature information of the module, the temperature balance in the cooling process is achieved, the heat dissipation rapidity of the power battery is improved, the temperature rise and the temperature difference of the battery module are effectively controlled, the use performance of the battery is improved, and the service life of the battery is prolonged.

Owner:JIANGSU UNIV

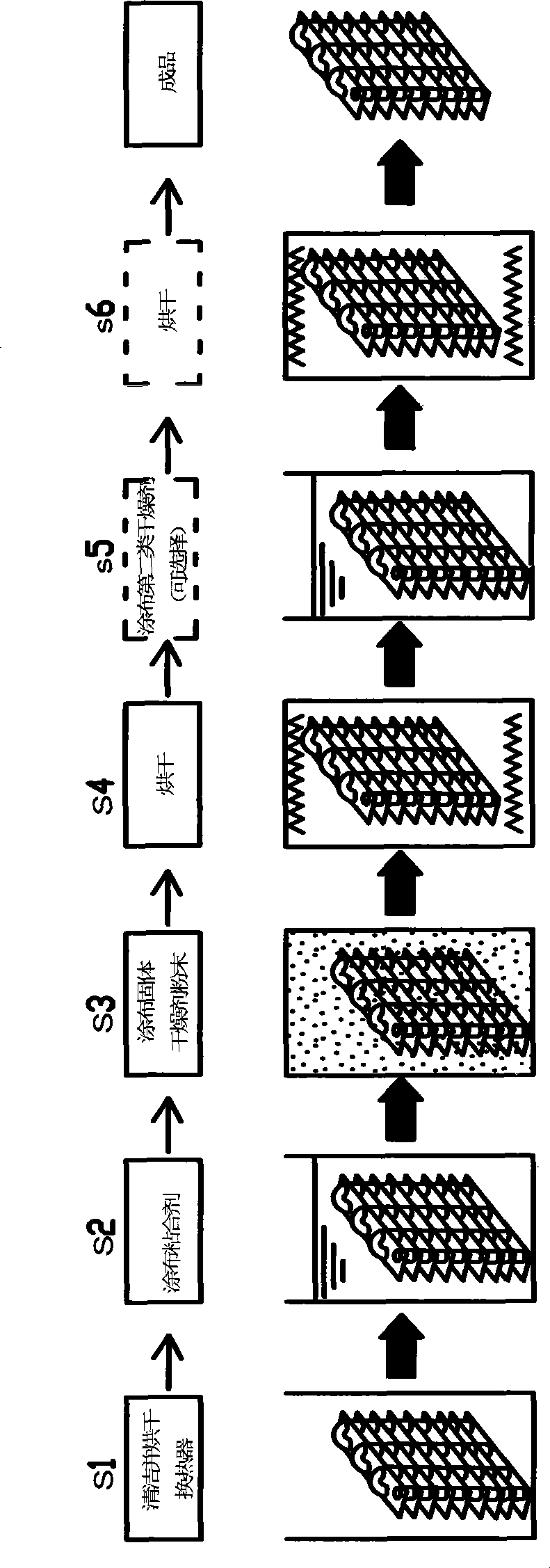

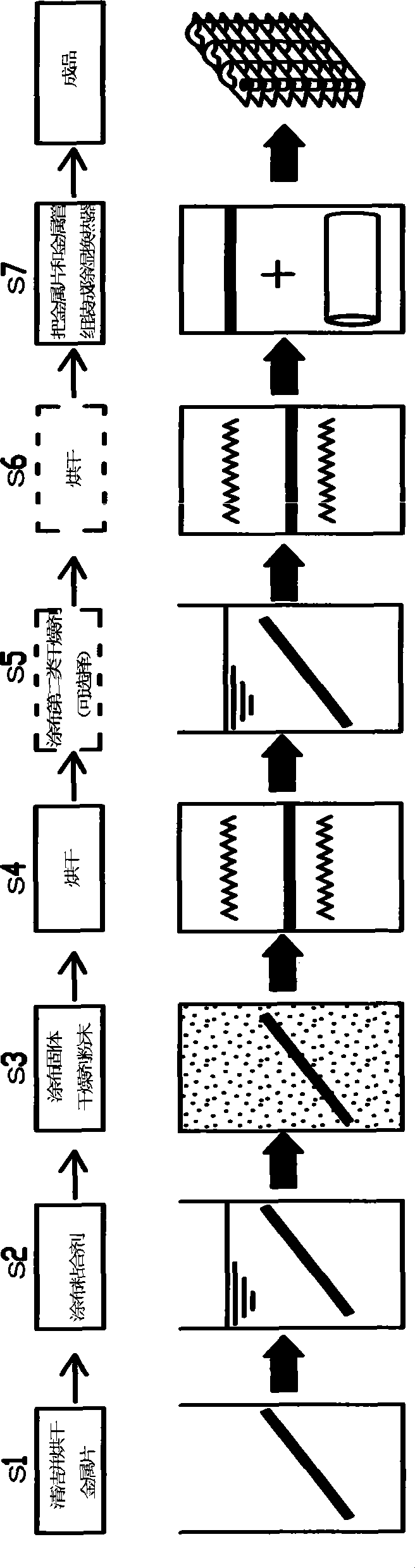

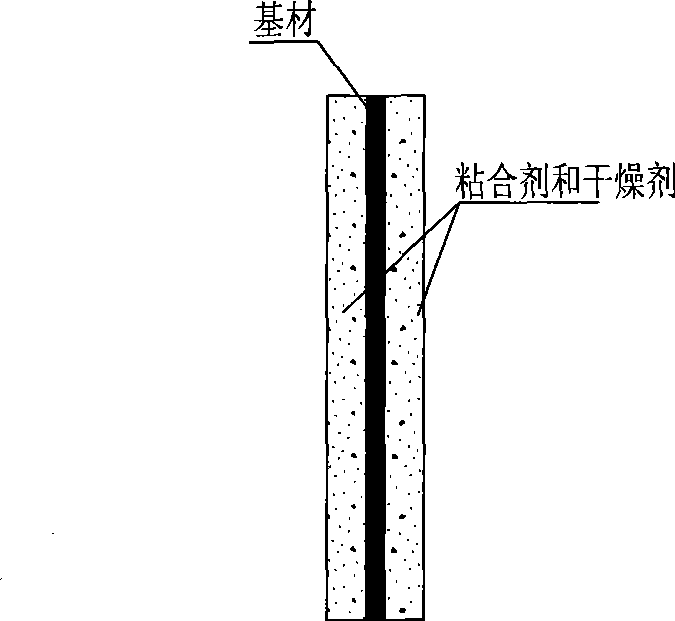

Regenerative dehumidifying heat exchanger and its production method

InactiveCN101464075AImprove utilization efficiencyImprove qualityLiquid surface applicatorsEvaporators/condensersDesiccantEngineering

Owner:SHANGHAI JIAO TONG UNIV

Efficient gas cooking appliance with backheating function

ActiveCN102788371AGuaranteed qualityImprove heat transfer performanceDomestic stoves or rangesLighting and heating apparatusProcess engineeringHot Temperature

The invention relates to an efficient gas cooking appliance with a backheating function. The efficient gas cooking appliance comprises a combustion area, an envelope heat exchange area and a pot placing area. A cooking pot is placed in the pot placing area, the envelop heat exchange area is positioned on the outer side of the combustion area, and the pot placing area is arranged above the combustion area and the envelop heat exchange area. The envelop heat exchange area comprises a radiation cross-flow heat exchanger, a heat exchanger with double fluid channels and a high-position smoke outlet, and high-temperature smoke of a cooking range is guided by the radiation cross-flow heat exchanger, the heat exchanger with the double fluid channels and the high-position smoke outlet jointly so as to flow close to the bottom of the cooking pot. Accordingly, a forced flowing channel of the high-temperature smoke is formed, heat exchange between the high-temperature smoke and the bottom of the cooking pot is promoted, heat exchange is realized between medium-temperature smoke which is cooled after heat exchange of the bottom of the cooking pot and low-temperature combustion-supporting air which is supplemented into the cooking range, a backheating mechanism of the smoke is formed, high-temperature radiation of the high-temperature smoke to an environment and diffusion of the smoke in the environment are reduced, the temperature of the combustion-supporting air is increased, the temperature of the high-temperature smoke of the cooking range is also increased, and technical problems of low heat efficiency and severe environmental pollution of an existing gas cooking appliance are solved.

