Patents

Literature

840 results about "Line scan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LINE SCAN. Line scan cameras contain a single row of pixels used to capture data very quickly. As the object moves past the camera, a complete image can be reconstructed in software line by line. Line scan systems are best employed in high-speed processing or fast-moving conveyor line applications.

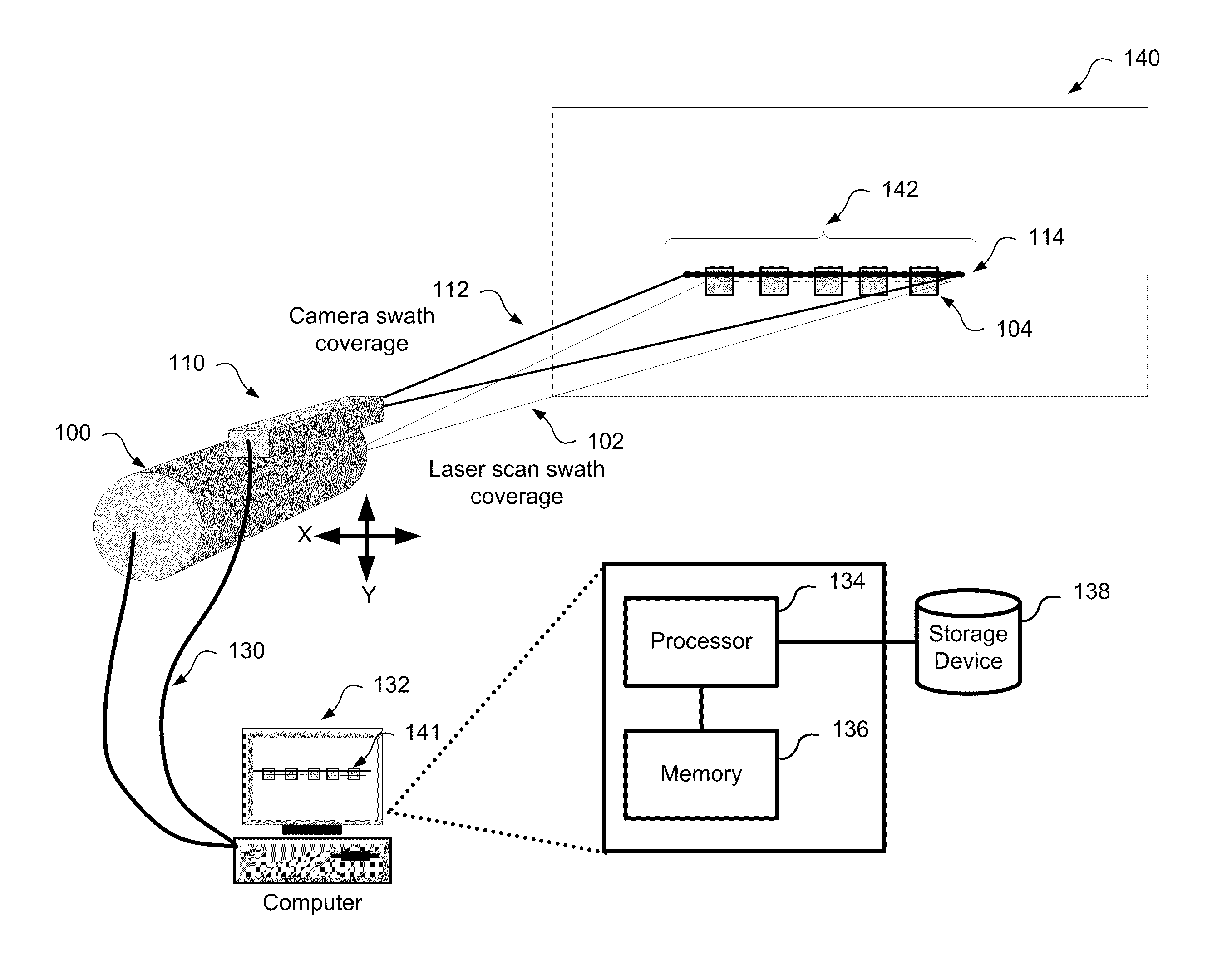

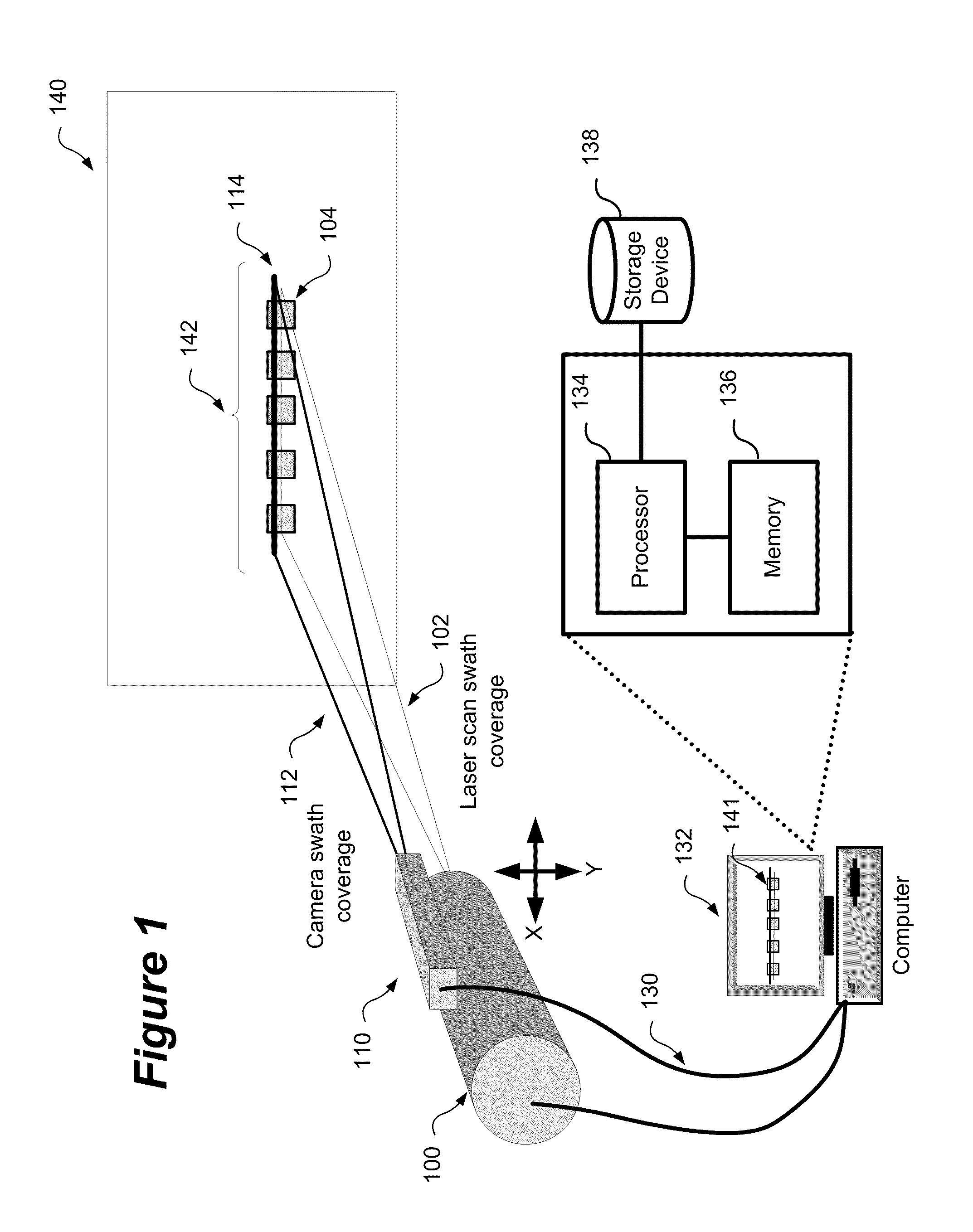

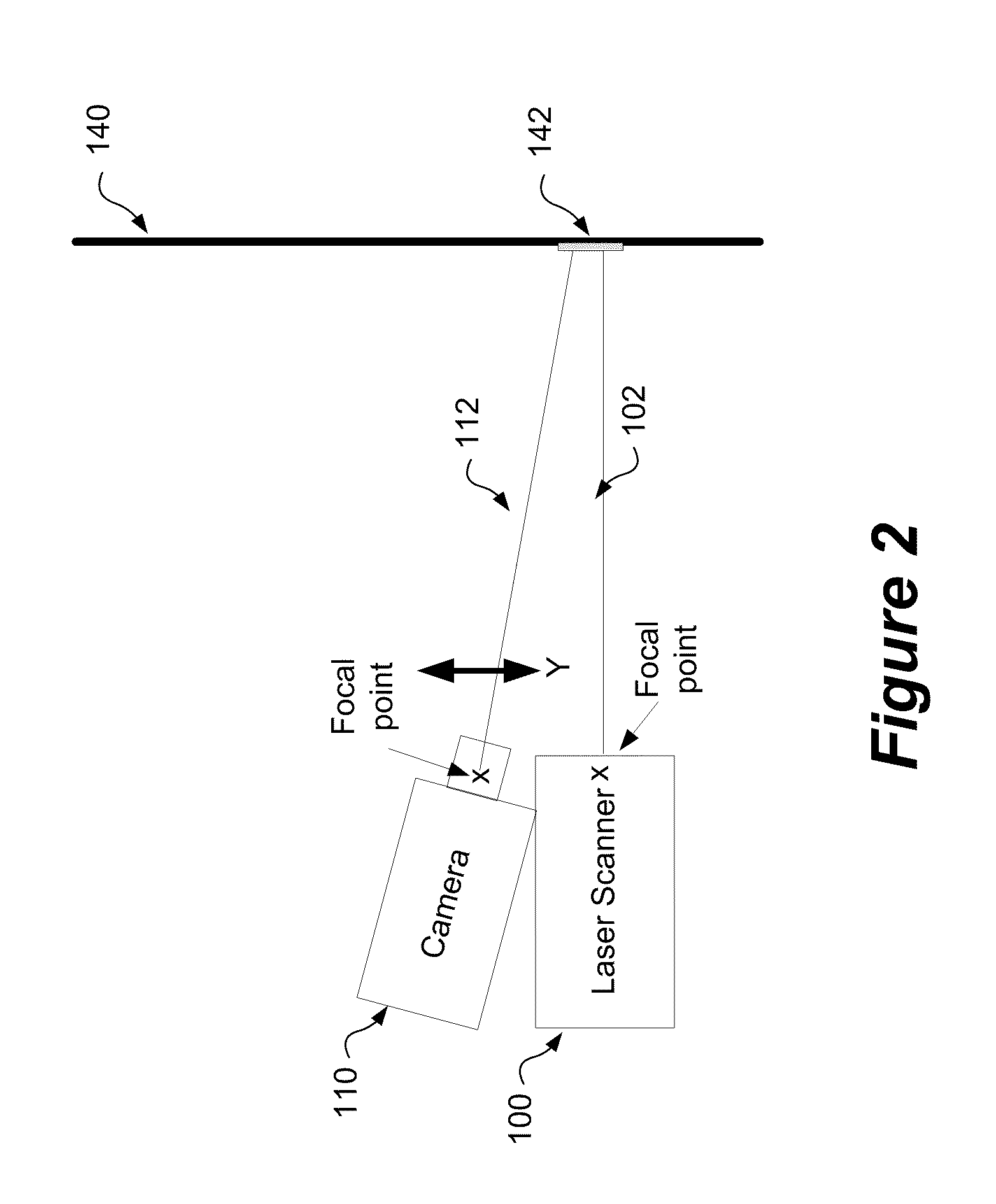

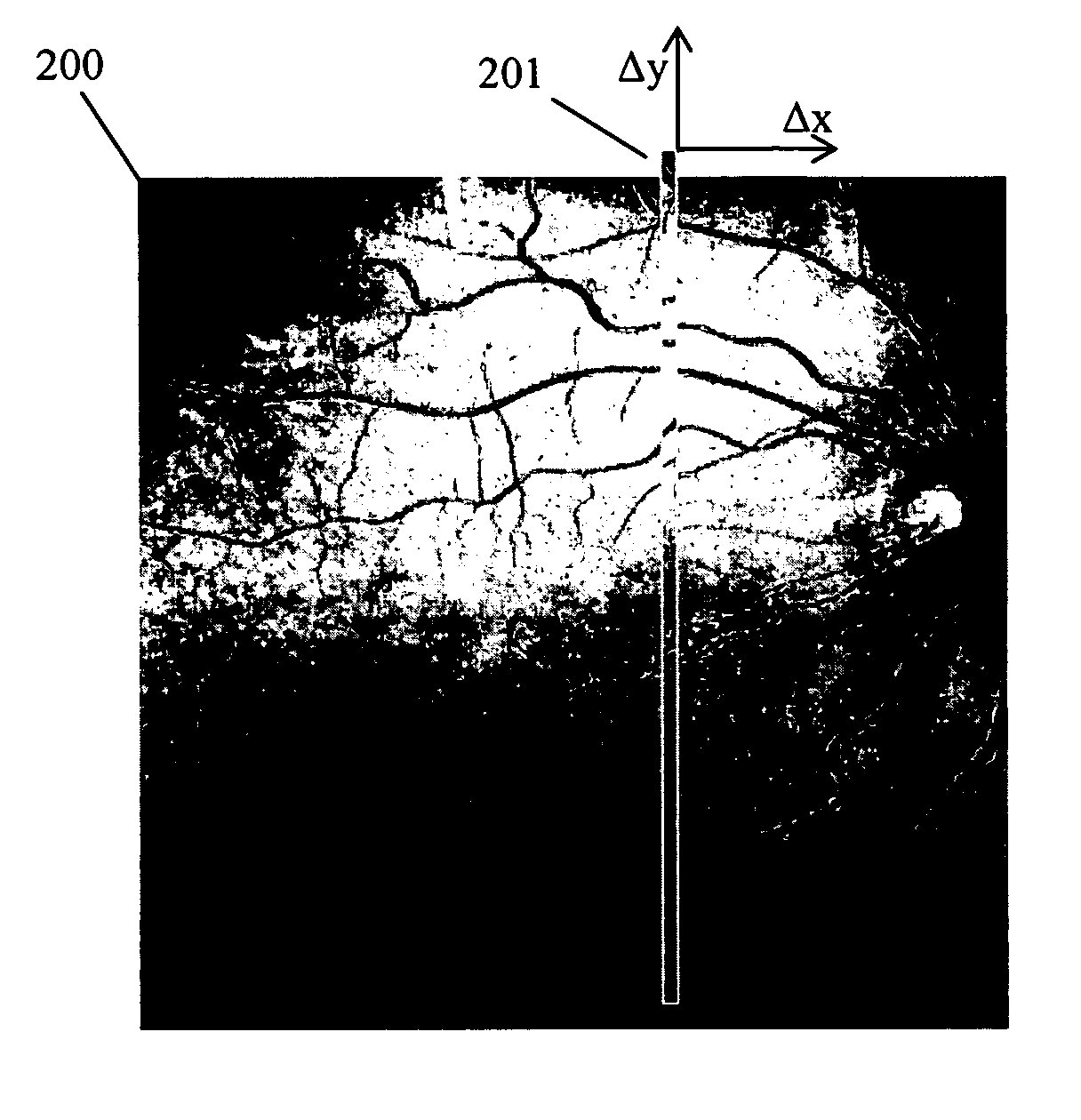

Method and system for aligning a line scan camera with a lidar scanner for real time data fusion in three dimensions

An apparatus and method for aligning a line scan camera with a Light Detection and Ranging (LiDAR) scanner for real-time data fusion in three dimensions is provided. Imaging data is captured at a computer processor simultaneously from the line scan camera and the laser scanner from target object providing scanning targets defined in an imaging plane perpendicular to focal axes of the line scan camera and the LiDAR scanner. X-axis and Y-axis pixel locations of a centroid of each of the targets from captured imaging data is extracted. LiDAR return intensity versus scan angle is determined and scan angle locations of intensity peaks which correspond to individual targets is determined. Two axis parallax correction parameters are determined by applying a least squares. The correction parameters are provided to post processing software to correct for alignment differences between the imaging camera and LiDAR scanner for real-time colorization for acquired LiDAR data.

Owner:AMBERCORE SOFTWARE

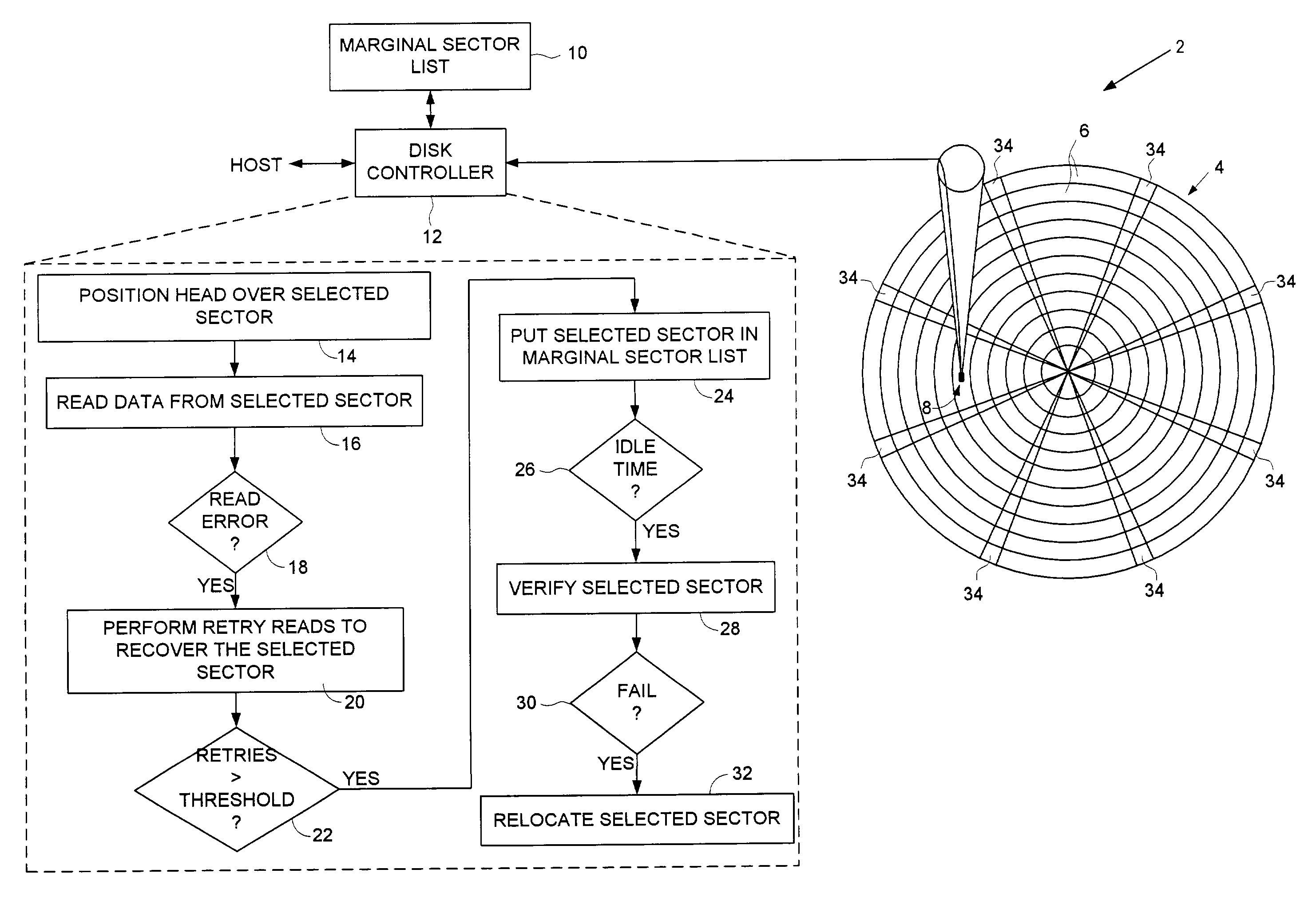

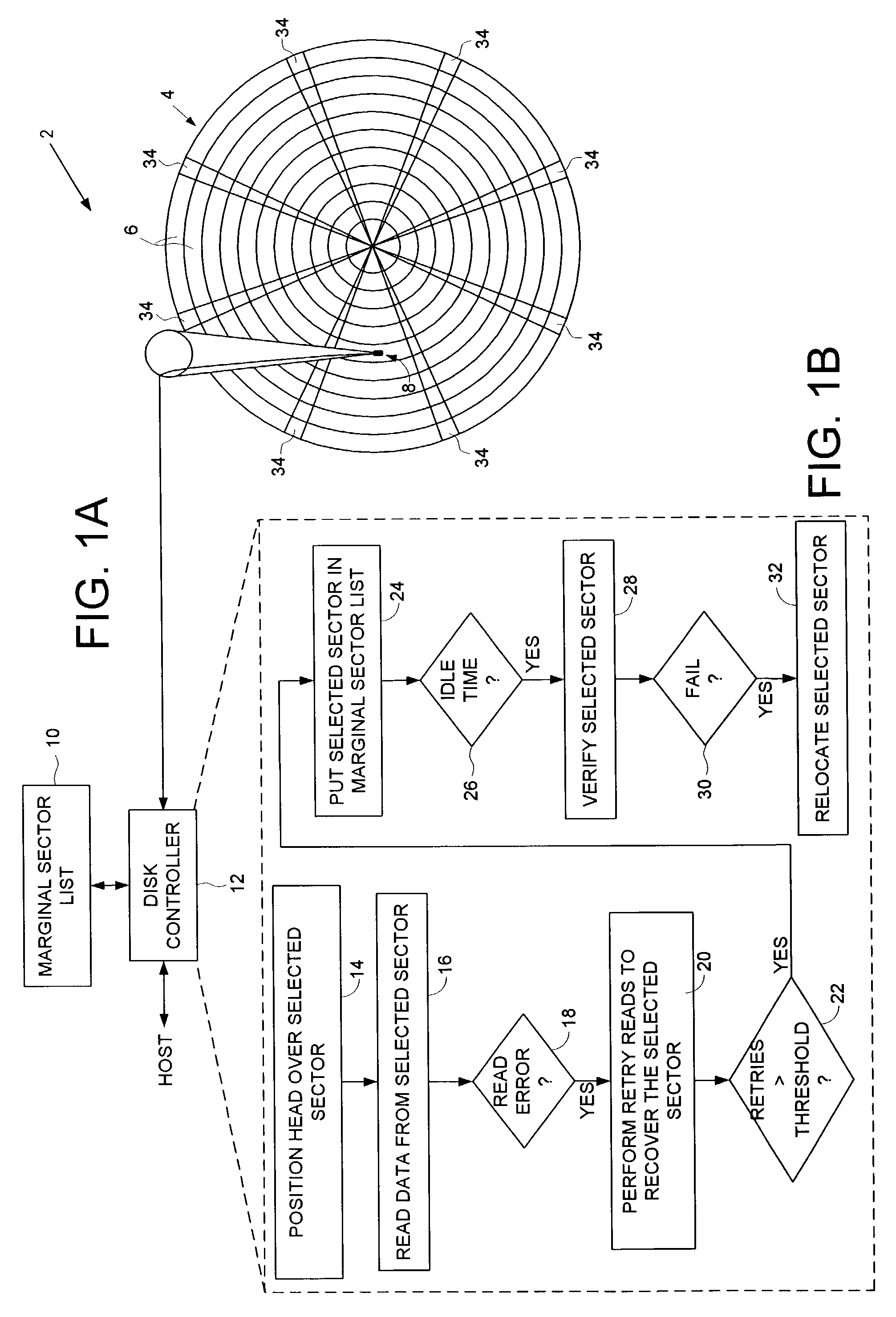

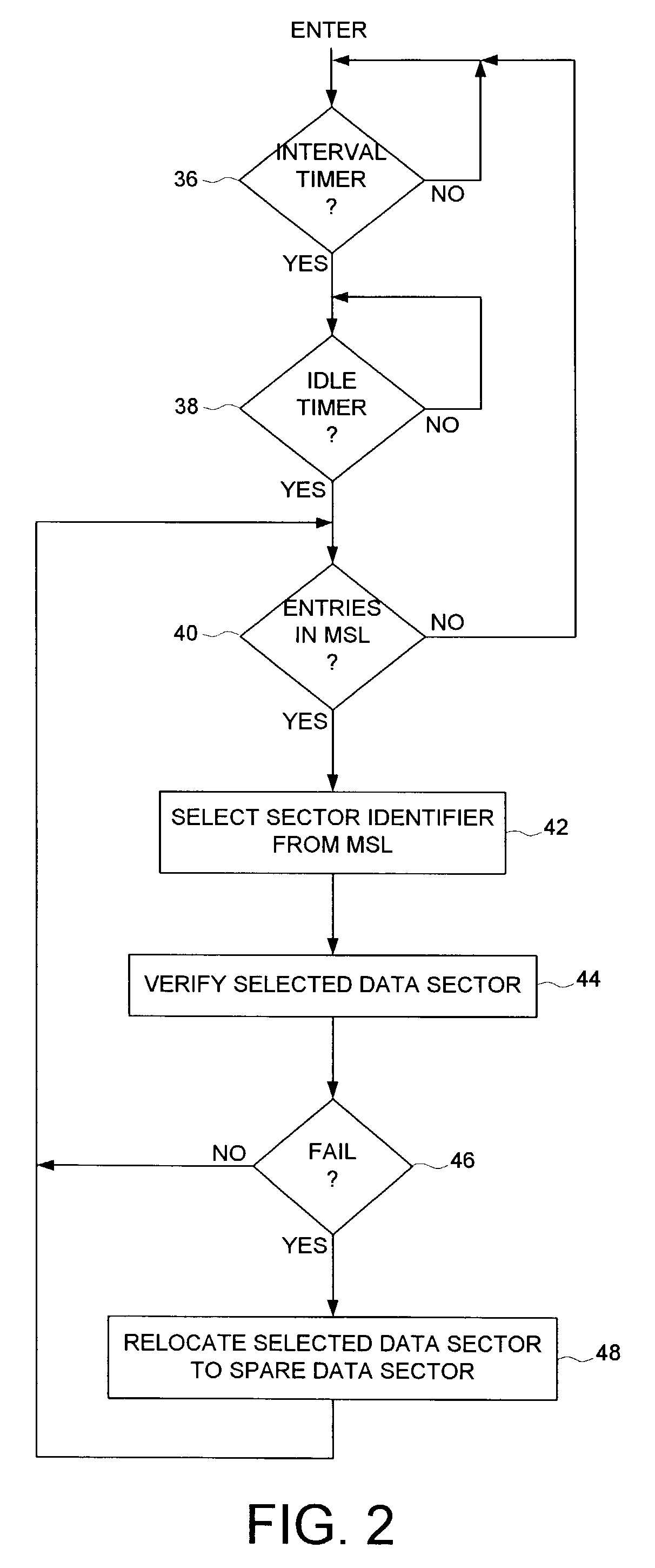

Disk drive employing off-line sector verification and relocation of marginal sectors discovered during read error recovery procedure

ActiveUS7050252B1Increase probabilityLower the thresholdDisc-shaped record carriersRecord information storageRecovery procedureLine scan

A disk drive is disclosed wherein if multiple retries beyond a threshold are required to recover a data sector during a normal read operation, the data sector is added to a marginal sector list. During an off-line scan, the data sectors in the marginal sector list are verified. If the verification of a data sector fails, the data sector is relocated.

