Patents

Literature

255results about How to "Change area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

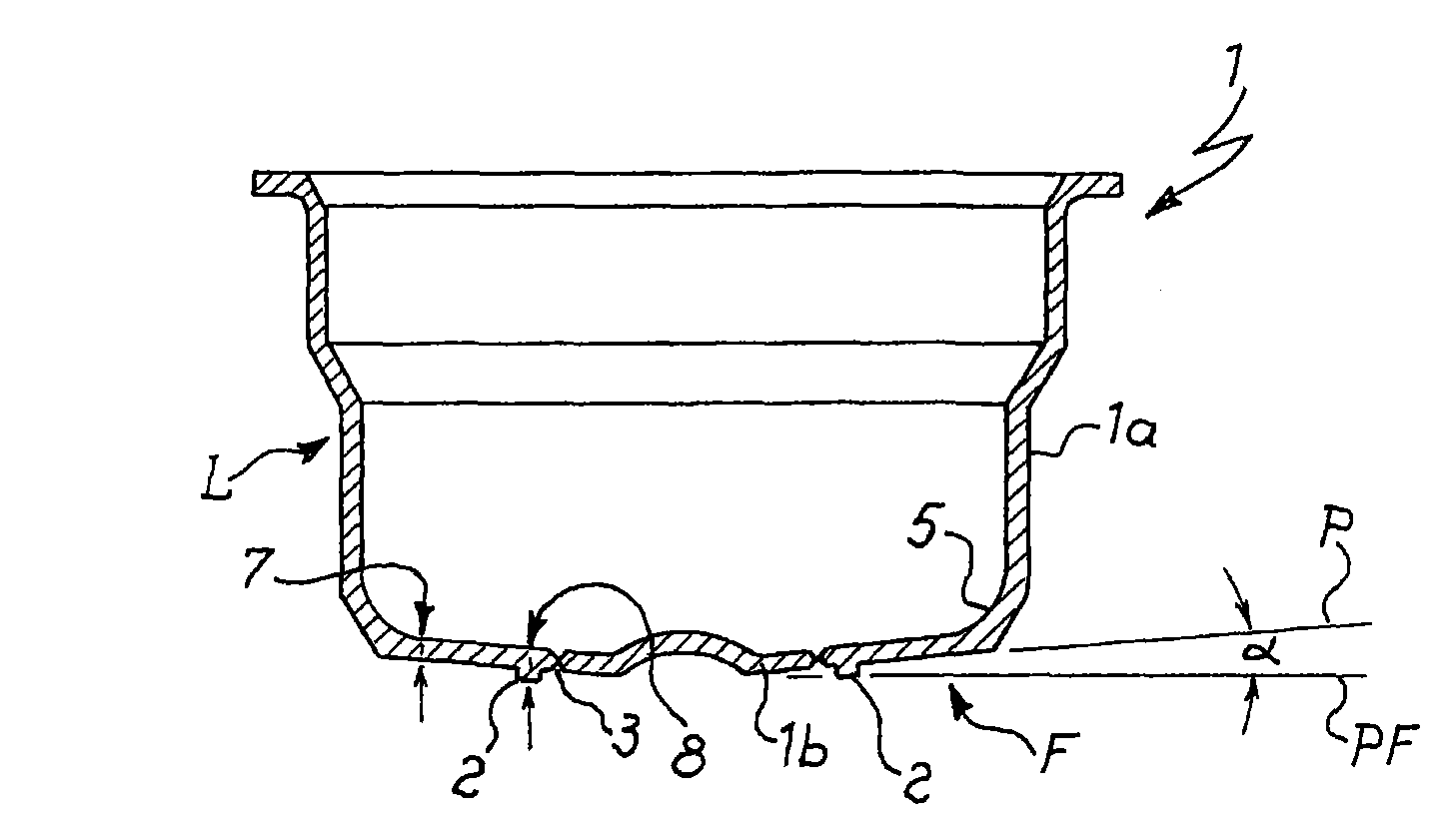

Process and capsule for preparing beverages

InactiveUS20090175986A1Obtain elasticityReduce pressureTea extractionTea substituesEngineeringBiomedical engineering

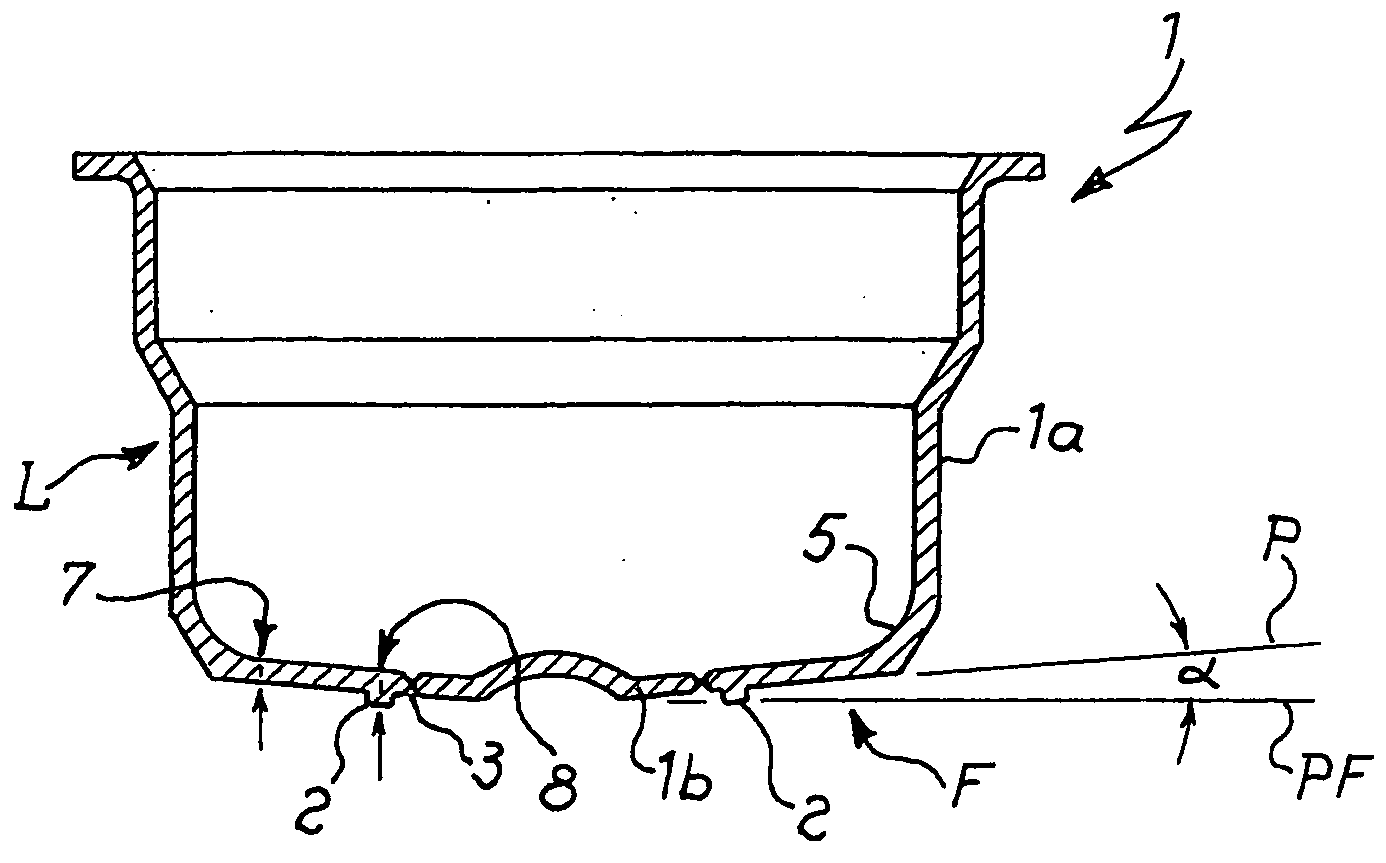

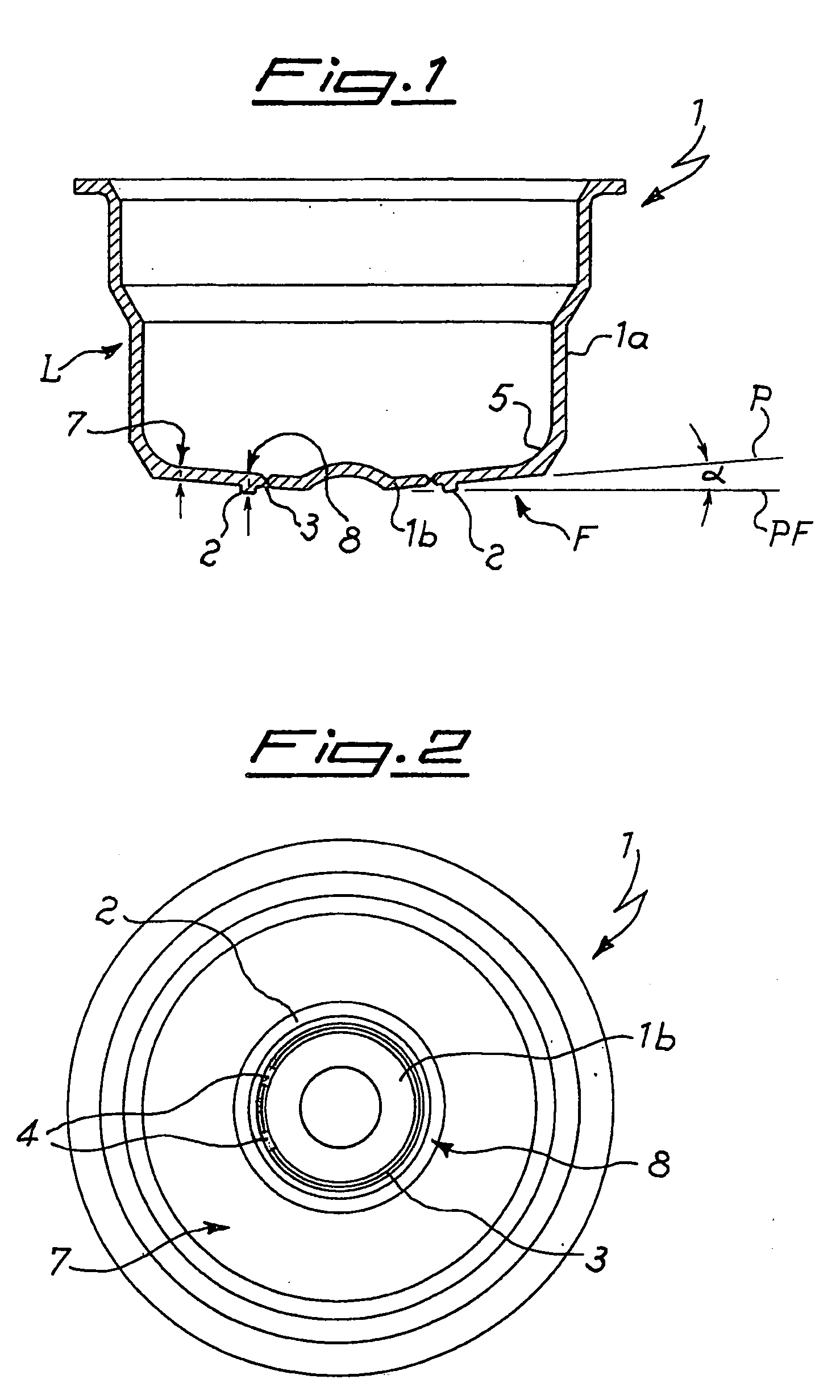

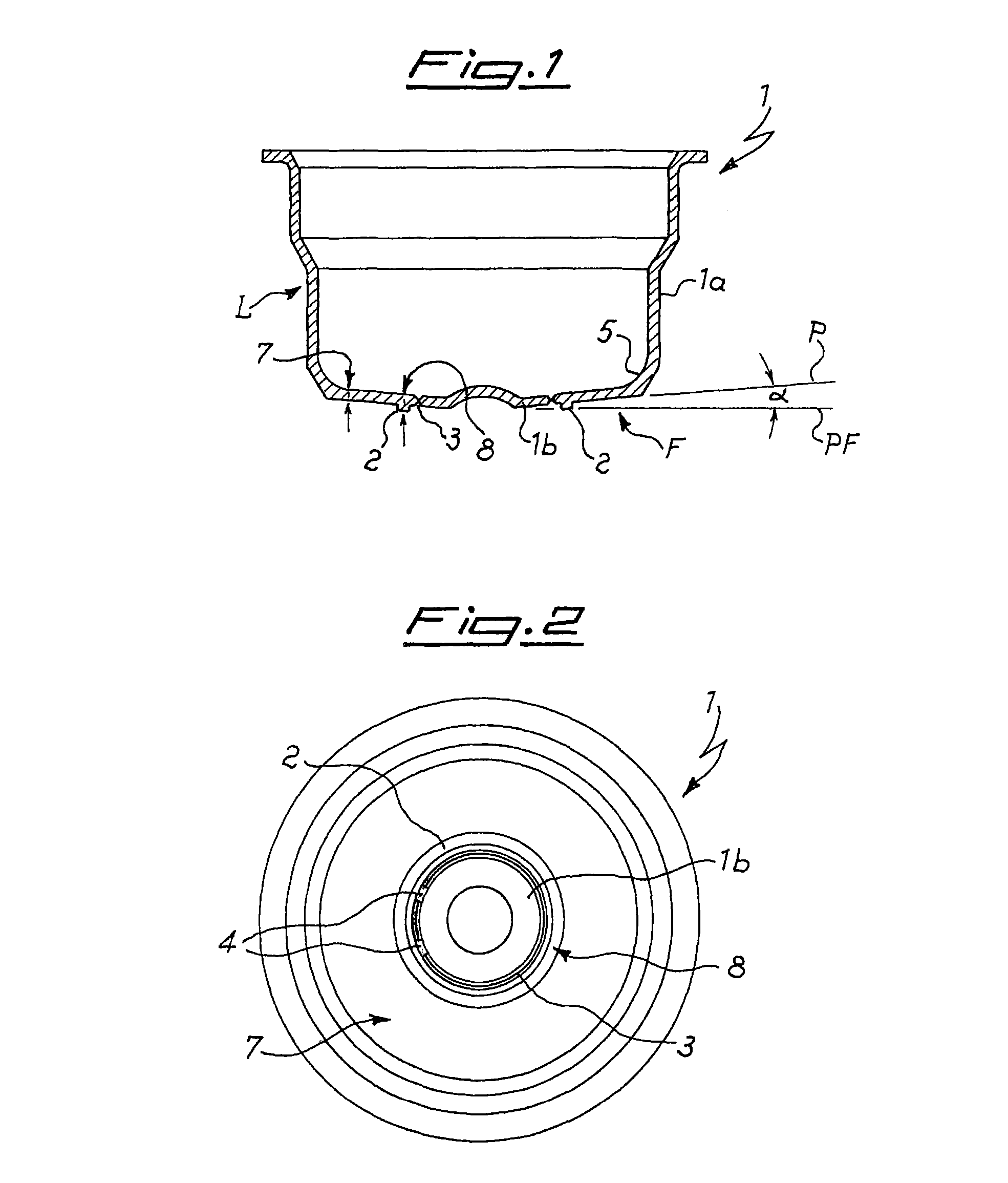

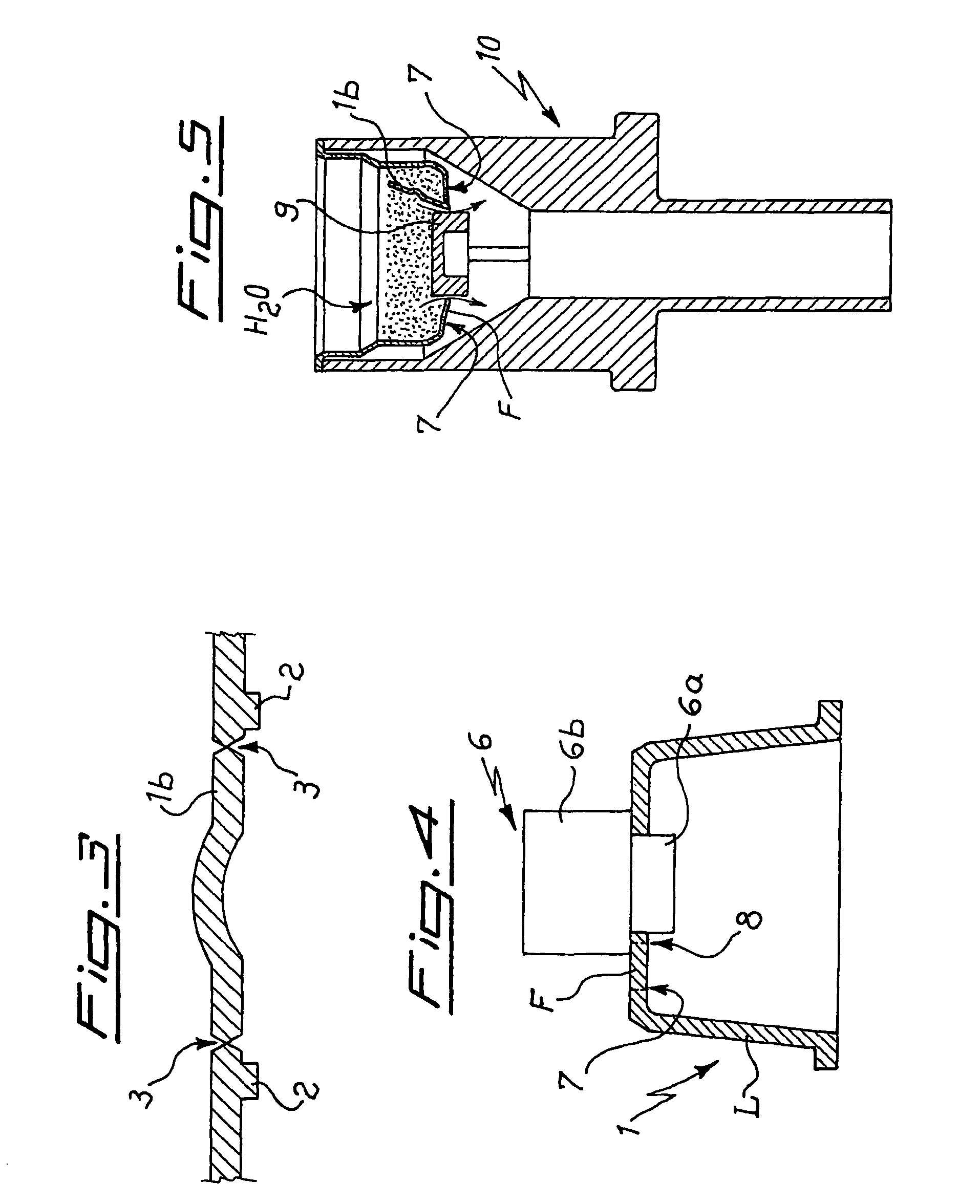

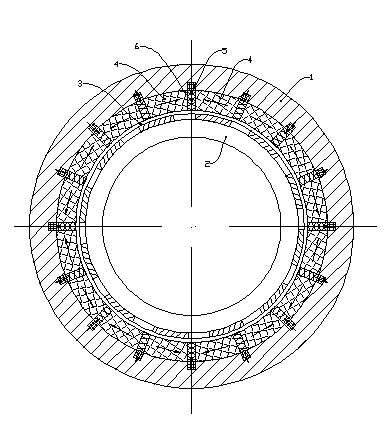

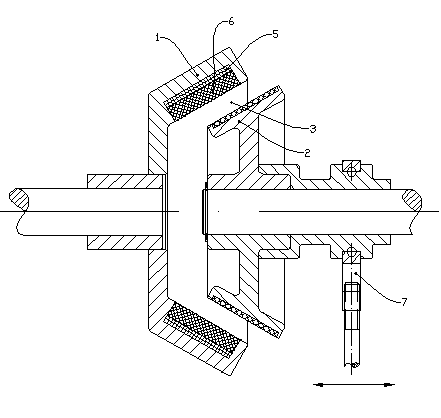

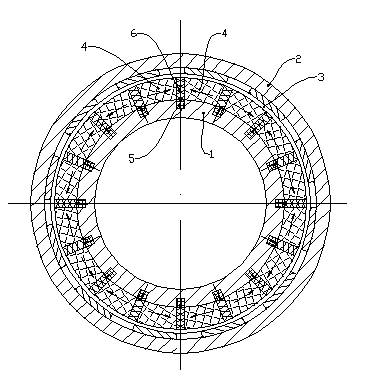

A single serve capsule (1) for the preparation of hot beverages such as coffee, cappuccino, tea or the like from soluble or ground preparations, having an outlet lid portion (1b) located on a dispensing wall (F) in order to form a dispensing opening (11) after a liquid has been introduced into the capsule, as well as means for changing the area of said dispensing opening during the dispensing step of the beverage.

Owner:TUTTOESPRESSO SPA (IT)

