Patents

Literature

133 results about "Grain density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grain density describes the density of solid or mineral grains of the rock. Grain density can give an indication of the mineralogy of the rock: Dolomite, ρ = 2.8–3.1 g/cm 3. Shales, ρ = 2.65–2.8 g/cm 3 . Shales are composed of several minerals that have different densities in different relative amounts.

Flavored coffee compositions and methods of making the same

InactiveUS6841185B2Minimize and inhibit segregationMinimize and inhibit and separationRoasted coffee treatmentFood preparationParticle densityFood flavor

The present invention relates to non-segregating flavored coffee compositions. In particular, the present invention relates to novel flavored coffee compositions that minimize or inhibit the segregation and separation of constituent components, and the corresponding processes for making such compositions. The flavored coffee compositions herein are characterized as having a roast and ground, an instant coffee component, or mixtures thereof. The roast and ground coffee component will have a moisture level in the range of from about 1% to about 15%, a particle density in the range of from about 0.1 g / cc to about 0.45 g / cc, and a mean particle size distribution in the range of from about 400 microns to about 1300 microns. The instant coffee components used herein will have a particle density in the range of from about 0.1 g / cc to about 0.8 g / cc, a mean particle size distribution in the range of from about 250 microns to about 2360 microns, and a moisture level in the range of from about 1% to about 4.5%. The flavored coffee composition further contains a flavoring component with a moisture level in the range of from about 1% to about 7%, a particle density in the range of from about 0.1 g / cc to about 0.8 g / cc, and a mean particle size distribution in the range of from about 5 microns to about 150 microns. The ratio of coffee component particle size to flavor component particle size is in the range of from about 100:1 to about 5:1.

Owner:THE PROCTER & GAMBLE COMPANY +3

Novel method to reduce Rs pattern dependence effect

ActiveUS20050085066A1Simple methodPrevent undesirably high Rs valueSemiconductor/solid-state device manufacturingCopper interconnectDielectric layer

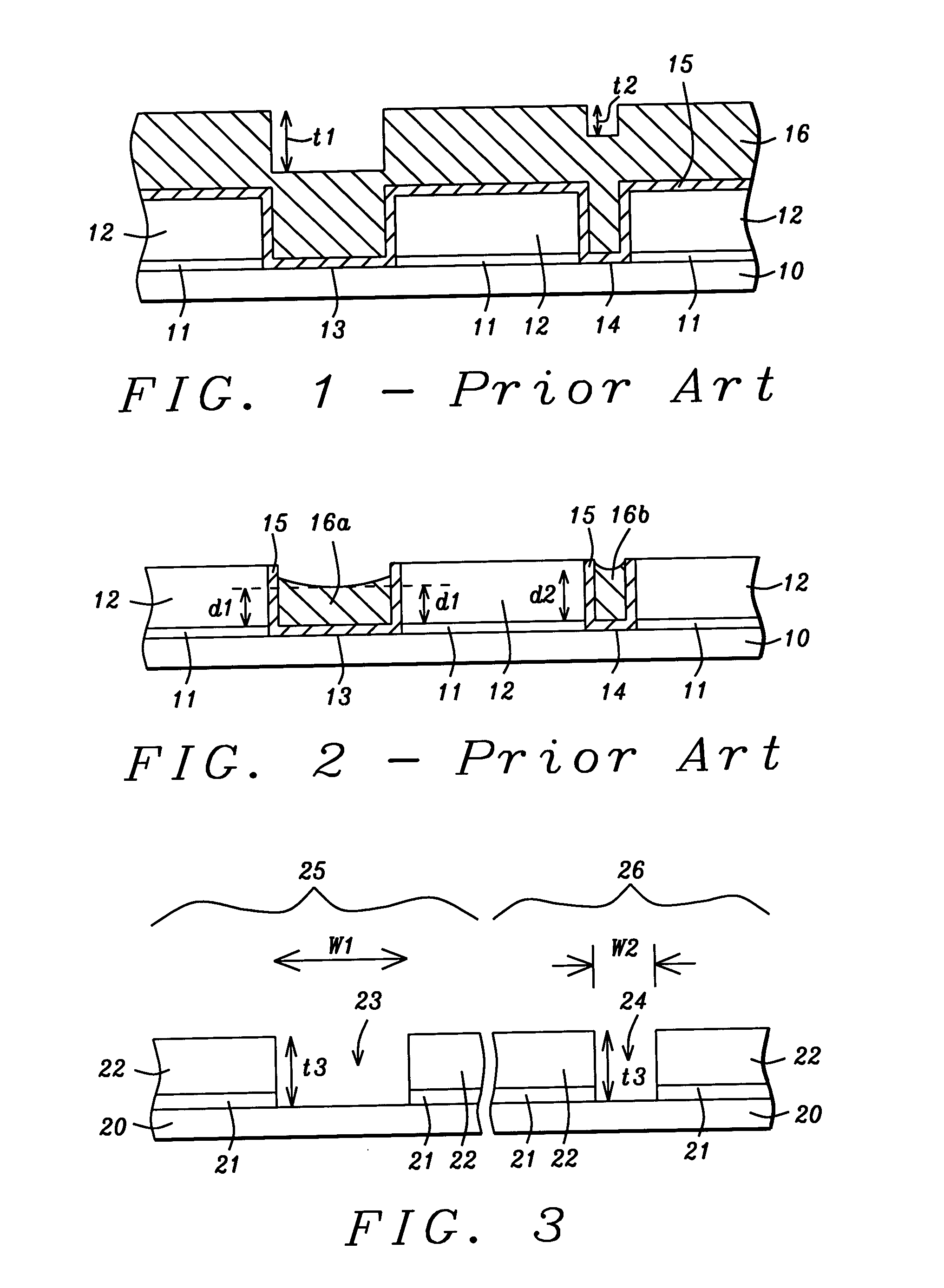

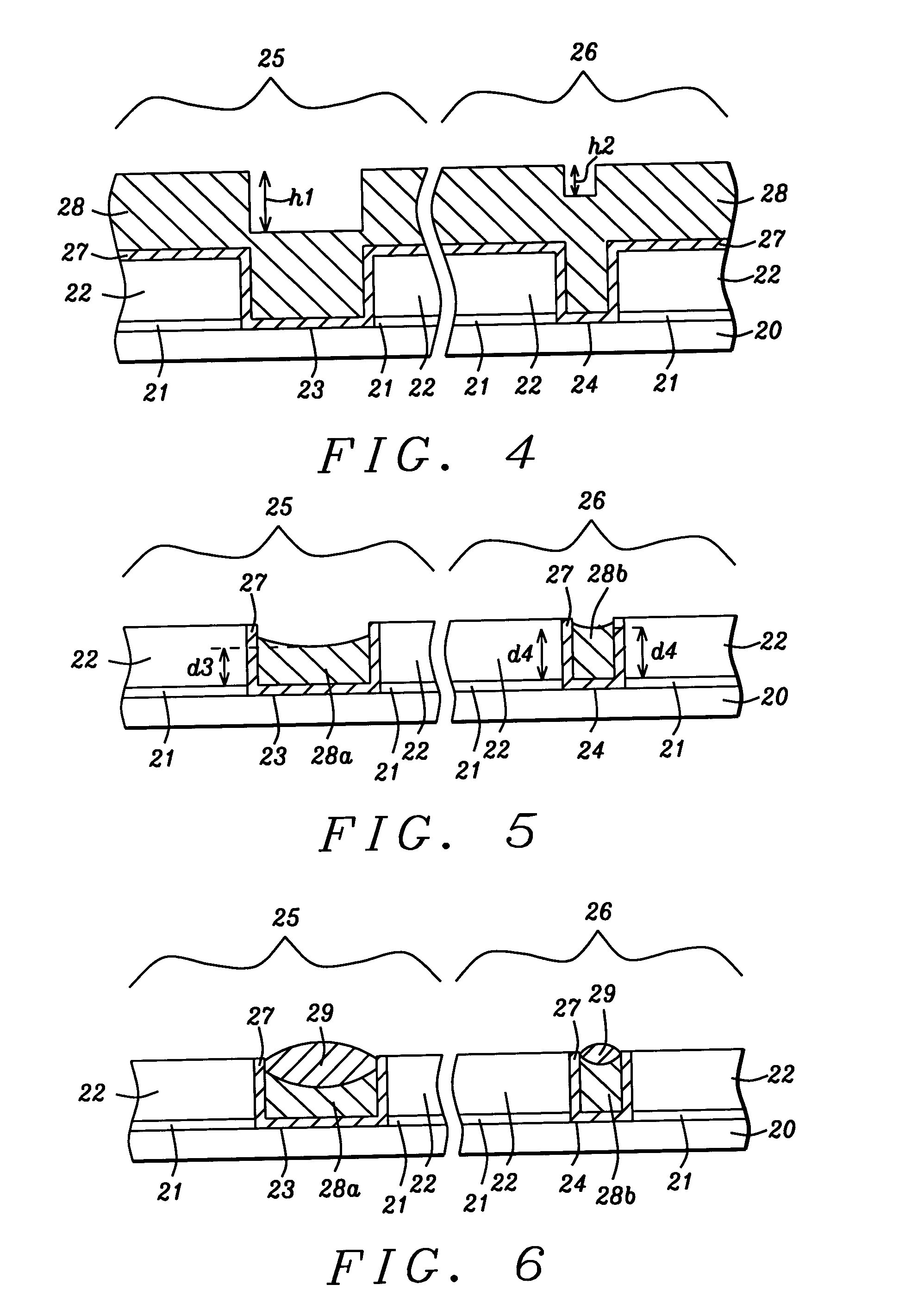

A method of forming a copper interconnect in an opening within a pattern is described. The copper interconnect has an Rs that is nearly independent of opening width and pattern density. A first copper layer having a concave upper surface and thickness t1 is formed in a via or trench in a dielectric layer by depositing copper and performing a first CMP step. A second copper layer with a thickness t2 where t2≦t1 and having a convex lower surface is deposited on the first copper layer by a selective electroplating method. The first and second copper layers are annealed and then a second CMP step planarizes the second copper layer to become coplanar with the dielectric layer. The invention is also a copper interconnect comprised of the aforementioned copper layers where the first copper layer has a grain density (GD1)≧GD2 for the second copper layer.

Owner:TAIWAN SEMICON MFG CO LTD

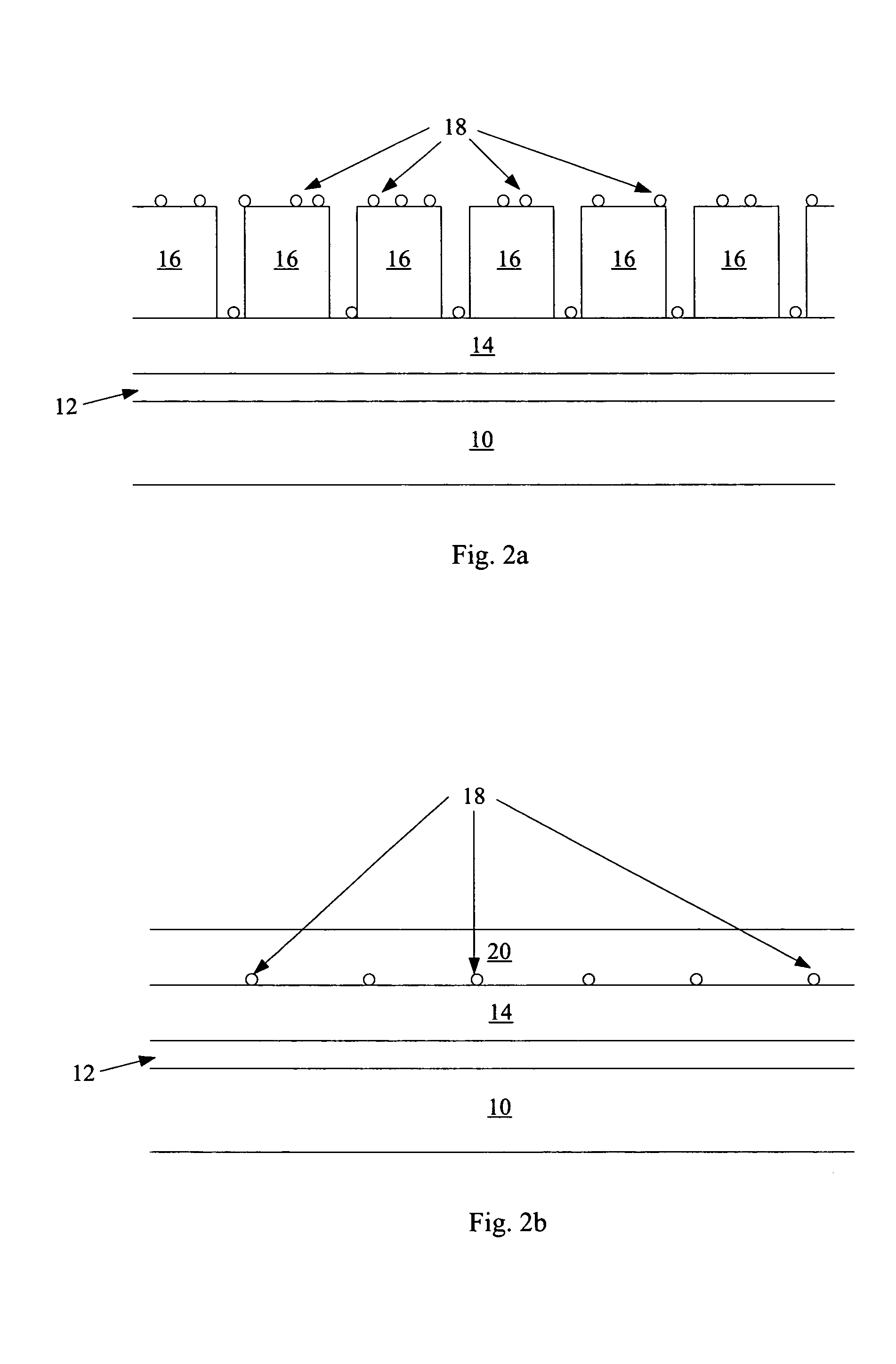

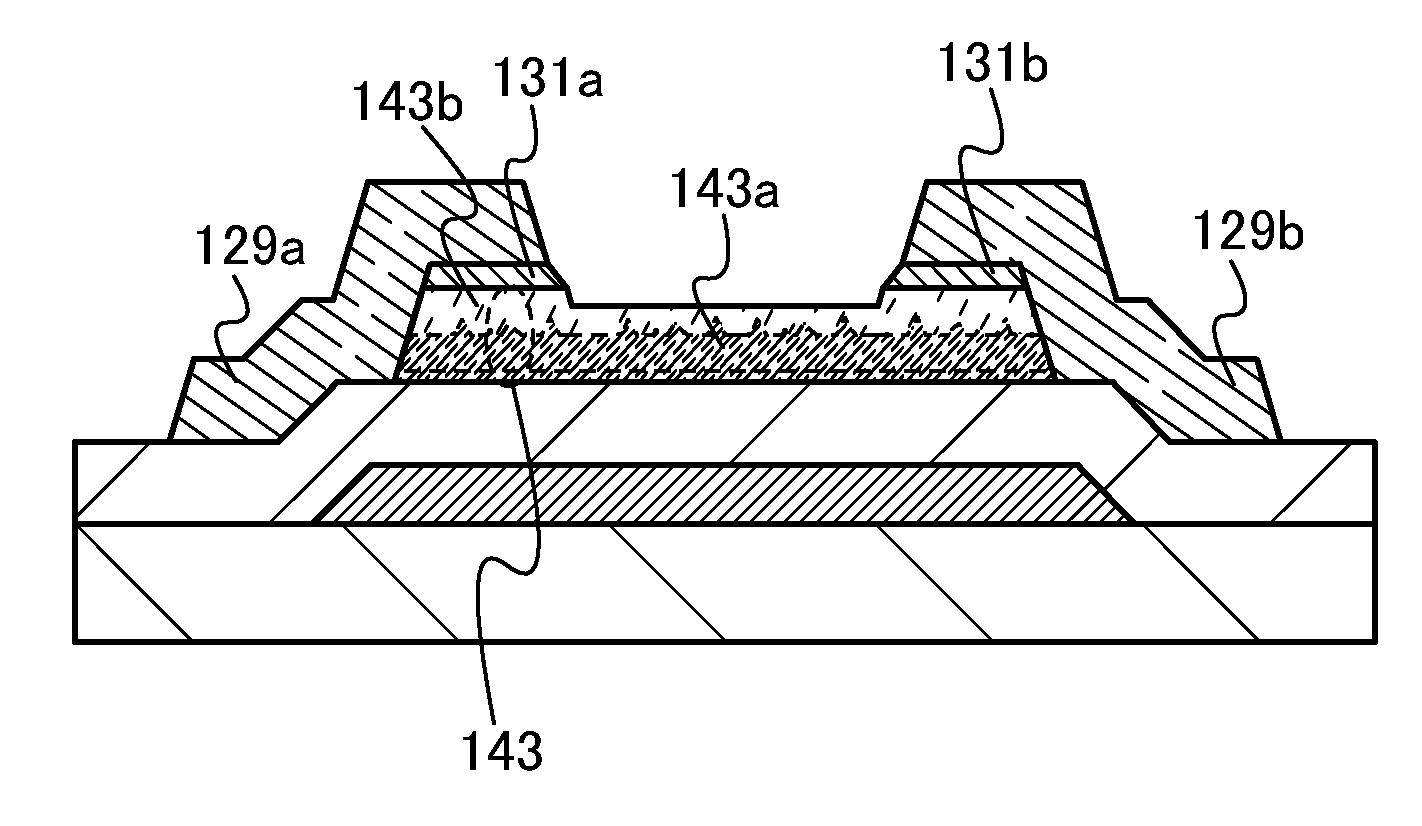

Uniform seeding to control grain and defect density of crystallized silicon for use in sub-micron thin film transistors

ActiveUS20050072976A1TransistorSemiconductor/solid-state device manufacturingAmorphous siliconOptoelectronics