Owner:WESTERN DIGITAL TECH INC

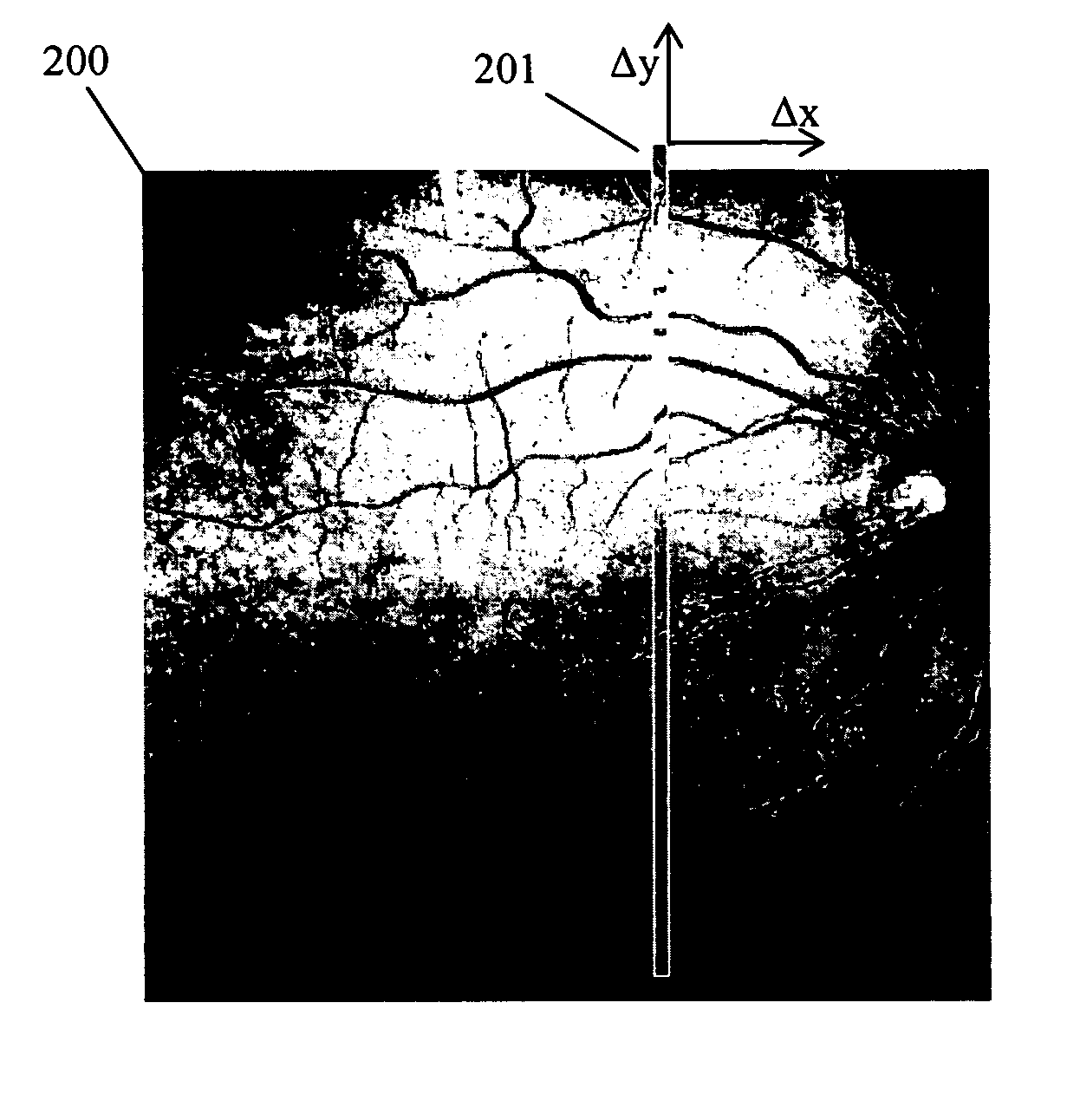

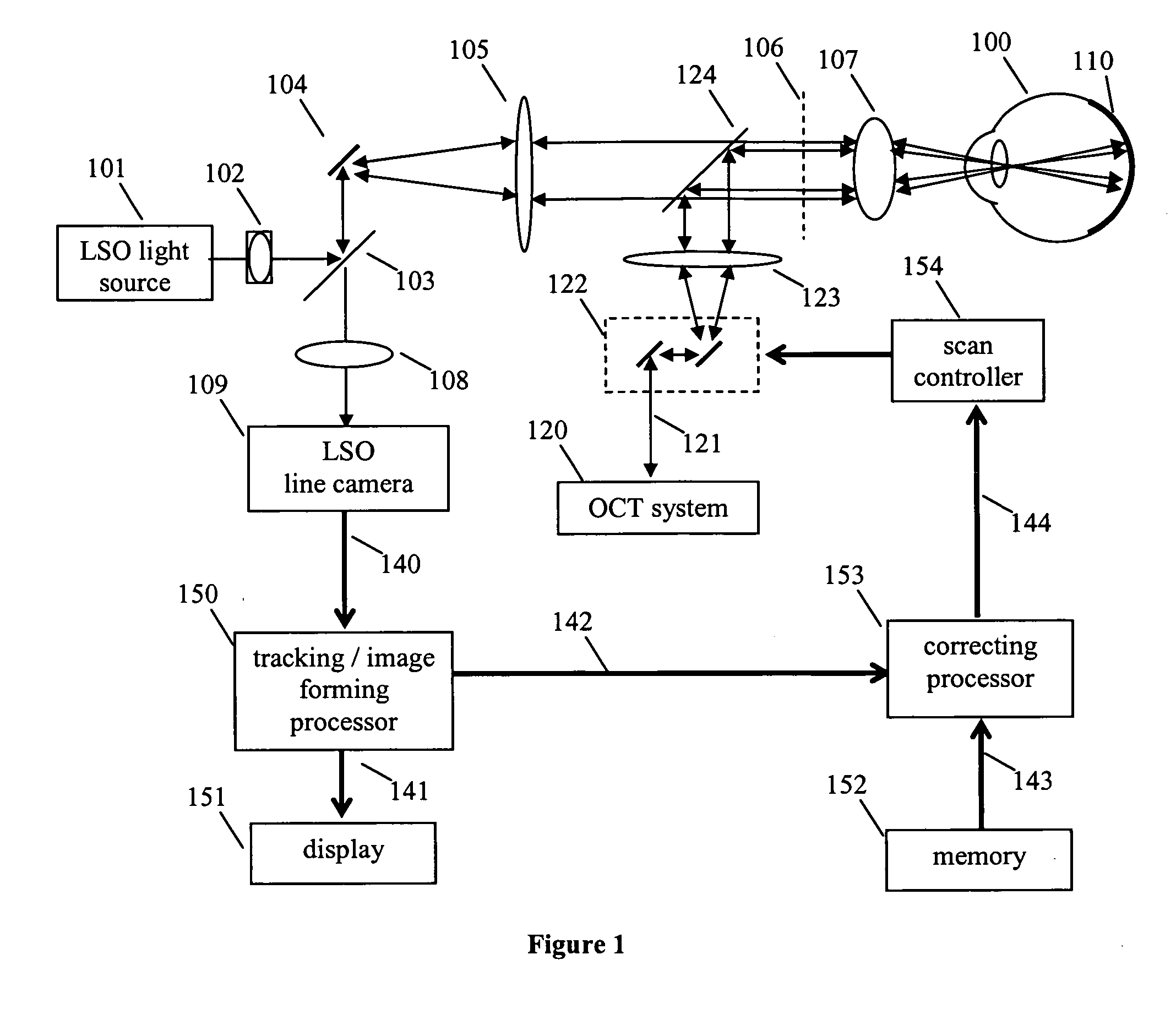

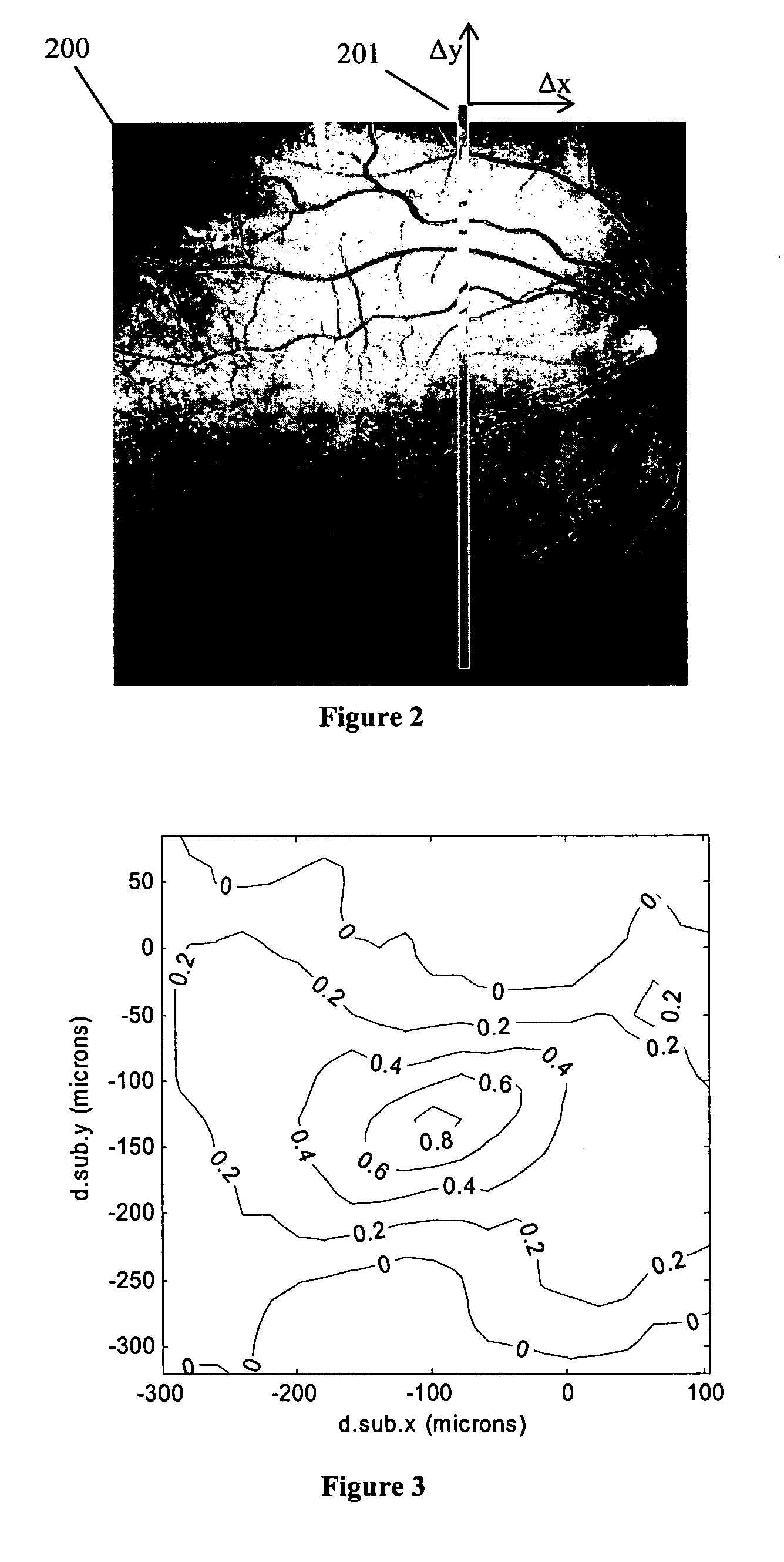

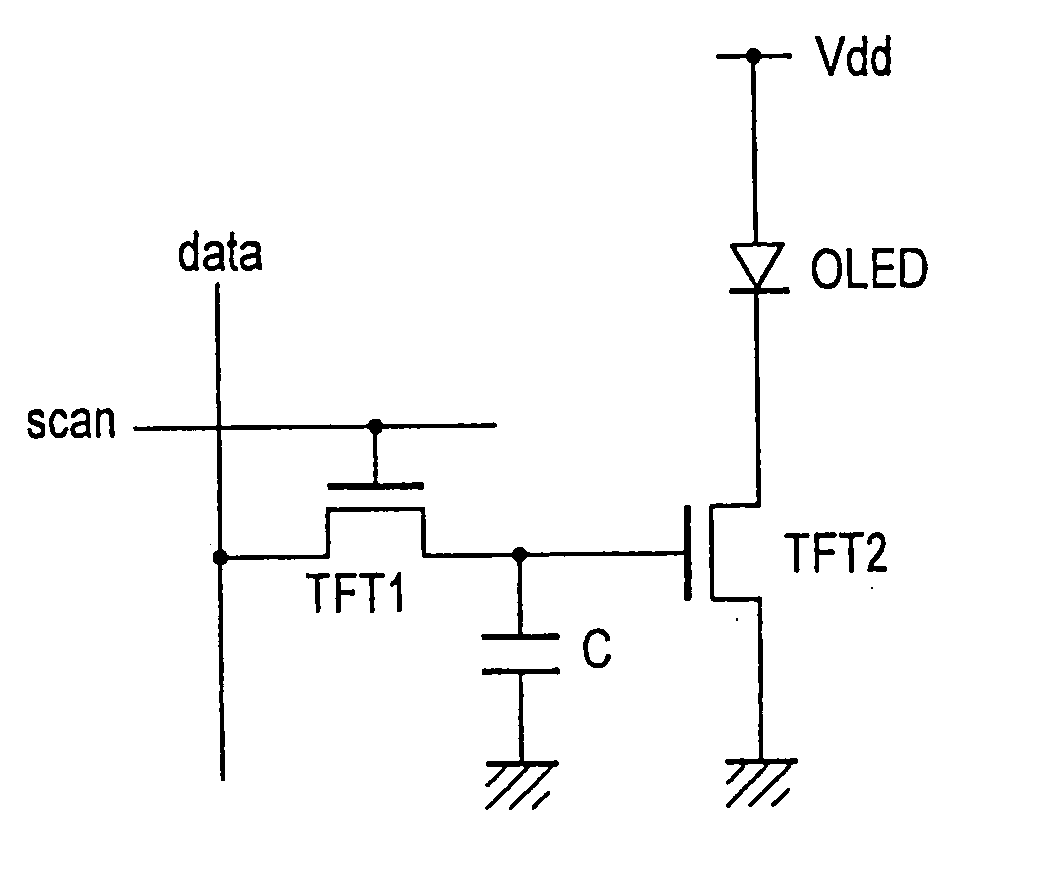

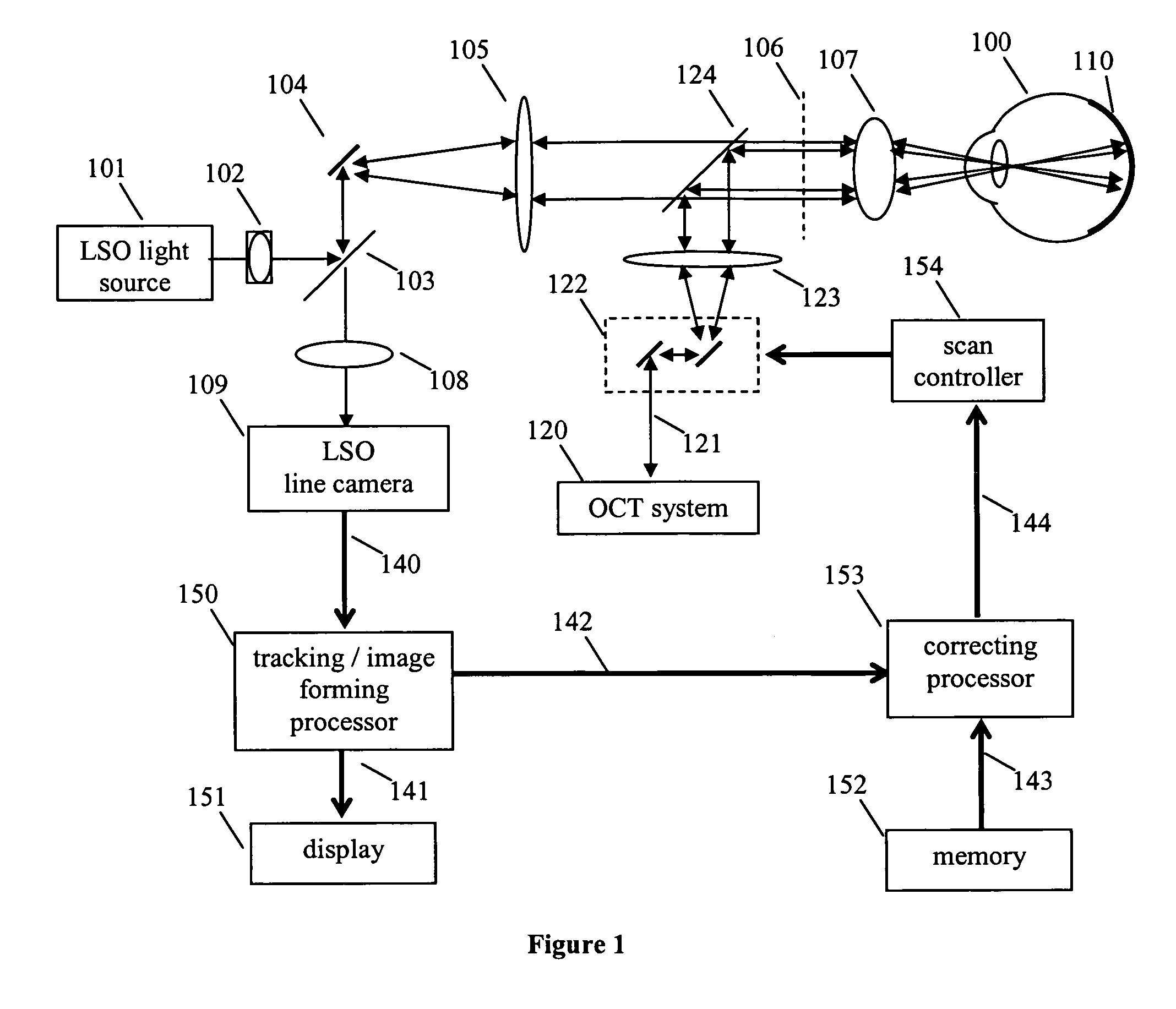

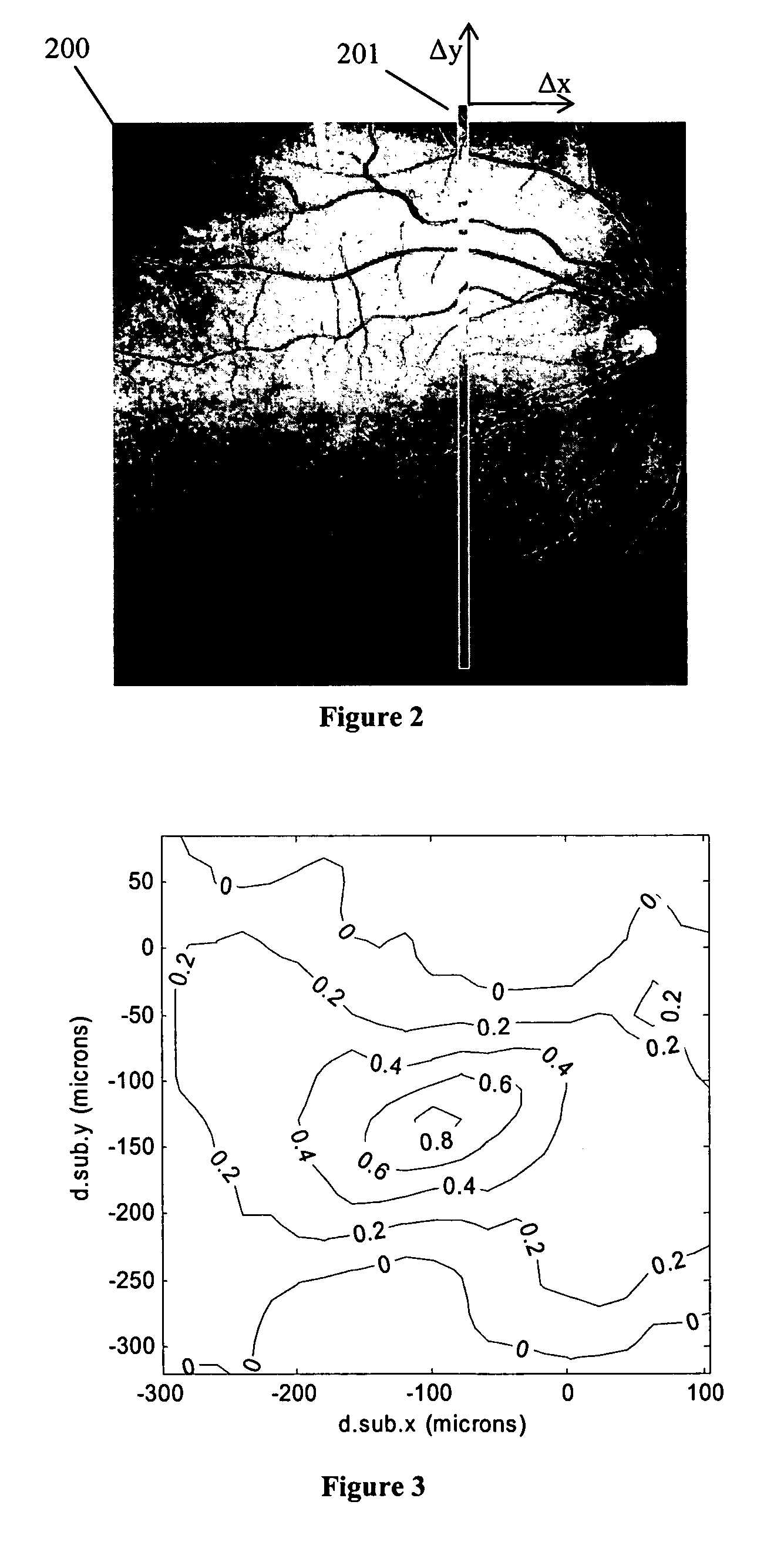

Method and apparatus for measuring motion of a subject using a series of partial images from an imaging system

ActiveUS20060228011A1Accurate placementCharacter and pattern recognitionCathode-ray tube indicatorsOptical radiationReference image

A line scan imager is used to determine the motion of a subject. Each line of image data from the line scan imager is compared with a reference image. The location of a matching line in the reference image reveals the displacement of the subject. The current subject displacement can be determined based on each line of image data. The resulting displacement information can be used to correctly place other optical beams on the subject. The method can be applied to tracking the human eye to facilitate measurement, imaging, or treatment with a beam of optical radiation.

Owner:CARL ZEISS MEDITEC INC

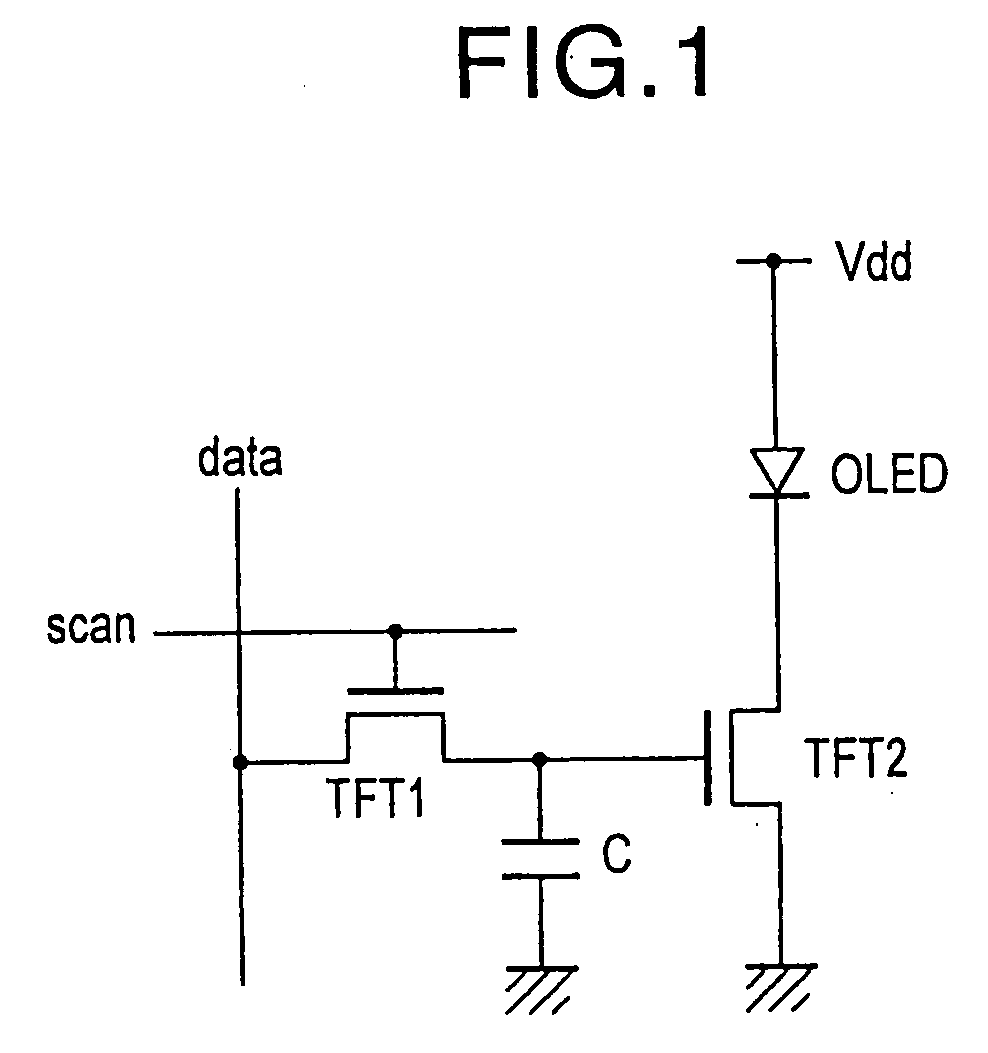

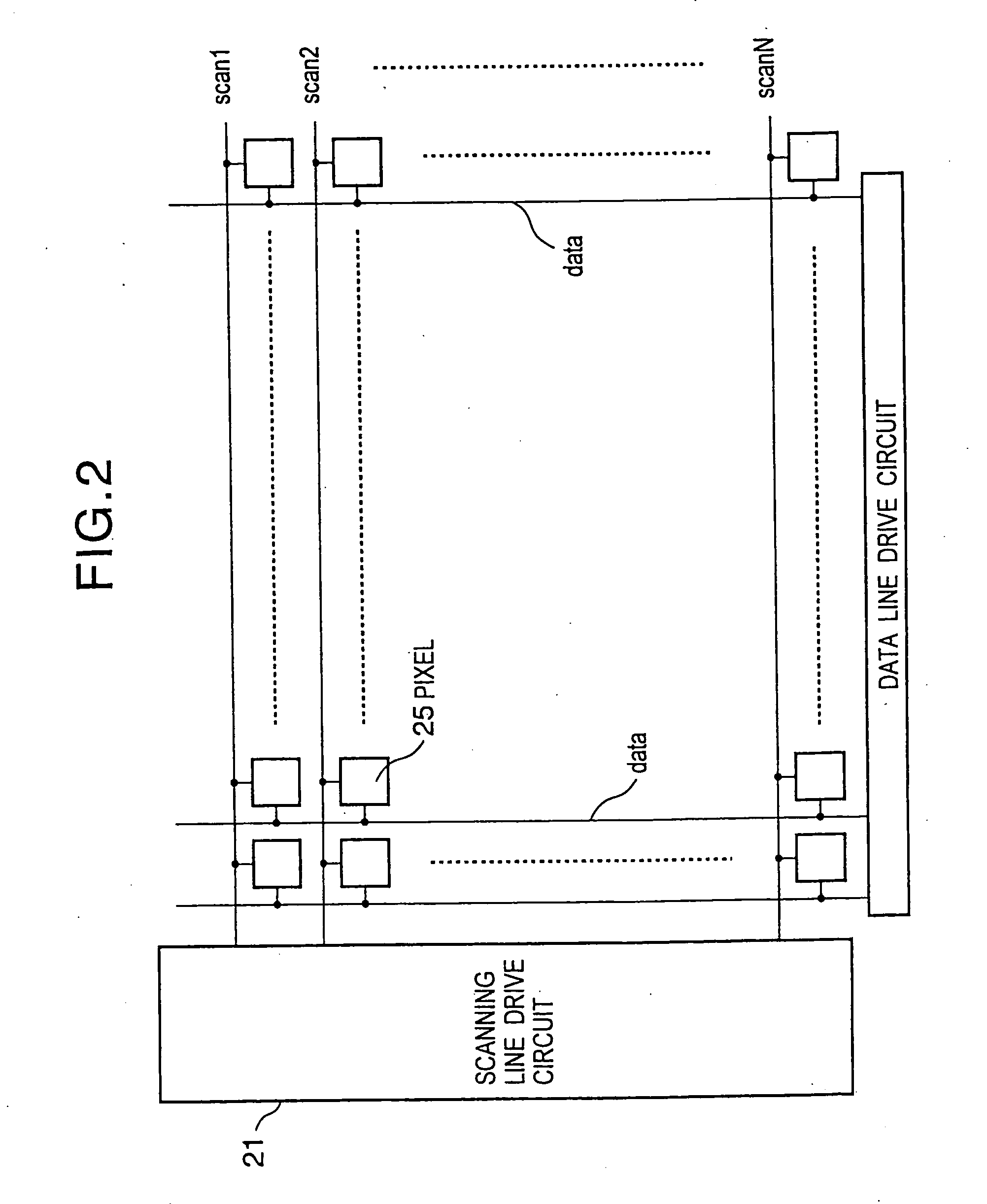

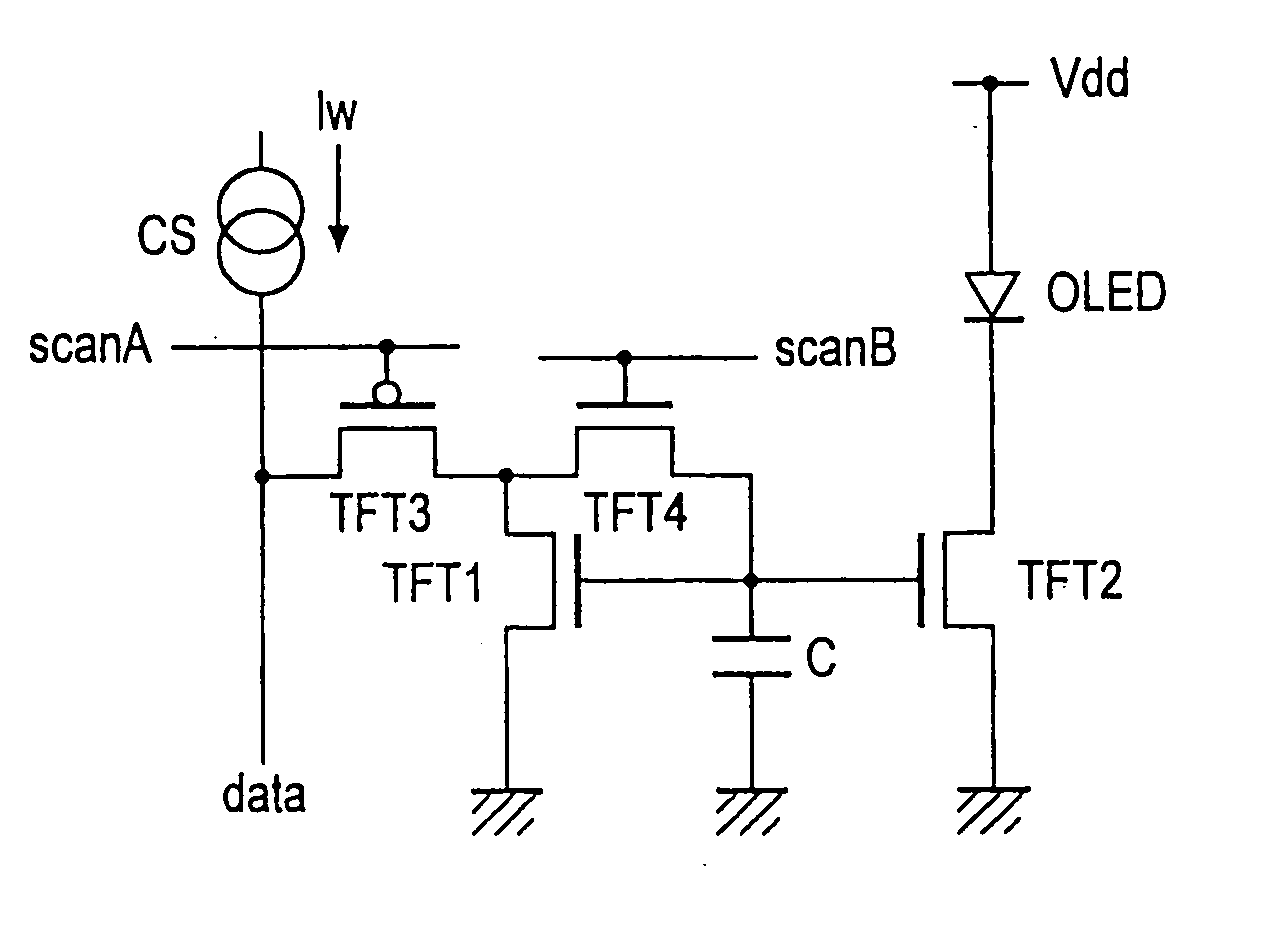

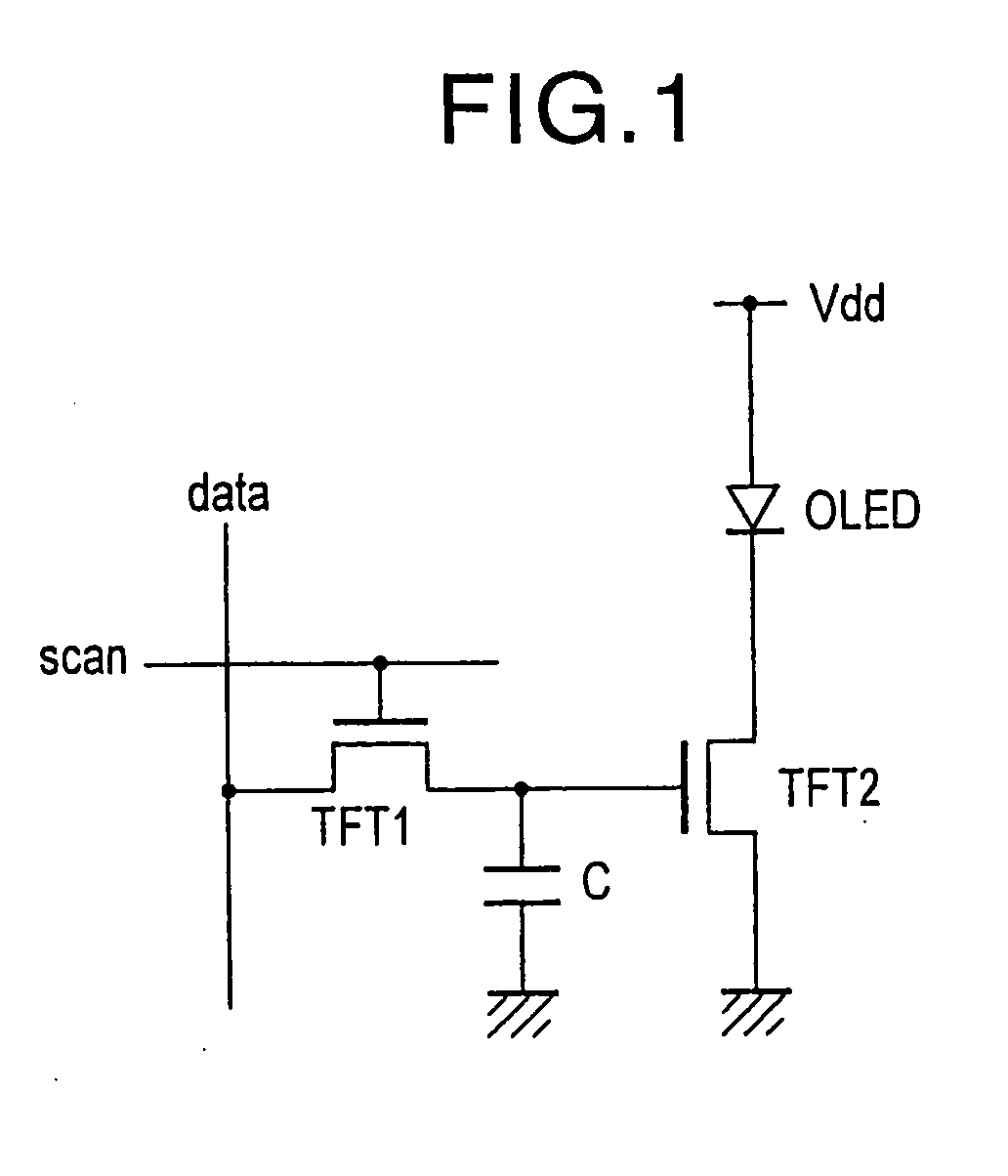

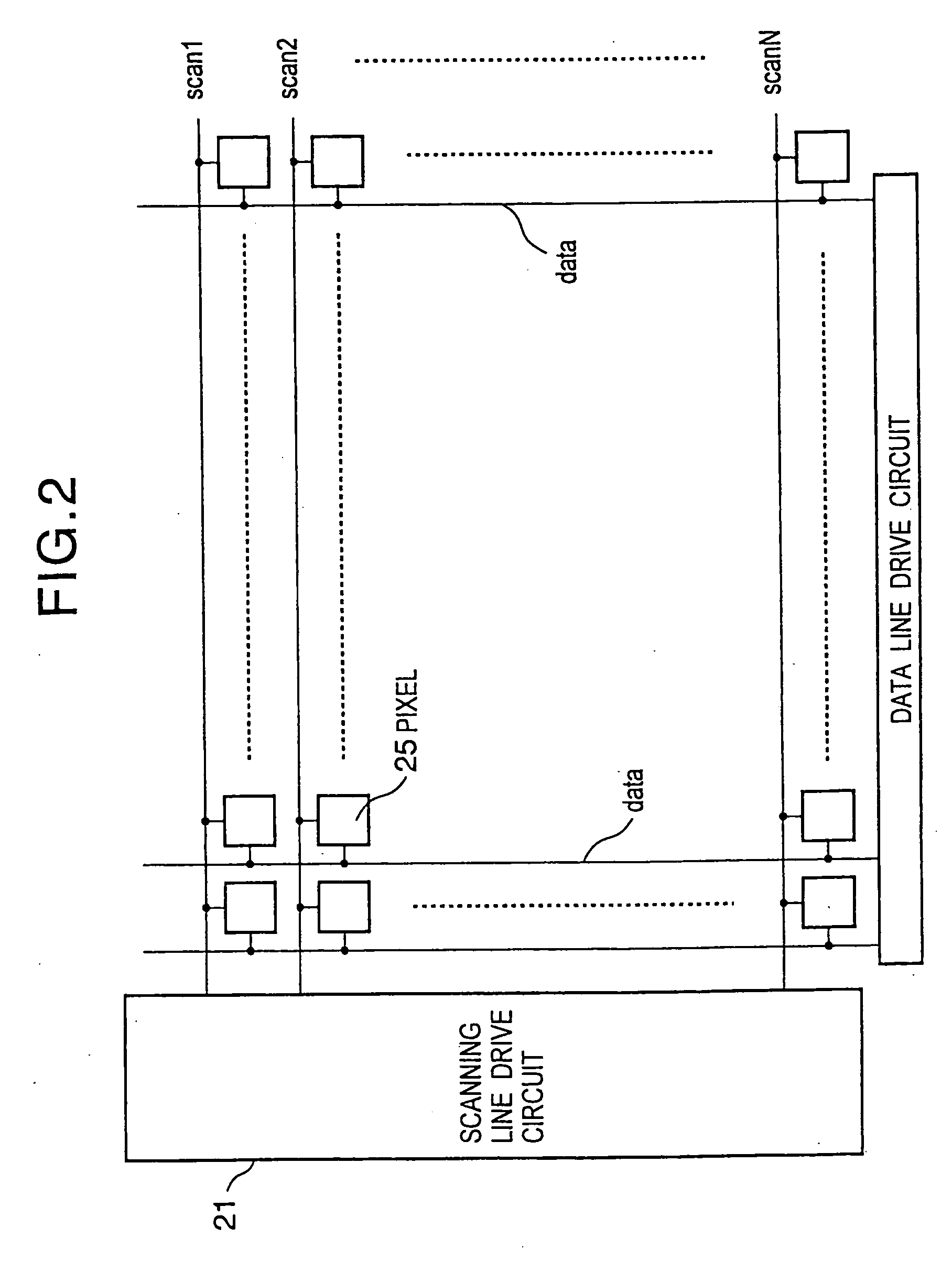

Current drive circuit and display device using same, pixel circuit, and drive method

InactiveUS20050190177A1Easy to replaceAdjustment of color balance is also easySolid-state devicesCathode-ray tube indicatorsDriving currentDisplay device

A display device including a current drive circuit capable of stably and correctly supplying an intended current to a light emitting element of each pixel without being affected by variations in characteristics of an active element inside the pixel and as a result capable of displaying a high quality image, wherein each pixel comprises a receiving use transistor TFT3 for fetching a signal current Iw from a data line DATA when a scanning line SCAN-A is selected, a conversion use transistor TFT1 for once converting a current level of a fetched signal current Iw to a voltage level and holding the same, and a drive use transistor TFT2 for passing a drive current having a current level in accordance with the held voltage level through a light emitting element OLED. The conversion use thin film transistor TFT1 generates a converted voltage level at its own gate by passing the signal current Iw fetched by the TFT3 through its own channel. A capacitor C holds the voltage level created at the gate of the TFT1. The TFT2 passes the drive current having a current level in accordance with the held voltage level through the light emitting element OLED.

Owner:SONY CORP

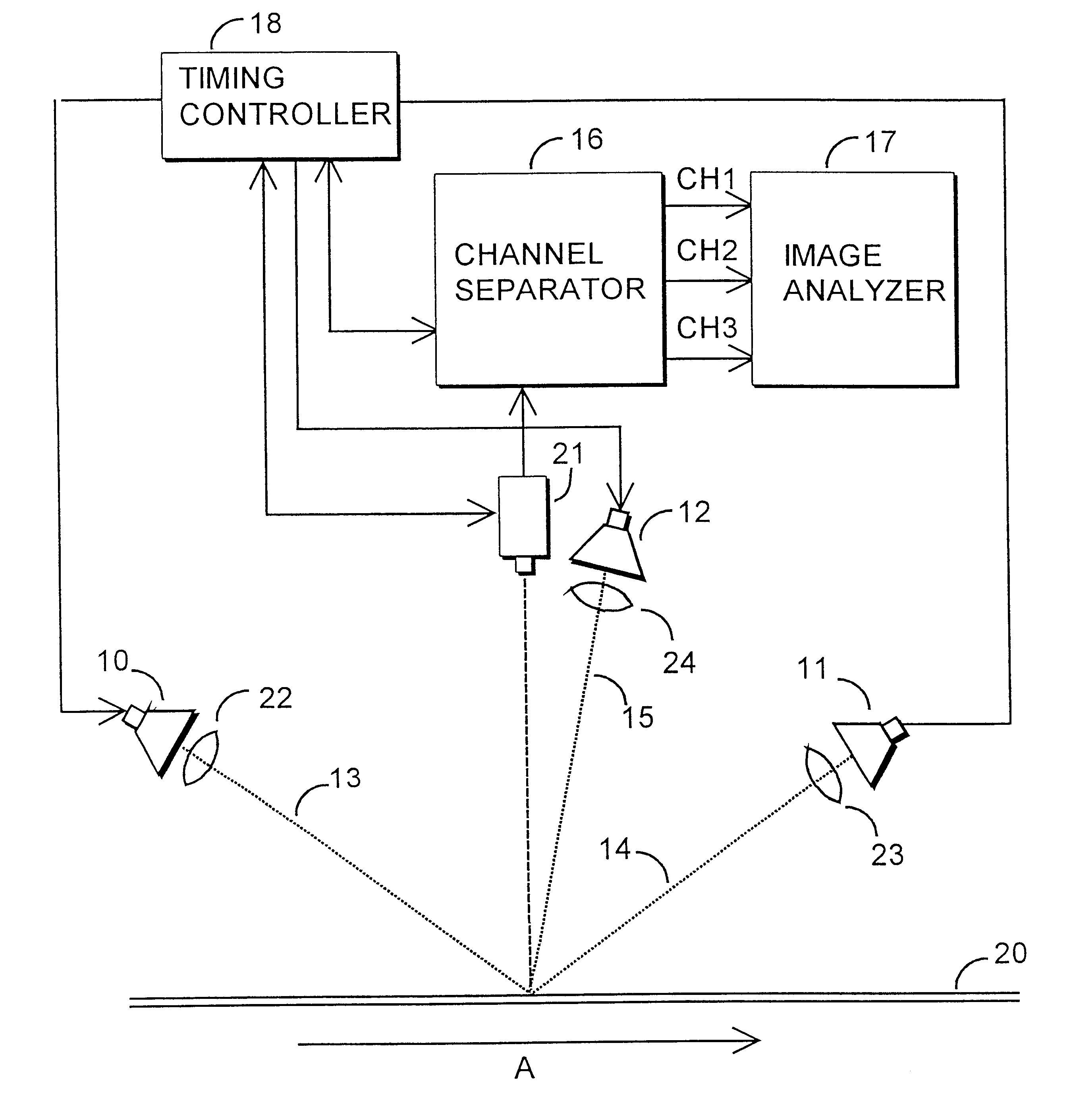

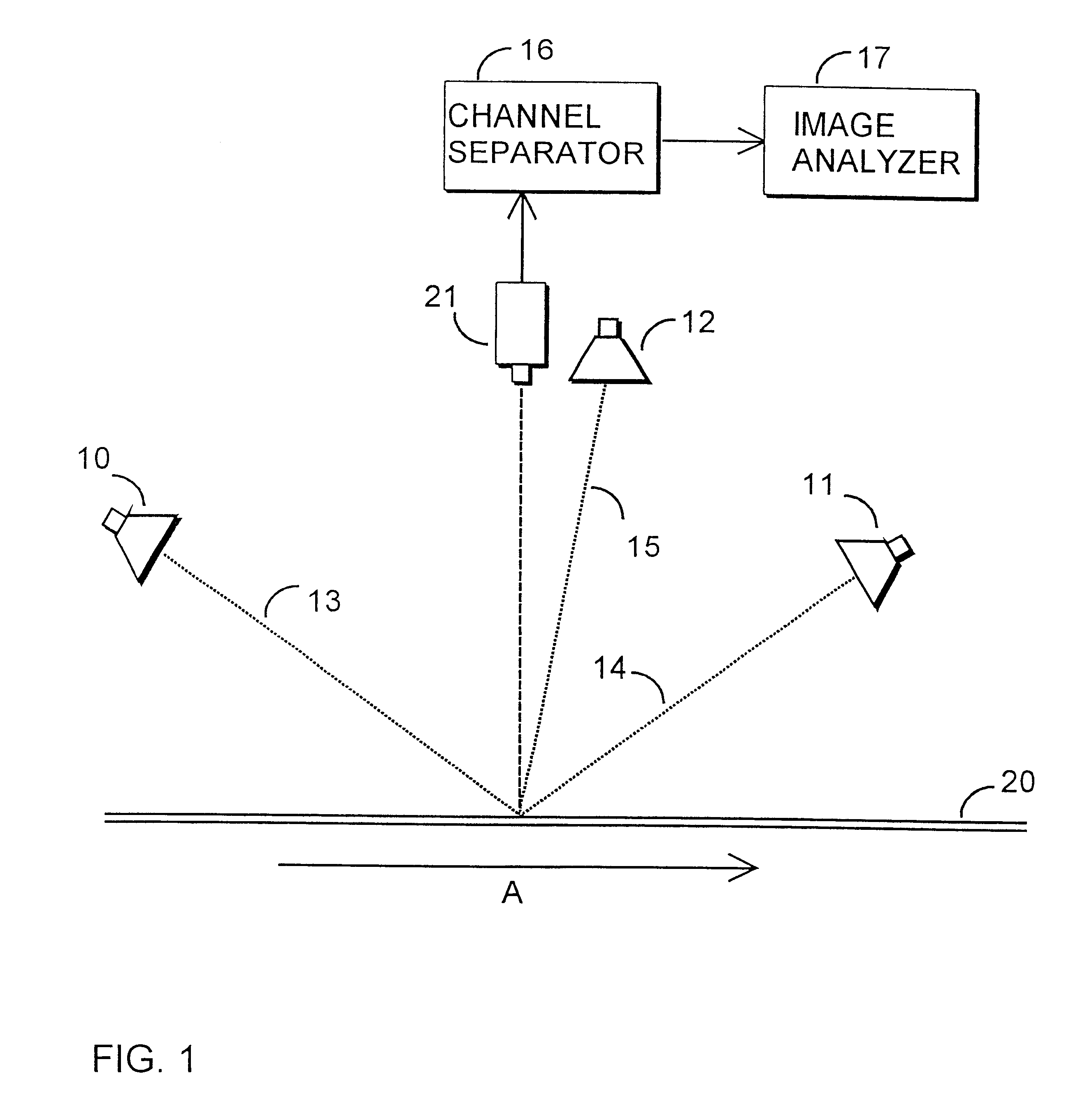

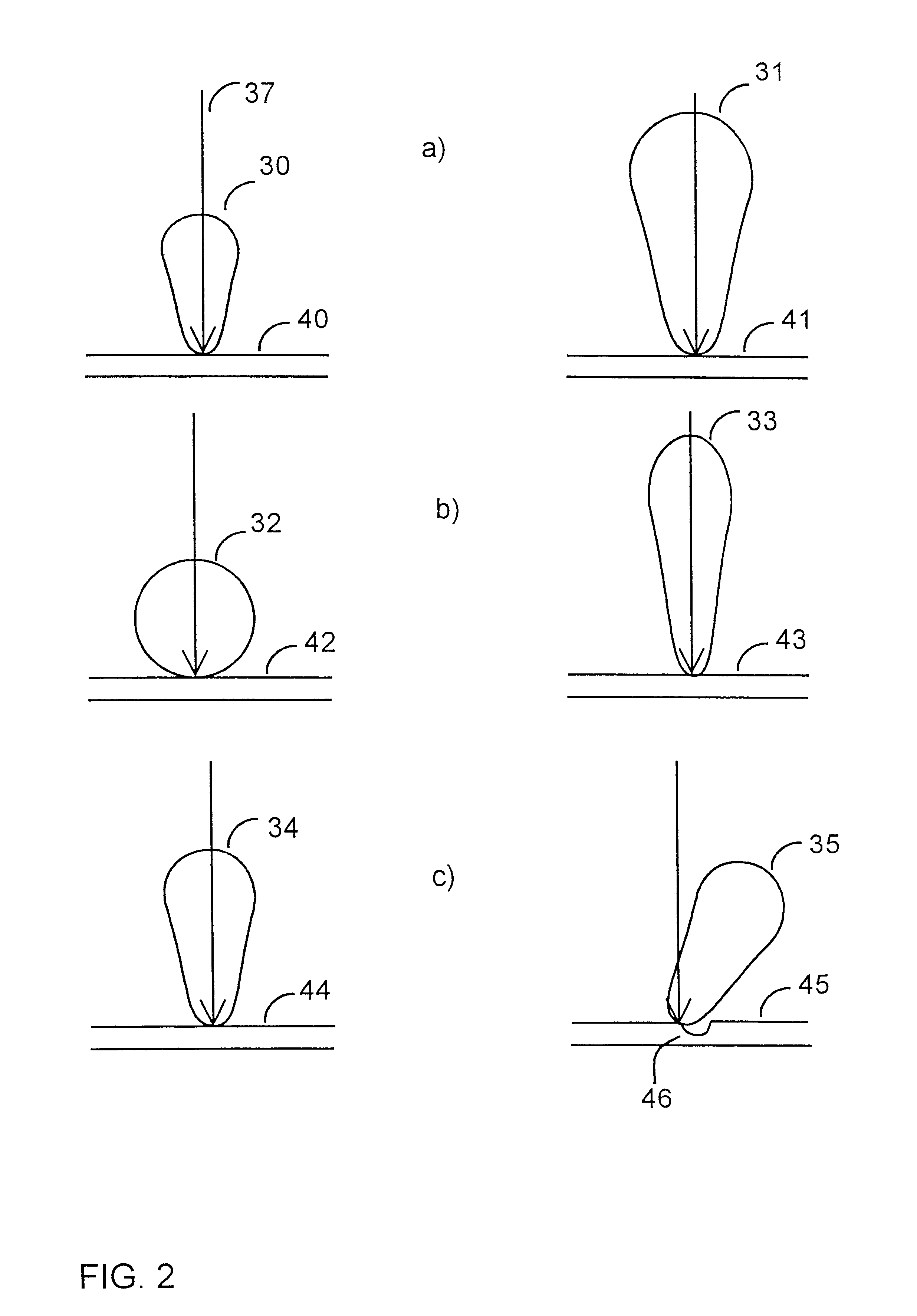

Arrangement and method for inspection of surface quality

InactiveUS6327374B1Enhances analysis of D characteristicEasy to analyzeScattering properties measurementsCharacter and pattern recognitionSuperficial massLine scan

The invention relates to a method for automatic inspection of the surface 20 of a moving object, in which a region on the object's surface is illuminated from at least two different illumination directions 13-15. The object's illuminated surface region is imaged with a camera to provide image information for analysis. The light sources in the different illumination directions 13-15 are pulsed to illuminate the object's surface region at different times, the pulsing frequency being >1 kHz The object's illuminated surface region is imaged as lines with a line scan camera 21 in sync with the above pulsing. The invention also relates to an arrangement for inspecting the surface 20 of a moving object, the arrangement comprising at least two light sources 10-12 in at least two different illumination directions 13-15 for illuminating the surface region of the object under inspection; a camera for imaging the object's surface region; and an image analyzer for analyzing the image information acquired from the object's surface 20 by imaging. The light sources 10-12 illuminate the object's surface 20 from the different illumination directions 13-15 at different times, and the camera is a line scan camera 21. The arrangement further comprises a timing controller 18 for synchronous pulsing of the light sources 10-12 and the at least one line scan camera 21, the pulsing frequency of the light sources 10-12 being >1 kHz.