Owner:广州万二二麦工程技术有限公司

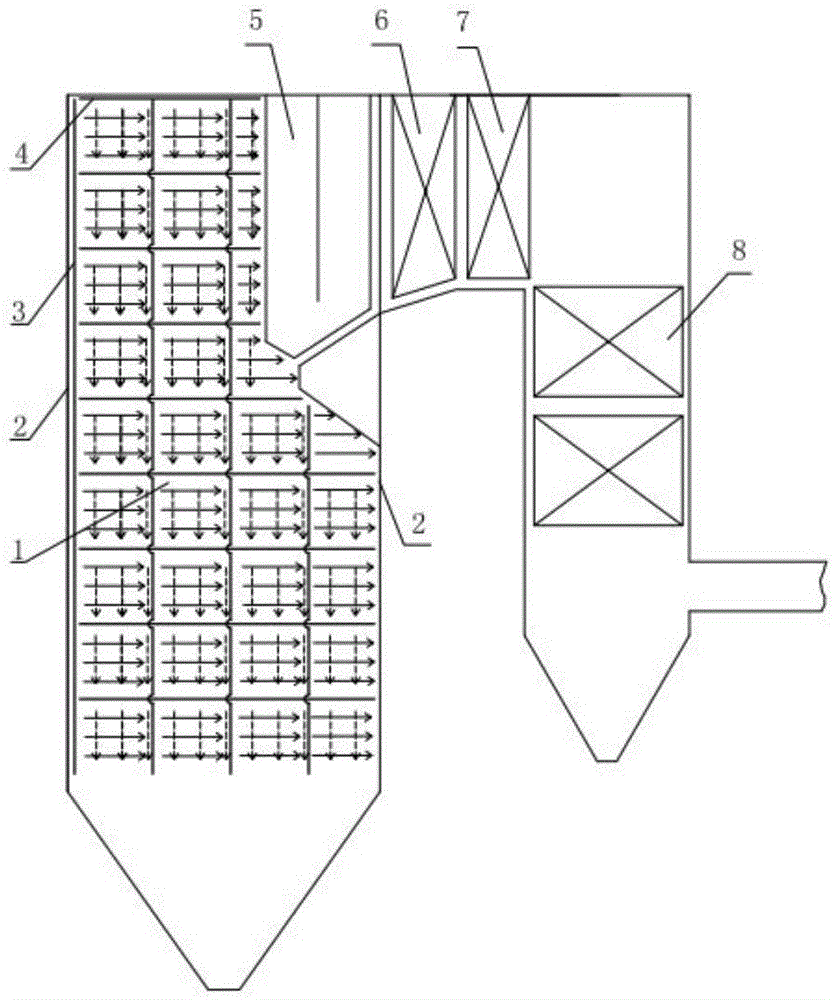

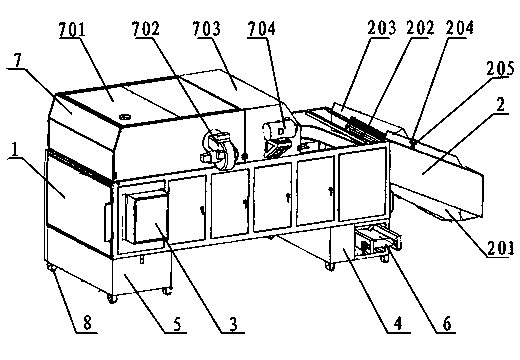

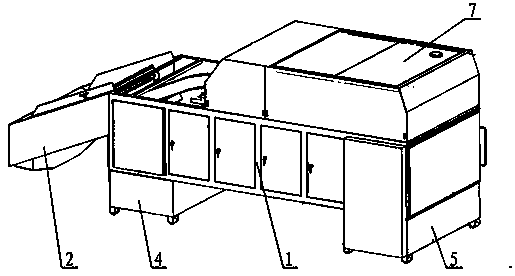

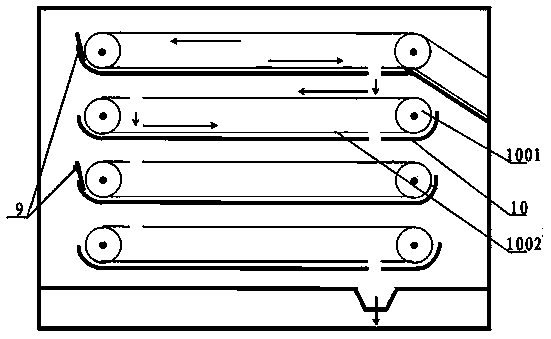

Oil-fired tea dryer

ActiveCN104034140AImprove precise controlSimple structurePre-extraction tea treatmentDrying gas arrangementsControl systemEngineering

The invention belongs to the technical field of tea processing machinery and provides an oil-fired tea dryer. The oil-fired tea dryer comprises a dryer box body, a hot air generating system, a tea feeding system and a tea discharging system, wherein the hot air generating system is arranged above the dryer box body and is communicated with the dryer box body, the tea feeding system is arranged on one side of the dryer box body, and the tea discharging system is arranged at the bottom of the dryer box body. A tea conveying system is arranged in the dryer box body. The tea conveying system comprises at least two conveying layers. The feeding end of the tea conveying system is matched with the tea feeding system. The discharging end of the tea conveying system is matched with the tea discharging system. The hot air generating system, the tea feeding system, the tea discharging system and the tea conveying system are controlled by a control system which is arranged on the dryer box body. According to the oil-fired tea dryer, the structure of the dryer box body is optimized, the path through which hot air enters the dryer box body is shortened, the inner ventilation of the box body is improved, convective heat transfer coefficient is increased through layered conveyance and air intake, and energy loss is reduced.

