Outer fin heat exchange tube and application method thereof

A technology of external fins and heat exchange tubes, applied in the field of high-efficiency and compact heat exchangers, to achieve the effect of variable cross-section design, optimized performance and manufacturing cost, and heat transfer with small temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

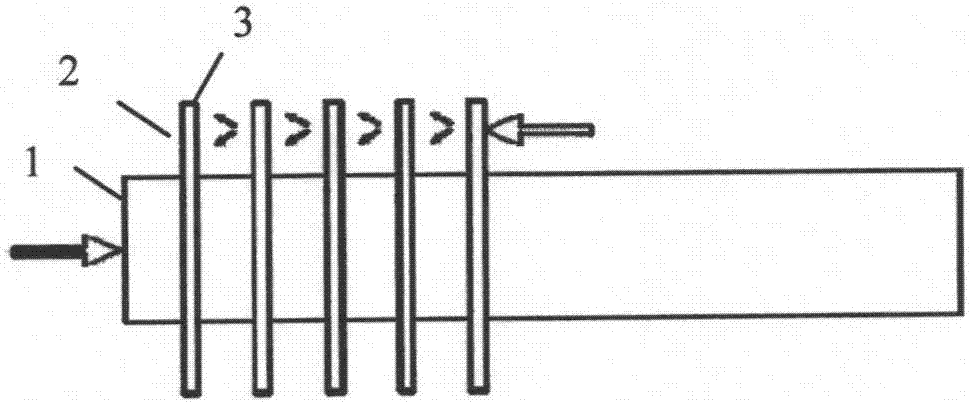

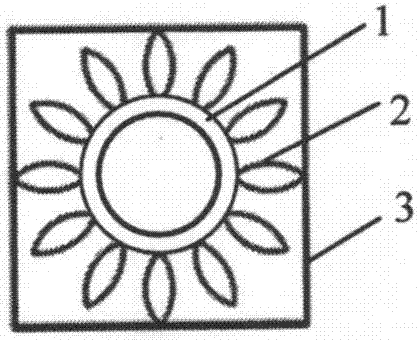

[0040] figure 1 The schematic diagram of the front view of the outer fin heat exchange tube provided in this embodiment, the outer fin heat exchange tube is composed of the following components:

[0041] The heat transfer tube 1 is used to separate the two fluids inside and outside the tube, and realize heat transfer mainly through convection and conduction;

[0042] The outer fin group 2 is used to expand the outer heat exchange surface of the heat transfer tube 1 to form a micro flow channel, restrict the counterflow of the fluid outside the tube along the axial direction of the heat transfer tube 1, and generate a disturbance effect at the same time;

[0043] The outer fin group frame 3 is used to reduce the lateral flow of the fluid outside the heat transfer tube 1 .

[0044] The outer wall of the heat transfer tube 1 is connected with a plurality of outer fin groups 2, and the plurality of outer fin groups 2 are arranged axially along the heat transfer tube 1; the outer ...

Embodiment 2

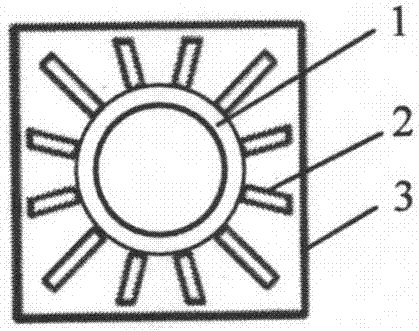

[0050] This embodiment is substantially the same as Embodiment 1, the difference being that the outer fin group 2 is a hollow rectangular frame structure formed of metal sheets or thin strips. A plurality of outer fin groups 2 are arranged around the heat transfer tube 1, and the surface of the outer fin group 2 is parallel to the axial direction of the heat transfer tube to form a symmetrical structure, such as image 3 shown.

Embodiment 3

[0052] This embodiment is substantially the same as Embodiment 1, the difference being that the outer fin group 2 is made of thin metal sheets or thin strips, forming a strip structure in which multiple hollow rings are sequentially connected. A plurality of outer fin groups 2 are arranged around the heat transfer tube 1, and the surface of the outer fin group 2 is parallel to the axial direction of the heat transfer tube to form a symmetrical structure, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com