Owner:THERMO RADIOMETRIE +1

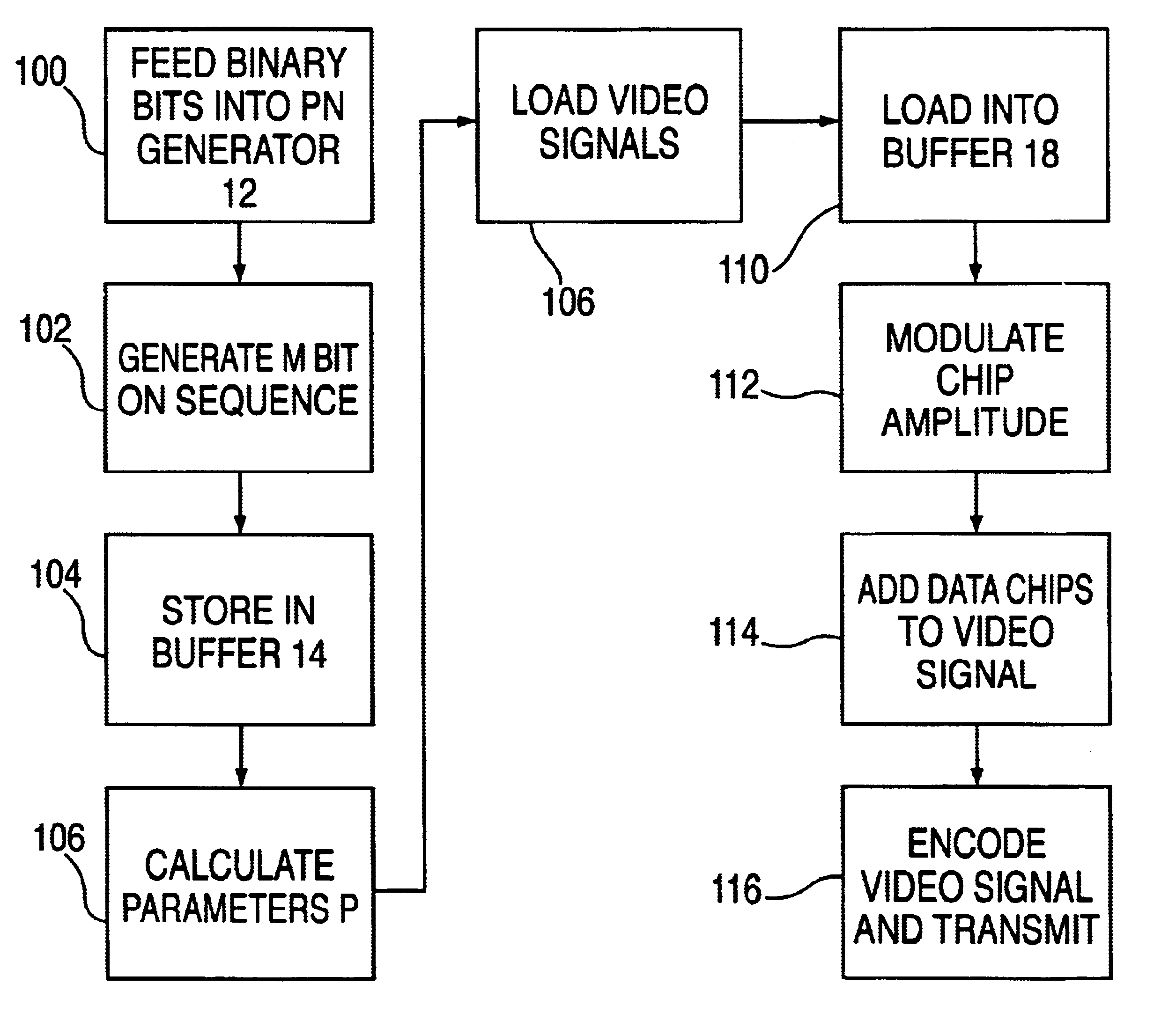

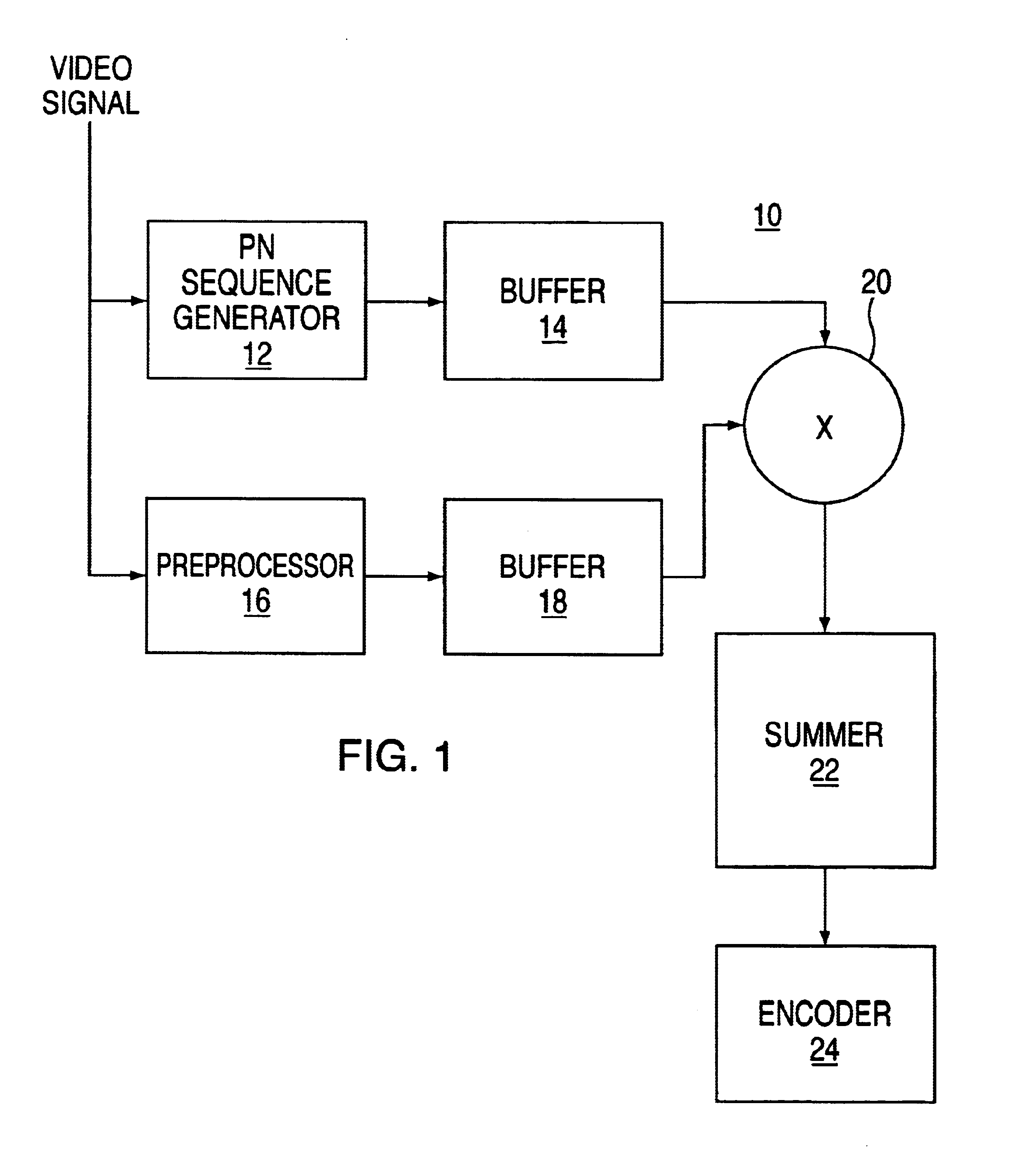

Method for transmitting data on a viewable portion of a video signal

InactiveUS6661905B1Improve reliabilityImprove efficiency and qualityCharacter and pattern recognitionSimultaneous/sequential multiple television signal transmissionComputer scienceLine scan

A method of encoding data in the visible portion of a transmitted video signal without degrading display of the received video signal, and for decoding the data in the received video signal. Each group of data bits to be transmitted, referred to a data symbol, is associated with one of a number of longer predetermined sequences of chips. Each chip sequence is divided into a multiplicity of lines of chips, and each line of chips together with its inverse are embedded, in pairwise fashion, in respective pairs of line scans of the video signal prior to its transmission. Received pairs of line scans are operated upon to detect the lines of chips they represent, and each of the number of chip sequences is correlated with the detected line of chips to derive a correlation magnitude. The chip sequence with the largest correlation magnitude is selected as the chip sequence whose data symbol was transmitted. The number of data lines exceeds the number of video lines required to define a video framer. In addition, each line has an amplitude which is modulated in accordance with a data carrying parameter determined by analyzing spatial and / or temporal characteristics of the video signal.

Owner:KOPLAR INTERACTIVE SYST INT

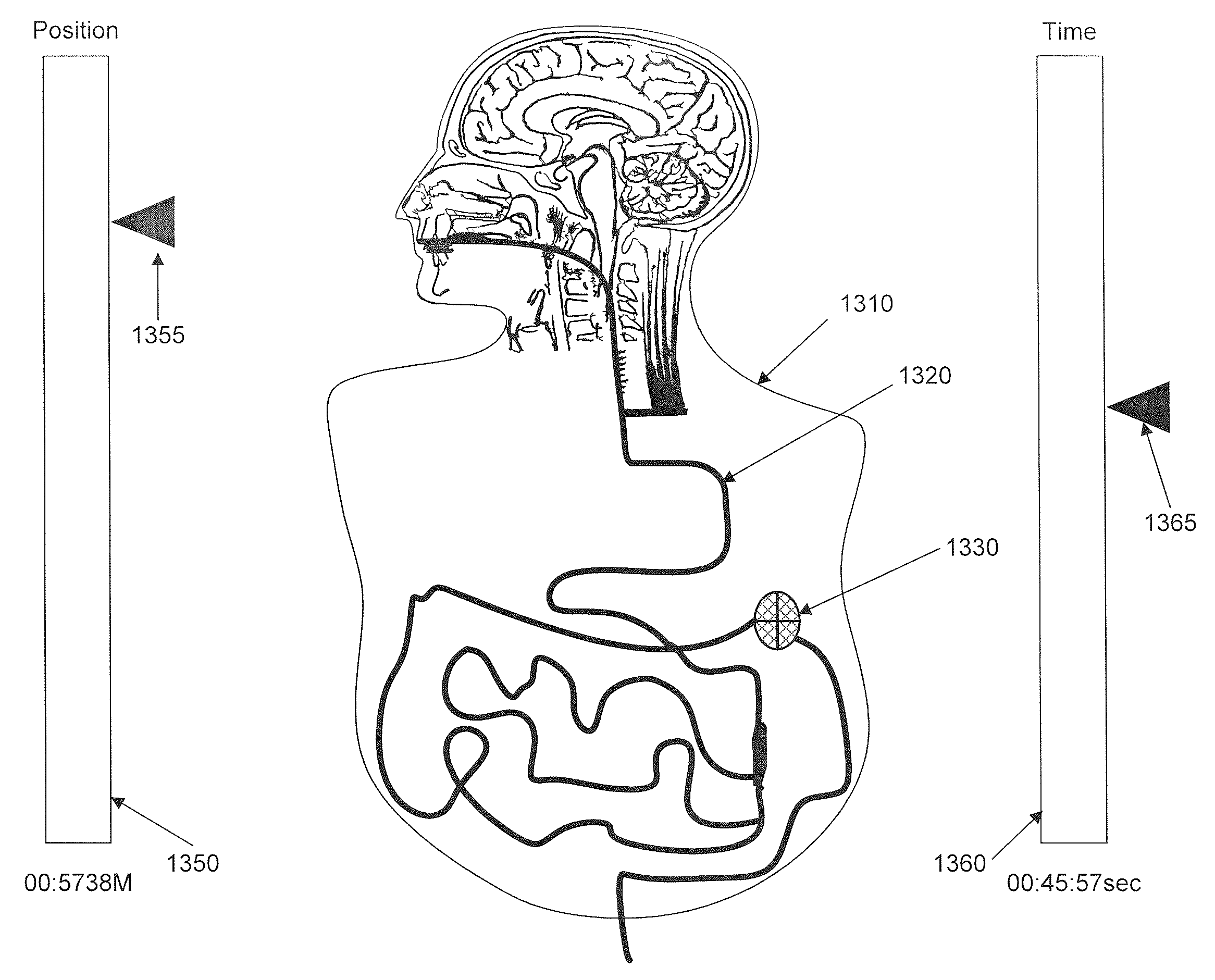

Displaying Image Data From A Scanner Capsule

An ingestible image scanning pill captures high resolution images of the GI tract as it passes through. Images communicated externally have exact location determination. Image processing software discards duplicate information and stitches images together, line scan by line scan, to replicate a complete GI tract as if it were stretched out in a straight line. A fully linear image is displayed to a medical professional as if the GI tract had been stretched in a straight line, cut open, laid flat out on a bench for viewing—all without making any incisions in a live patient.

Owner:INNURVATION

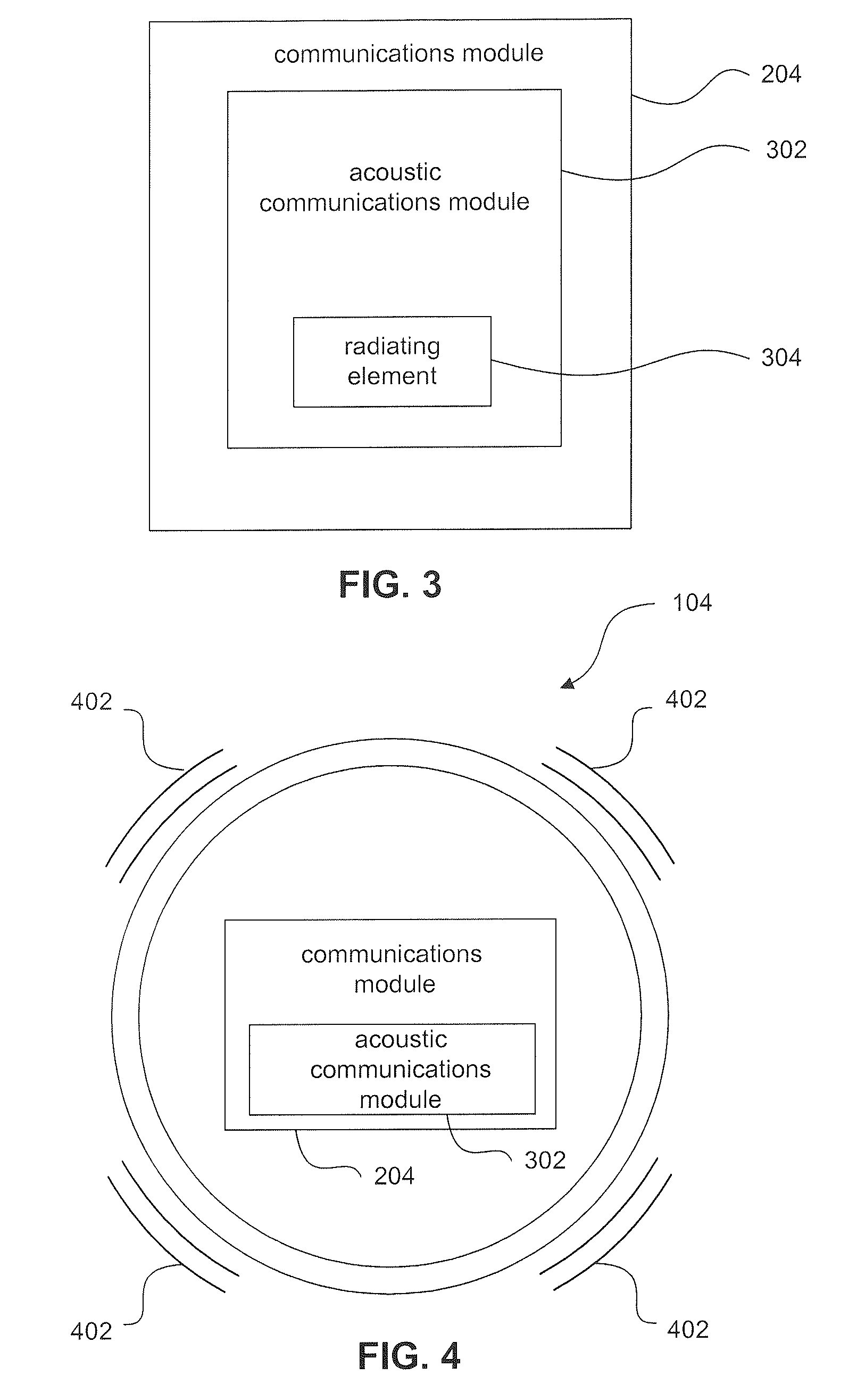

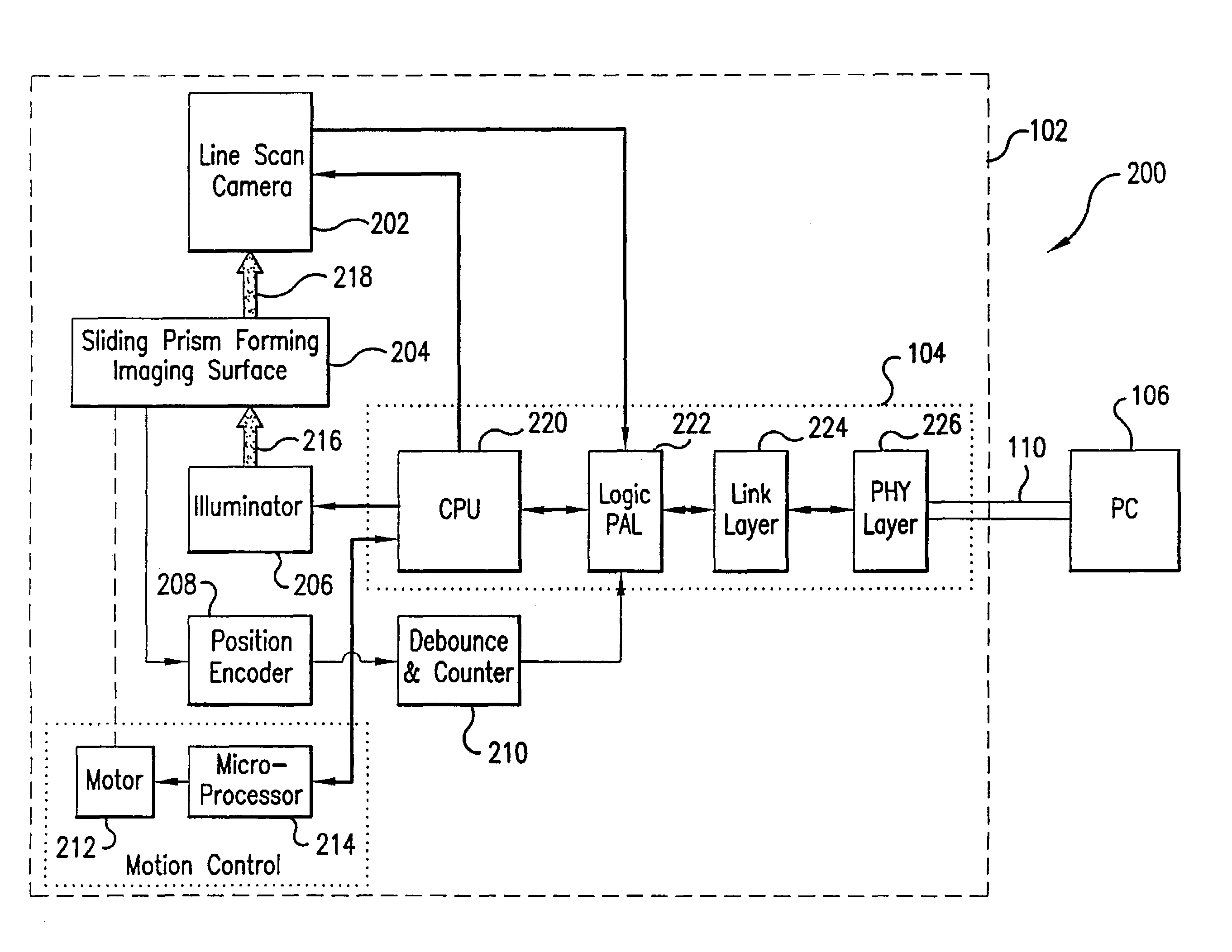

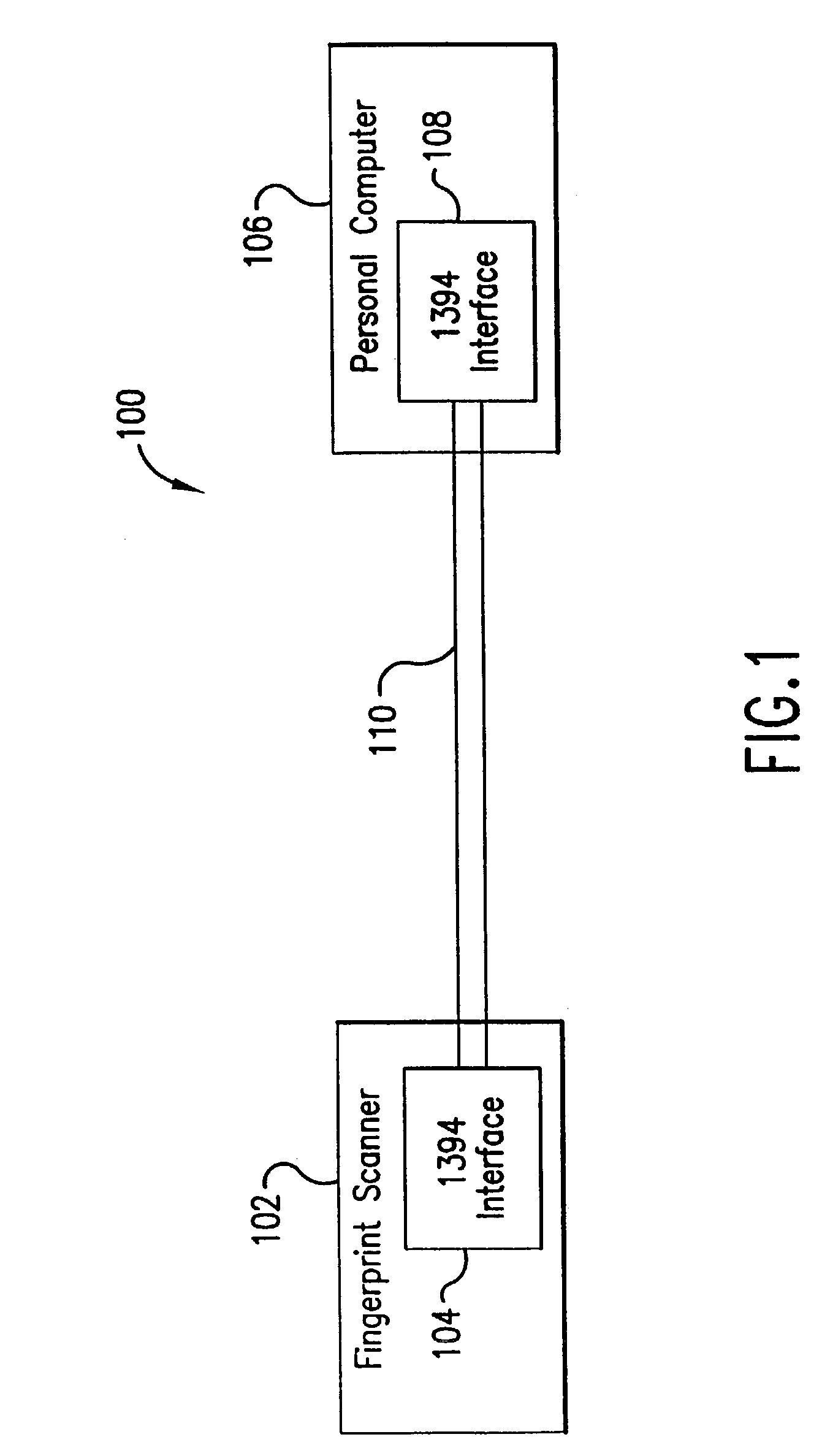

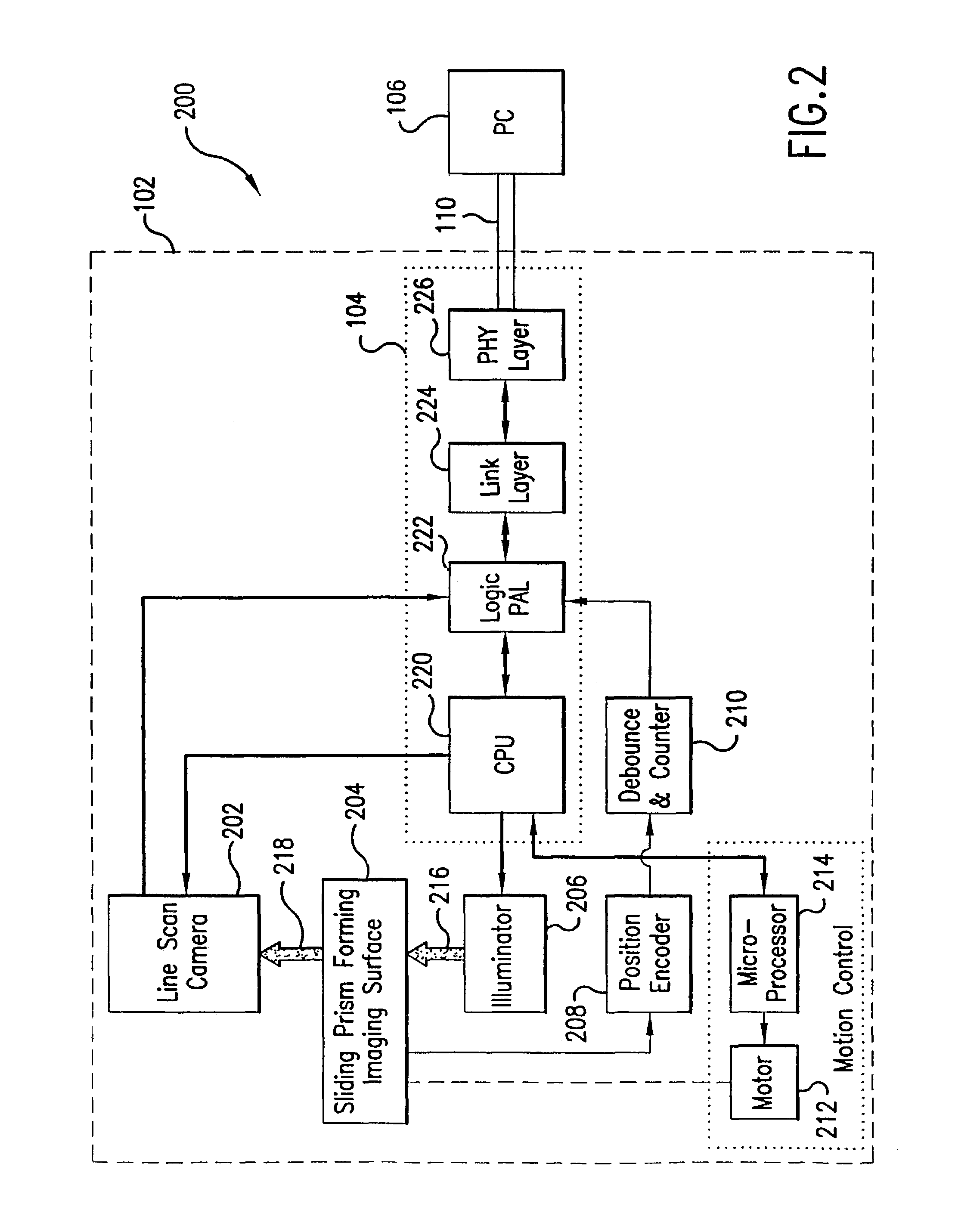

System and method for sending a packet with position address and line scan data over an interface cable

InactiveUS7068822B2Cost-effectiveProvide flexibilityHybrid switching systemsCharacter and pattern recognitionComputer graphics (images)Network packet

A system and method for sending a packet with a position address and line scan data from a first device over a 1394 interface to a second device. The present invention loads a camera, an illuminator, and a microprocessor with set-up instructions and a start pulse. The camera captures a line-by-line image of an object placed on the surface of a sliding prism. Position data, corresponding to the captured line-by-line image, is logged as the position address. The position address is combined with the line-by-line image to form a packet. The packet is sent to the second device for processing and viewing the image.

Owner:AUTHORIZER TECH INC

Current drive circuit and display device using same, pixel circuit, and drive method

InactiveUS20050200300A1Stably and accurately supplyingHigh quality imagingSolid-state devicesCathode-ray tube indicatorsDriving currentDisplay device

A display device including a current drive circuit capable of stably and correctly supplying an intended current to a light emitting element of each pixel without being affected by variations in characteristics of an active element inside the pixel and as a result capable of displaying a high quality image, wherein each pixel comprises a receiving use transistor TFT3 for fetching a signal current Iw from a data line DATA when a scanning line SCAN-A is selected, a conversion use transistor TFT1 for once converting a current level of a fetched signal current Iw to a voltage level and holding the same, and a drive use transistor TFT2 for passing a drive current having a current level in accordance with the held voltage level through a light emitting element OLED. The conversion use thin film transistor TFT1 generates a converted voltage level at its own gate by passing the signal current Iw fetched by the TFT3 through its own channel. A capacitor C holds the voltage level created at the gate of the TFT1. The TFT2 passes the drive current having a current level in accordance with the held voltage level through the light emitting element OLED.

Owner:SONY CORP

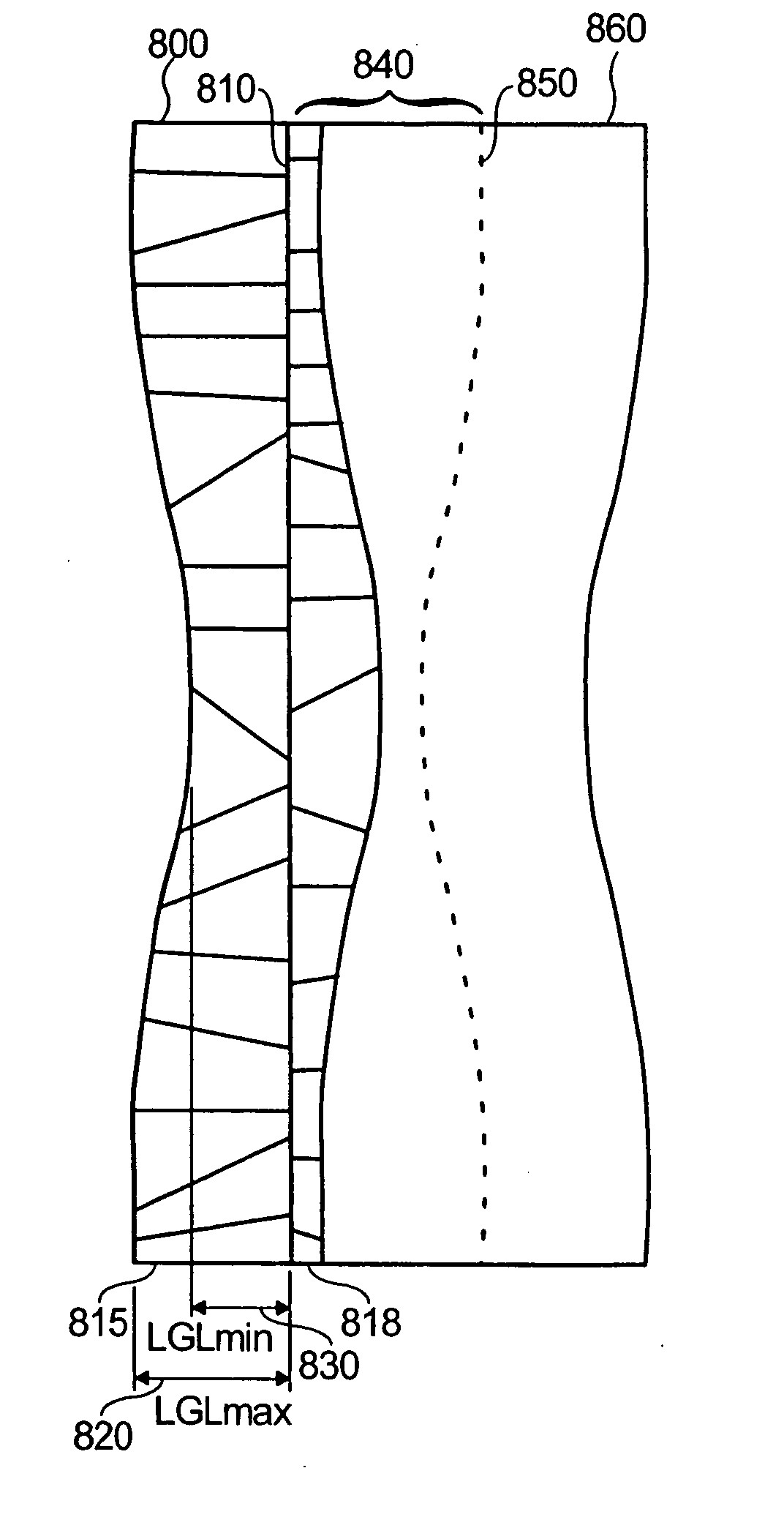

Line scan sequential lateral solidification of thin films

ActiveUS20060254500A1Improve uniformityReduce sharpnessFrom gel statePolycrystalline material growthOptoelectronicsNucleation

A polycrystalline film is prepared by (a) providing a substrate having a thin film disposed thereon, said film capable of laser-induced melting, (b) generating a sequence of laser pulses having a fluence that is sufficient to melt the film throughout its thickness in an irradiated region, each pulse forming a line beam having a predetermined length and width, said width sufficient to prevent nucleation of solids in a portion of the thin film that is irradiated by the laser pulse, (c) irradiating a first region of the film with a first laser pulse to form a first molten zone, said first molten zone demonstrating a variation in width along its length to thereby define a maximum width (Wmax) and a minimum width (Wmin), wherein the first molten zone crystallizes upon cooling to form one or more laterally grown crystals, (d) laterally moving the film in the direction of lateral growth a distance that is greater than about one-half Wmax and less than Wmin; and (e) irradiating a second region of the film with a second laser pulse to form a second molten zone having a shape that is substantially the same as the shape of the first molten zone, wherein the second molten zone crystallizes upon cooling to form one or more laterally grown crystals that are elongations of the one or more crystals in the first region.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

