Method for preparing activated carbon with ultrahigh specific surface area from soapberry residue as raw material

A technology with ultra-high specific surface area and Sapindus chinensis, applied in the field of comprehensive utilization of resources, to achieve the effect of broad market prospects, high specific surface area and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

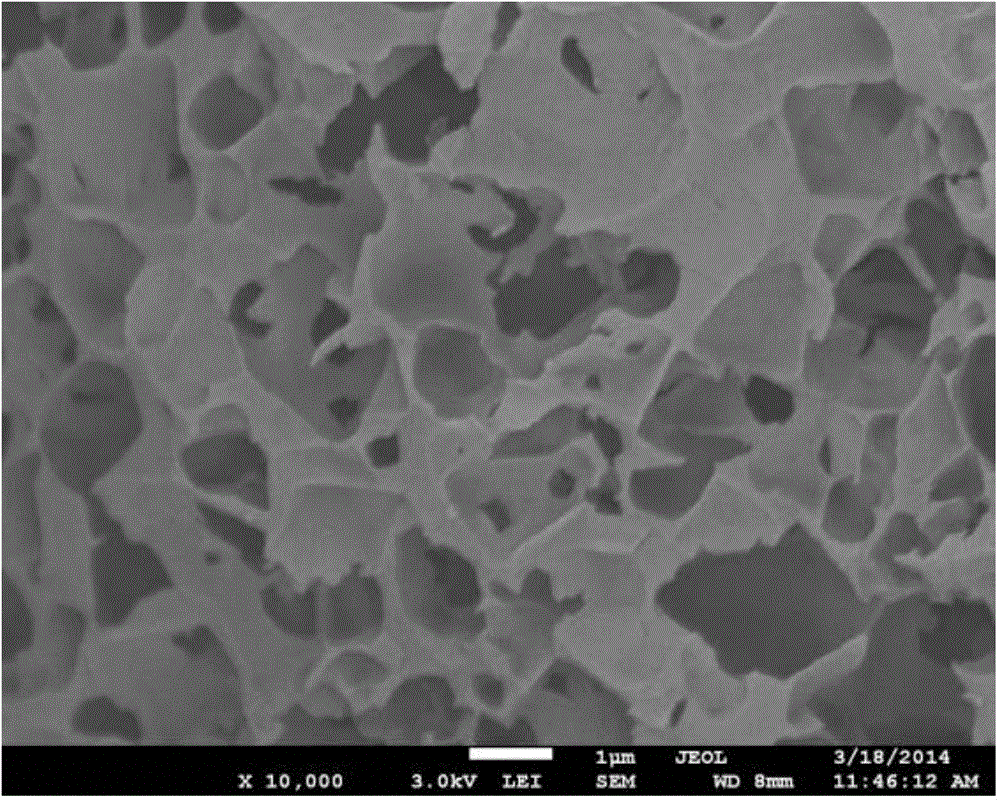

Image

Examples

Embodiment 1

[0027] 1. The residue of Sapindus chinensis is dried in the sun, crushed, washed 8 times with aqueous solution, and then dried. Then put the washed Sapindus residue into the microwave reactor, feed N with the flow rate of 50ml / min 2 , under the action of microwave power 2000W, the temperature was raised to 600°C at a heating rate of 200°C / min, and the carbonization time was 50min to obtain carbonized products.

[0028] 2. Mix 1000g of the obtained carbide with 1000g of KOH, 100g of LiOH, and 100g of K 2 CO 3 Mix evenly, put it into the atmosphere furnace, and feed N at a flow rate of 100ml / min 2 , at a heating rate of 30°C / min to 900°C for 100min activation to obtain the primary product of activated carbon.

[0029] 3. Finally, the prepared activated carbon primary product is washed with hydrochloric acid, washed with water to neutrality, and dried to obtain a powdered activated carbon final product. It has been determined that the BET specific surface area of the prepar...

Embodiment 2

[0032] 1. Dry the residue of Sapindus chinensis in the sun, crush it, wash it with 30% ethanol solution for 5 times, and then dry it. Then put the processed Sapindus residue into the microwave reactor, feed N with the flow rate of 200ml / min 2 , under the microwave power of 1500W, the temperature was raised to 500°C at a heating rate of 80°C / min and the carbonization time was 100min to obtain a carbonized product.

[0033]2. Mix 1000g of the obtained carbonized product with 3000g of NaOH and 1000g of LiOH evenly, put it into the atmosphere furnace, and feed N at a flow rate of 90ml / min 2 , at a heating rate of 10°C / min to 850°C for 200min activation to obtain the primary product of activated carbon.

[0034] 3. Finally, the prepared activated carbon primary product is washed with hydrochloric acid, washed with water to neutrality, and dried to obtain a powdered activated carbon final product. It has been determined that the prepared activated carbon has the following properti...

Embodiment 3

[0037] 1. Dry the residue of Sapindus chinensis in the sun, crush it, wash it with 50% methanol solution for 3 times, and then dry it. Then put the processed Sapindus residue into the microwave reactor, feed N with the flow rate of 350ml / min 2 , under the microwave power of 1000W, the temperature was raised to 350°C at a heating rate of 150°C / min and the carbonization time was 110min to obtain a carbonized product.

[0038] 2. Mix 1000g of the obtained carbonized product with 5000g of LiOH evenly, put it into the atmosphere furnace, and feed N at a flow rate of 120ml / min 2 , at a heating rate of 40°C / min, the temperature was raised to 1000°C for 60 minutes to activate the activated carbon primary product;

[0039] 3. Finally, the prepared activated carbon primary product is washed with hydrochloric acid, washed with water to neutrality, and dried to obtain a powdered activated carbon finished product. The prepared activated carbon has the following properties: BET specific s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com