Owner:宁波市姚江源机械有限公司

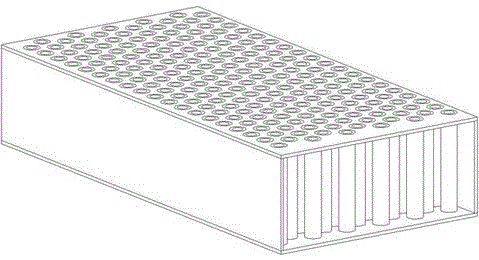

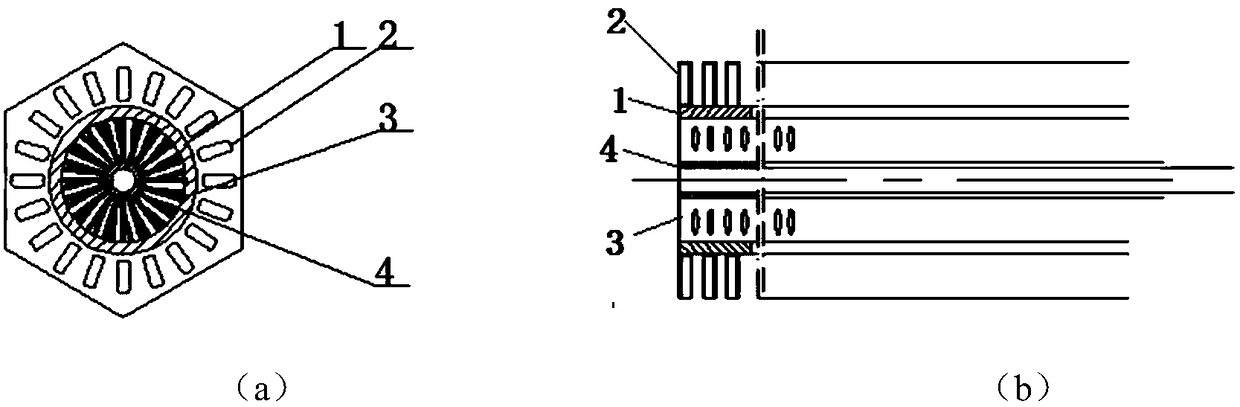

Compact type gas-gas heat exchange tube and manufacturing and use methods thereof

PendingCN109059601ARealize complete countercurrent heat exchangeFull turbulenceStationary tubular conduit assembliesHeat transfer modificationEngineeringTemperature difference

The invention provides a compact type gas-gas heat exchange tube which comprises a heat transfer tube, an inner fin set and an outer fin set. The heat transfer tube is used for separating fluid insideand outside the tube and transferring heat between the fluid inside and outside the tube in a convection heat conduction mode; the inner fin set is used for expanding the inside heat exchange surfaceof the heat transfer tube, forming miniature fluid channels, separating the fluid in the tube, making the fluid flow in the axial direction of the heat transfer tube and meanwhile generating a turbulent flow effect and enhancing a convection heat exchange effect; the outer fin set is used for expanding the outside heat exchange surface of the heat transfer tube, forming miniature fluid channels,restraining the fluid outside the tube to reversely flow in the axial direction of the heat transfer tube and meanwhile generating the turbulent flow effect and enhancing the convection heat exchangeeffect; and holes are formed in fins of the inner fin set or / and the outer fin set. The invention further provides manufacturing and use methods of the compact type gas-gas heat exchange tube. Complete reverse flow efficient heat transfer is achieved under the heat exchange working condition of the limited space and the small tube number average temperature difference, the equipment spatial size is reduced, and meanwhile the weight of each area is reduced, so that the total weight and the manufacturing cost are reduced.