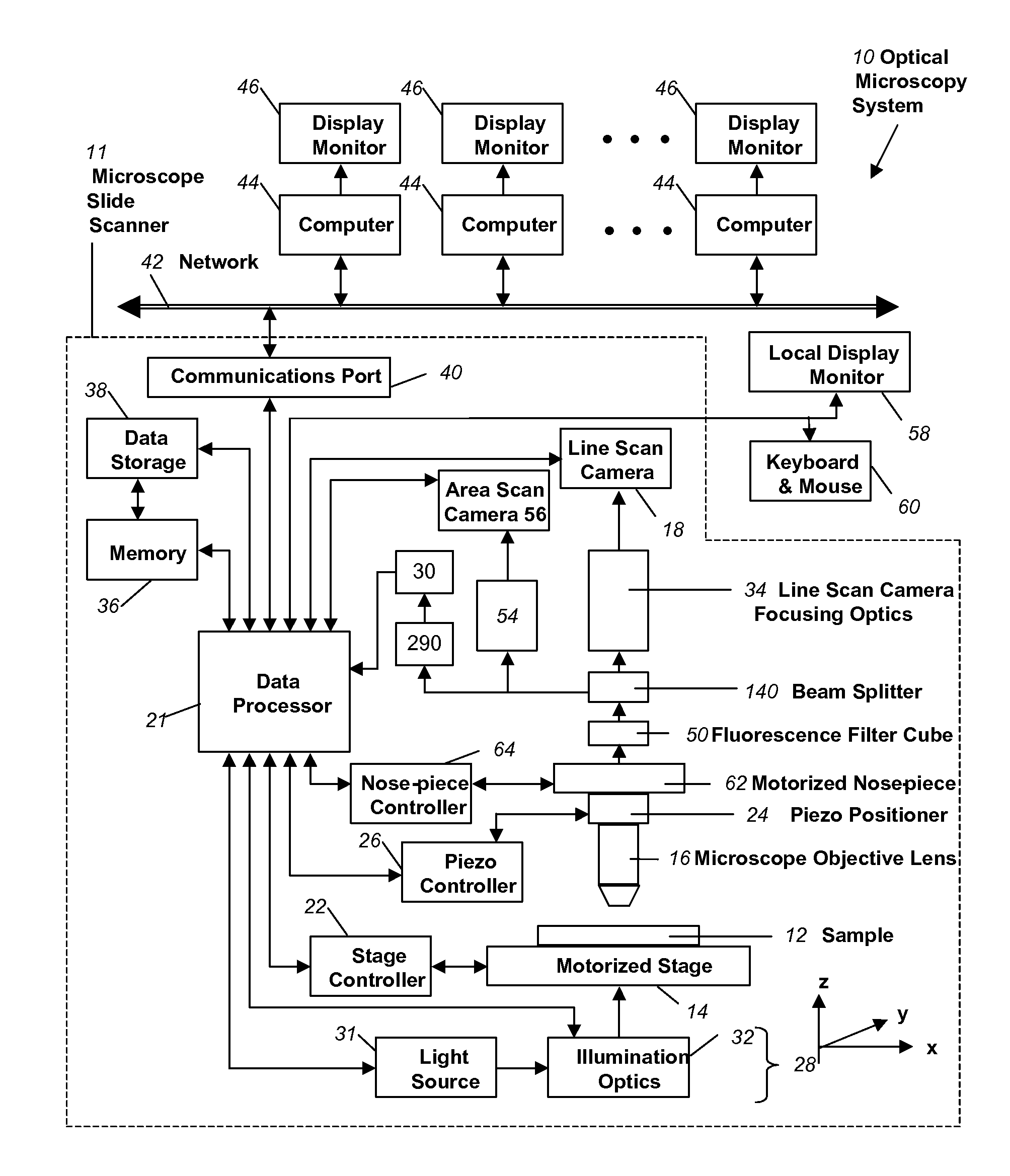

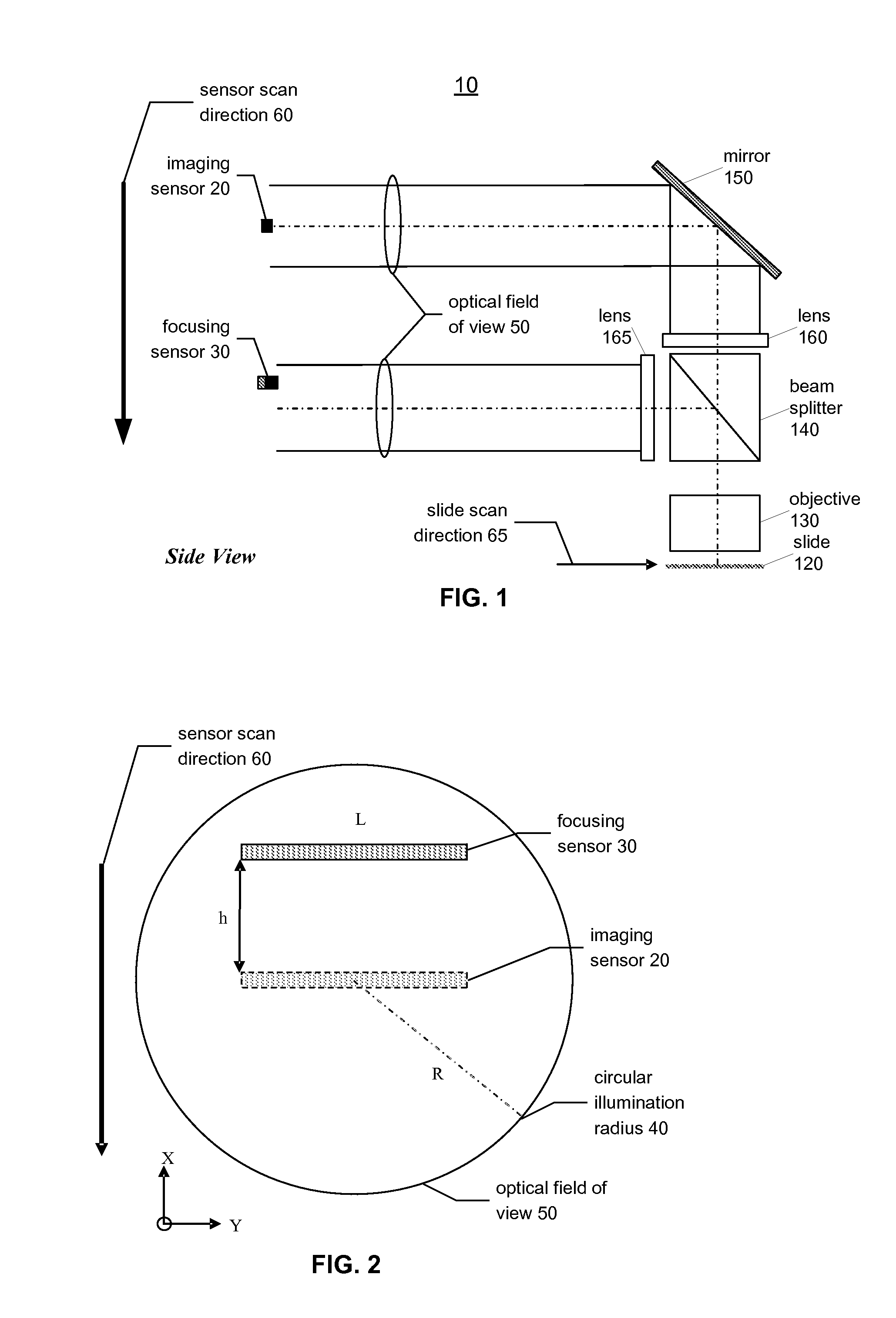

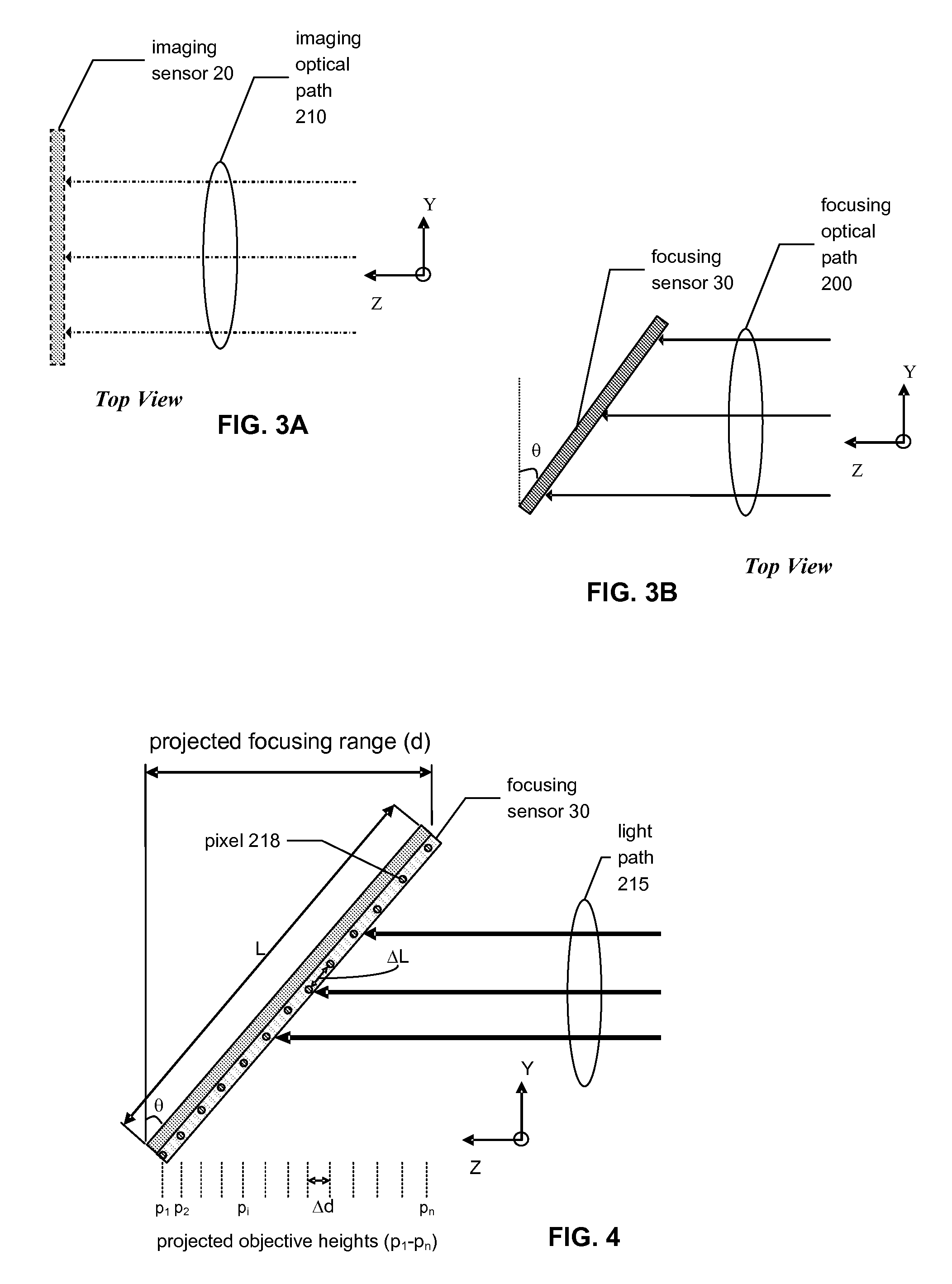

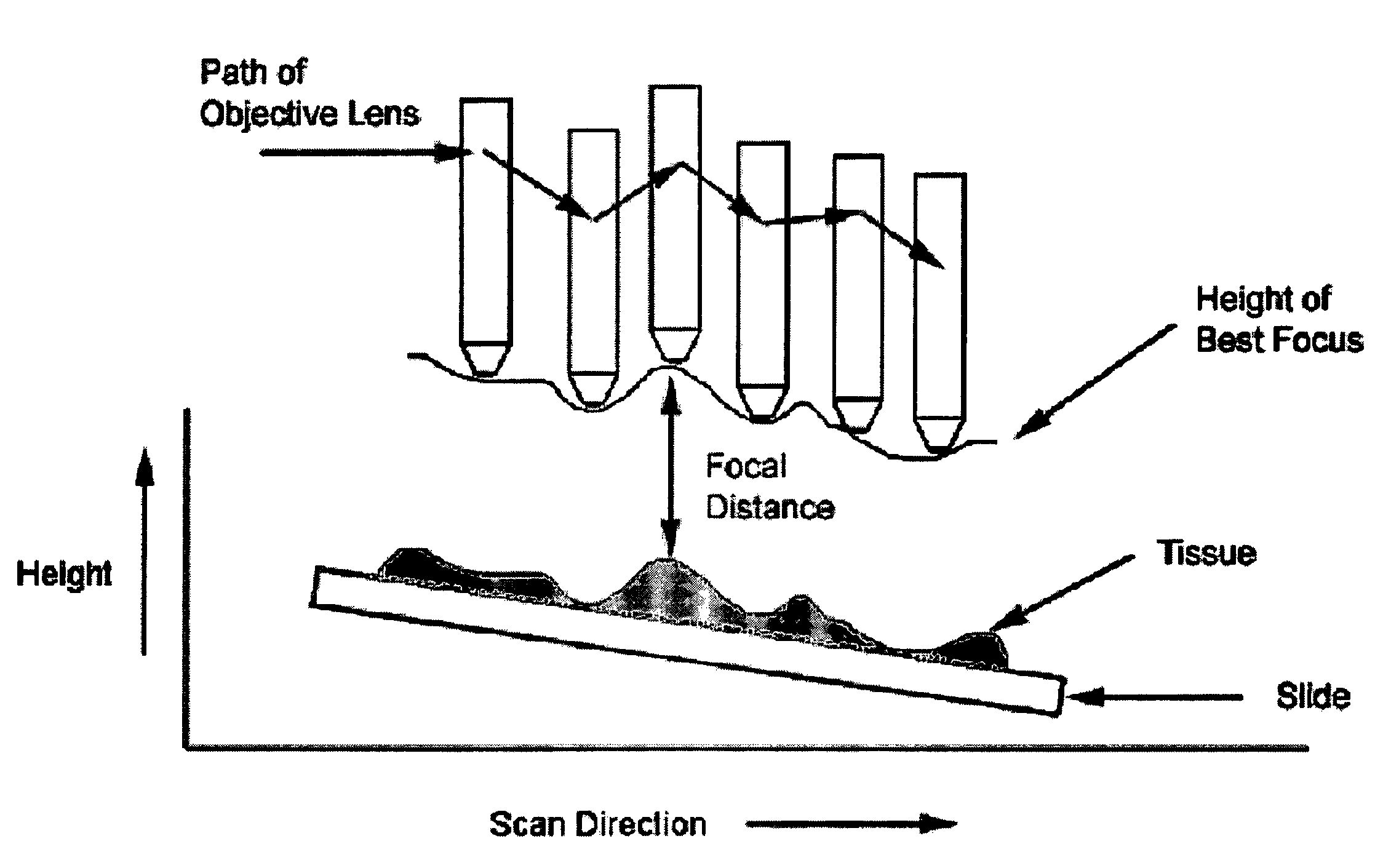

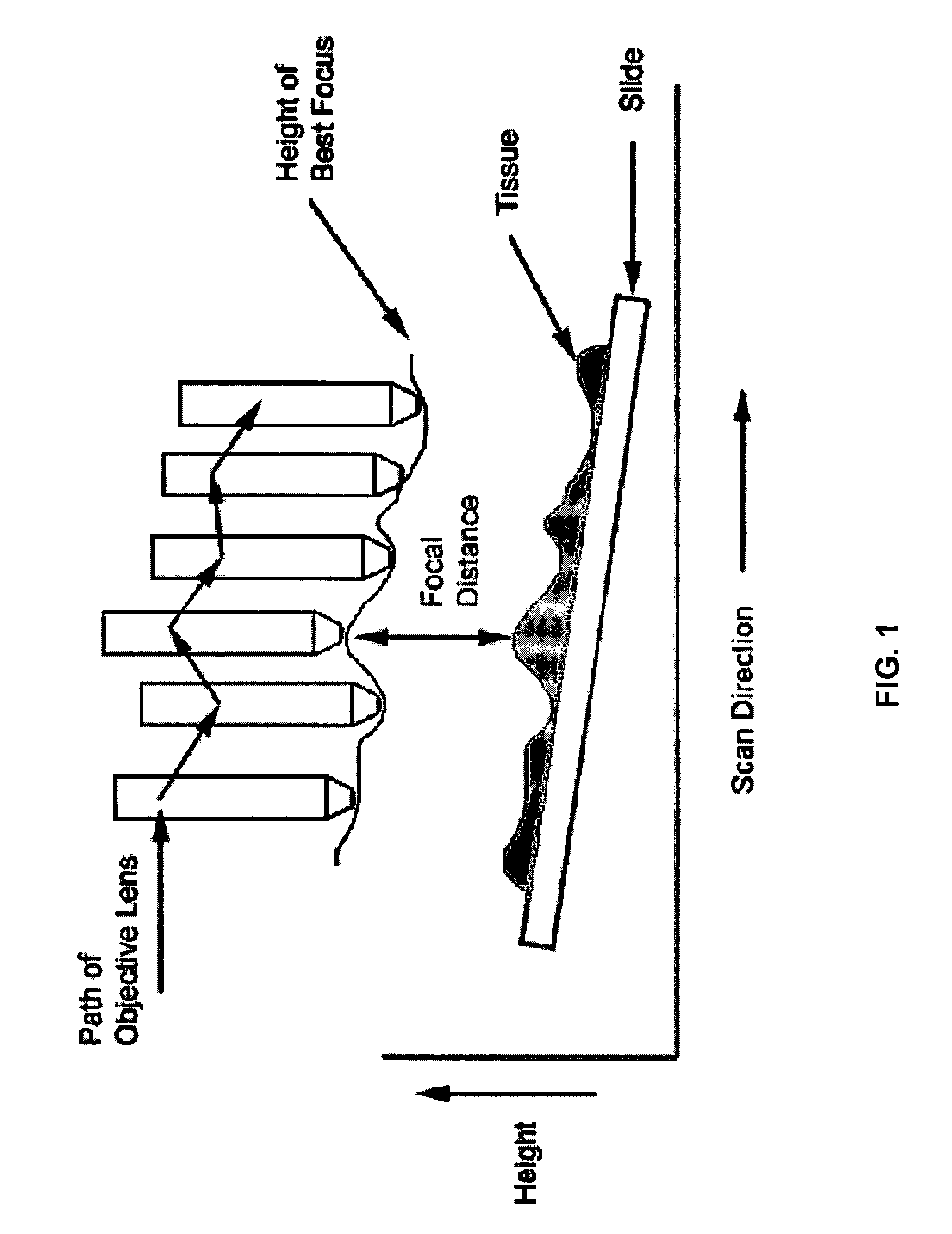

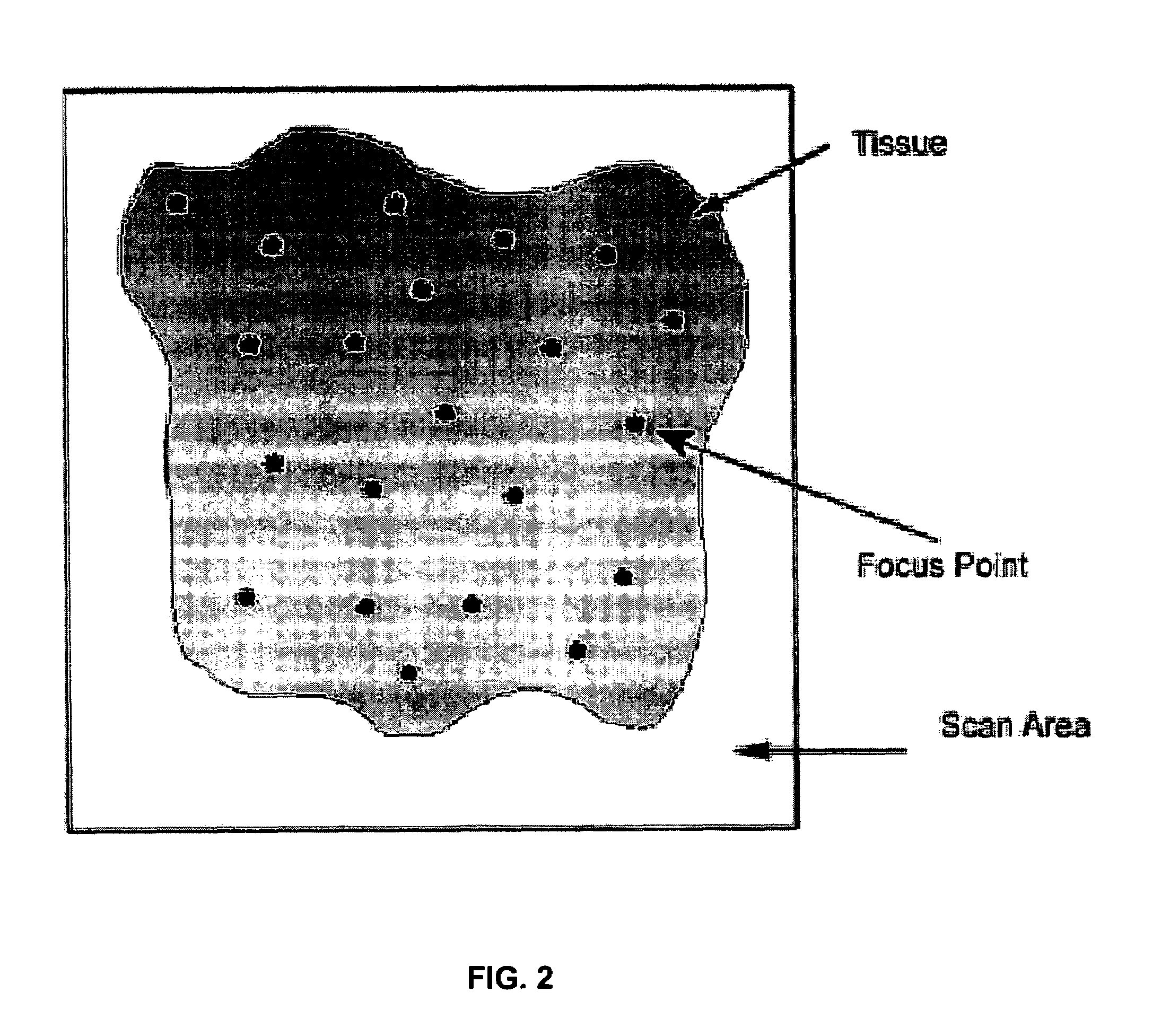

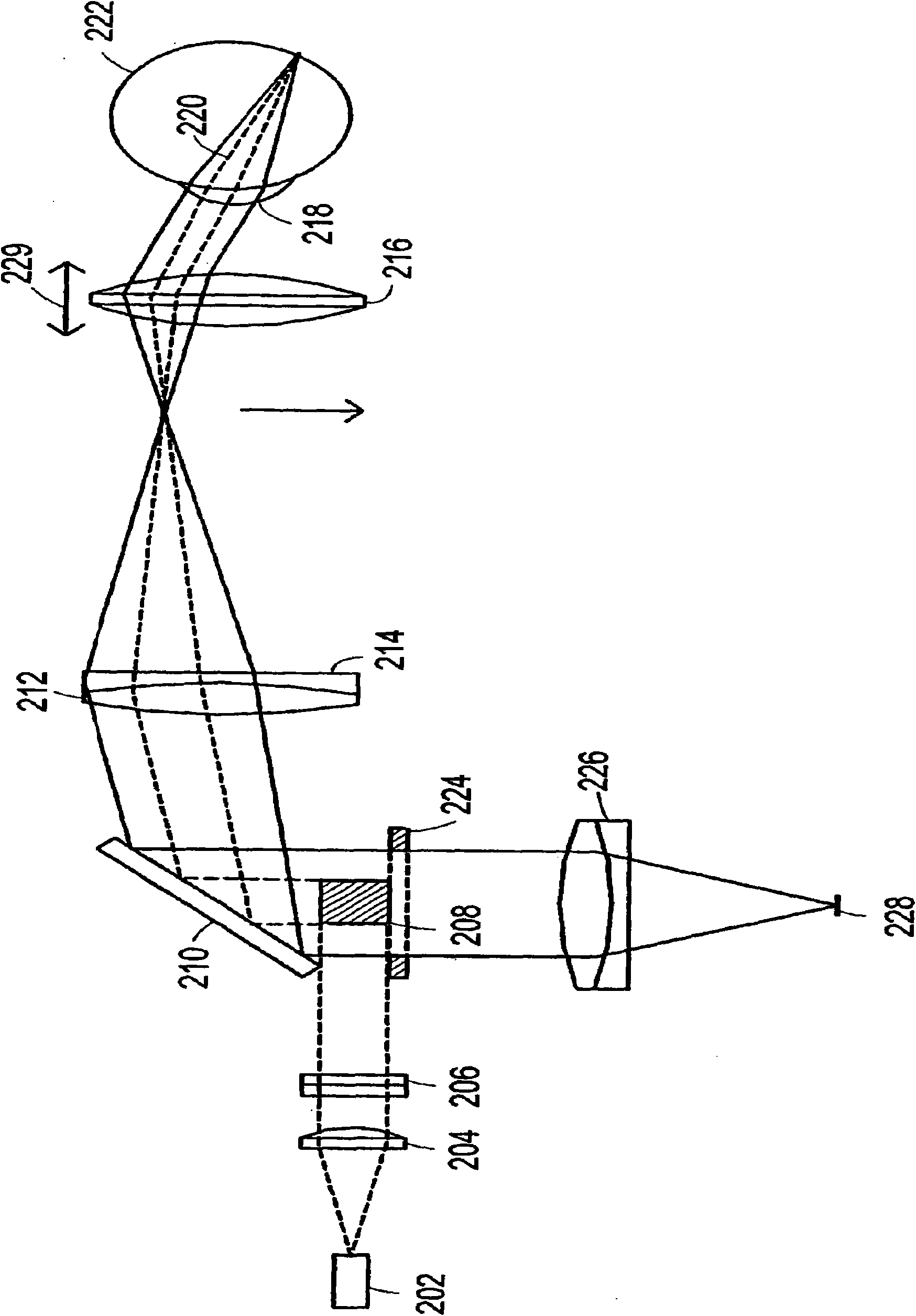

Real-time focusing in line scan imaging

ActiveUS20150130920A1Eliminate time lagAccurate real-time auto-focusingColor television detailsClosed circuit television systemsLine sensorBeam splitter

Systems and methods for capturing a digital image of a slide using an imaging line sensor and a focusing line sensor. In an embodiment, a beam-splitter is optically coupled to an objective lens and configured to receive one or more images of a portion of a sample through the objective lens. The beam-splitter simultaneously provides a first portion of the one or more images to the focusing sensor and a second portion of the one or more images to the imaging sensor. A processor controls the stage and / or objective lens such that each portion of the one or more images is received by the focusing sensor prior to it being received by the imaging sensor. In this manner, a focus of the objective lens can be controlled using data received from the focusing sensor prior to capturing an image of a portion of the sample using the imaging sensor.

Owner:LEICA BIOSYST IMAGING

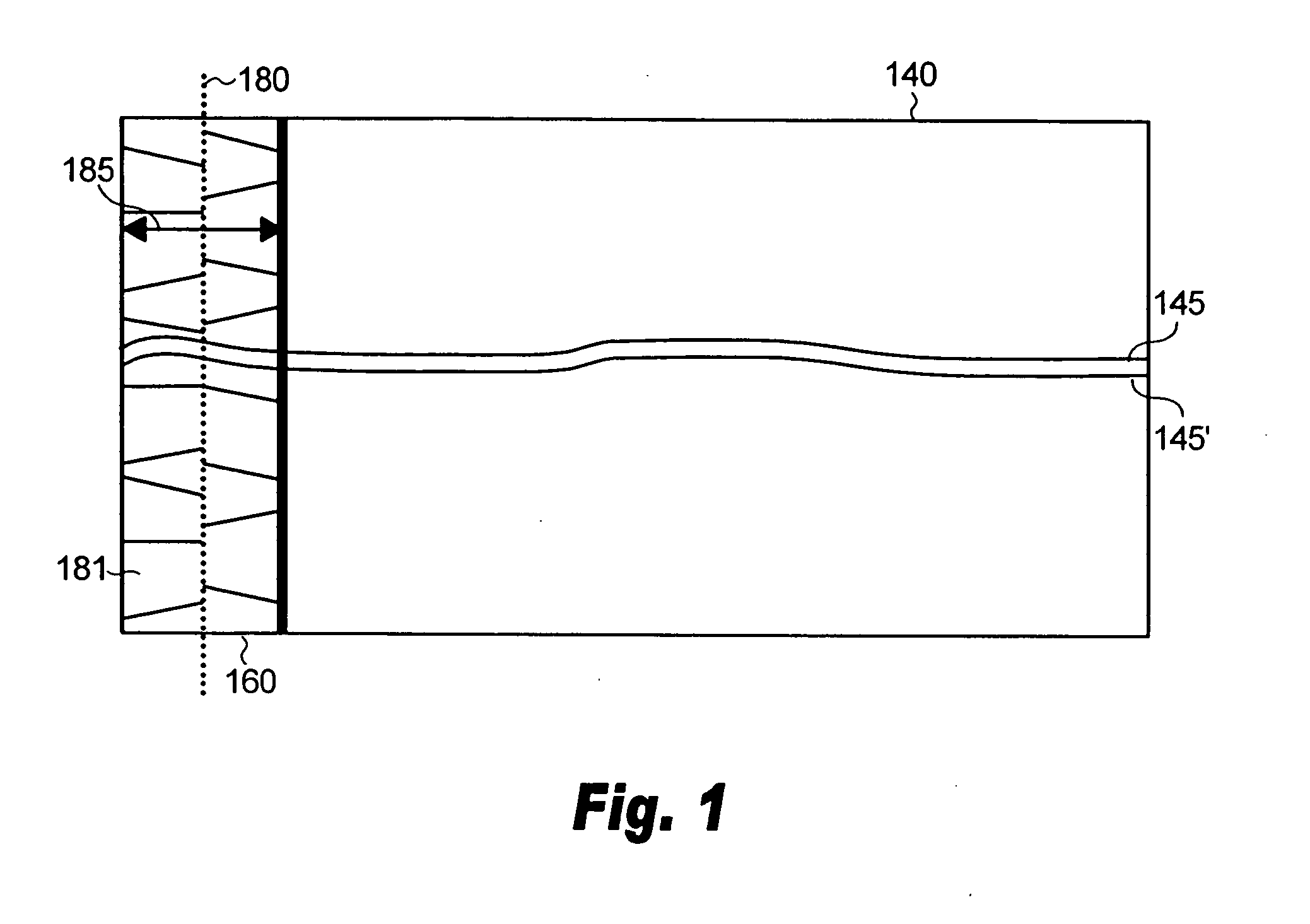

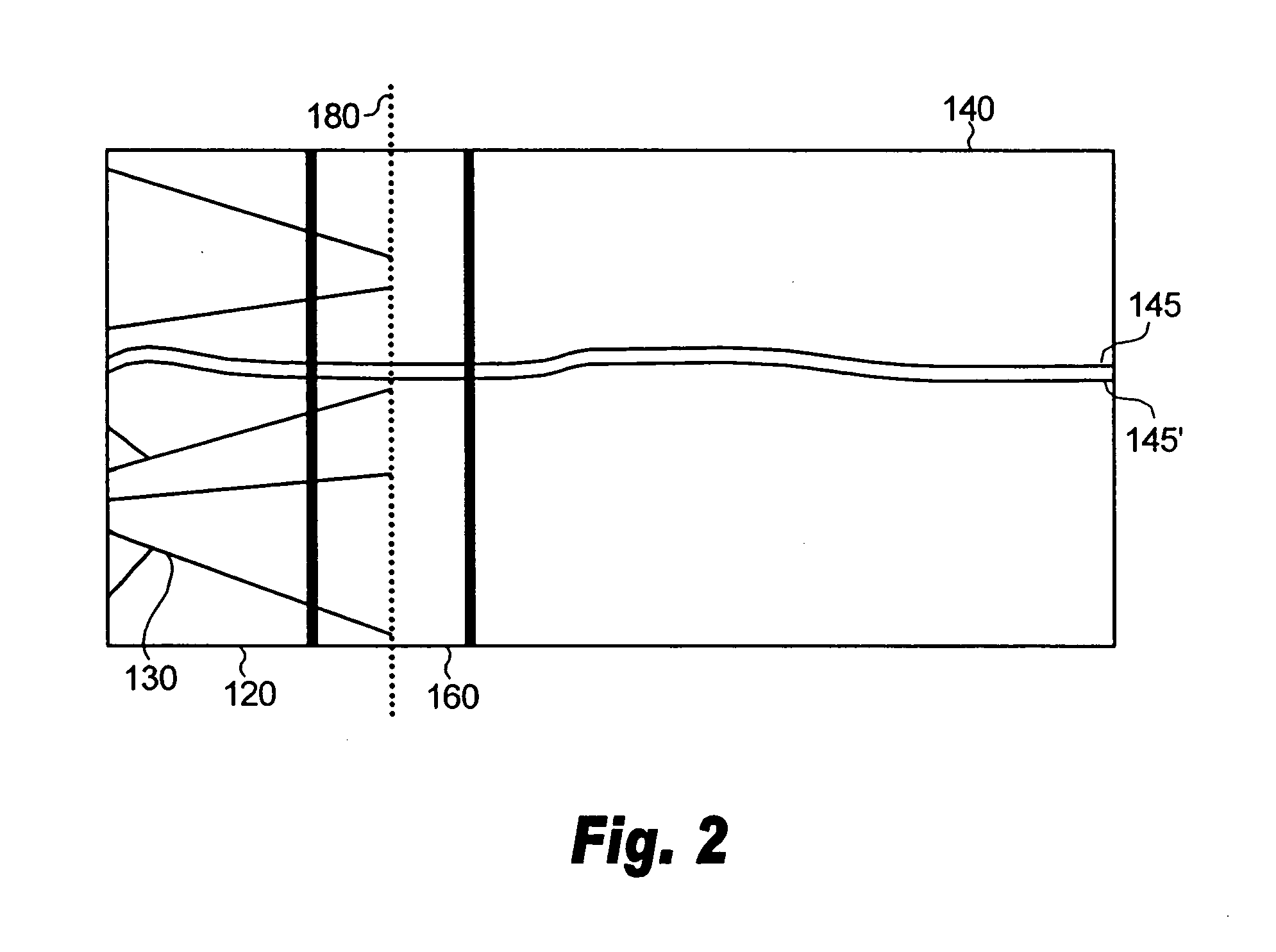

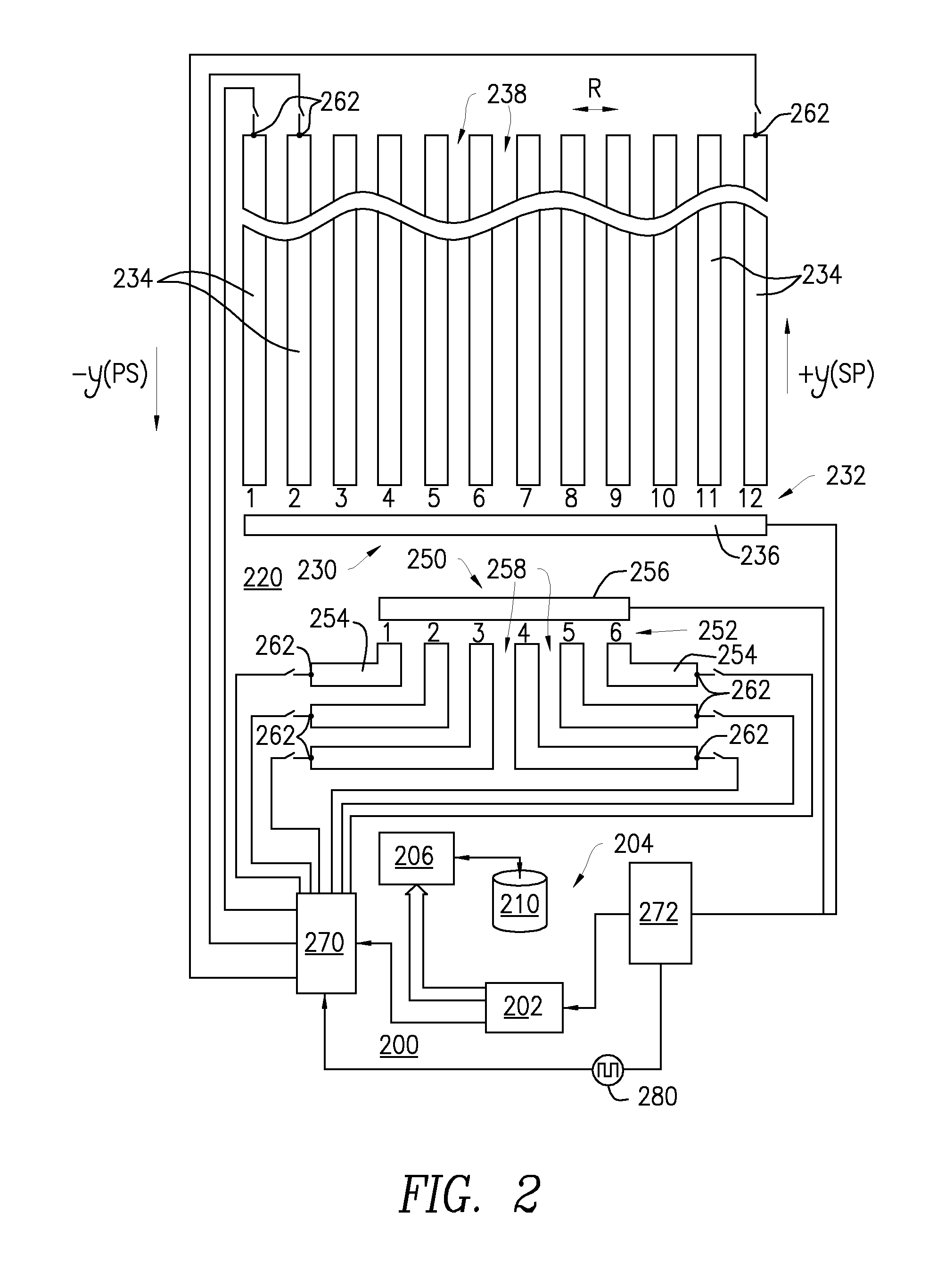

Method and apparatus for pre-focus in a linear array based slide scanner

InactiveUS7518652B2Television system detailsMaterial analysis by optical meansMicroscope slideBand pattern

Methods and apparatus are provided for computing focus information prior to scanning microscope slides with a line scan camera. The methods include a point-focus procedure that works by moving the slide to the desired measurement location, moving the objective lens through a predefined set of height values, acquiring imagery data at each height, and determining the height of maximum contrast. The methods also include a ribbon-focus procedure whereby imagery data are acquired continuously, while the slide and objective lens are in motion. Both methods may be applied with either a static or a dynamic implementation.

Owner:LEICA BIOSYST IMAGING

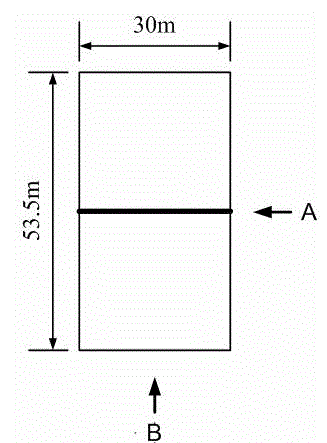

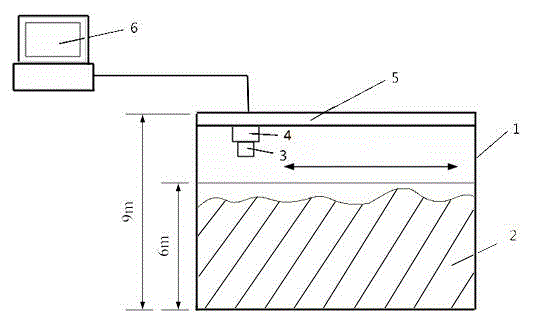

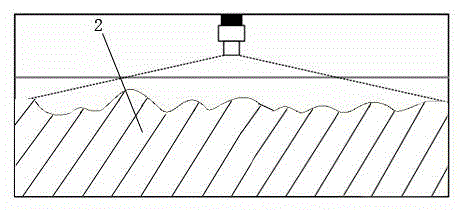

Method for measuring volume of large irregular bulk grain pile based on dynamic three-dimensional laser scanning

The invention relates to a method for measuring the volume of a large irregular bulk grain pile based on dynamic three-dimensional laser scanning. The method comprises the following steps of: arranging a guide rail in the middle of the top of a barn along the width direction, wherein the guide rail is provided with a slide block controlled by a stepping motor, and a laser radar scanner is installed on the slide block; moving the slide block from one end to the other end of the top of the barn at a constant speed to drive the laser radar scanner by the slide block to finish scanning on the surface of the whole bulk grain pile, wherein the laser radar device is a one-dimensional scanning device to realize linear scanning and returning coordinate data, and the master control computer is used for transmitting pulses to the stepping motor and processing the signal; acquiring point cloud data of the surface of the bulk grain pile through the master control computer, determining the distribution density of scanned points for calculating the volume according to an allowed error value of the grain pile measured by the user, and calculating the weight of the grain pile according to the grain density provided by the user; and generating a point cloud graphic matrix attached with coordinates through scanning space morphology by guide rail moving type three-dimensional laser, performing surface fitting to form an irregular bulk grain pile appearance, and thus obtaining the volume of the irregular bulk grain pile. The volume of the large irregular bulk grain pile can be rapidly and effectively measured at high precision, and remote monitoring can be realized; and moreover, the method is low in cost and easy to implement.