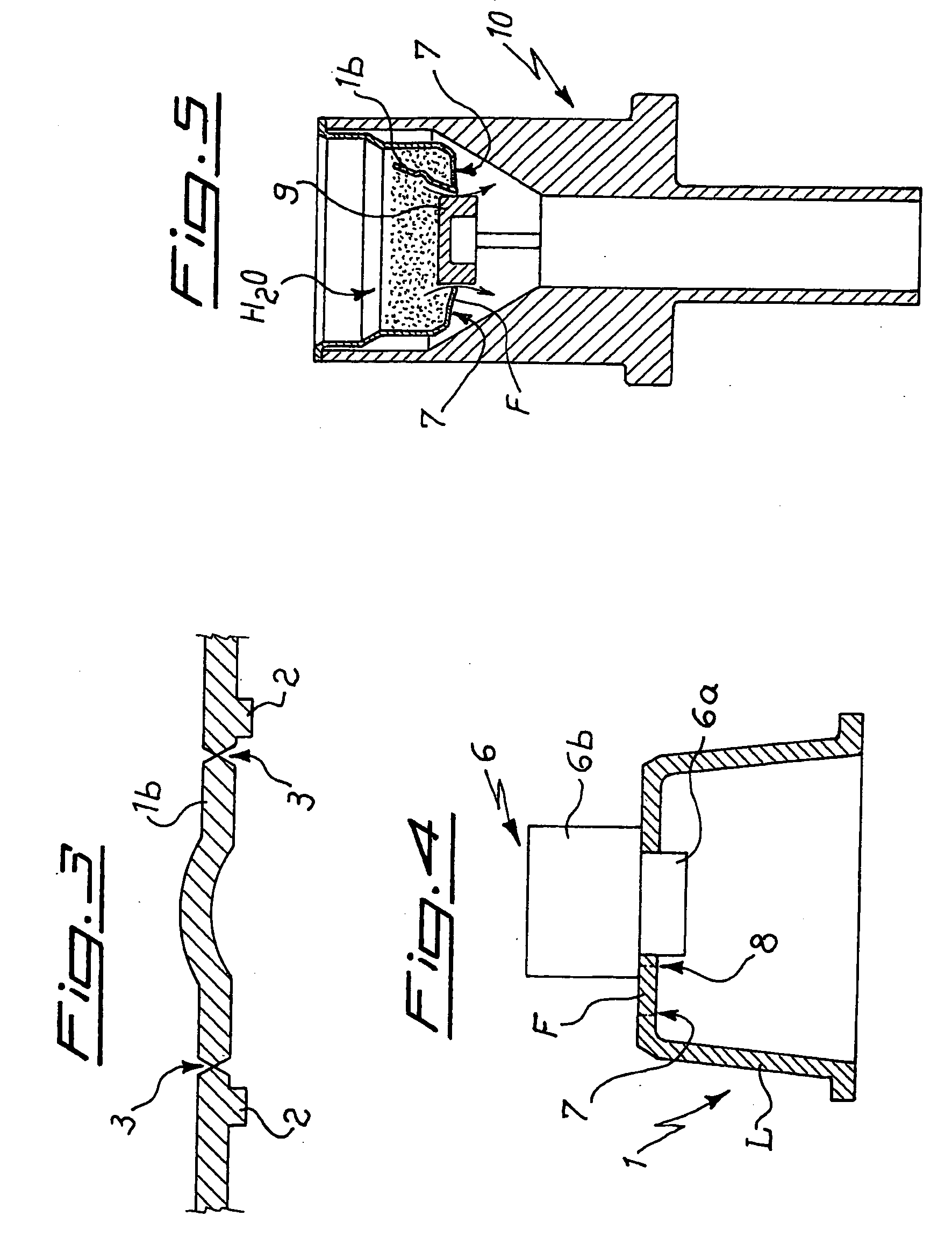

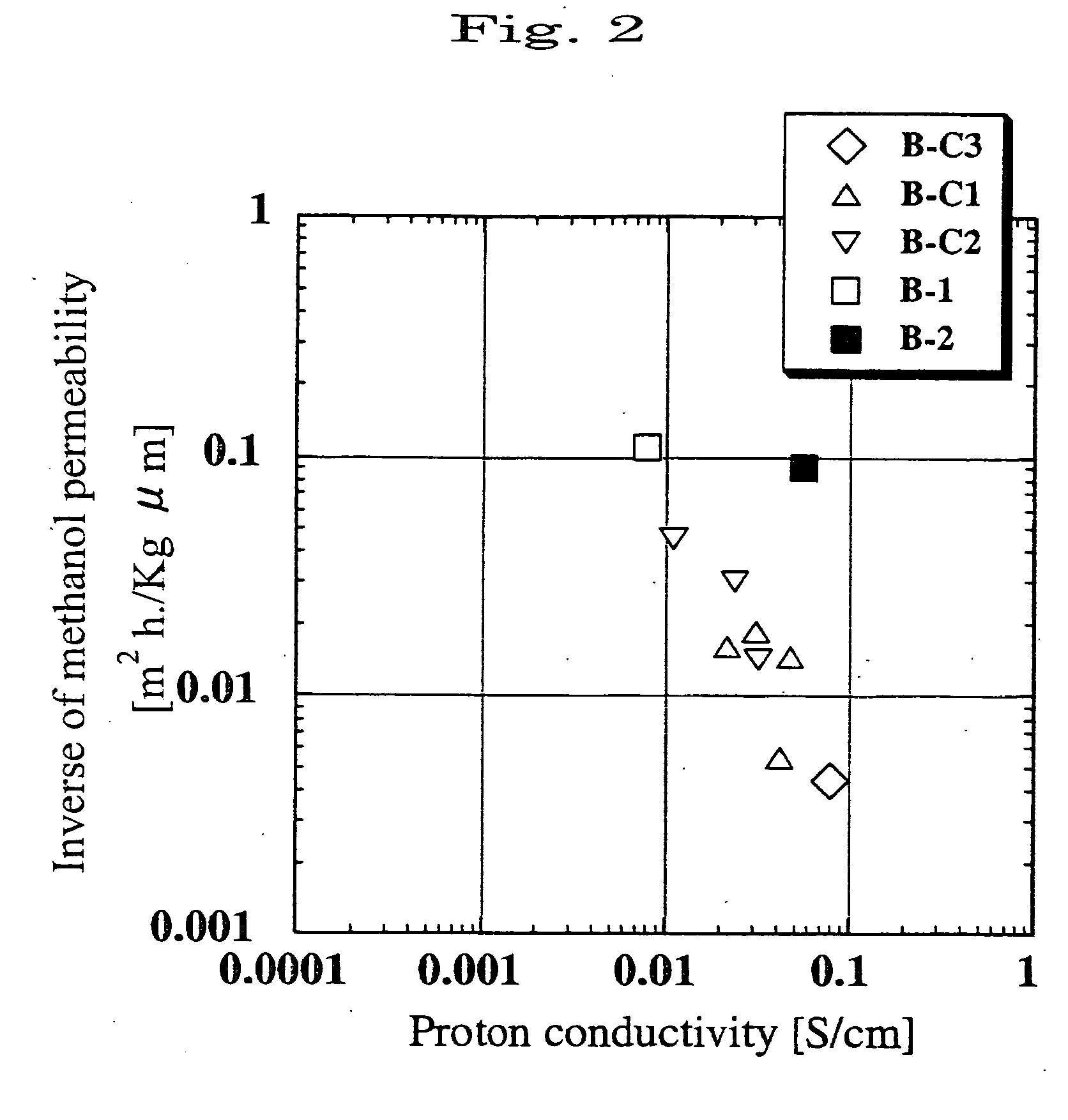

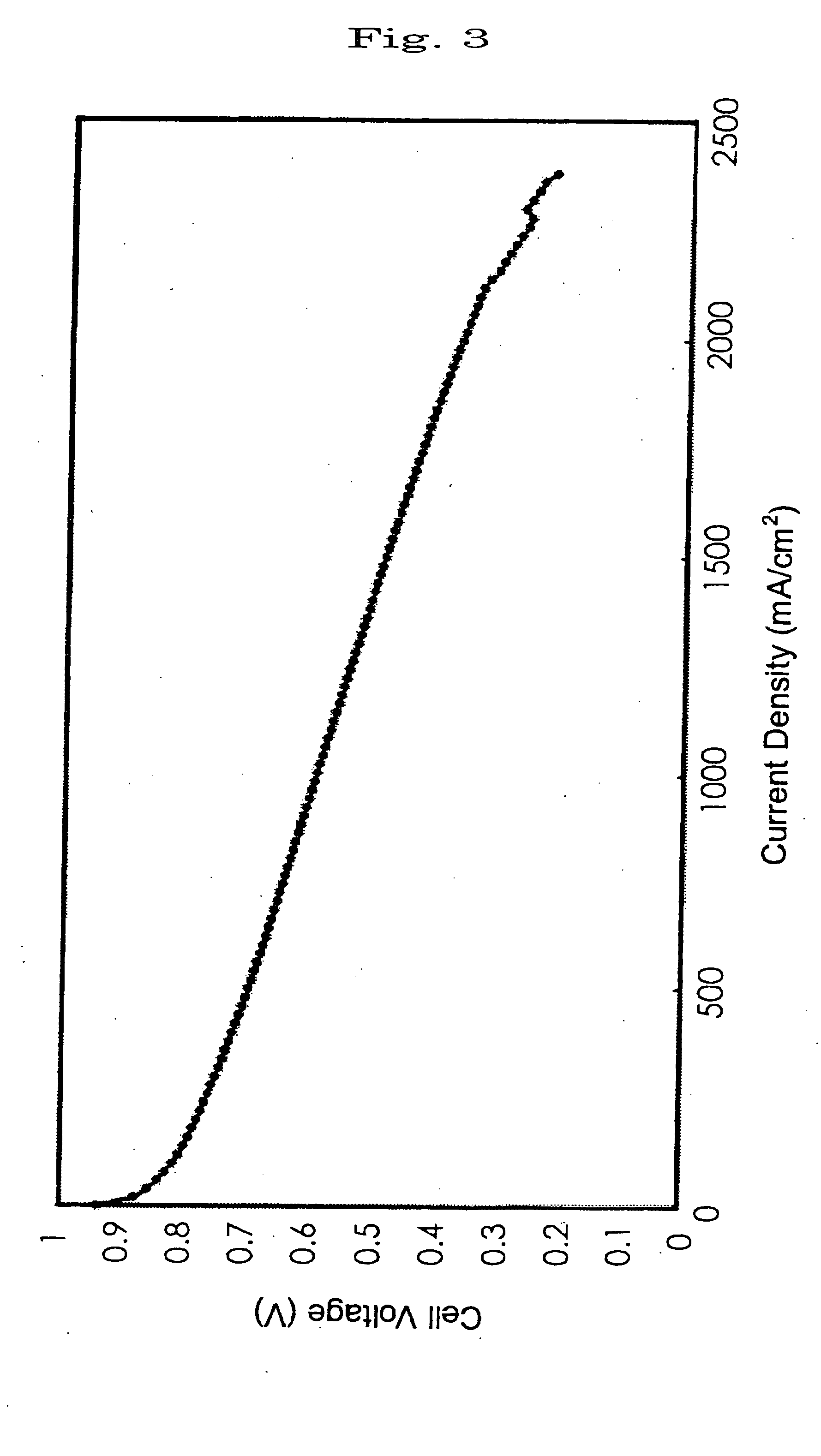

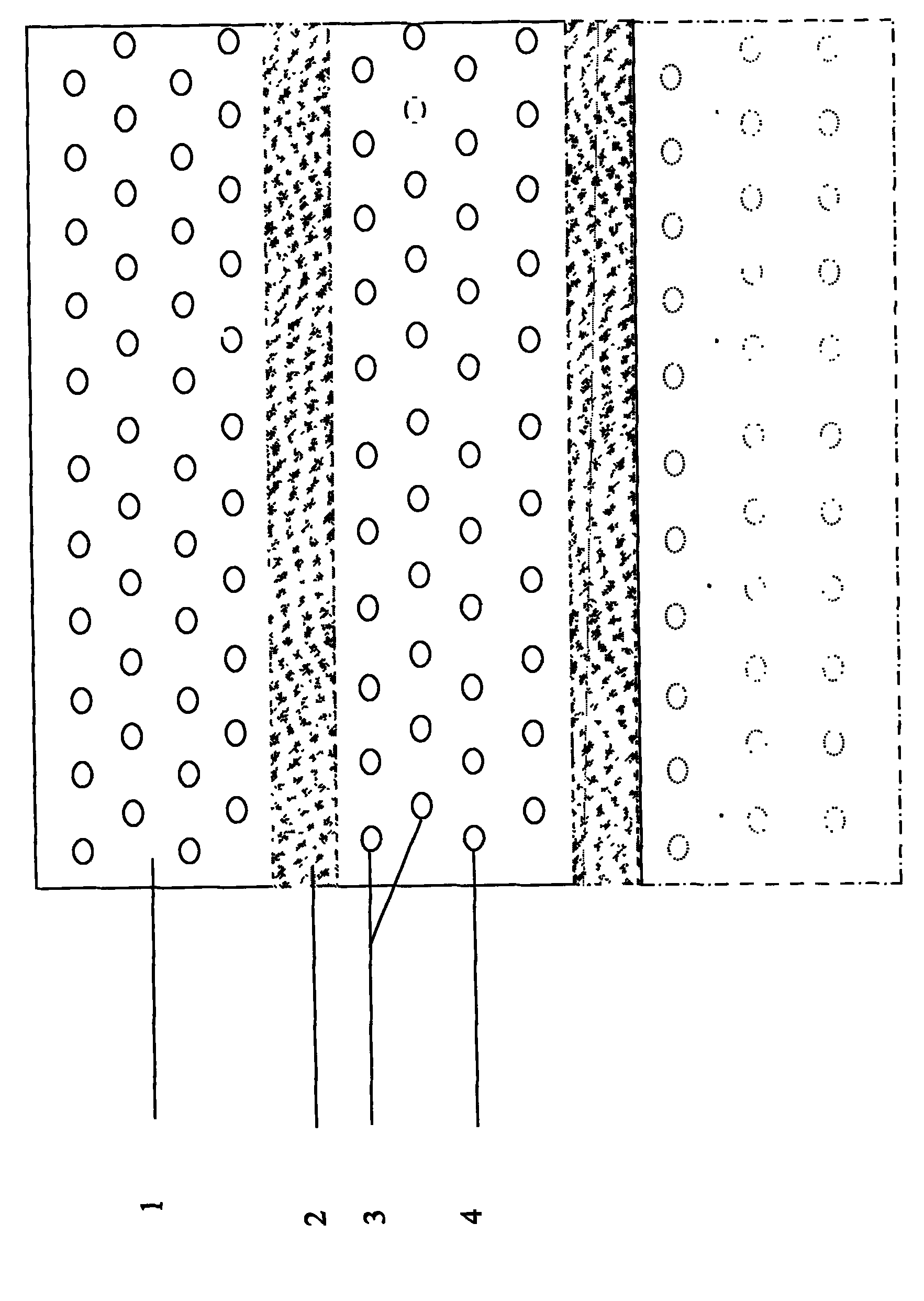

Electrolyte film and solid polymer fuel cell using the same

InactiveUS20050118479A1Proton conductivitySatisfies requirementNon-metal conductorsSemi-permeable membranesFuel cellsPolyamide

An electrolyte membrane having a porous base material having pores filled with a first polymer capable of conducting a proton, wherein the porous base material comprises at least one second polymer selected from the group consisting of polyimides and polyamides; and a fuel cell, particularly a solid polymer fuel cell, more specifically a direct methanol polymer fuel cell, using the electrolyte membrane. The electrolyte membrane is excellent in the inhibition of permeation of methanol, exhibits no or reduced change in its area, and is excellent in proton conductivity.

Owner:UBE IND LTD

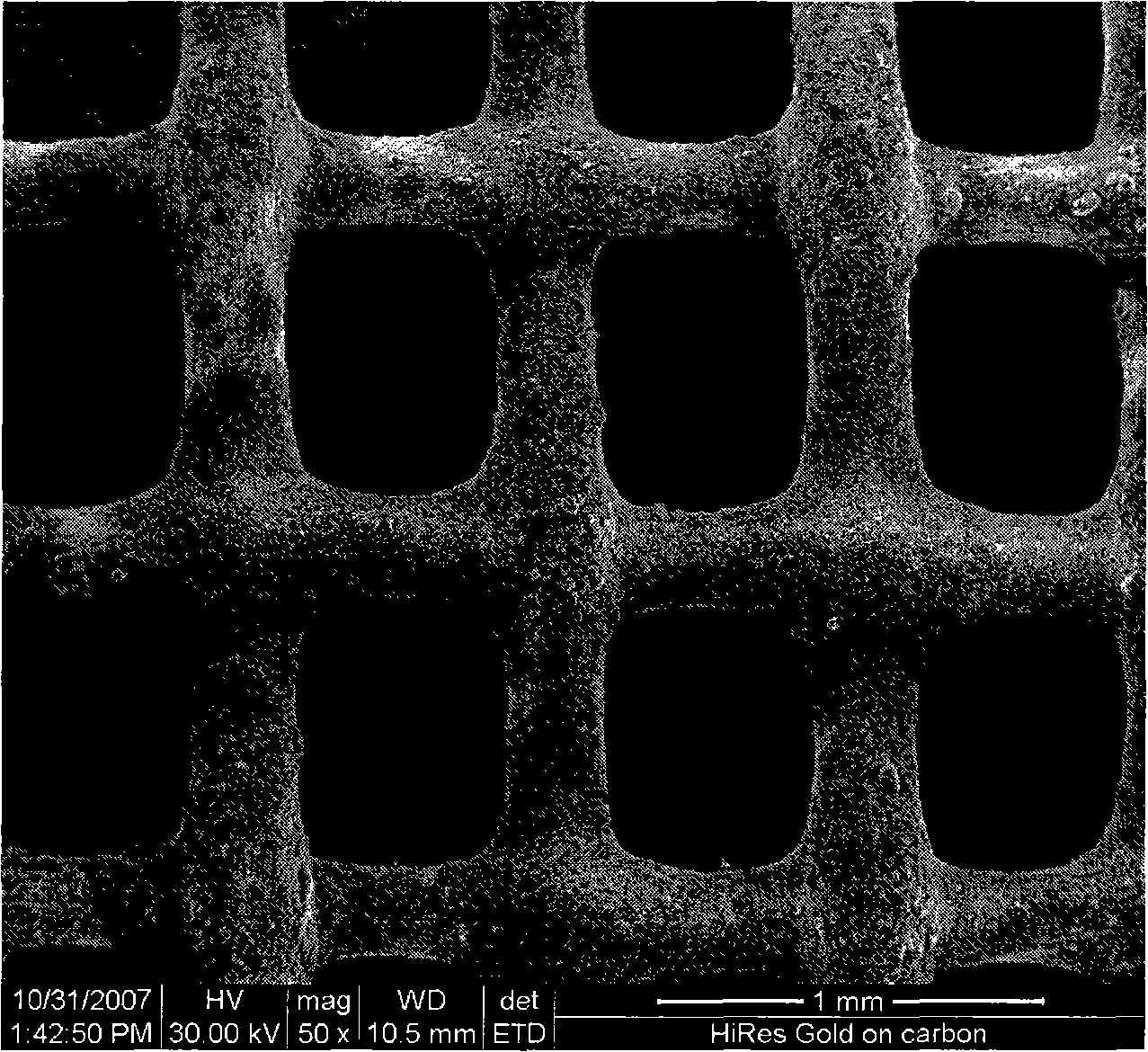

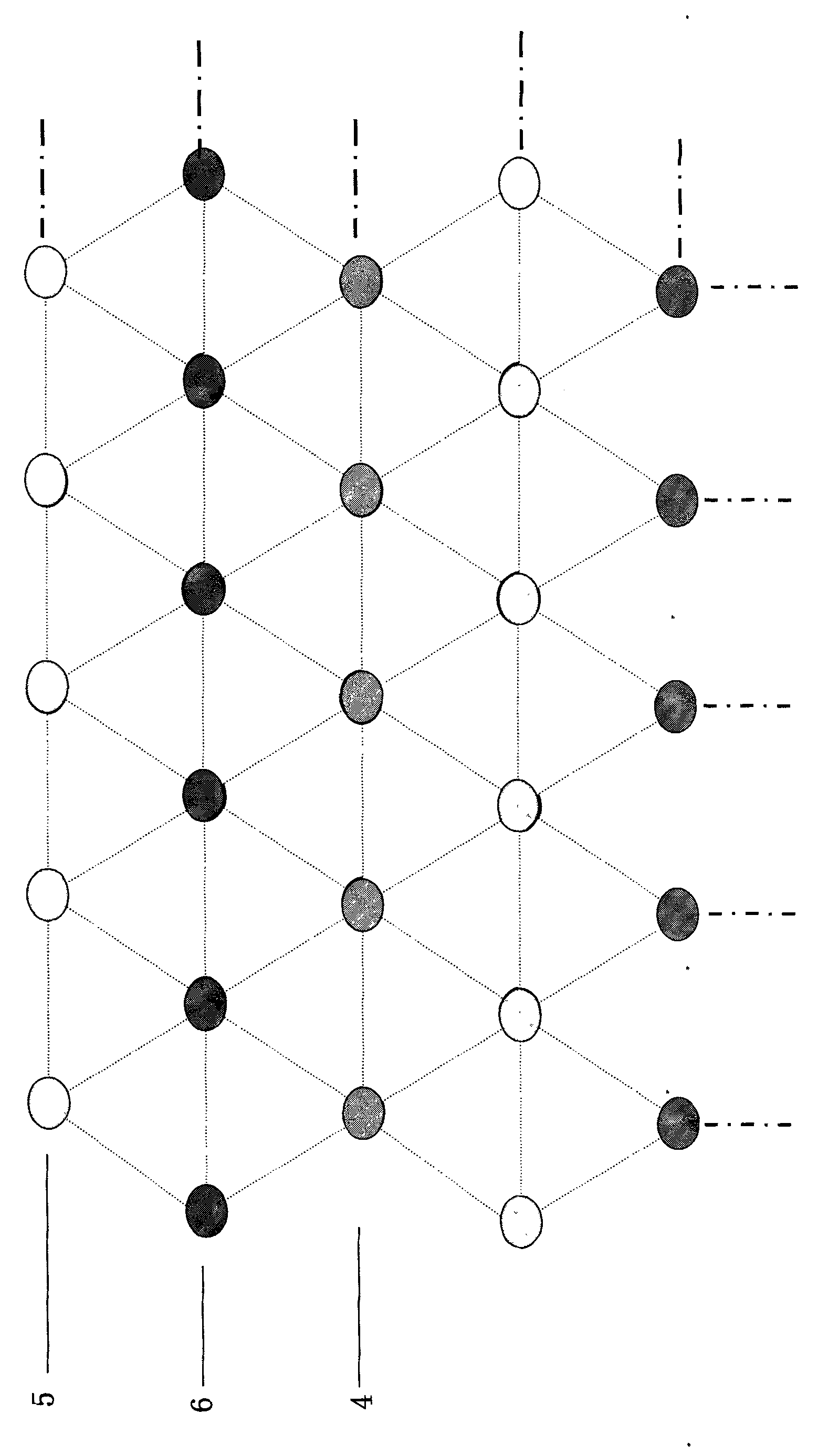

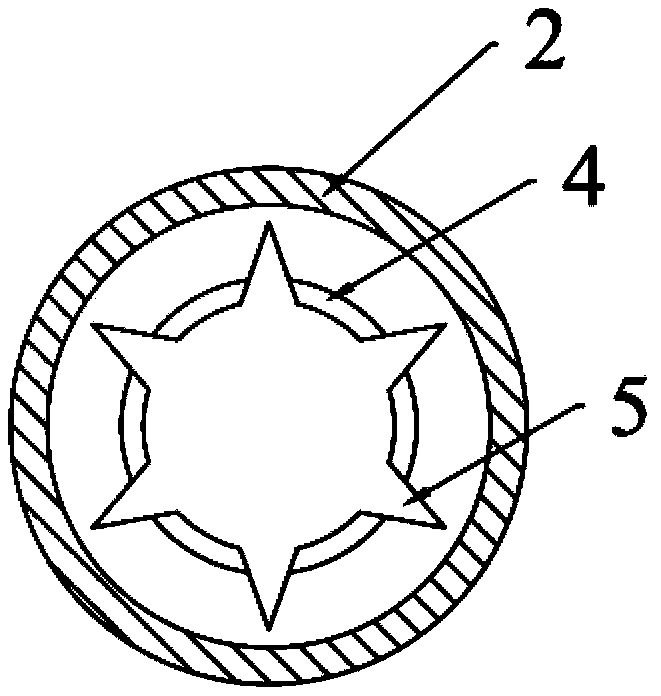

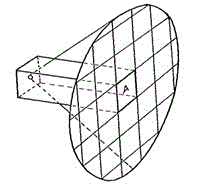

Method for covering aluminum oxide coating on honeycomb shaped wire mesh carrier

InactiveCN101274291AStrong adhesionNo crackCatalyst carriersCatalyst activation/preparationHoneycomb likeThermal shock

The invention discloses a method for coating an alumina coating layer on a faviform metal wire mesh carrier, which belongs to the technical field of the preparation of the coating layers of metal carriers, and is characterized in that after the faviform metal wire mesh carrier is molded, a pretreatment is implemented on the metal surface, and then the faviform metal wire mesh carrier is soaked in a sizing agent that contains Gamma-Al2O3 powder and aluminum powder, the Gamma-Al2O3 powder and the aluminum powder are sedimentated on the surface of the faviform metal wire mesh carrier through the electrolytic deposition method, and finally the faviform metal wire mesh carrier coated with the coating layer is roasted, wherein, the faviform metal wire mesh carrier takes the material of a stainless metal wire mesh that contains aluminum, the coating layer is distributed evenly on the surface of the faviform metal wire mesh carrier and does not chap, the thickness of the coating layer is 30 to 80Mum; the addition of the aluminum powder improves the thermal shock resistance and the mechanical vibration resistance of the coating layer, as well as the conglutination degree between the coating layer and the faviform metal wire mesh. The method for coating the alumina coating layer on the faviform metal wire mesh carrier of the invention has the advantages that the method is applicable to the preparation of the coating layers of the catalyst carriers which are used in the gas-solid catalytic reactions that are related to the environmental protection field such as the fields of the tail gas burning of motor vehicles and fixed sources and catalytic burning.

Owner:DALIAN UNIV OF TECH

A method for underground coal gasification

InactiveCN102287177AEfficient developmentChange areaConstructionsFluid removalMultiple injectionChemical reaction

An underground coal gasification method. The method comprises disposing multiple injection wells (3) and gas collection wells (4) in a gasification operation zone; adding a catalyst and a propping agent into injection wells and gas collection wells by means of a fluid medium; fracturing and reforming the coal layer using a fracturing device to form large areas of fissures and cracks; forming gasification paths in the form of directional wells between the injection wells and gas collection wells; adding a gasification agent, a catalyst, and water through the injection wells to cause coal layer combustions and chemical reactions; collecting at the gas collection wells the gas produced by means of collection devices. The fissure paths between the wells formed by reforming large fractures, and the metal mineral particles used as a propping agent for the paths between wells effectively enable the maintenance of the effective communication in the injection well network for long durations; the metal mineral particles also function as a catalyst and an aggregating agent during gasification, thereby substantially enhancing the coal gasification volume.

Owner:秦勇 +2

Process and capsule for preparing beverages

InactiveUS8425964B2Constant optimalAvoid poor resultsTea substituesTea alkaloid content reductionBiomedical engineering

A single serve capsule (1) for the preparation of hot beverages such as coffee, cappuccino, tea or the like from soluble or ground preparations, having an outlet lid portion (1b) located on a dispensing wall (F) in order to form a dispensing opening (11) after a liquid has been introduced into the capsule, as well as means for changing the area of said dispensing opening during the dispensing step of the beverage.

Owner:TUTTOESPRESSO SPA (IT)

