Aluminium-silicon-copper-magnesium pack alloy and its preparing process

A technology of casting aluminum alloy and preparation process, applied in the field of metal materials, can solve the problems of air leakage, shrinkage porosity and poor plasticity of die-casting products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

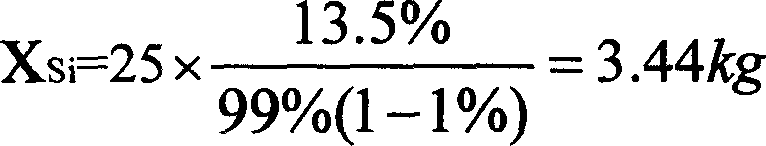

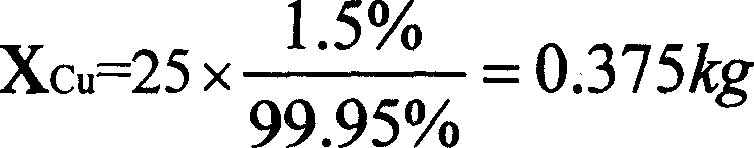

[0025] Prepare 25 kg of aluminum-silicon-copper-magnesium die-casting aluminum alloy containing 13.5% silicon, 1.5% copper, 0.3% magnesium, 0.8% iron, 0.25% manganese, and the balance is aluminum (the composition ratios are all mass percentages, the same below). The process is as follows:

[0026] (1). Resistance crucible furnace and cast steel crucible are used;

[0027] (2). Raw material preparation: aluminum ingot (aluminum≥99.7wt%); silicon block (silicon≥99.0wt%); pure copper block (copper≥99.95wt%); pure magnesium block (magnesium≥99.95wt%); Iron master alloy (containing 80wt% aluminum, 20wt% iron); aluminum-manganese master alloy (containing 90wt% aluminum, 10wt% manganese);

[0028] Refer to "Casting Handbook" (Volume 3, Casting Non-ferrous Alloys, 2nd Edition, Machinery Industry Press, 2001.10, P187-188) and empirically determine the burning loss of alloying elements, aluminum: 1.5%, silicon: 1%, magnesium : 20%, Manganese: 0.8%

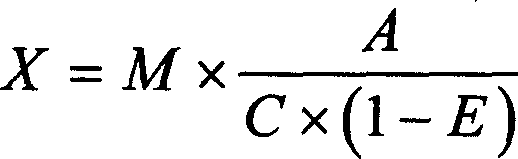

[0029] Addition calculation formul...

Embodiment 2

[0056] Prepare 25 kg of aluminum-silicon-copper-magnesium die-casting aluminum alloy containing 15.0% silicon, 3.5% copper, 0.3% magnesium, 1.0% iron, 0.3% manganese, and the balance is aluminum.

[0057] Take the same processing steps as in Example 1, wherein the amount of each raw material added in step (2) is: 18.67 kilograms of aluminum ingot, 3.82 kilograms of silicon block, 0.875 kilogram of pure copper, 0.094 kilogram of magnesium block, 1.25 kilogram of aluminum-iron master alloy, aluminum Manganese master alloy 0.76 kg;

[0058] The composition of the obtained alloy is: 15.0% of silicon, 3.5% of copper, 0.3% of magnesium, 1.0% of iron, 0.3% of manganese, impurity content≤0.15%, and the balance is aluminum. The tensile strength of the alloy in the as-cast state is 266.4MPa, the elongation after fracture is 1.98%, and the hardness is HB102.

Embodiment 3

[0060] Prepare 25 kilograms of aluminum-silicon-copper-magnesium die-cast aluminum alloy containing 14.5% silicon, 2.3% copper, 0.3% magnesium, 1.0% iron, 0.3% manganese, and the balance is aluminum.

[0061] Take the same processing steps as in Example 1, wherein the amount of each raw material added in step (2) is: 19.10 kilograms of aluminum ingot, 3.69 kilograms of pure silicon, 0.575 kilograms of pure copper, 0.094 kilograms of pure magnesium block, 1.25 kilograms of aluminum-iron master alloy, 0.76 kg of aluminum-manganese master alloy.

[0062] The composition of the obtained alloy is: 14.5% of silicon, 2.3% of copper, 0.3% of magnesium, 1.0% of iron, 0.3% of manganese, impurity content≤0.15%, and the balance is aluminum. The tensile strength of the alloy in the as-cast state is 264.1MPa, and the elongation after fracture is 2.01%. Hardness HB98.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com