Owner:MENG FAN'GANG

Method and apparatus for measuring motion of a subject using a series of partial images from an imaging system

ActiveUS7805009B2Accurate placementCharacter and pattern recognitionEye diagnosticsOptical radiationReference image

A line scan imager is used to determine the motion of a subject. Each line of image data from the line scan imager is compared with a reference image. The location of a matching line in the reference image reveals the displacement of the subject. The current subject displacement can be determined based on each line of image data. The resulting displacement information can be used to correctly place other optical beams on the subject. The method can be applied to tracking the human eye to facilitate measurement, imaging, or treatment with a beam of optical radiation.

Owner:CARL ZEISS MEDITEC INC

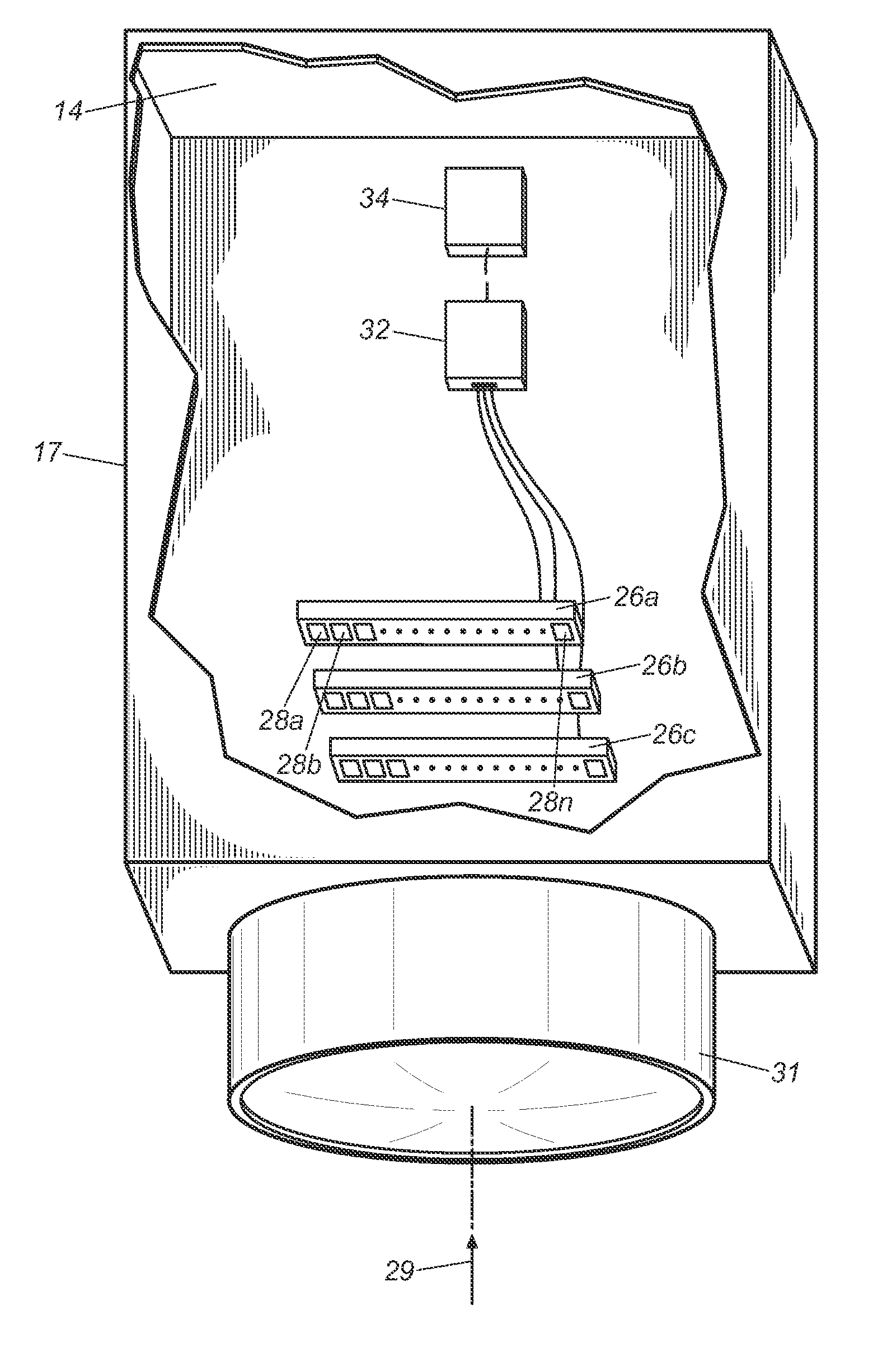

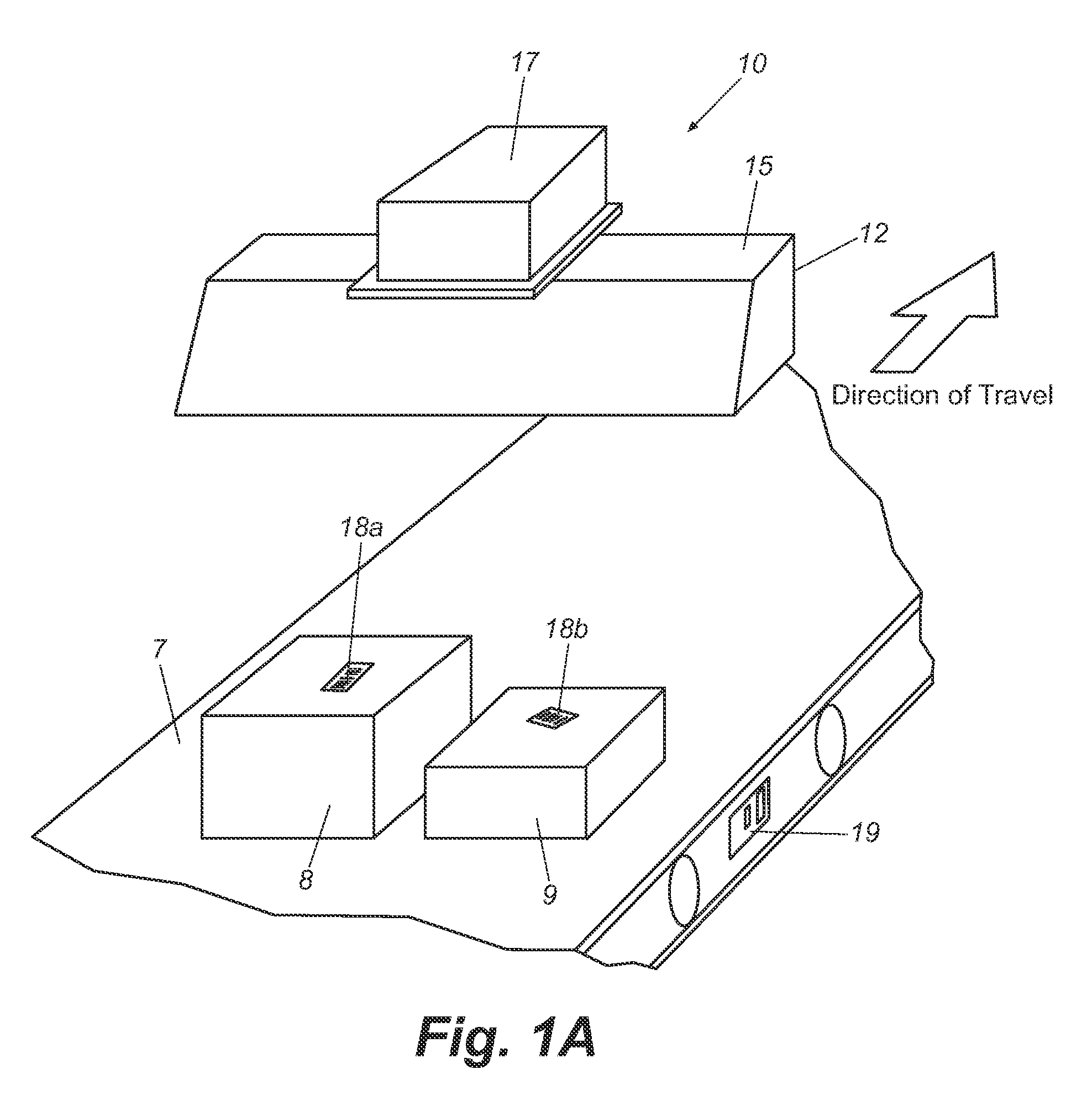

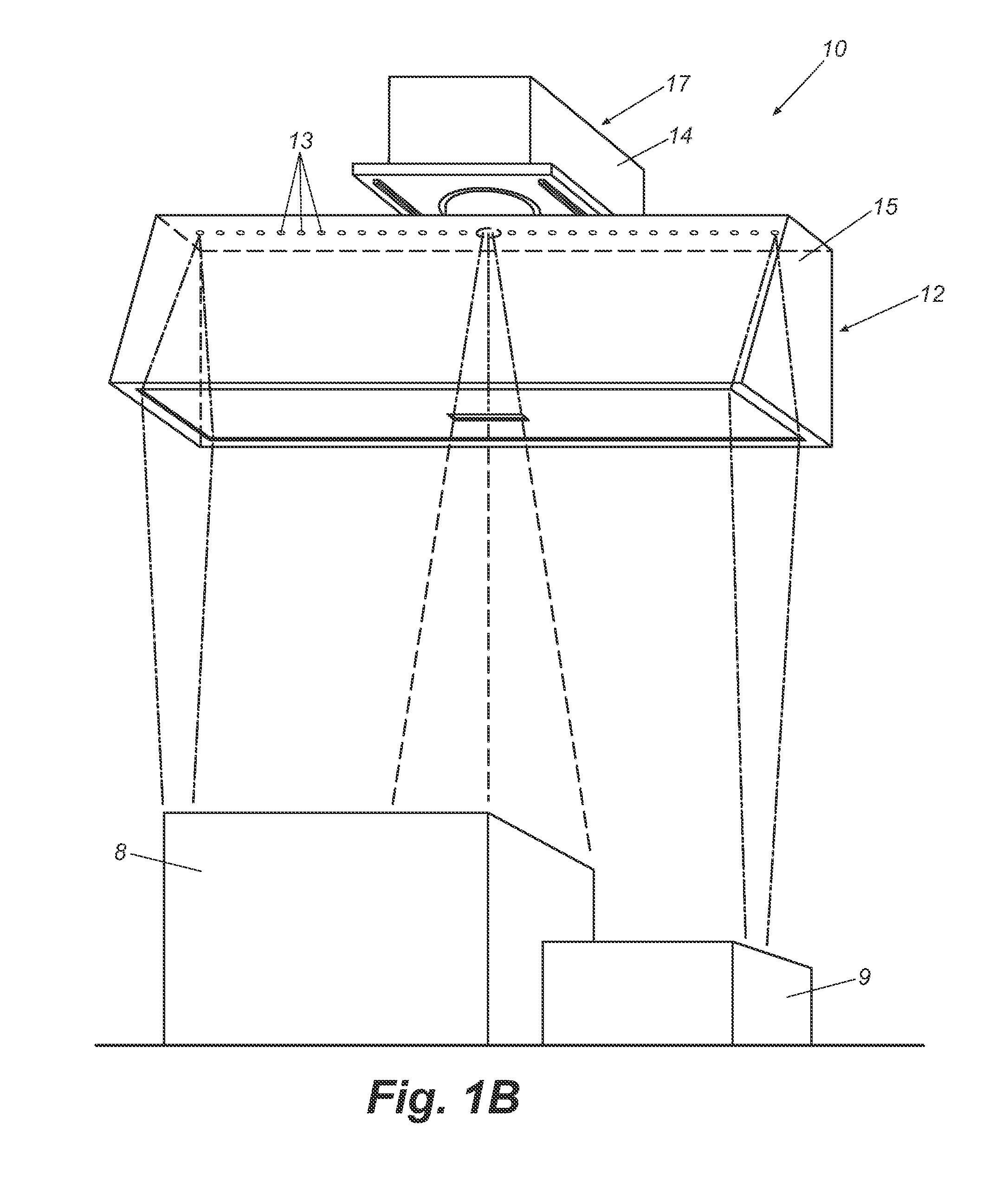

LED lighting system for line scan camera based multiple data matrix scanners

InactiveUS7336197B2Reduce noiseElectric/electromagnetic visible signallingIlluminated signsEffect lightEngineering

A LED lighting system for reading multiple data matrix codes on device populated transport media with a line scan camera, includes a light housing, a plurality of LED circuit bars, having a plurality of LEDs, mounted to an inner surface of the light housing arranged to provide high angle lighting and low angle lighting and a light controller operatively connected to the light housing to selectively control the light intensity, the light distribution and the angle of the LEDs on each of the plurality of LED array bars, whereby the LED lighting system can reduce texture noise and detect contrast in color or contrast in texture on the device populated transport media. The LED lighting system includes a device cooling system having an air compressor for cooling the LEDs such that they can operate at an optimal level.

Owner:DELTA DESIGN

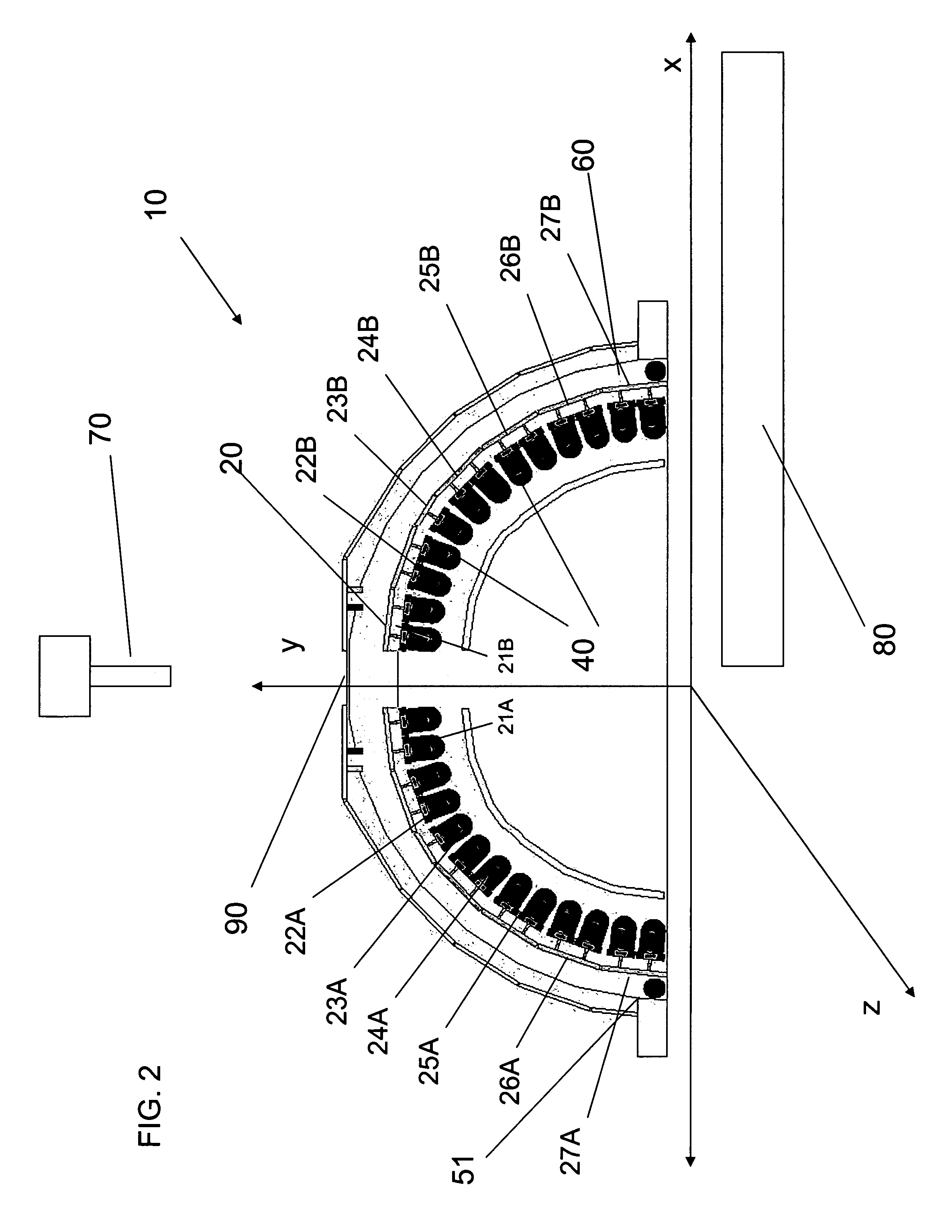

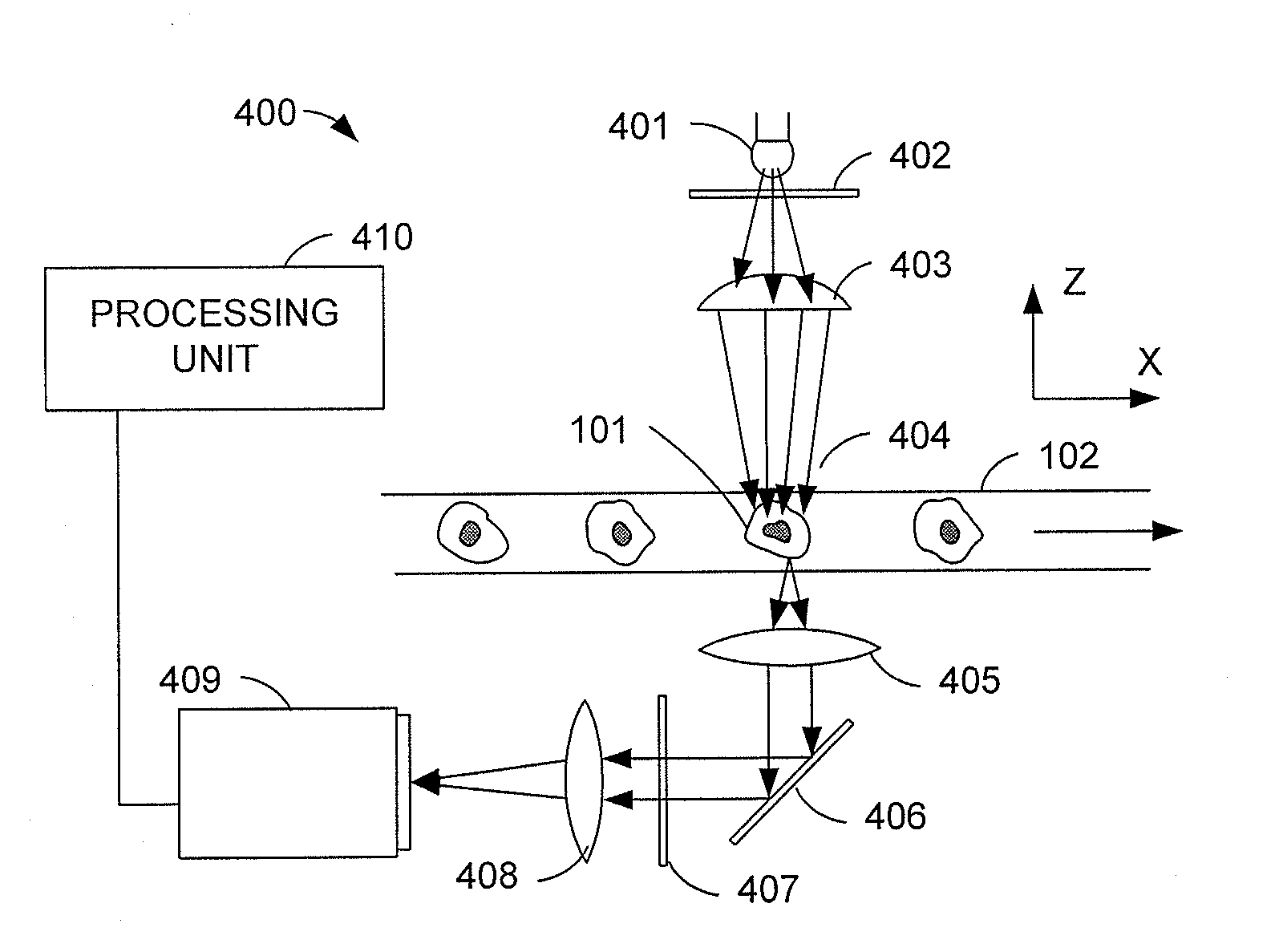

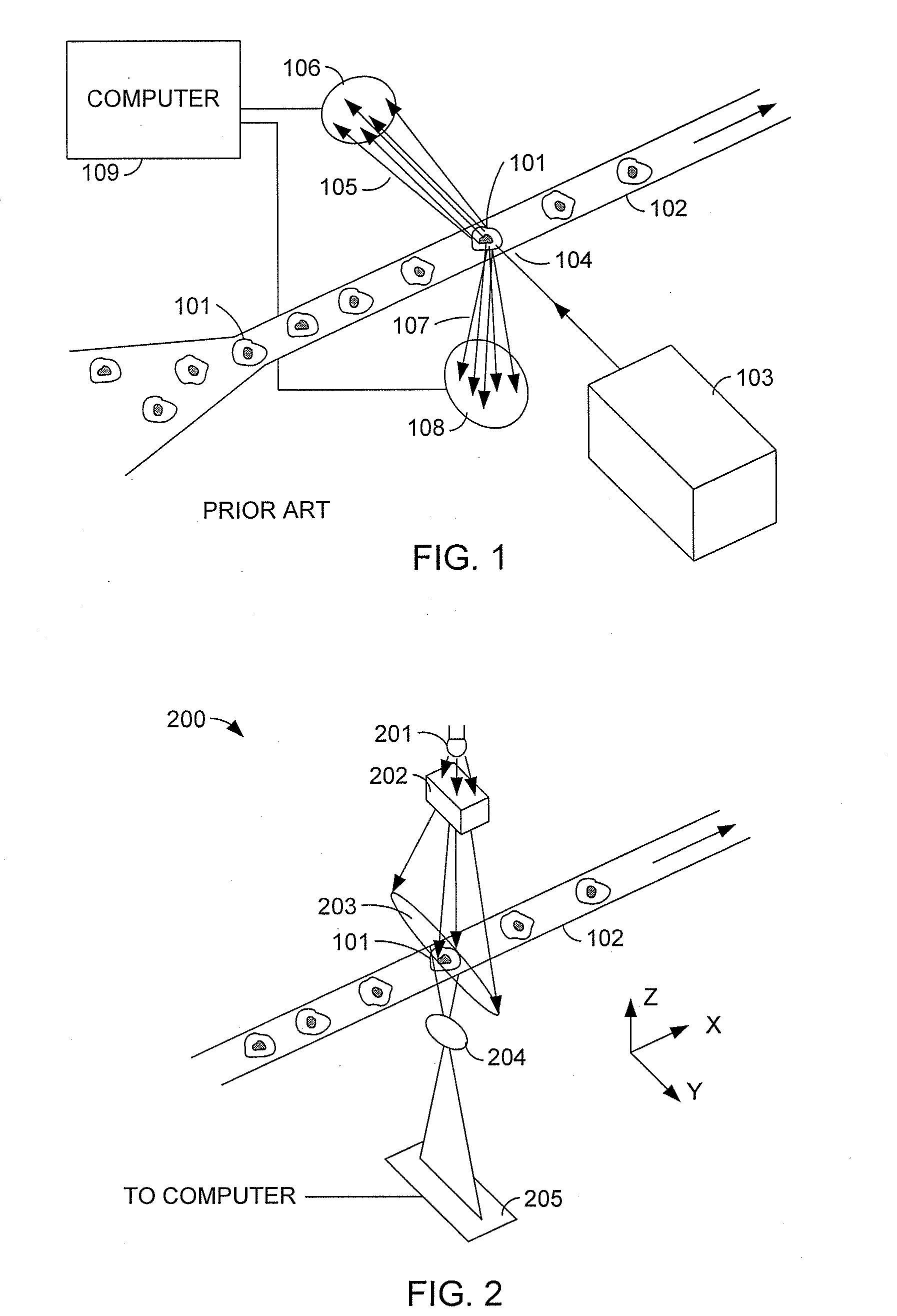

Serial-line-scan-encoded multi-color fluorescence microscopy and imaging flow cytometry

InactiveUS20100238442A1Improved signal-to-noise ratioRaman/scattering spectroscopyPhotometryHigh resolution imagingSerial line

A system for performing high-speed, high-resolution imaging cytometry utilizes a line-scan sensor. A cell to be characterized is transported past a scan region. An optical system focuses an image of a portion of the scan region onto at least one linear light sensor, and repeated readings of light falling on the sensor are taken while a cell is transported though the scan region. The system may image cells directly, or may excite fluorescence in the cells and image the resulting light emitted from the cell by fluorescence. The system may provide a narrow band of illumination at the scan region. The system may include various filters and imaging optics that enable simultaneous multicolor fluorescence imaging cytometry. Multiple linear sensors may be provided, and images gathered by the individual sensors may be combined to construct an image having improved signal-to-noise characteristics.

Owner:BIO RAD LAB INC

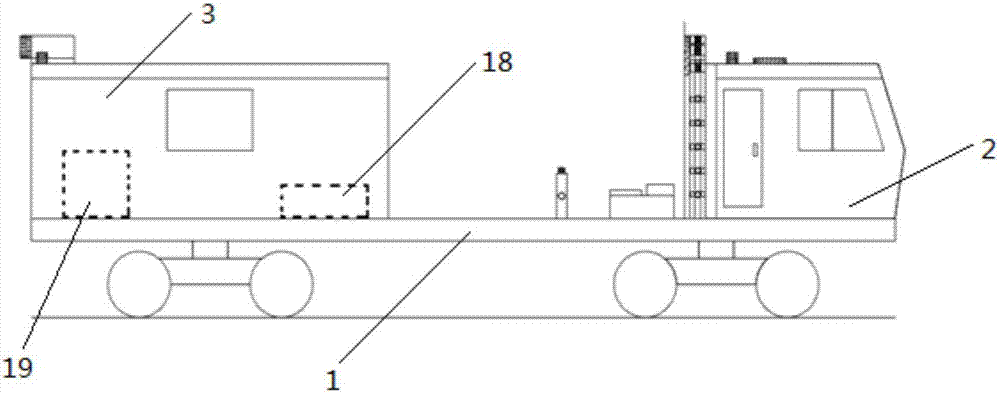

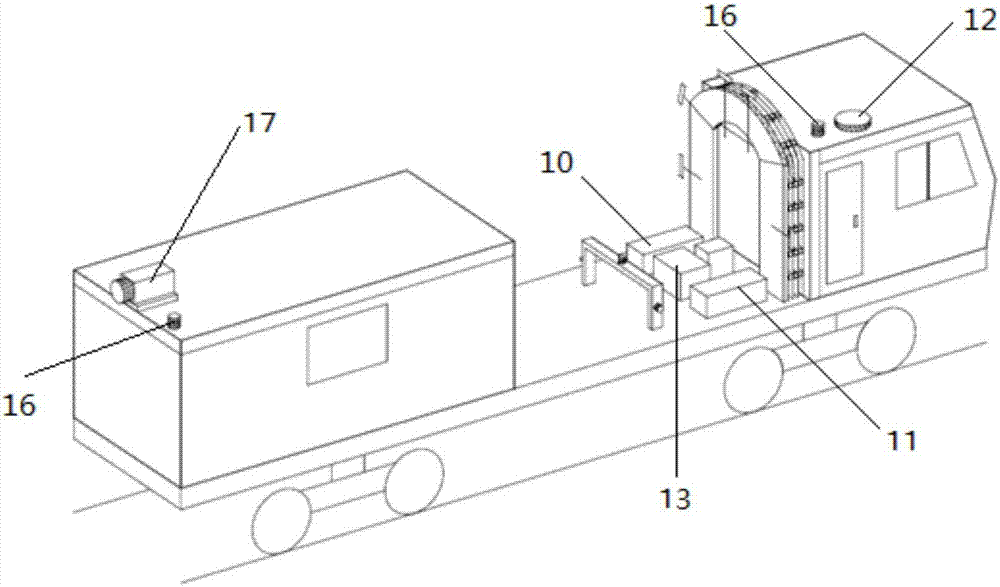

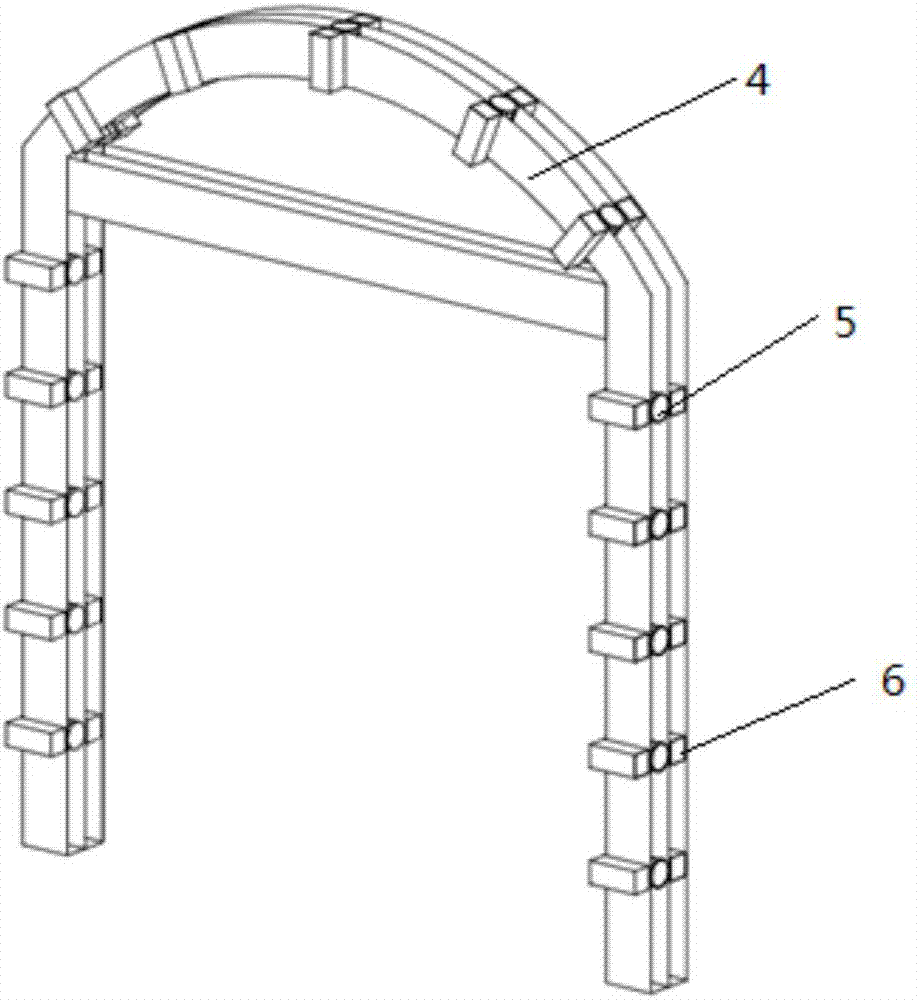

Method and rail vehicle for full-section comprehensive detection of railway tunnels

PendingCN107014352AAvoid time-consuming and inefficientDetection speedSatellite radio beaconingProfile tracingRailway tunnelBody compartment

The invention belongs to the technical field of tunnel detection of railway engineering systems and particularly relates to a method and a rail vehicle for full-section comprehensive detection of railway tunnels. The rail vehicle comprises a rail vehicle floor board, a cab and a carriage. Line-scan cameras are arranged on an arch frame which is arranged on the rail vehicle floor board, air-coupled shield antennas, and a GPS (global positioning system) mainframe, ground penetrating radar and infrared thermal imagers are arranged on the rail vehicle floor board. A GPS receiver is arranged at the top end of the cab, a laser scanner is arranged at the tail of the top plate of the carriage, and an industrial personal computer is arranged in the carriage. By multiple detection systems, one-time full-section detection of tunnel lining states and tunnel bottom damages can be realized, high detection accuracy, high efficiency, shortening of maintenance time and saving of maintenance cost are realized, influences on normal transportation of the railway tunnels are low, and loss caused by stopping of transportation is reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

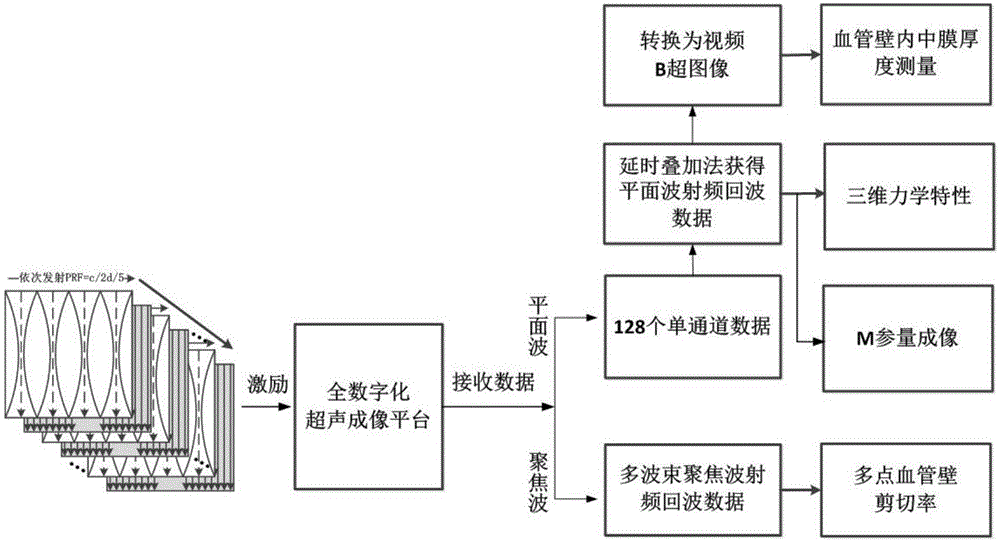

Method using three-dimensional mechanics and tissue specific imaging of blood vessels and plaques for detection

InactiveCN104398271ARealize three-dimensional mechanical property detectionRealize simultaneous measurementOrgan movement/changes detectionInfrasonic diagnosticsVulnerable plaqueShear rate

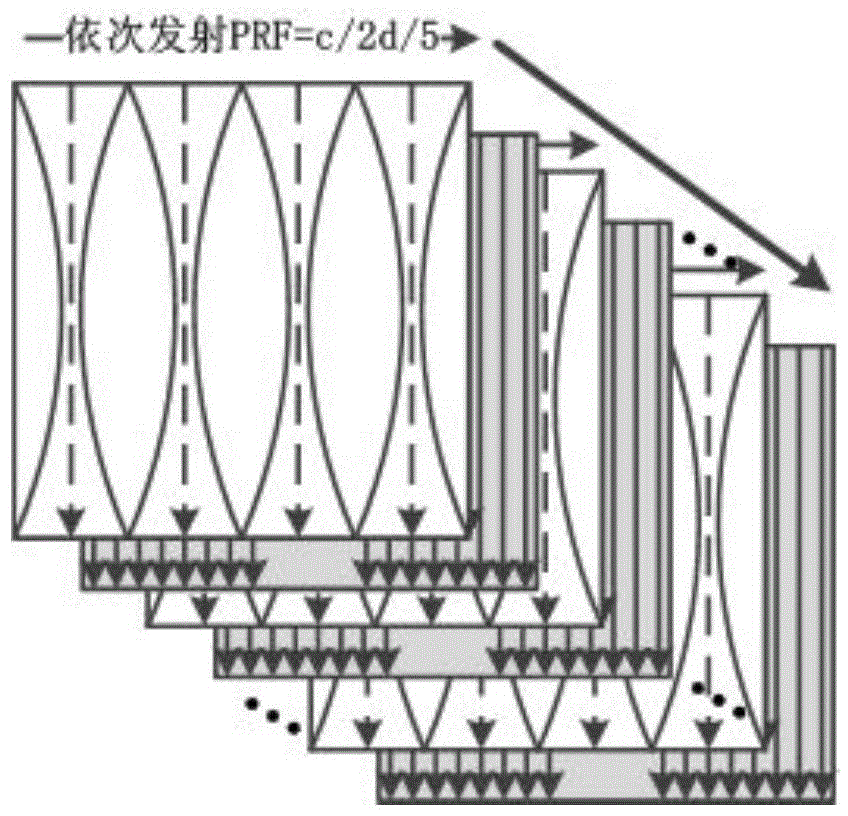

The invention relates to a method using three-dimensional mechanics characteristics and tissue specific imaging of blood vessels and plaques for detection. The method is on the basis of a multi-beam focus wave and superfast plane wave alternative transmitting sequence and can also be extended to a line-by-line scan imaging manner; the forms and the functions of the blood vessels and the plaques are evaluated and imaged respectively from the aspects of the radial-direction, circumferential and axial-direction three-dimensional mechanics characteristics, blood vessel wall shear rate, plaque form and tissue characterization, and the like; the new method which is provided for detection of the vulnerable plaques of a carotid artery is regarded as the improvement of the existing method.

Owner:XI AN JIAOTONG UNIV

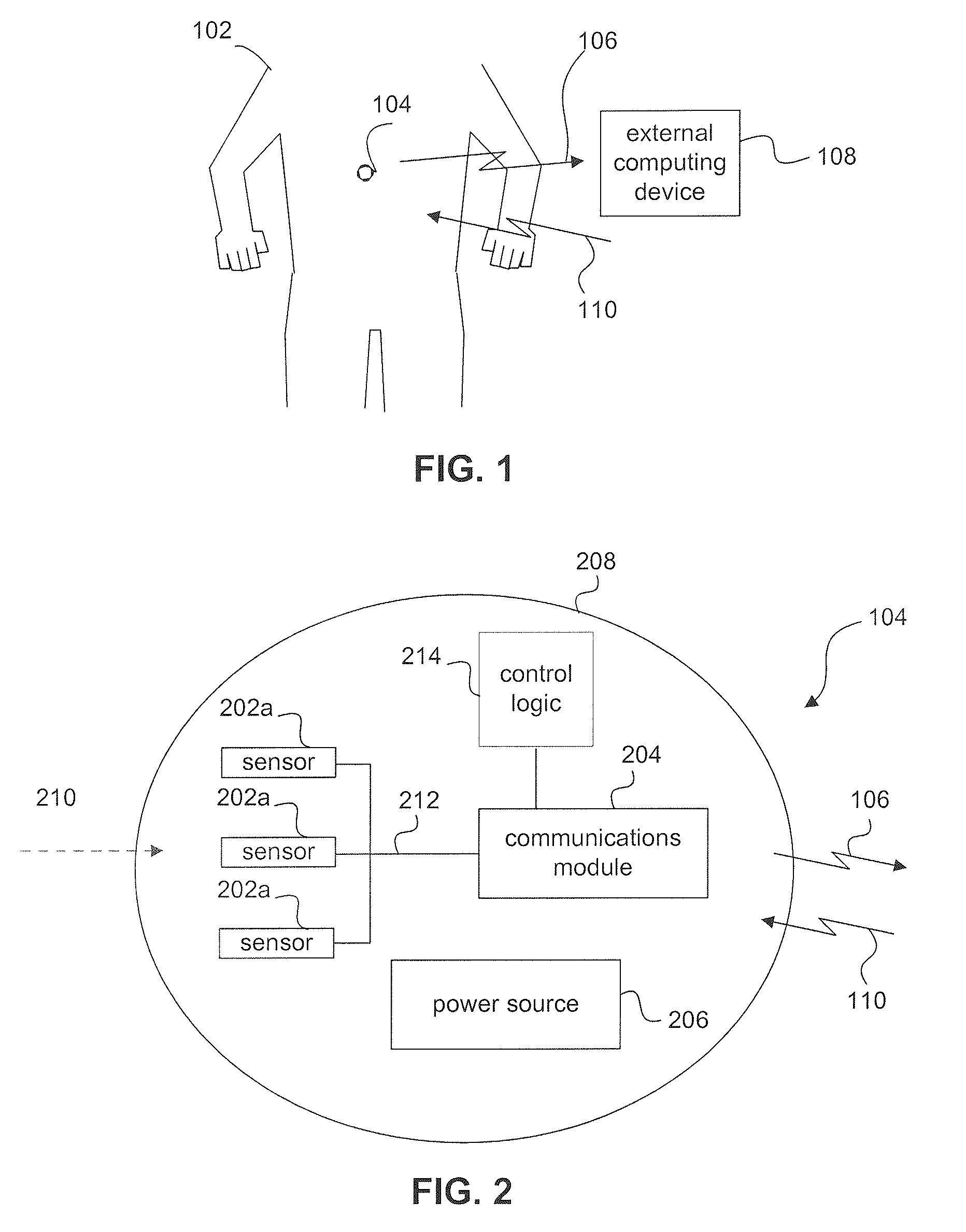

User input utilizing dual line scanner apparatus and method

ActiveUS20120189166A1Input/output for user-computer interactionCharacter and pattern recognitionComputational scienceLine sensor

A user input method and apparatus may comprise a two line object imaging sensor having a primary line scan-sensor providing a primary line scan-sensor output and a secondary line scan-sensor providing a secondary line scan-sensor output, representing pixels in a current primary scan row and a current secondary scan row, and adapted to scan an object; storing for each scan time each current primary line scan-sensor output and each current secondary line scan-sensor output and a correlation unit correlating at least one of the current representations of pixels in a primary line sensor output with stored representations and the current representations of pixels in a secondary line sensor output with stored representations and, the correlation unit providing as an output a motion indicator.