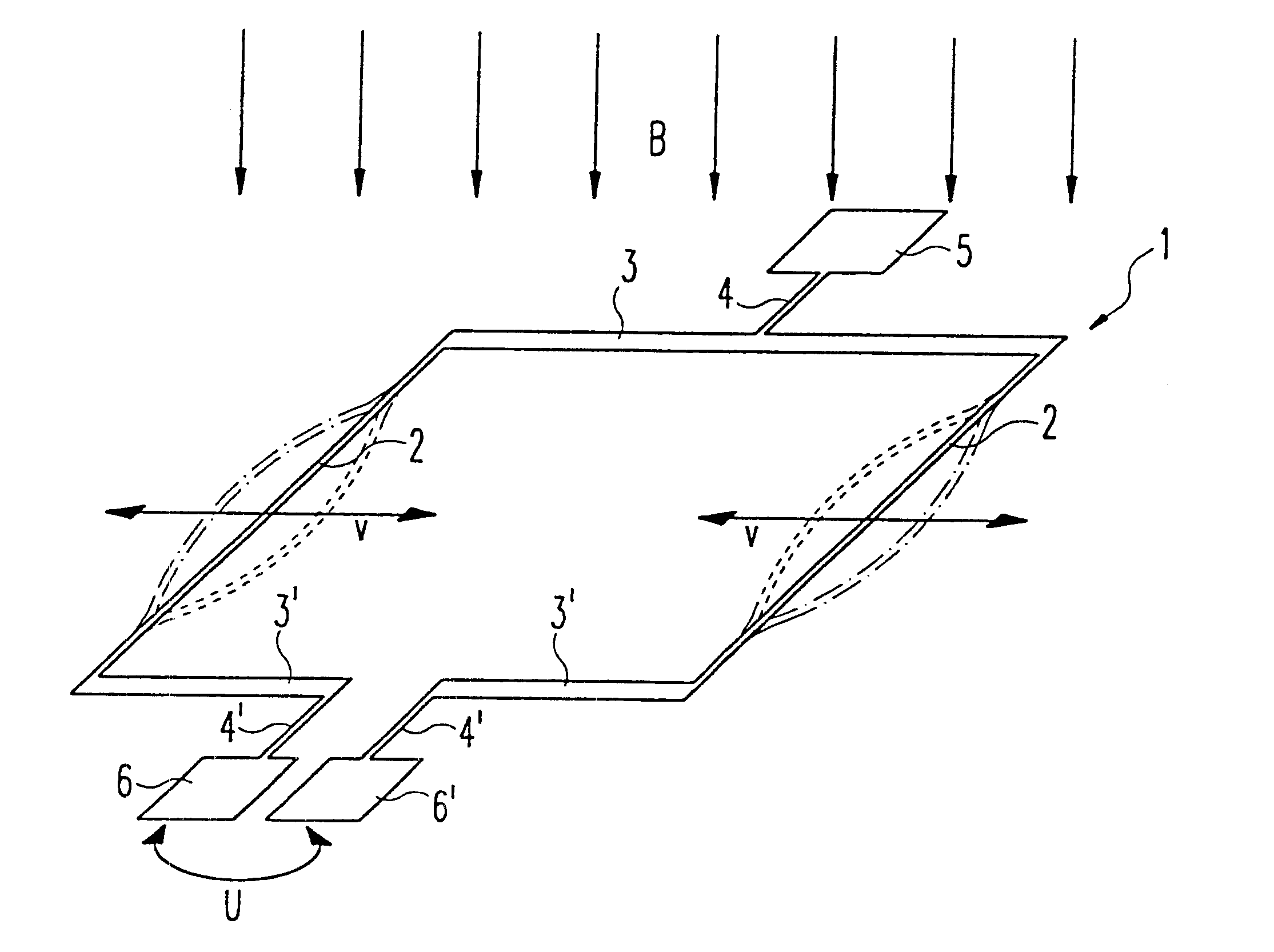

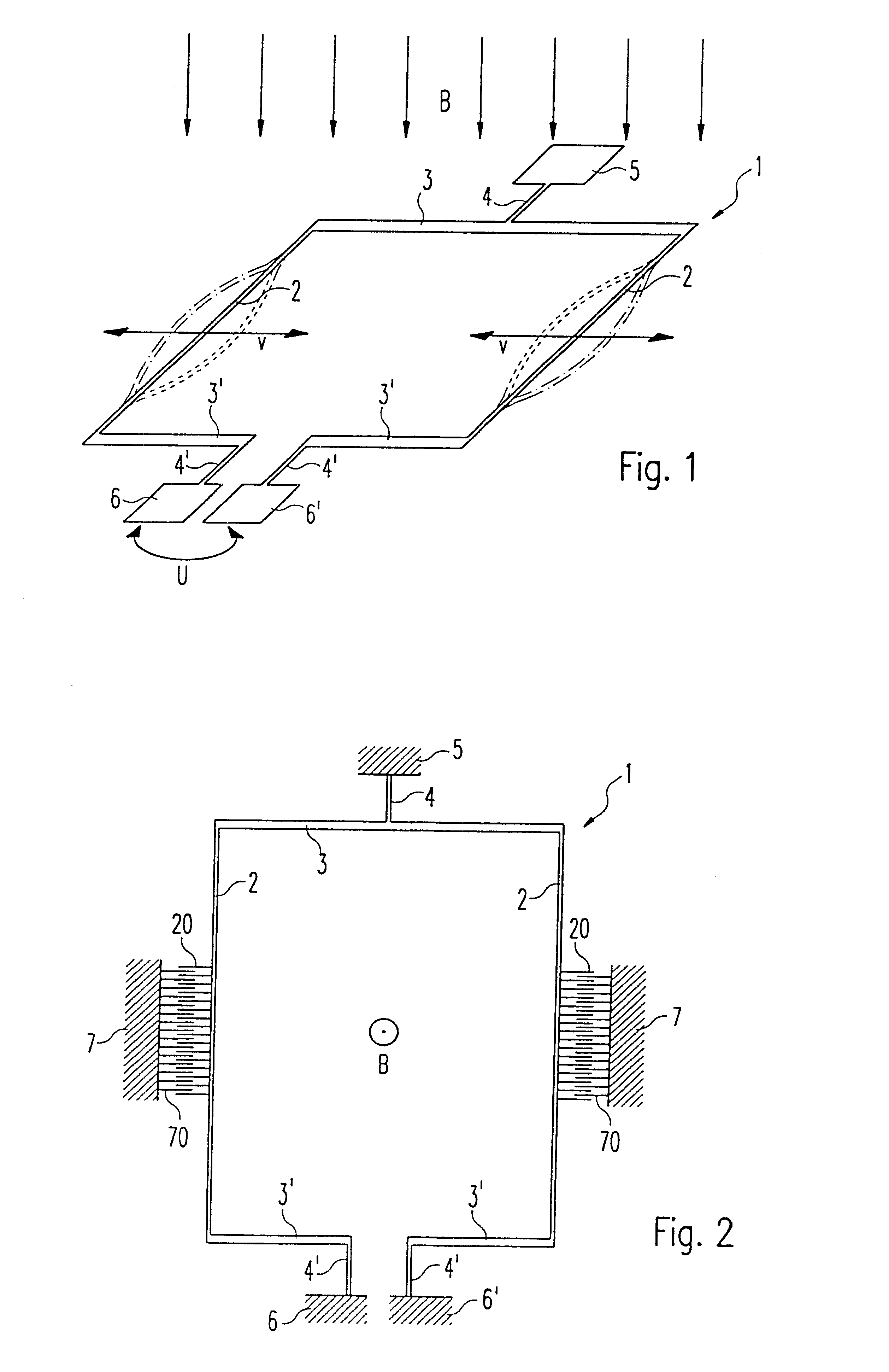

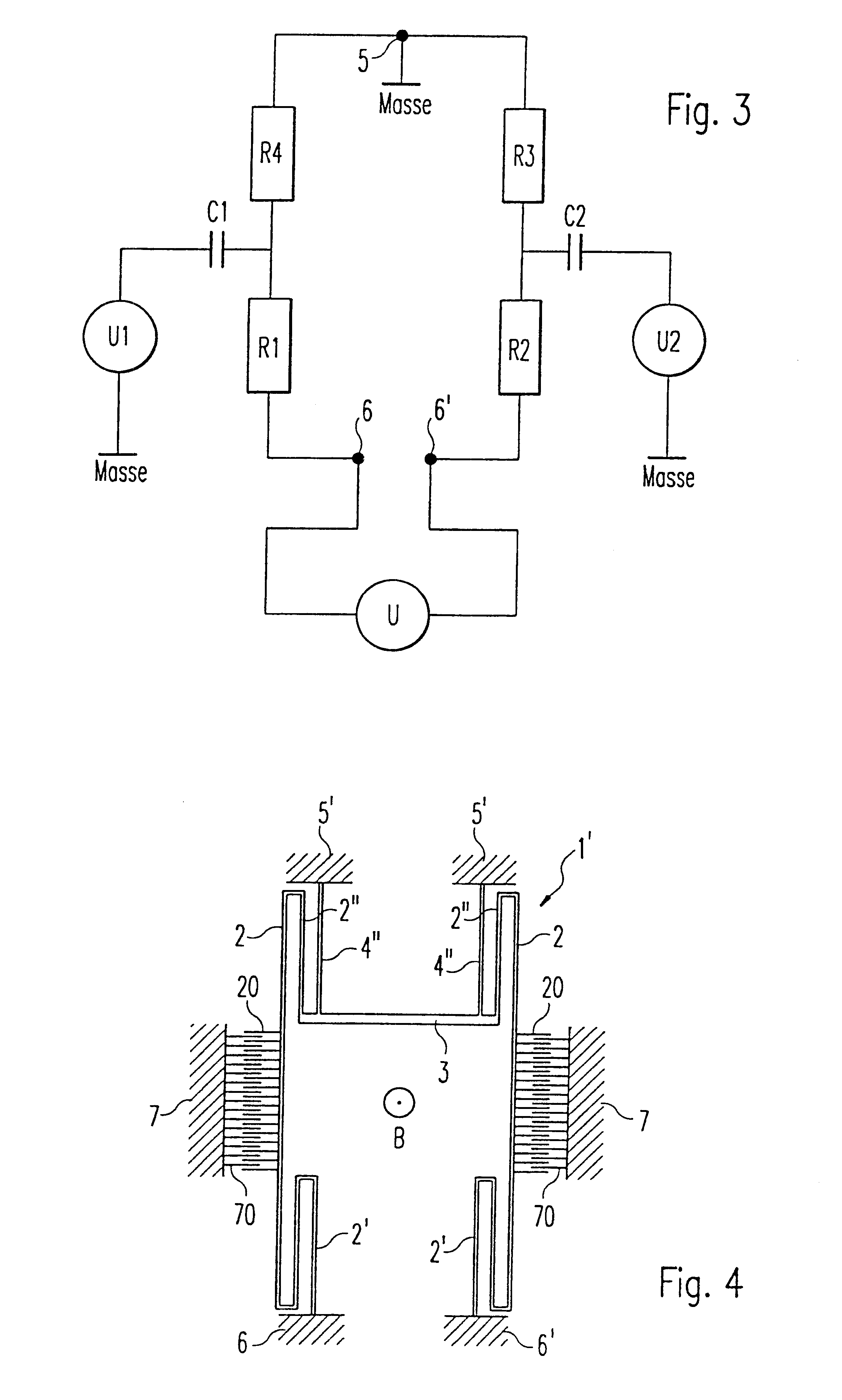

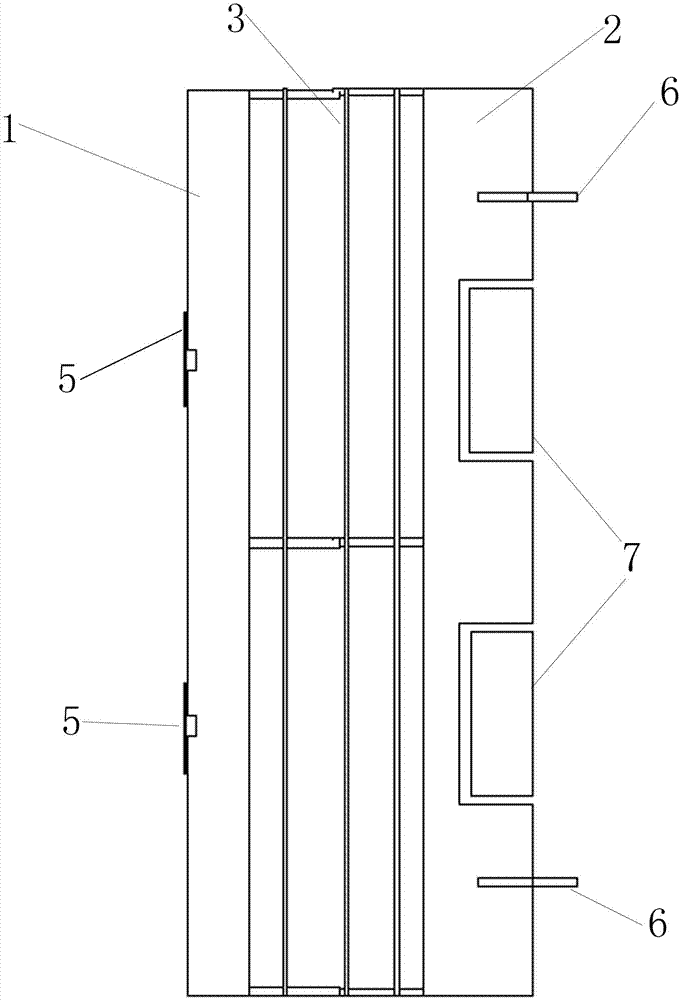

Magnetic field sensor having deformable conductor loop segment

InactiveUS6486665B1Change areaSignificant changeMagnetic property measurementsUsing electrical meansElectrical conductorVoltage sensing

A magnetic field sensor that can be manufactured using the technology of surface micromechanics, having a conductor loop that has at least one deformable segment; a deformation device for deforming the deformable segment of the conductor loop with a predeterminable time dependence; a voltage sensing device for sensing the voltage induced at the ends of the conductor loop upon deformation in the presence of a magnetic field; and a magnetic field determining device for determining the present static and / or dynamic magnetic field in consideration of at least the time dependence of the deformation.

Owner:ROBERT BOSCH GMBH

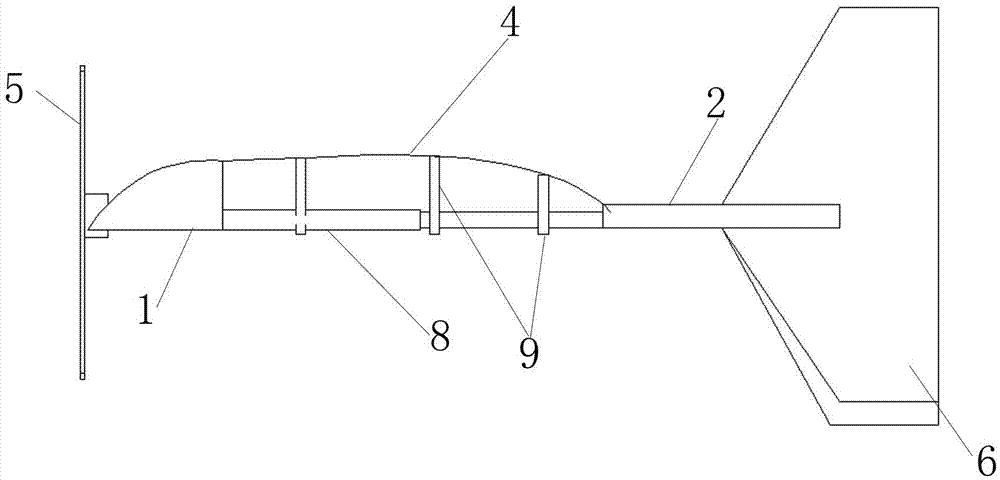

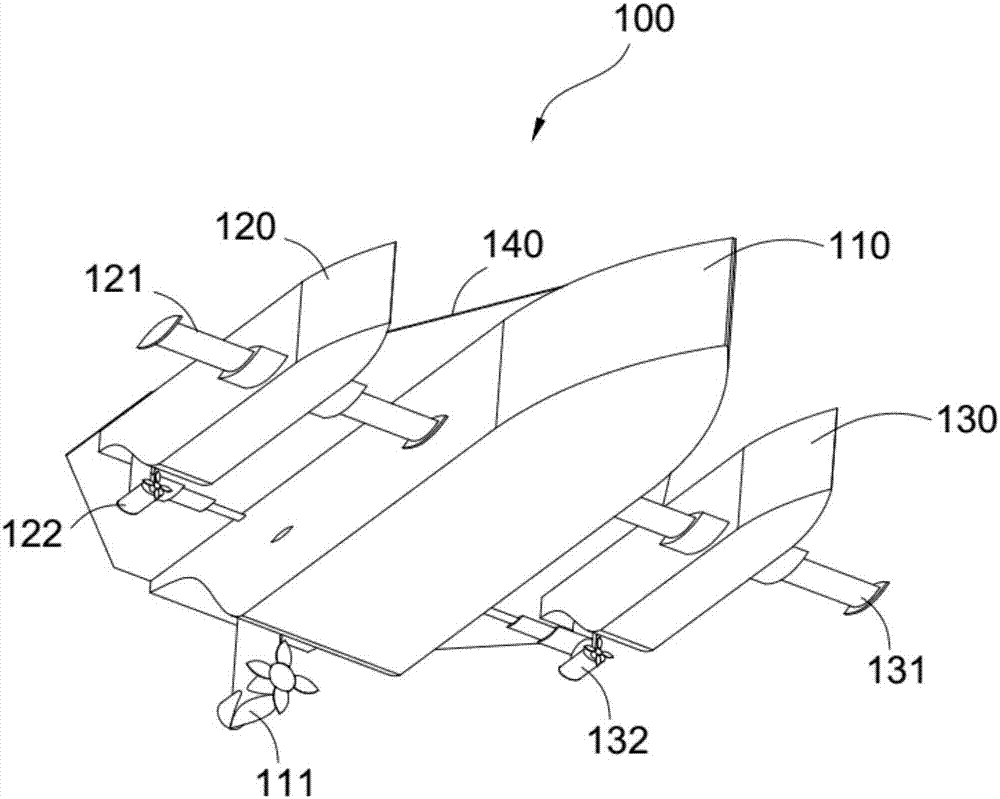

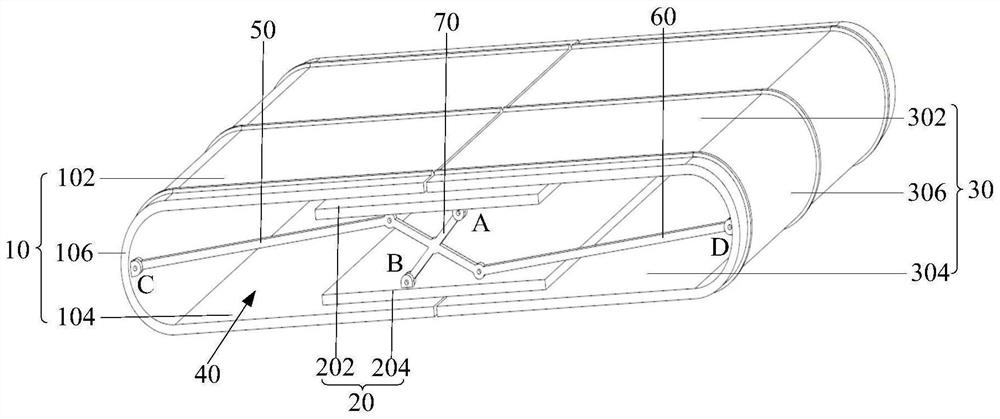

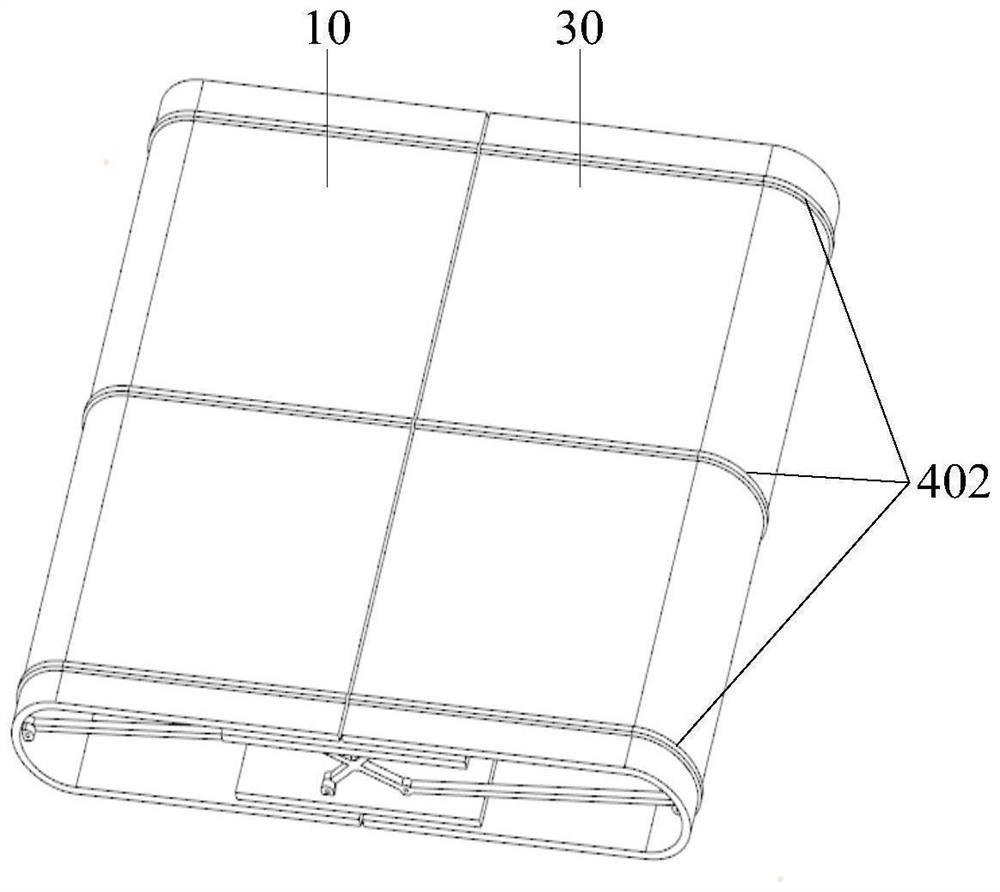

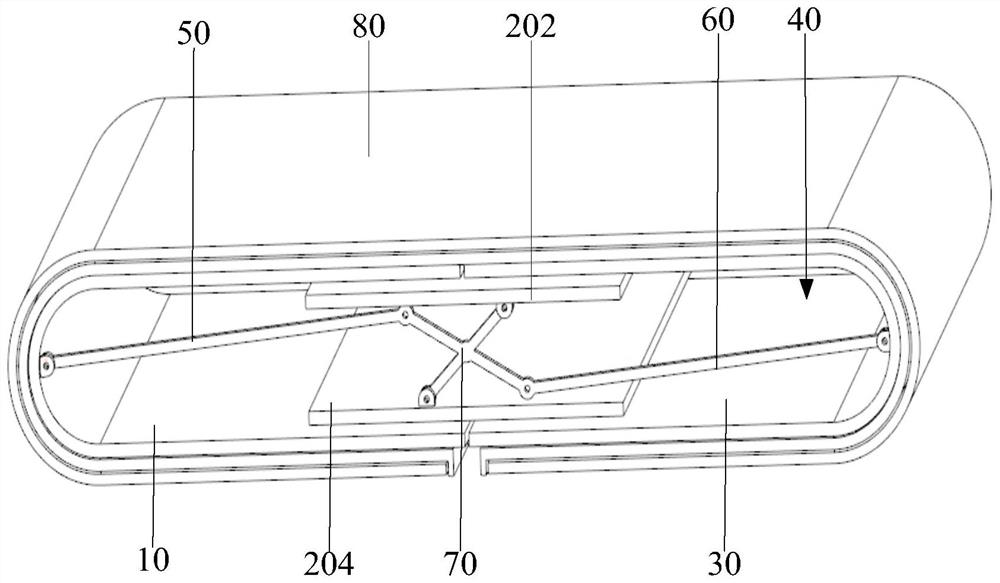

Deformable wings and vertical take-off and landing aircraft using wings

The invention relates to aircraft wings, in particular to deformable wings and a vertical take-off and landing aircraft using the wings. The technical problems that the wingspan area of a vertical take-off and landing aircraft is large at present, and the vertical take-off and landing aircraft is prone to being affected by wind power in the state of vertical take-off and landing so that the posture is unstable are solved. The deformable wings serve as an integrated airframe of the vertical take-off and landing aircraft. Each deformable wing comprises a wing leading edge and a wing trailing edge. Spreading and contracting between each wing leading edge and the corresponding wing trailing edge are achieved through a sliding assembly. A folding skin is connected between each wing leading edge and the corresponding wing trailing edge. According to the designed deformable wings, the size of the chord length can be expanded, contracted and changed, and the wing area is changed; meanwhile, the advantages of a fixed wing aircraft and the advantages of a multi-rotor-wing aircraft are combined, so that the function that the same aircraft can fly by arbitrarily switching two flight modes is achieved.

Owner:SHANXI UNIV

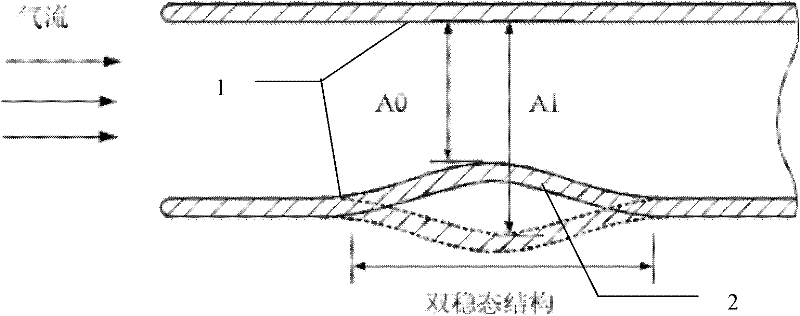

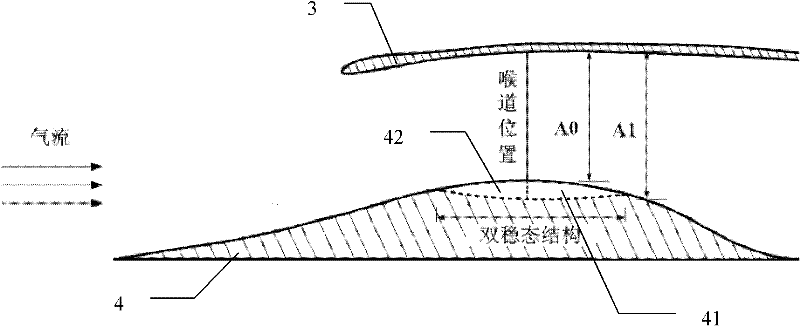

Bistable air inlet, its application as aircraft air inlet and design method of bistable air inlet

InactiveCN102518517ASolve non-adjustable problemsChanging throat areaGas turbine plantsJet propulsion plantsAirframeDesign methods

The invention discloses an aircraft air inlet with a bistable structure, and simultaneously relates to a design method of the bistable air inlet. The bistable structure area is designed differently according to different forms of aircraft air inlets. When an aircraft has an independent air inlet pipeline, the bistable structure can be arranged on the wall of the inlet pipeline; when the air inlet area of the aircraft is formed by an air inlet enclosure and an airframe bump profile, the bistable structure can be disposed in a bump area of the airframe bump profile. The design method designs the bistable structure area, and finally determines its structural parameters. The air inlet of the invention with a bistable and deformable structure realizes local concave-convex deformation of an air inlet, such as the compression profile of a bump air inlet, so that the throat area of the air inlet is changed, and the problem of an unadjustable compression profile of the bump air inlet is solved. Thus, under different flying states, the aircraft can have the optimal air inlet performance and inlet-engine matching property.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

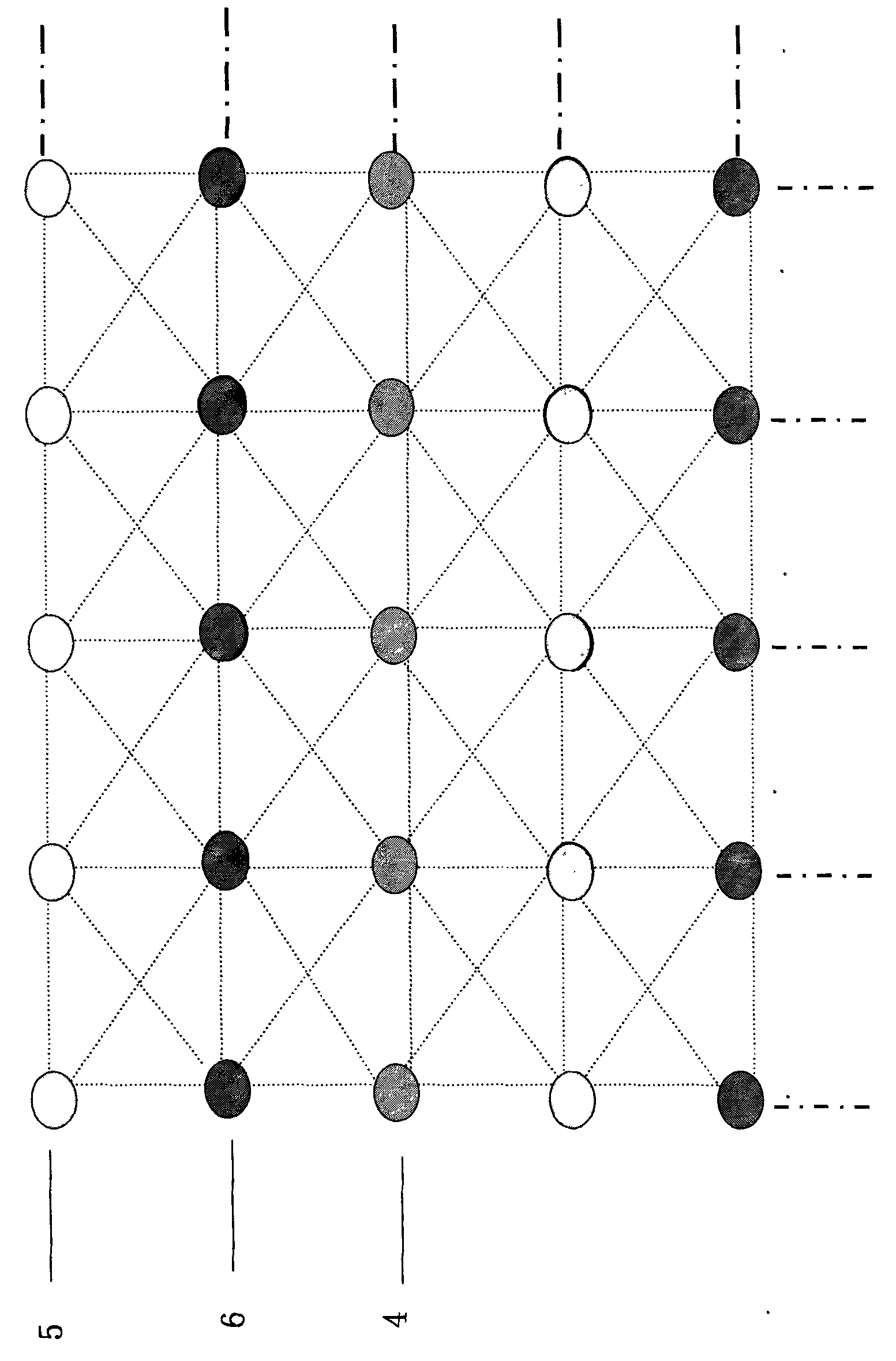

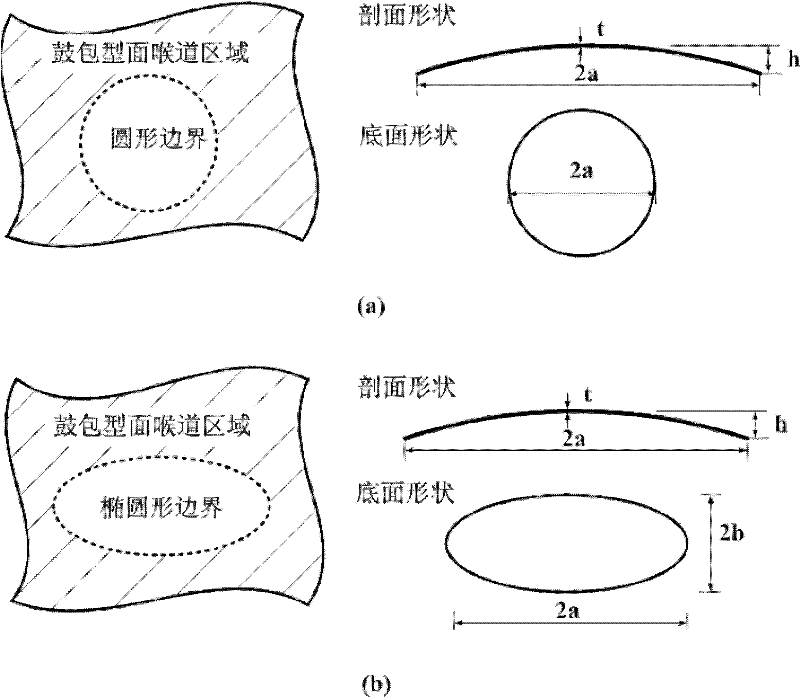

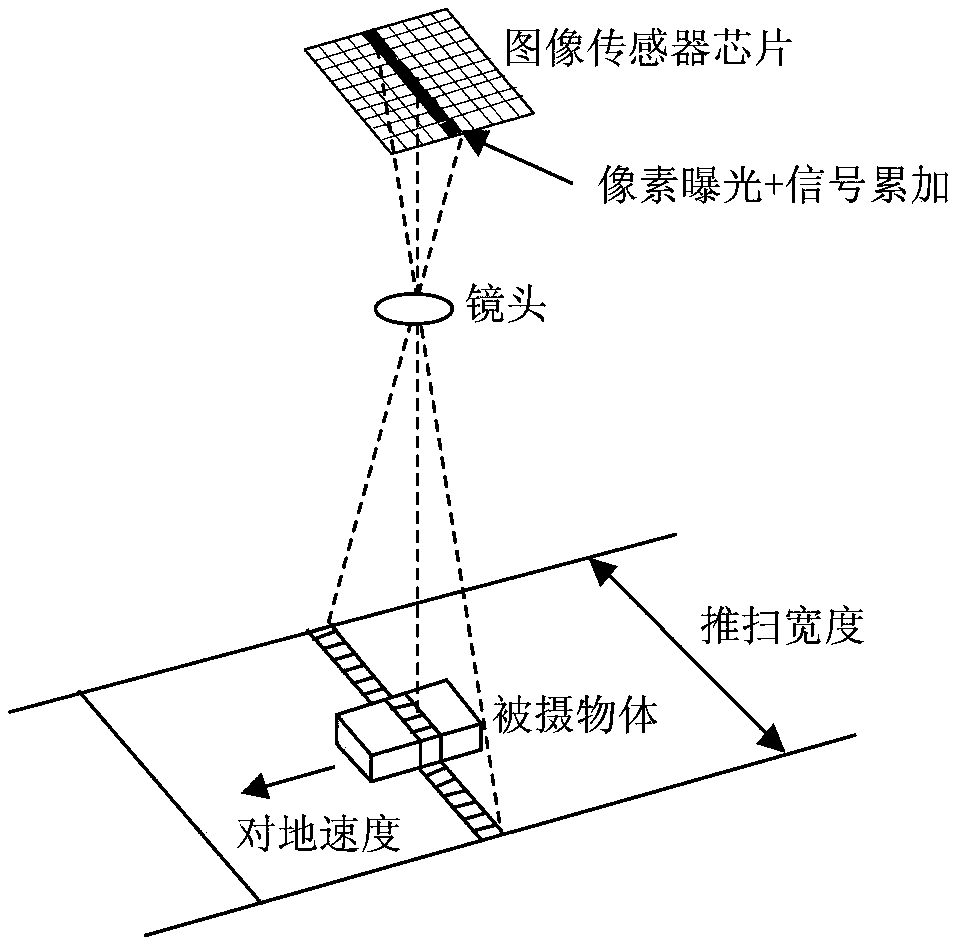

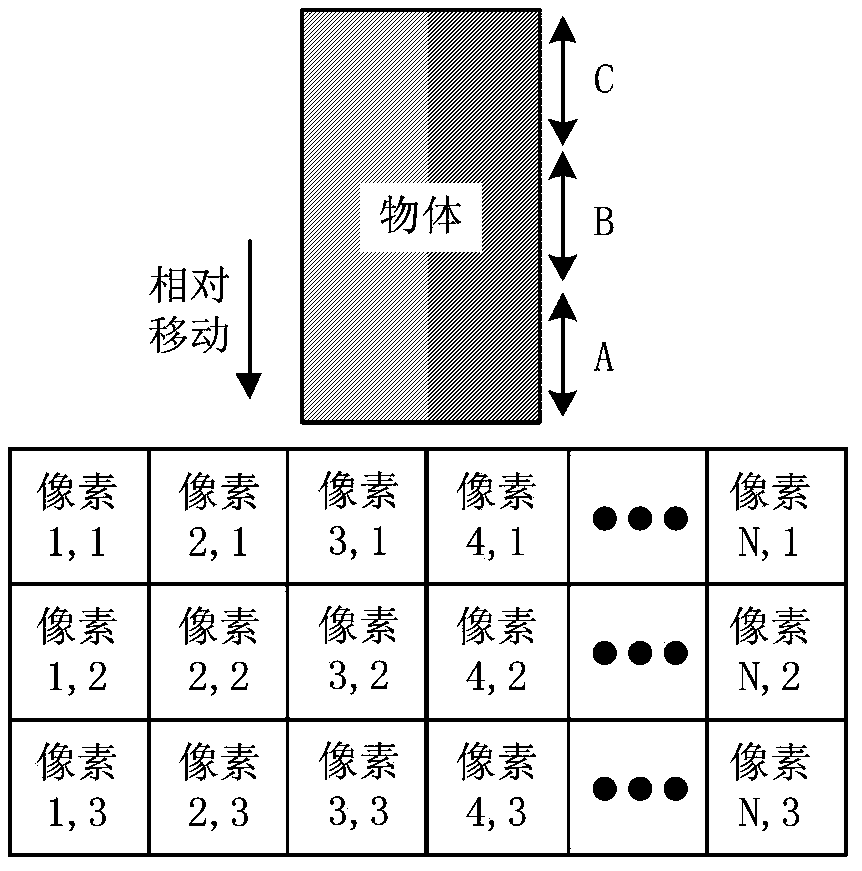

CMOS TDI image sensor and charge transfer control method thereof

ActiveCN103402061AChange sizeChange areaTelevision system detailsColor television detailsCMOSSignal-to-noise ratio (imaging)

The invention relates to a CMOS TDI image sensor and a charge transfer control method thereof. Polycrystalline silicon grids in the M row of the sensor are manufactured on N lines of semi-conductor strips and isolation strips; the polycrystalline silicon grids are isolated from the semi-conductor strips through insulating medium, and are connected with a time sequence generation circuit; the semi-conductor strips are connected with a readout circuit. The charge transfer control method comprises the following steps: in each equal time interval, the area of a charge collection area is changed from nxm to nxi, or from nxi to nxm by controlling a switched network connected with the output positions of the semi-conductor strips and signals of the polycrystalline silicon grid; in each two equal time intervals, the electricity collection area moves for m - i rows in the vertical direction; n is the number of combined horizontal charge collection units; m and i are the numbers of combined vertical charge collection units; charge signals are read out through the readout circuit after being combined by the switched network. The CMOS TDI image sensor and the charge transfer control method have the advantages that the signal-to-noise ratio of the CMOS TDI image sensor can be improved; the sizes and areas of effective pixels can be adjusted; the image resolution is improved.

