Method for connecting ceramic and metal

A ceramic and metal technology, applied in the field of ceramic and ceramic and ceramic and metal connection, can solve the problems of shape and surface accuracy constraints, casting defects, difficult to guarantee dimensional accuracy, etc., and achieve good physical and mechanical properties, and the effect of dense organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

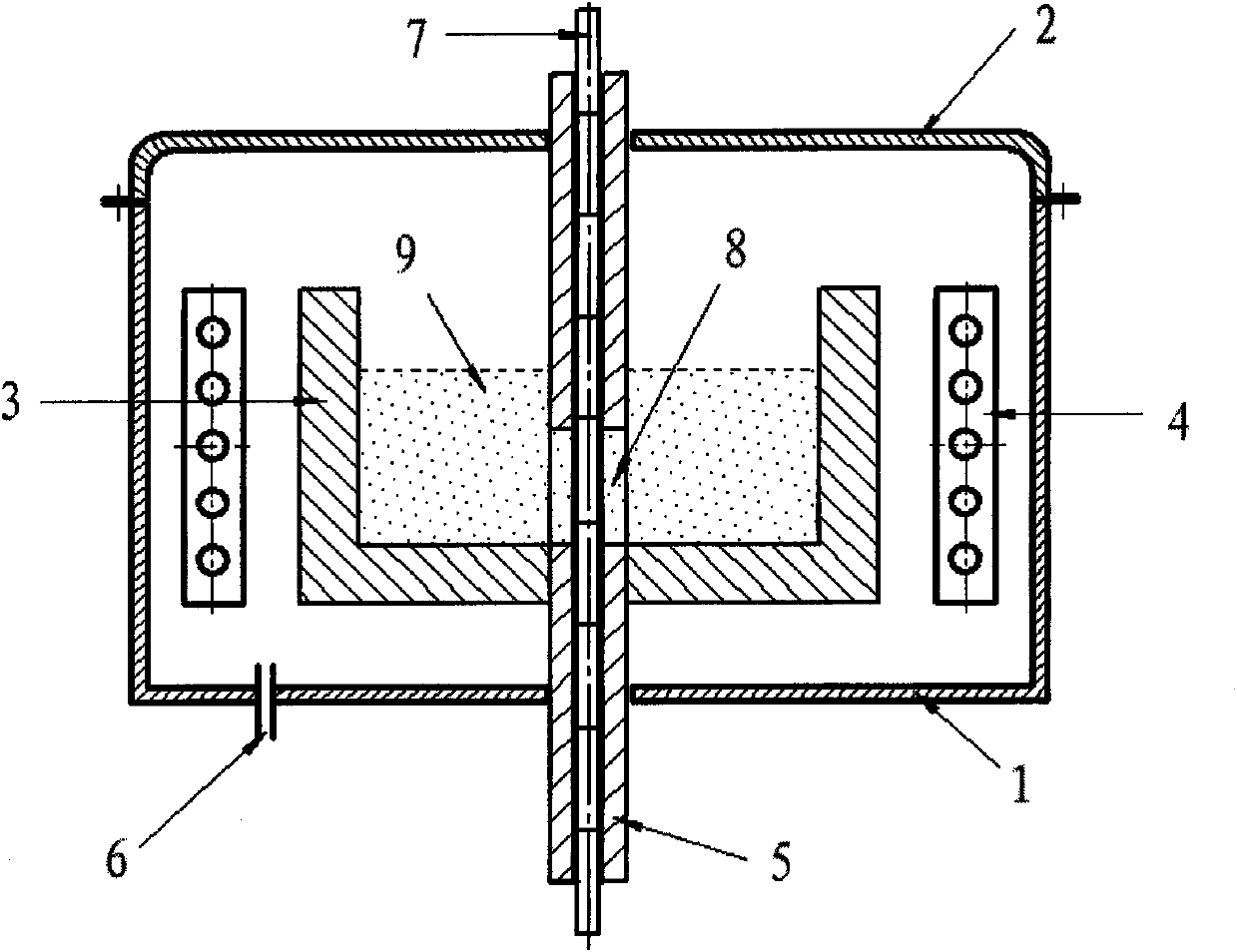

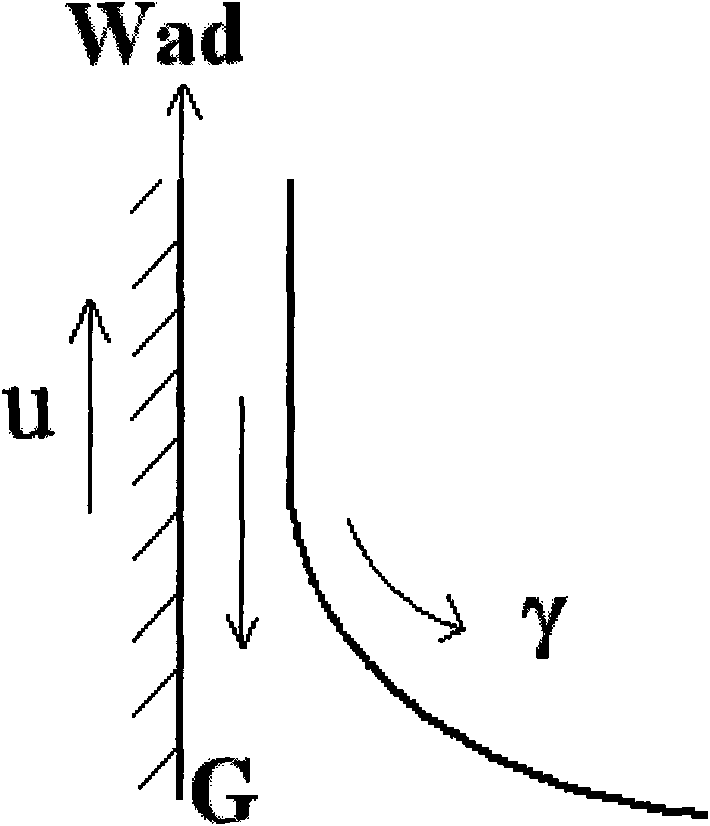

Method used

Image

Examples

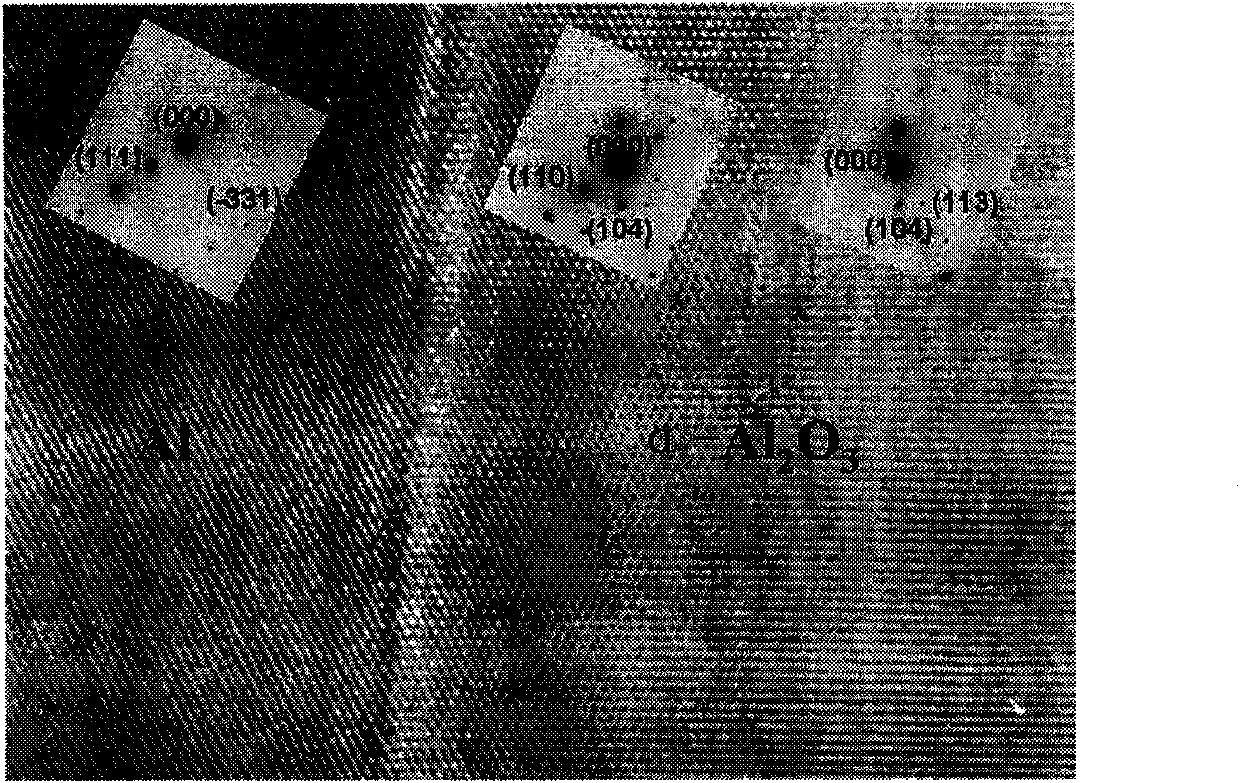

Embodiment 1

[0025] Embodiment 1. Using the above-mentioned ceramic surface metallization device, put pure aluminum into a graphite crucible, and insert an alumina ceramic plate (137 mm long, 35 mm wide, and 0.64 mm thick, produced by Tsinghua Yueke, with an alumina purity greater than 95%) through the In the graphite guide rail of the crucible, then feed nitrogen in the furnace (the nitrogen flow rate is 15 liters / min) (the oxygen volume content in the atmosphere in the furnace is 30 / million (i.e. 30ppm)) and energized heating to melt the aluminum and heat up to 700°C. The molten aluminum height after melting is 137mm. Insert another alumina ceramic plate into the guide rail at a speed of 68.5mm / min from the guide rail entrance at the lower part of the device, and push the ceramic plate inserted into the guide rail to move vertically upward at the same speed. During the moving process, the ceramic plate is in contact with the molten aluminum in the crucible through the window on the guid...

Embodiment 2

[0032] Embodiment 2, except that the brazing material is changed to Ak-8wt% Si alloy, the rest is the same as embodiment 1. There is no defect in the interface after connecting with aluminum, and the crack occurs in the clamping part of aluminum during the tear strength test. The experiment was repeated three times, and the tear strength was greater than 10.2kg / cm, indicating that the connection strength of the connection interface between the aluminum plate and the ceramic was at least greater than 10.2kg / cm.

Embodiment 3

[0033] Embodiment 3, except that the brazing material is changed to Al-4wt%Si alloy, the rest is the same as embodiment 1. After connecting with aluminum, there is no defect in the connection interface, and the fracture of the tear strength sample occurs in the clamping part of aluminum. The experiment was repeated three times, and the tear strength was greater than 9.7kg / cm, indicating that the interface connection strength between the aluminum plate and the ceramic was at least greater than 9.7kg / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com