Owner:SHANGHAI POWER EQUIP RES INST

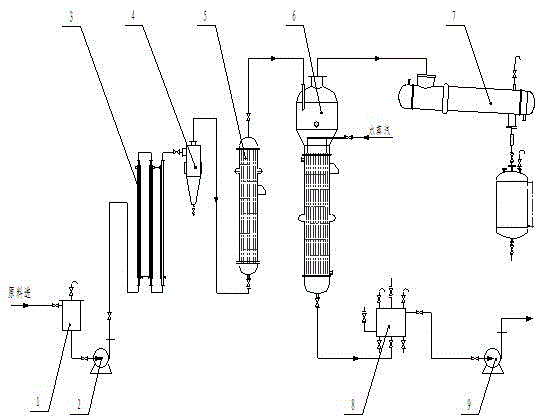

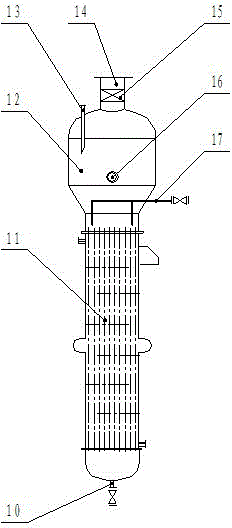

Method and apparatus for continuously and rapidly separating pyrolysis oil

InactiveCN102827633BAlleviate cokingPrevent static electricityTreatment with plural serial refining stagesLiquid hydrocarbon mixture productionWaste rubberProcess engineering

The invention discloses a method and an apparatus for continuously and rapidly separating a pyrolysis oil, which is characterized in that a waste rubber, a waste plastic or the pyrolysis oil generated by thermal cracking of biomass is filtered and enters into a first preheater, the preheated pyrolysis oil enters into a cyclone hydraulic separator in a tangential direction, and enables spiral movement downwardly, the impurities spirally flow downwards to an outlet of a cone base due to inertial centrifugal force, the pyrolysis oil is discharged from a center tube at the top and enters into a second preheater for heating, then enters into an evaporator, the certain temperature is kept in the evaporator, steam is continuously introduced in the evaporator, the steam carries the distilled components enter into a condenser from the top of the evaporator together for condensate recovery, and the heavy components are sent from the bottom of the evaporator and cooled to obtain the finished product. The apparatus comprises a filter, a charge pump, the first preheater, the cyclone hydraulic separator, the second preheater, the evaporator in series, the top of the evaporator is connected to the condenser, the bottom of the evaporator is connected to a cooler. The method and apparatus for continuously and rapidly separating the pyrolysis oil have the advantages of high automation degree, and convenient and easy operation.

