Method for measuring volume of large irregular bulk grain pile based on dynamic three-dimensional laser scanning

A three-dimensional laser, irregular technology, used in measuring devices, optical devices, instruments, etc., can solve problems such as failure to effectively solve, affecting grain quantity statistics and inventory inspection, and inability to effectively measure grain quantity, etc., to save costs. , high precision, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

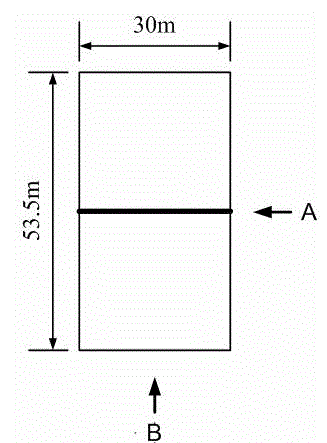

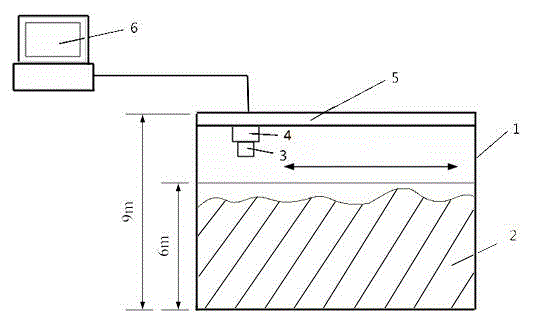

[0025] The condition of the experimental warehouse: No. 2 warehouse of Donghu Grain and Oil Reserve Depot in Changchun City, with a length of 53.5m, a width of 30m, and a grain loading line of 6m.

[0026] The corn that entered the warehouse in February 2012 had a moisture content of 14.4%, a bulk density of 746g / L, and a quantity of 3063.360 tons.

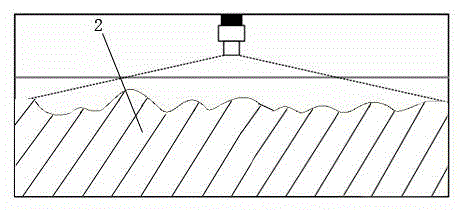

[0027] 3D laser scanner calculation: the scanner obtains the 3D coordinates of each point in the granary, that is, the prism inside the 3D laser scanner converts the 1D laser emitted by the laser head into a 2D laser through rapid rotation. At the same time, the servo motor also Rotate to obtain information in the third dimension. The angle β between the laser beam and the vertical direction can be obtained by the rotation of the recording prism, the angle α between the laser beam and the initial horizontal direction can be obtained by the rotation of the servo motor, and the measured distance R can be calculated by combining the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com