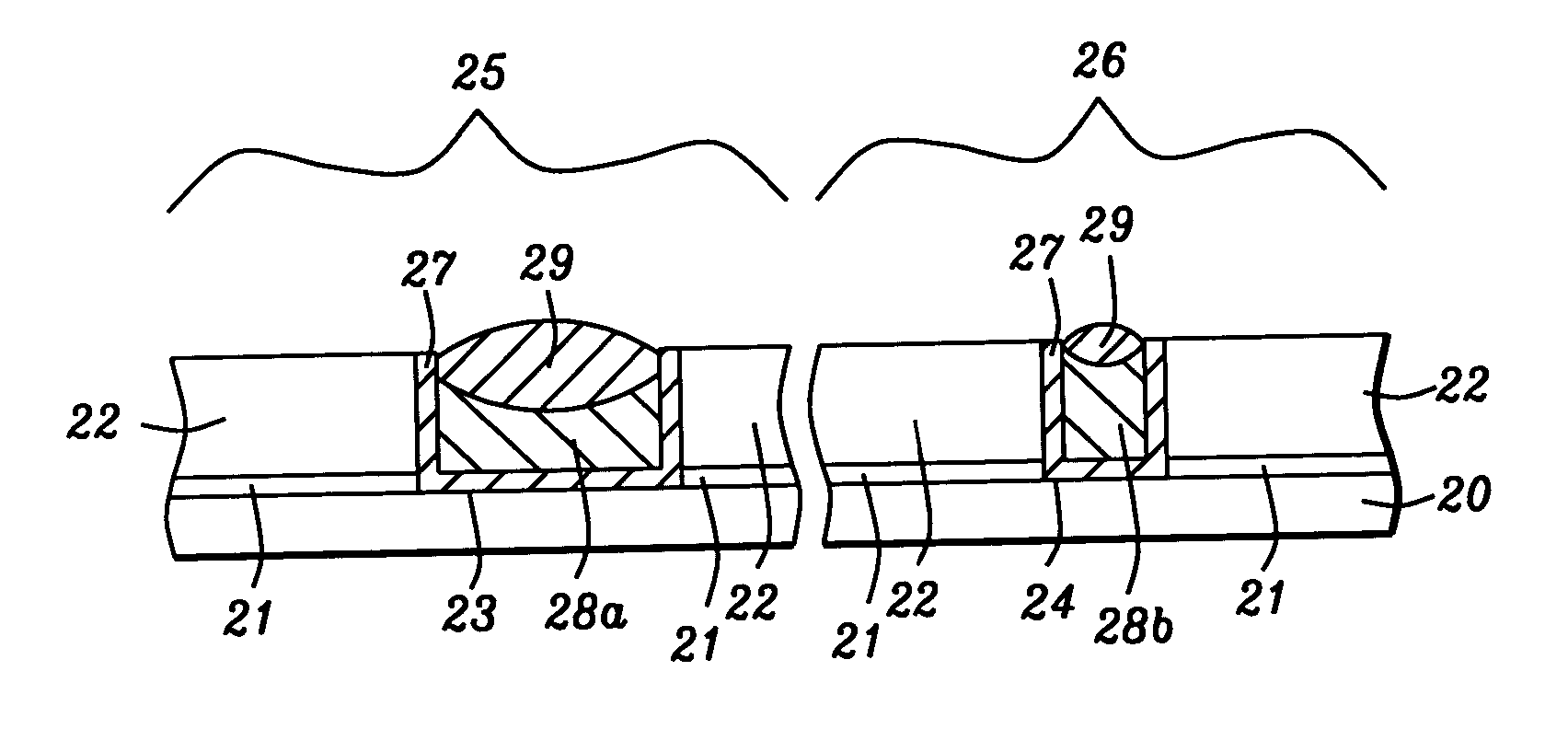

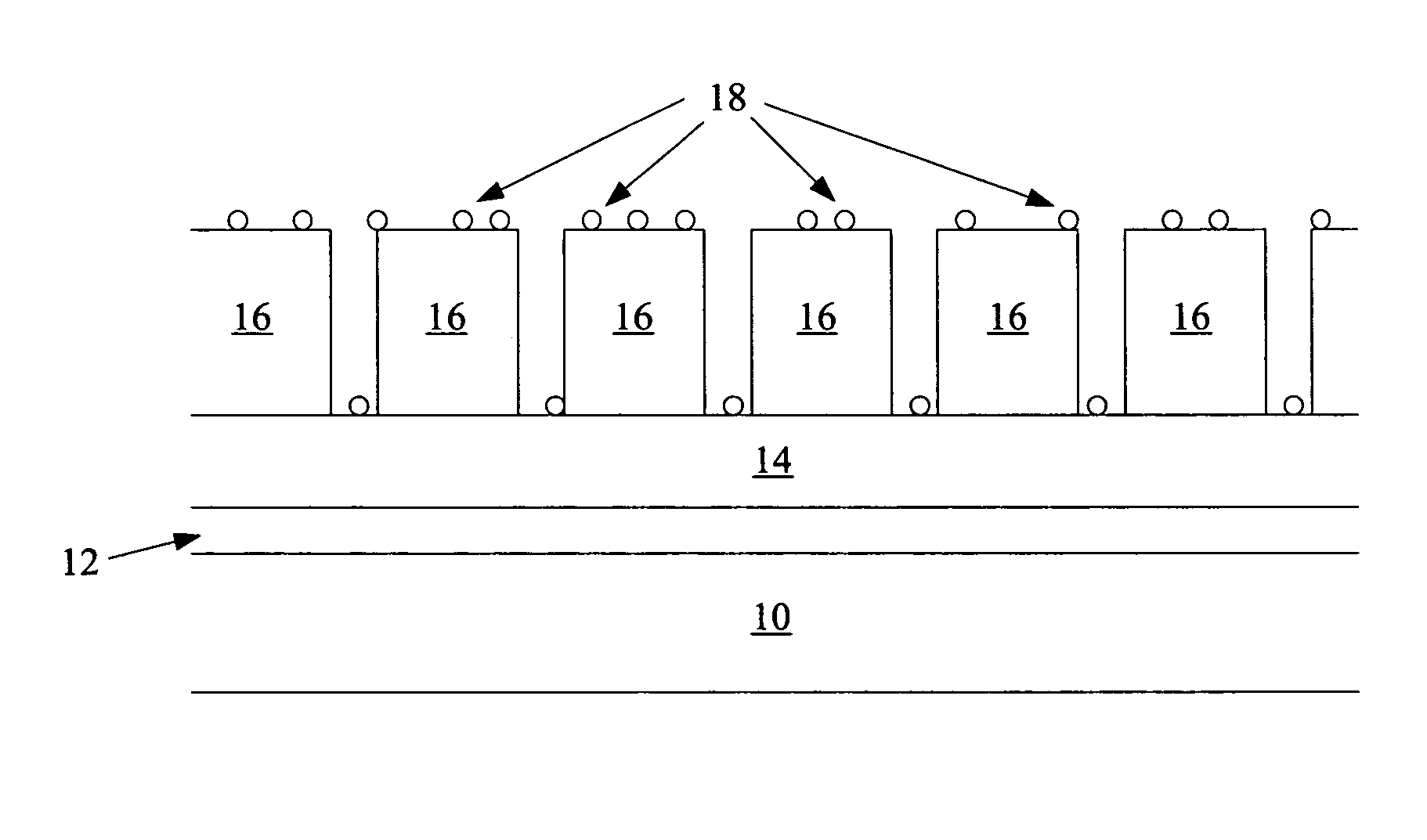

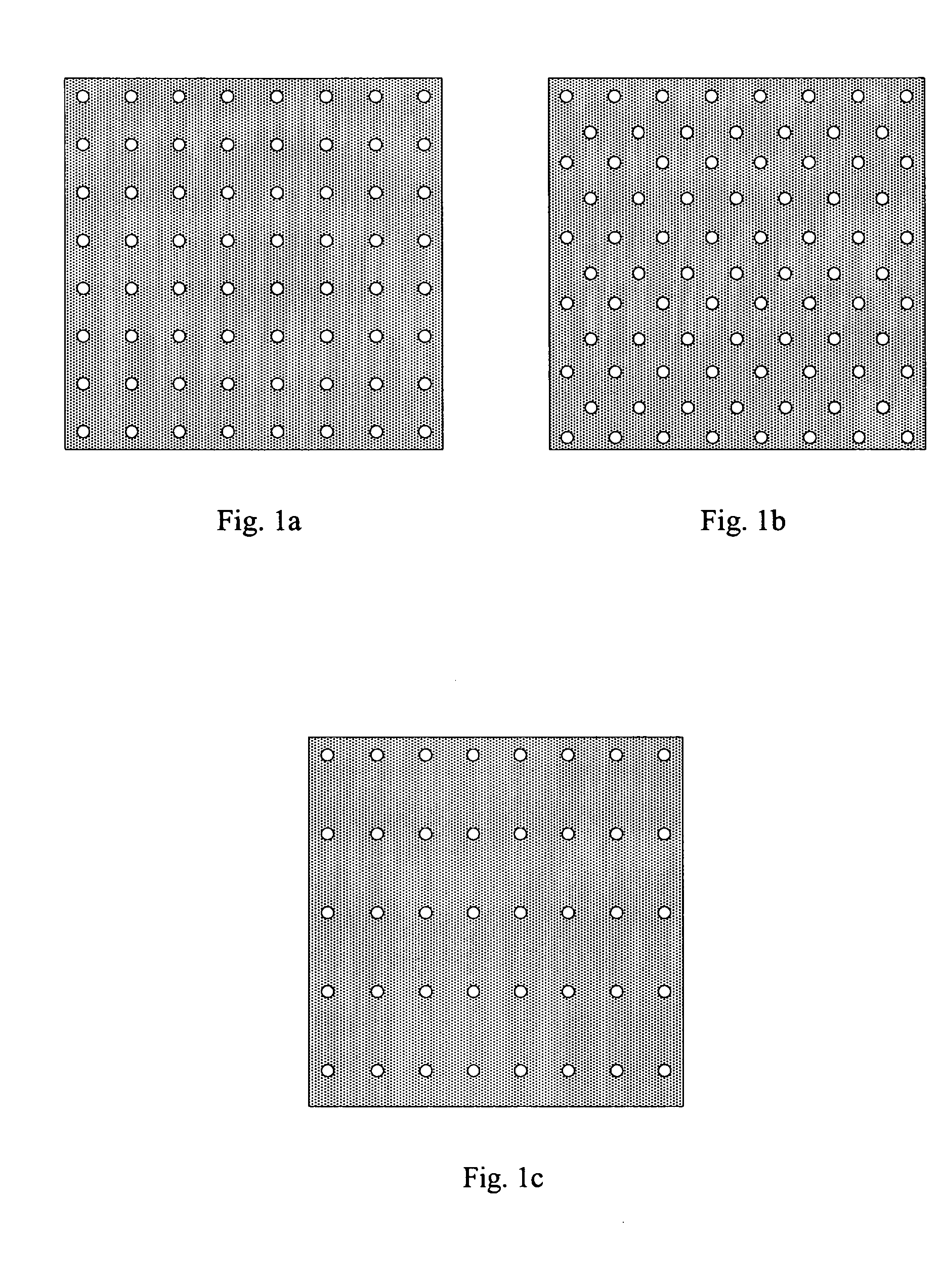

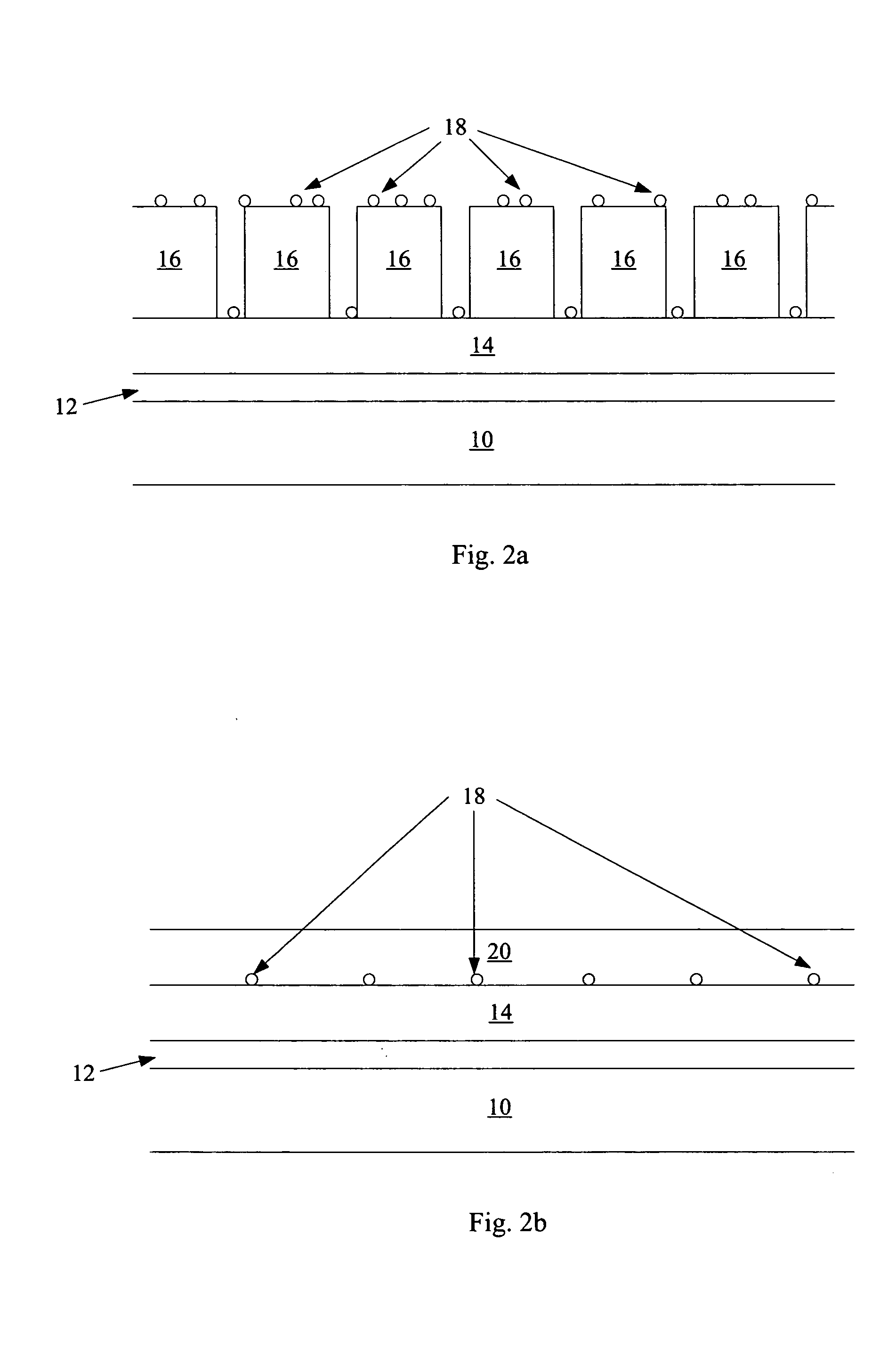

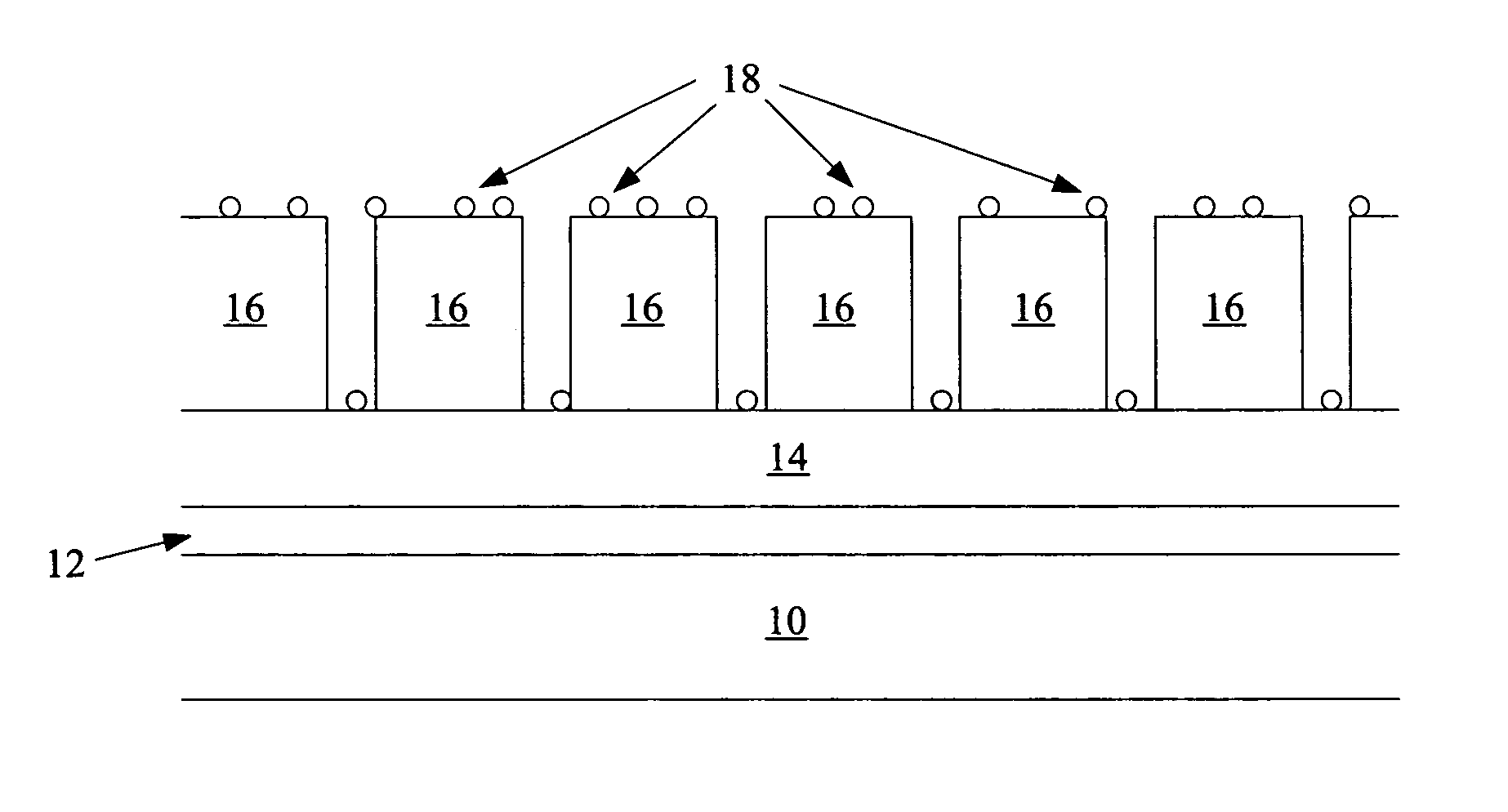

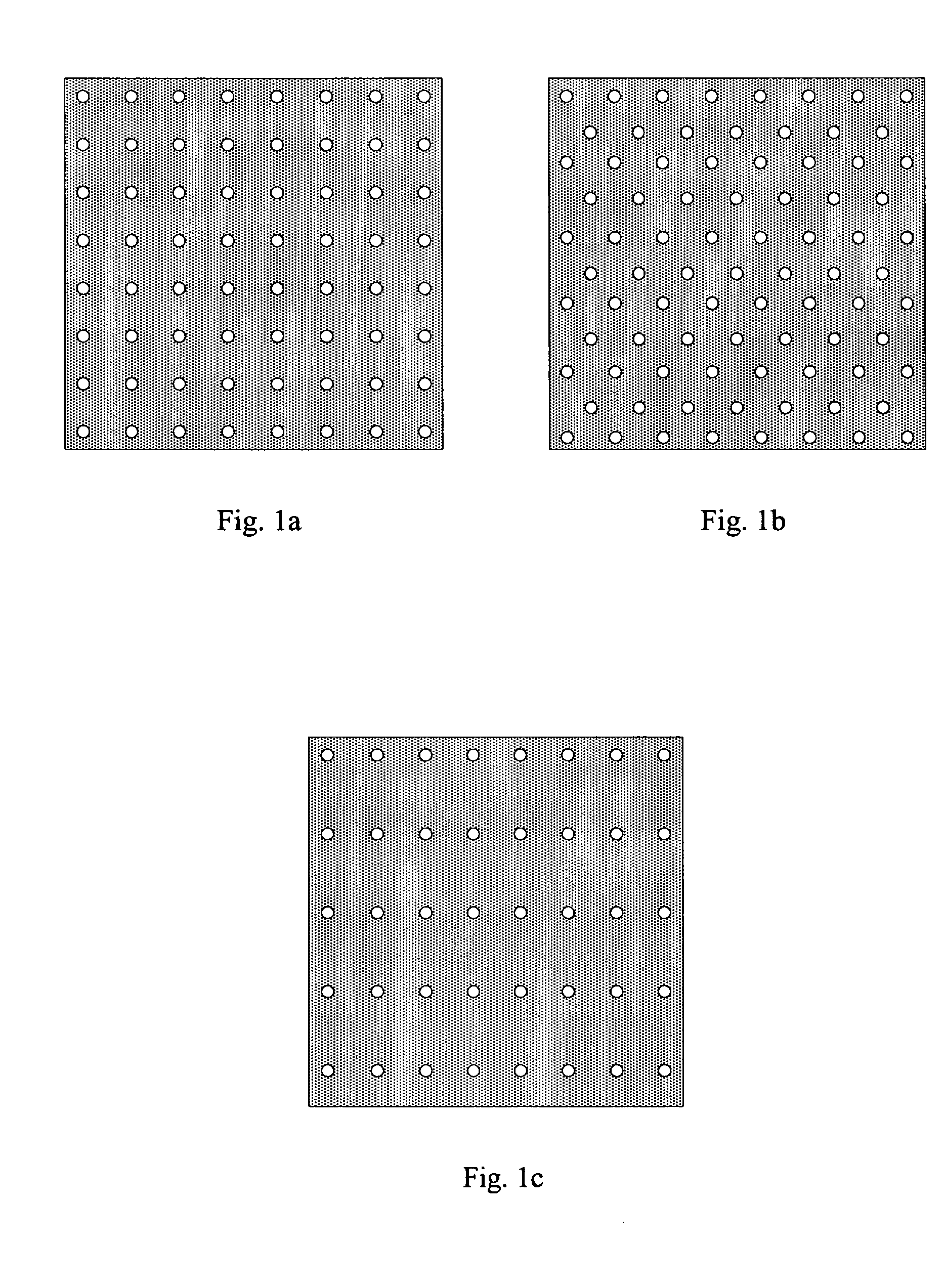

A method to create a polysilicon layer with large grains and uniform grain density is described. A first amorphous silicon layer is formed. A crystallizing agent is selectively introduced in a substantially symmetric pattern, preferably symmetric in two dimensions, across an area of the first amorphous layer. The crystallizing agent may be, for example, silicon nuclei, germanium, or laser energy. A mask layer is formed on the amorphous silicon layer, and holes etched in the mask layer in a symmetric pattern to expose the amorphous layer to, for example, silicon nuclei or germanium) only in the holes. The mask layer is removed and a second amorphous layer formed on the first. If laser energy is used, no mask layer or second amorphous layer is generally used. The wafer is annealed to form a polysilicon layer with substantially no amorphous silicon remaining between the grains.

Owner:SANDISK TECH LLC

Method of making flavored coffee compositions

InactiveUS7763300B2Minimize and inhibit segregation and separationLow costRoasted coffee treatmentFood preparationParticle densityFood flavor

The present invention relates to non-segregating, non-agglomerated flavored coffee compositions. In particular, the present invention relates to novel flavored coffee compositions that minimize or inhibit the segregation and separation of constituent components, and the corresponding processes for making such compositions. The flavored coffee compositions herein are characterized as having a roast and ground, an instant coffee component, or mixtures thereof. The roast and ground coffee component will have a moisture level in the range of from about 1% to about 15%, a particle density in the range of from about 0.1 g / cc to about 0.45 g / cc, and a mean particle size distribution in the range of from about 400 microns to about 1300 microns. The instant coffee components used herein will have a particle density in the range of from about 0.1 g / cc to about 0.8 g / cc, a mean particle size distribution in the range of from about 250 microns to about 2360 microns, and a moisture level in the range of from about 1% to about 4.5%. The flavored coffee composition further includes a flavoring component with a moisture level in the range of from about 1% to about 7%, a particle density in the range of from about 0.1 g / cc to about 0.8 g / cc, and a mean particle size distribution in the range of from about 5 microns to about 150 microns. The ratio of coffee component particle size to flavor component particle size is in the range of from about 100:1 to about 5:1.

Owner:THE FOLGERS COFFEE +2

Method of uniform seeding to control grain and defect density of crystallized silicon for use in sub-micron thin film transistors

ActiveUS7195992B2TransistorSemiconductor/solid-state device manufacturingAmorphous siliconSeed crystal

A method to create a polysilicon layer with large grains and uniform grain density is described. A first amorphous silicon layer is formed. A crystallizing agent is selectively introduced in a substantially symmetric pattern, preferably symmetric in two dimensions, across an area of the first amorphous layer. The crystallizing agent may be, for example, silicon nuclei, germanium, or laser energy. A mask layer is formed on the amorphous silicon layer, and holes etched in the mask layer in a symmetric pattern to expose the amorphous layer to, for example, silicon nuclei or germanium) only in the holes. The mask layer is removed and a second amorphous layer formed on the first. If laser energy is used, no mask layer or second amorphous layer is generally used. The wafer is annealed to form a polysilicon layer with substantially no amorphous silicon remaining between the grains.

Owner:SANDISK TECH LLC

Alpha-alumina-based abrasive and preparation method thereof

The invention specifically relates to an alpha-alumina-based abrasive and a preparation method thereof. The abrasive is characterized in that a particle density is higher than 3.88g / cm<3>, a micro hardness is higher than 20GPa, and particle-forming grain size is 0.15-0.3 micrometers. The preparation method comprises the steps that: (1) pure water, a boehmite half-finished product and alumina seed grind solution are added into a stirrer with a vacuum pumping function, and the raw materials are stirred and beaten into slurry; (2) dilute nitric acid with a concentration of 20% is added into the slurry, and a sol and then a gel are gradually formed in a vacuum state; (3) the gel is bake-dried under a temperature of 140 DEG C, and is crushed; on-sieve particles are obtained by using a 120-mesh sieve; (4) the obtained particles are calcined, and the calcined particles are sintered; and (5) finished product particles are obtained by sieving. The method provided by the invention has the advantages of low raw material cost, and mature and stable process. With the abrasive particles provided by the invention, a prepared abrasive product has the characteristics such as high grinding efficiency, good self-sharpening performance, and long durability.

Owner:山东英格瓷四砂泰山磨料有限公司

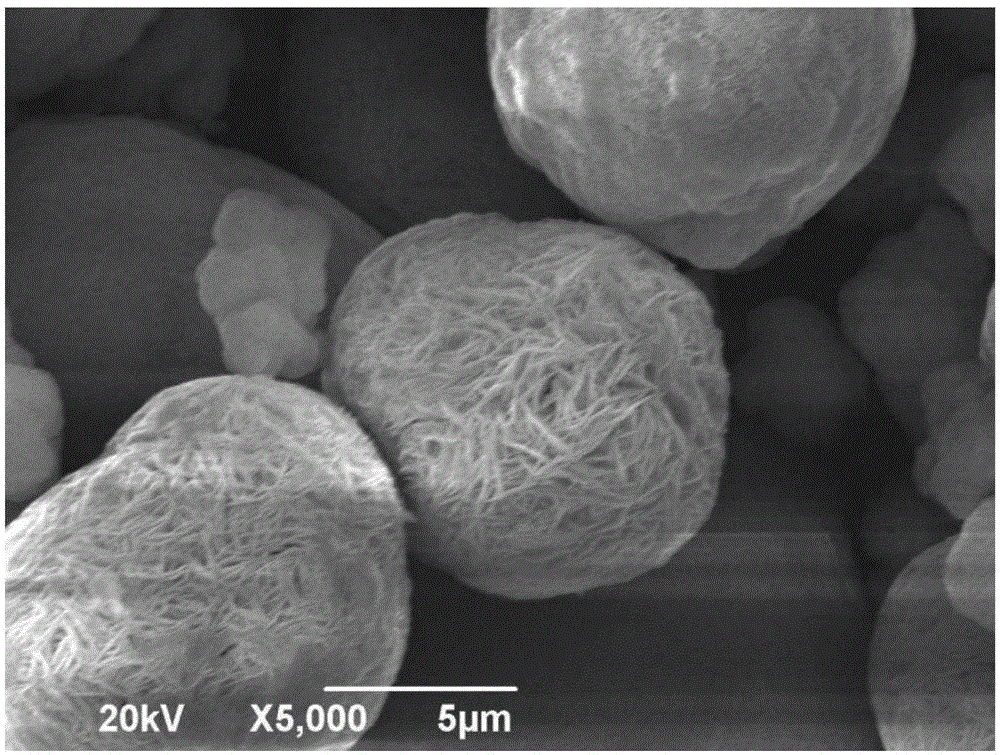

Alpha-alumina-based abrasive containing sheet-shaped structures, and preparation method thereof

The invention specifically relates to an alpha-alumina-based abrasive containing sheet-shaped structures, and a preparation method thereof. The abrasive is characterized in that particle density is higher than 3.88, a microhardness is higher than 20GPa, sizes of grains forming particles are lower than 5 micrometers, and the abrasive contains sheet-shaped structures. The preparation method comprises the steps that: (1) pure water and a boehmite semi-finished product are added into a stirring machine with a vacuum pumping function; and the mixture is stirred into slurry; (2) dilute nitric acid with a concentration of 20% is added; stirring is carried out under a vacuum state, such that a sol and then a gel are gradually formed; (3) the gel is bake-dried and crushed; on-sieve particles with a size higher than 120 meshes are obtained by sieving; (4) the sieved particles are calcined, and the calcined particles are sintered; and (5) finished-product particles are obtained by sieving. The preparation method provided by the invention has the advantages of low raw material cost, and mature and stable process. With the method provided by the invention, the prepared abrasive particles contain sheet-shaped structures. Prepared abrasive product has the characteristics such as high grinding efficiency, good self-sharpening performance, long durability, and the like.

Owner:山东英格瓷四砂泰山磨料有限公司

Anti-glare sheet for image display device

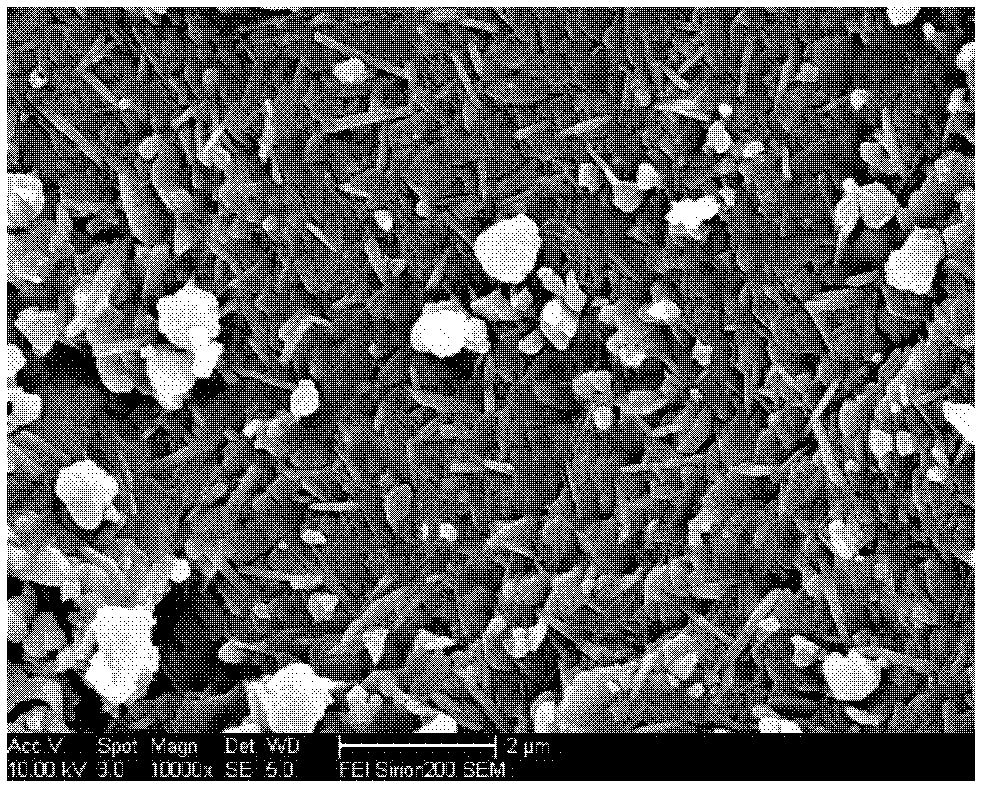

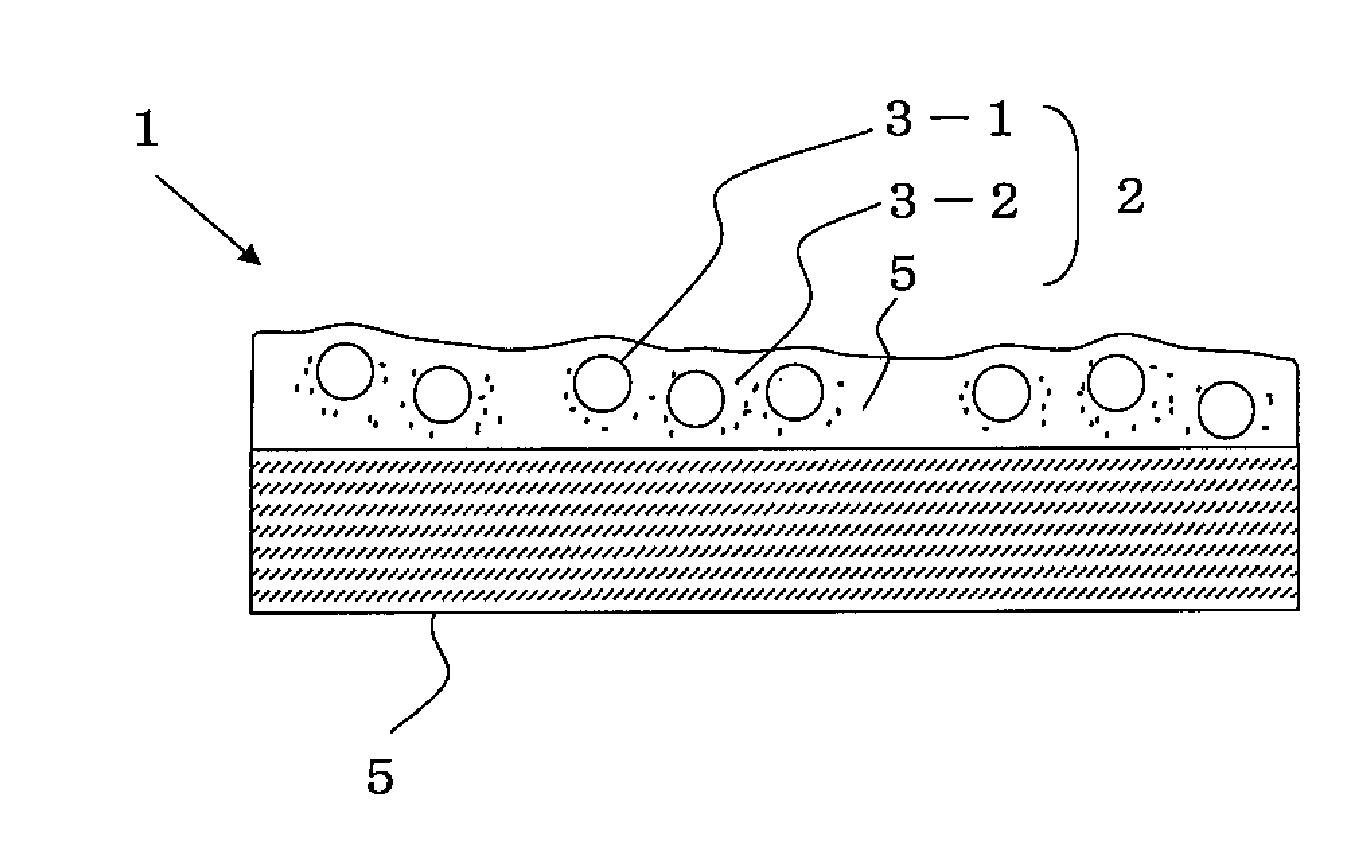

ActiveUS20140211316A1High blacknessExcellent vivid complexionDiffusing elementsSynthetic resin layered productsParticulatesVolumetric Mass Density

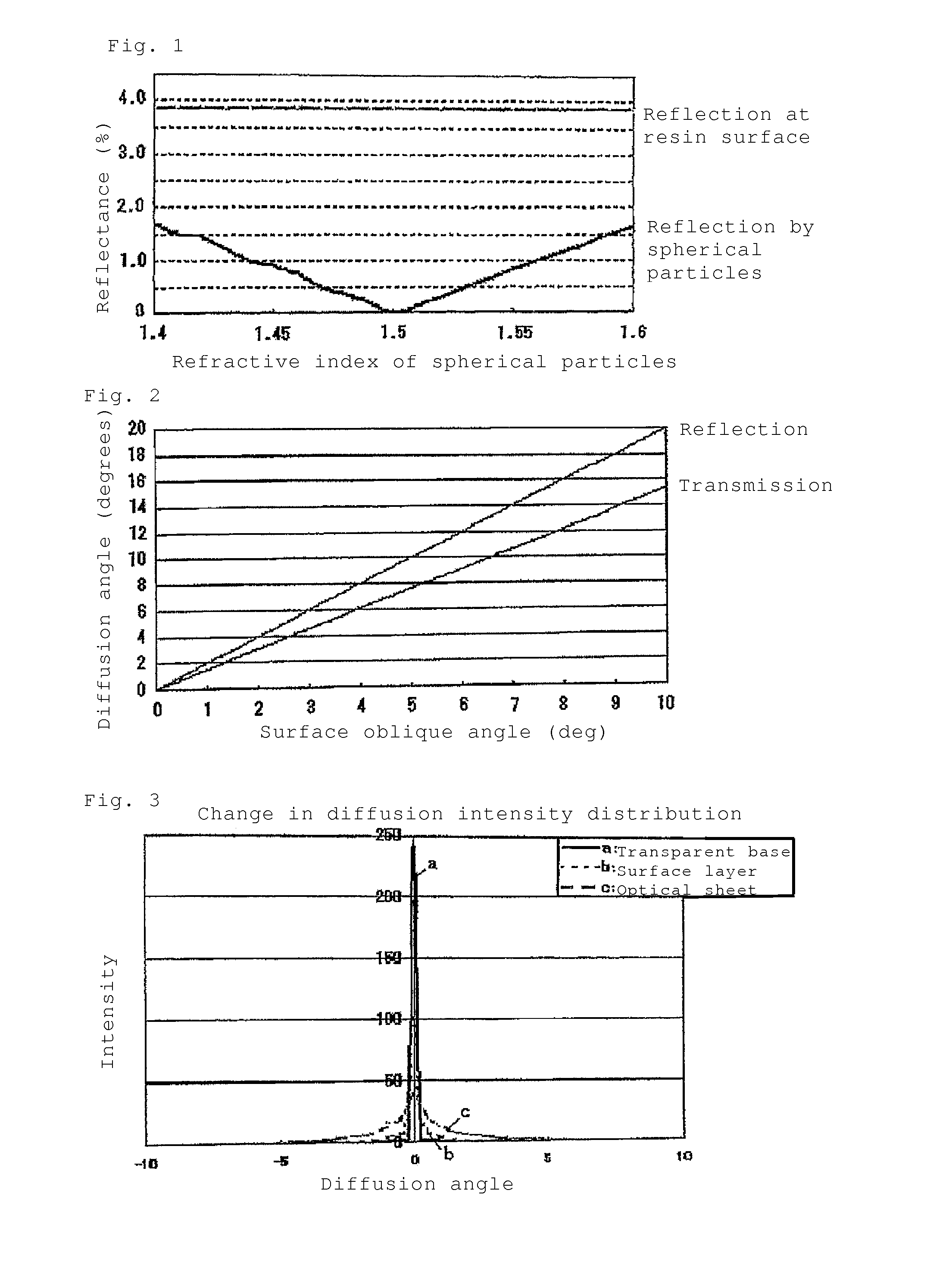

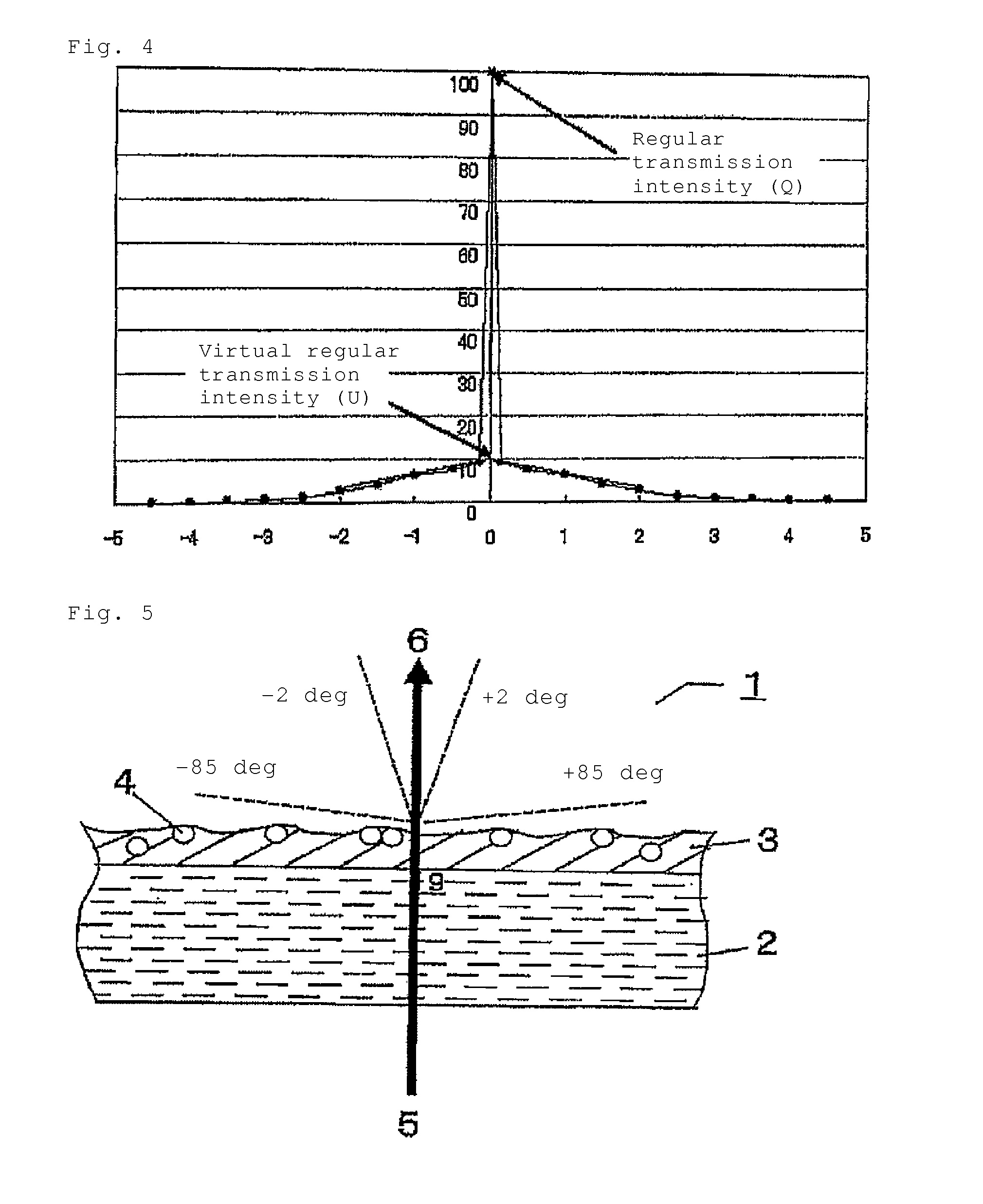

An anti-glare sheet that exhibits excellent glossy black textures, blackness in dark locations, and anti-glare properties for dynamic images, and that is suited to the implementation of high quality images. The anti-glare sheet has, on at least one surface of a transparent substrate, an anti-glare layer comprising binder resin, diffusion particles, and binder particulates. The anti-glare sheet is characterized by the anti-glare layer having protrusions and recesses on the surface on the opposite side thereof to the transparent substrate, the protrusions and recesses being formed by protrusions based on agglomerations of the diffusion particles and / or diffusion particles having in the vicinity thereof a localized layer in which the density of binder particulates is high, and equation (1) and equation (2) being satisfied where Q is the luminance in the direction of regular transmission when visible light is perpendicularly irradiated on the anti-glare sheet from the transparent substrate side, Q30 is the luminance in a direction 30 degrees from regular transmission; and U is the average value of the transmission intensity obtained by respectively extrapolating, to a regular transmission, a straight line joining the luminance in a direction +2 degrees from regular transmission to the luminance in a direction +1 degree from regular transmission, and a straight line joining the luminance in a direction −2 degrees from regular transmission to the luminance in a direction −1 degree from regular transmission.10<Q / U<36 Equation (1)Log10(Q30 / Q)<−6 Equation (2)