Owner:GPIXEL

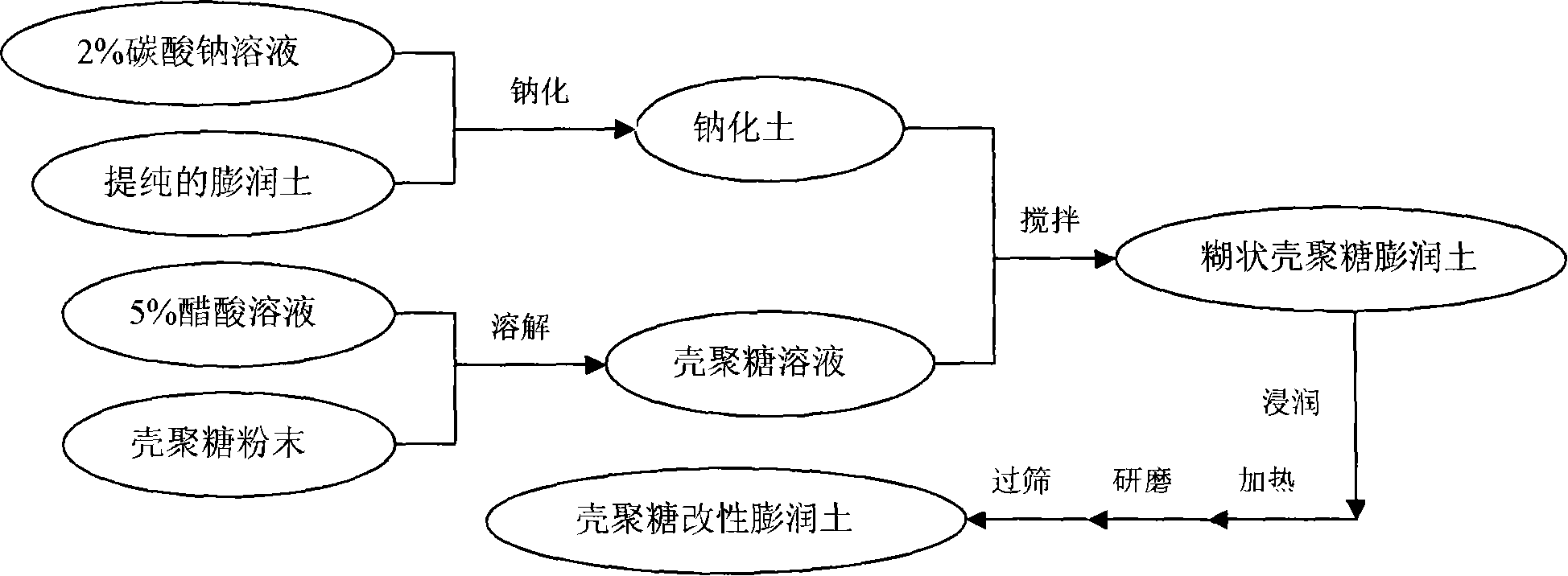

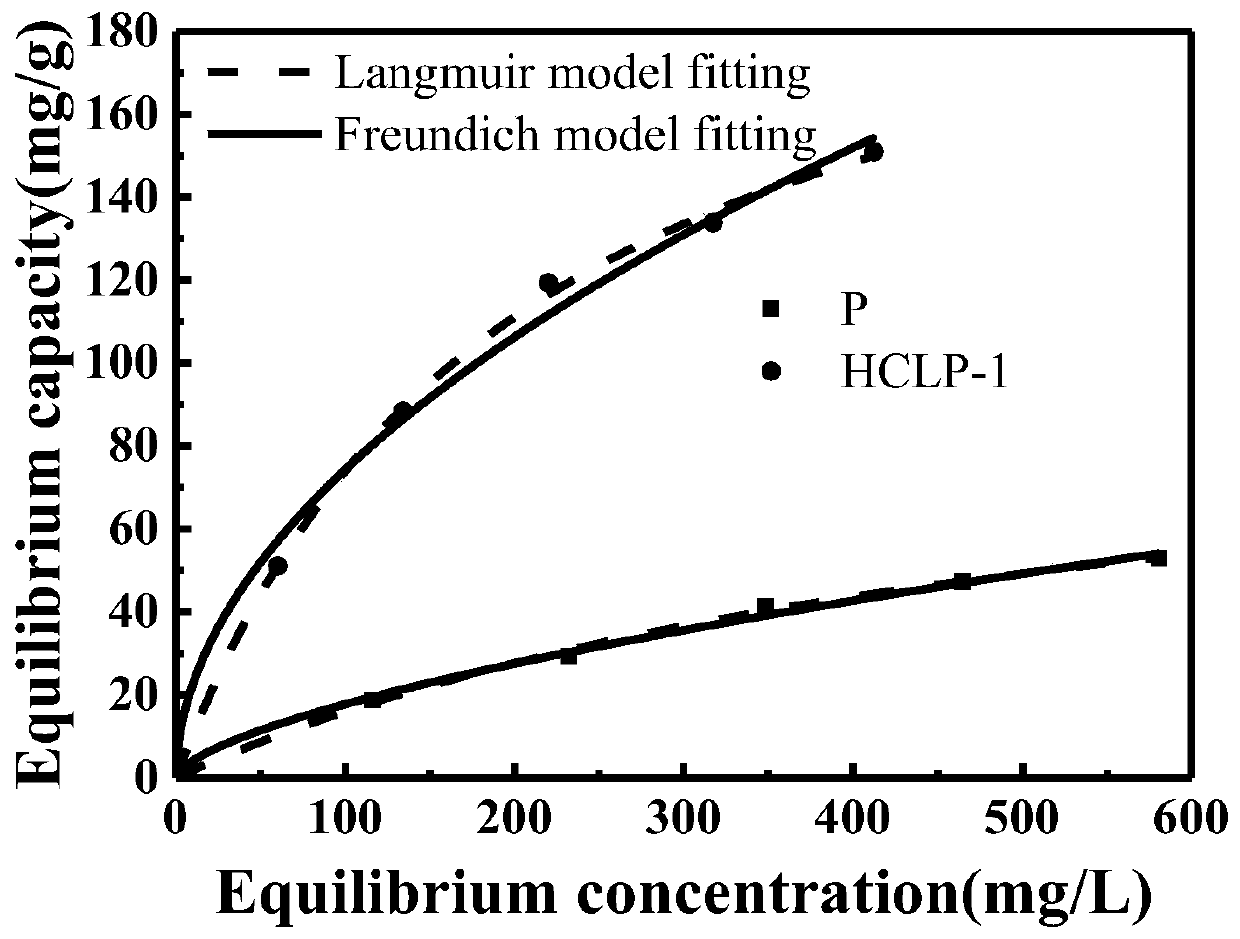

Environment-friendly modified bentonite and preparation method thereof

The invention discloses an environment-friendly modified alta-mud and making method, which comprises the following steps: adopting natural polysaccharide without toxicity and harm such as chitosan as modifier to modify sodium-based alta-mud; disposing original mud; allocating chitosan acetic solution; weighing 50-60ml chitosan solution with density at 0. 5-1. 0% and diacetyl degree at 90%; allocating 50g alta-mud into paste-shaped material; stewing; infiltrate the alta-mud completely; placing the paste-shaped material into microwave oven; heating to dry; grinding finely; sieving in the screen at 0. 16mm; obtaining the product with low price, good property and environment friendly without any polluting; fitting for disposing industrial waste water, manufacturing drug and food industry.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

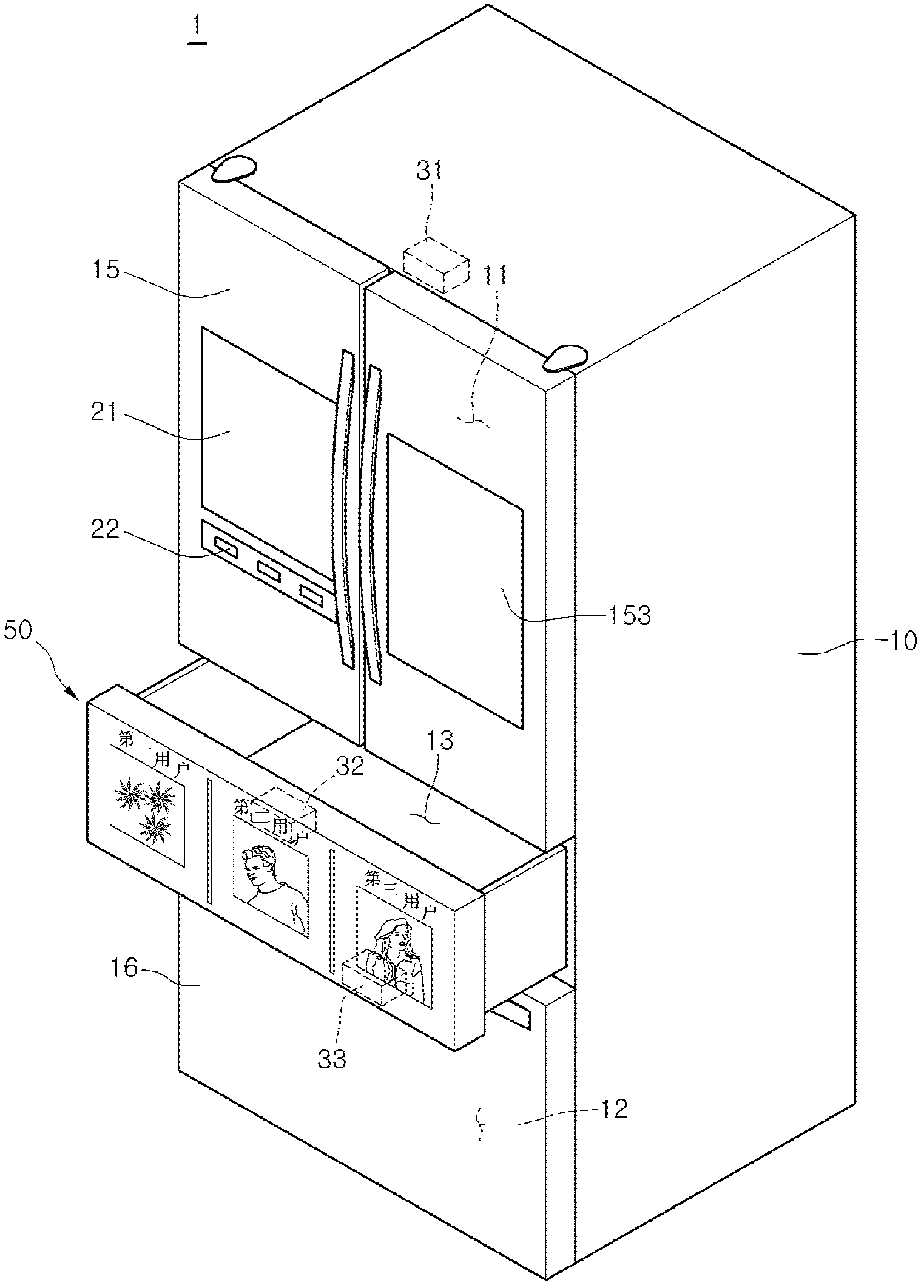

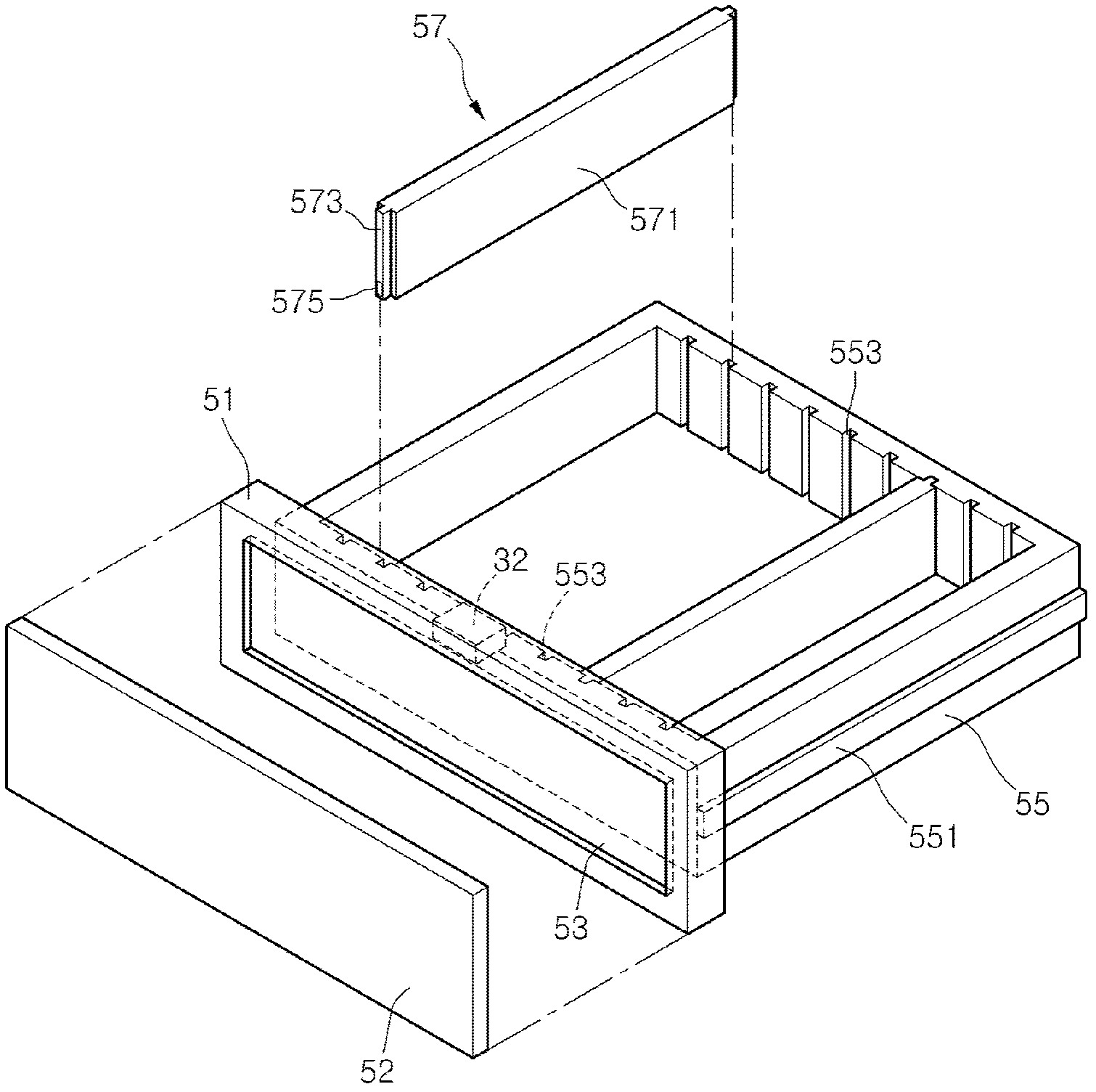

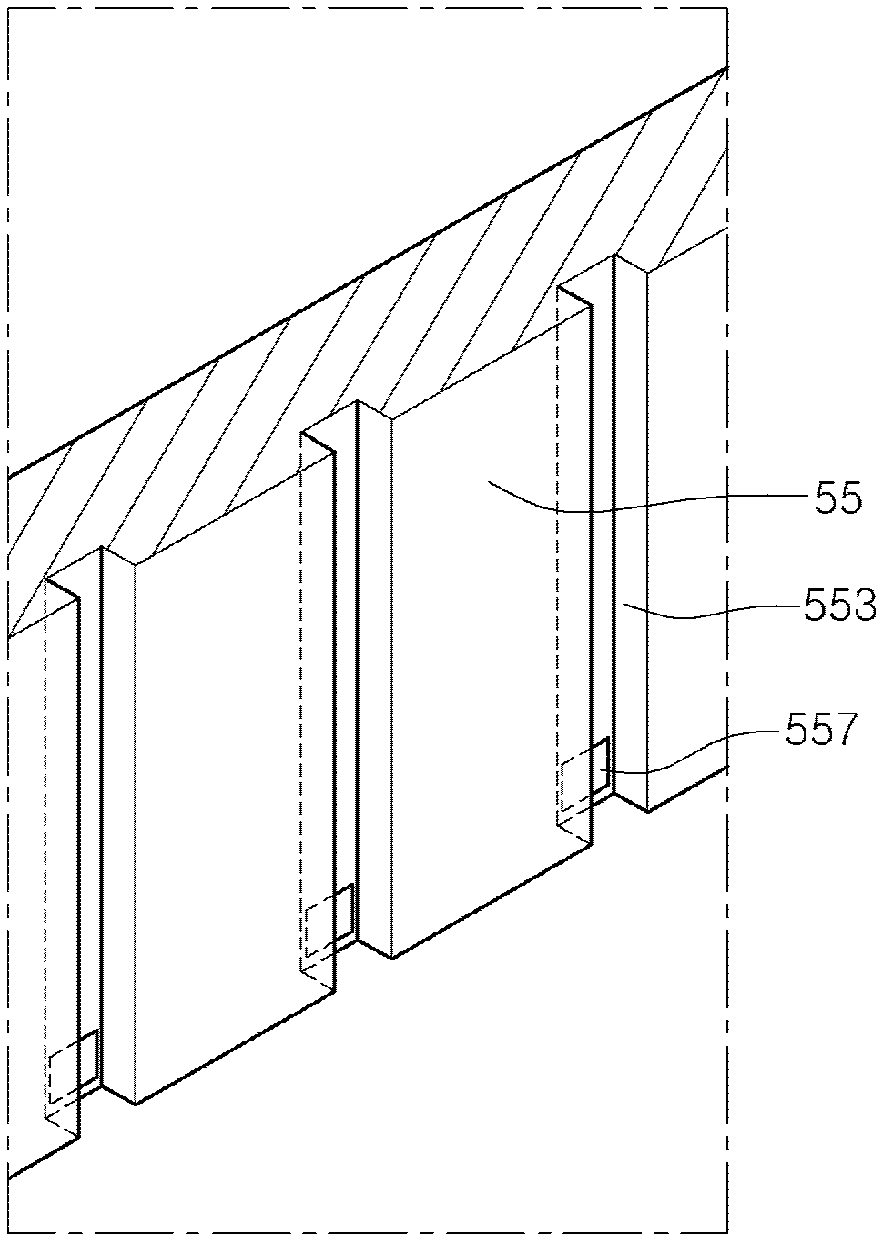

Refrigerator

InactiveCN102405387AImprove satisfactionChange areaLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

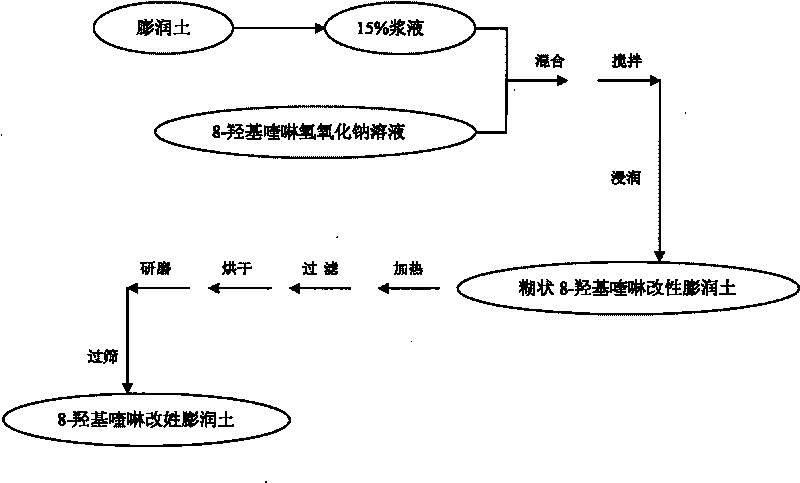

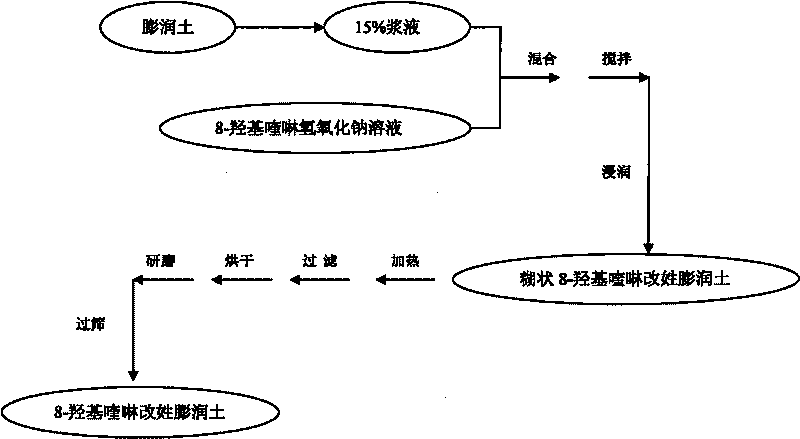

Organic modified bentonite and preparation method thereof

InactiveCN101734678AGood performanceSimple and efficient operationSilicon compoundsWater/sewage treatment by sorptionChemistryHydroxyquinolines

The invention discloses an organic modified bentonite and a preparation method thereof, and relates to an organic mineral and a preparation method thereof. 8-hydroxyquinoline is used as a modifying agent to modify calcium-based bentonite so as to prepare the modified bentonite-8-hydroxyquinoline modified bentonite. The preparation method for the 8- hydroxyquinoline modified bentonite comprises the following steps: firstly, processing raw soil; then, preparing solution of 8-hydroxyquinoline sodium hydroxide; and finally preparing the 8-hydroxyquinoline modified bentonite. The preparation method for the 8-hydroxyquinoline modified soil particularly comprises the following steps: adding distilled water into a certain amount of the bentonite, and stirring the mixture to prepare 15 percent soil suspension; adding 0.2 to 0.3 g / L solution of 8-hydroxyquinoline sodium hydroxide into the suspension for uniform mixing,; and stirring and heating for 60 minutes in a water bath, filtering, drying, grinding, and sifting through a 0.096 mm sieve to prepare the 8-hydroxyquinoline modified soil. The organic modified bentonite serving as an adhesive, a thickener, a purification decolorant, a catalyst and the like has quite wide application prospect in the fields of metallurgy, mechanical foundry, drilling, petrochemical engineering, agriculture, forestry, animal husbandry and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Permanent magnet coupling mechanism between shafts

InactiveCN103326541ACreative optimizationChange areaDynamo-electric gearsPermanent magnet rotorCoupling

The invention relates to a permanent magnet coupling mechanism between shafts. The permanent magnet coupling mechanism between the shafts is used for transmitting torque between the two rotating shafts. The mechanism comprises a permanent magnet rotor and a conductor rotor, wherein a conical air gap is formed between the permanent rotor and the conductor rotor. A permanent magnet on the permanent magnet rotor comprises main magnets and auxiliary magnets. The multiple main magnets are circumferentially distributed. A magnetizer made of permeability magnetic materials is arranged between every two adjacent main magnets. One auxiliary magnet is arranged on one side, away from the conductor rotor, of each magnetizer. The directions of the magnetic poles of the main magnets are located in the circumferential direction of the permanent magnet rotor. The directions of the magnetic poles of the adjacent main magnets are in the face-to-face direction or the back-to-back direction. The directions of the magnetic poles of the auxiliary magnets are the radial directions of the permanent magnet rotor. The directions of the magnetic poles of the adjacent auxiliary magnets are opposite. The magnetic poles of the positions of the side faces where the two main man magnets and one auxiliary magnet are contacted with the same magnetizer are respectively the same polarity. The permanent magnet coupling mechanism between the shafts is large in transmitting torque, adjustable in transmitting torque, compact in structure, convenient to install, and stable and reliable in transmission and adjustment.