Owner:SYNAPTICS INC

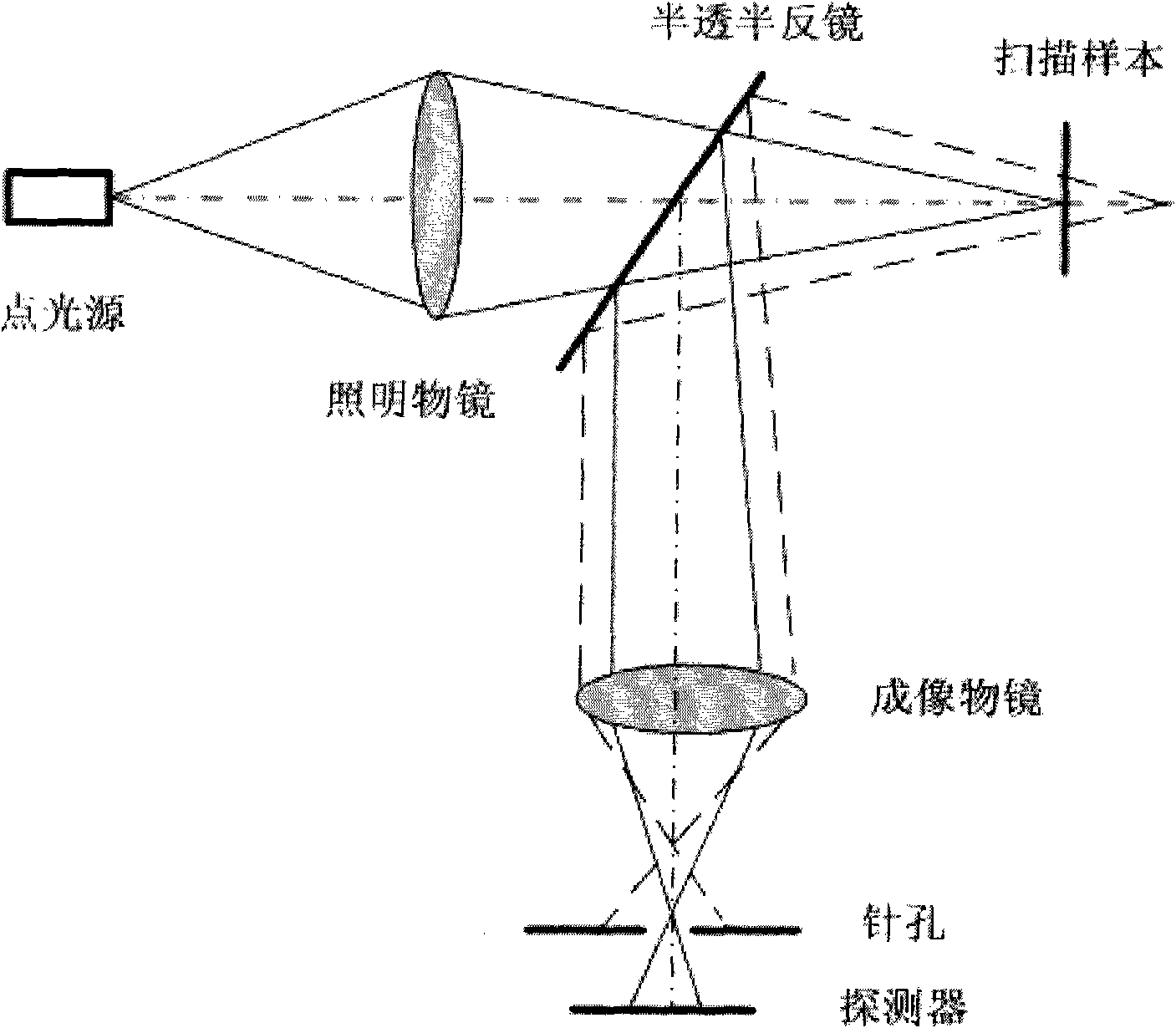

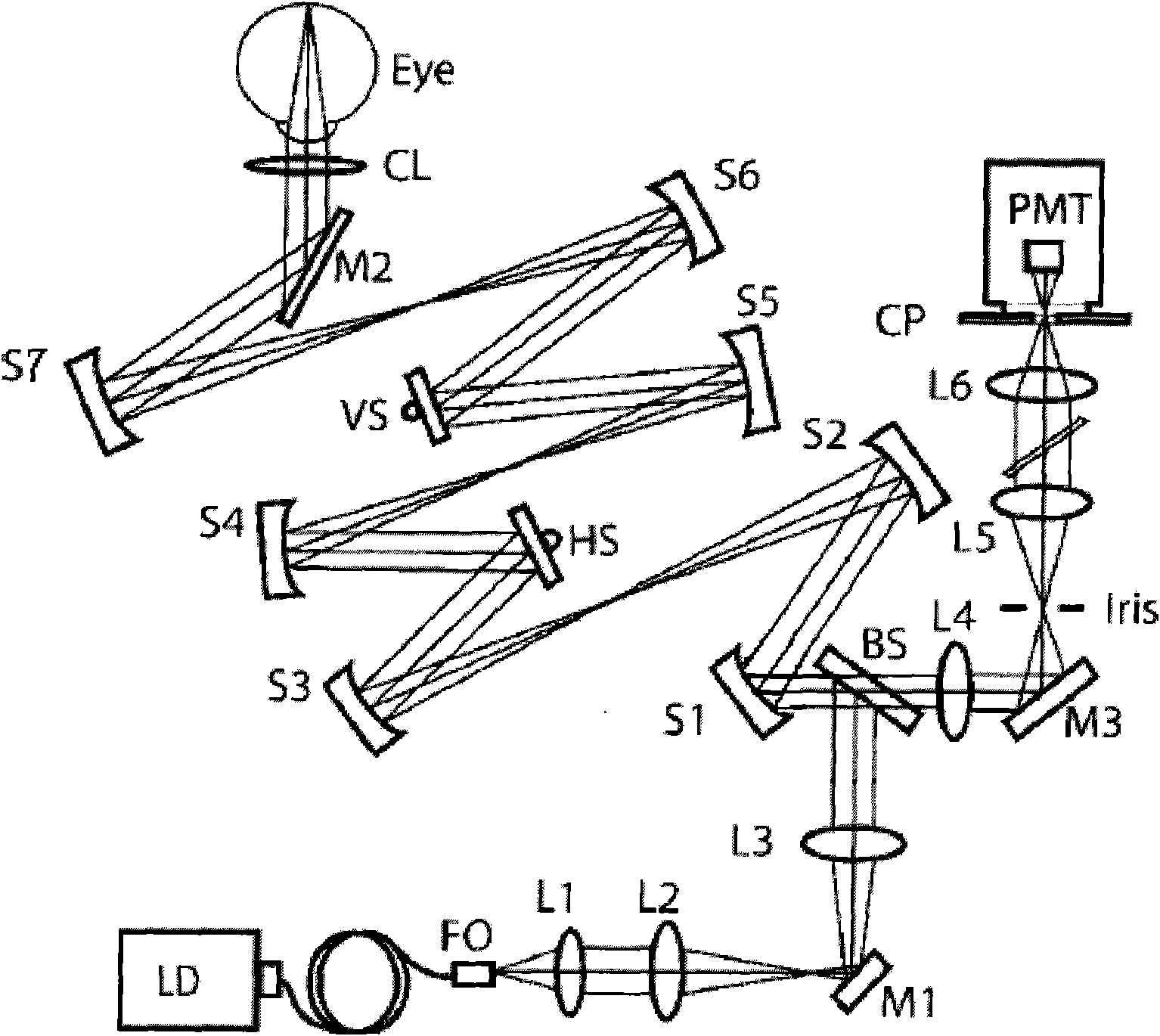

System and method for line scan confocal ophthalmoscope

InactiveCN102008288AEasy to adjustFulfill control requirementsOthalmoscopesImaging qualityLight beam

The invention relates to a system and method for a line scan confocal ophthalmoscope. The system comprises a linear light beam generation module, a splitting module, a scanning module, an imaging module and an output module. A linear light beam is subject to one-dimensional space scanning by the line scan confocal ophthalmoscope to illuminate fundus oculi retina, simultaneously a linear detector is used for image non-scan light beams reflected from the fundus oculi retina, the system only uses one scanning galvanometer and one linear detector, and the number of active members is small; and simultaneously, a confocal slit is conjugated with the plane of the fundus oculi retina, thereby eliminating the influence of eliminate stray light of a non-retina plane on imaging quality and obtaining high resolution by using the confocal imaging principle. The invention has the advantages of simple structure, short light path, good stability and high imaging frame frequency, is easy for manufacture and suitable for adjustment, and is small and exquisite.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Large depth of field line scan camera

InactiveUS20070164202A1Material analysis by optical meansPhotoelectric discharge tubesDepth of fieldLinearity

A system for imaging an object comprising a surface for receiving the object to be imaged and an imaging device. The imaging device comprises a housing and a fixed focusing optical device mounted to the housing, whereby the fixed focusing optics comprises a lens for focusing light reflected from the object. A plurality of independent linear imaging sensors are positioned in the housing at different distances from the fixed focusing lens so that a face of each of the plurality of independent linear imaging sensors is aligned parallel to the surface. A processor is coupled to the plurality of independent linear imaging sensors for receiving an output signal from each of the plurality of independent linear imaging sensors representative of the reflected light. The lens defines a plane parallel to the surface, and the plurality of independent linear imaging sensors are adapted to receive reflected light from the object.

Owner:ACCU SORT SYST

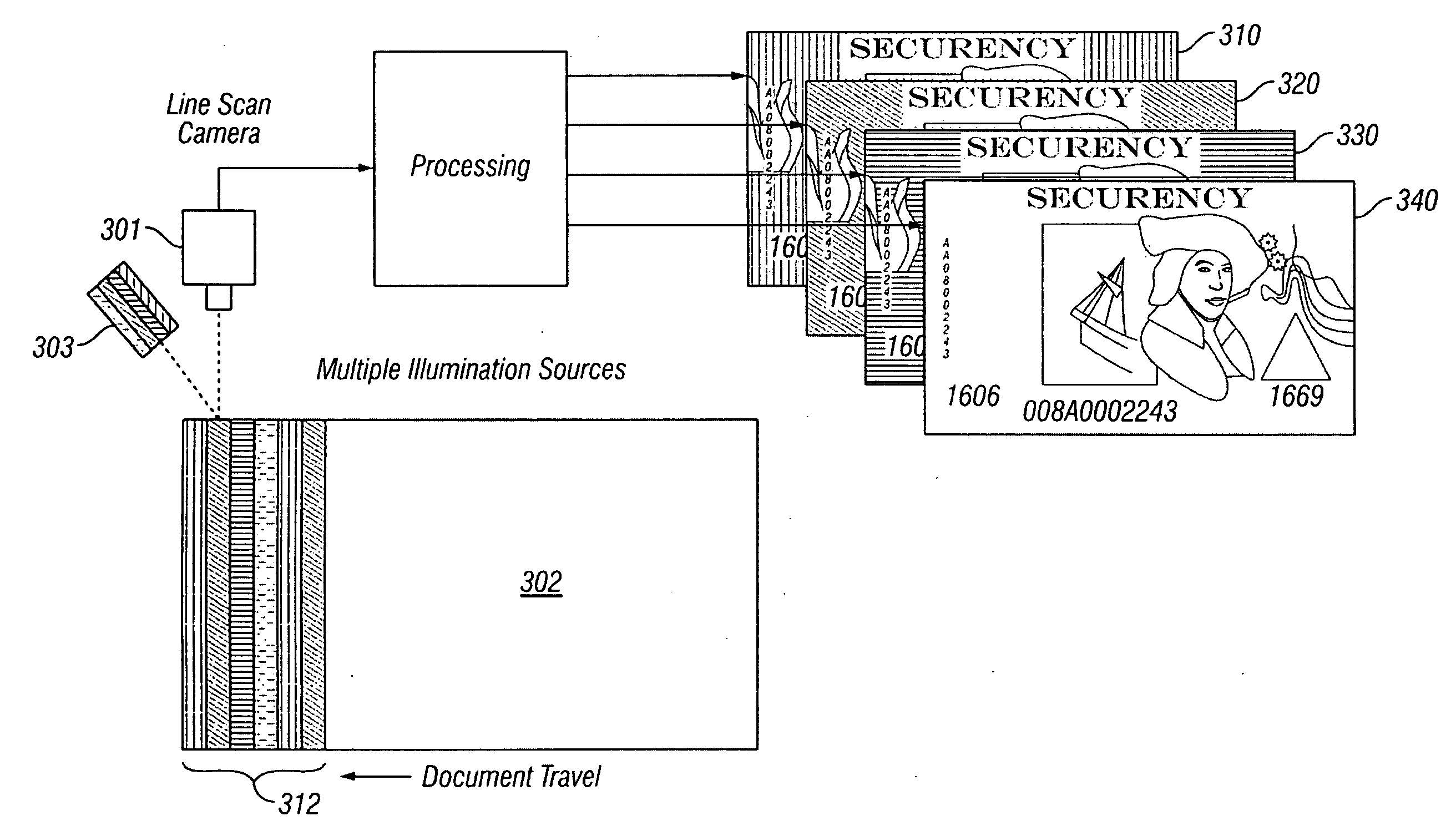

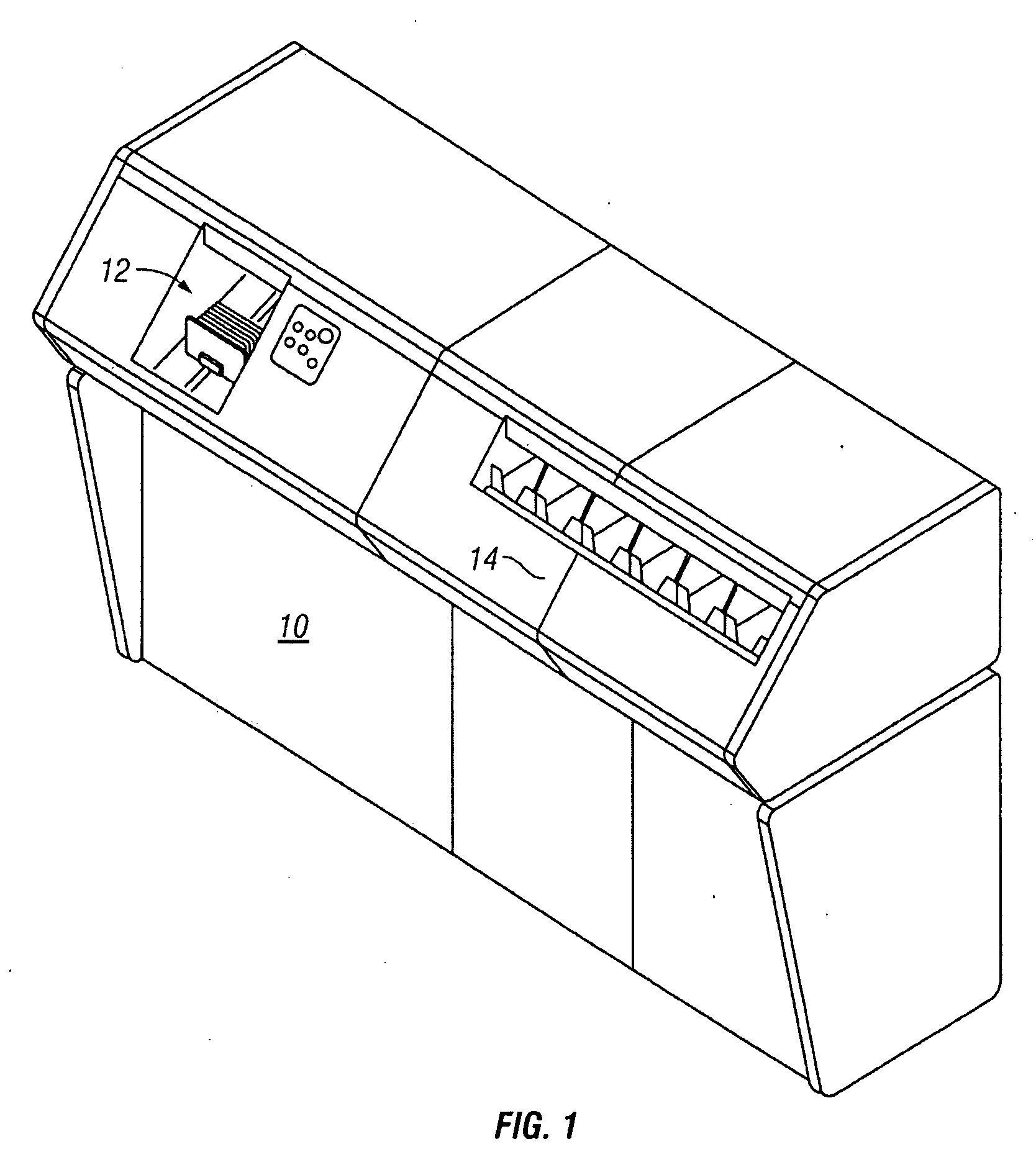

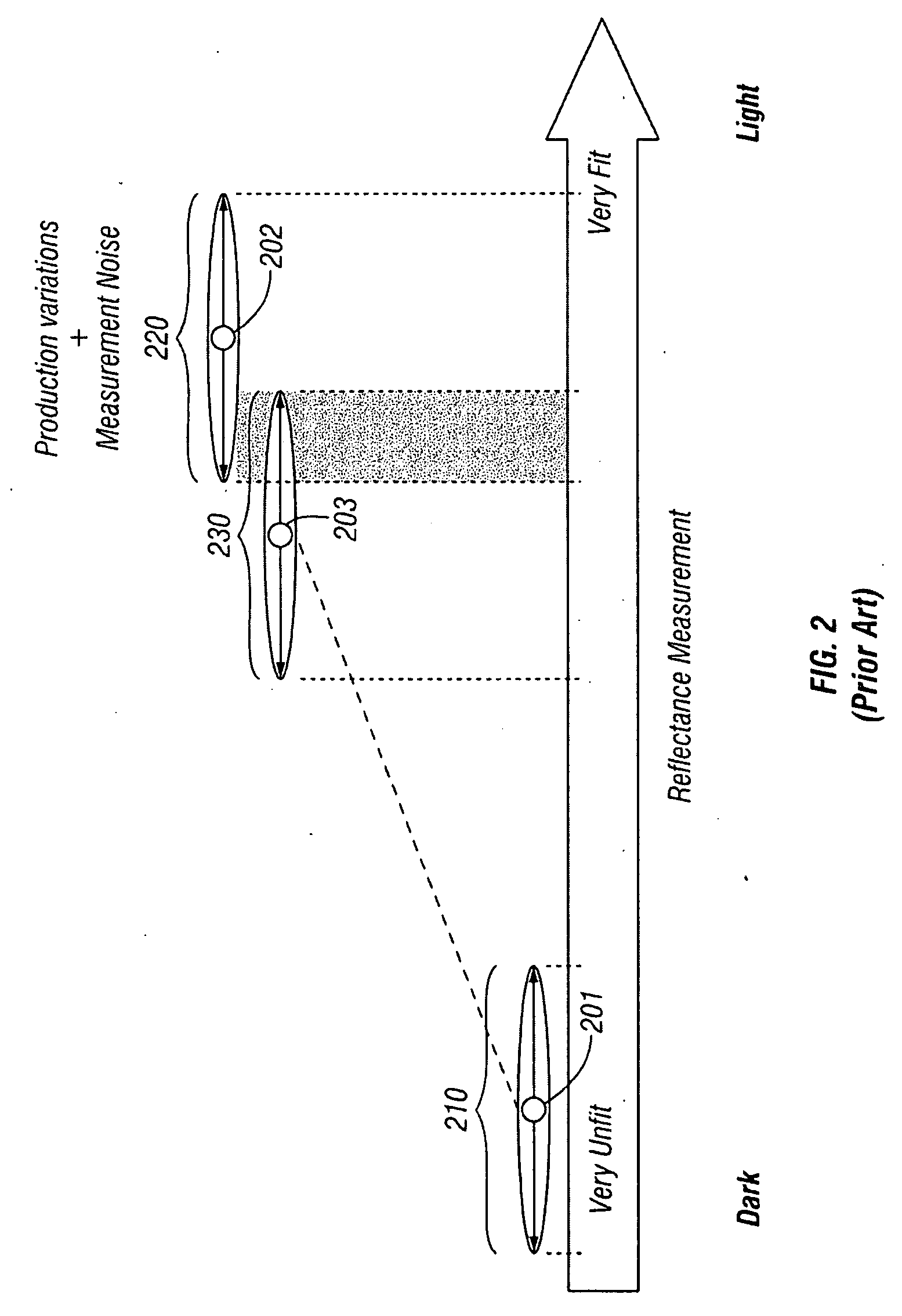

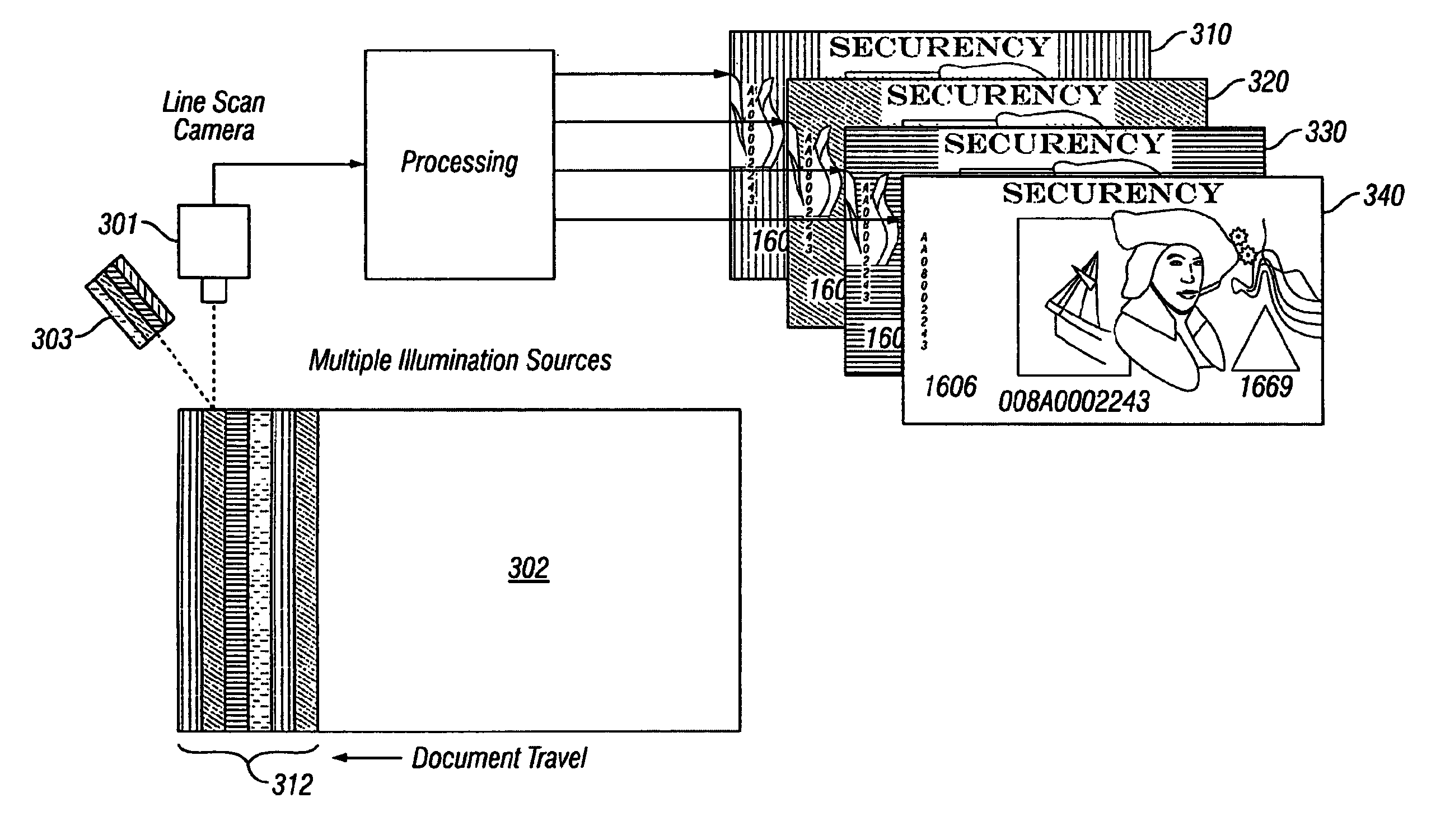

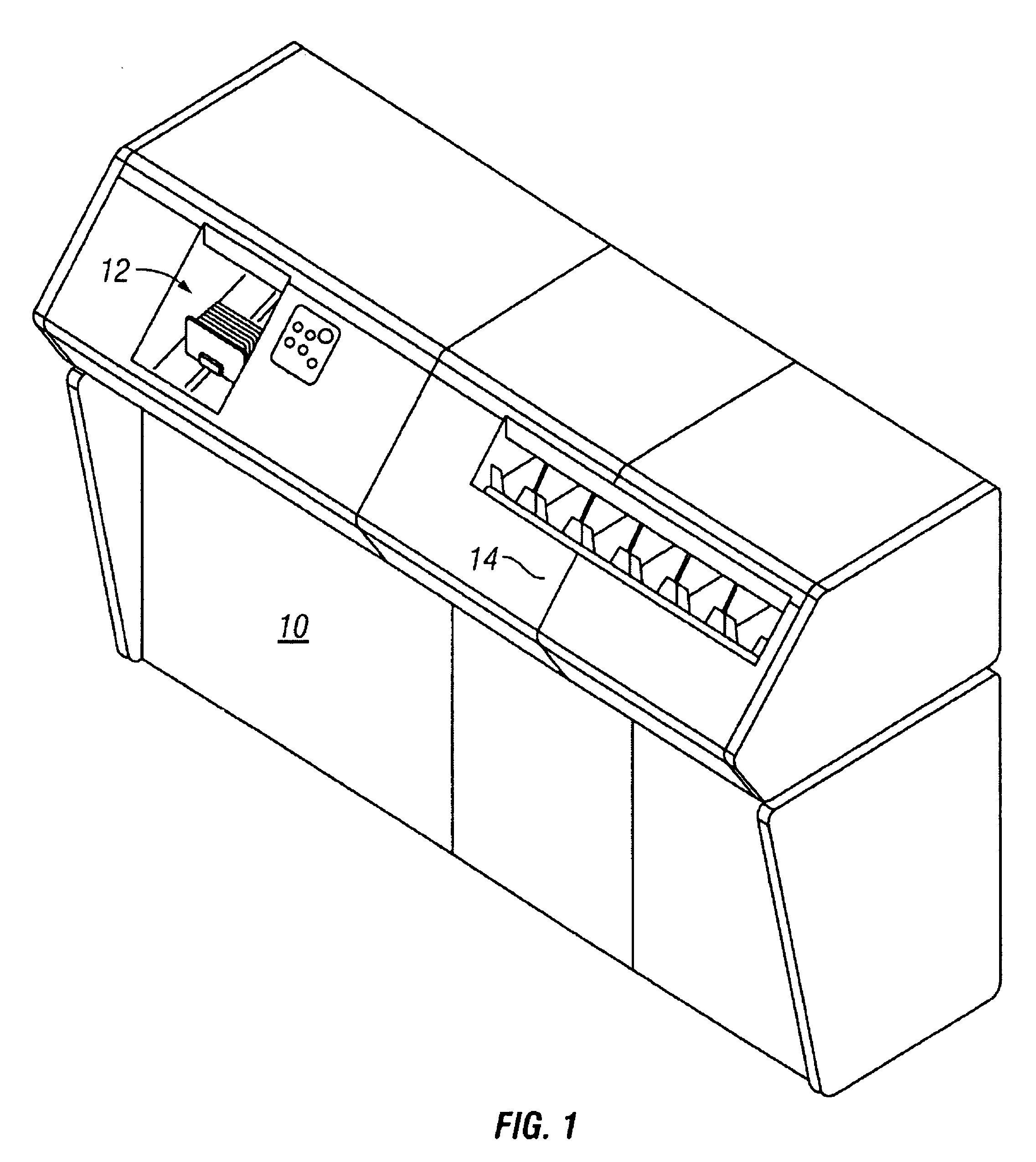

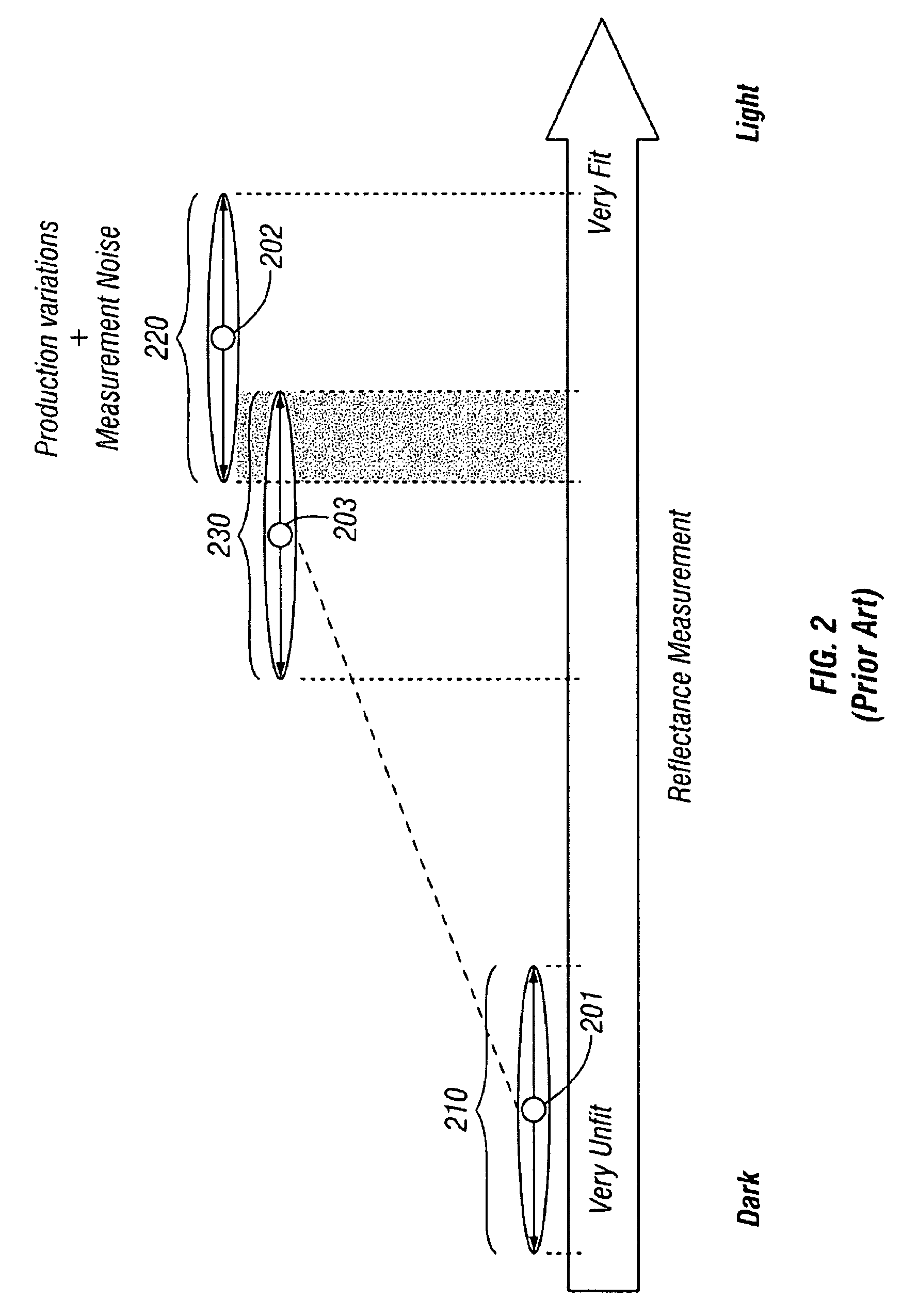

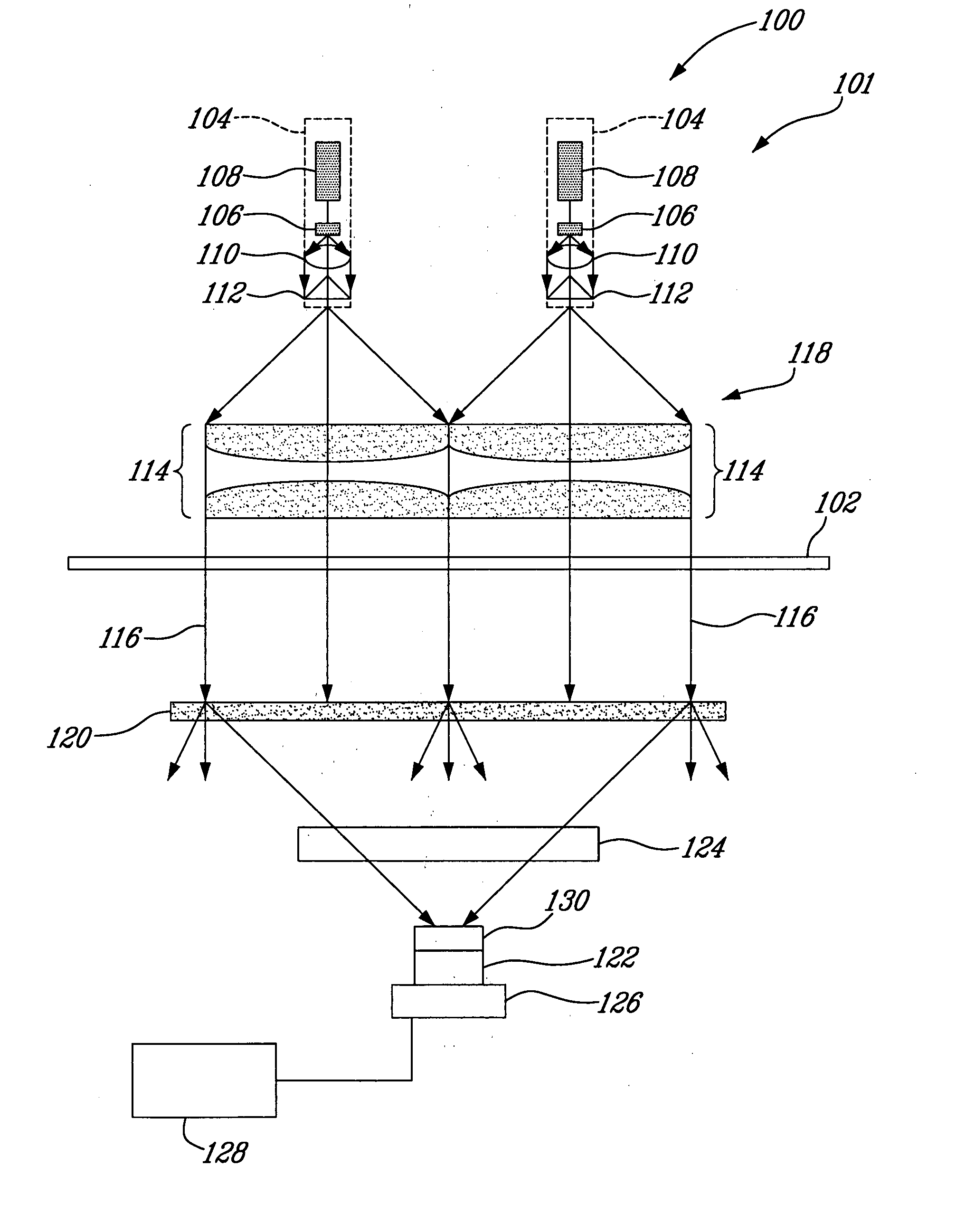

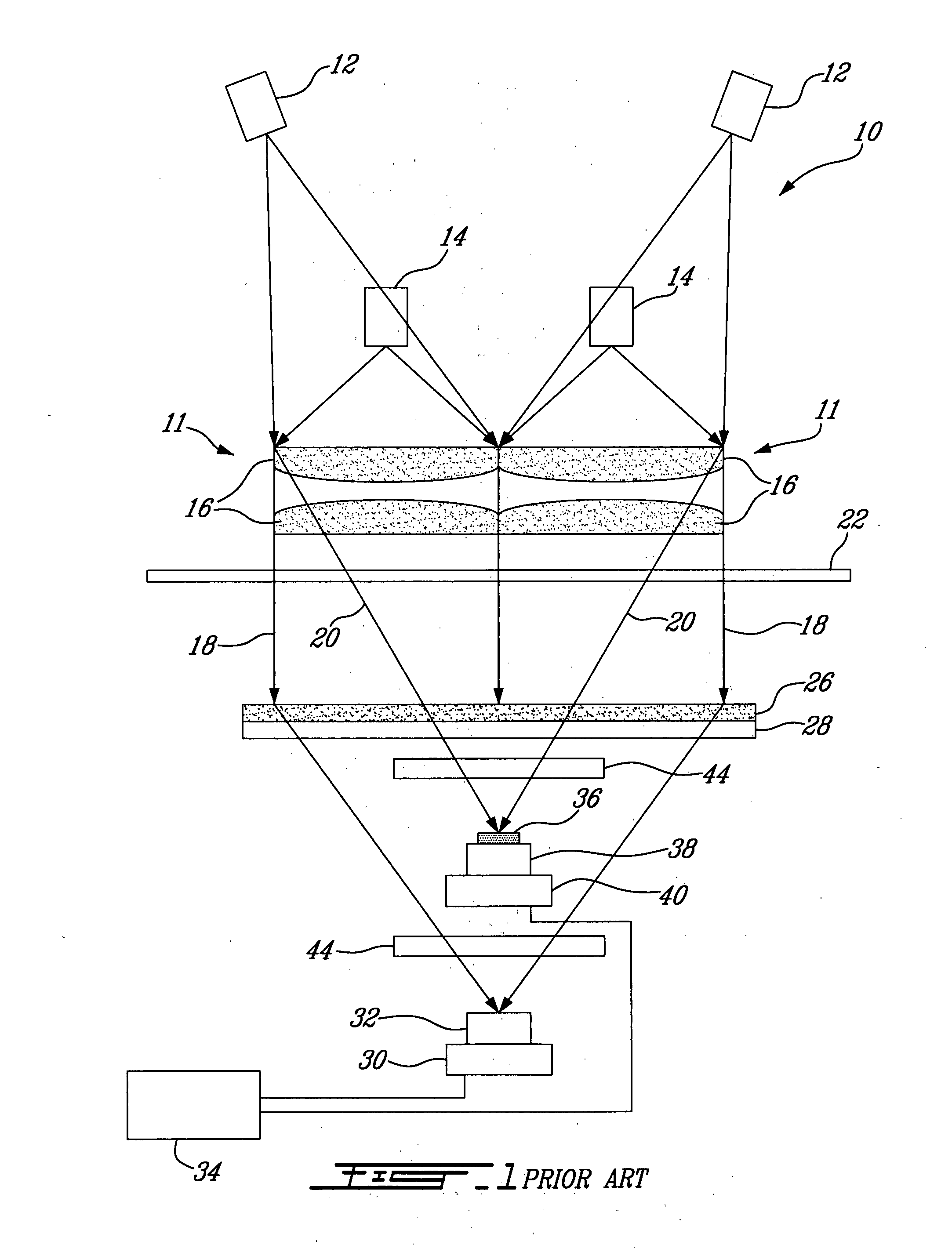

Determining Document Fitness Using Sequenced Illumination

InactiveUS20100128965A1Television system detailsPaper-money testing devicesDocumentationMulti dimensional

The present invention provides a method for determining the physical fitness of documents such as bank notes. The method comprises passing a document past an image sensor while sequentially illuminating the document using multi-mode illumination, wherein a predetermined mode of illumination is used for each line scanned by the image sensor, producing an interleaved image of the document. A multi-dimensional transformation function is applied to this interleaved image to produce a composite measurement, which is then projected onto an empirically determined fitness vector to yield a scalar fitness value for the document. This value is compared against empirically prescribed fitness values to determine if the document is fit enough to remain in circulation or should be taken out of circulation and retired (destroyed).