Owner:DAI NIPPON PRINTING CO LTD

Gallium nitride thin film epitaxial growth structure and method

ActiveCN101302648AReduce dislocation densityQuality improvementPolycrystalline material growthFrom chemically reactive gasesSingle crystalGallium nitride

The invention relates to a gallium nitride membrane epitaxial growth structure and a method. The structure is as follows: an SOI substrate is provided with an AIN nucleation layer which is provided with a low V / III ratio GaN cushioning layer; and the low V low V / III ratio / III ratio cushioning layer is provided with a GaN single-crystal membrane. The method is as follows: the SOI substrate is selected and arranged inside an MOCVD reaction chamber; the SOI substrate is roasted and cooled down, and then trimethyl aluminum is added to the SOI substrate so as to grow the AIN nucleation layer; the trimethyl aluminum is closed and cooled down, and then ammonia gas is injected to the rimethyl aluminum so as to grow the GaN cushioning layer; the GaN cushioning layer is heated up and injected with ammonia gas and trimethyl gallium so as to grow the GaN single-crystal membrane; finally, the temperature is cooled down to room temperature. The gallium nitride membrane epitaxial growth structure and the method have the advantages that: when the low V / III ratio GaN cushioning layer is converted into quasi-two-dimensional growth from three-dimensional growth with prolonging a GaN membrane, crystal grain is fully grown up so as to reduce crystal grain density, release mismatch stress and increase the mass of a GaN membrane crystal; moreover, the mismatch stress of the SOI substrate GaN single-crystal membrane is reduced by means of the low V / III ratio GaN cushioning layer, thereby reducing dislocation density and increasing crystal quality.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

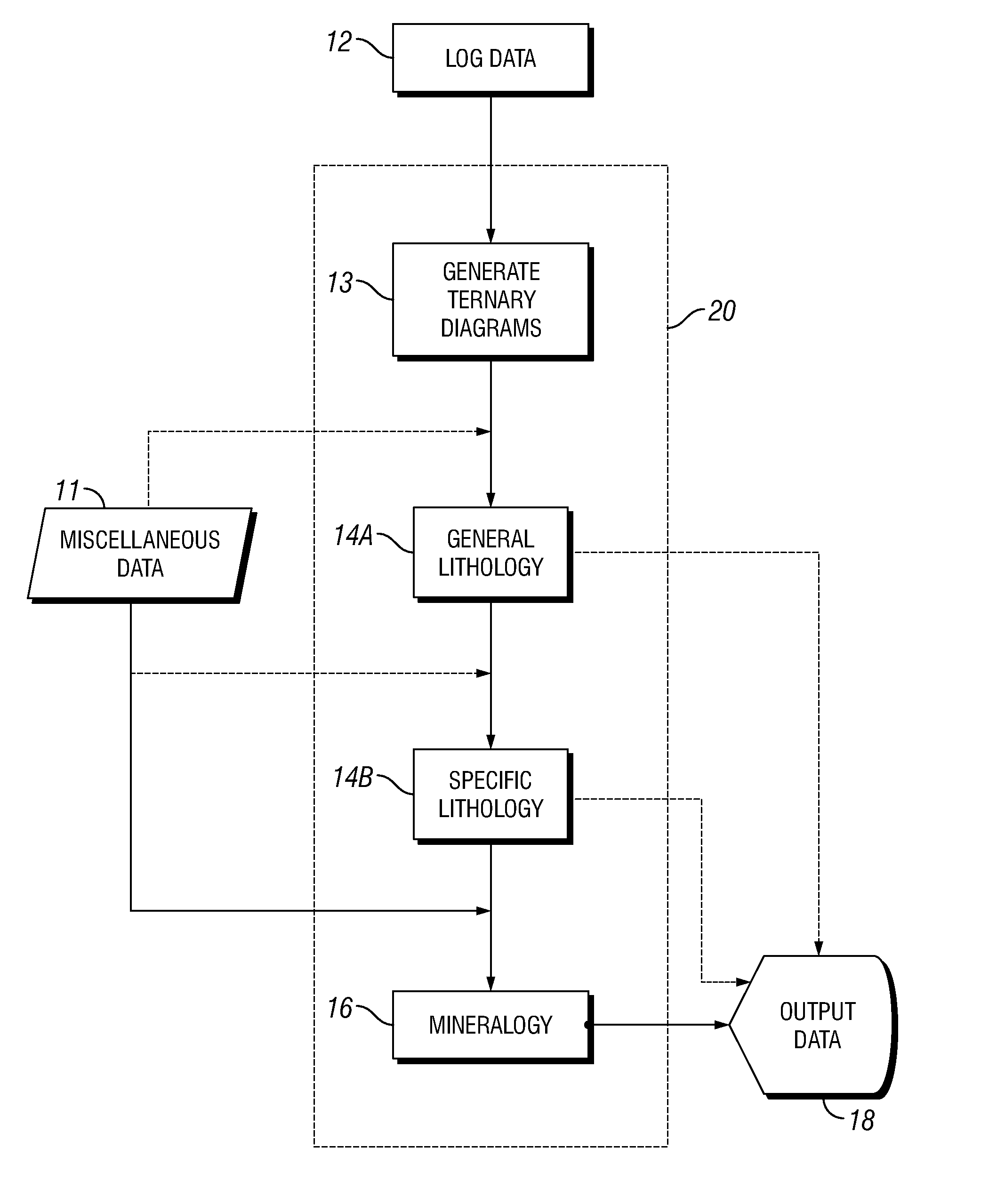

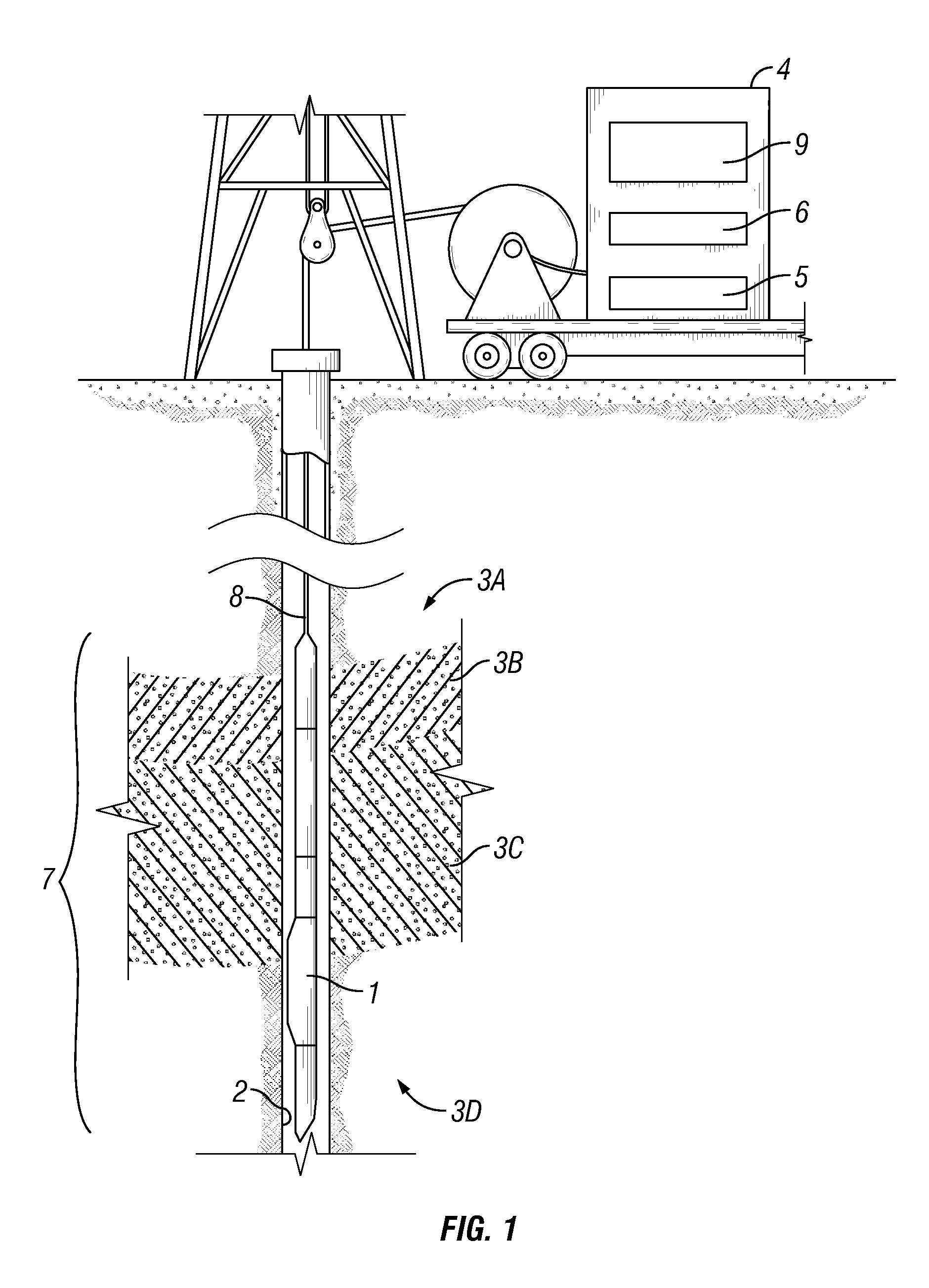

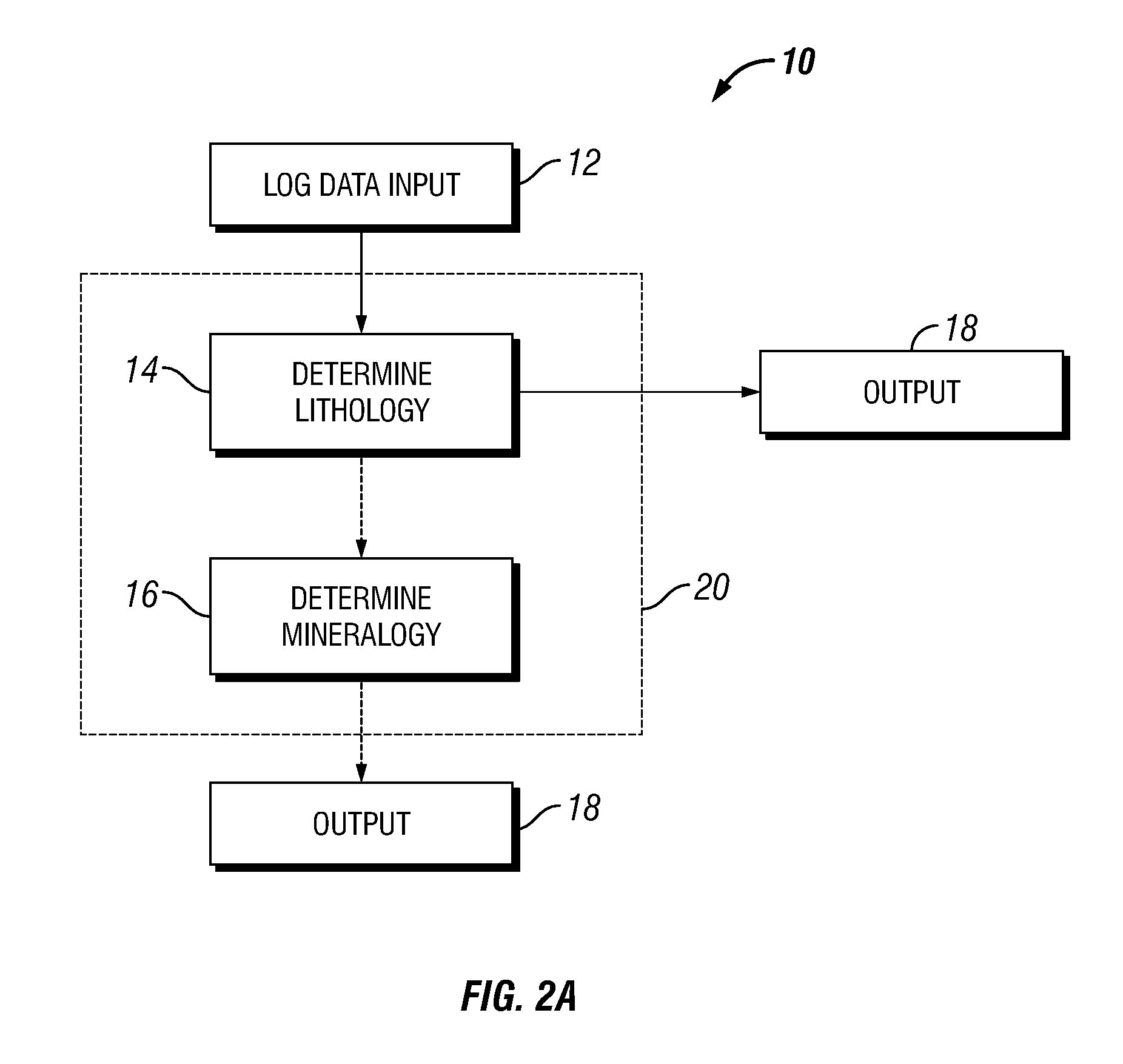

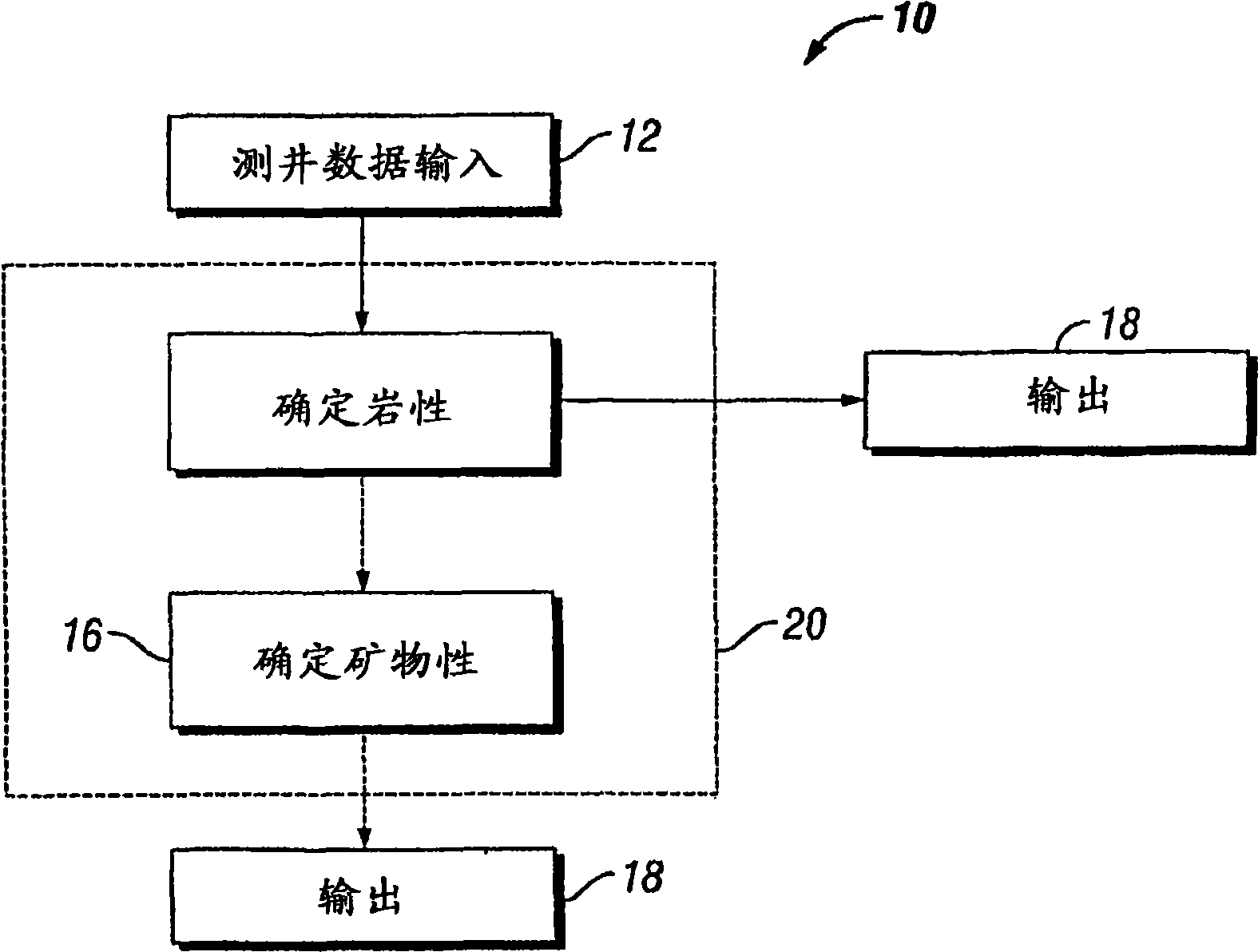

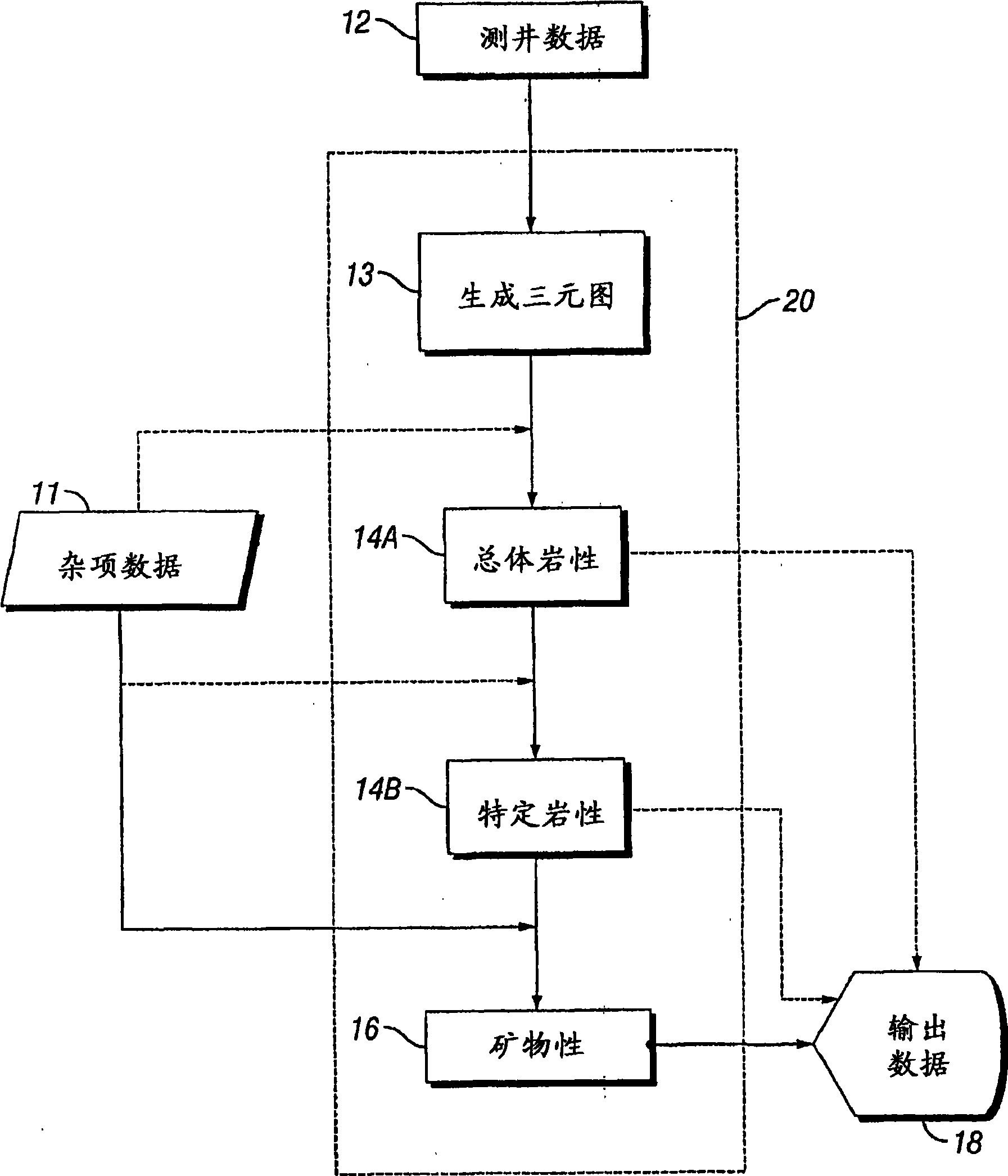

Methods for quantitative lithological and mineralogical evaluation of subsurface formations

Owner:BAKER HUGHES INC

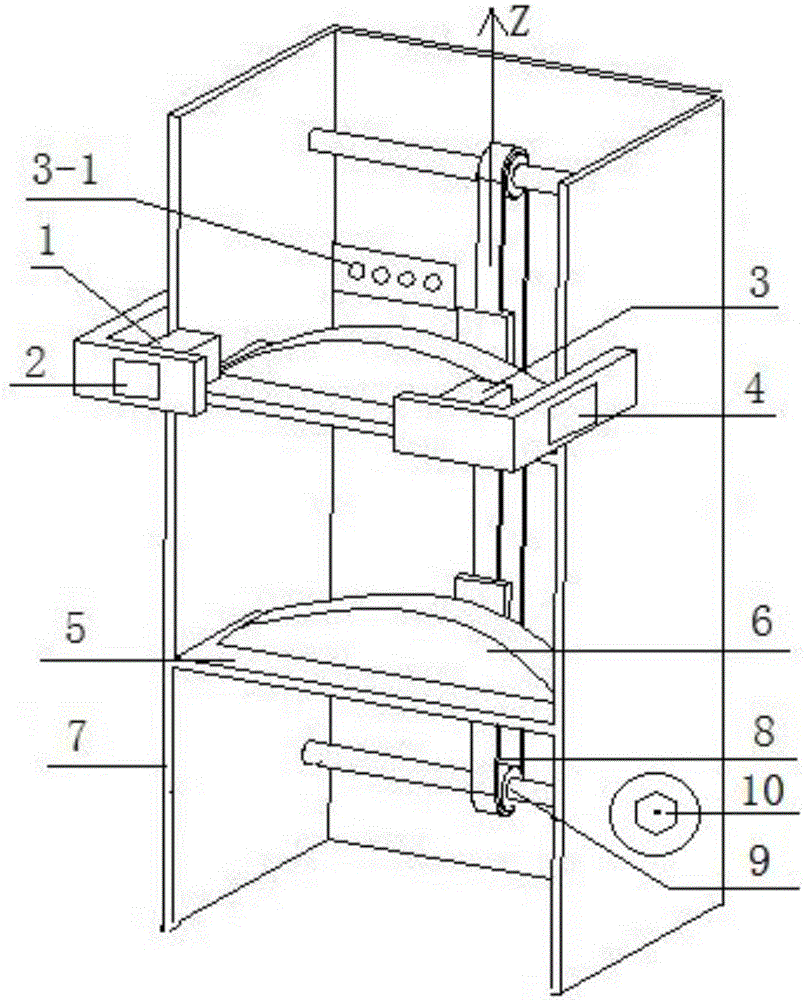

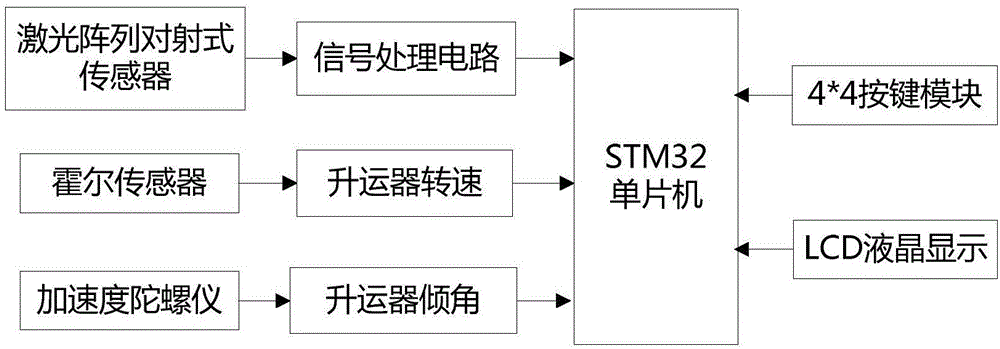

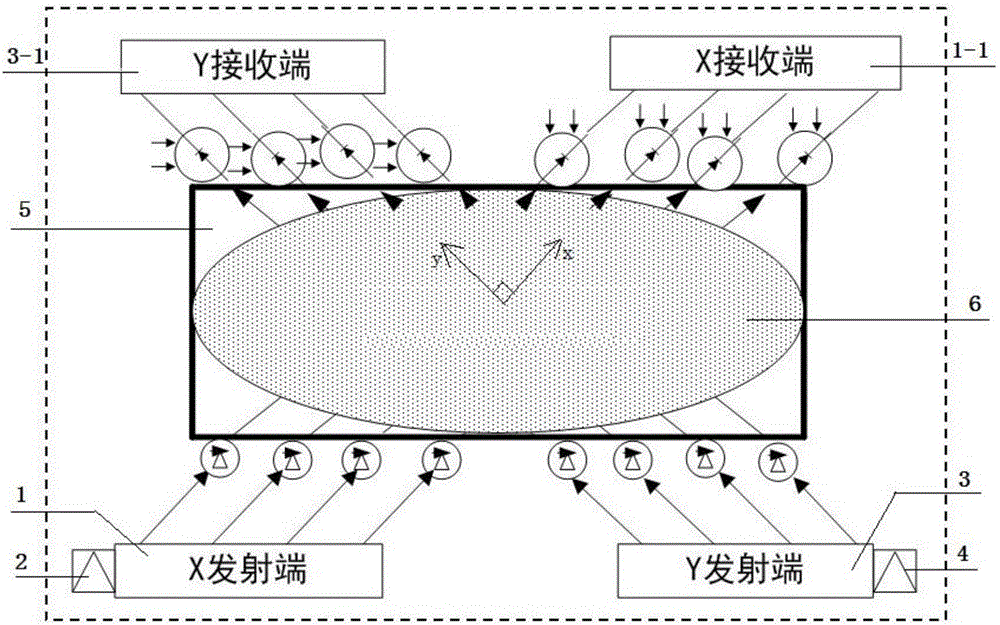

Grain flow measurement device and method based on opposite laser emission type array sensors

PendingCN106197584AShorten the development cycleReduce mistakesVolume/mass flow measurementObservational errorMeasurement device

The invention discloses a grain flow measurement device and method based on opposite laser emission type array sensors. The grain flow measurement device comprises a sensor unit and a single chip microcomputer connected with the sensor unit, wherein the sensor unit comprises eight pairs of opposite laser emission type array sensors, a rotation speed sensor and a dip angle sensor; time consumed when grains shield the eight pairs of sensors from emitting light is calculated through a single chip microcomputer timer, and the volume of the grains in the operation process is calculated in combination with the rotation speed of a scraper; besides, the dip angle of an elevator scraper is measured by the aid of the dip angle sensor, and measurement errors caused by uneven ground are compensated; the grain density is input by means of a keyboard circuit, and the mass flow in unit time of the grains is calculated in combination with the calculated grain volume; the single chip microcomputer calculates grain flow information according to information measured by a sensor module and saves the grain flow information in a storage module, and the grain flow information is displayed in real time through a display. The device and the method can adapt to grain measurement in different environments, and non-contact precision measurement of the grain flow in the scraper of a scraper elevator is realized.