Owner:JIANGSU MAGNET VALLEY TECH

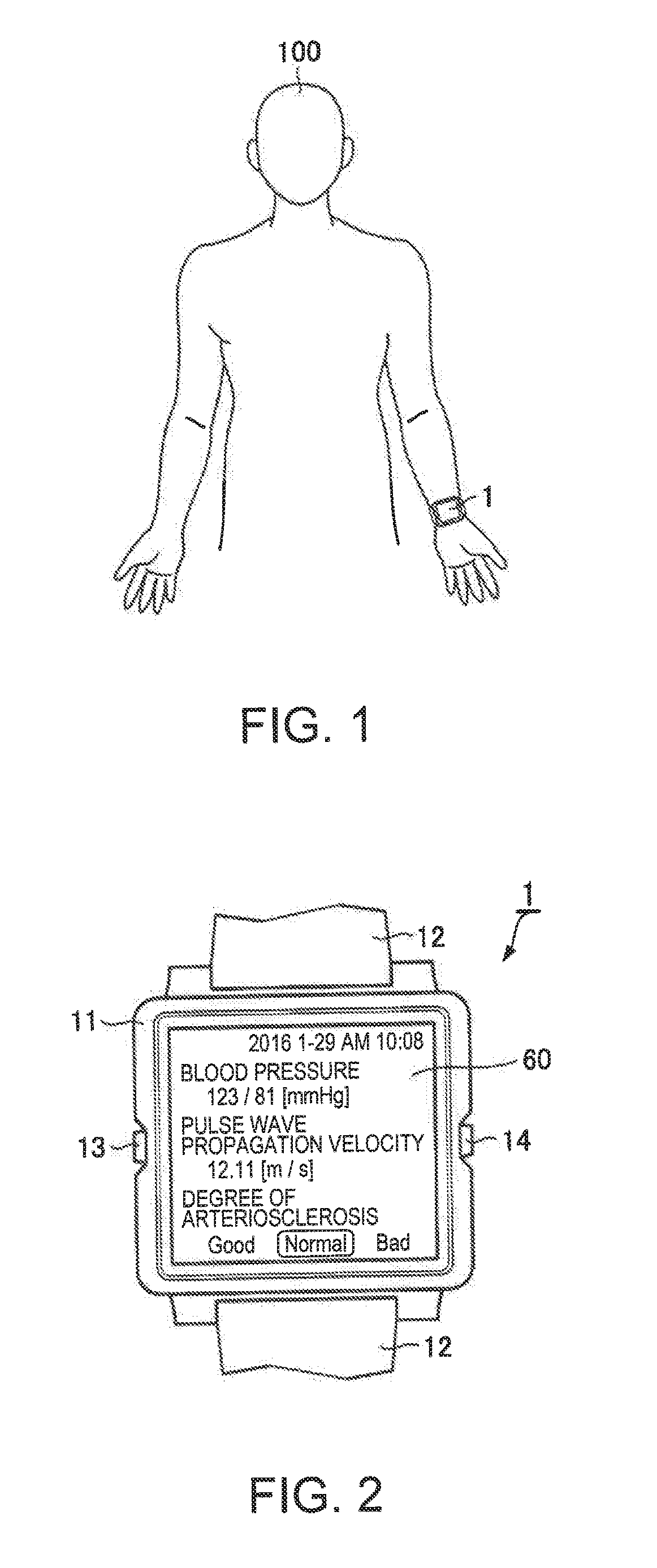

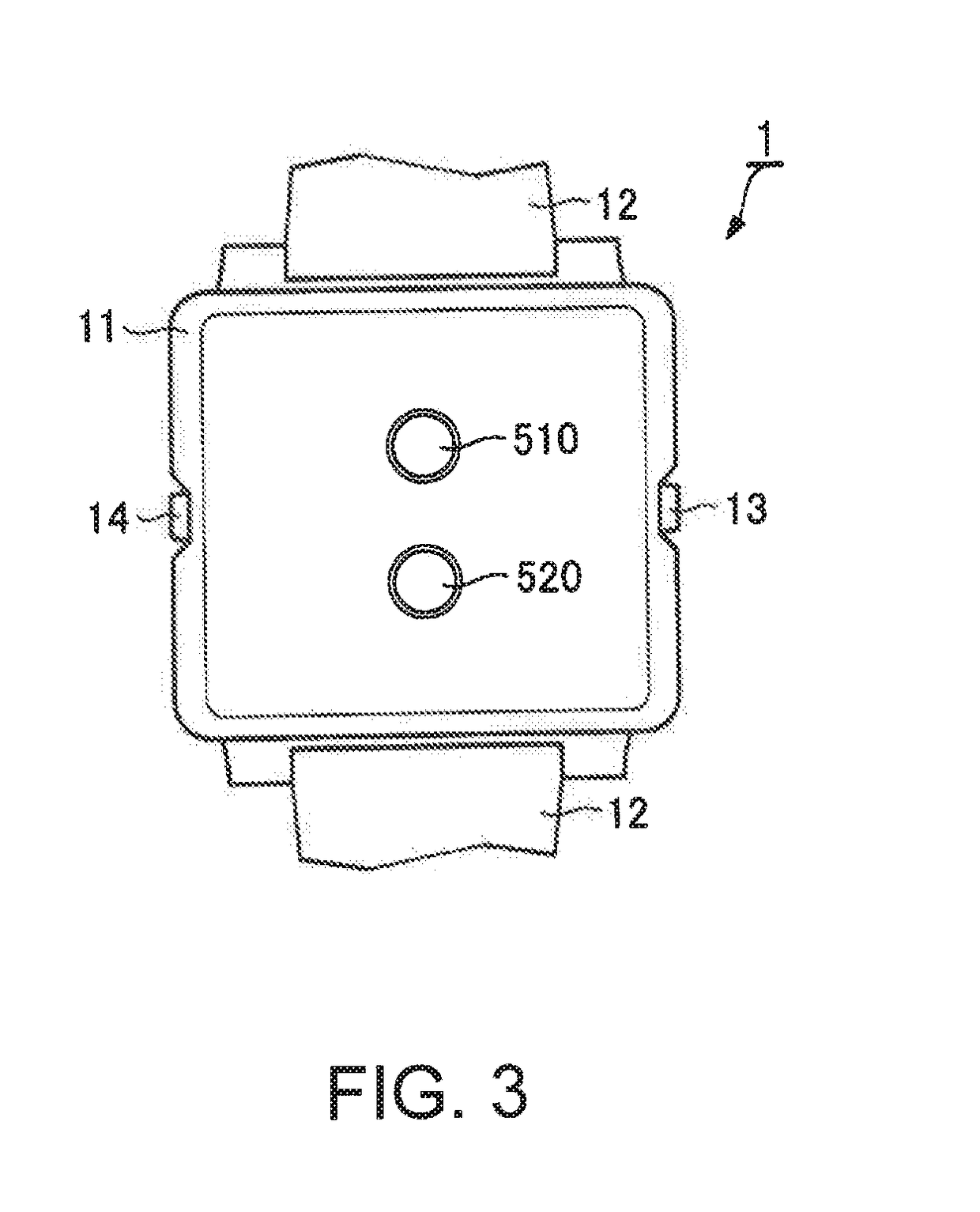

Biological information measurement apparatus and biological information measurement method

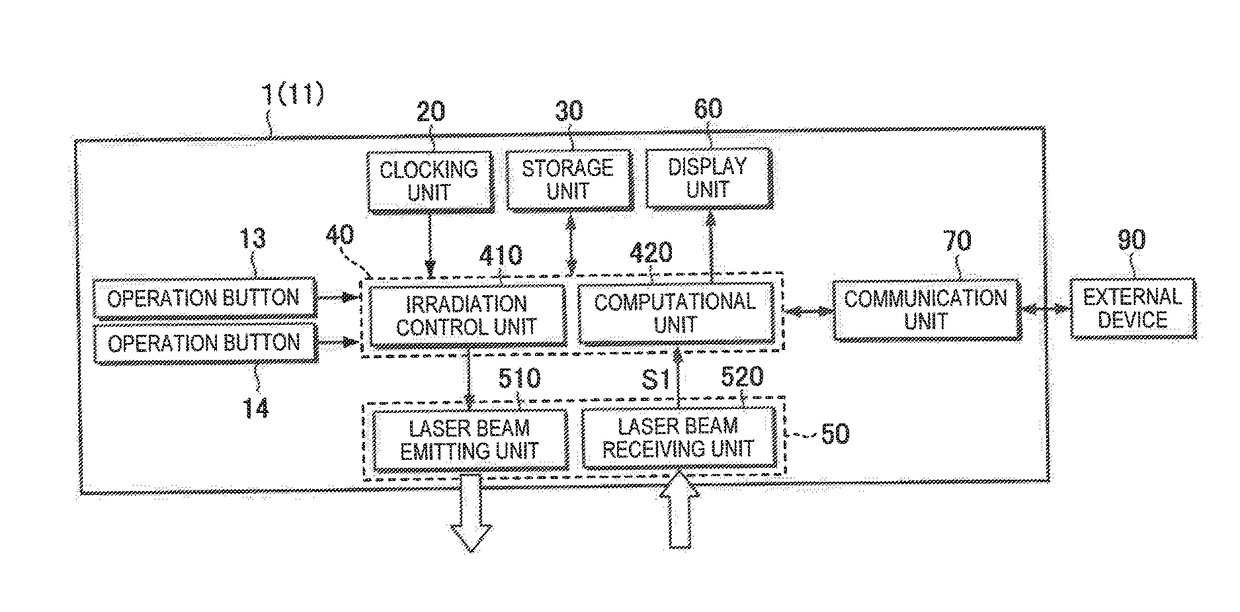

InactiveUS20170251936A1Small sizeChange over time in blood vessel cross-sectional areaBlood flow measurement devicesOrgan movement/changes detectionMeasurement deviceAcoustic wave

A biological information measurement apparatus includes an irradiation unit configured to irradiate a living body with light or sound waves as measurement waves; a detection unit configured to detect the measurement waves having passed through the inside of the living body; and a computational unit configured to obtain a change over time in blood flow rate and a change over time in blood vessel cross-sectional area based on a detection result from the detection unit, and to obtain a pulse wave propagation velocity from the change over time in blood flow rate or the change over time in blood vessel cross-sectional area.

Owner:SEIKO EPSON CORP

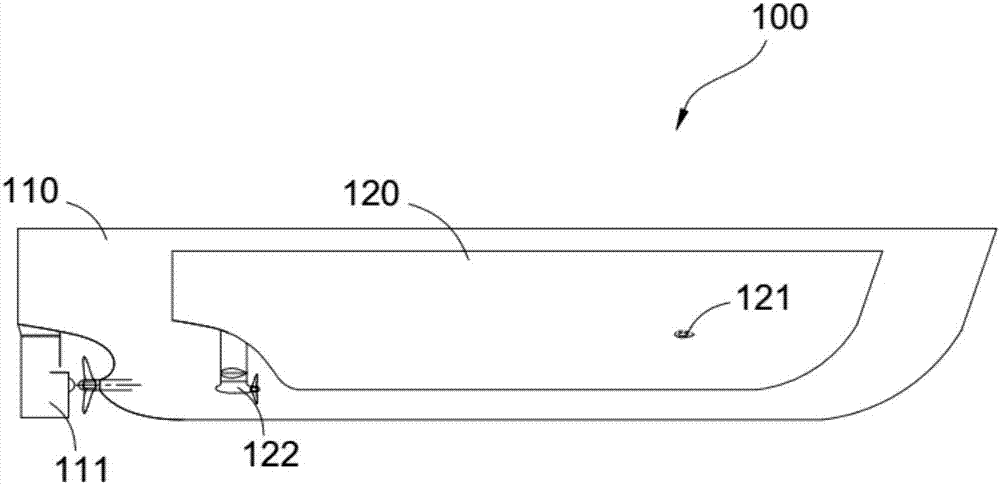

Composite triple-hulled vessel with aid-to-navigation hydrofoils

ActiveCN107089296AAvoid shockChange areaHydrodynamic/hydrostatic featuresMarine engineeringMarine navigation

The invention discloses a composite triple-hulled vessel with aid-to-navigation hydrofoils. The composite triple-hulled vessel comprises a deck, a main vessel body and two side vessel bodies, wherein the main vessel body and the two side vessel bodies are fixedly connected to the lower surface of the deck; the two side vessel bodies are located at the left and right sides of the main vessel body, and a deep-immersed aid-to-navigation hydrofoil is arranged at the tail portion of each side vessel body. According to the composite triple-hulled vessel with the aid-to-navigation hydrofoils, the design ideas of two high-performance vessels which are added with hydrofoils and side bodies correspondingly to be propelled are combined together, while the advantages of a triple-hulled vessel is ensured, the aid-to-navigation hydrofoils added with propelling devices assist the side vessel bodies to propel, so that the turning ability and the maneuverability of the triple-hulled vessel are enhanced, and the lengths of the deep-immersed aid-to-navigation hydrofoils and wave energy recycling hydrofoils are adjusted to change the areas of the hydrofoils, so that the flotation of the triple-hulled vessel in the sailing process is controlled.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

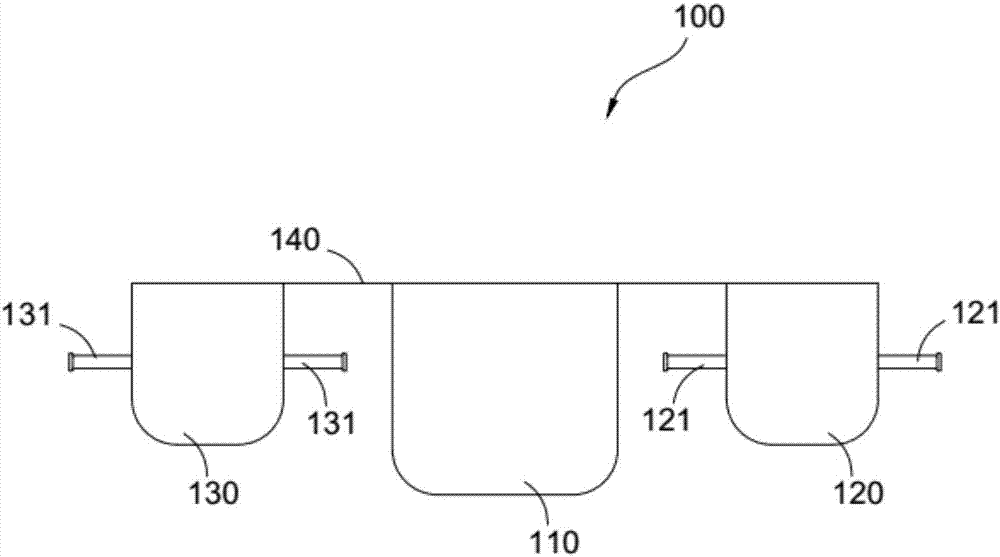

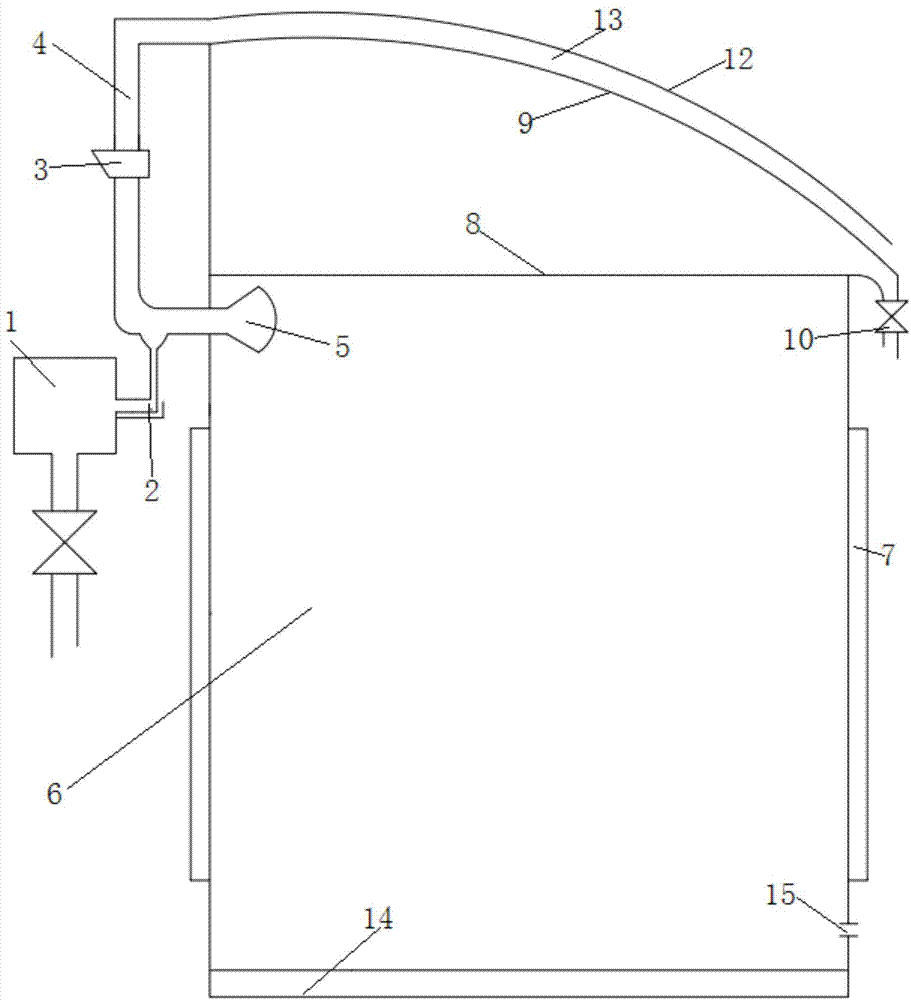

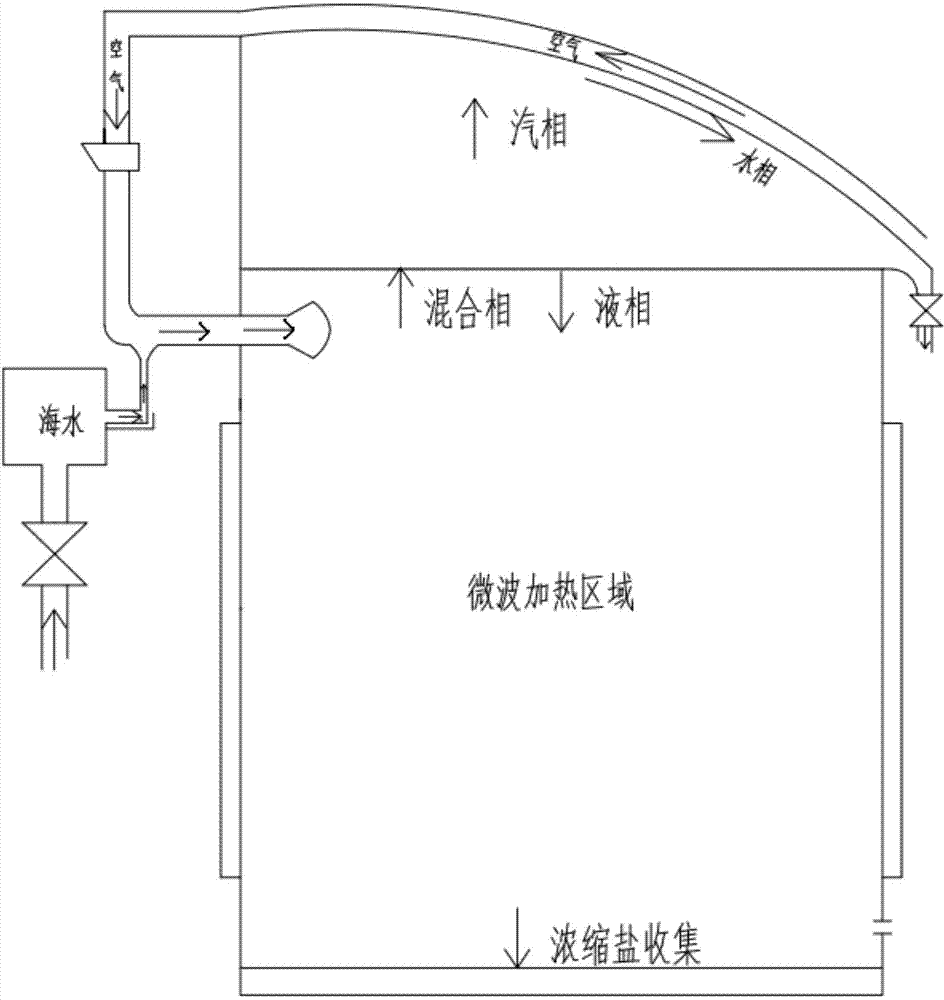

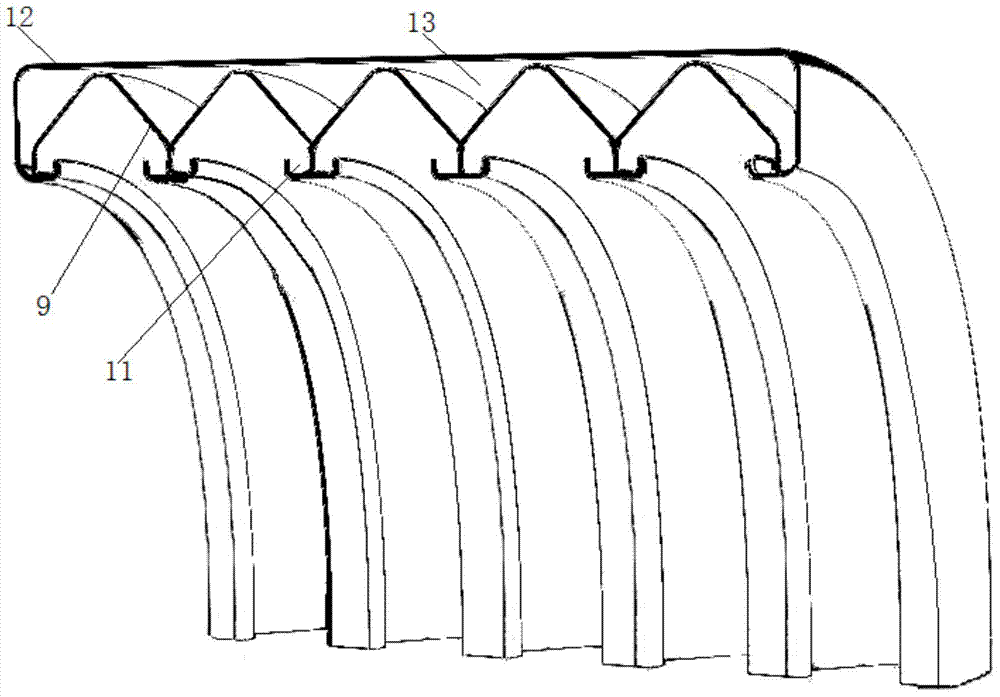

Seawater desalting device

InactiveCN103693700AAdjustable sizeIncrease temperatureWater/sewage treatment by irradiationGeneral water supply conservationGratingWater storage tank

The invention provides a seawater desalting device. The seawater desalting device at least comprises a water storage tank, an ultrasonic atomizer, a gas-liquid mixing unit, an evaporating and condensing unit, and pipelines used for enabling the parts to be communicated with each other, wherein seawater is stored in the water storage tank, and the ultrasonic atomizer is connected with the water storage tank through the pipeline; the gas-liquid mixing unit consists of an air compressor, a gas inlet pipeline and a nozzle; the evaporating and condensing unit at least comprises an evaporator, a microwave heater, a grating filter, a condensing deflector and a water outlet pipe, a hollow evaporating cavity is formed inside the evaporator, the microwave heater is mounted on the inner wall of the evaporating cavity, the grating filter covers the top of the evaporating cavity, the condensing deflector is mounted above the grating filter, and a deflecting trench is formed in the condensing deflector. The device has the advantages that sprayed liquid drops are small; uniformity of atomized liquid drops is good; evaporating speed is high; energy utilization rate is high during the evaporation of water by a microwave heating method; the size of atomized particles can be adjusted; the energy utilization rate is high.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