Owner:DE LA RUE NORTH AMERICA

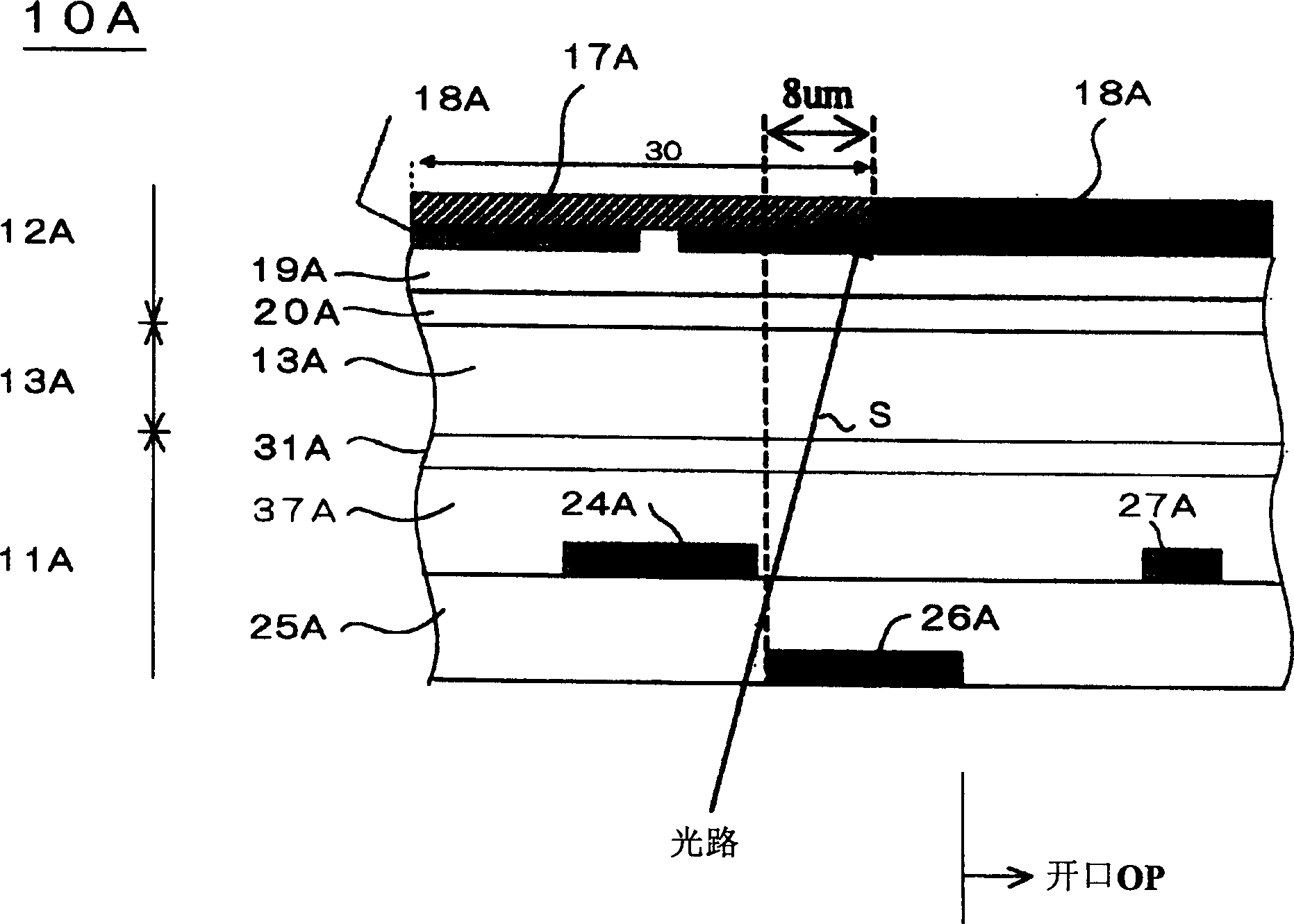

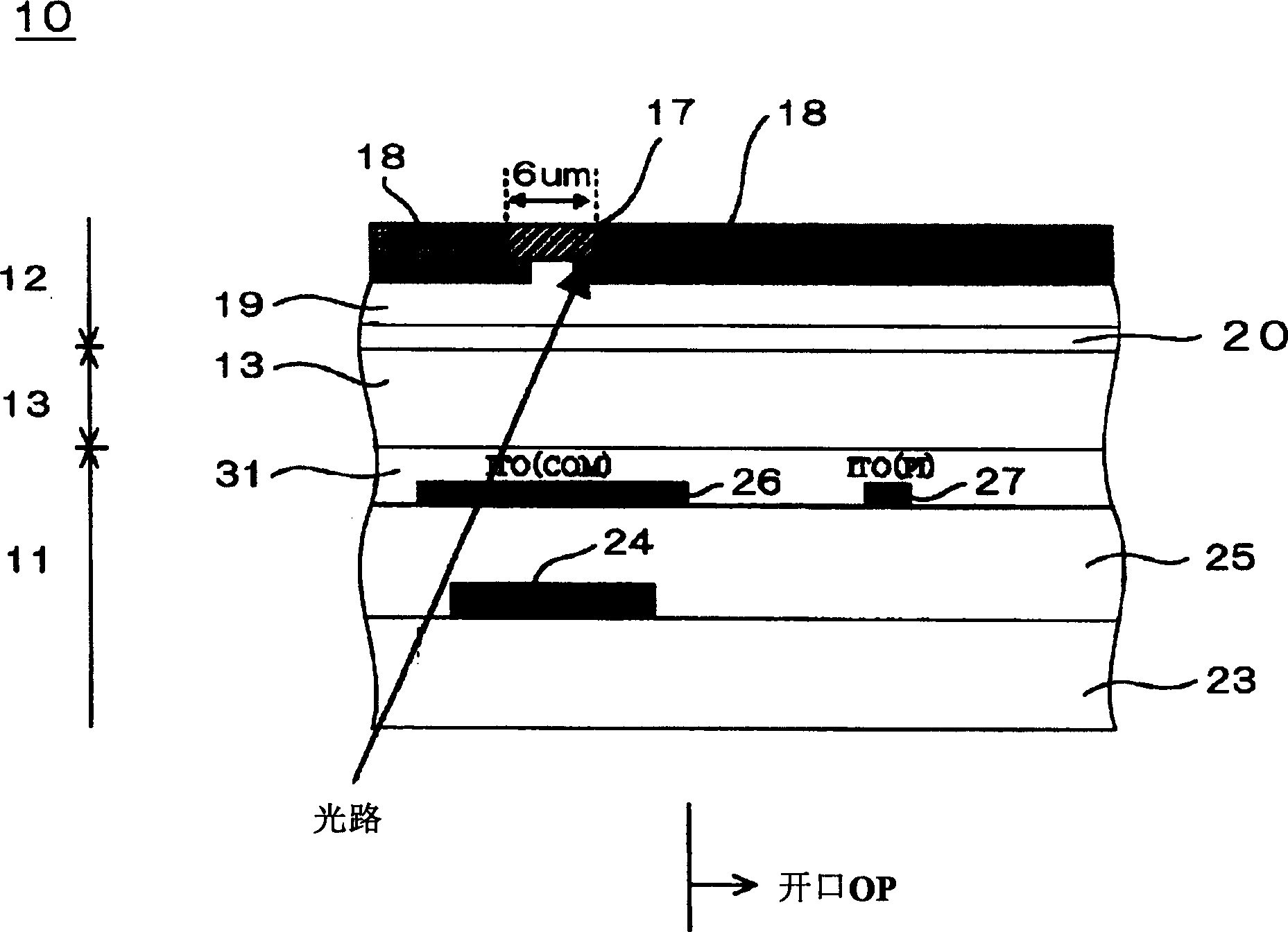

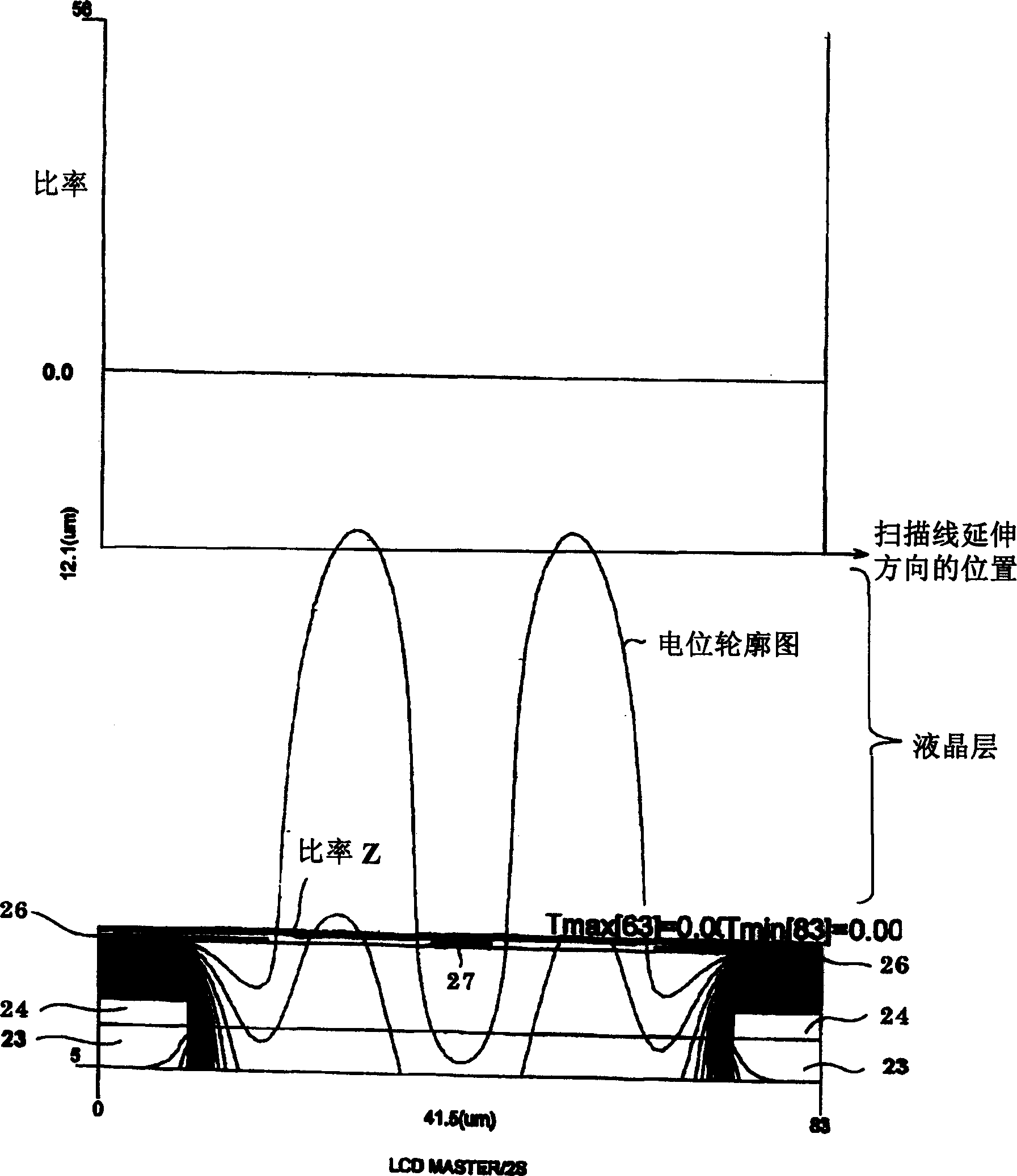

Plane switch mode active matrix liquid crystal display device and mfg. method thereof

InactiveCN1420386APrevent vertical crosstalkDoes not reduce porosityTransistorStatic indicating devicesActive-matrix liquid-crystal displayScan line

An in-plane switching mode active matrix type liquid crystal display device includes a first substrate, a second substrate located opposing the first substrate, and a liquid crystal layer sandwiched between the first and second substrates. The first substrate includes a thin film transistor, a pixel electrode each associated to a pixel to be driven, a common electrode to which a reference voltage is applied, data lines, a scanning line, and common electrode lines. Molecular axes of liquid crystal are rotated in a plane parallel with the first substrate by an electric field substantially parallel with a plane of the first substrate to thereby display certain images. The common electrode is composed of transparent material, and are formed on a layer located closer to the liquid crystal layer than the data lines. The common electrode entirely overlaps the data lines except an area where the data lines are located in the vicinity of the scanning line. The liquid crystal display device further includes a light-impermeable layer in an area where the common electrode entirely overlaps the data lines. The light-impermeable layer is comprised of a black matrix layer having a width smaller than a width of the common electrode.

Owner:NEC LCD TECH CORP

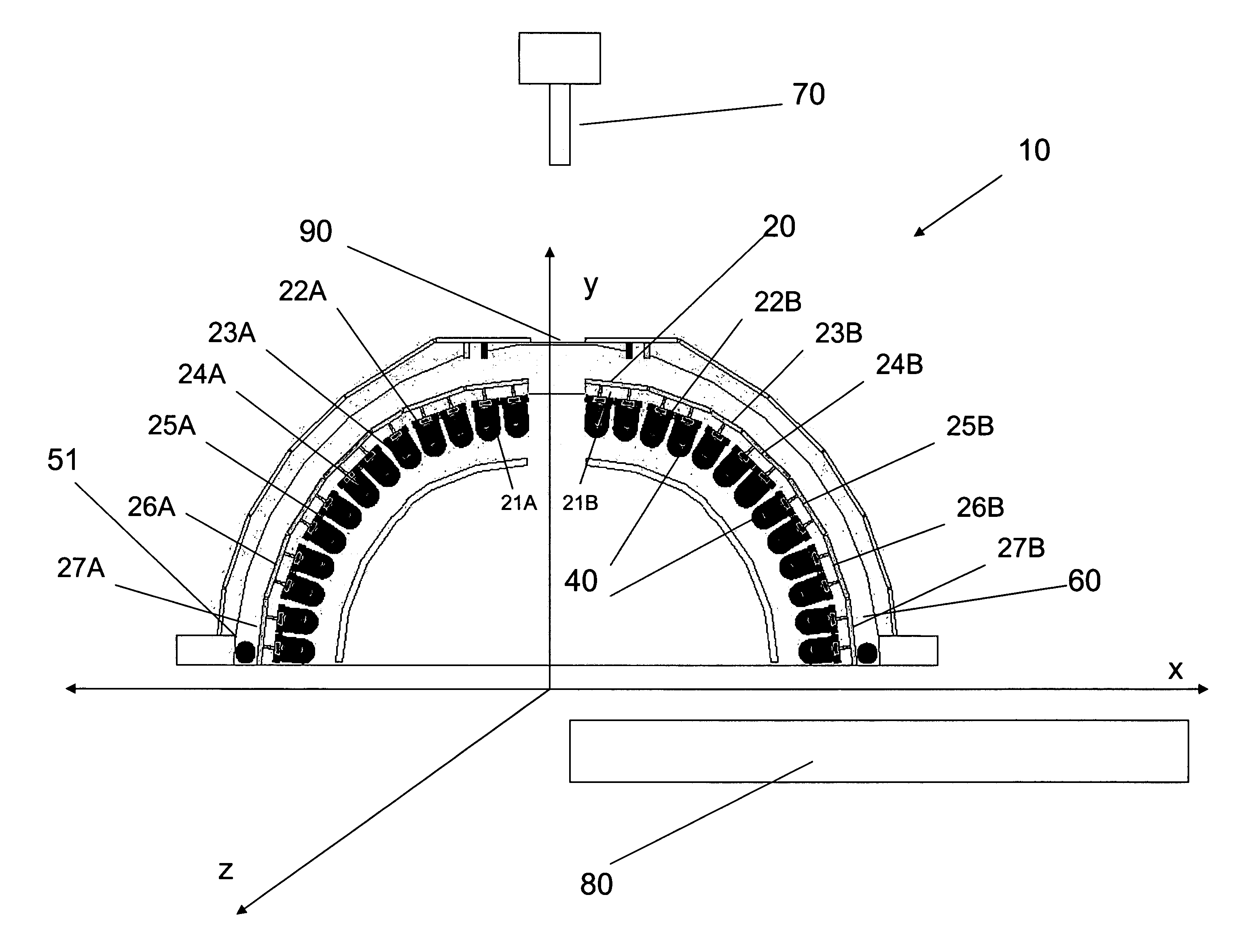

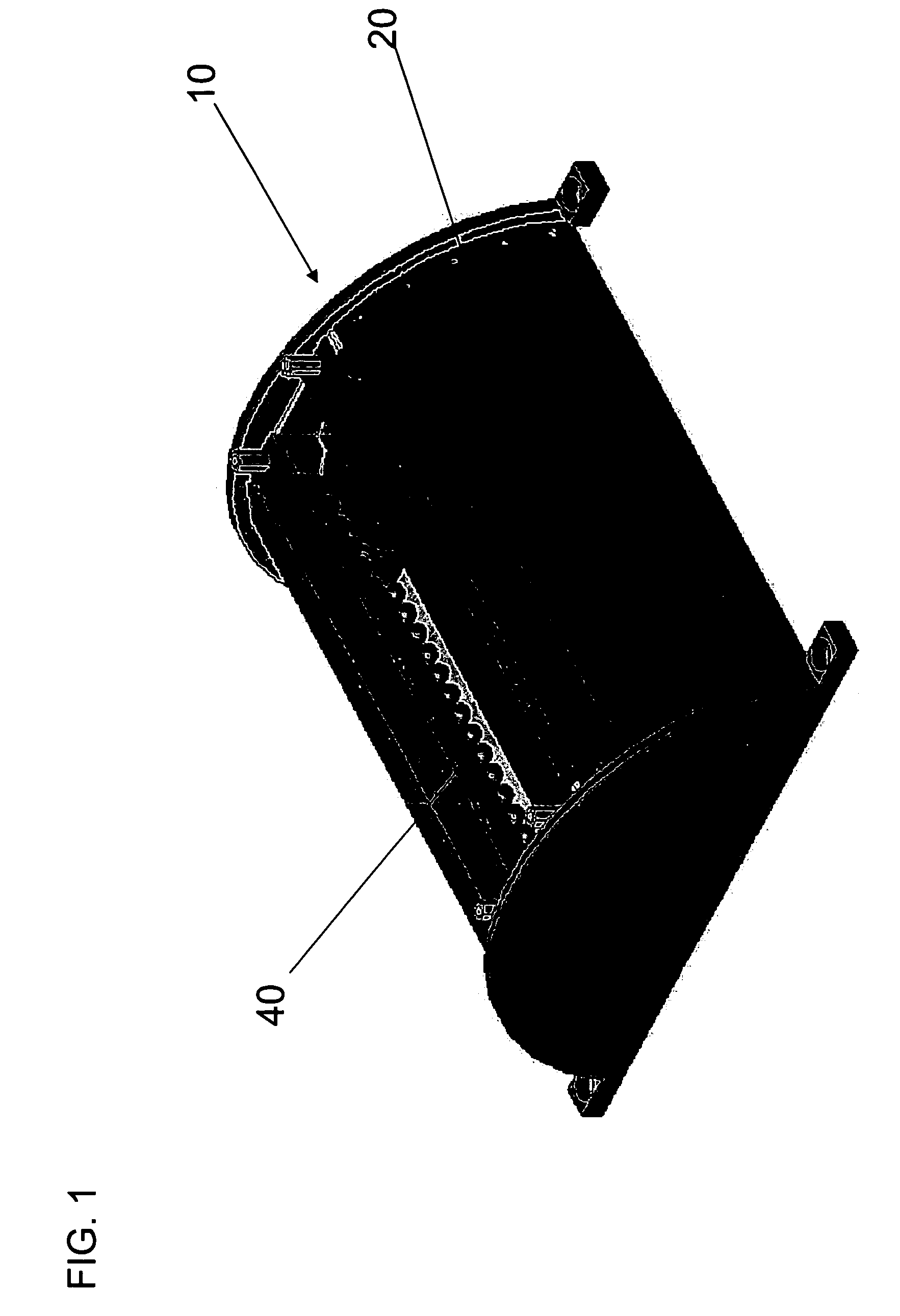

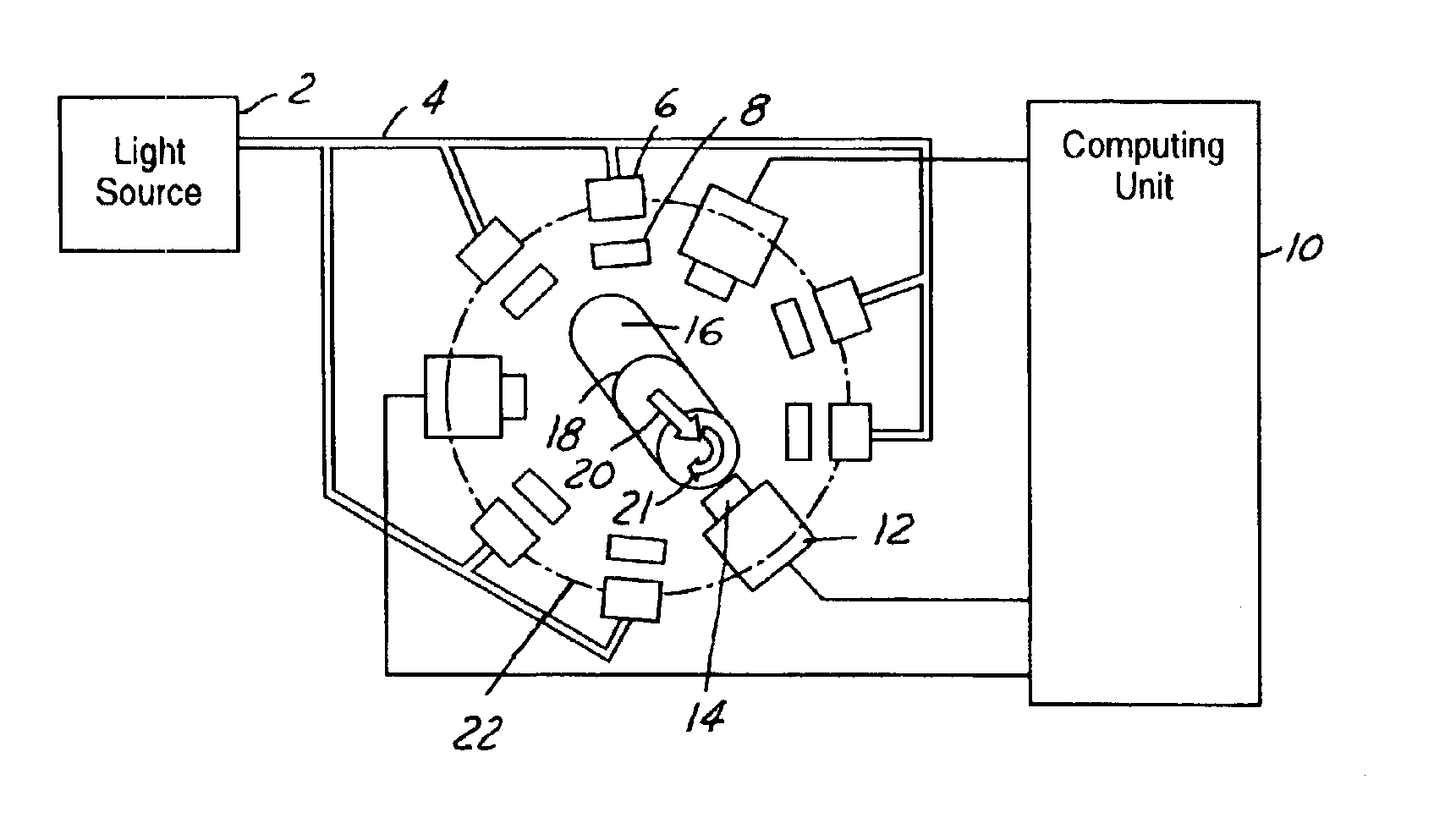

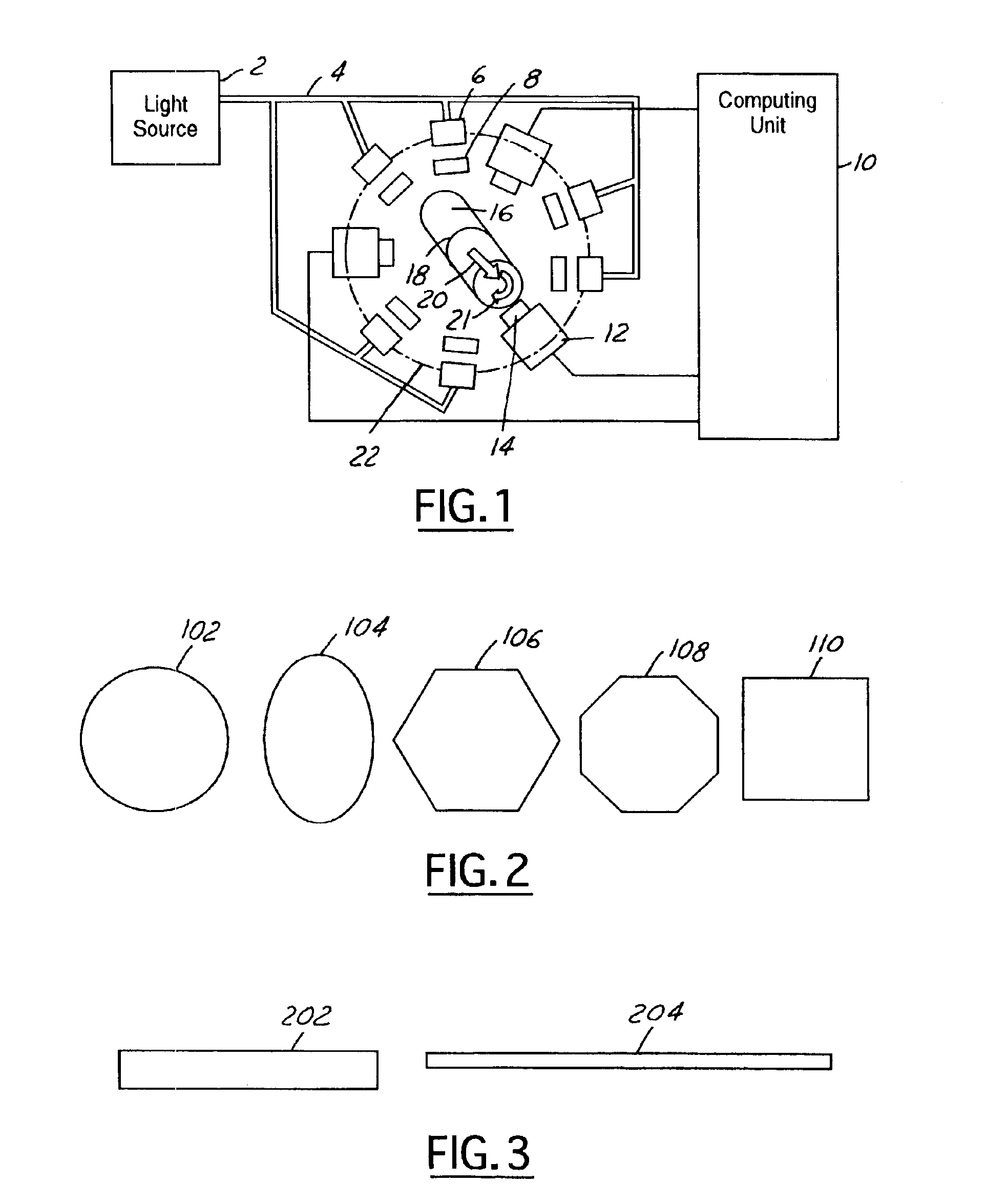

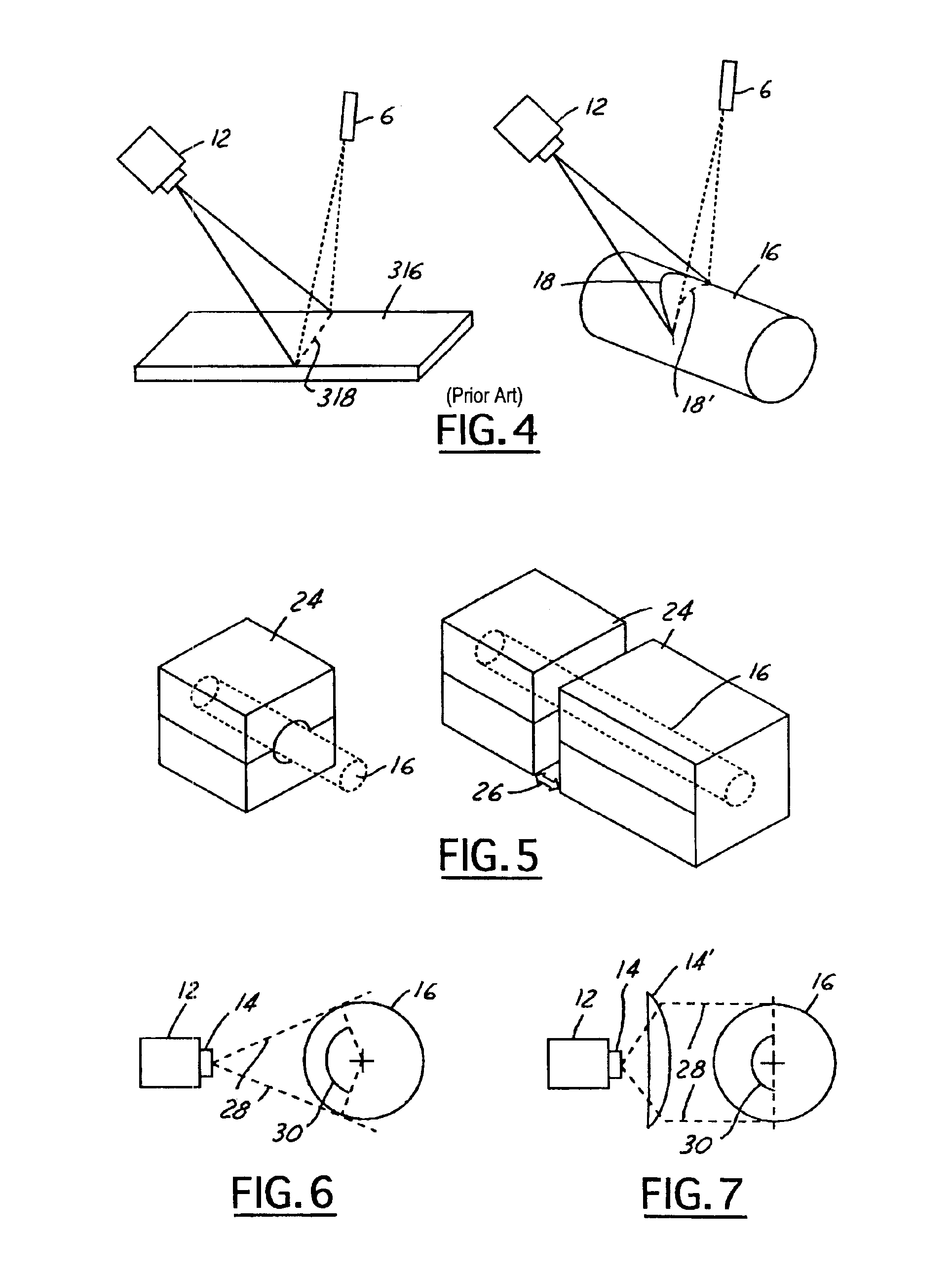

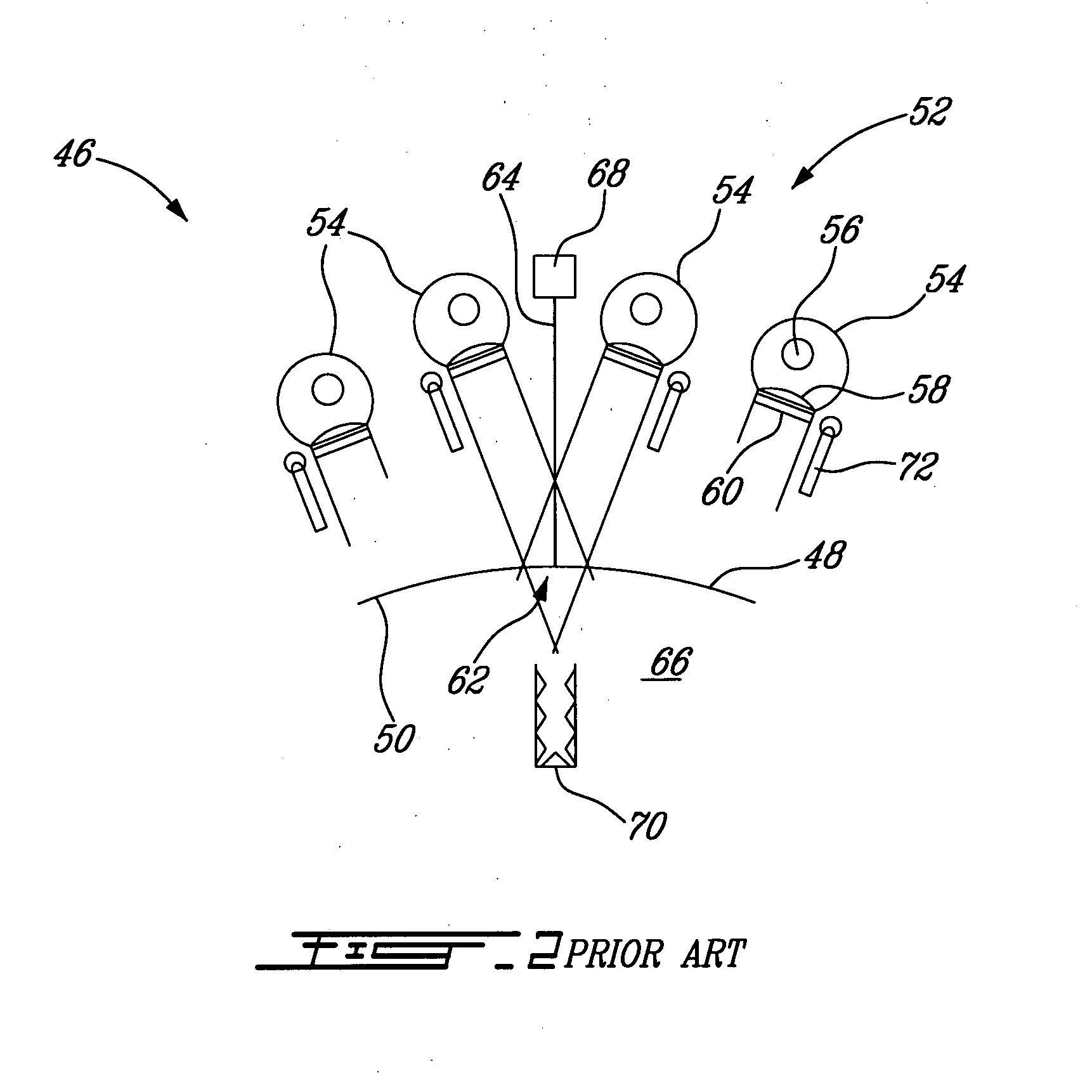

Apparatus and method for detecting surface defects on a workpiece such as a rolled/drawn metal bar

ActiveUS6950546B2Efficiently employedIncrease the working distanceCharacter and pattern recognitionColor synchronisationNon destructiveEngineering

The present invention is directed to solving the problems associated with the detection of surface defects on metal bars as well as the problems associated with applying metal flat inspection systems to metal bars for non-destructive surface defects detection. A specially designed imaging system, which is comprised of a computing unit, line lights and high data rate line scan cameras, is developed for the aforementioned purpose. The target application is the metal bars (1) that have a circumference / cross-section-area ratio equal to or smaller than 4.25 when the cross section area is unity for the given shape, (2) whose cross-sections are round, oval, or in the shape of a polygon, and (3) are manufactured by mechanically cross-section reduction processes. The said metal can be steel, stainless steel, aluminum, copper, bronze, titanium, nickel, and so forth, and / or their alloys. The said metal bars can be at the temperature when they are being manufactured.