Owner:JIANGSU UNIV

Delivery of particulate material below ground

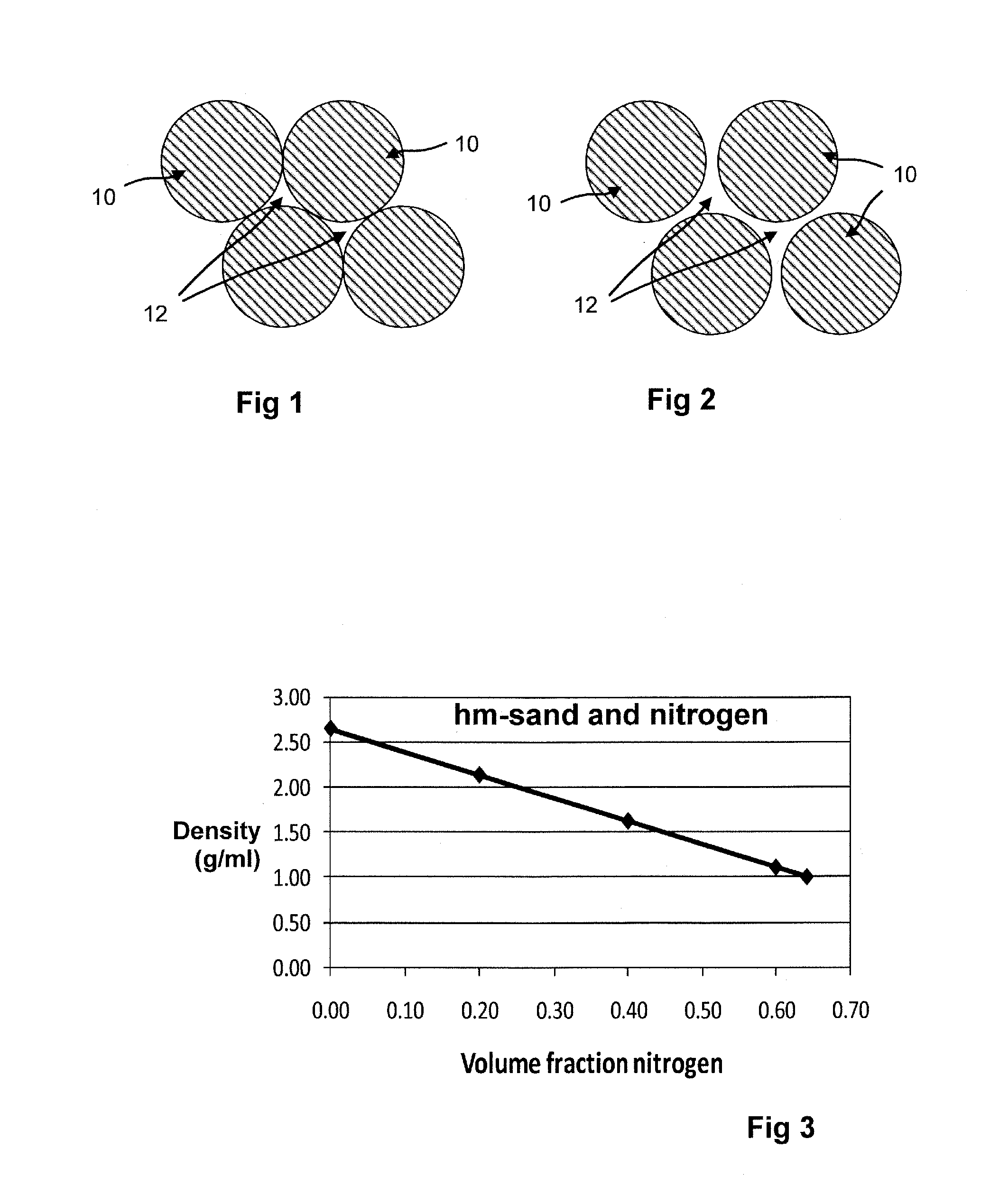

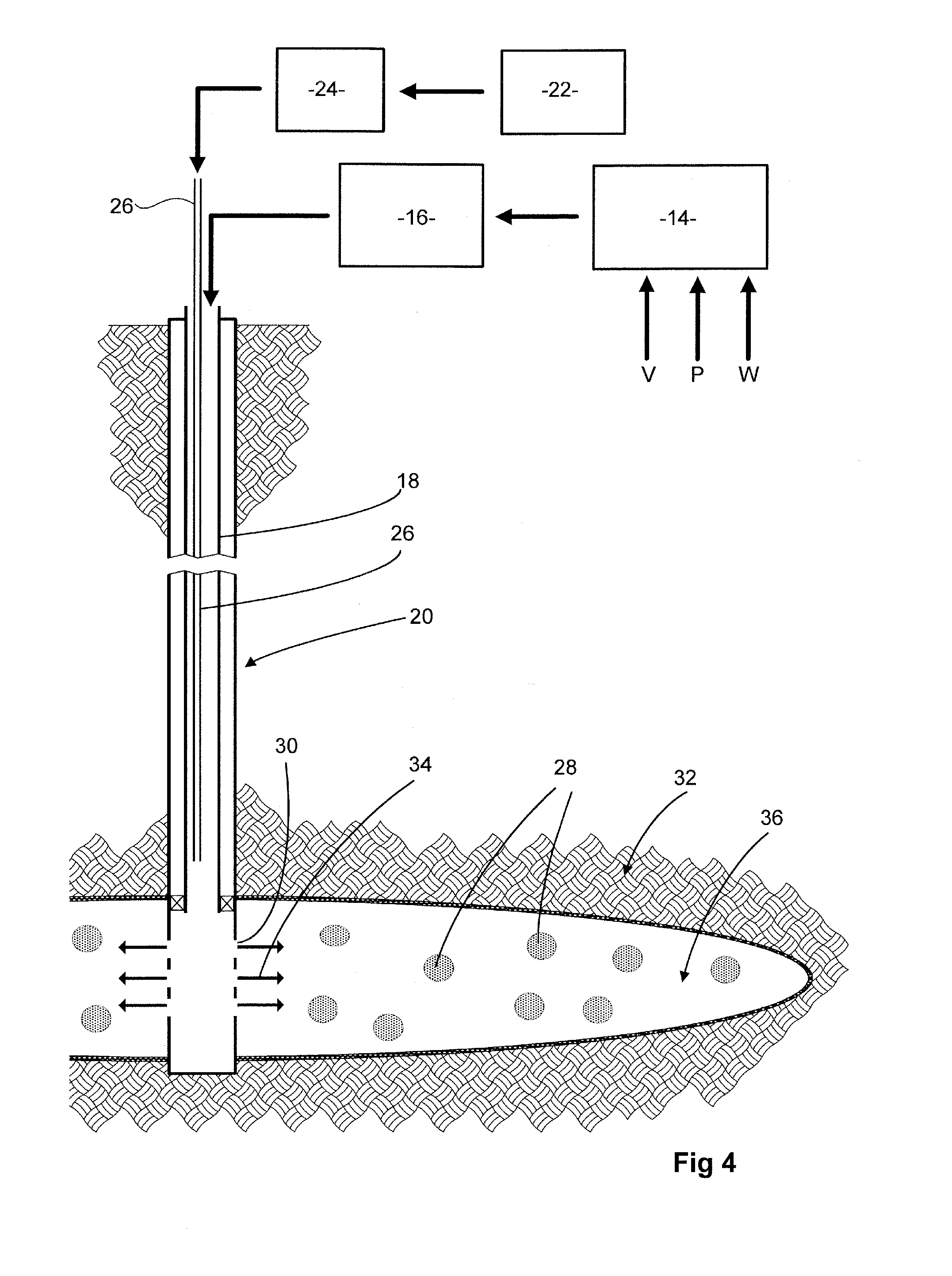

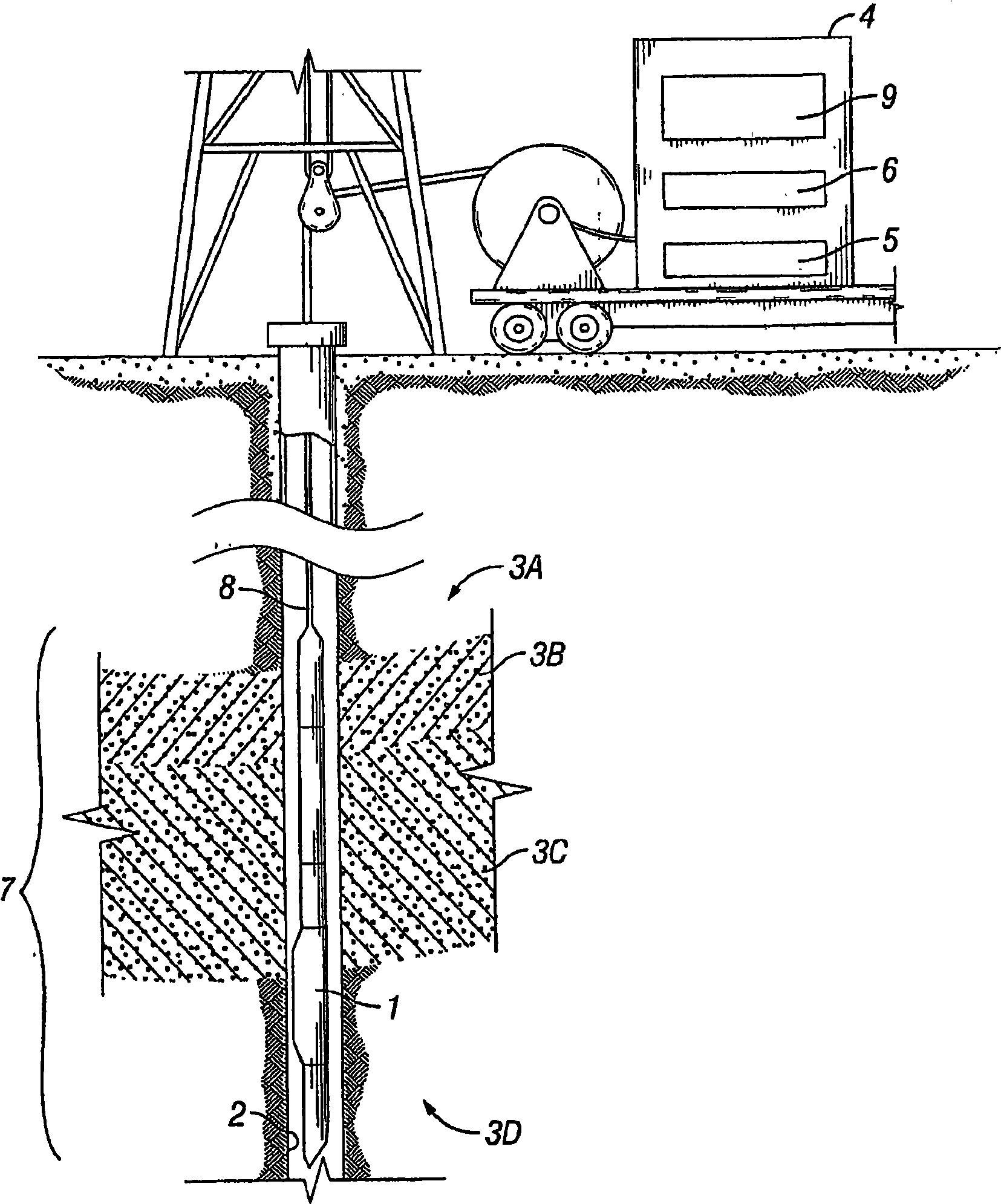

ActiveUS20120048554A1Reduce penetrationEnhancing fracture conductivityFluid removalFlushingSuspended particlesFracturing fluid

A wellbore fluid comprises an aqueous carrier liquid, hydrophobic particulate material suspended therein and a gas to wet the surface of the particles and bind them together as agglomerates. The hydrophobic particulate material has a specified maximum particle size and / or minimum surface area: namely a volume median particle size d50 of not more than 200 micron, determined as median diameter of spheres of equivalent volume and / or a surface area of at least 30 m2 per liter (0.03 m2 per milliliter), determined as surface area of smooth spheres of equivalent volume.The agglomeration of the particles by gas leads to the formation of agglomerates which contain gas and so have a bulk density lower than the density of the particles. This reduces the rate of settling. The fluid is particularly envisaged as a slickwater fracturing fluid in which the suspended particles are proppant. We have found that the small particle size and / or substantial surface area increases the amount of gas which can be retained within agglomerates and so enhances the buoyancy of the agglomerates. The end result is that a greater proportion of a hydraulic fracture is propped open.

Owner:SCHLUMBERGER TECH CORP

Hydroisomerization catalyst manufactured using a high nanopore volume alumina supports

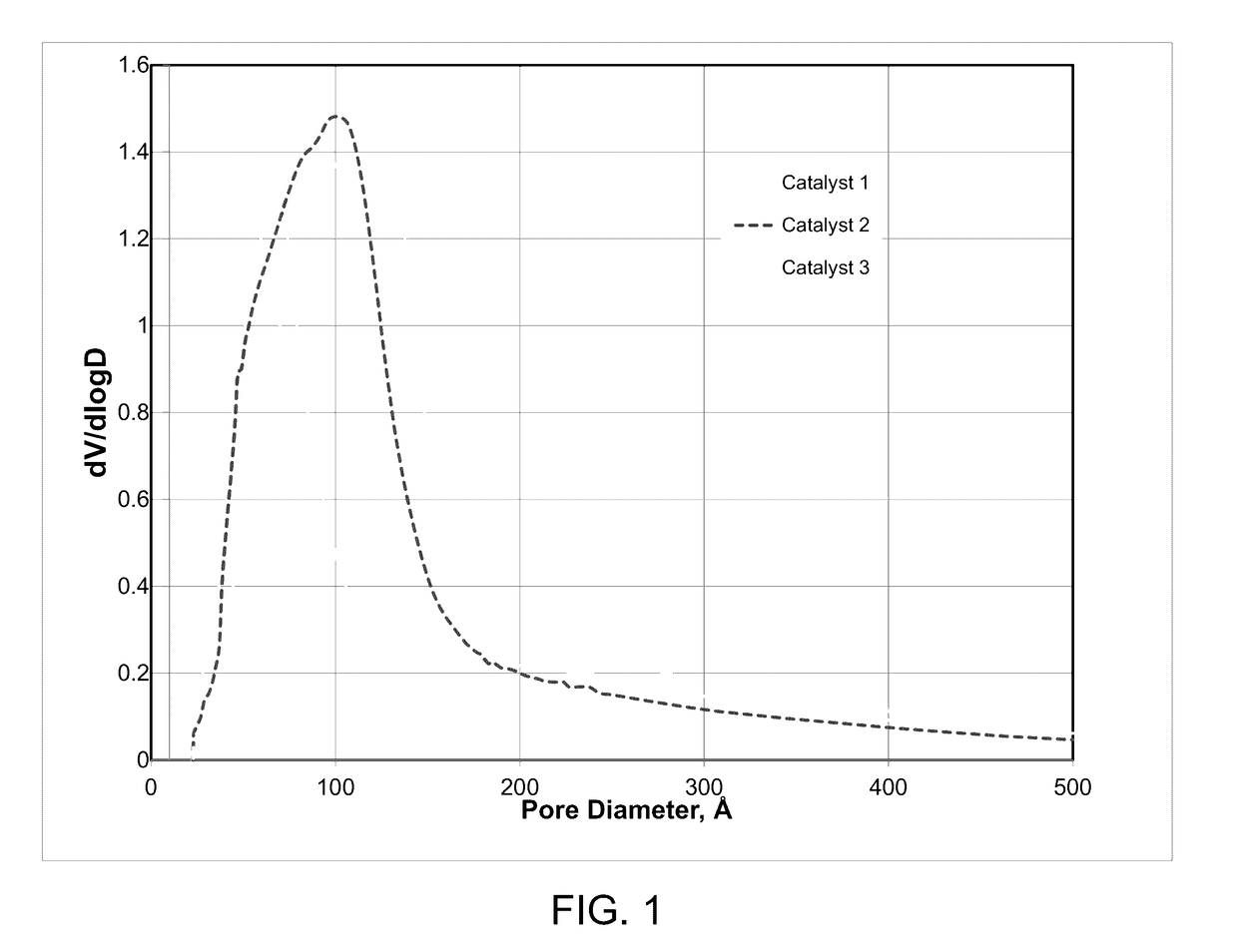

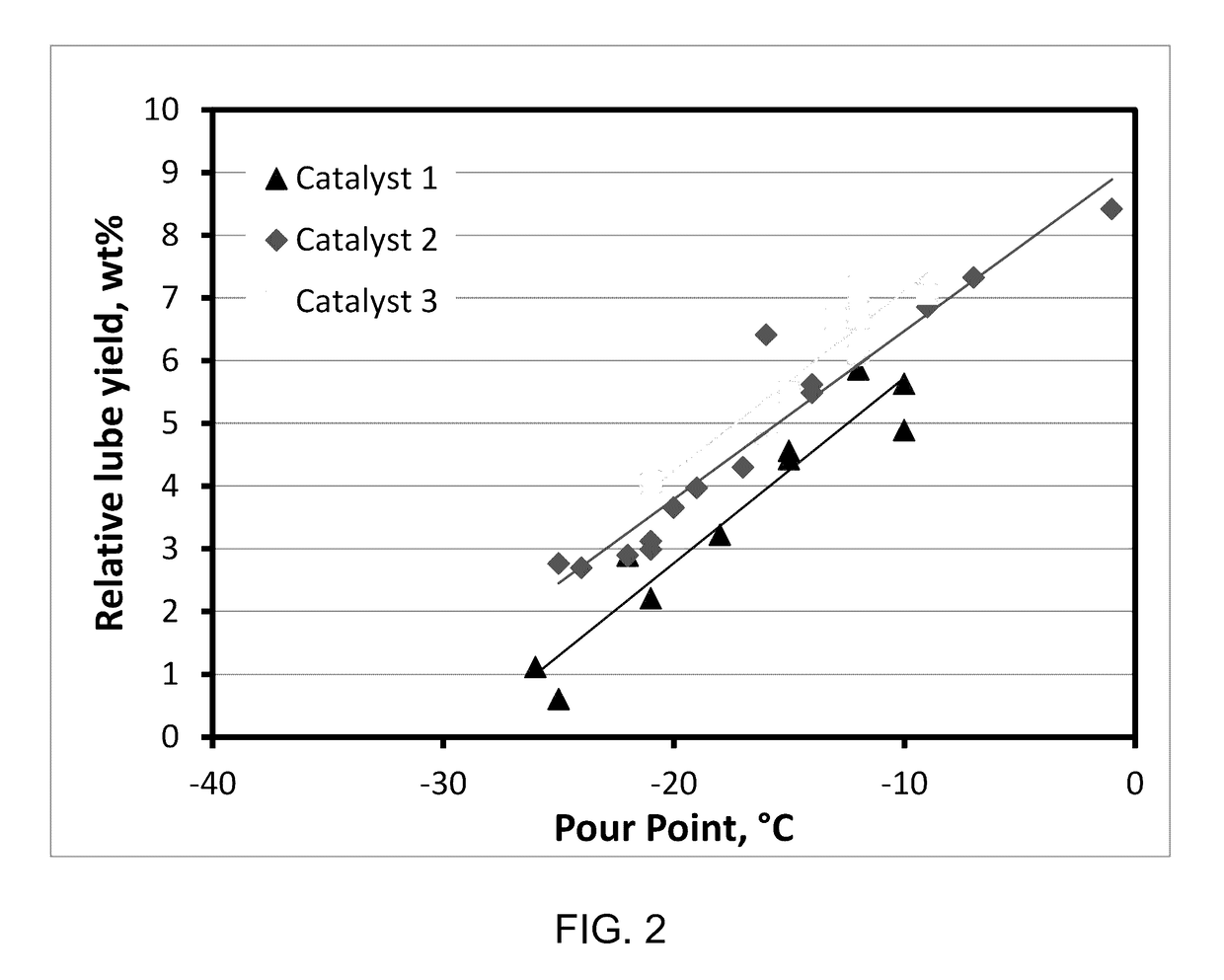

ActiveUS9616419B2Improve efficiencyQuality improvementMolecular sieve catalystsHydrocarbon oils refiningFull width at half maximumParticle density

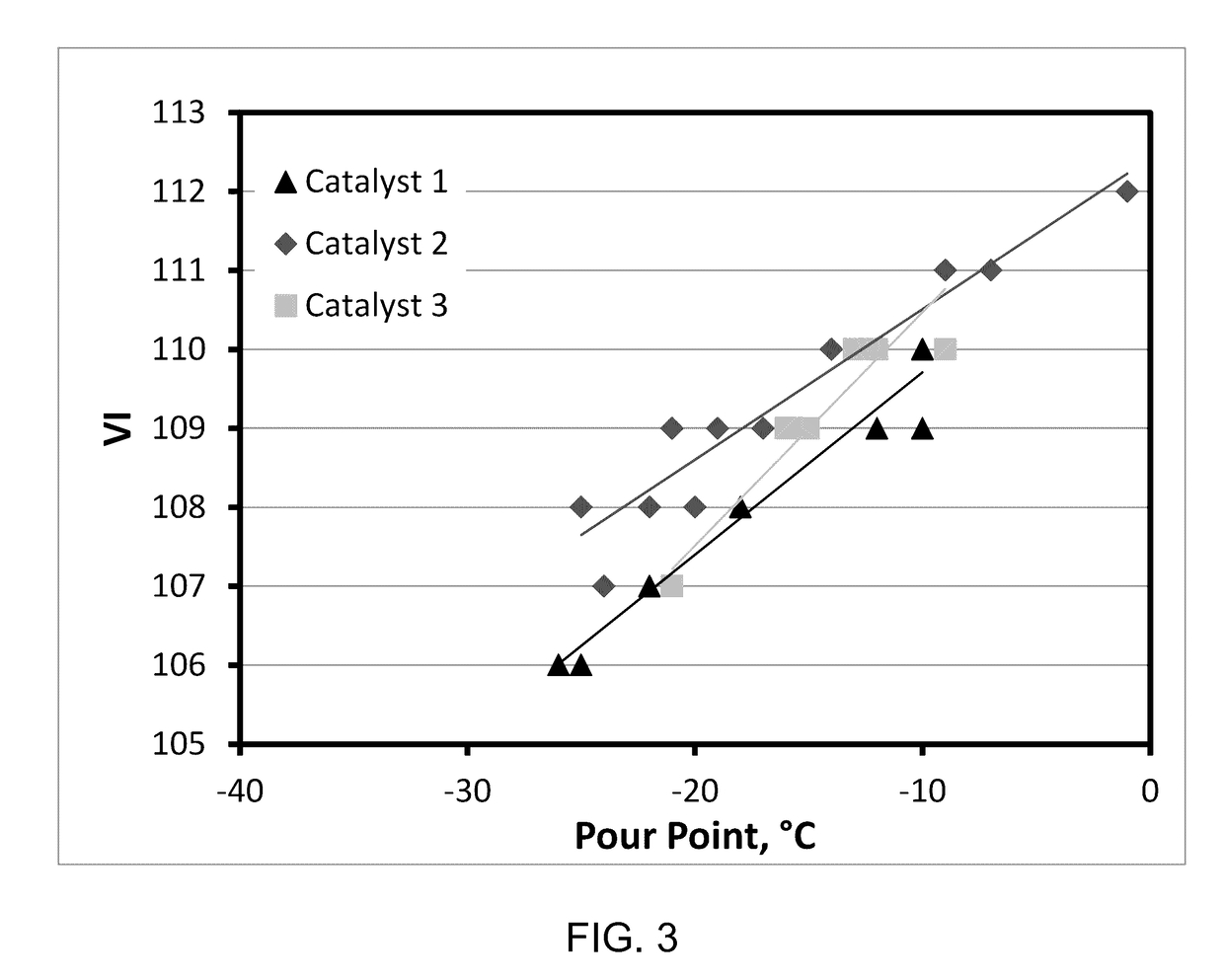

The present invention is directed to an improved finished hydroisomerization catalyst manufactured from a first high nanopore volume (HNPV) alumina and a pore size distribution characterized by a full width at half-maximum, normalized to pore volume, of 15 to 25 nm·g / cc, and a second HNPV alumina having a pore size distribution characterized by a full width at half-maximum, normalized to pore volume, of 5 to 15 nm·g / cc. Their combination yields a HNPV base extrudate having a low particle density as compared to a conventional base extrudates.

Owner:CHEVROU USA INC

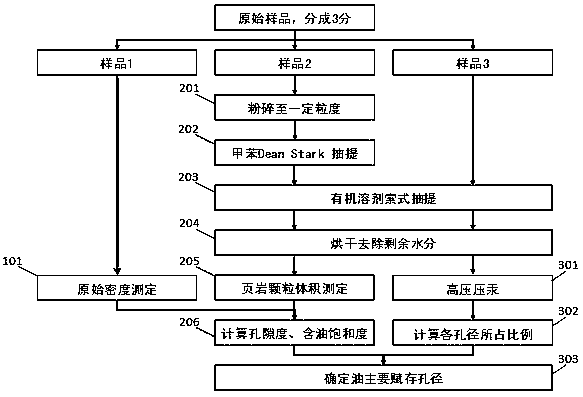

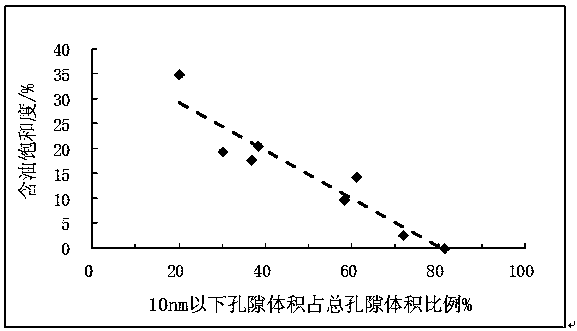

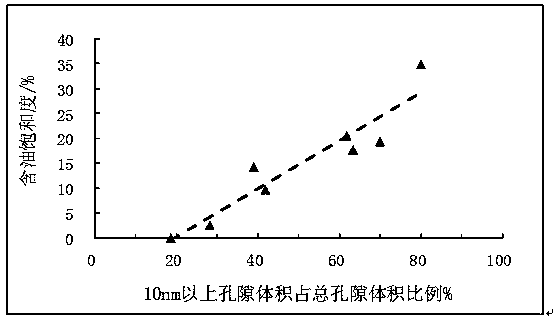

Method for researching main pore size range of shale oil

ActiveCN107907461AMeasure objectivelyWeighing by removing componentPermeability/surface area analysisSoil sciencePore diameter

The invention provides a method for researching the main pore size range of shale oil. The method for researching the main pore size range of shale oil comprises the following steps: selecting a series of oil-bearing shale samples in a research unit, and dividing the oil shale sample into three parts which are a sample 1, a sample 2 and a sample 3 respectively; determining the bulk density of theshale by using the sample 1; determining the oil content and the grain density of the shale by using the sample 2; calculating the proportions of pores having different pore sizes by using the sample3; calculating the porosity and the oil saturation of the shale according to the bulk density, the grain density and the oil content of the shale, obtained in experiments; and determining the main pore size range of the shale oil according to the relationship between the oil saturation of the shale and the volume proportion of pores having different pore sizes in the total pore volume of the shale. The relationship between the oil saturation and the proportions of all the pore sizes, established through the method for researching the main pore size range of shale oil can objectively quantitatively research the main pore size range of shale oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for solving water lock effect

ActiveCN103450867AThe technical method is simpleEasy to operateDrilling compositionMetallurgySmall hole

The invention discloses a method for solving a water lock effect. By adopting the method, functional powder is added to a duct for producing a water lock, so as to remove the water lock. The functional powder is mixed powder formed by amphiphilic powder or super-hydrophilic powder and hydrophobic powder; the grain density of the functional powder is greater than 1 g / cm<3>; the mean grain size of the functional powder is smaller than 100 microns. The method disclosed by the invention is simple and feasible, convenient to operate, wide in material source, and low in cost. Meanwhile, the liquid-phase interfacial tension can be reduced by the functional powder in the using process of the method disclosed by the invention; the functional powder is in a small-granule solid state, so that the functional powder is easily left in a small hole or a gap in the rock surface, and has strong durability on inhibition of a damage of the water lock. In addition, compared with an acidification method, the flow-back effect of the method is greatly improved, so that the water lock effect can be better solved; the productivity of an oil well is greatly also improved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