Owner:JIANGSU QIANGLIN BIO ENERGY +1

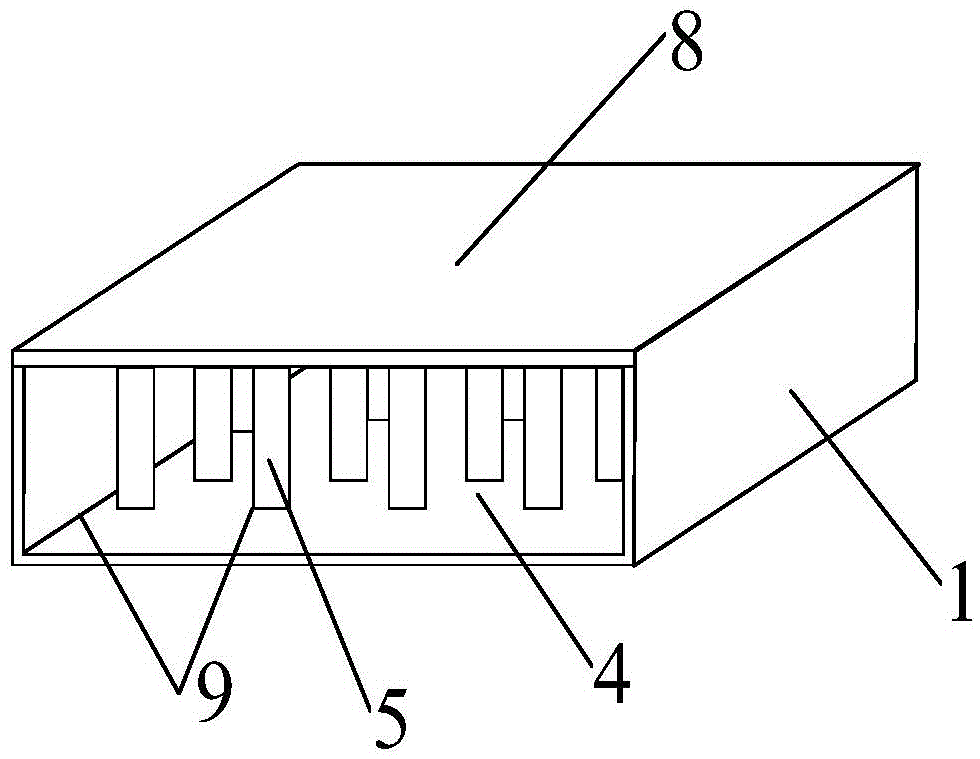

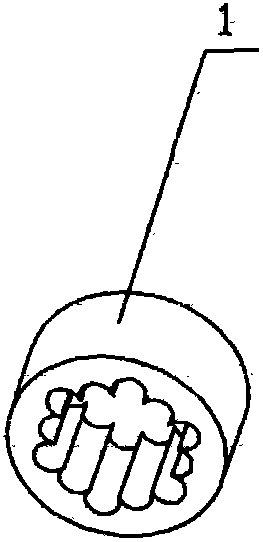

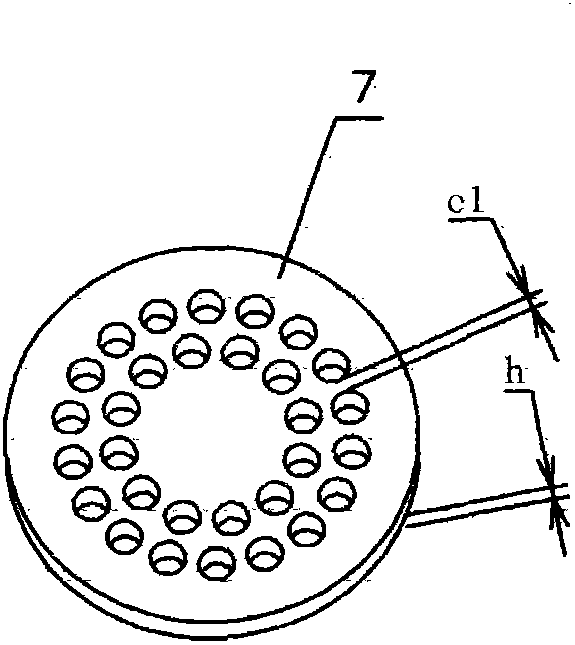

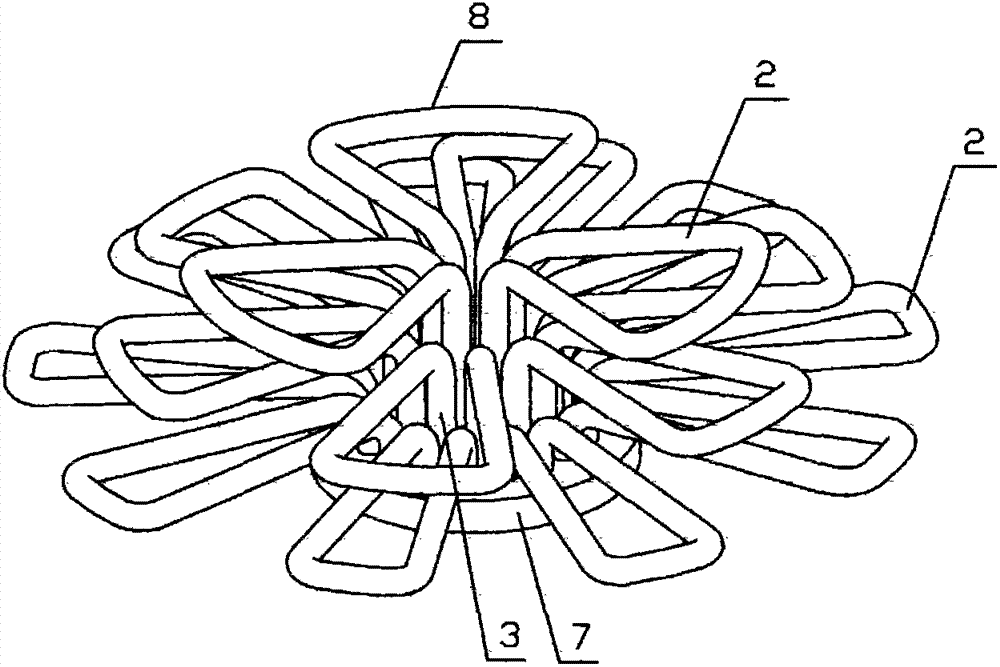

Rib-line-type radiator and manufacturing method

InactiveCN103199066ASmall heightLarge transfer heat transfer areaSemiconductor/solid-state device detailsLighting heating/cooling arrangementsEngineeringSemiconductor