Owner:OG TECH INC

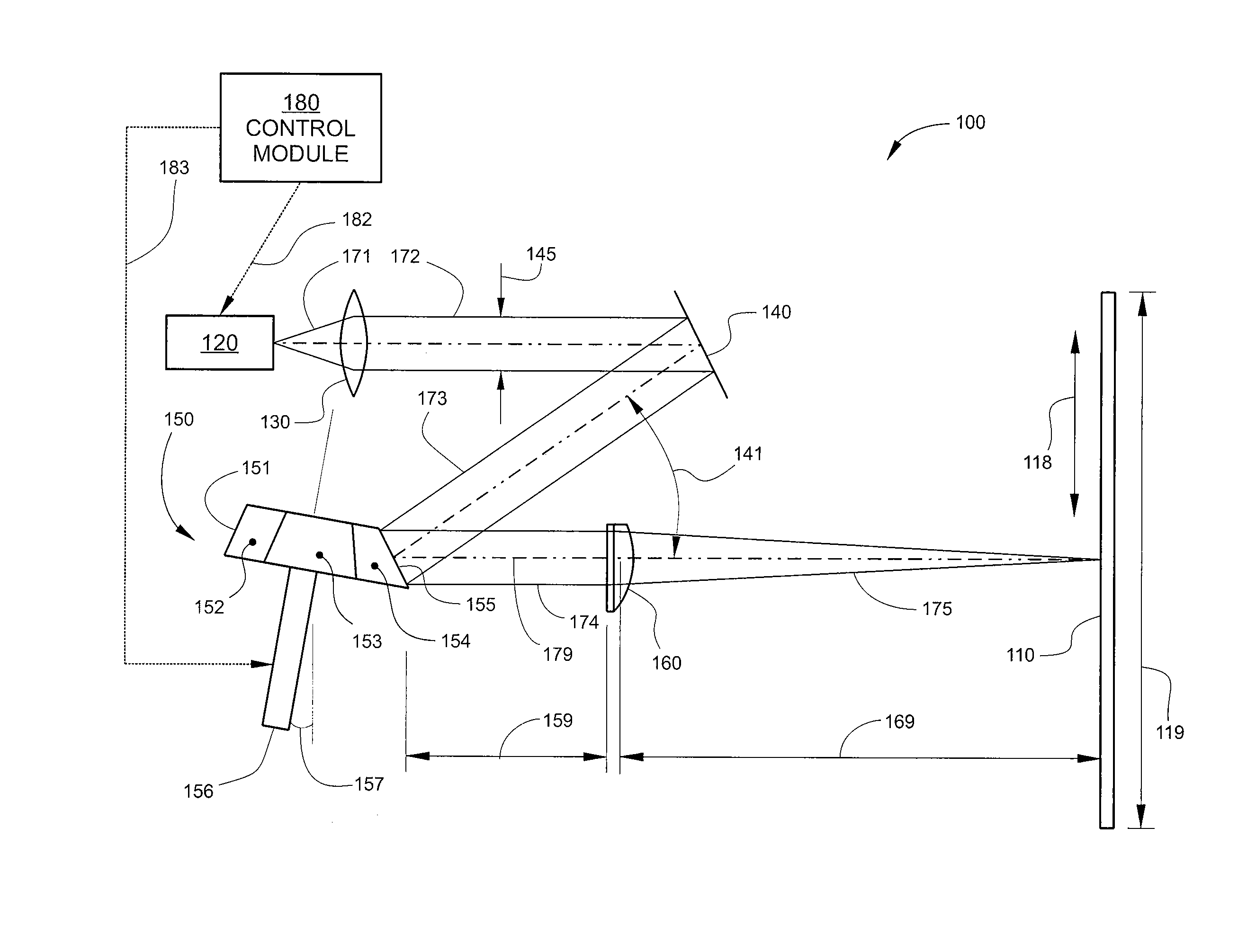

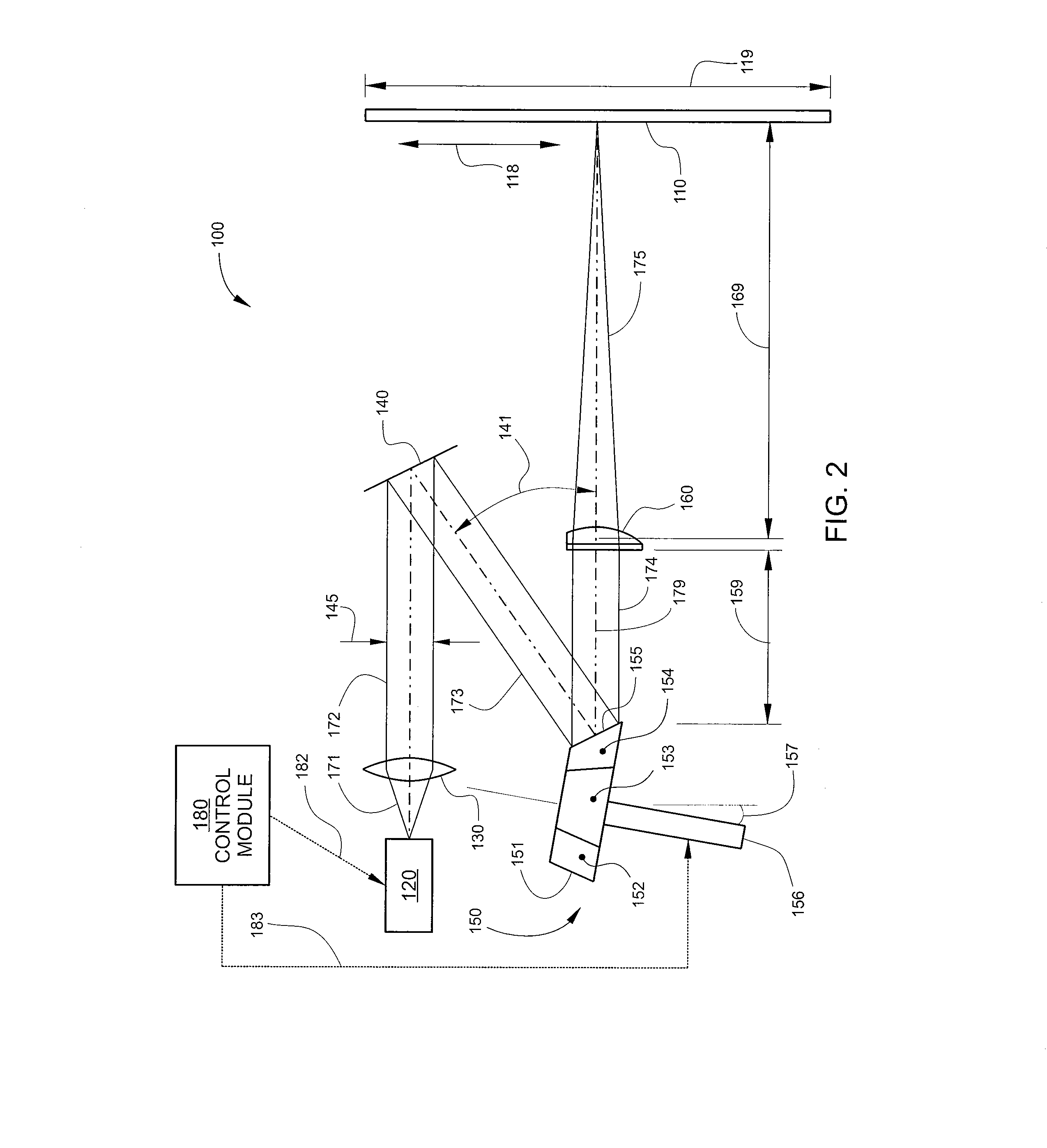

2-d straight-scan on imaging surface with a raster polygon

A 2-D scanning system uses a fast-rotating raster-polygon as a single scanning component to produce straight scan lines over a 2-D image surface. An approach angle of incident light beams to the raster-polygon is selected to minimize pin-cushion distortion of scan lines introduced by polygon scanning on the image surface, and a tilt angle of the rotational axis of the raster-polygon is selected to position said polygon-scanning distortion symmetrically on the image surface. In addition, scan optics are configured to generate a predetermined amount of barrel distortion of scan lines on the image surface to compensate for pin-cushion distortion introduced by polygon scanning.

Owner:PRYSM SYST INC

Determining document fitness using sequenced illumination

InactiveUS8265346B2Television system detailsPaper-money testing devicesDocumentationMulti dimensional

The present invention provides a method for determining the physical fitness of documents such as bank notes. The method comprises passing a document past an image sensor while sequentially illuminating the document using multi-mode illumination, wherein a predetermined mode of illumination is used for each line scanned by the image sensor, producing an interleaved image of the document. A multi-dimensional transformation function is applied to this interleaved image to produce a composite measurement, which is then projected onto an empirically determined fitness vector to yield a scalar fitness value for the document. This value is compared against empirically prescribed fitness values to determine if the document is fit enough to remain in circulation or should be taken out of circulation and retired (destroyed).

Owner:DE LA RUE NORTH AMERICA

Bright field and dark field channels, used for automotive glass inspection systems

InactiveUS20100051834A1Overcomes or mitigates one or more disadvantagesInvestigating moving sheetsOptically investigating flaws/contaminationTime delaysImage formation

An inspection system for inspecting a sheet of glass comprises an illumination module, a collimating lens system, a telecentric imaging lens system and a Time Delay Integration line-scan camera. The illumination module has a low coherence light source emitting light. The collimating lens system has a focal point on the main axis thereof on which focal point its light source is located. The collimating lens system produces a collimated sheet of light from the emitted light. This collimated sheet of light passes through the sheet of glass. The telecentric imaging lens system concentrates the sheet of light passed through the sheet of glass on an image formation plane. The Time Delay Integration line-scan camera is positioned in a general area of the image formation plane. The camera is equipped with an antiblooming device. In another embodiment, an inspection system for inspecting a sheet of glass comprises a camera and a peripheral RDF illumination module. The camera is positioned on and points toward a first side of the sheet of glass. The peripheral RDF illumination module surrounds the camera and side, outside a field of view of the camera. The RDF illumination module is operative to illuminate the field of view with its RDF emitted light. The RDF illumination module is oriented so that the sheet of glass reflects the RDF emitted light away from the camera. The camera is positioned so as to be operative to receive the RDF emitted light if a RDF detectable defect is present on the sheet of glass and to avoid the RDF emitted light if no RDF detectable defect is present on the sheet of glass.

Owner:SYNERGX TECH

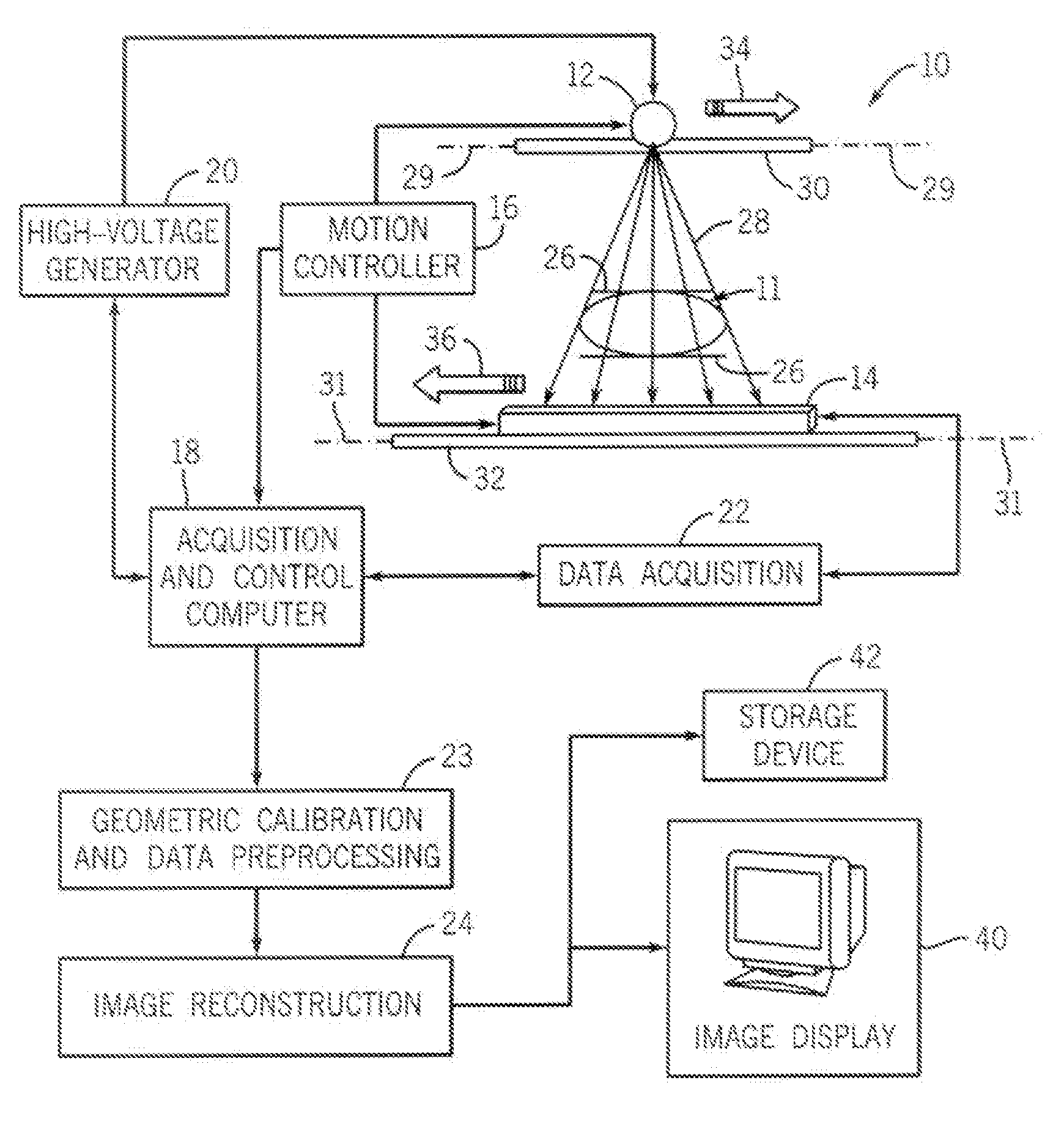

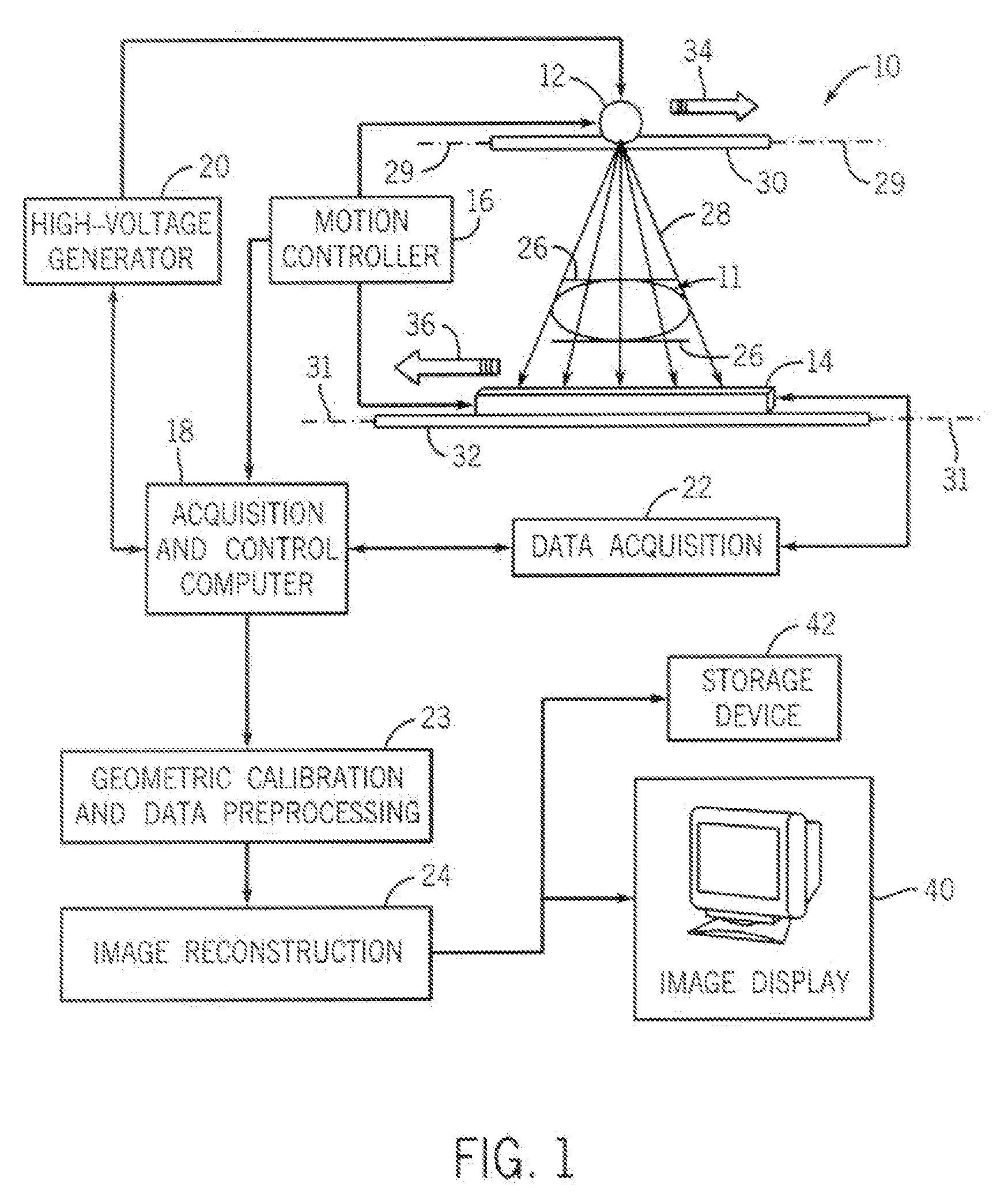

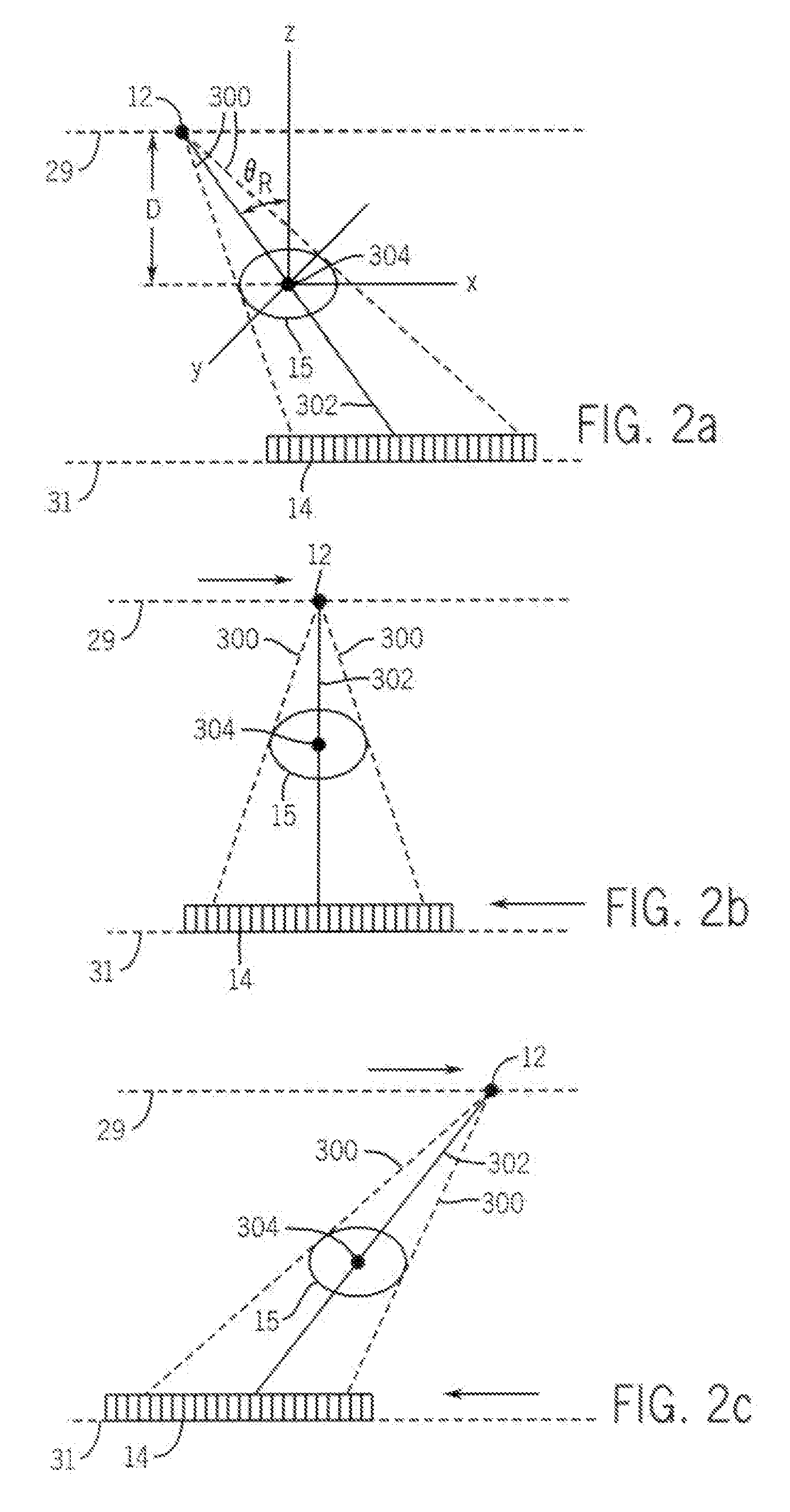

Ultra Low Radiation Dose X-Ray CT Scanner

ActiveUS20080267484A1High in-plane spatial resolutionExcellent low contrast detectabilityReconstruction from projectionTomosynthesisData setTotal variation minimization

A line scan cone beam CT imaging system irradiates an object with an x-ray cone beam for multiple views. A projection data set of the object is acquired at each view. Between views, the cone beam and detector array are translated along parallel lines in opposite directions. An image is generated by converting the cone beam projection data set of the real object into a parallel-beam projection data set corresponding to a virtual object and using a total variation minimization image reconstruction algorithm to reconstruct a virtual image of the virtual object. The reconstruction algorithm includes the constraint that the Fourier transform of the reconstructed virtual image matches the known Fourier coefficients in the set of converted parallel-beam projections of the virtual object. The constructed virtual image is then transformed into an image of the real object.

Owner:WISCONSIN ALUMNI RES FOUND

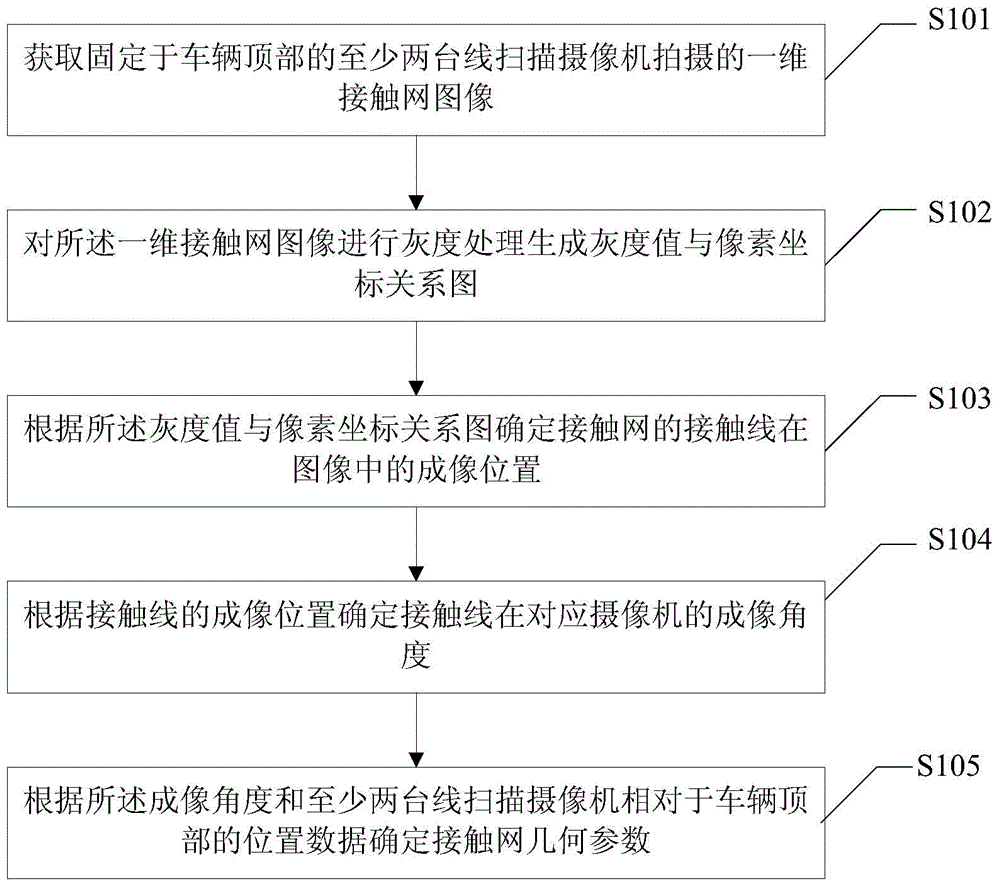

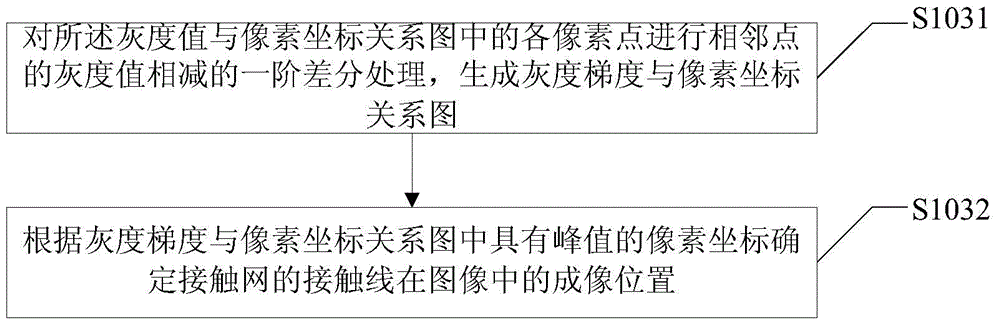

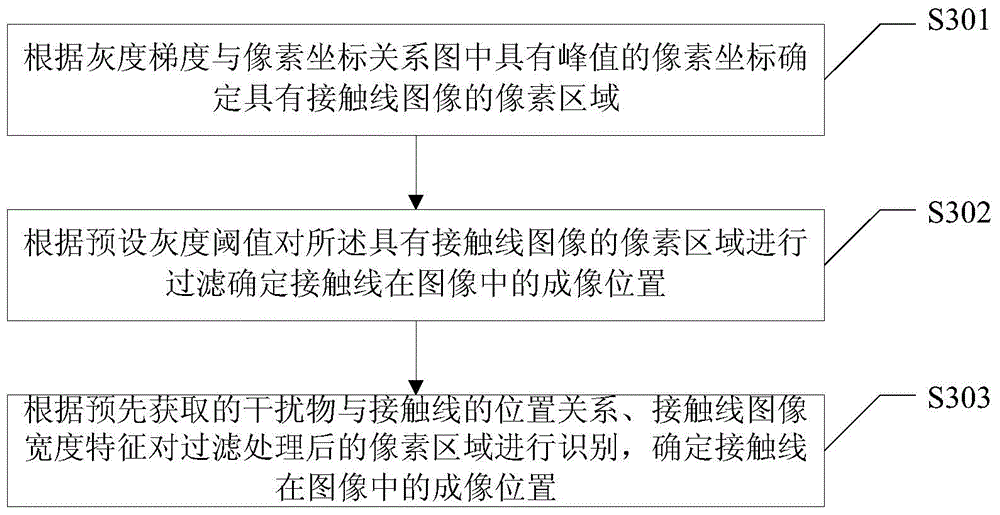

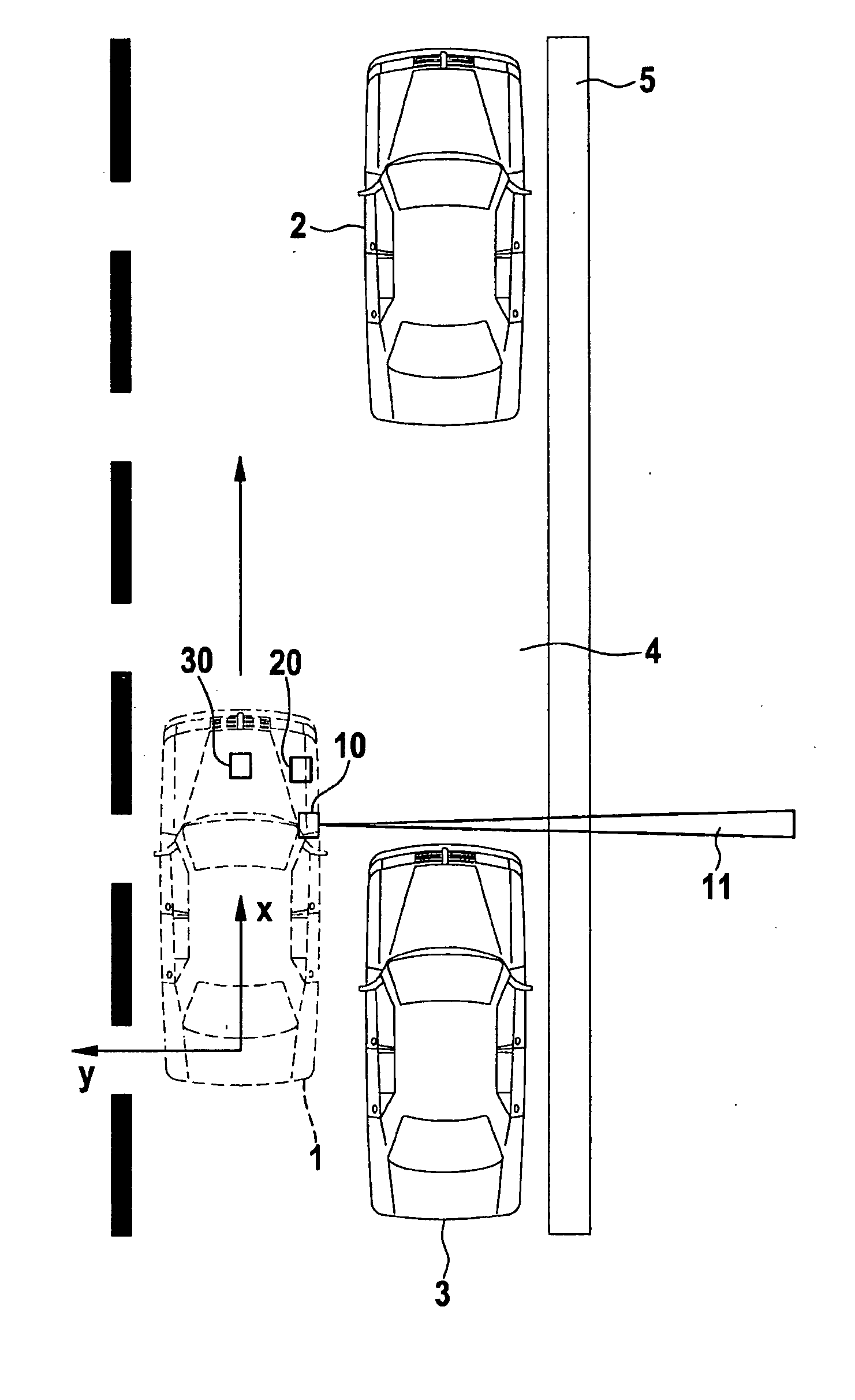

Contact network geometrical parameter detection method and device

ActiveCN104567684AImprove work efficiencyOne-dimensional imaging with high precisionUsing optical meansContact networkContact line

The invention provides a contact network geometrical parameter detection method and device. The contact network geometrical parameter detection method comprises the steps of obtaining one-dimensional contact network images shot by at least two line-scan cameras fixed on the top of a vehicle, carrying out grey processing on the one-dimensional contact network images to generate a grey value and pixel coordinate relation diagram, determining the imaging position of contact lines of a contact network in the images according to the grey value and pixel coordinate relation diagram, determining the imaging angle of each contact line in the corresponding camera according to the imaging position of the contact line, and determining the geometrical parameters of the contact network according to the imaging angles and the position data of the line-scan cameras relative to the top of the vehicle. Geometrical parameter detection is carried out by utilization of the images collected by the line-scan cameras, the line-scan speed is high, a detection result is accurate, detection efficiency is high, the time for maintaining a skylight is not occupied, a reliable technical means is provided for measurement and evaluation of dynamic and static geometrical parameters of the contact network, and the working efficiency for checking and maintaining a power supply unit is improved.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

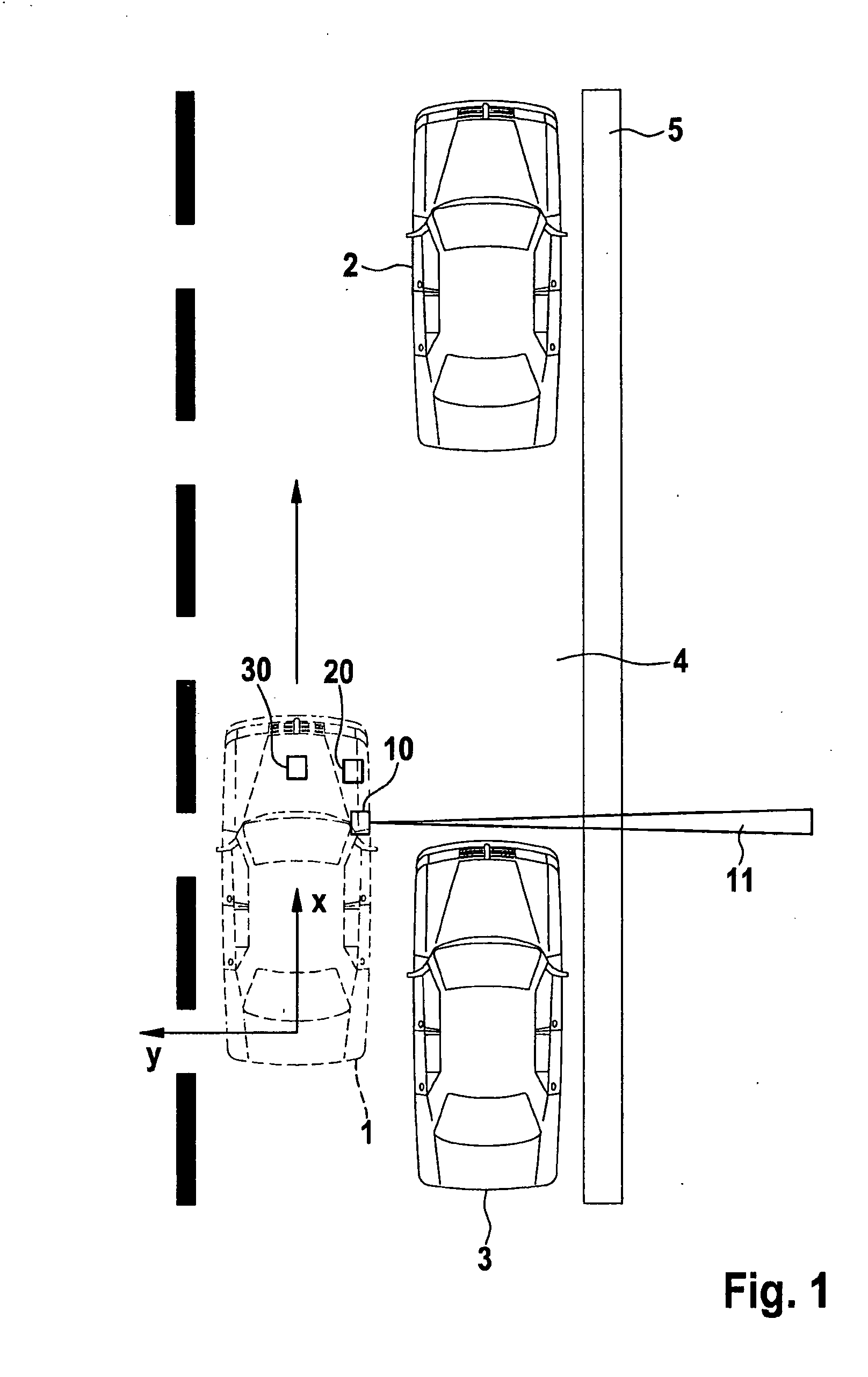

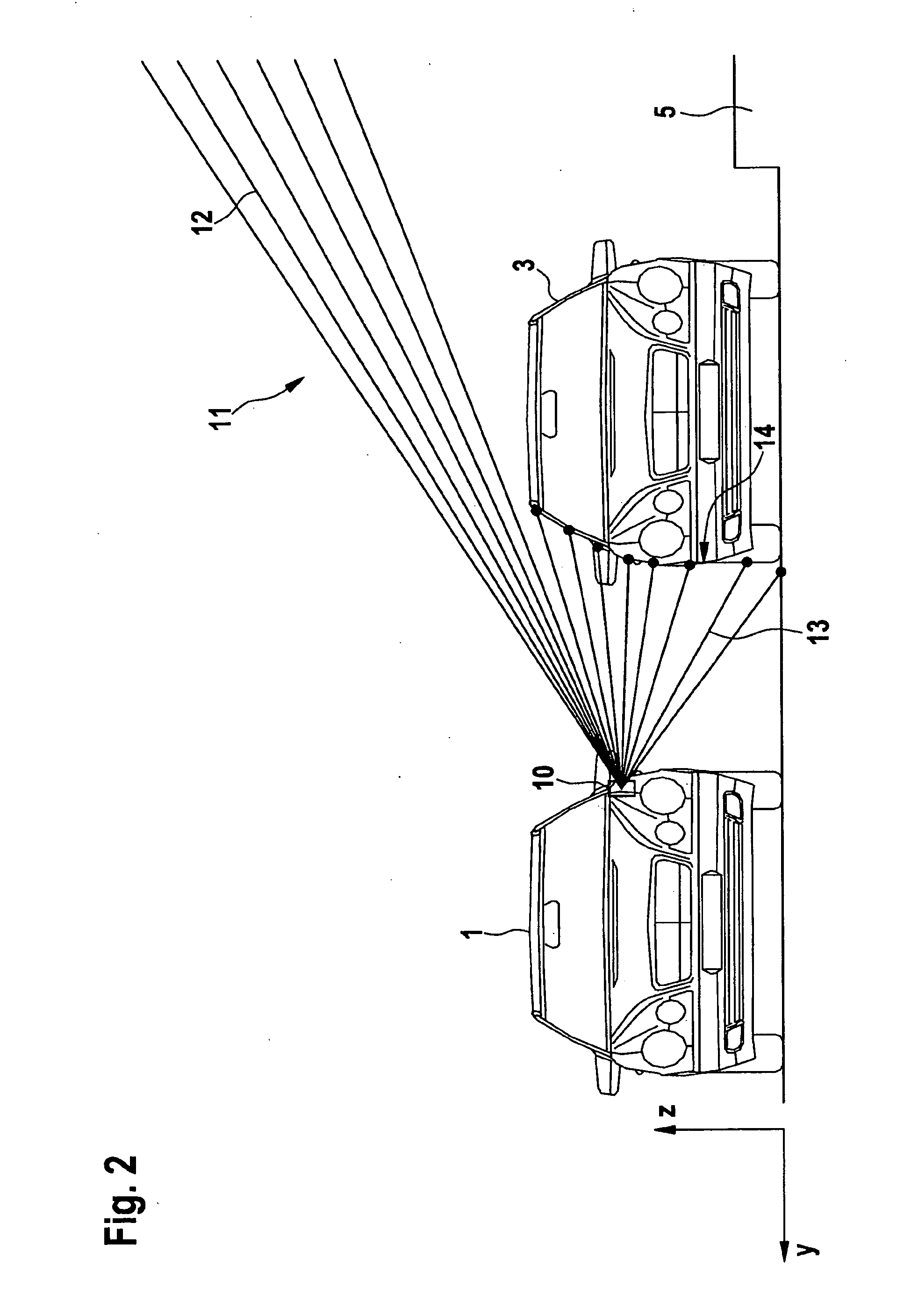

Device and method for measuring a parking space

InactiveUS20110013201A1Low costAccurate measurementUsing optical meansElectromagnetic wave reradiationParking spaceEngineering

A device for measuring a parking space as a vehicle drives past the parking space includes a depth-measuring line scan camera movable together with the vehicle for acquiring individual images of the environment surrounding the vehicle transverse to a longitudinal direction of the vehicle, an arrangement for acquiring the movement of the vehicle, and an evaluation device. The individual images of the environment surrounding the vehicle contain depth information that is resolvable in a vertical direction.

Owner:ROBERT BOSCH GMBH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com