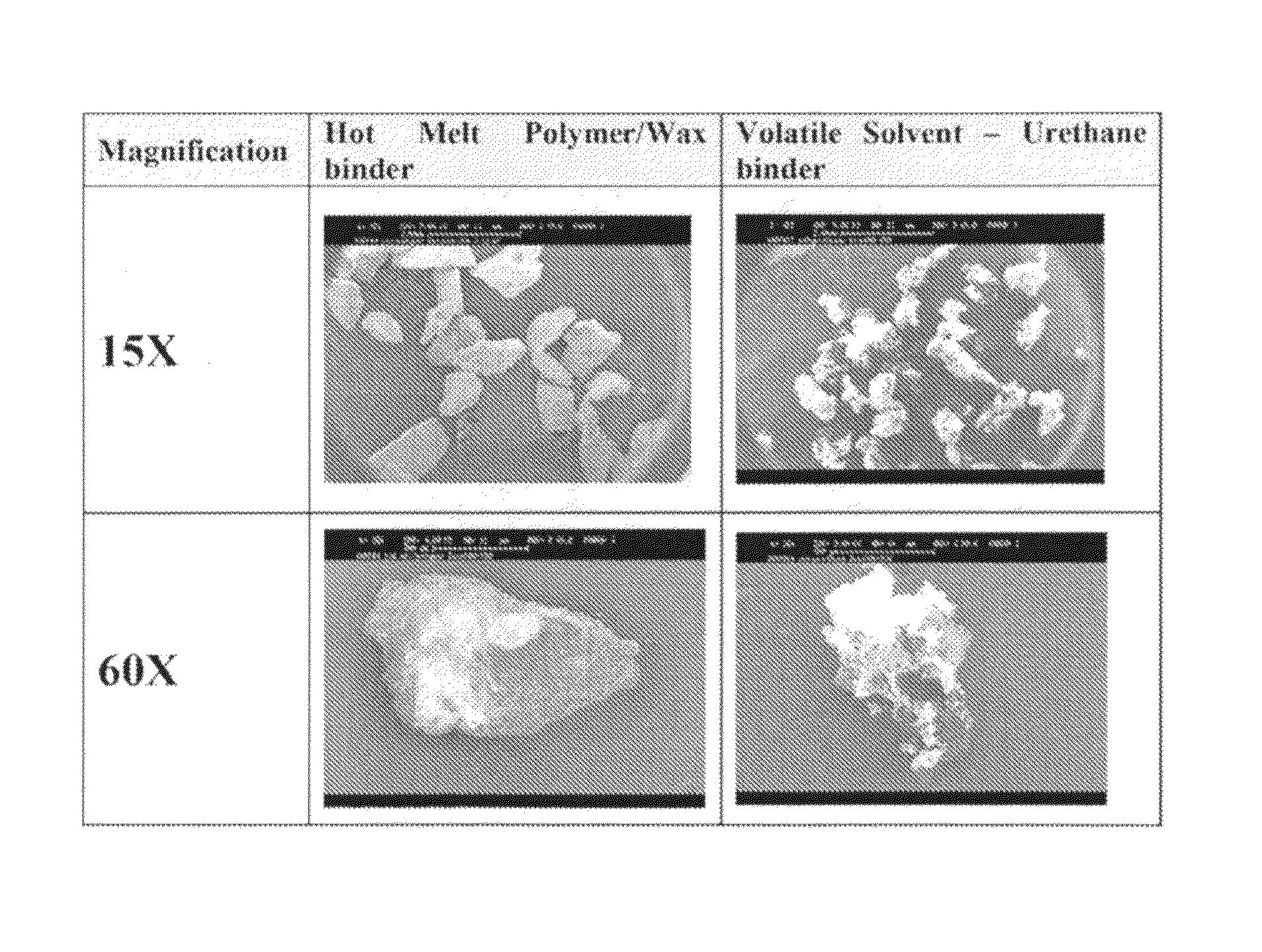

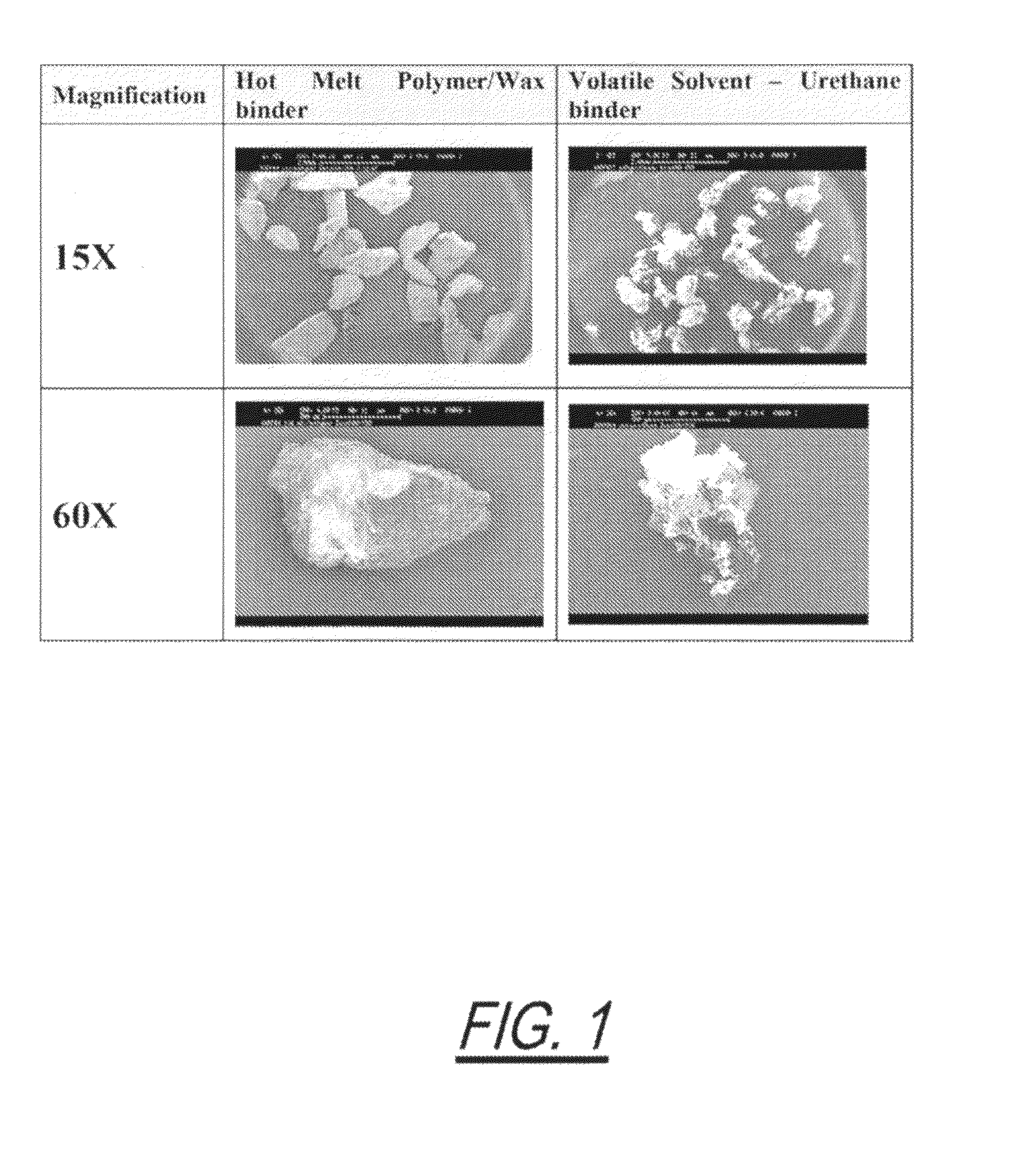

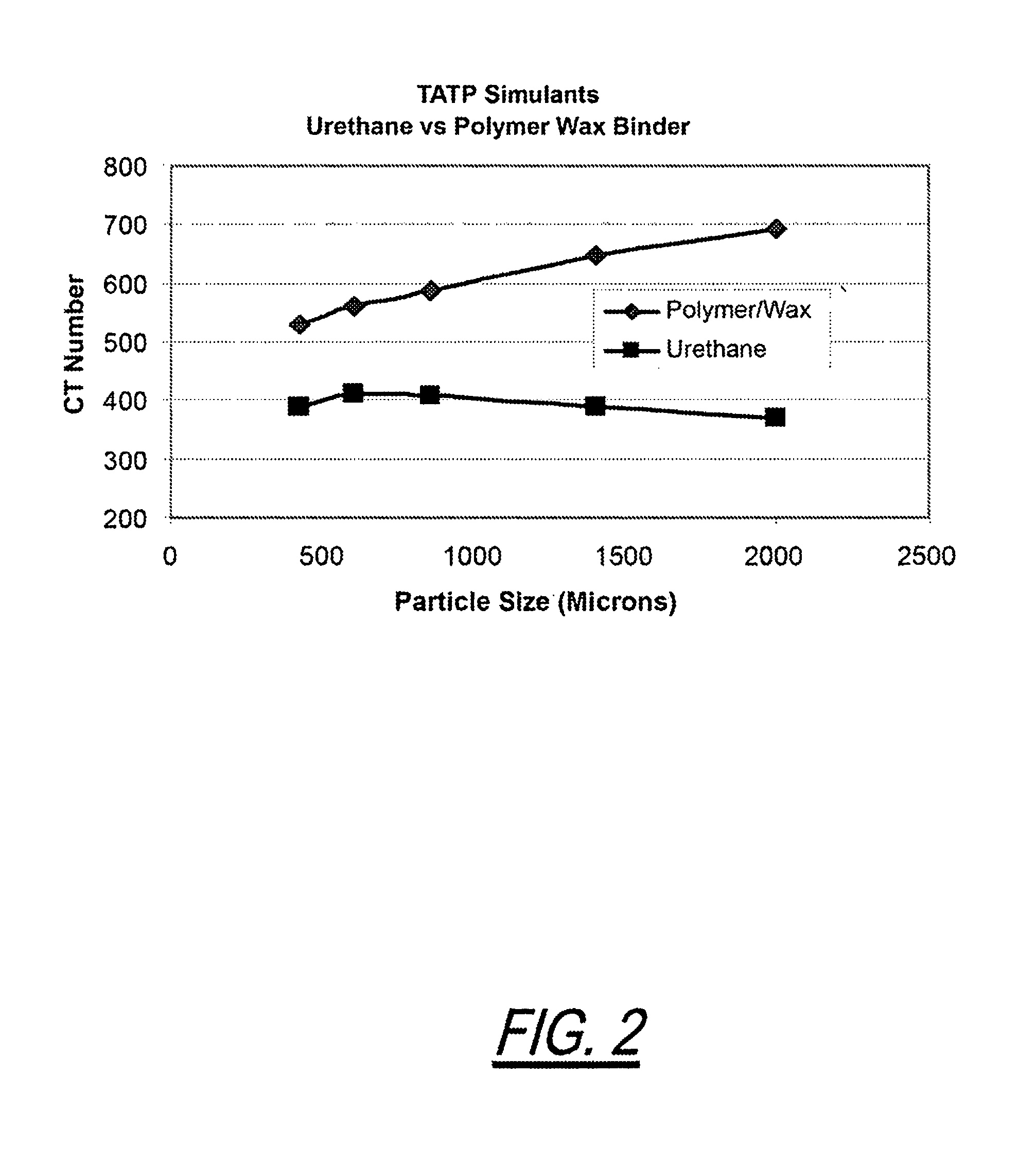

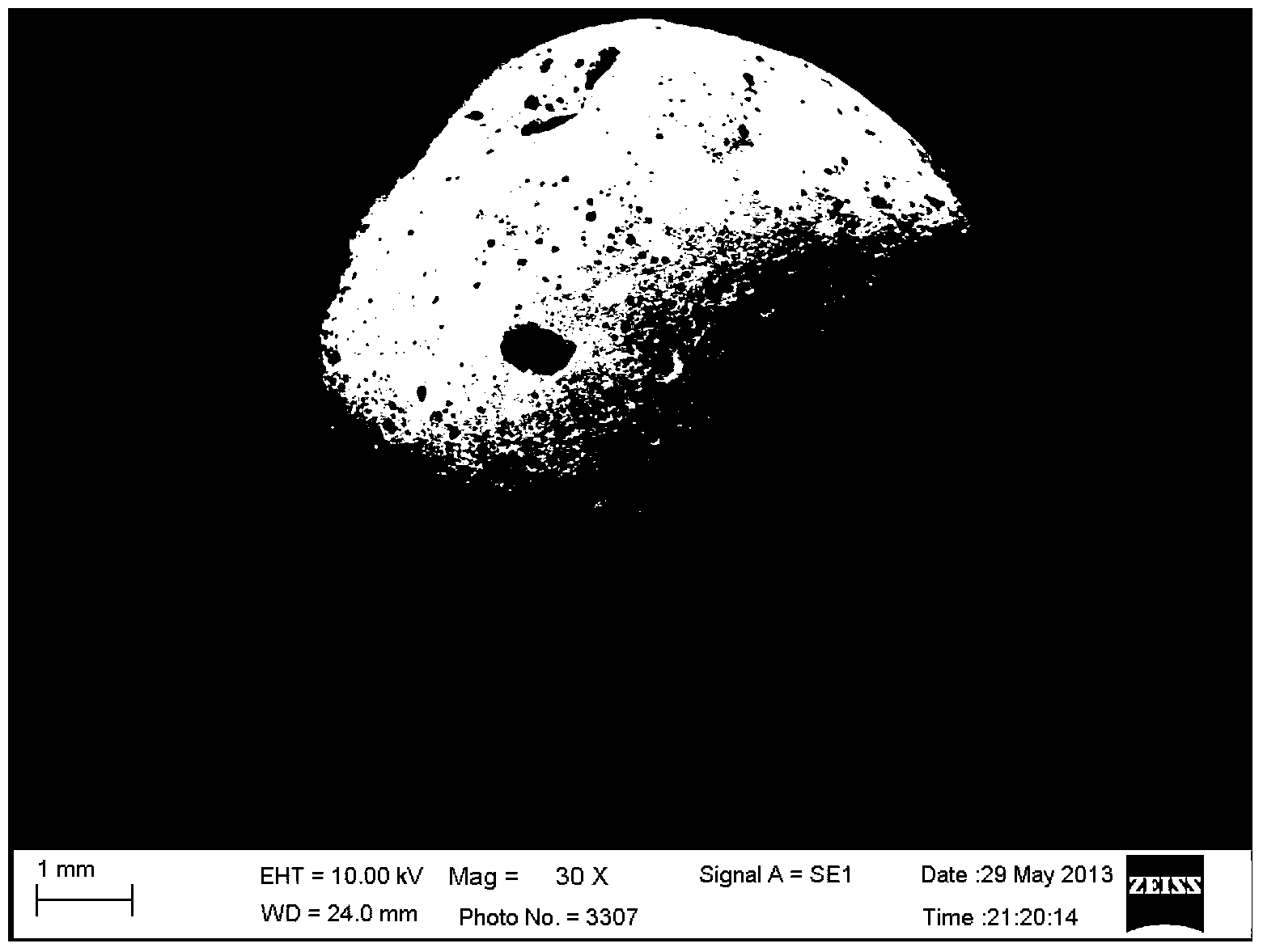

Inert and non-toxic explosive simulants and method of production

The present disclosure describes simulants and methods of production thereof that imitate characteristics of known explosives, including characteristics at the microscopic and macroscopic level. For instance, the present disclosure includes a simulant with the same texture, granularity, bulk density, particle density, and porosity of a known explosive. The simulants described herein provide the macroscopic bulk physical properties and the microscopic scale properties of actual explosives.

Owner:US DEPT OF HOMELAND SECURITY

Suspension ceramsite filter material for water treatment and production method thereof

InactiveCN103304241AReduce breakage rateReduce wear rateSustainable biological treatmentBiological water/sewage treatmentPorosityWater source

The invention discloses a suspension ceramsite filter material for water treatment and a production method of the suspension ceramsite filter material. The method comprises the following steps of: crushing shale which serves as a raw material through a crusher, drying the shale, milling the shale through a ball mill, granulating the shale through a rotary table granulator, and firing in a rotary kiln at the firing temperature of 1,100 to 1,300 DEG C for 18 to 22min; naturally cooling and sieving ceramsites, selecting a grain size of 8 to 12mm, and floating in a water pool under the aeration intensity of 3 to 5L / (m<2>.s) to obtain floatation ceramsites; and wetting the floatation ceramsites in water to obtain the grain density of 0.9 to 1.1g / cm<3>. Shale ceramsites have the characteristics of hydrophilic surface, roughness, porosity, film formation, difficulty in dropping of a bio-film, large specific surface area and high mechanical strength, have the advantages of difficulty in hardening of a suspension filler, uniform water distribution and air distribution, low filtering head loss, light weight and washability, and are suitable for serving as bio-mass carriers for biological sewage treatment and biological micro-polluted water source water supply treatment.

Owner:SOUTH CHINA UNIV OF TECH

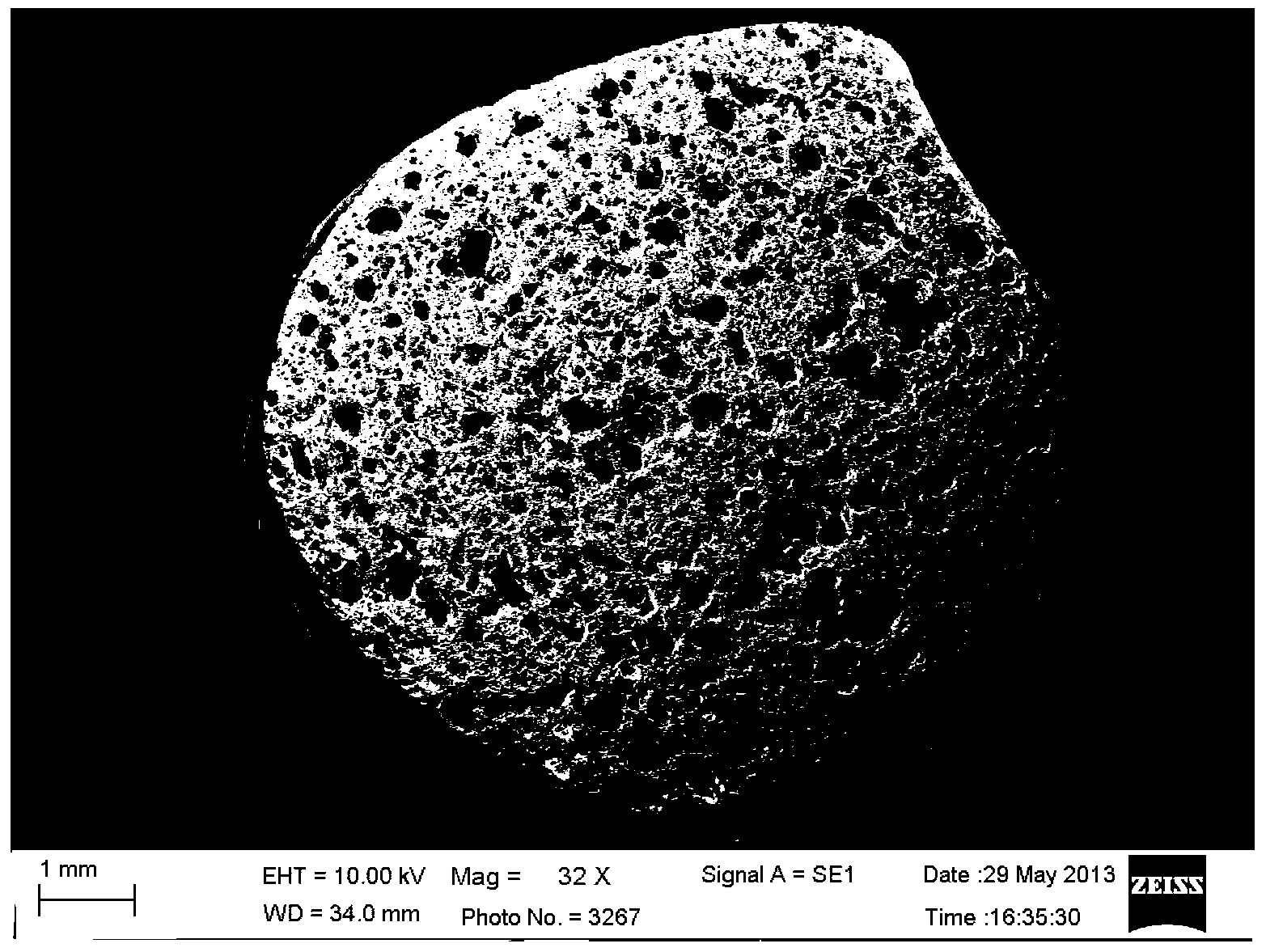

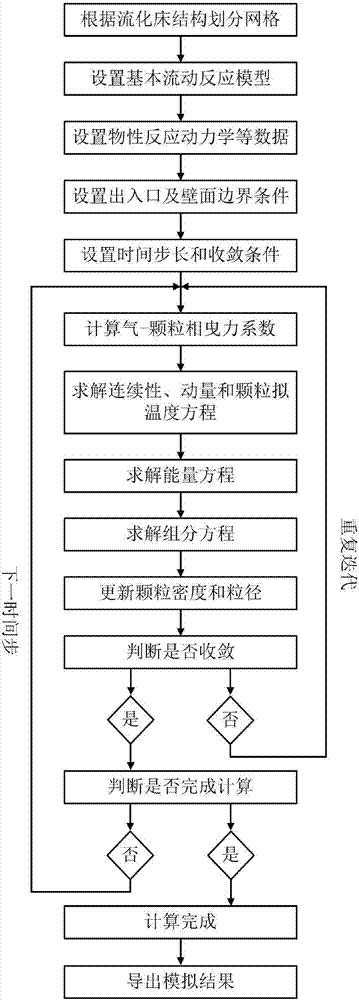

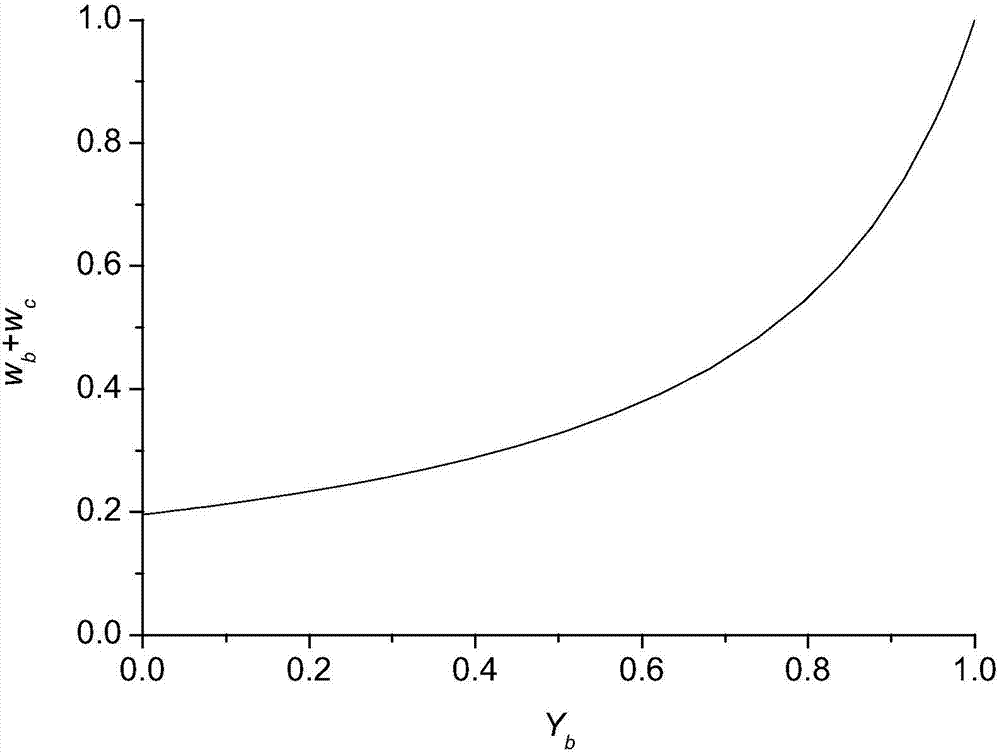

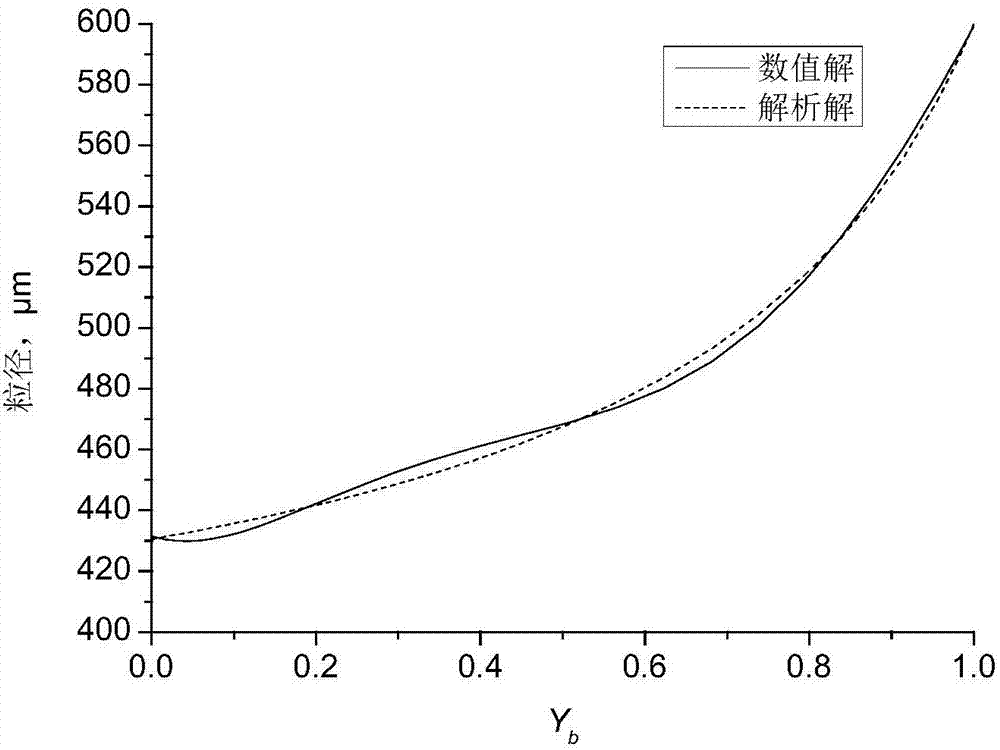

Method for simulating fluidized bed with dynamic changes of grain density and particle size

ActiveCN107132156APredicting Flow Response PropertiesSave human effortFlow propertiesDesign optimisation/simulationExperimental researchMathematical model

The invention discloses a method for simulating a fluidized bed with dynamic changes of grain density and particle size. The method comprises the following steps: 1, establishing a basic flow reaction model in the fluidized bed; 2, establishing a mathematical model for describing a change rule of the grain phase density and particle size; 3, establishing a particle type sectioned drag model; and 4, predicting flow reaction characteristics in the fluidized bed. According to the method disclosed by the invention, the fluidized bed with dynamic changes of grain density and particle size is subjected to simulation study by adopting a computational fluid mechanics method, the mathematical model for describing a change rule of the grain phase density and particle size is combined to perform real-time correction on the density and particle size of the particles, and the acting force between gas-particle phases in a coexisting system of multiple particle types through the particle type sectioned drag model, so that the flow reaction characteristics in the fluidized bed with the dynamic changes of grain density and particle size are accurately predicted. According to the method, lots of complicated and expensive experiment researches are not needed, and lots of manpower and material resources and time cost can be saved.

Owner:XI'AN PETROLEUM UNIVERSITY

Method of high shear comminution of solids

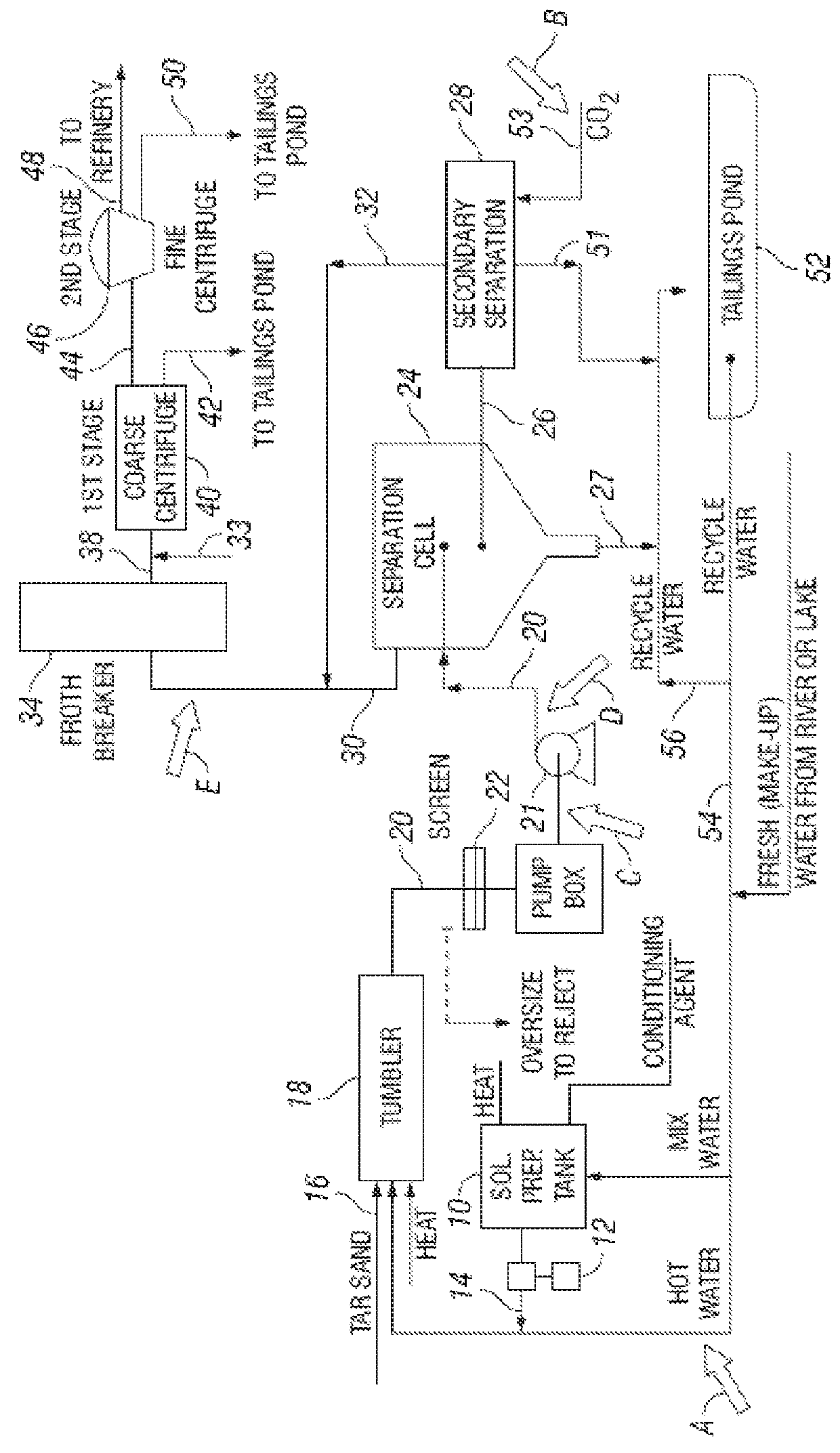

InactiveUS9227196B2Refining by water treatmentLiquid hydrocarbon mixture productionSolid componentParticle density

Herein disclosed in a method comprising: shearing a feed comprising a solid component in a high shear device to produce a product, at least a portion of which comprises sheared solids; and separating at least some of the sheared solids from the product to produce a component-reduced product, wherein the solid component in the feed stream comprises a first particle density, and wherein the sheared solids in the product comprise a second particle density greater than the first particle density. In some embodiments, the solid component of the feed comprises gas trapped therein, and wherein at least a portion of said gas is released from the solid component upon shearing. Herein also is disclosed a method of comminuting solids in a feed stream comprising a solid component by processing the feed stream in a high shear device to produce a product stream comprising comminuted solids.