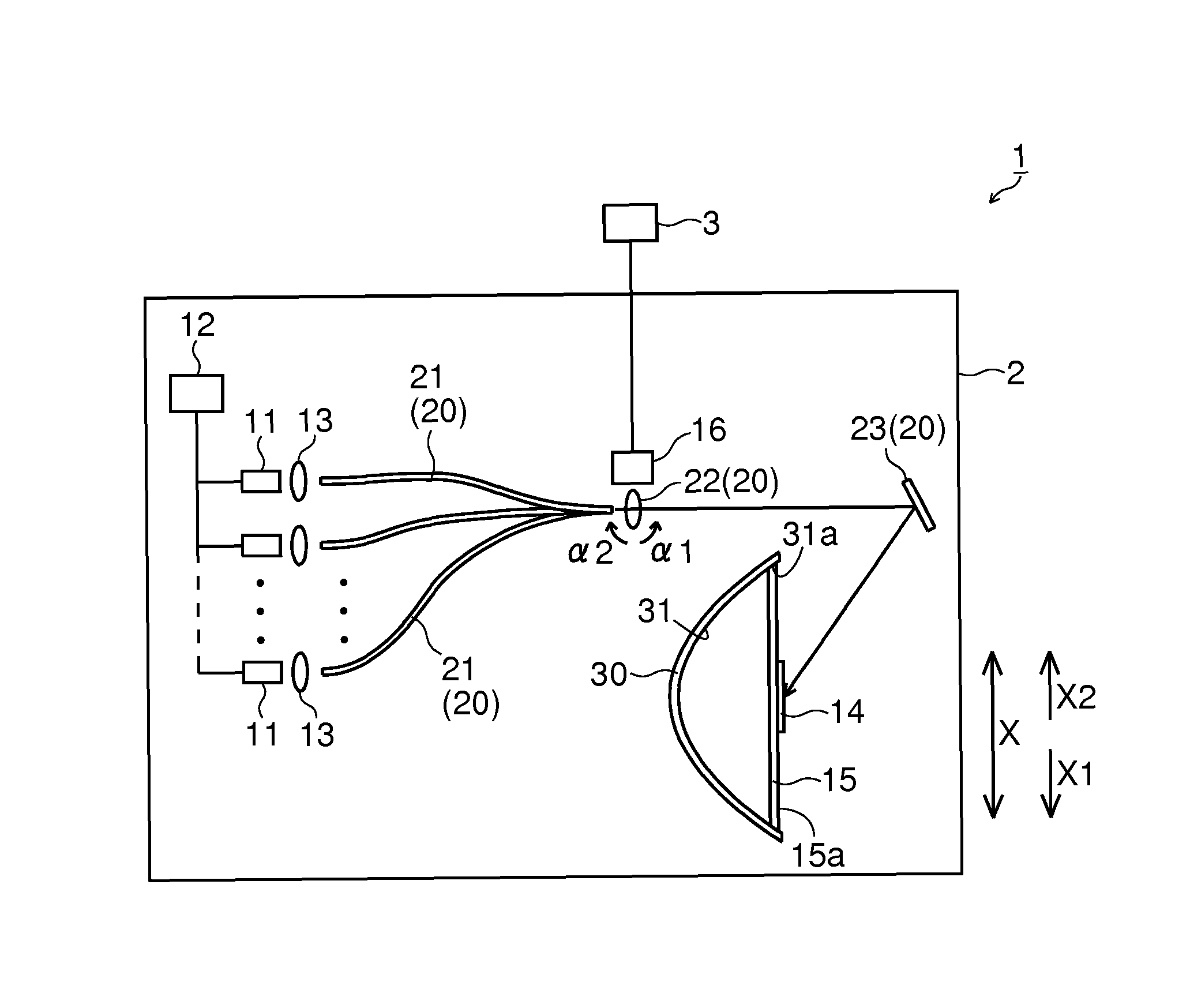

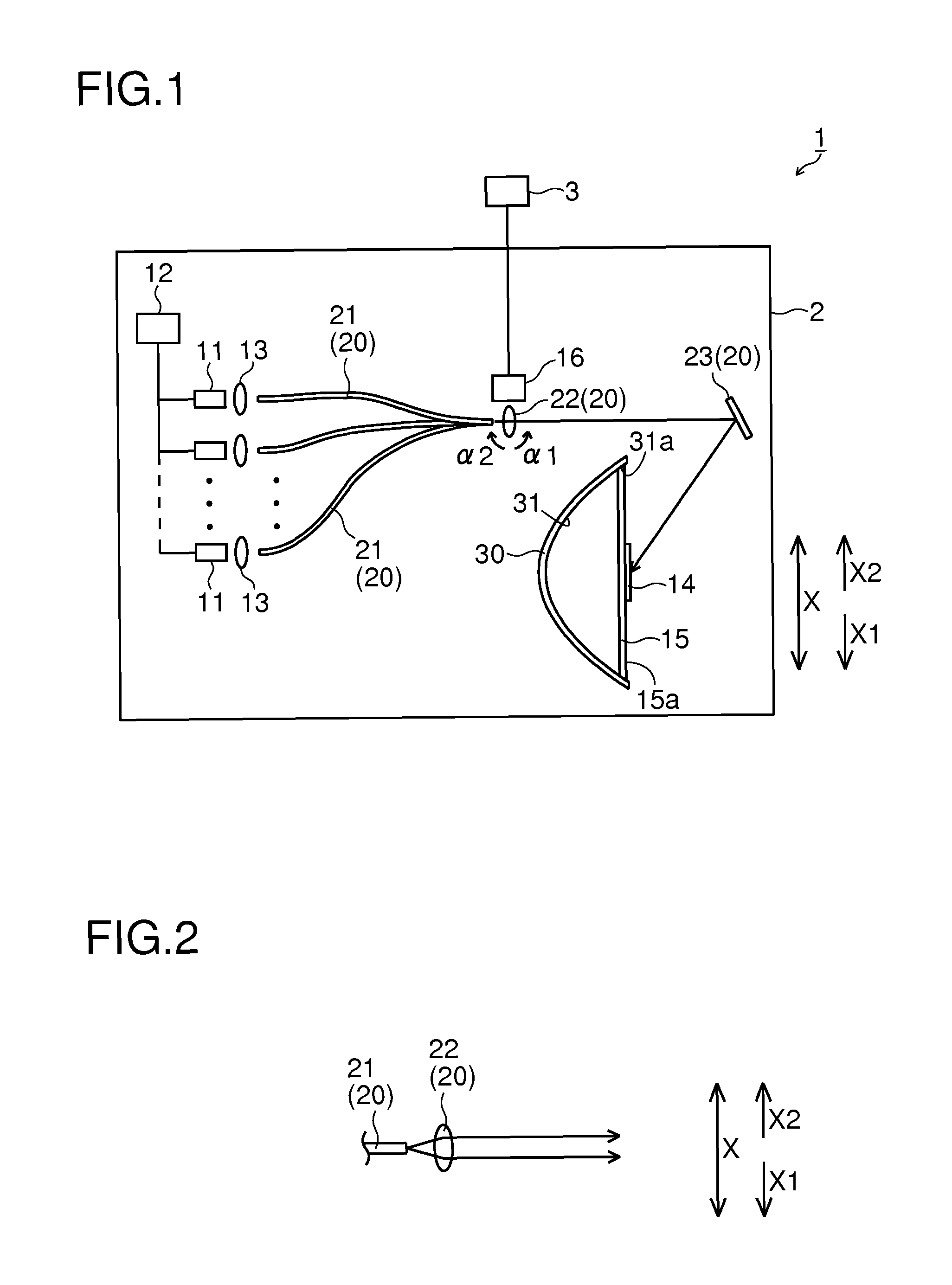

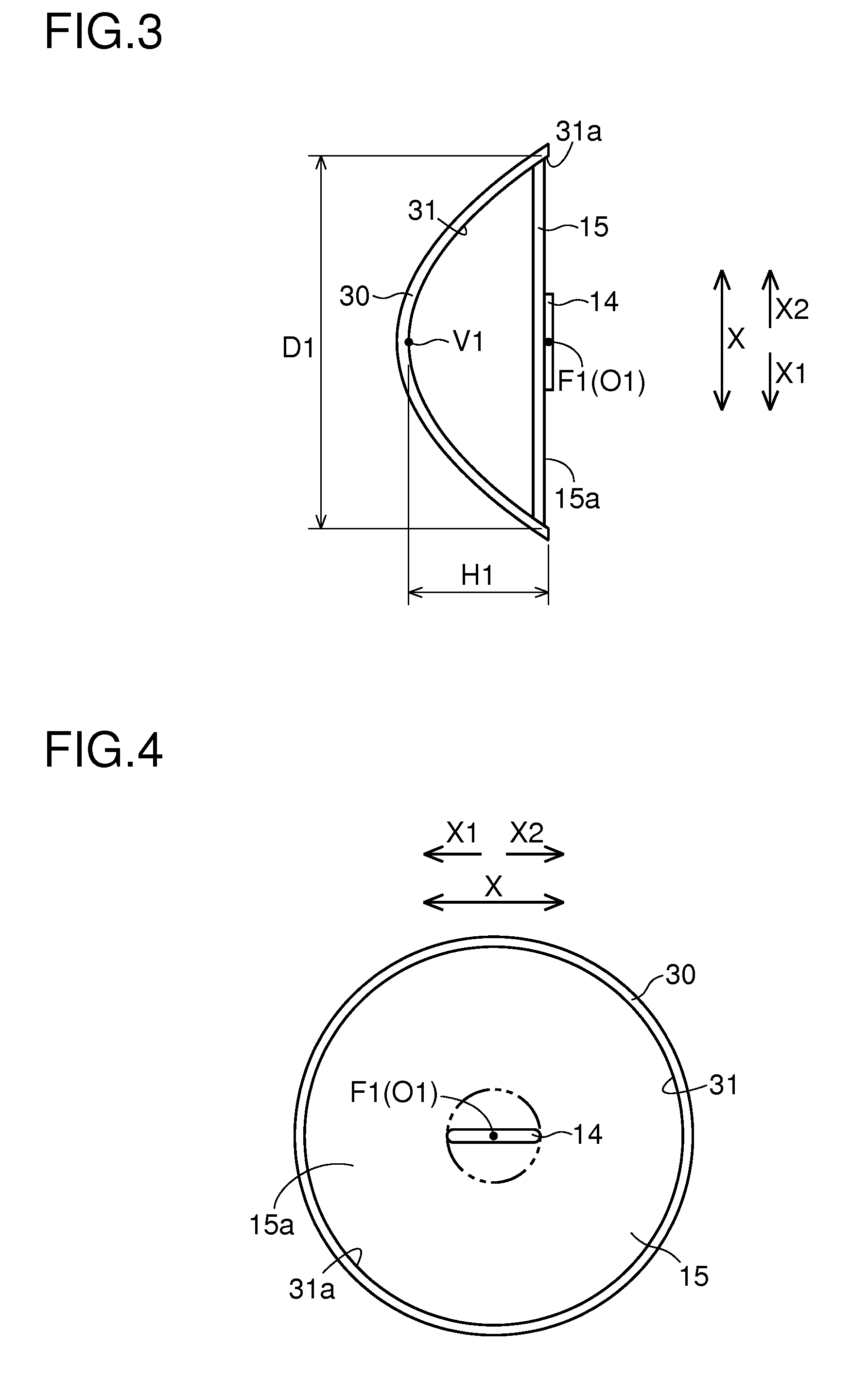

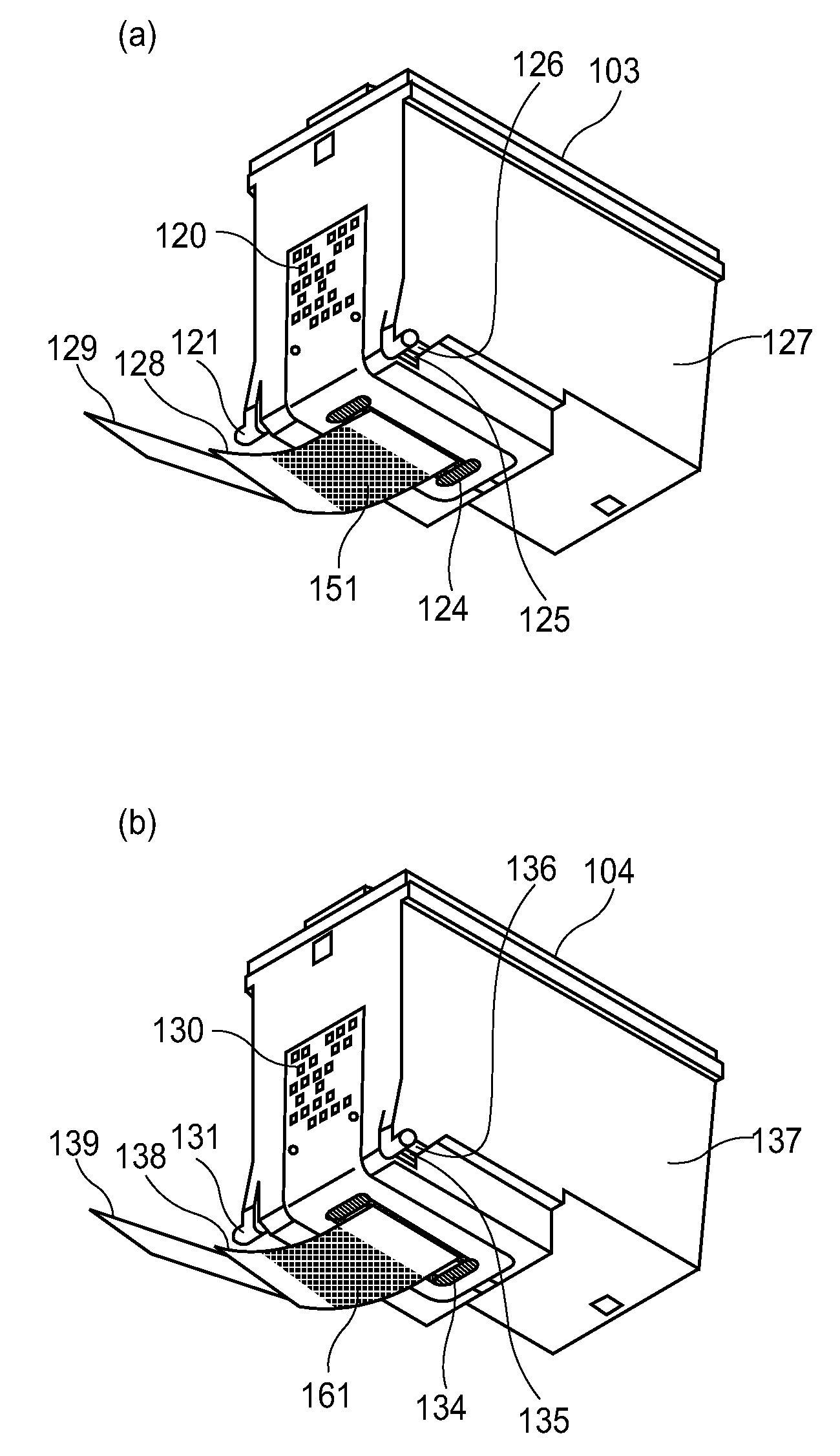

Lighting apparatus, headlamp, and mobile body

ActiveUS8708537B2Change areaPoint-like light sourcePortable electric lightingEffect lightLaser light

A lighting apparatus is provided that, while suppressing an increase in size, can change the illuminating direction. The lighting apparatus has: a laser generator which emits laser light; a light emitting member which is irradiated with the laser light emitted from the laser generator to emit light; an irradiated position changer which moves and thereafter stops an irradiated position at which the light emitting member is irradiated with the laser light; and a light projecting member which projects the light emitted from the light emitting member.

Owner:SHARP FUKUYAMA LASER CO LTD

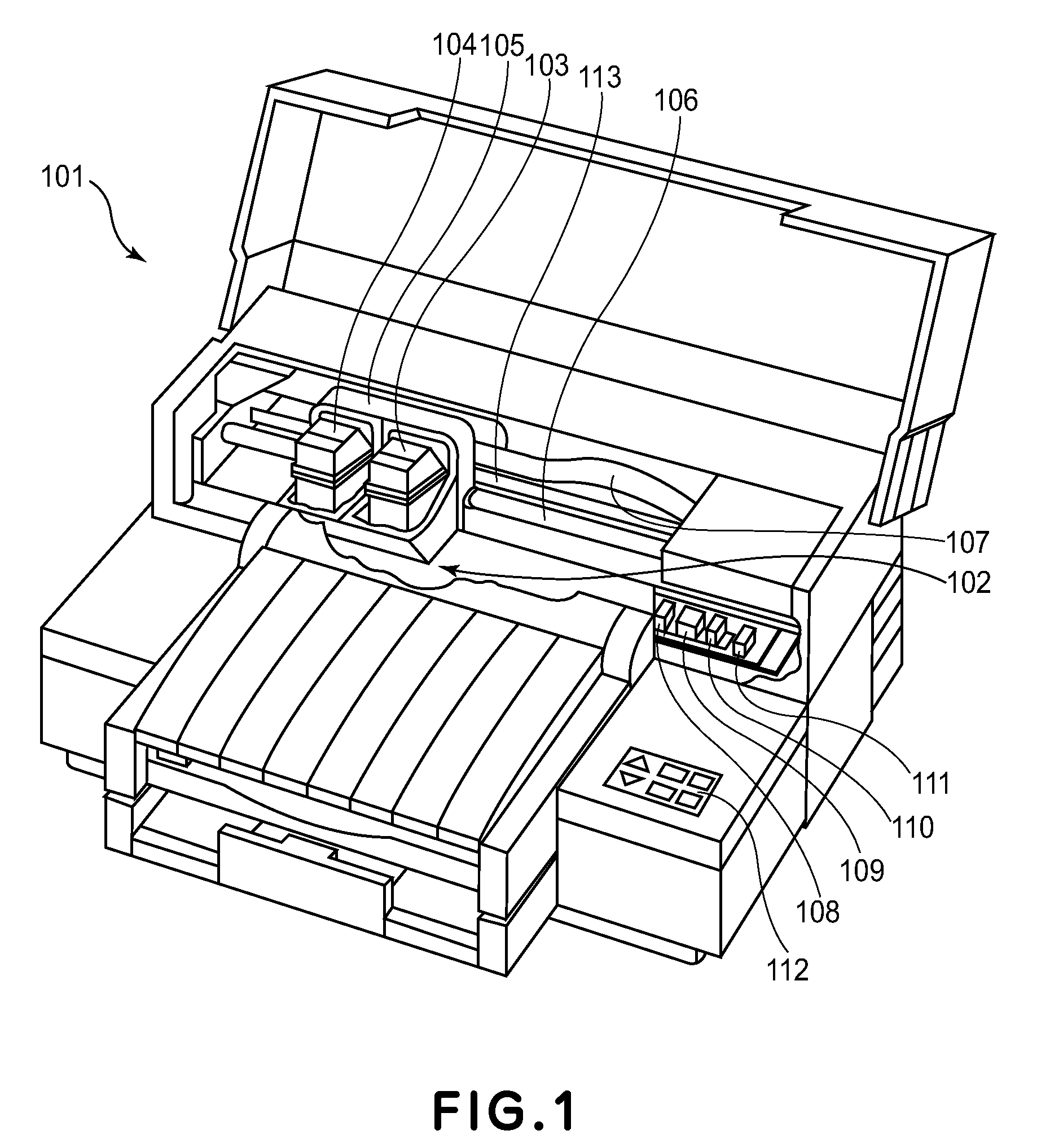

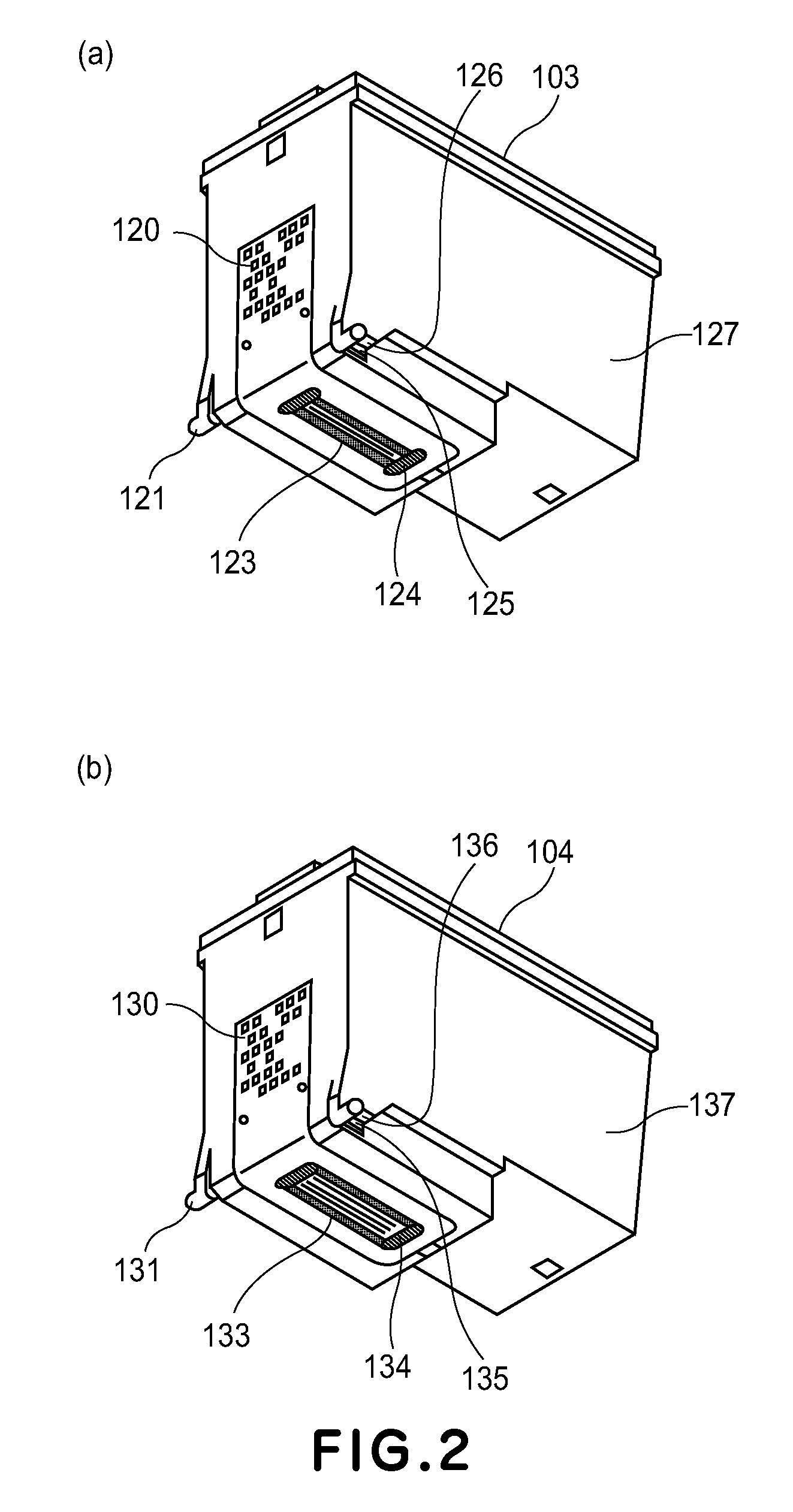

Ink jet recording head, ink jet cartridge, and method for manufacturing ink jet recording head

An ink jet recording head having an array of ink ejection outlets in an ejection outlet forming surface on which a protection tape is stuck in transportation, wherein the ejection outlet forming surface has an outside area which is outside of each of opposite ends of the array with respect to a direction of the array, and the outside area has a peel resistance, provided by surface modification, which resistance is higher than in another portion of the ejection outlet forming surface.

Owner:CANON KK

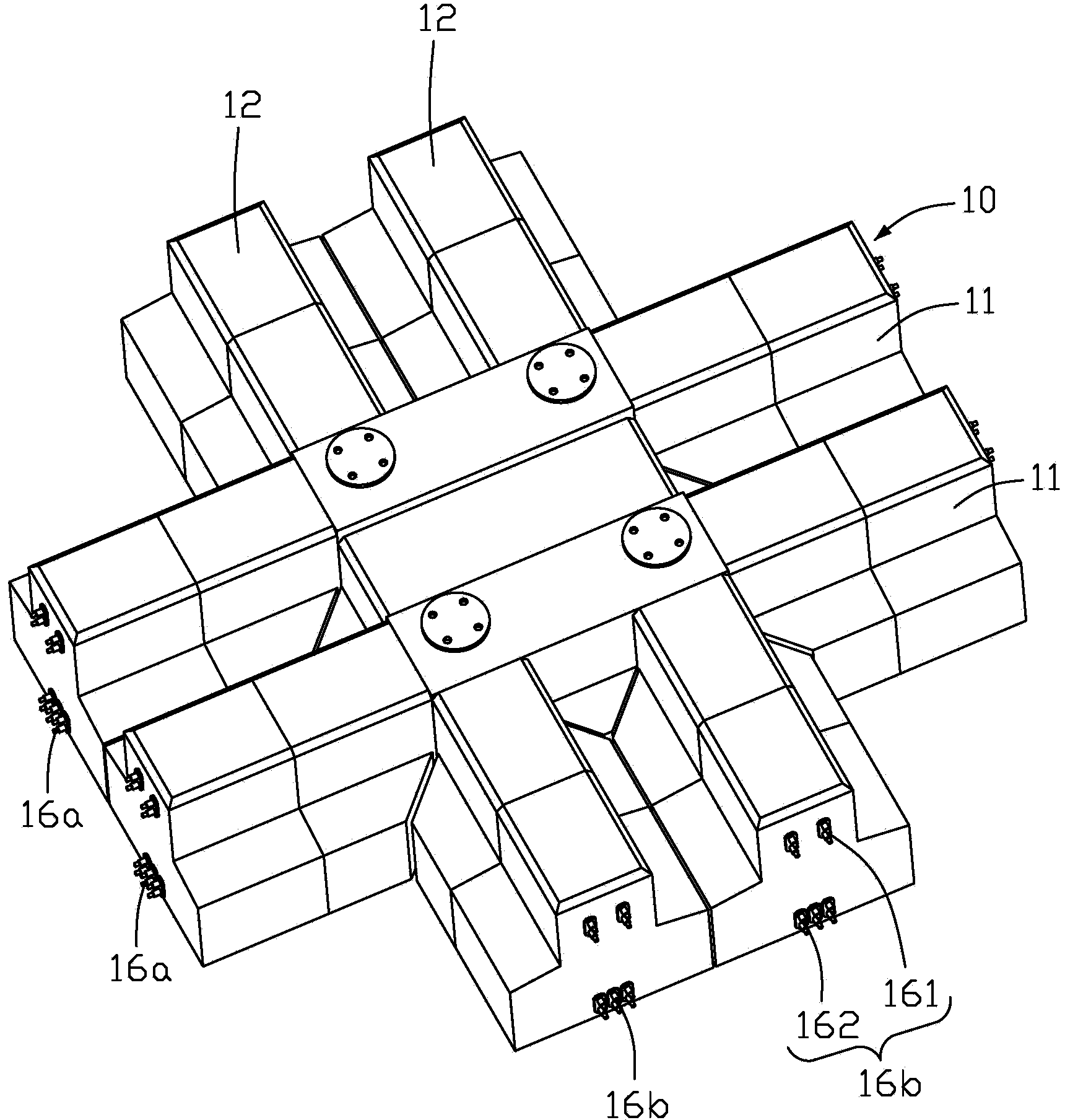

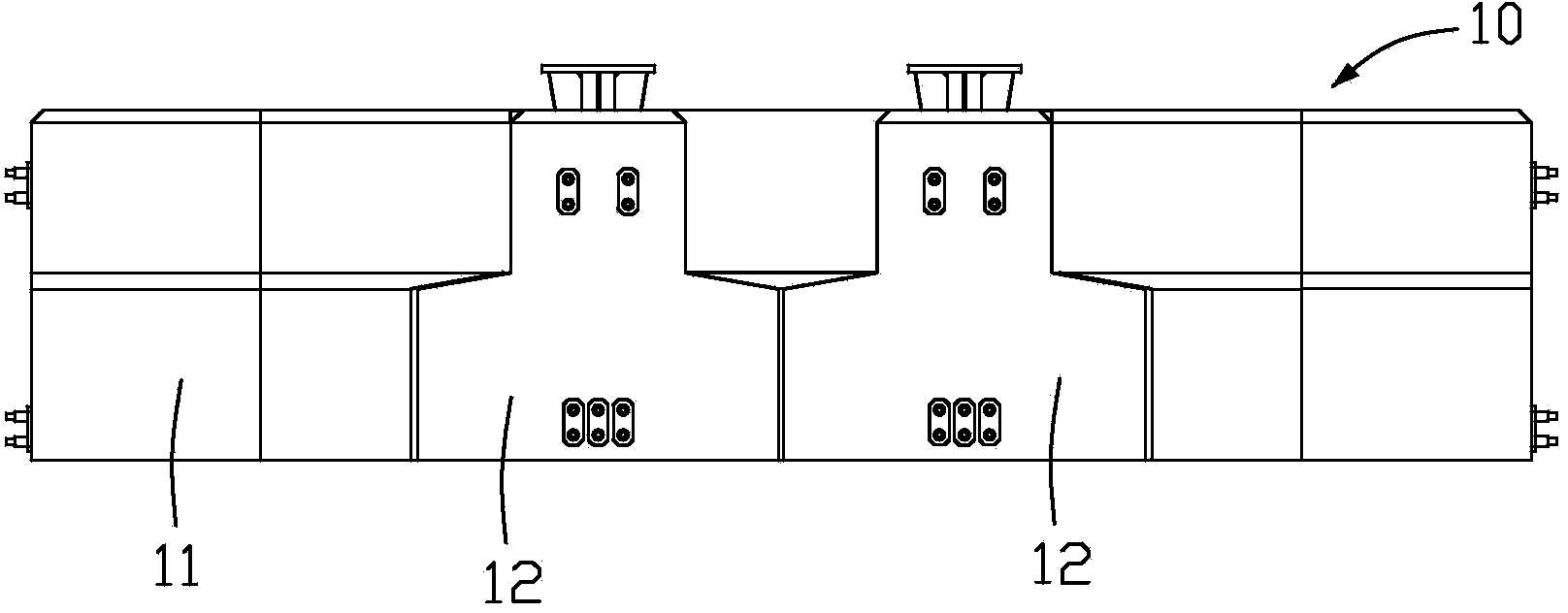

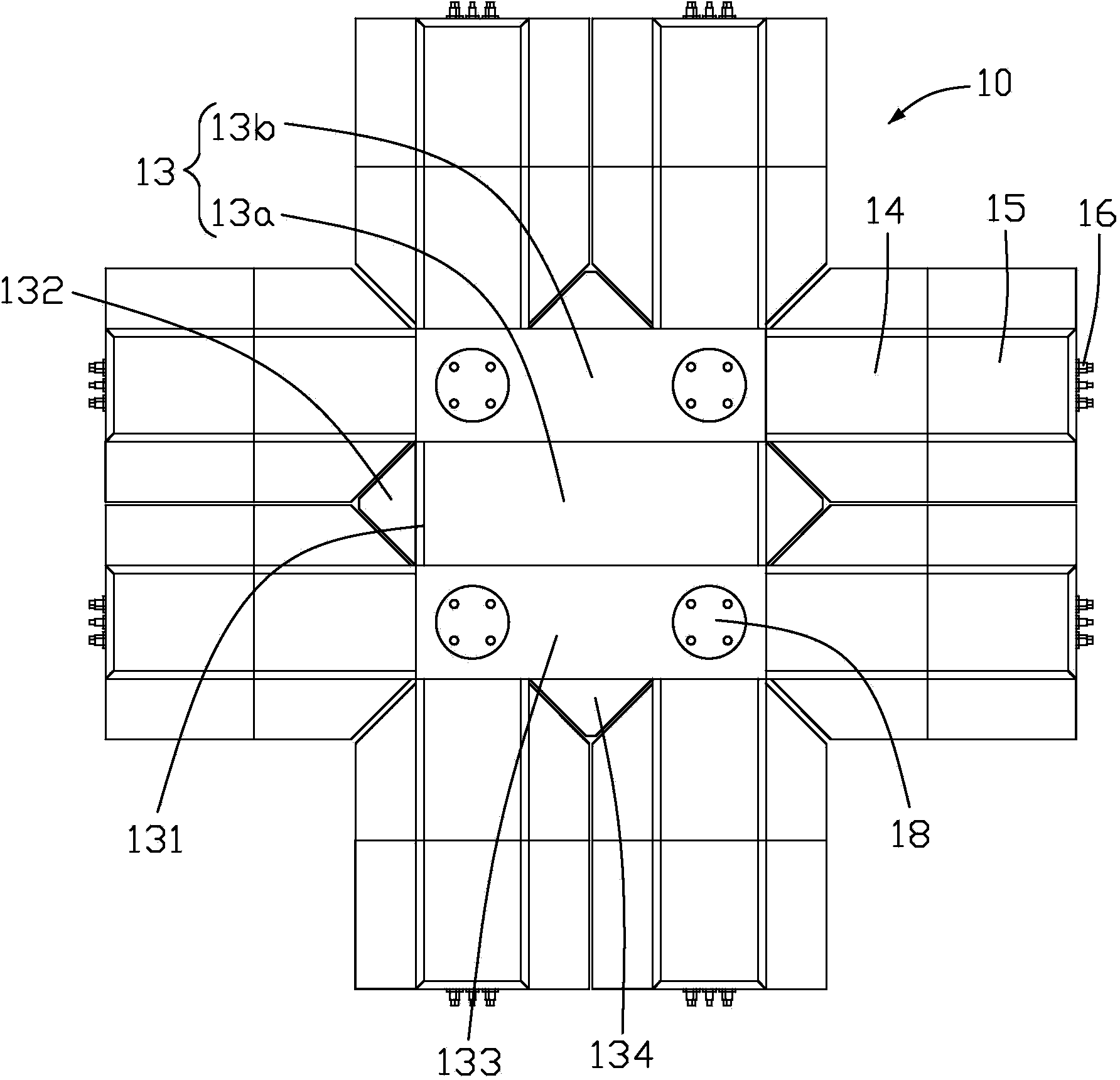

Prefabricated and assembled tower crane foundation

The invention discloses a prefabricated and assembled tower crane foundation, which is formed by assembling concrete prefabricated parts, wherein the tower crane foundation comprises two groups of first prefabricated foundations which are parallel to each other in a transverse direction and two groups of second prefabricated foundations which are parallel to each other in a longitudinal direction; the two groups of first prefabricated foundations and the two groups of second prefabricated foundations are distributed in a grid-shaped manner, and are connected and locked through steel strands, the steel strands consist of two groups of first steel strands which are respectively arranged in the two groups of first prefabricated foundations and two groups of second steel strands which are respectively arranged in the two groups of second prefabricated foundations, and the two groups of first steel strands and the two groups of second steel strands are also distributed in a grid-shaped manner. The tower crane foundation can be recycled and has a larger contact area with the ground, and the steel strands are more uniformly distributed and dispersed in the foundation, so that the stress of the tower crane foundation is more uniform.

Owner:ZOOMLION HEAVY IND CO LTD

Electronic equipment

ActiveCN111683166AImprove portabilityMeet the needs of useDigital data processing detailsTelephone set constructionsEngineeringHigh electron

The embodiment of the invention provides electronic equipment. The electronic equipment comprises a shell and a display screen covering the shell, wherein the shell comprises a first shell part, a second shell part and a third shell part; when the electronic equipment is in a first state, the first shell part and the third shell part are spliced, the electronic equipment performs display through adisplay screen covering the first shell part and the third shell part, the first shell part and the third shell part form an accommodating space, and the second shell part is accommodated in the accommodating space; when the electronic equipment is in a second state, the first shell part, the second shell part and the third shell part are spliced, the second shell part is located between the first shell part and the third shell part, and the electronic equipment performs display through a display screen covering the first shell part, the second shell part and the third shell part. According to the electronic equipment, through contraction and extension of the shell, the available display area of the display screen is changed, the portability of the electronic equipment is improved, and meanwhile the use requirement of a user for the large display screen can be met.