The invention provides a rib-line-type radiator and a manufacturing method. The rib-line-type radiator is characterized by comprising rib lines (8) and a heat conduction fixed plate (7) or a ring-shrouding cover (1). Rib foot ends (3) of a plurality of rib lines (8) are inserted in a hole of the heat conduction fixed plate (7), and the sections of the rib foot ends (3) of the plurality of rib lines (8) are connected in a welding mode or the sections of the rib foot ends (3) of the plurality of rib lines (8) are tighten to a bundle, and the ring-shrouding cover (1) is covered outside the bundle, and then the ring-shrouding cover (1) is crimpled through a crimpling jig technology, and at last, a heat transfer contact surface (5) of the radiator is processed through turning or grinding until all end surfaces (4) of the rib feet and the bottom surface of the heat conduction fixed plate (7) or the bottom end surface of the ring-shrouding cover (1) is neat and smooth. The rib-line-type radiator is high in heat dispersion, simple in production technology, high in material using rate, and has an unprecedented significance in pushing forward with and popularizing a present semiconductor solid state lighting technology with high heat dissipation costs.

Owner:深圳市核创新新能源科技有限公司

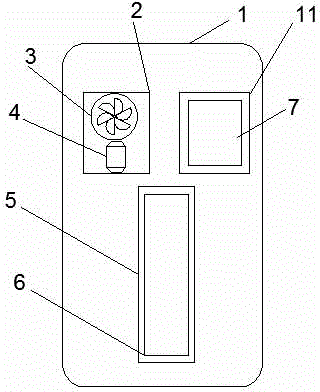

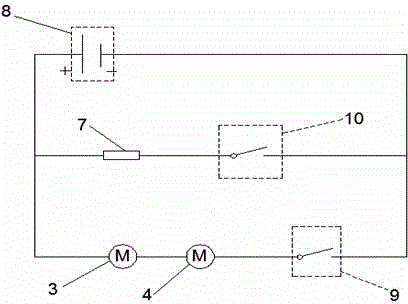

Heat radiation mobile phone shell

InactiveCN104902042AImprove cooling effectImprove your own performanceTelephone set constructionsSemiconductor materialsEngineering

The invention discloses a heat radiation mobile phone shell, including a shell. An energy source part and a refrigeration part are arranged on an outer surface of the shell, the energy source part includes a battery, the refrigeration part includes a semiconductor refrigeration unit and a fan refrigeration unit which are connected in parallel at two ends of the battery, the semiconductor refrigeration unit includes a switch and a semiconductor refrigeration sheet which is formed by joining an N type semiconductor material and a P type semiconductor material, and the fan refrigeration unit includes a fan, a motor and a switch. Compared with the prior art, a heat radiation method of the heat radiation mobile phone shell effectively relieves heat generation of a mobile phone, thereby preventing damage of the mobile phone battery, reduction of the life of the battery and damage of a CPU due to overtemperature, and improving use comfortableness.