Owner:HRD CORP

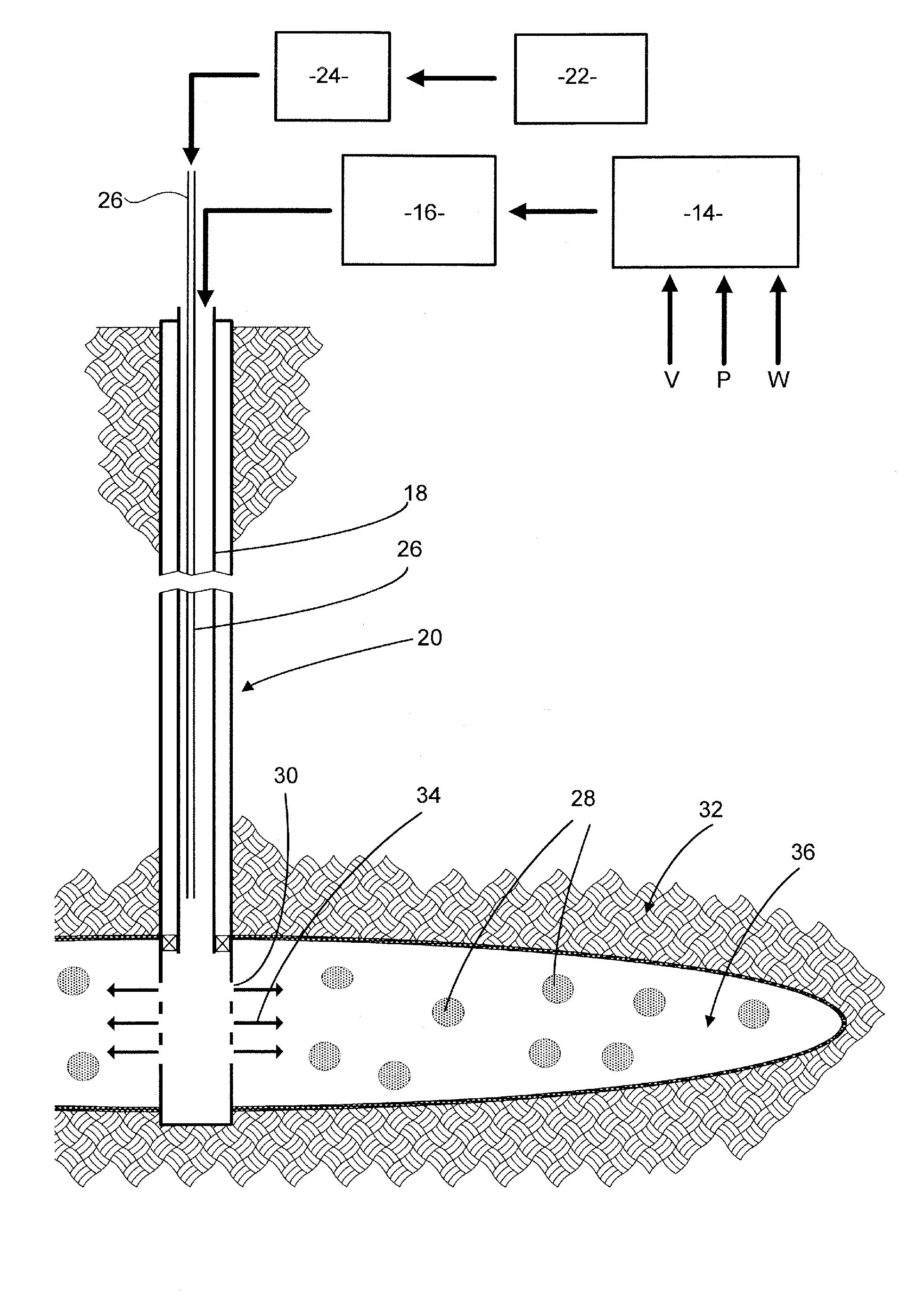

Methods for quantitative lithological and mineralogical evaluation of subsurface formations

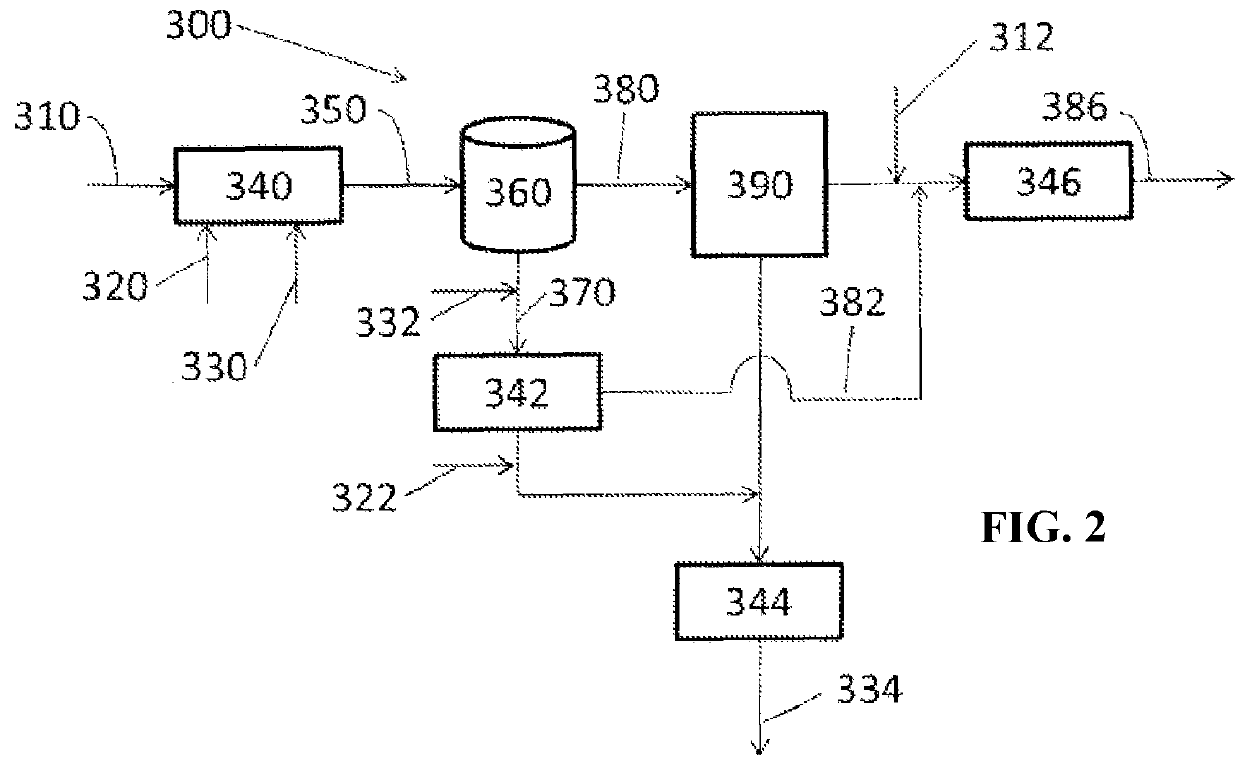

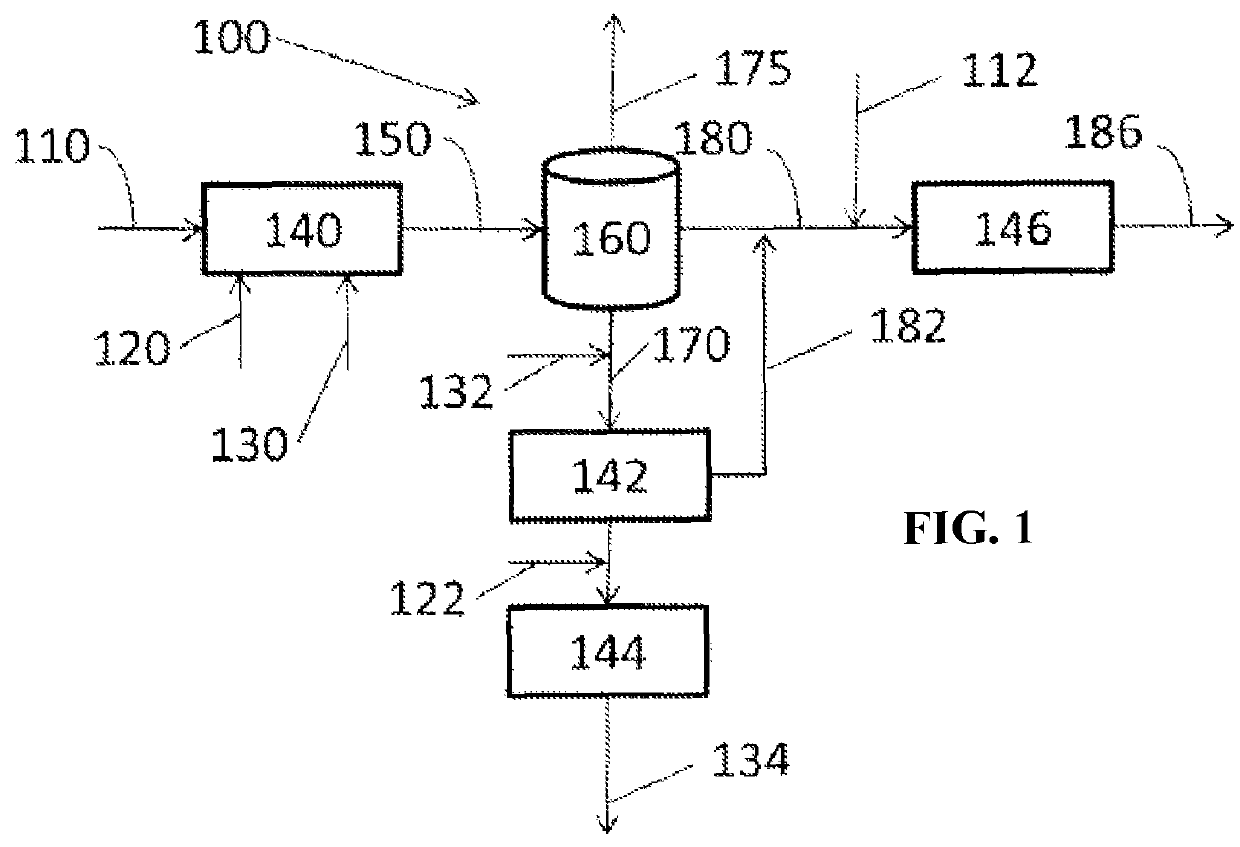

Methods and processes for determining the lithology as well as the mineralogy are described. According to the methods and processes, well log data measurements from neutron spectroscopy applications and associated tool response parameters are solved using an artificial intelligence system, such as an expert system, which in turn generates an appropriate discriminator and / or compositional model that estimates both general and specific lithology as well as the mineralogy constraints of the subterranean formation being analyzed. The methods exhibit good elemental correlation between conventional methods of lithology and mineralogy determination, and can provide numerous output data, including grain density and porosity data within zones of the formation.

Owner:BAKER HUGHES INC

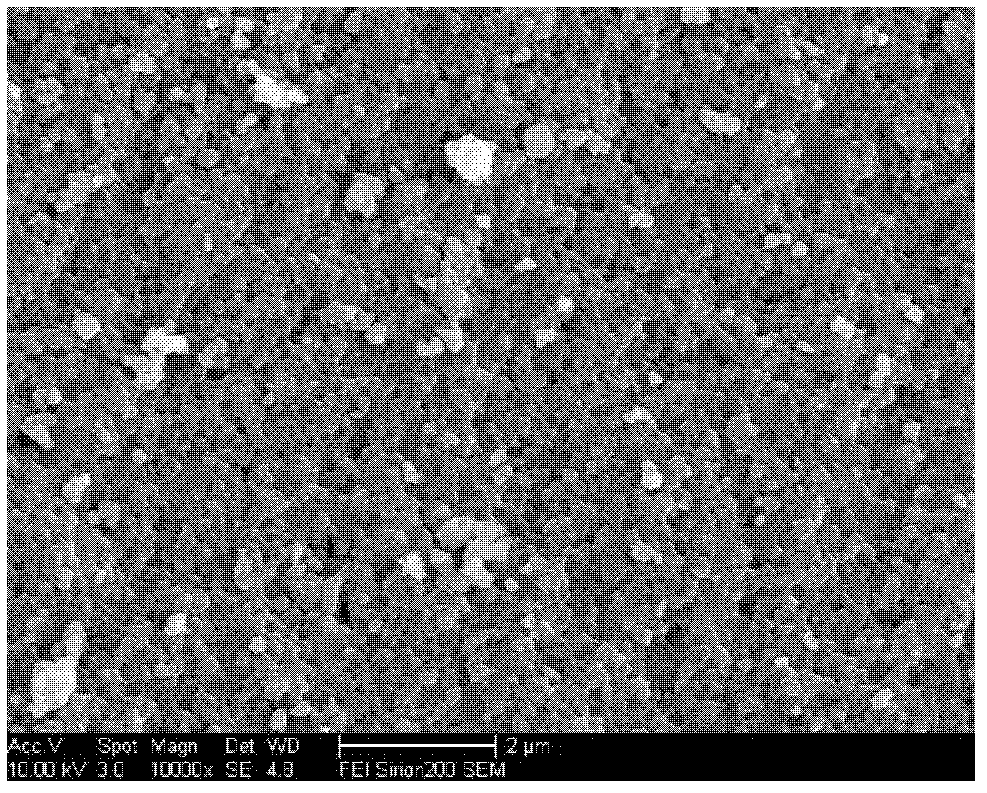

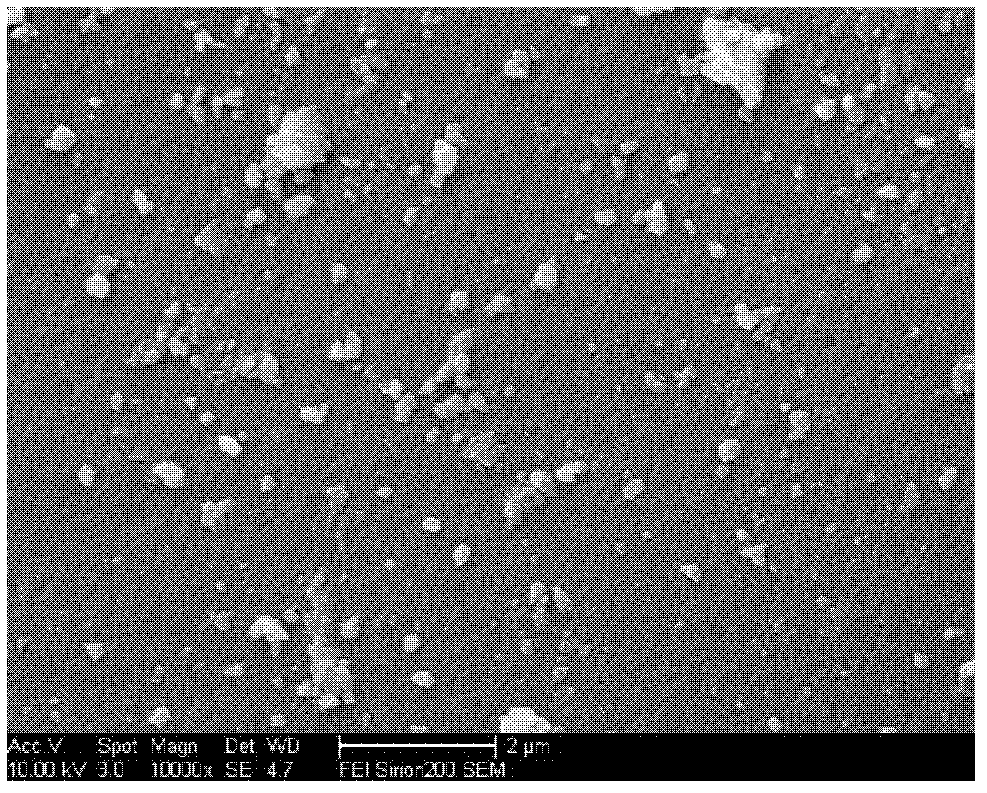

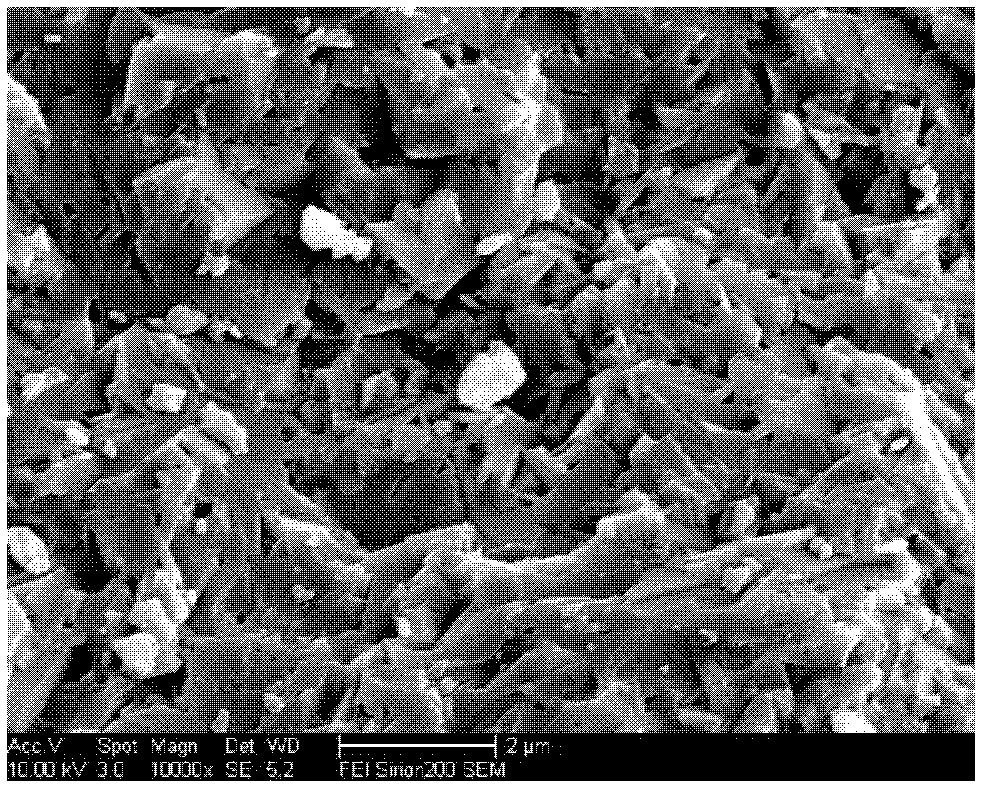

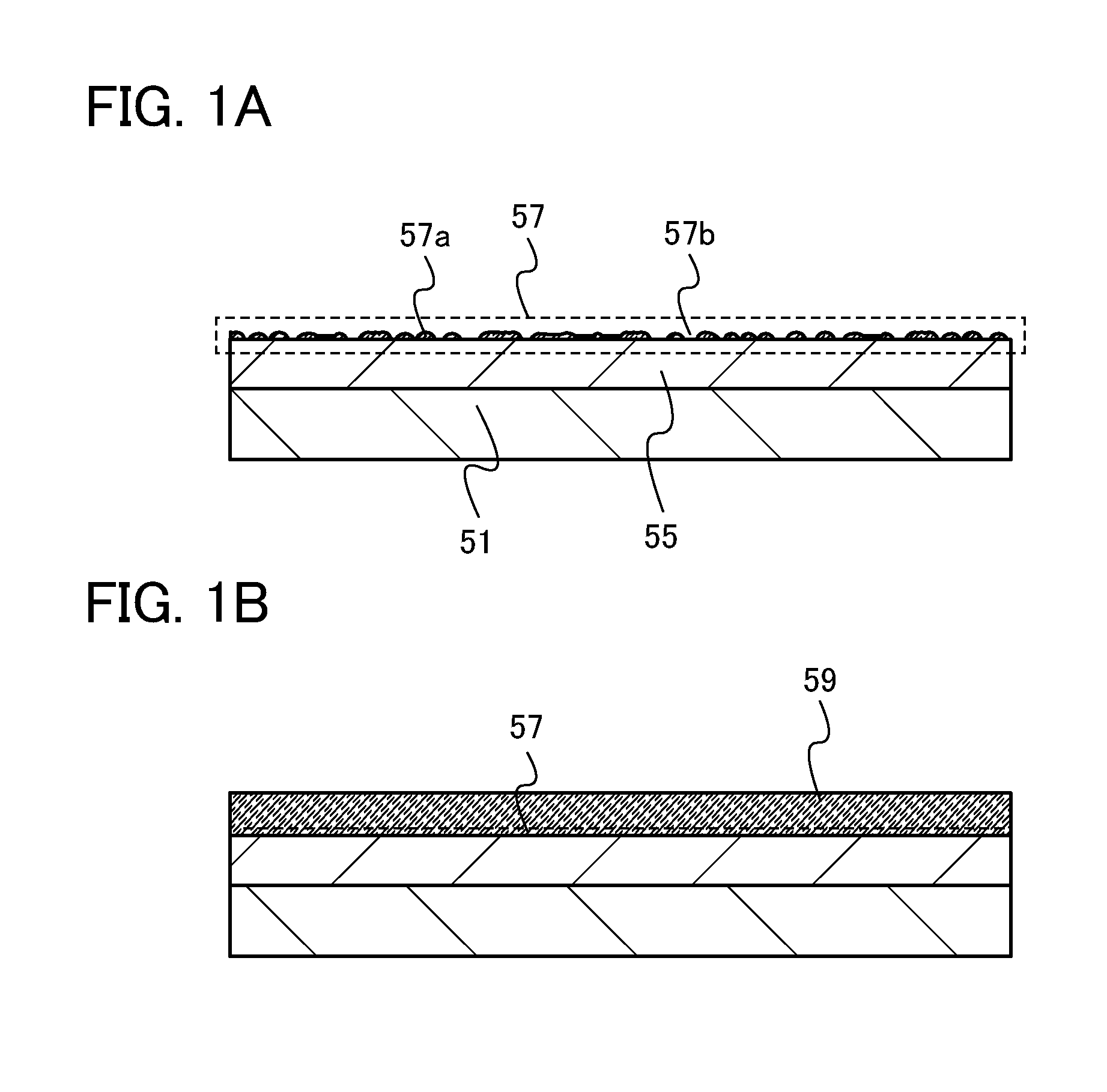

Method for forming microcrystalline semiconductor film and method for manufacturing semiconductor device

InactiveUS20120021570A1High crystallinityExcellent electrical propertiesPolycrystalline material growthSemiconductor/solid-state device manufacturingPower semiconductor deviceHydrogen

A seed crystal including mixed phase grains having high crystallinity with a low grain density is formed under a first condition, and a microcrystalline semiconductor film is formed over the seed crystal under a second condition which allows the mixed phase grains in the seed crystal to grow to fill a space between the mixed phase grains. In the first condition, the flow rate of hydrogen is 50 times or greater and 1000 times or less that of a deposition gas containing silicon or germanium, and the pressure in a process chamber is greater than 1333 Pa and 13332 Pa or less. In the second condition, the flow rate of hydrogen is 100 times or greater and 2000 times or less that of a deposition gas containing silicon or germanium, and the pressure in the process chamber is 1333 Pa or greater and 13332 Pa or less.

Owner:SEMICON ENERGY LAB CO LTD

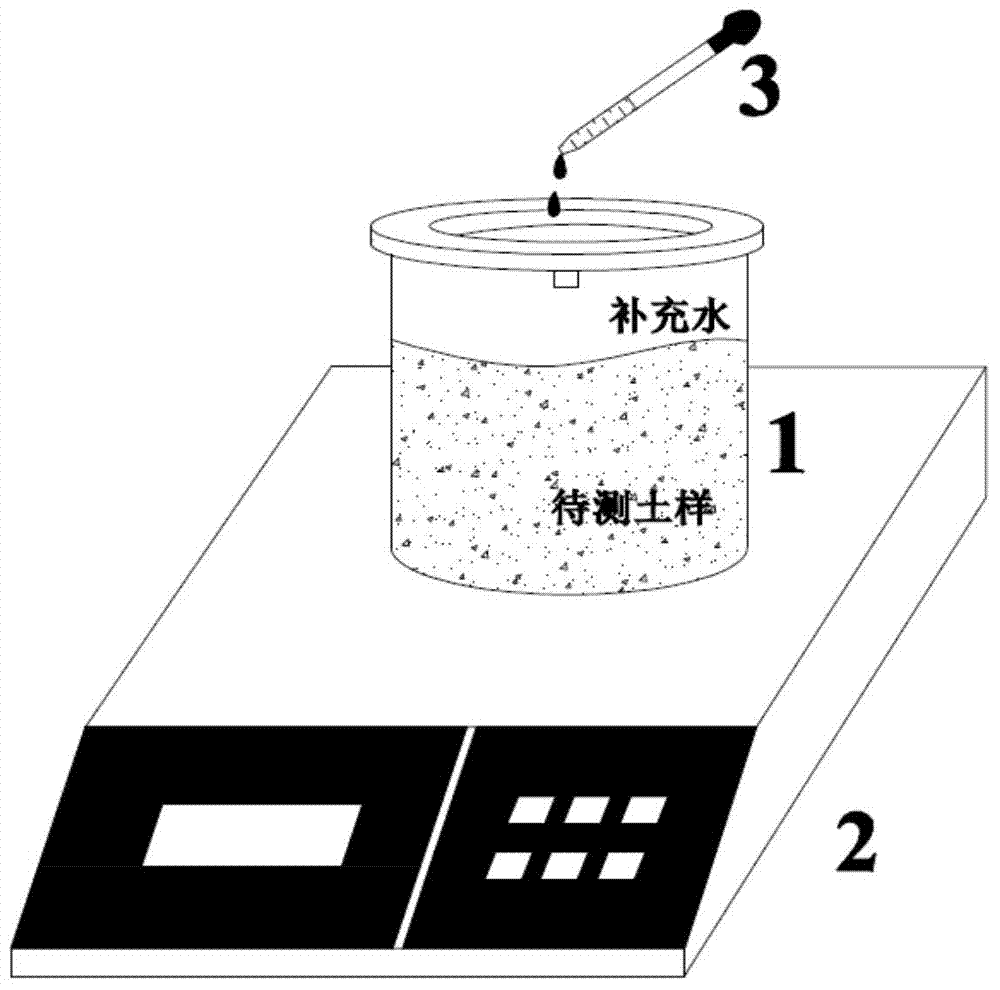

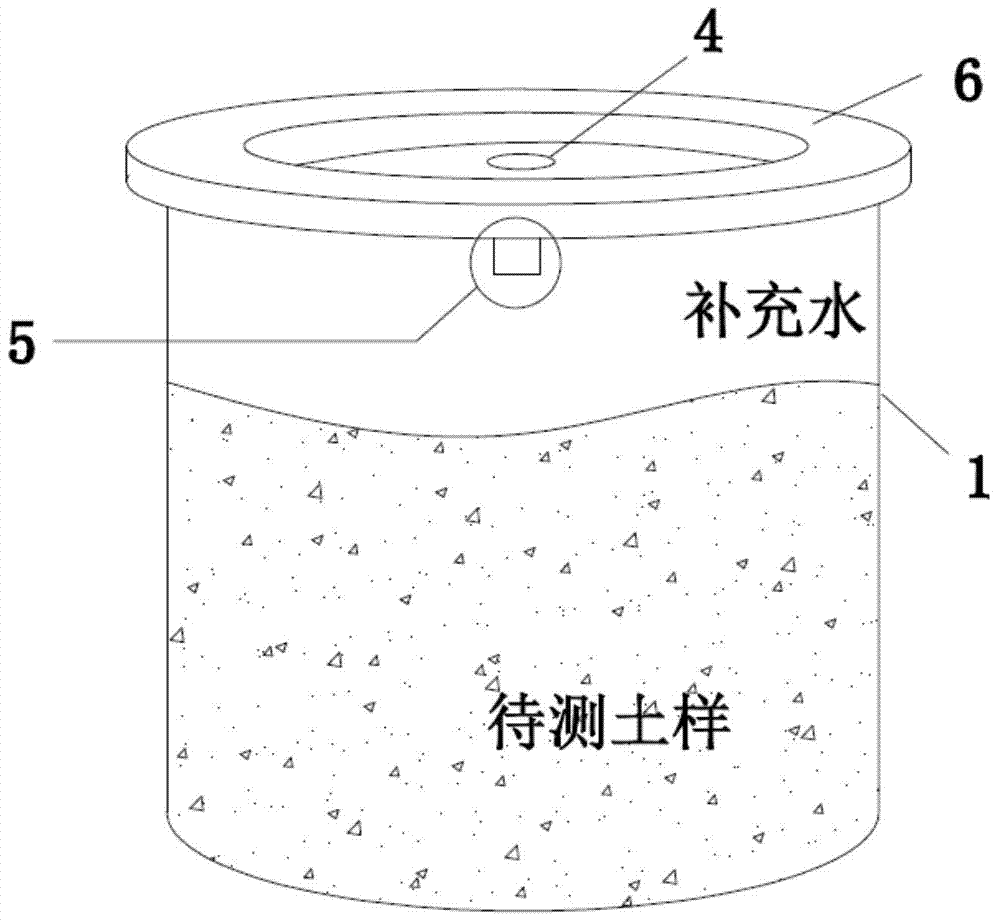

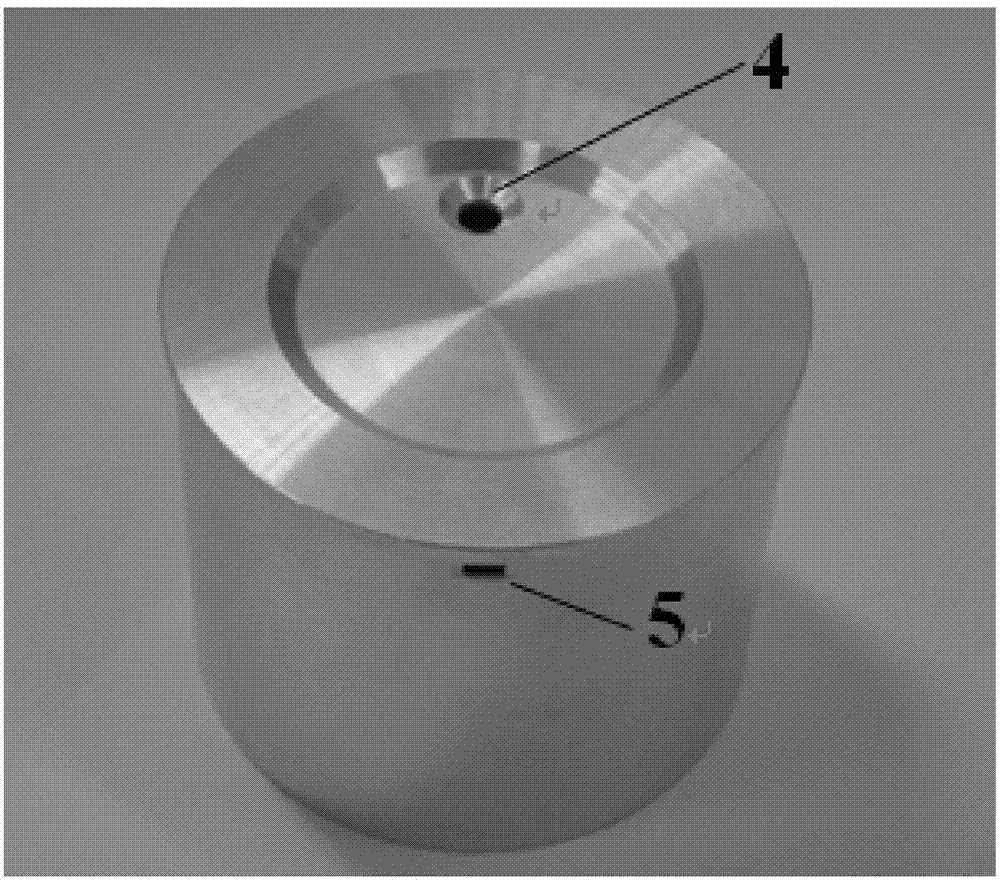

Volume substitution method for measuring soil grain density and equipment

InactiveCN103592201AEasy to operateOvercome operational complexitySpecific gravity measurementSubstitution methodEquipment use

The invention provides a volume substitution method for measuring soil grain density. A soil grain volume is calculated according to a water injection volume by a volume substitution mode; the soil grain mass can be obtained through drying and weighing, and therefore, the soil grain density can be calculated. The volume substitution method for measuring the soil grain density is implemented by a wet method or a dry method. The invention also provides equipment used in the method. The equipment consists of a constant volume vessel, weighing equipment, water injection equipment and drying equipment, wherein the constant volume vessel is used for containing a soil sample to be measured; the water injection equipment is used for injecting water into the constant volume vessel; the drying equipment is used for drying the soil sample to be measured; the weighing equipment is used for weighing the mass. The method disclosed by the invention can be suitable for measurement of the grain density of soil with any property; the operation process is simple and convenient; the long-term problems of complexity in operation, boundedness in measurement range and the like which exist in a pycnometer method, a floating weighing method, a siphon tube method and the like which are used for measuring the soil grain density are solved.

