CMOS TDI image sensor and charge transfer control method thereof

An image sensor and charge transfer technology, applied in image communication, television, electrical components, etc., can solve the problem of reducing image quality and achieve the effect of improving image resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

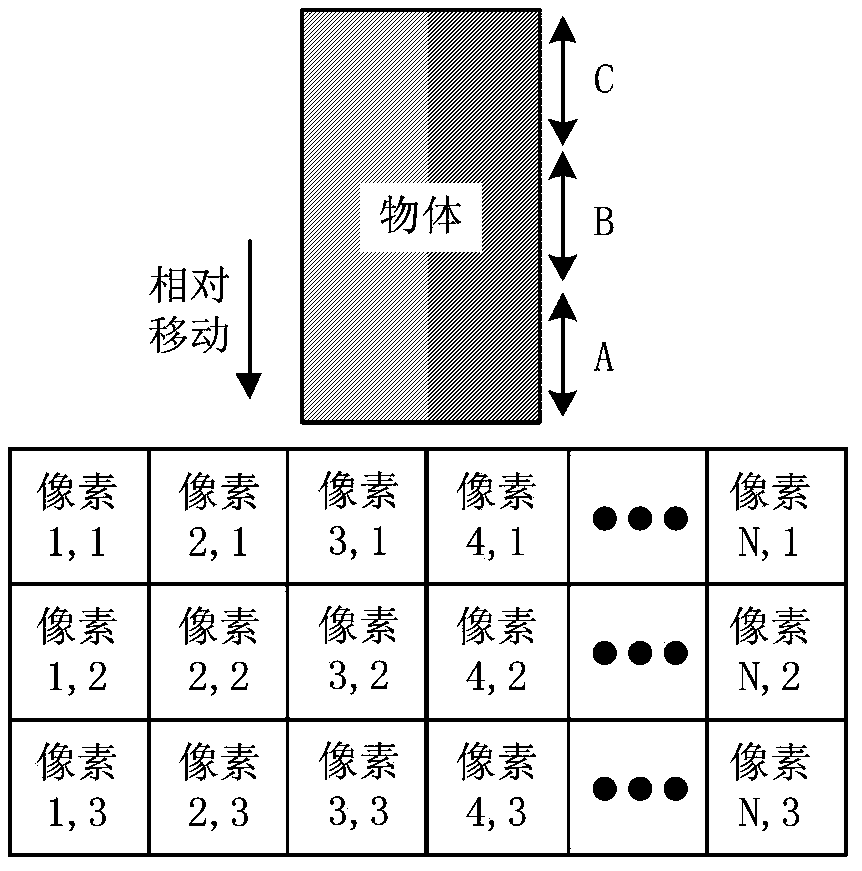

[0055] The case of n=3, m=2, i=1 (the area of the pixel area is 3x3 area of the charge collection unit). The combined number of charge transfer channels is 3.

[0056] like Figure 13 As shown, the dotted box indicates the charge storage area (ie, the charge collection area), and the obliquely shaded area indicates the pixel area (the area of the pixel area is 3×3). like Figure 14 As shown, the charge in the charge collection area is represented by the black solid line, and the pixel charge in other areas is represented by the gray solid line)

[0057] At time t1, the area of the charge storage area is 3×2; at time t2, the area of the charge storage area is 3×1; at time t3, the area of the charge storage area is 3×2; at time t4, the area of the charge storage area is 3× 1;....... At equal intervals, the area of the charge storage region changes from 3x2 to 3x1 or from 3x1 to 3x2. Every two equal time intervals, the charge storage region moves one charge t...

Embodiment 2

[0059] n=4, m=3, i=2 case (the area of the pixel area is 4x4 area of the charge collection unit). The combined number of charge transfer channels is 4.

[0060] like Figure 15 As shown, the dotted line box represents the charge storage area (that is, the charge collection area), and the obliquely shaded area represents the pixel area (the area of the pixel area is 4×4). like Figure 16 As shown, the charge in the charge collection area is represented by the black solid line, and the pixel charge in other areas is represented by the gray solid line)

[0061] At time t1, the area of the charge storage area is 4×3; at time t2, the area of the charge storage area is 4×2; at time t3, the area of the charge storage area is 4×3; at time t4, the area of the charge storage area is 4× 2;....... At equal intervals, the area of the charge storage region changes from 4x3 to 4x2 or from 4x2 to 4x3. Every two equal time intervals, the charge storage region moves one cha...

Embodiment 3

[0063] The case of n=4, m=3, i=1 (the area of the pixel area is 4x4 area of the charge collection unit). The combined number of charge transfer channels is 4.

[0064] like Figure 17 As shown, the dotted line box represents the charge storage area (that is, the charge collection area), and the obliquely shaded area represents the pixel area (the area of the pixel area is 4×4).

[0065] At time t1, the area of the charge storage area is 4×3; at time t2, the area of the charge storage area is 4×1; at time t3, the area of the charge storage area is 4×3; at time t4, the area of the charge storage area is 4× 1;....... At equal intervals, the area of the charge storage region changes from 4x3 to 4x1 or from 4x1 to 4x3. Every two equal time intervals, the charge storage region moves one charge transfer control electrode along the direction of charge movement. Compared with the charge transfer mode of embodiment 2, the charge transfer speed of this embodiment is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com