Owner:SOUTHEAST UNIV

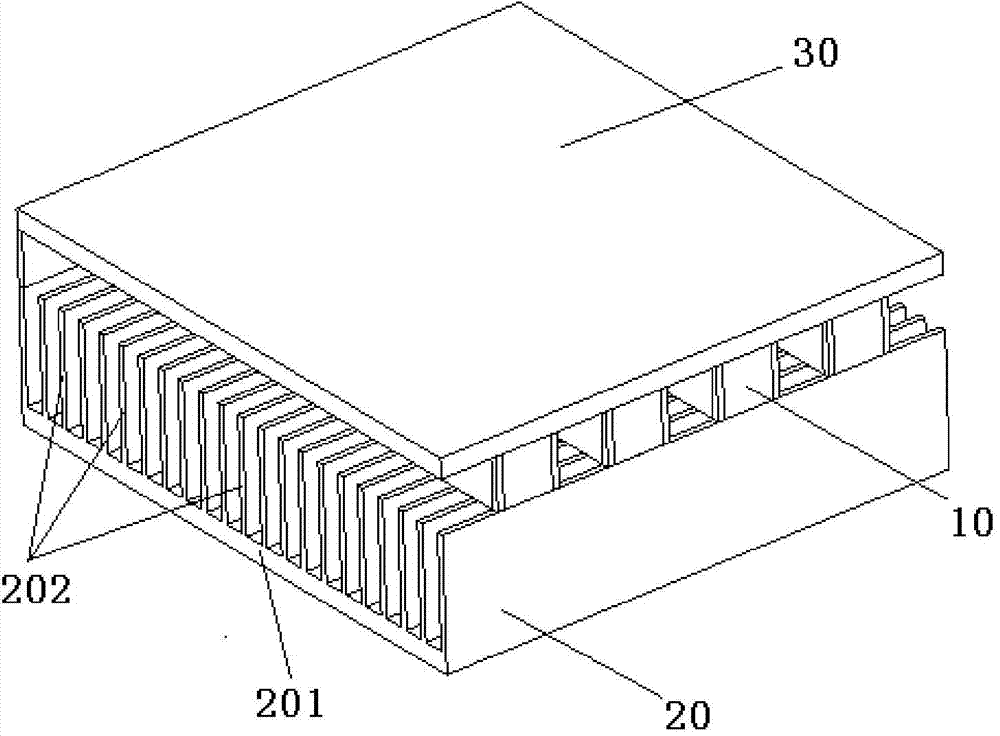

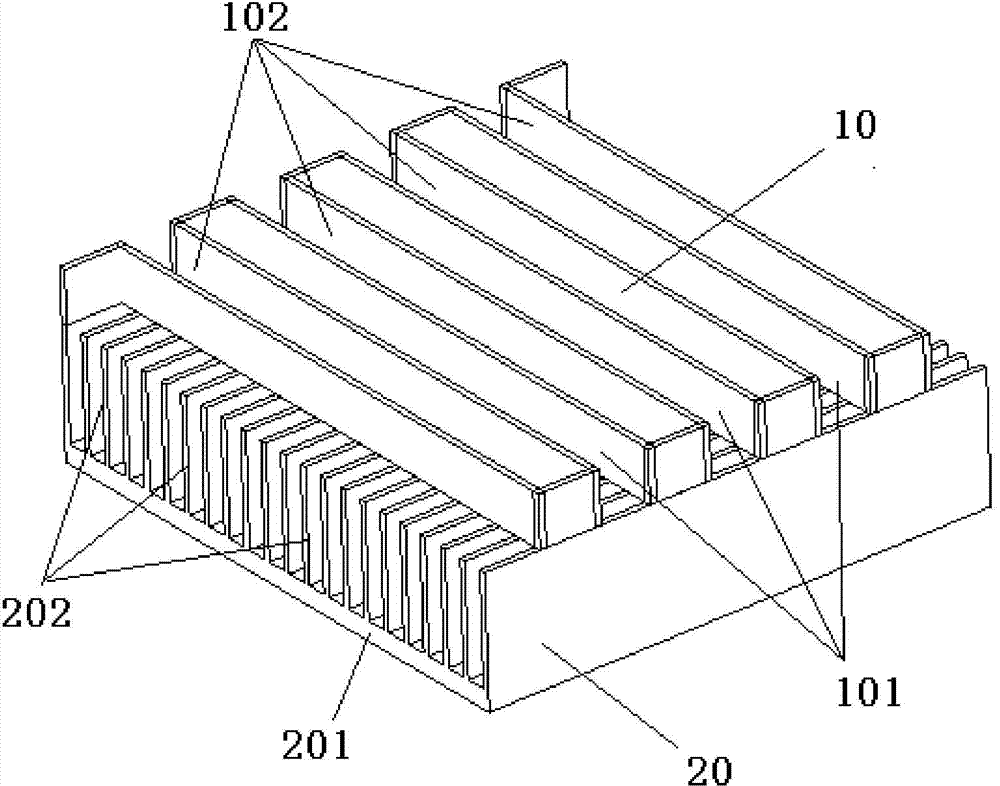

Radiator and radiator group

ActiveCN104752374ARealize the heat dissipation functionImprove convective heat transfer coefficientSemiconductor/solid-state device detailsSolid-state devicesInlet channelEngineering

The embodiment of the invention discloses a radiator. An air guide cover is arranged to be vertical to a first micro channel, and a baffle is arranged above the air guide cover. The air guide cover comprises at least one air inlet channel and at least one air outlet channel, and the air inlet channels and the air outlet channels are arranged adjacent to each other and at intervals. The first micro channel comprises a bottom plate and at least two fins, the fins are erected on the bottom plate in parallel, and two adjacent fins form a radiating channel. The air inlet channels and the air outlet channels of the air guide cover and the radiating channels of the first micro channel perpendicularly intersect in arrangement. The embodiment of the invention further discloses a radiator group. According to the embodiment of the invention, the radiating capability per unit volume of the radiator can be improved, and the air-cooling radiating problem of a high-power-consumption chip can be solved.

Owner:河北永洋特钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com