Owner:VIVO MOBILE COMM CO LTD

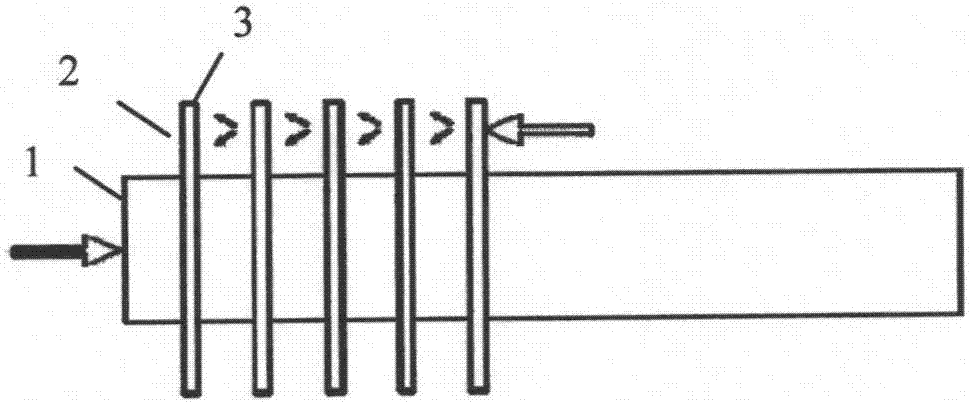

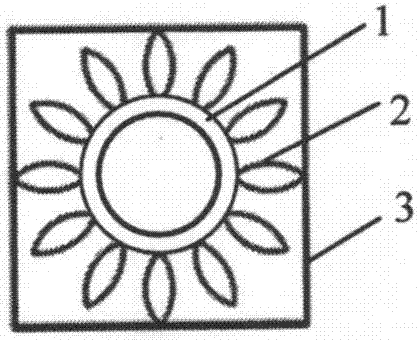

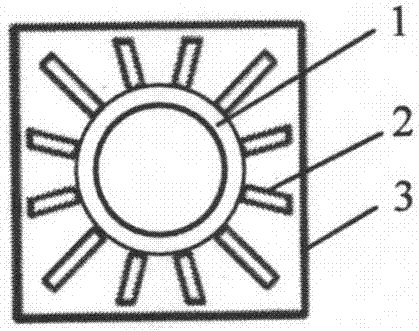

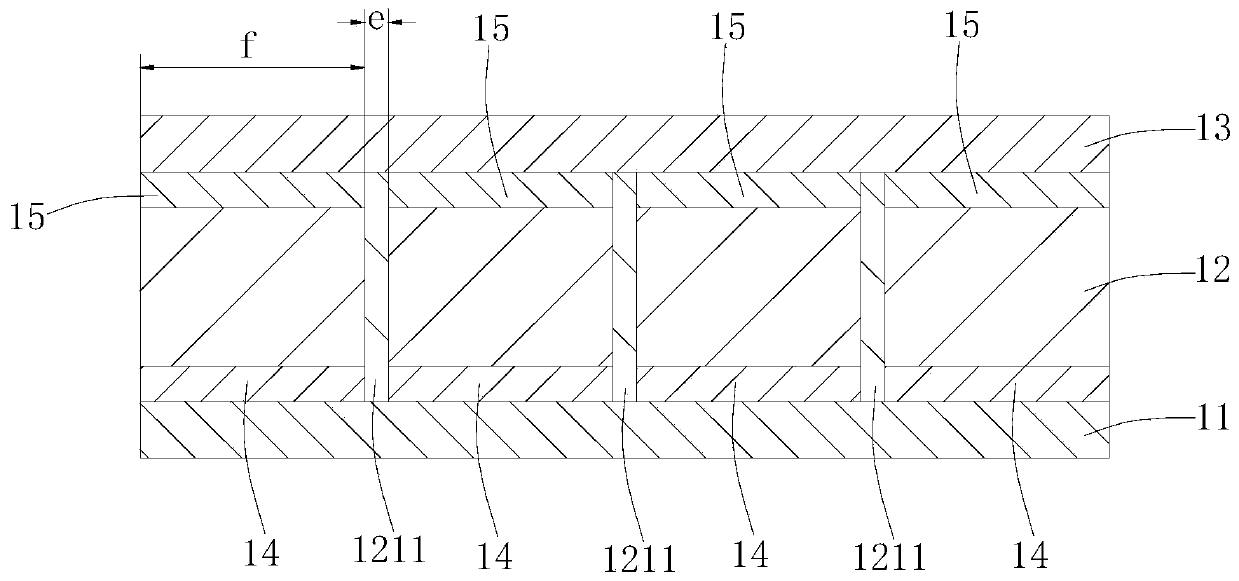

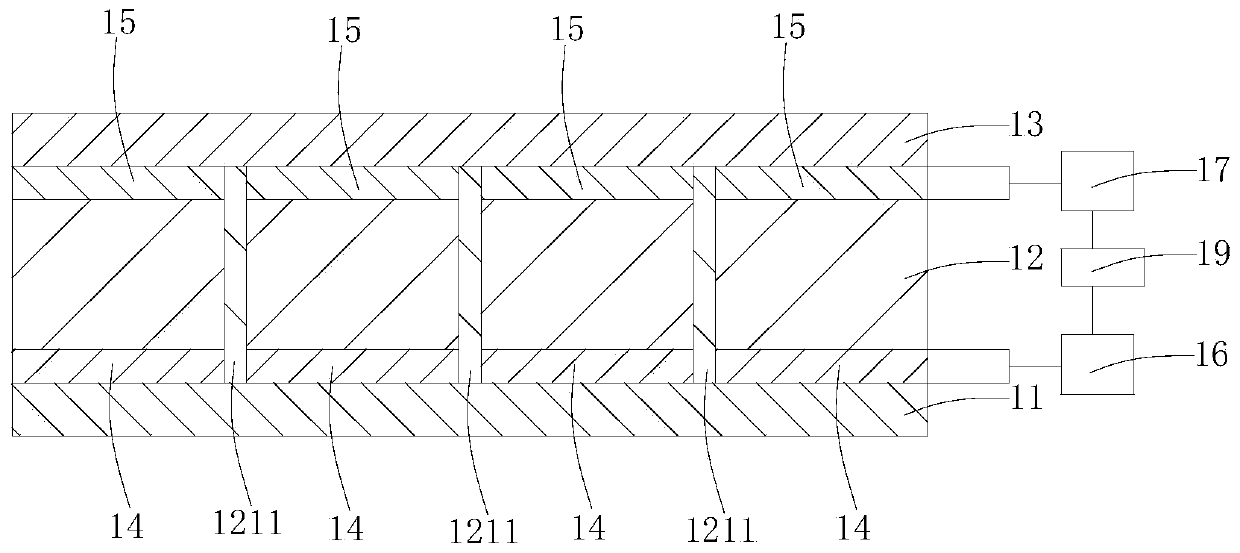

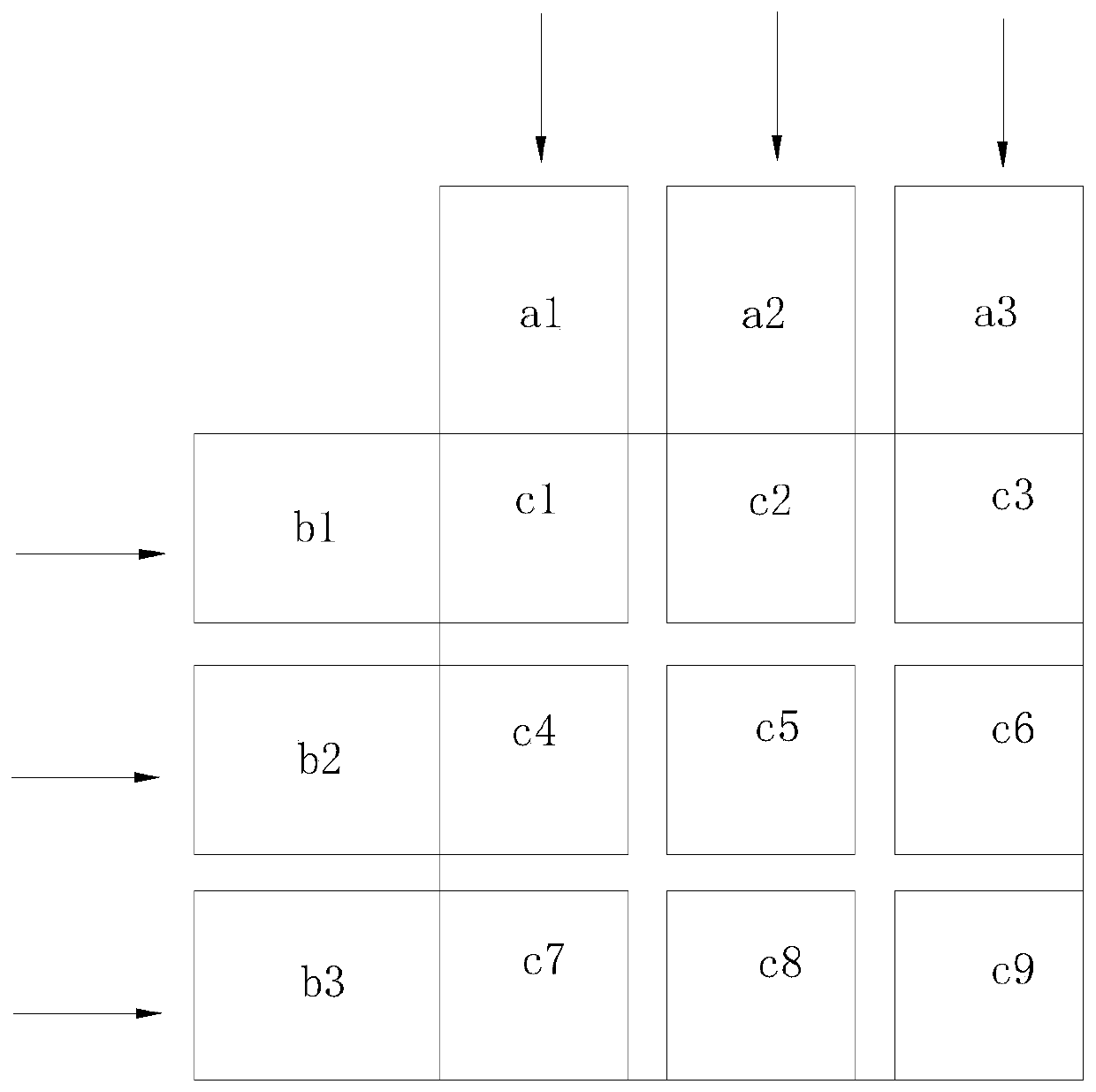

Outer fin heat exchange tube and application method thereof

ActiveCN107976101ARealize complete countercurrent heat exchangeRealize small temperature difference heat transferChemical industryHeat exhanger finsPlate heat exchangerEngineering

The invention provides an outer fin heat exchange tube, which comprises a heat transfer tube, outer fin groups, and an outer fin group frame. Each outer fin group is used for extending an outside heatexchange surface of the heat transfer tube, forming a micro-channel, restraining an adverse current of an outside tube fluid along an axial direction of the heat transfer tube, and producing a turbulent flow action at the same time; the outer fin group frame is used for reducing transverse flow of the outside tube fluid of the heat transfer tube; an outer wall of the heat transfer tube is connected with the multiple outer fin groups; the outer fin groups are arrayed along an axial direction of the heat transfer tube; holes are formed in the outer fin groups; the holes of the multiple outer fin groups form the micro-channel parallel to the axial direction of the heat transfer tube; and the peripheries of the outer fin groups are connected with the outer fin group frame. The invention further provides an application method of the outer fin heat exchange tube. According to the outer fin heat exchange tube provided by the invention, complete countercurrent flow heat exchange is realized between fluids inside and outside the tube, so that small temperature-difference heat transfer can be realized; when the outside tube fluid passes through the micro-channel structure of the outer fin groups, fins have the sufficient turbulent flow action, so that a convective heat-transfer coefficient is improved; and the outer fin heat exchange tube can be used for manufacturing a high-efficient and compact heat exchanger, and is particularly applicable to a gas-gas heat exchange working condition.

Owner:SHANGHAI POWER EQUIP RES INST

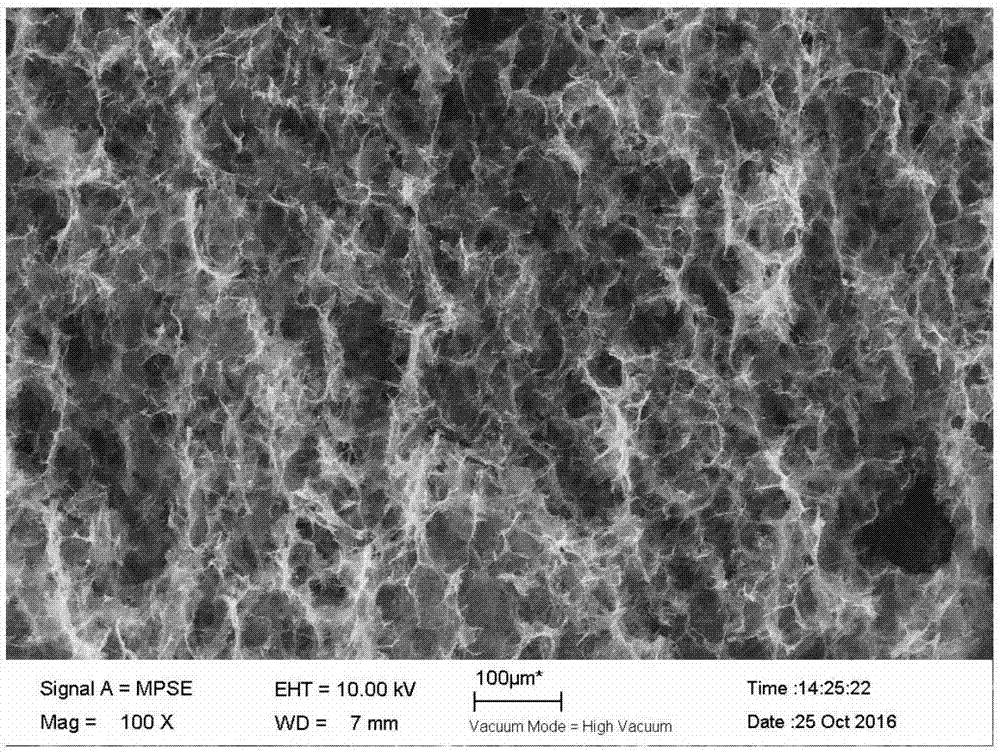

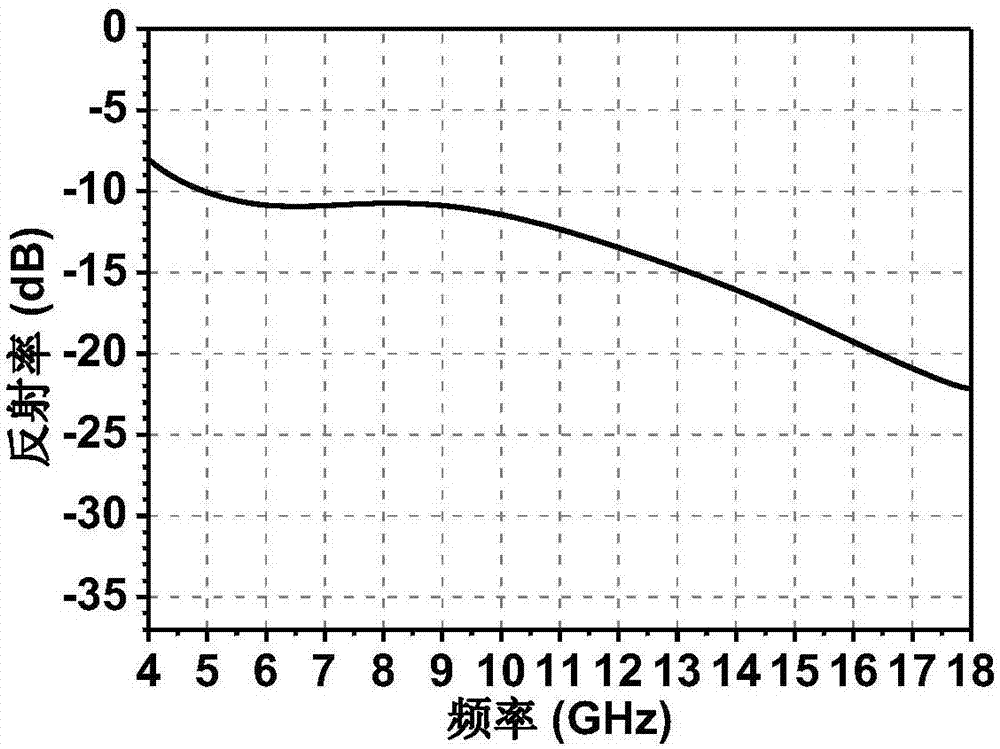

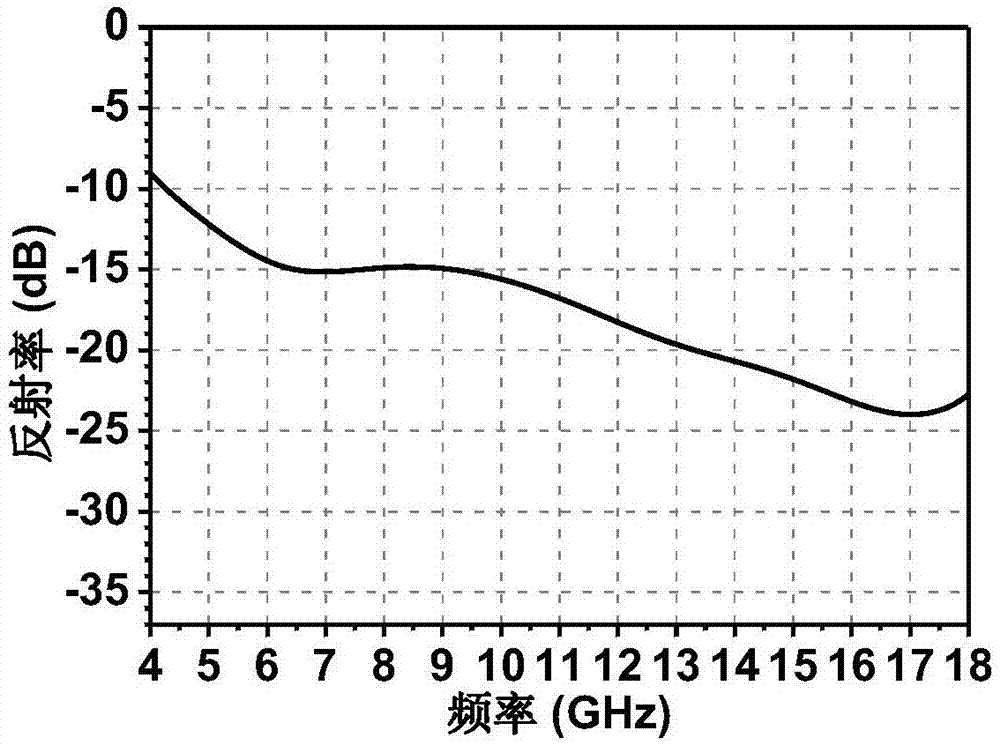

Broadband electromagnetic wave absorbing material based on polyaniline graphene three-dimensional porous structure

ActiveCN107072128AChange absorbencyChange in absorbencyMagnetic/electric field screeningFiberMicrowave

The invention relates to a broadband electromagnetic wave absorbing material and particularly relates to a broadband electromagnetic wave absorbing material based on a polyaniline graphene three-dimensional porous structure. The wave absorbing material has a remarkable absorbing effect for incident electromagnetic waves in 4 to 18GHz frequency bands, the density is not larger than 25mg / cm3, and both the thickness and area are controllable. The density of the electromagnetic wave absorbing material is far smaller than that of wave absorbing materials such as carbonyl iron, carbon black and carbon fiber, the total mass per cubic metre is not larger than 25g, the reflectivity of the electromagnetic wave absorbing material for micro waves in a frequency range of 6 to 18GHz is lower than -10dB.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

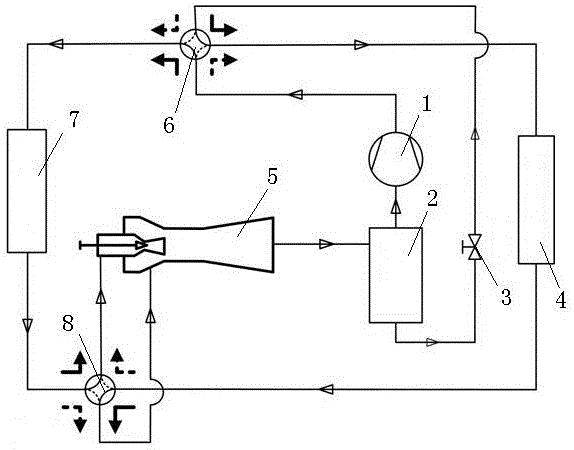

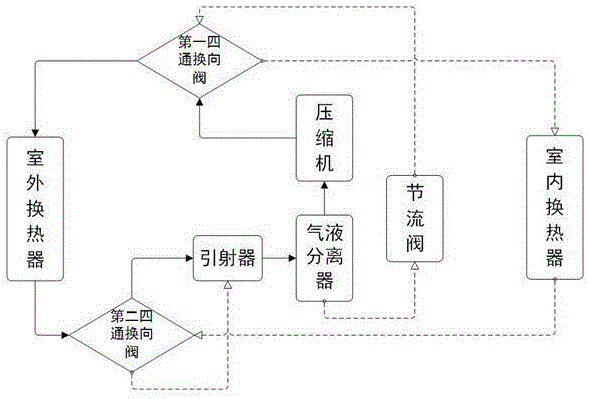

Dual-operation compression-ejection heat pump air conditioner system

InactiveCN105805981ALower pressure ratioImprove efficiencyMechanical apparatusFluid circulation arrangementVapor–liquid separatorEngineering

The invention relates to a dual-operation compression-ejection heat pump air conditioner system. The dual-operation compression-ejection heat pump air conditioner system comprises an ejector and two four-way reversing valves. An exhaust port of a compressor is connected with an inlet of an outdoor heat exchanger and an inlet of an indoor heat exchanger through the first four-way reversing valve. An outlet of the outdoor heat exchanger is connected with a work nozzle inlet and a suction chamber inlet of the ejector through the second four-way reversing valve. An outlet of the ejector is connected with an inlet of a gas-liquid separator through a pipeline. A gas outlet of the gas-liquid separator is connected with a gas inlet of the compressor through a pipeline. A liquid outlet of the gas-liquid separator is connected with an inlet of a throttle valve through a pipeline. An outlet of the throttle valve is connected with the inlet of the indoor heat exchanger and the inlet of the outdoor heat exchanger through the first four-way reversing valve. An outlet of the indoor heat exchanger is connected with the work nozzle inlet and the suction chamber inlet of the ejector through the second four-way reversing valve. The ejector is used for replacing an expansion valve to recycle expansion work, so that the refrigeration efficiency is improved, and the two four-way reversing valves are used for switching to achieve the refrigeration and heating dual-operation function.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