Owner:CHINA AGRI UNIV

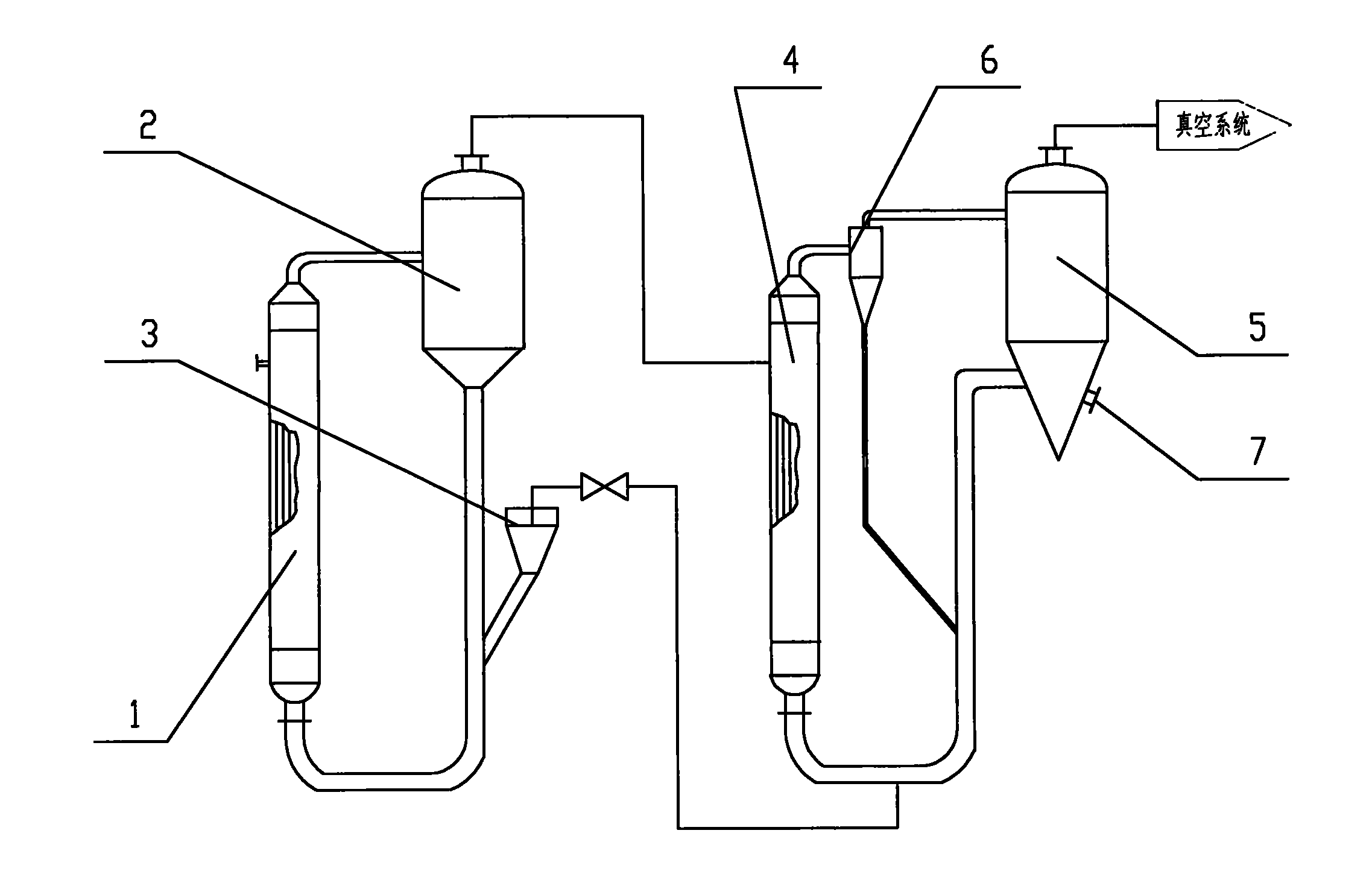

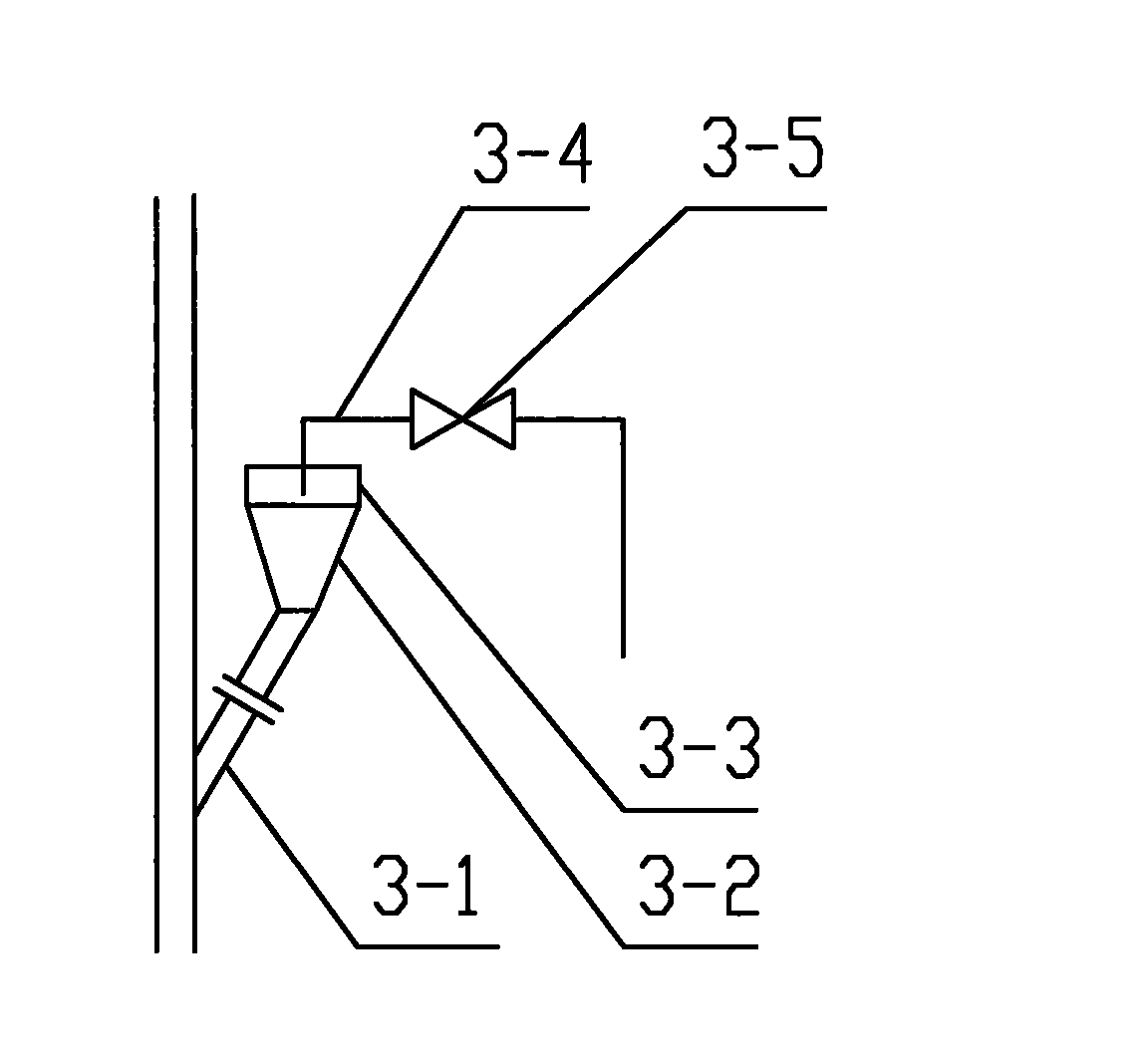

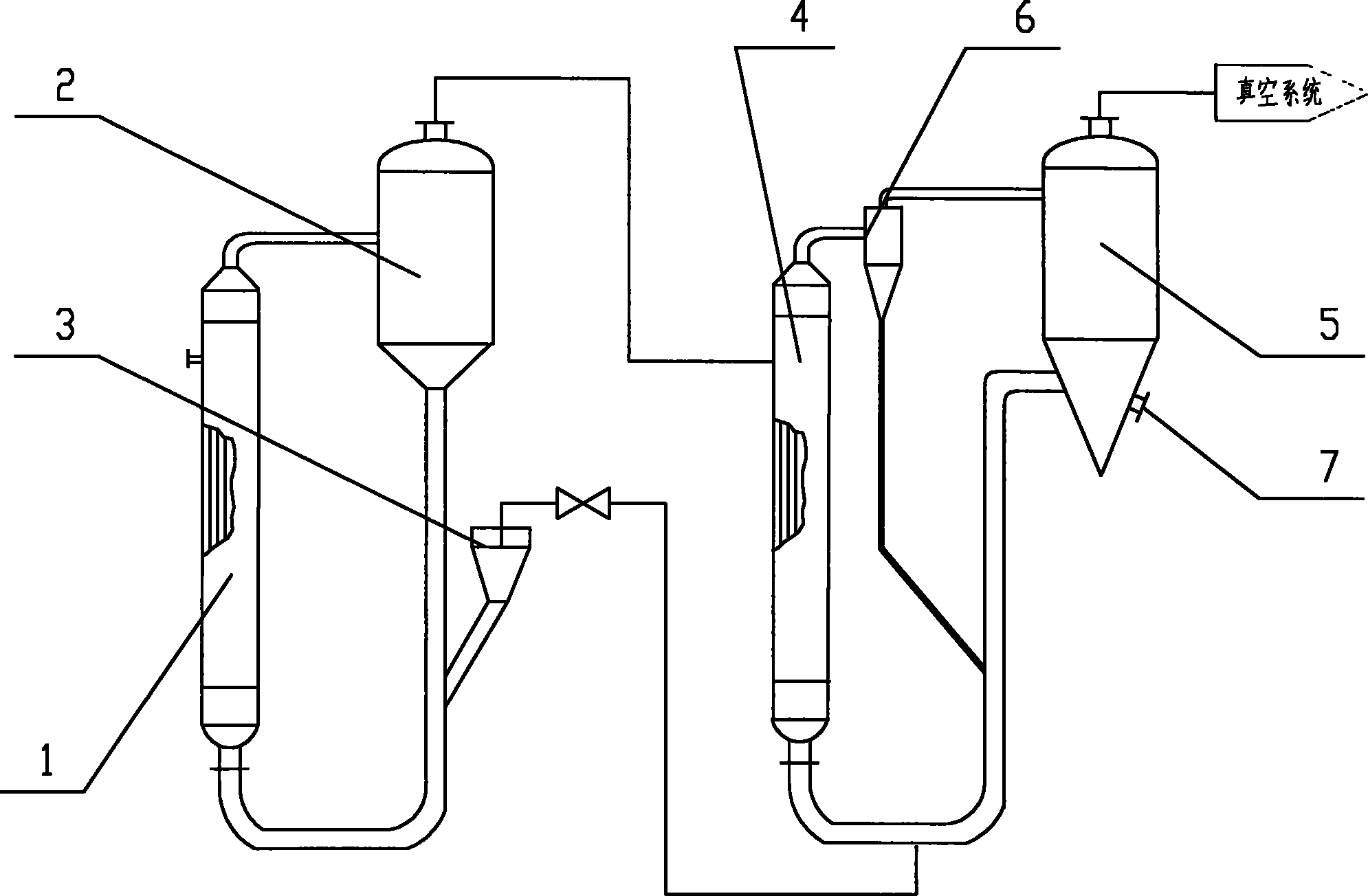

Two-effect scale-preventing evaporating and crystallizing device used for evaporating sodium chloride solution and operation method

ActiveCN102674399AAvoid foulingStable particle sizeProductsReagentsChemical industryHeat transmission

The invention provides a two-effect scale-preventing evaporating and crystallizing device used for evaporating and crystallizing sodium chloride solution, comprising a two-effect multiphase flow evaporator, a vacuum system and a connecting pipeline, wherein a first effect is a natural circular evaporator, a second effect is a natural circular evaporating crystallizer; a material delivering device is arranged between two effects; and the second effect is provided with a grain circulating device. Specially-made aluminum oxide and polytetrafluoroethylene composite material grains are added in the two-effect evaporating and crystallizing device; the grain density is 1200-3000kg / m3, the grain diameter is 0.32-3.8 mm, and the specific heat is 0.5-1.5kJ / kg.K. The sodium chloride crystal is prevented from attaching on the wall face of the heating pipe in the process of evaporating, simultaneously, the heat transmission is enhanced. The two-effect scale-preventing evaporating and crystallizing device has the characteristics of being simple in structure, likely to operate, capable of running continuously and preventing scaling; the two-effect scale-preventing evaporating and crystallizing device can be used for evaporating and crystallizing the sodium chloride solution and the sodium chloride waste liquid in chemical industry, medicine, sea water chemical industry and the other fields.

Owner:南通曙光新能源装备有限公司

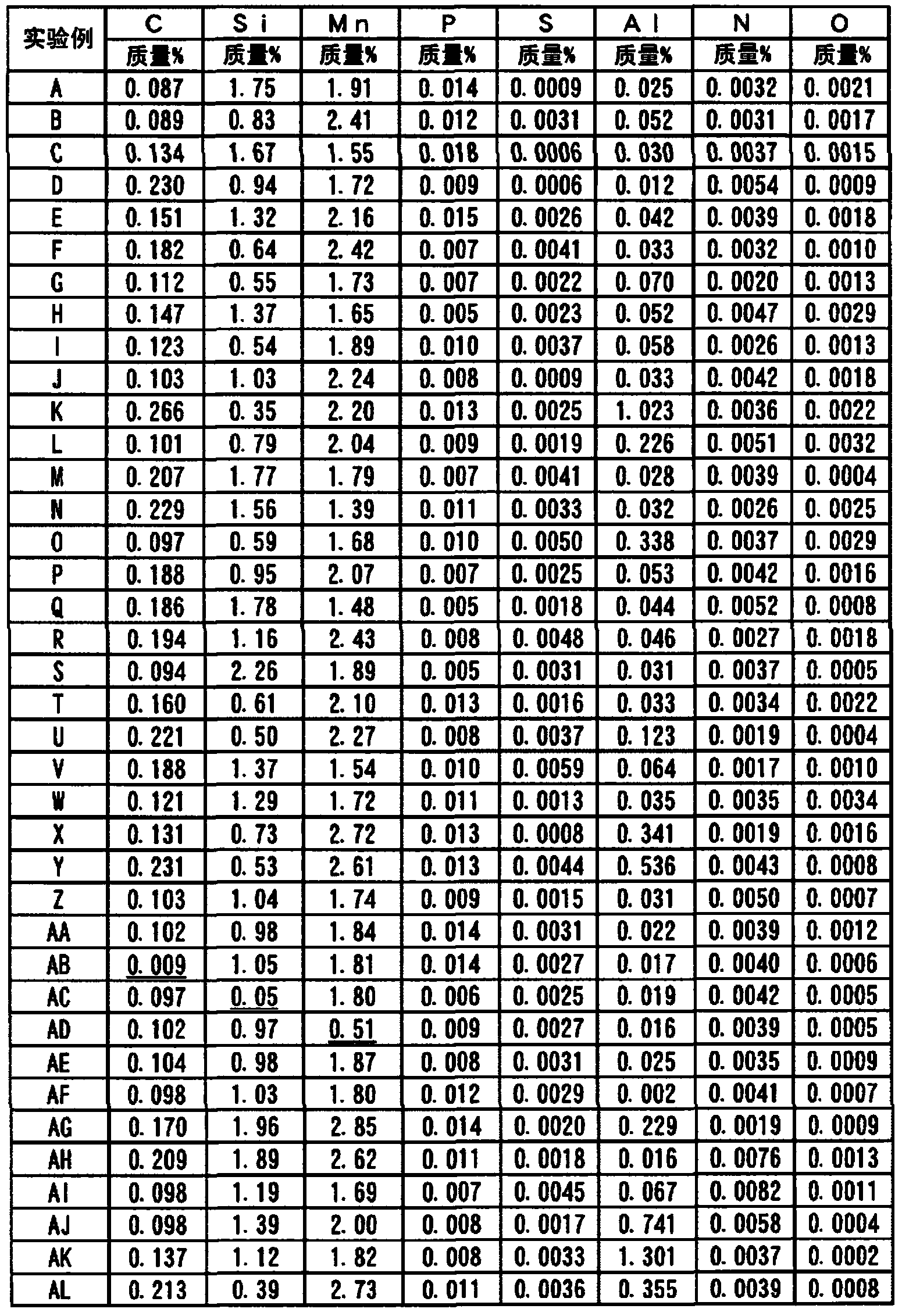

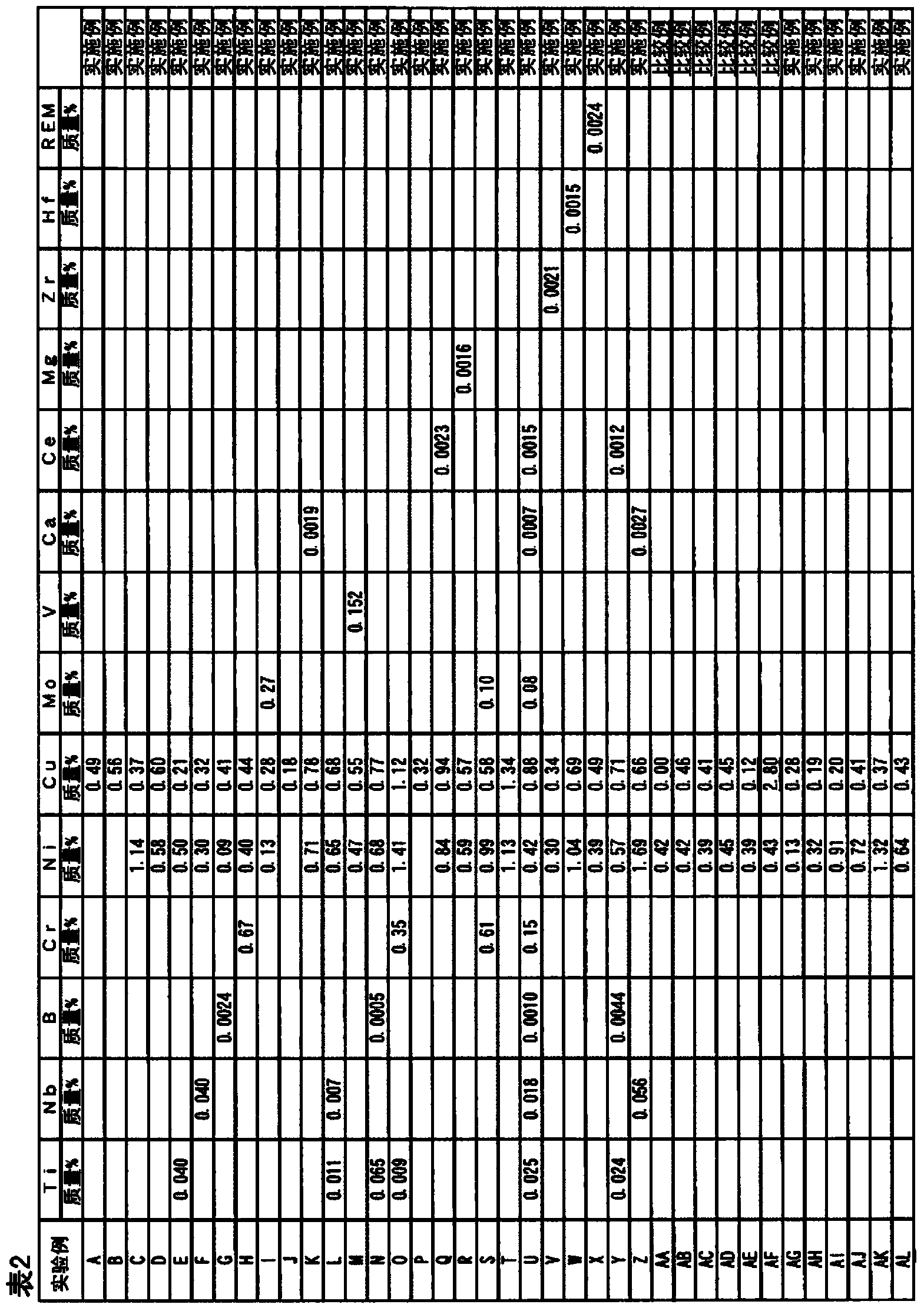

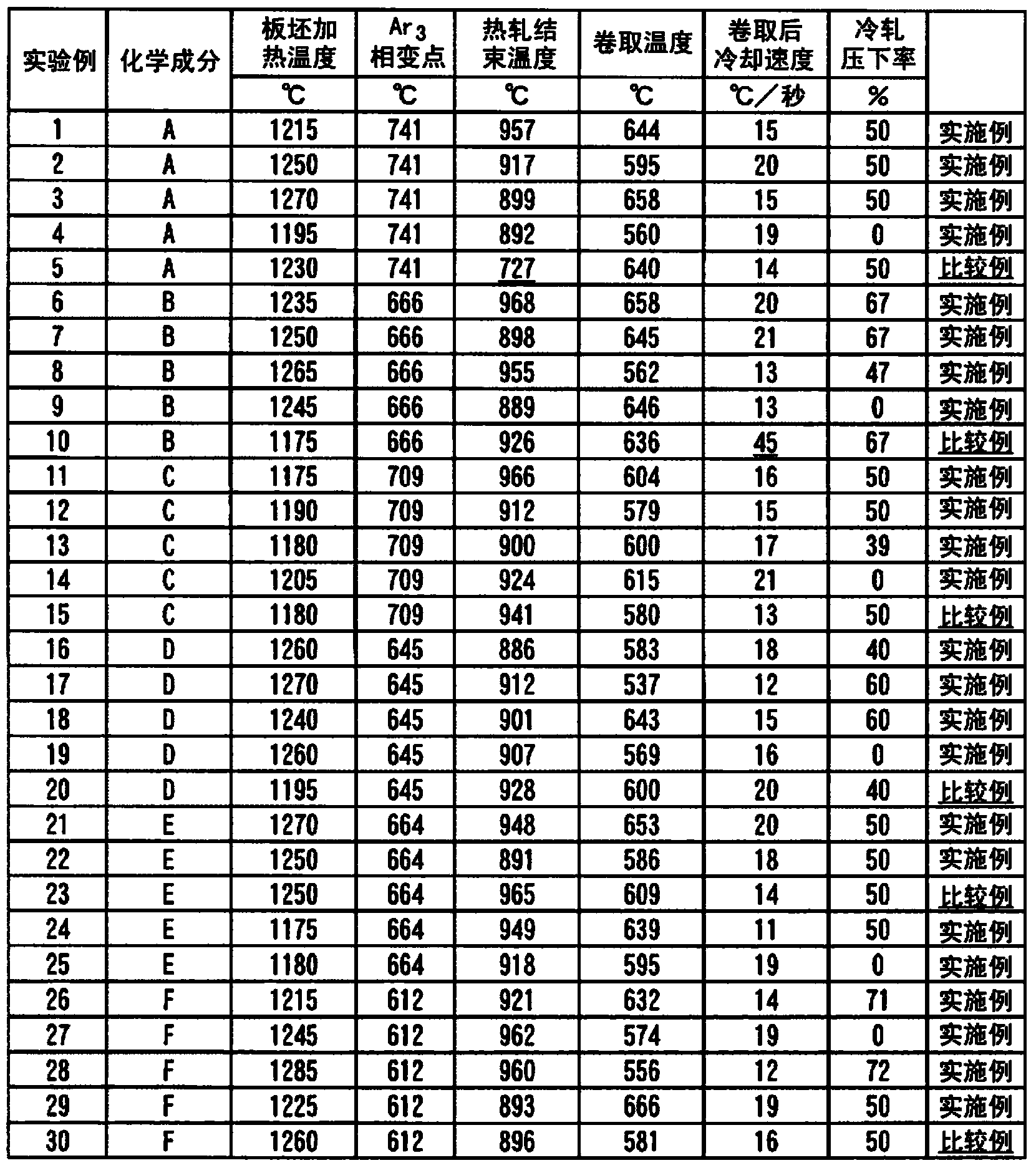

High-strength zinc-plated steel sheet and high-strength steel sheet having superior moldability, and method for producing each

ActiveCN103703156AExcellent stretch flangeabilityGood formabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

This high-strength steel sheet having superior moldability while securing the high strength of a maximum tensile strength of at least 900 MPa is characterized by having a predetermined component composition, the steel sheet structure containing a ferrite phase and an austenite phase, the ratio of bcc iron and unaligned Cu grains being at least 15% of the Cu grains overall, the Cu grain density in the ferrite phase being at least 1.0x1018 grains / m3, and the average grain size of the Cu grains in the ferrite phase being at least 2.0 nm.

