Method for simulating fluidized bed with dynamic changes of grain density and particle size

A particle density and simulation method technology, applied in the field of fluid mechanics, can solve the problems of inability to accurately control the reactor, optimize design and process amplification, and it is difficult to accurately describe the force between gas and particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

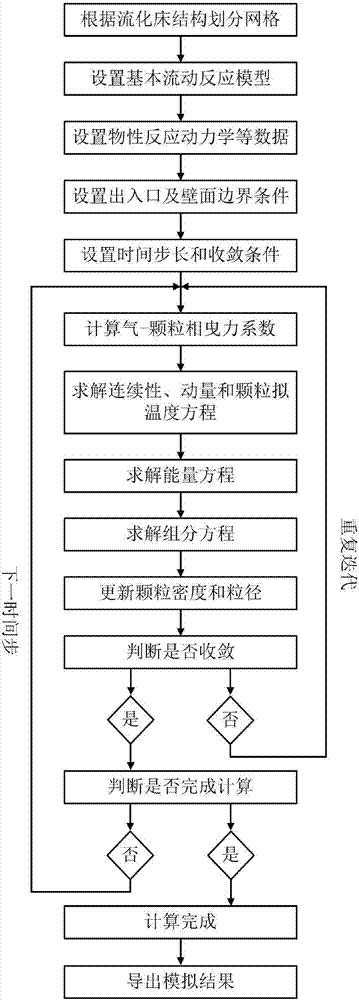

Method used

Image

Examples

Embodiment Construction

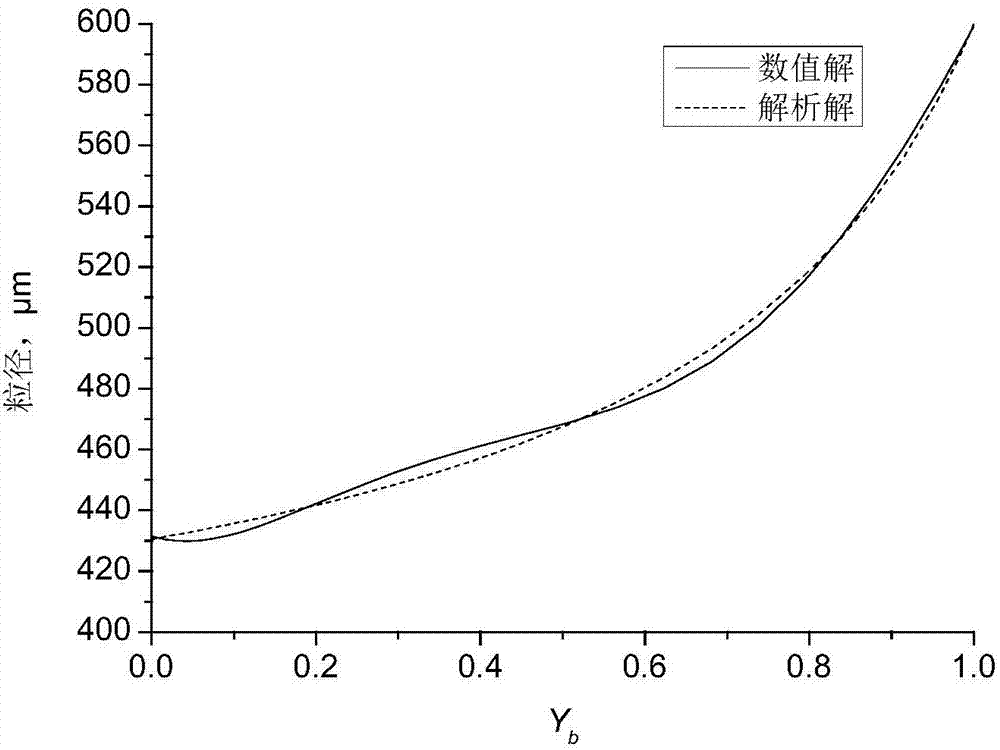

[0125] The present invention will be further described in detail by taking the rapid pyrolysis process of biomass fluidized bed as a specific example.

[0126] Biomass undergoes rapid pyrolysis reaction in a small fluidized bed. The inner diameter of the fluidized bed is 3.81 cm, and the height is 34.29 cm. Nitrogen enters from the bottom of the fluidized bed, while biomass enters the system at a height of 1.7 cm with accompanying nitrogen. The temperature of nitrogen at the bottom is 773K, and the velocity is 1.5m / s. The biomass flow rate is 100g / h, accompanied by nitrogen gas velocity of 0.143m / s, and the temperature is 300K. The reaction temperature was maintained at 773K by a heating thermostat. The initial bed is filled with 5.5cm high sand with a density of 2649kg / m 3 , the particle size is 520 μm. The pyrolysis chemical reaction of biomass is represented by the following formula:

[0127]

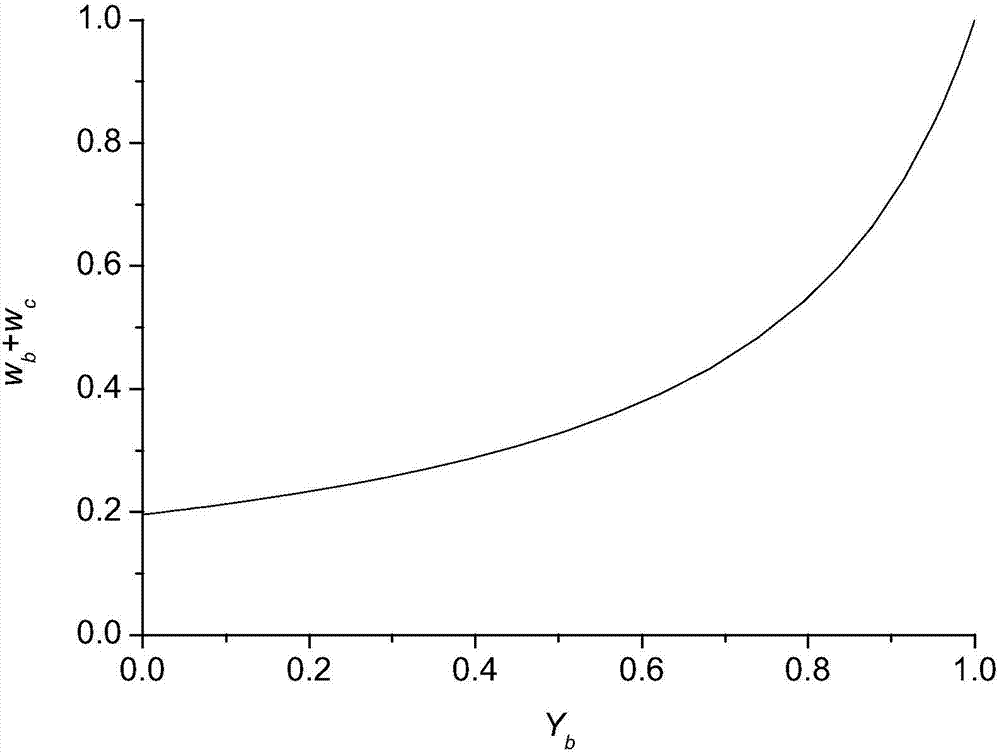

[0128] Where b is biomass, density ρ b 660kg / m 3 , c is biochar, dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com