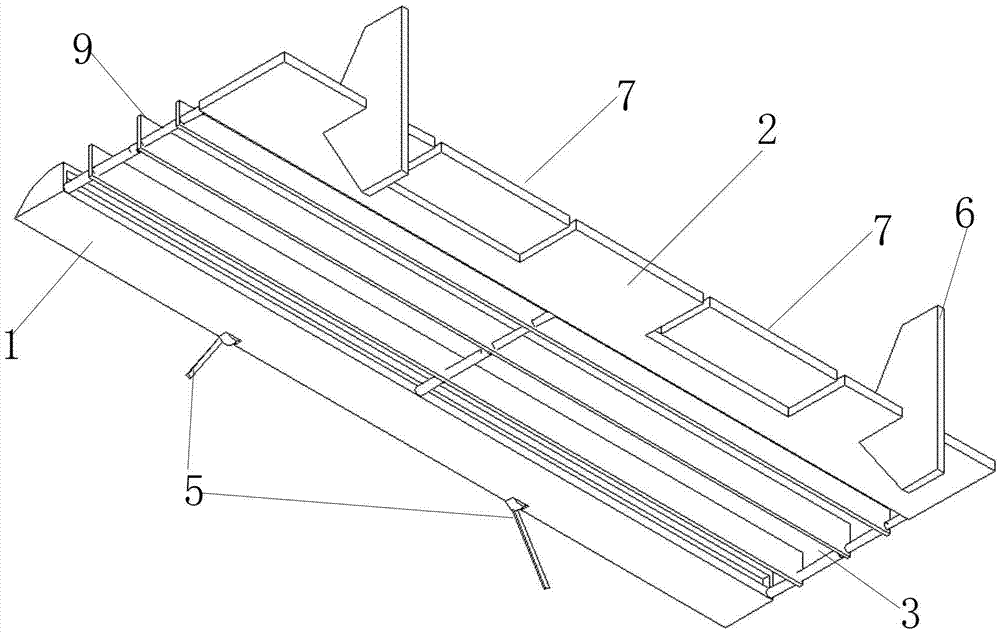

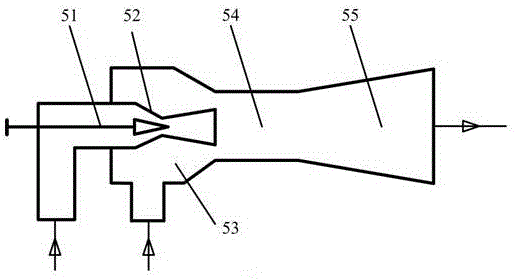

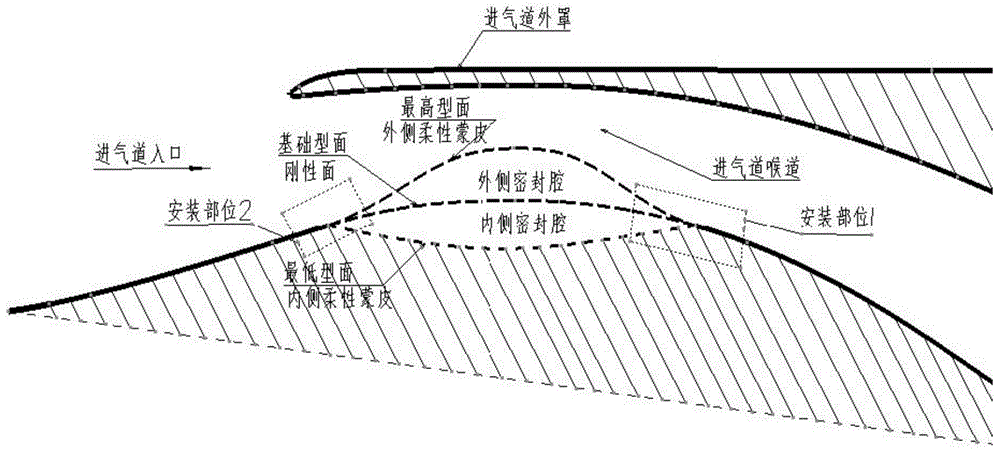

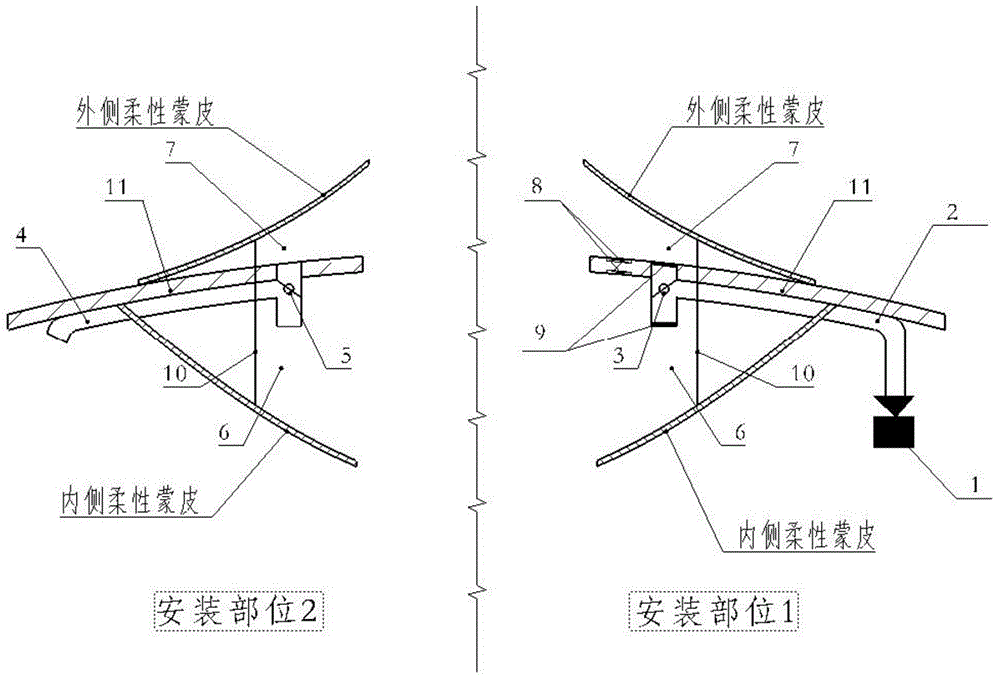

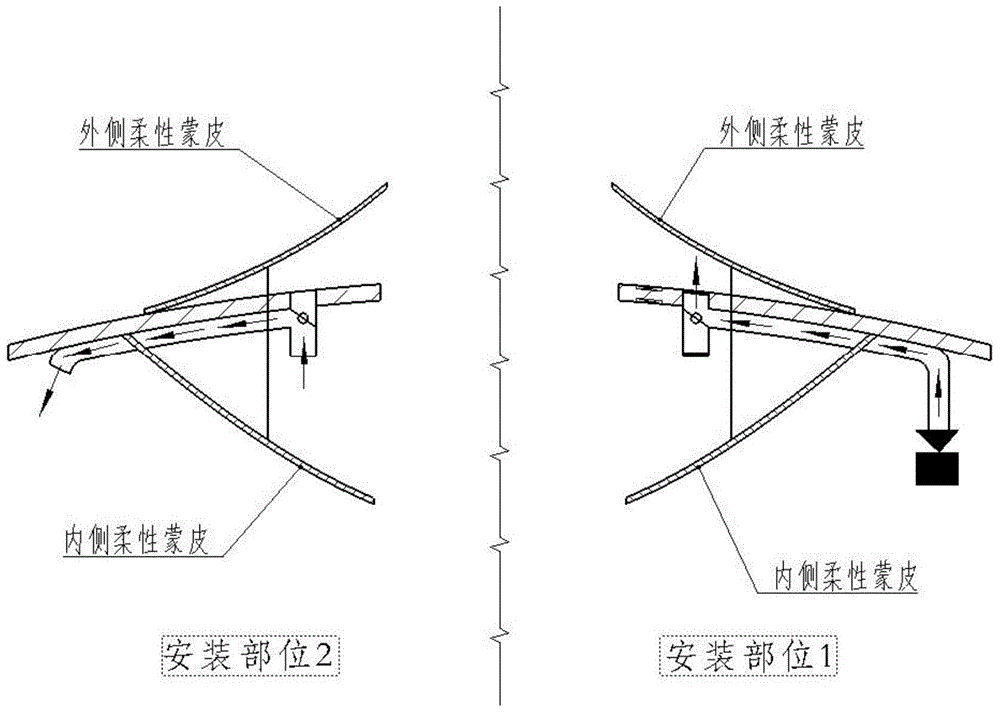

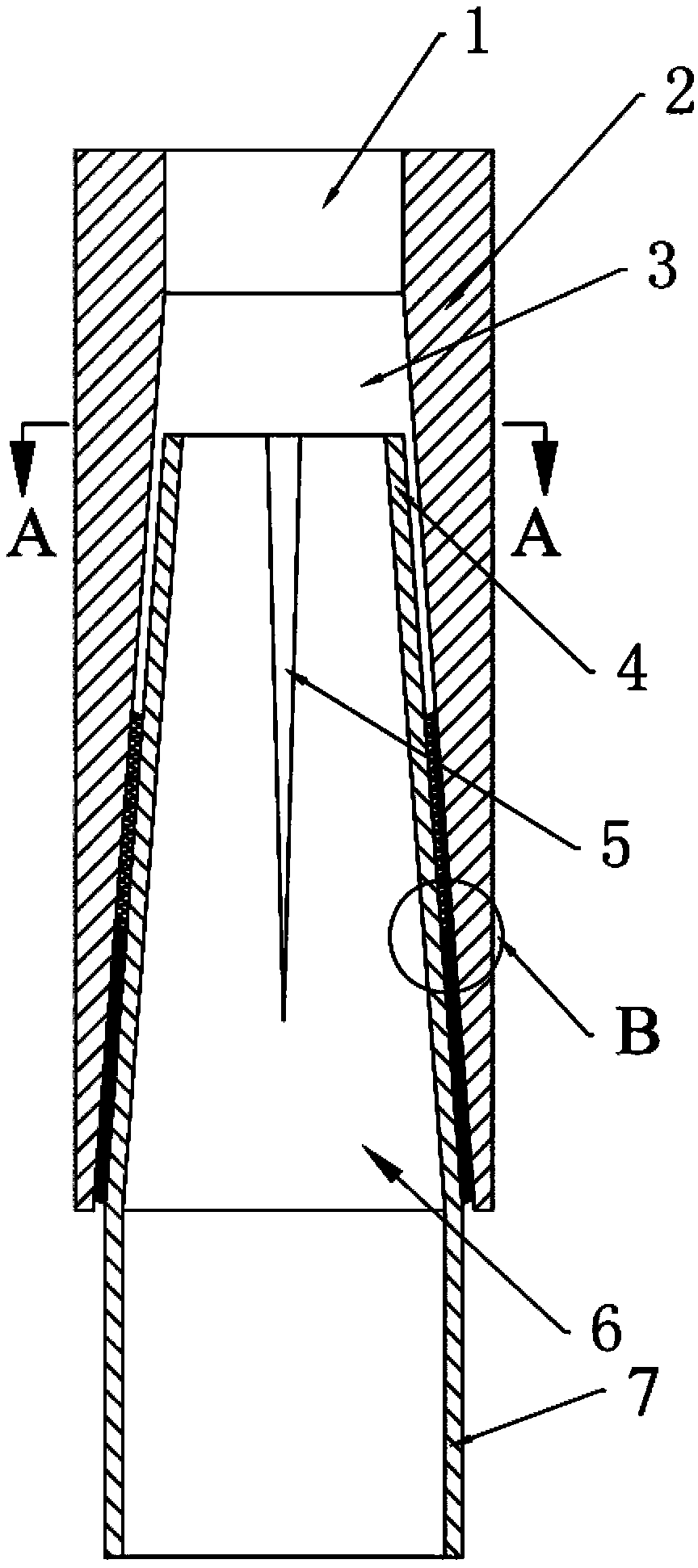

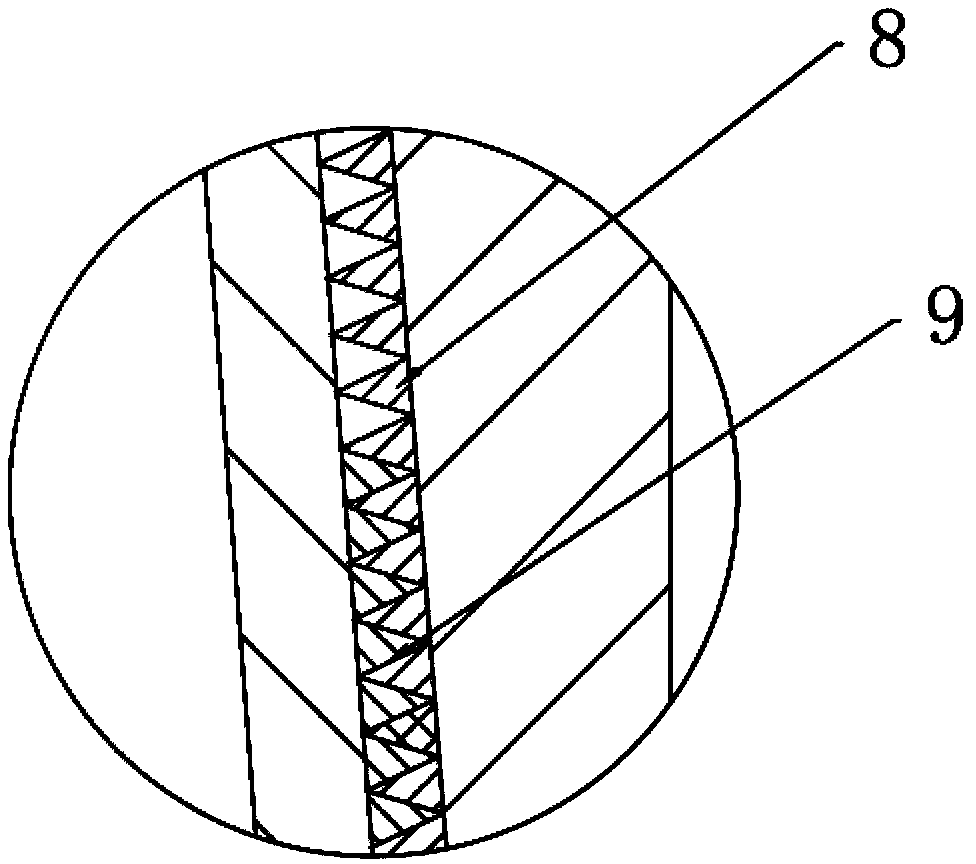

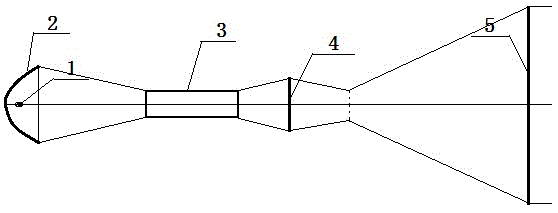

Adaptive bulging air inlet channel deformation driving device based on flexible skin

ActiveCN104401498ASolve the problem of insufficient out-of-plane stiffnessSolve the non-adjustableFuselagesPower plant air intake arrangementsAviationShape change

The invention belongs to the technical field of aviation structural design, and relates to an adaptive bulging air inlet channel deformation driving device based on flexible skin. The driving device comprises an inflation pump (1), an inflation pipeline (2), an inflation valve (3), a deflation pipeline (4), a deflation valve (5), an inner-side sealing cavity (6), an outer-side sealing cavity (7), a pressure sensor (8), a flow sensor (9), a skin connecting belt (10) and a basic profile mounting region (11). According to the driving device, shape change of the bulging profile of an air inlet channel in a large range is realized by using a gas pressurizing way, and the shape of the bulging profile is controlled by using pressure and flow information, so that the throat area of the air inlet channel is changed, and the problem of non-adjustability of the profile of the bulging air inlet channel is solved.

Owner:沈阳飞机设计研究所扬州协同创新研究院有限公司

Aperture structure, camera and electronic device

PendingCN110794634AImprove controllabilityEasy to set upTelevision system detailsColor television detailsTransmittanceEngineering

The invention provides an aperture structure, a camera and an electronic device. The aperture structure comprises a substrate and a plurality of electrochromic units, wherein the plurality of electrochromic units are arranged on the substrate; and the plurality of electrochromic units are arranged in an array on the substrate, and each electrochromic unit is used for changing the light transmittance of the electrochromic unit after being applied with voltage, so as to change the light transmittance of the aperture structure. According to the aperture structure, the camera and the electronic device provided by the embodiment of the invention, the states of different electrochromic units can be changed according to requirements, so that the area of the light-transmitting part of the aperturestructure is changed, the controllability of the aperture structure is enhanced by adopting the plurality of electrochromic units, and the aperture structure can be conveniently arranged on electronic devices such as a mobile phone and a notebook computer.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Flow-adjustable nozzle

The invention relates to a flow-adjustable nozzle which comprises a housing and a core body, wherein the core body can be screwed out of or into the housing freely; the area of the water outlet of the core body changes when the core body is screwed out of or into the housing; the interior of the housing is hollow; the upper part of the housing is a cylindrical water outlet; the lower part of the housing is a conical body; the core body comprises a conical cylinder body; a plurality of notches are formed in the core body; the widths of the notches become smaller and smaller from the top end of the conical cylinder body to the bottom end of the conical cylinder body gradually. The flow-adjustable nozzle is simple in structure, and convenient to mount; the area of the water outlet of the core body can be changed fast conveniently by rotating the housing of the nozzle, so as to control flow rate, and further achieve the purpose of flow adjustment.

Owner:JIANGSU UNIV

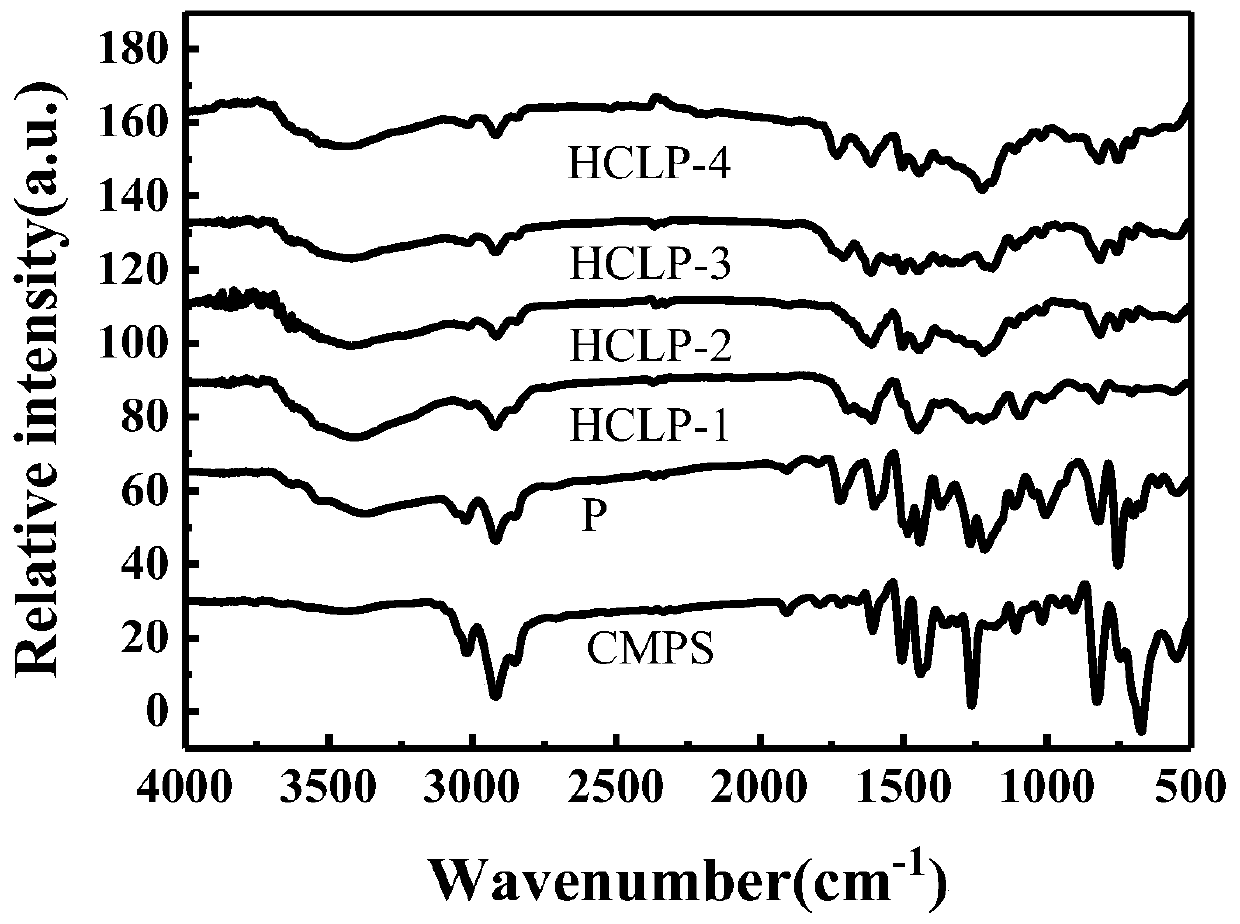

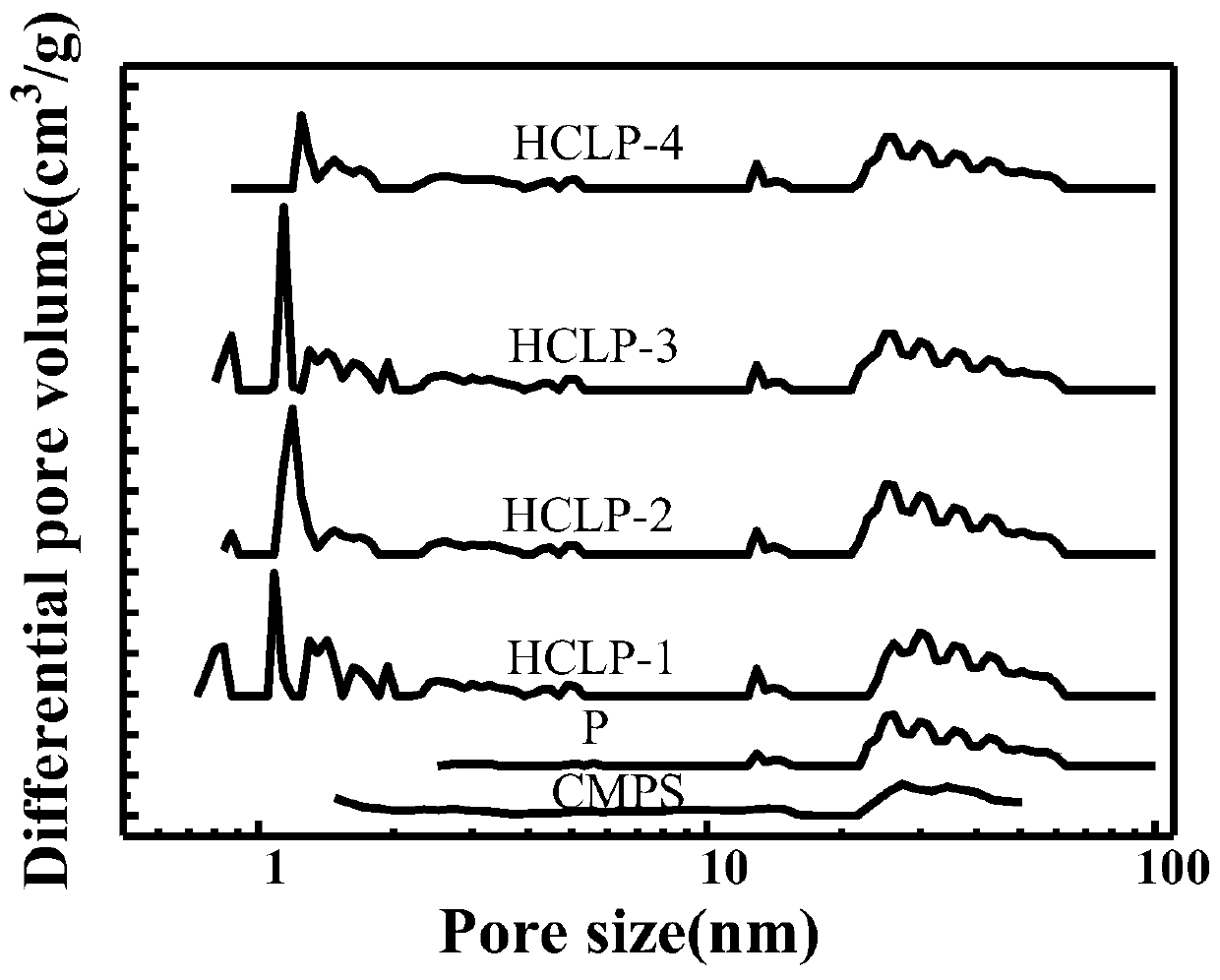

Preparation method of hydrogen bond acceptor oxygen atom-rich super-crosslinked polymer and application of super-crosslinked polymer

InactiveCN111040226AAperture size can be adjusted arbitrarilyChange areaOther chemical processesWater contaminantsPolymer sciencePolystyrene

The invention relates to a preparation method of a hydrogen bond acceptor oxygen atom-rich super-crosslinked polymer and an application of the super-crosslinked polymer. The preparation method comprises the following steps: (1) preparation of a precursor polymer: carrying out a nucleophilic substitution reaction process on chloromethylated polystyrene and a phenol compound in an alkaline environment, and introducing a monomer containing hydrogen bond acceptor oxygen atoms into a polymer skeleton, and (2) preparation of a super-crosslinked polymer: carrying out a Friedel-Crafts alkylation reaction on the precursor polymer prepared in the step (1) and an external crosslinking agent under the catalysis of Lewis acid, and weaving a precursor polymer skeleton. The super-crosslinked polymer prepared by the method can realize regulation and control of the pore structure size, has a high-selectivity adsorption effect on aromatic organic compounds with specific molecular sizes, is easy to eluteafter adsorption, can be repeatedly used, and can be widely applied to the fields of chemical analysis, drug separation and purification, environmental pollution treatment and the like.

Owner:CENT SOUTH UNIV

Solar simulator optical device with variable radiation surface sizes and variable collimation angles

InactiveCN102943995AImprove collimationReasonable designLighting device detailsPhysicsSolar simulator

The invention relates to a solar simulator optical device with variable radiation surface sizes and variable collimation angles. The light beam emitted by a spherical xenon lamp light source enters a light guide pipe after being reflected and focused by an ellipsoidal reflecting bowl, and then passes through a specific structure composed of two lenses to meet the radiation requirement of different radiation surface sizes and different radiation collimation degrees by changing the focal length of one lens or changing the focal length ratio of the two lenses. Meanwhile, the double-lens specific structure can transform radiation surface uniformity into radiation space uniformity. The solar simulator optical device provided by the invention can be applied to solar simulated radiation of areas with different sizes, and can also be applied to suitable occasions of a solar simulator with high requirement on collimation degree. In addition, the solar simulator optical device has the advantages of reasonable design, simple structure, convenience in specific measurement operation and high practicability.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

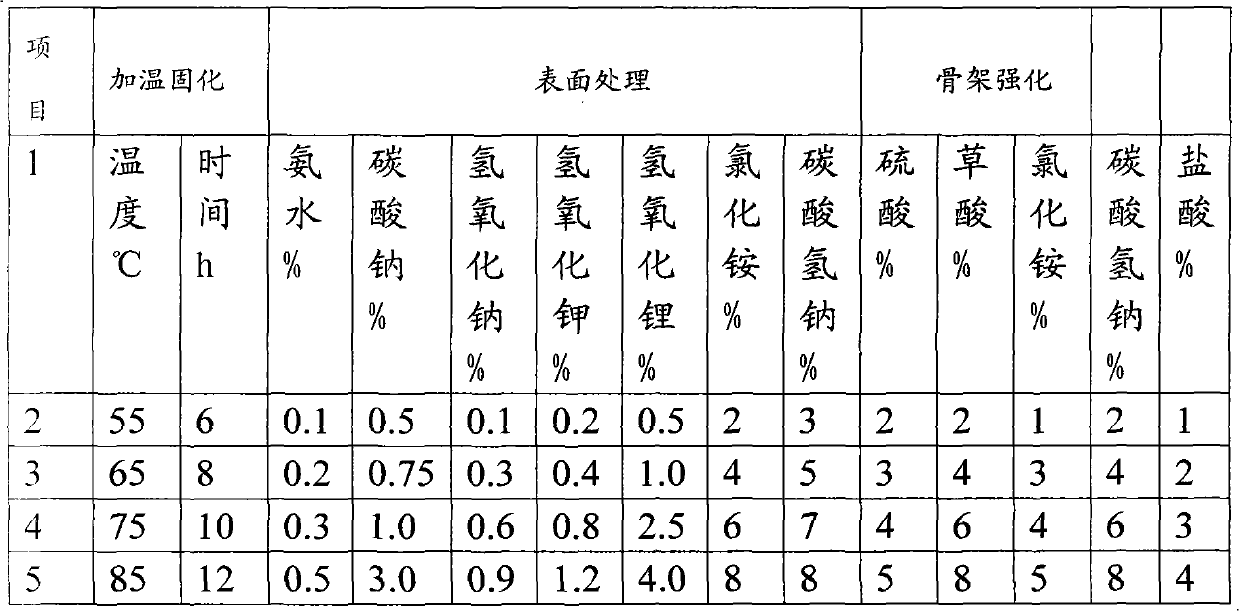

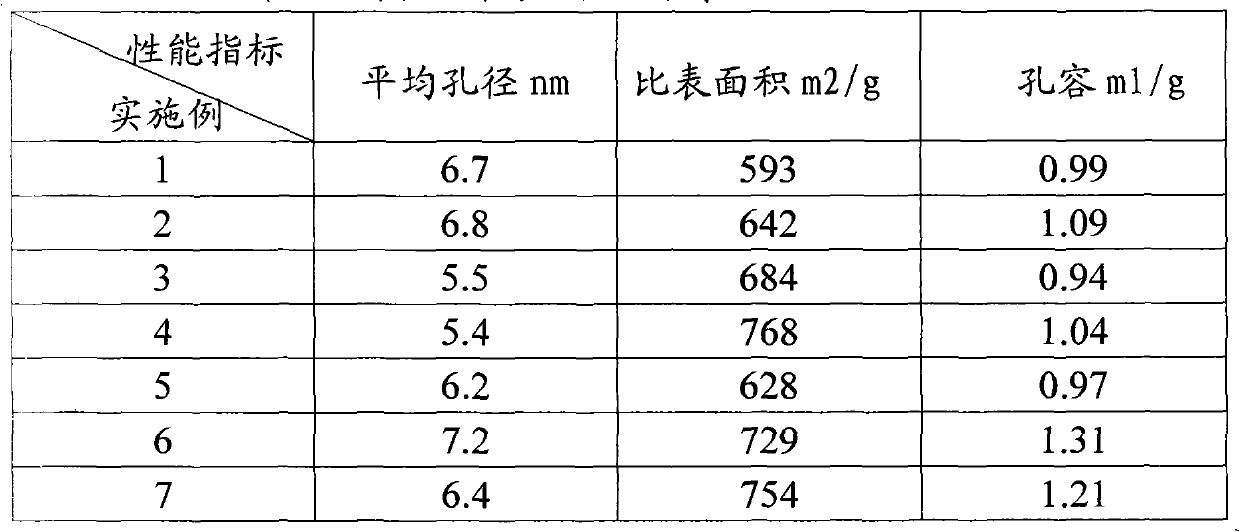

Novel B type large-pore volume silica gel and manufacture method thereof

The invention provides a novel B type large-pore volume silica gel and a manufacture method of the novel B type large-pore volume silica gel. The manufacture method comprises the following steps of A, generating orthosilicic acid in a vortex type mixing reactor through sodium silicate solution and diluted mineral acid according to the conventional silica gel technology, and then standing and curing, and granulating twice; B, heating and curing, transferring the silica gel in an environment at 40 to 90 DEG C for being retained for 8 to 24 hours; C, surfacing the washed silica gel through inorganic salt and inorganic base, wherein for modifying the internal silanol on the internal surface of the silica gel hole, the alkaline can be sodium hydroxide, potassium hydroxide and lithium hydrate; and the inorganic salt can be ammonium chloride, sodium chloride, sodium carbonate, sodium bicarbonate and ammonium bicarbonate; and D, reinforcing the framework through the technology of dipping mineral acid and inorganic salt and thermally processing. According to the manufacture method, the silica gel is transferred into 0.01 to 10% of inorganic salt solution for being heated in water bath, and then is parched in a thermal environment at 100 to 200 DEG C, thus obtaining the silica gel provided by the invention. The manufacture method provided by the invention is simple, and easy to achieve mass production.

Owner:山东辛化硅胶有限公司

In-situ nitrogen-doped ultra large aperture mesoporous carbon material and preparation method thereof

ActiveCN106744805AOvercome the toxic effectEliminate the possibilityInorganic non-active ingredientsCarbon preparation/purificationIonSolvent

The invention discloses an in-situ nitrogen-doped ultra large aperture mesoporous carbon material and a preparation method thereof. The aperture is concentrated between 17.4 and 26.8nm, the BET specific surface area is 428-984 m<2> / g, the pore volume is 0.72-2.38 cm<3> / g, the nitrogen element content is 4.17-4.63wt%, and the doping form of nitrogen atoms is pyridine nitrogen, pyrrole nitrogen or quaternary ammonium nitrogen. According to the preparation method, nitrogen-containing biopolymer chitosan is used as a carbon source, tetraethoxysilane (TEOS) is used as a silicon source, commercial surfactant F127 is used as a structure-directing agent, deionized water is used as a main solvent, the chitosan is combined with the hydrolyzed tetraethoxysilane into a high-polymerization hybrid material by using a sol-gel method, the hybrid material is assembled with the structure-directing agent F127 into a mesoporous structure via hydrogen bonding, and the mesoporous carbon material is obtained after template removal. The method is simple, the raw materials are readily available, and the aperture size can be adjusted.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com