Owner:NIPPON STEEL CORP

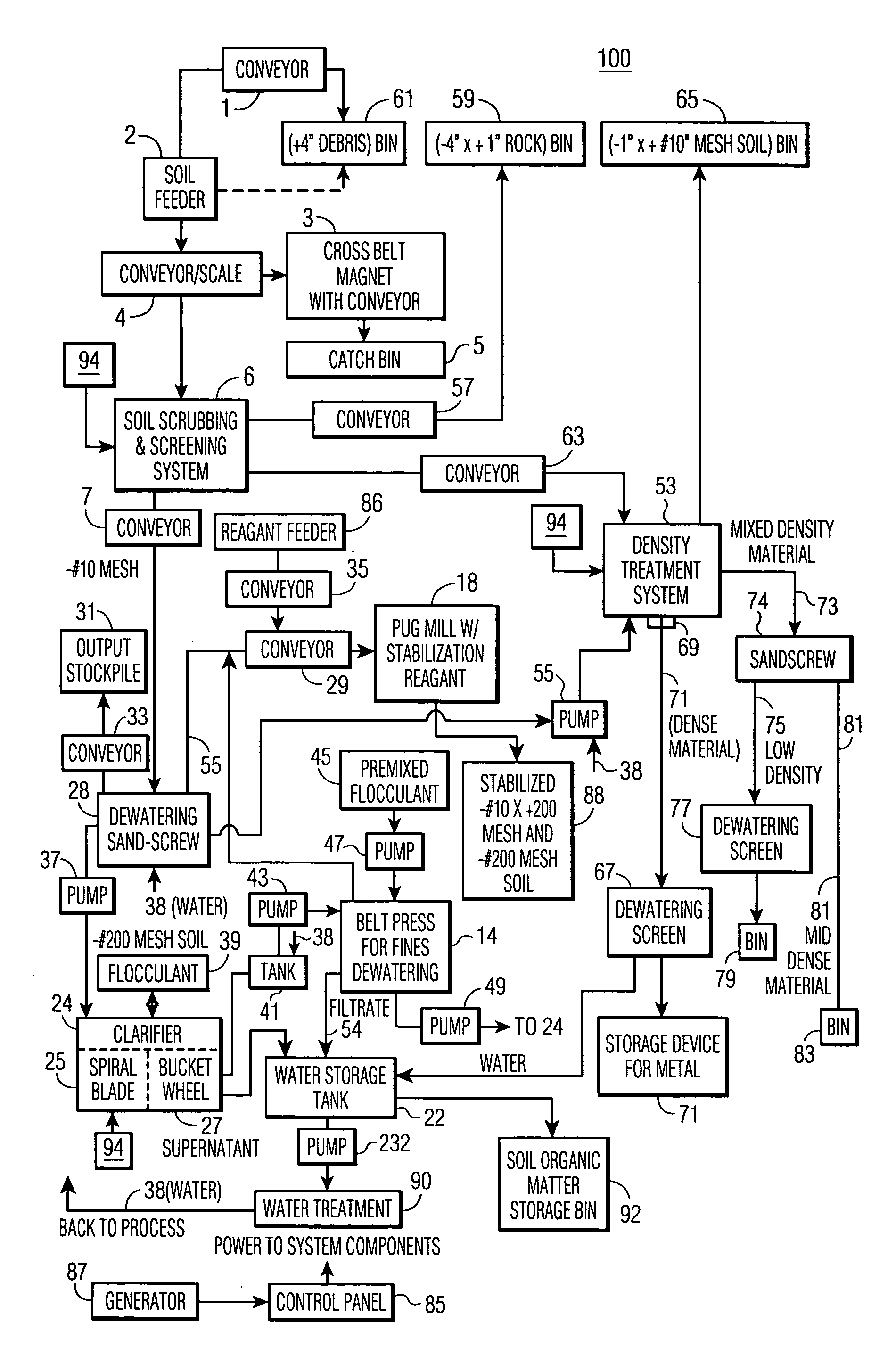

Method and system for removing contaminants from soil

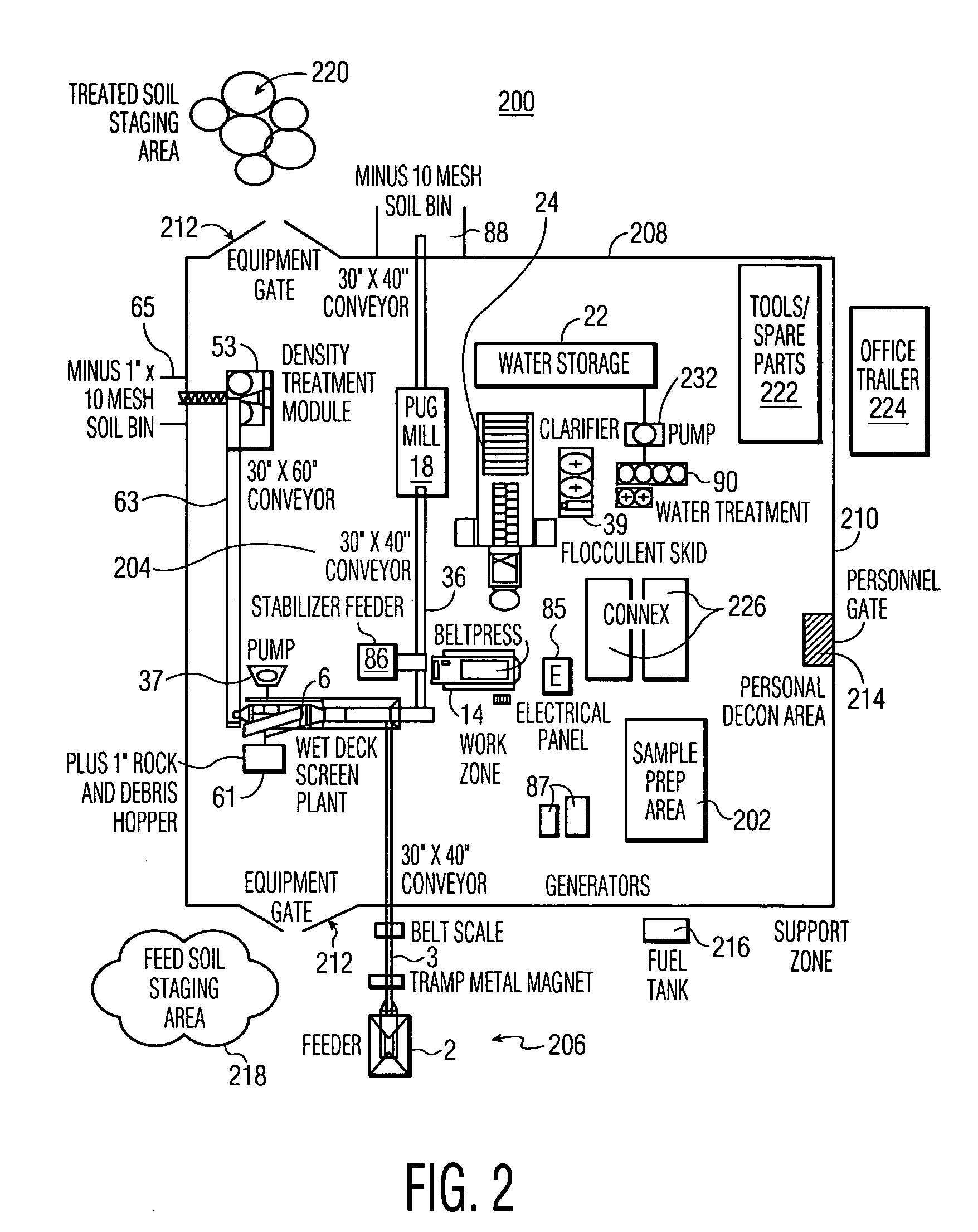

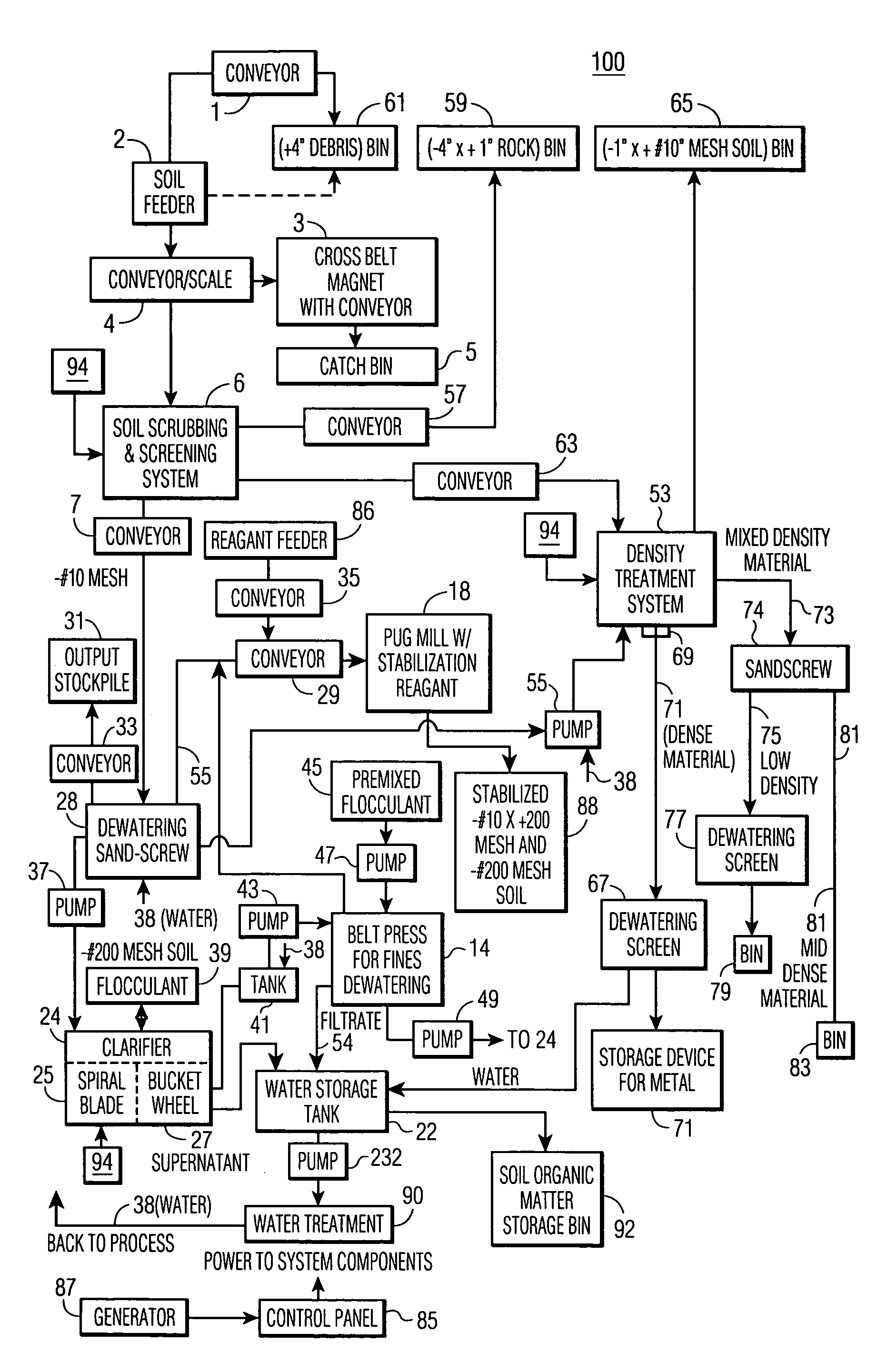

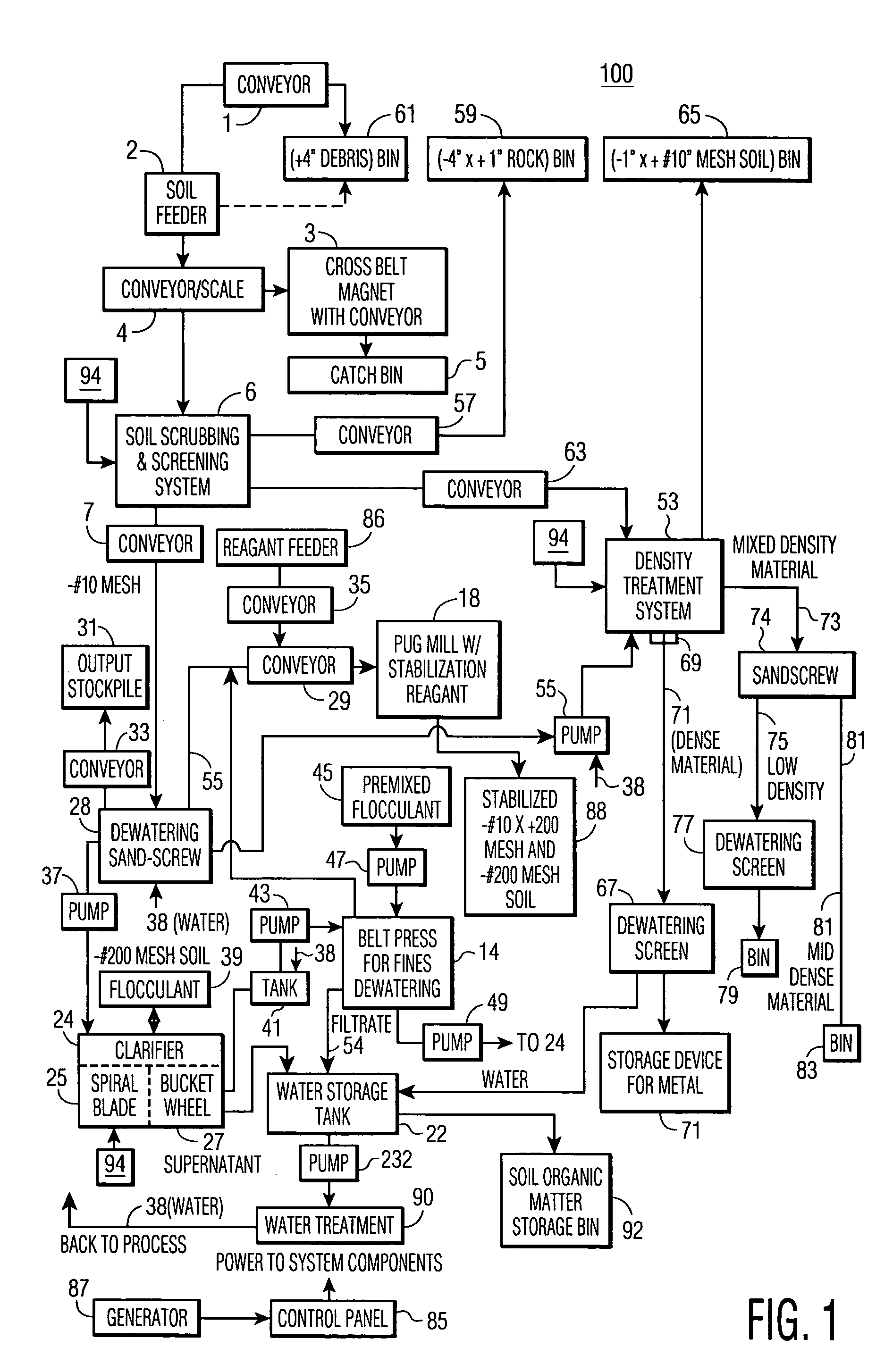

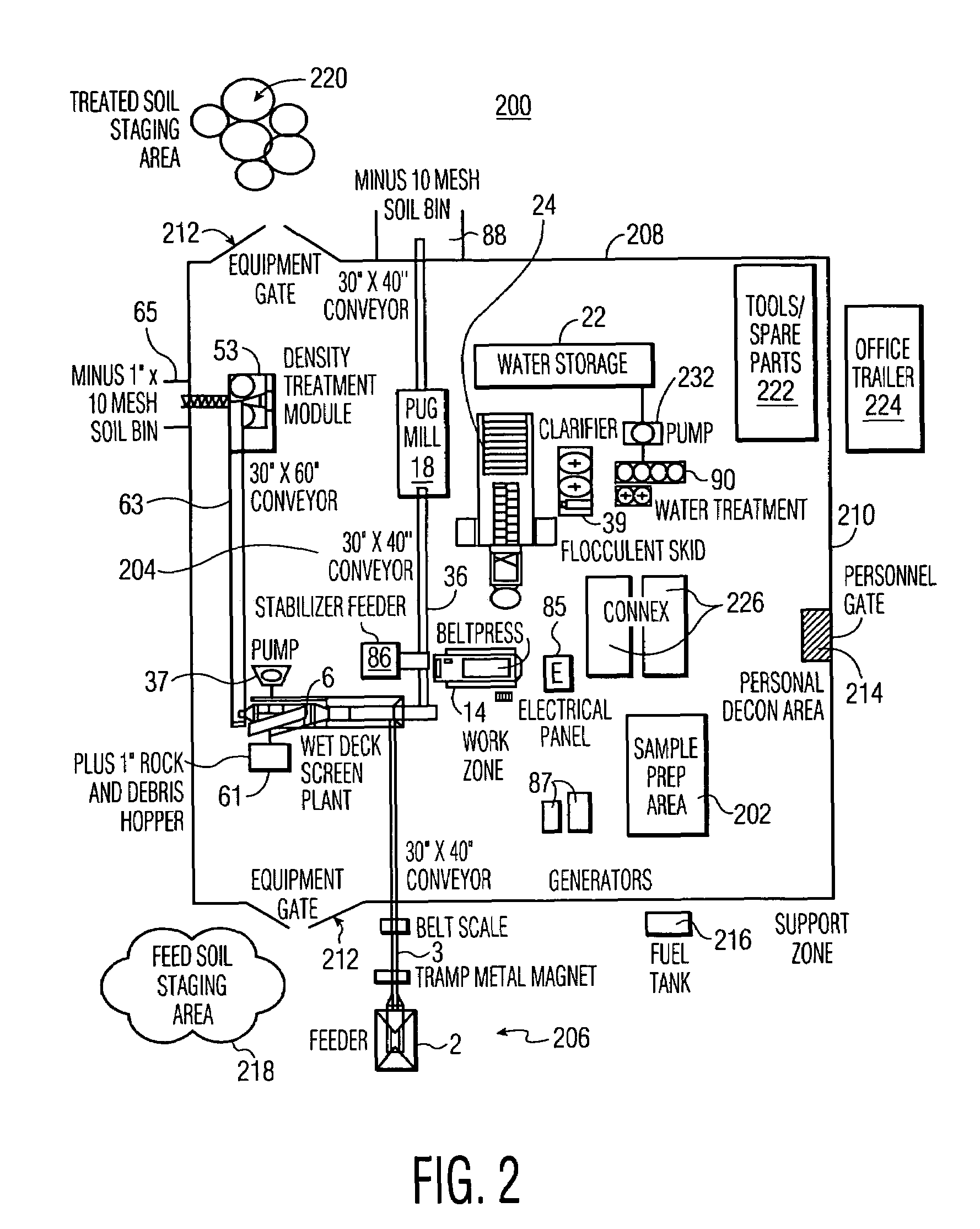

ActiveUS20060140725A1Improve productivityFacilitates on-site soil reuseSolid separationContaminated soil reclamationSoil scienceParticle density

A method and system for removing contaminants from contaminated soil at a site utilizes particle size segregation and particle density segregation to yield a plurality of fractions, whereby each of the fractions are tested and identified for the presence of unacceptable levels of contaminants, and the soil fractions from the contaminated soil at the site corresponding to the identified contaminated fractions are collected for subsequent disposal or treatment, while the remaining untainted soil fractions are homogenized and returned to the site.

Owner:BRICE ENVIRONMENTAL SERVICES CORP

Method for preparing activated carbon with ultrahigh specific surface area from soapberry residue as raw material

The invention discloses a method for preparing activated carbon with an ultrahigh specific surface area from soapberry residues as a raw material. The method specifically comprises the following steps: (1) drying carbon-containing residues such as soapberry fruits, shells and peels in the sun, crushing, washing for 1-8 times with water or alcohol solution, and drying for later use; (2) putting the raw materials treated in the step (1) into a microwave reactor for carbonization in microwaves; (3) uniformly mixing the carbide obtained in the step (2) with a composite activating agent, putting into an atmosphere furnace, heating to activate, and cooling to be the room temperature, thereby obtaining a primary activated carbon product; (4) washing the prepared primary product to be neutral, and drying, thereby obtaining a finished product, that is, powder activated carbon. The activated carbon prepared by using the method is high in specific surface area, rich in mesopores, reasonable in pore structure distribution, moderate in apparent density, uniform in grain density, stable in property and very high in adsorption capability, the BET specific surface area is greater than 2500m<2> / g, and the total pore volume is 0.50-2.00cm<3> / g.

Owner:FUJIAN NORMAL UNIV

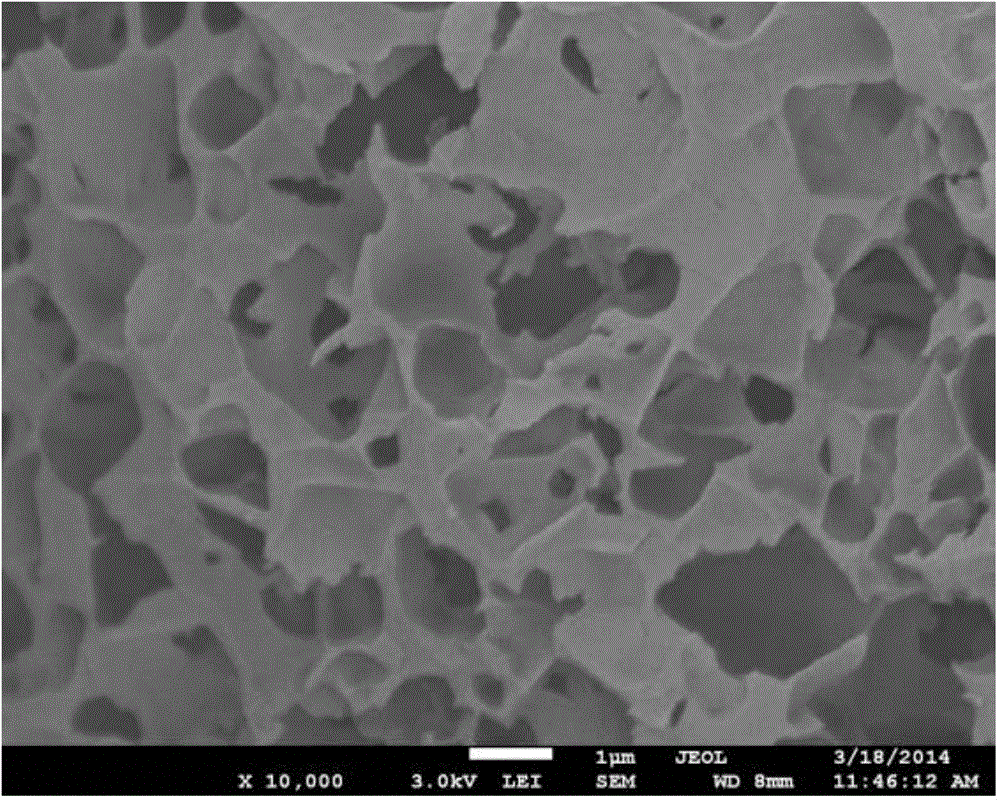

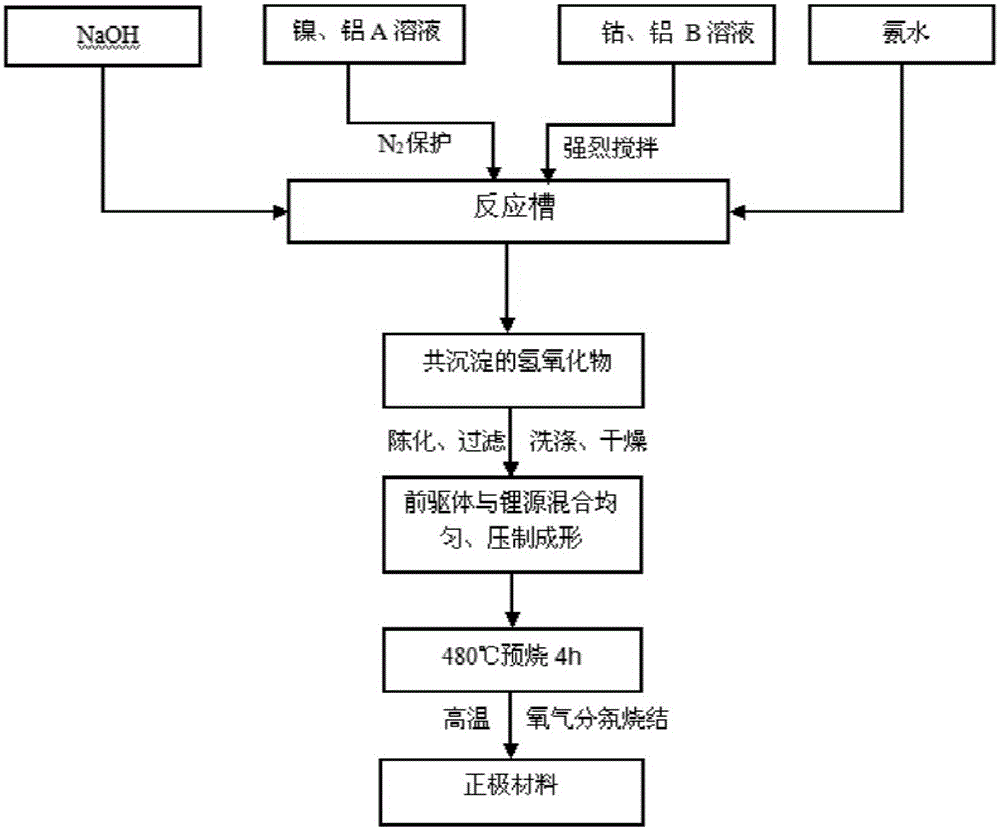

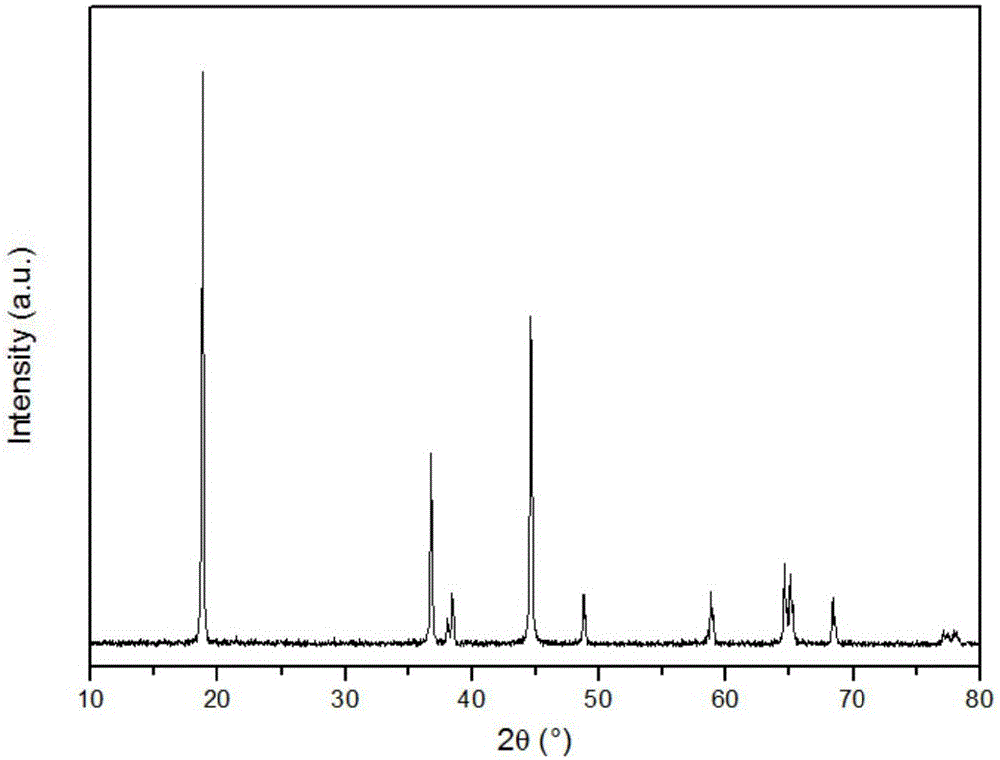

Lithium ion battery cathode material and preparation method thereof

InactiveCN105024065ASimple preparation processShort sintering timeCell electrodesSecondary cellsHigh rateAluminium-ion battery

The invention belongs to the field of a lithium ion battery, and provides a doped and modified layered lithium ion battery cathode material LiNi<1-x-y>CoxAlyO2 and a preparation method thereof, wherein x is more than 0 and less than or equal to 0.2, y is more than or equal to 0 and less than or equal to 0.1, and (x+y) is more than 0 and less than or equal to 0.3. The lithium ion battery cathode material LiNi<1-x-y>CoxAlyO2 is obtained by simultaneously doping trivalent elemental aluminum and divalent element cobalt to replace elemental nickel in the cathode material. The cathode material is endowed with high discharging specific capacity and excellent cyclic stability performance, and the high-rate charging and discharging demand can be met; parallel flow and co-precipitation of four solutions combined with a solid-phase synthesis method are used for preparing the cathode material; and by the method, the defects of long preparation time, difficulty in controlling stoichiometric proportion, non-uniform distribution of product grain sizes, poor electrochemical property and the like of the solid-phase synthesis method are overcome, the prepared product is high in purity and high in crystalline quality, high and uniformly-distributed product grain density is achieved, electrochemical property is excellent, and manufacturing cost is low.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method and system for removing contaminants from soil

ActiveUS7255514B2Increase chanceEasy to reuseSolid separationContaminated soil reclamationSoil sciencePollution soil

A method and system for removing contaminants from contaminated soil at a site utilizes particle size segregation and particle density segregation to yield a plurality of fractions, whereby each of the fractions are tested and identified for the presence of unacceptable levels of contaminants, and the soil fractions from the contaminated soil at the site corresponding to the identified contaminated fractions are collected for subsequent disposal or treatment, while the remaining untainted soil fractions are homogenized and returned to the site.

Owner:BRICE ENVIRONMENTAL SERVICES CORP

Method for preparing odorless radish red pigment powder

The invention provides a method for preparing an odorless radish red pigment powder. The method comprises the following steps of: (1) killing enzymes with steam by using a crawler-type steam sterilization cabinet; (2) crushing by using a fruit / vegetable crusher and filtering to obtain a radish paste; (3) finely grinding by using a colloid mill; (4) preparing microcapsules by using cyclodextrin; (5) uniformly mixing by high pressure homogenization; (6) granulating through fluidization to prepare odorless radish red pigment powder. The obtained radish red pigment powder is microencapsulated particles which have small grain density, are loose, smooth, and good in fluidity, namely strong in dissolubility. The prepared radish red pigment powder is prepared into a solution, and a spectrophotometry used for analyzing and testing the solution shows that the pH value of the solution is 3.6-4.3 and the absorbance is 4.8 at 535 nm, which fully meet the requirements of the national standard GB6718-1986 (pH value of 3.5-4.5, and absorbance is more than or equal to 4.0 at 535 nm). The method directly prepares a radish red pigment powder by adopting the ultramicrotechnique technology and microcapsule technology, simplifies the production process, reduces the product price, avoides the generation of odors, protects the stability of pigments, and ensures that the application of radish in food coloring is feasible.

Owner:罗合春

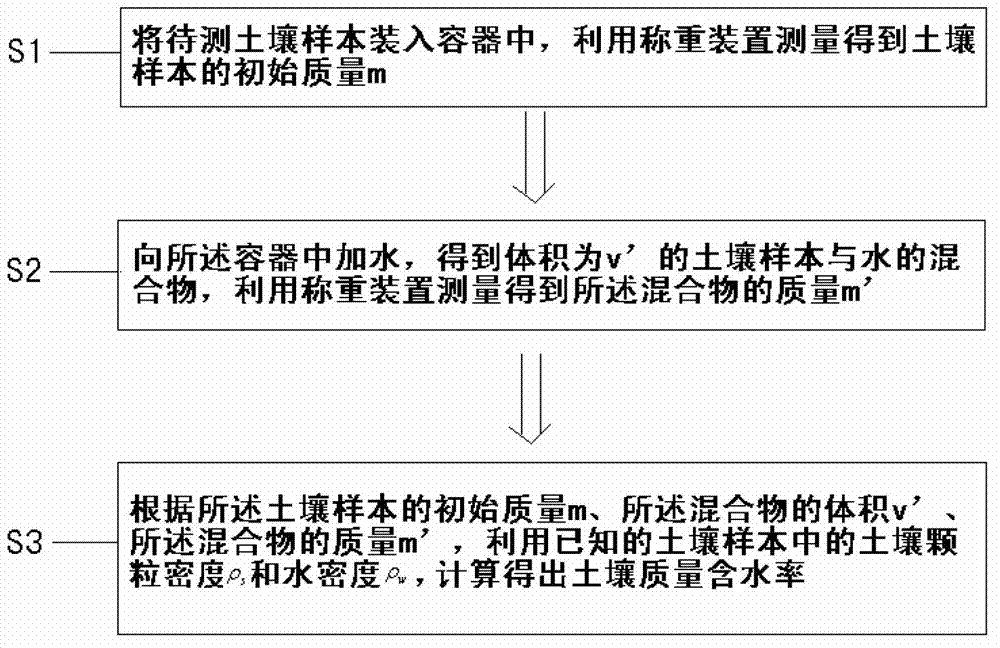

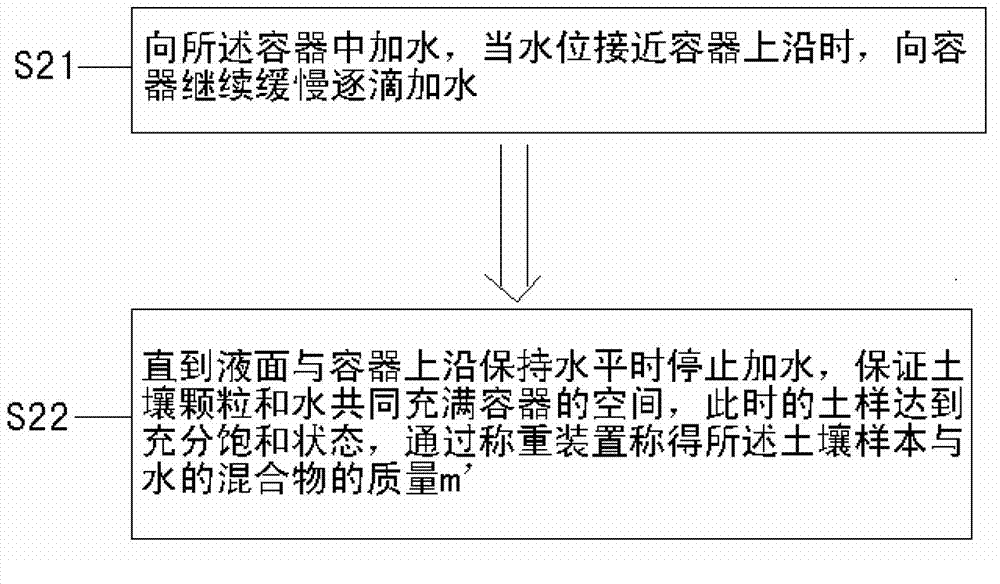

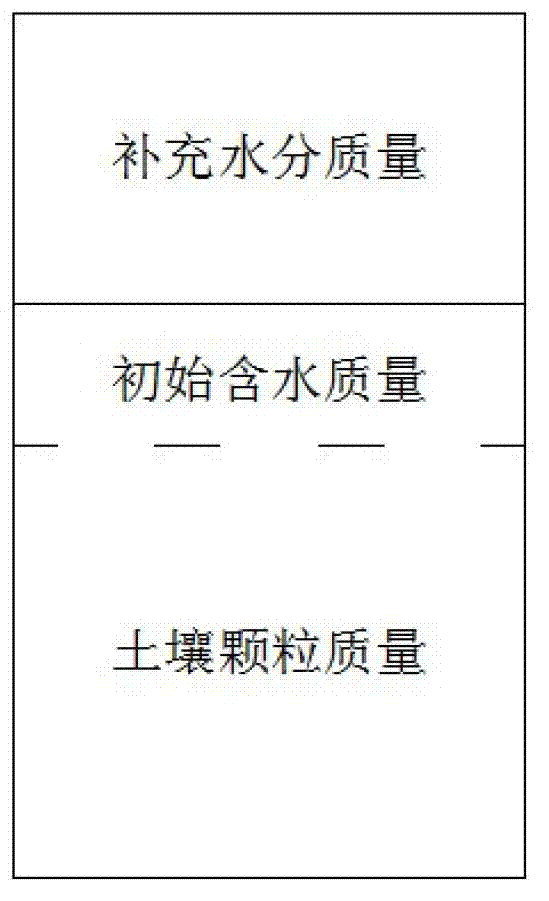

Method and device for measuring soil mass moisture content

InactiveCN103115836AEasy to operateGood measurement stabilityWeighing by absorbing componentSoil qualityMoisture

The invention discloses a method and a device for measuring soil mass moisture content. The method comprises the steps of S1. putting a soil sample to be measured into a container, and measuring by using a weighing device to obtain the primary mass m of the soil sample; and S2. adding water into the container so as to obtain a mixture, of which the volume is v', of the soil sample and the water, measuring by using the weighing device to obtain the mass m' of the mixture; and S3. calculating the soil mass moisture content by utilizing the known soil granular density ps and the water density pw in the soil sample according to the primary mass m of the soil sample, the volume v' of the mixture and the mass m' of the mixture. The device comprises a computer, an electronic balance, a soil container, a water pipe and a data line. The method and the device for measuring the soil mass moisture content are applicable to direct measurement of the soil mass moisture content, simple and convenient in operation process and good in stability.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com