Patents

Literature

75results about How to "Solve Wetting Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

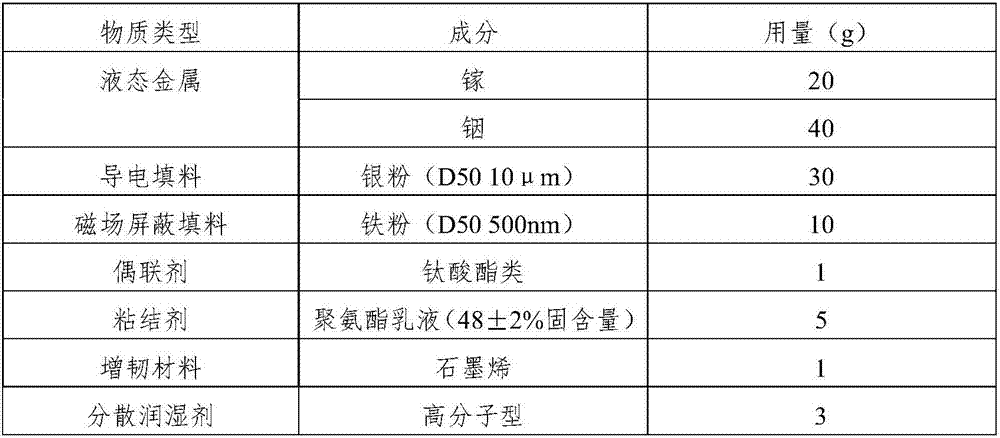

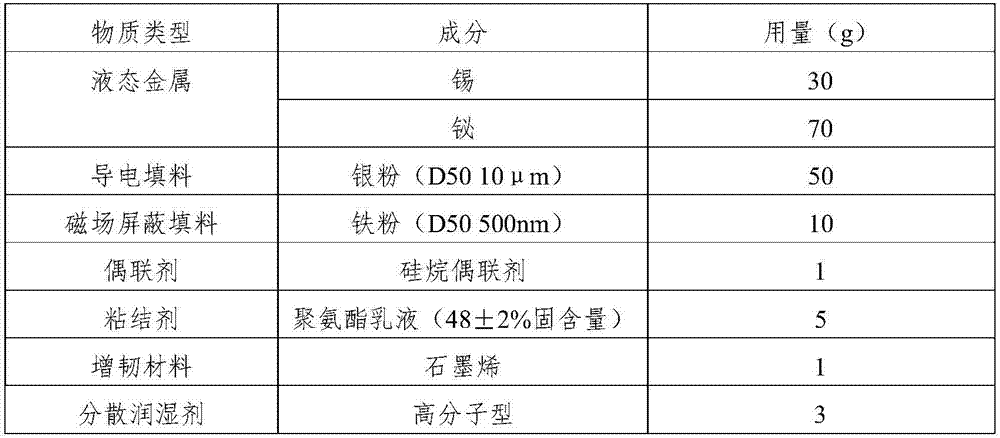

Electromagnetic shielding coating material and preparation method thereof

ActiveCN107573745AGood compatibilityImprove dispersion stabilityMagnetic/electric field screeningElectrically-conductive paintsHazardous substanceLiquid metal

The invention provides an electromagnetic shielding coating material. The electromagnetic shielding coating material comprises 40-70% of liquid metal, 10-40% of a conductive filler, 5-15% of a magnetic shielding filler, 0.5-2% of a coupling agent, 1-10% of a binder, 0.5-2% of a toughening material and 0.5-2% of a wetting dispersing agent, wherein the liquid metal is low-melting-point metal with the melting point of 300 DEG C or below or a conductive nanofluid formed by mixing low-melting-point metal nanoparticles with a fluid dispersant. For the first time, the concept of taking the liquid metal as a conductive auxiliary binder and a conductive auxiliary flow aid is put forward and implemented, and the liquid metal replaces a non-conductive solvent and a non-conductive binder to form the electromagnetic shielding coating material system. Besides, the electromagnetic shielding coating material neither contains any toxic or harmful substances nor produce any volatile organics, is high infilm forming speed, has the characteristics of being safe and environmentally friendly, convenient to construct and low in cost, and can be widely applied to a plurality of fields including militaryscience, electronics, aerospace, buildings and the like.

Owner:BEIJING DREAM INK TECH CO LTD

Polyether ester-based adhesive agent for solvent-free double-component polyurethane composite membrane and preparation method thereof

ActiveCN102174308AHigh bonding strengthImprove hydrolysis resistancePolyureas/polyurethane adhesivesVegetable oilPolyol

The invention relates to a polyether ester-based adhesive agent for a solvent-free double-component polyurethane composite membrane and a preparation method thereof. The preparation method of the adhesive agent comprises the following steps of: firstly, mixing 100 parts of polyisocyanates and 30 to 150 parts of polyol, and then raising temperature for reacting; secondly, adding a stabilizing agent to prepare a component A of the adhesive agent; and then, synthesizing a polyether ester polyol, and matching with 0.5 to 2 parts of polyether polyol, 0.1 to 1.0 part of vegetable oil polyol and 0.01 to 0.2 part of micromolecular polyol to prepare a component B of the adhesive agent. When the components A and B are in use, the functional group mole ratio of NCO to OH is (1.0 -2.0):1. The invention has the following advantages: the preparation method is safe and environmentally-friendly without solvent discharge; and the adhesive agent has low sizing quantity, high base material wetting property, wide serviceable range, high bonding strength and long usable life, and can be boiled at a high temperature (100 DEG C) for 40 minutes.

Owner:WANHUA CHEM BEIJING +1

Method for connection between composite type green low-melting solder glass and silicon carbide reinforced aluminum matrix composites

ActiveCN103894694AFirmly connectedSolve Wetting ProblemsWelding/cutting media/materialsWelding/soldering/cutting articlesWhiskersSoldering

The invention provides a method for connection between composite type green low-melting solder glass and silicon carbide reinforced aluminum matrix composites and relates to a method for connecting the silicon carbide reinforced aluminum matrix composites. The method aims at solving the problems that the silicon carbide reinforced aluminum matrix composites connected through an existing connection method are low in strength and the joint strength, and the surface of existing solder and the surface of the silicon carbide reinforced aluminum matrix composites are incompatible when the content of silicon carbide reinforced bodies in existing silicon carbide reinforced aluminum matrix composites is increased. The method includes the steps of classifying basis glass power, weighing, pretreating beta-SiC whiskers, preparing composite type lead-free low-temperature sealing glass powder, mixing, stirring, removing impurities, coating and assembling and welding test pieces. Through the method, the silicon carbide reinforced aluminum matrix composites can be connected in a low-temperature soldering mode.

Owner:HARBIN INST OF TECH

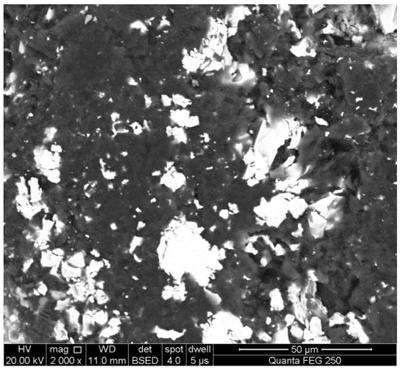

Preparation method of surface-modified ZTA ceramic particle reinforced steel based composite material

ActiveCN109706438AEnhanced interface bindingHigh yield strengthLiquid/solution decomposition chemical coatingAl powderNi cr alloy

The invention discloses a preparation method of a surface-modified ZTA ceramic particle reinforced steel based composite material. The preparation method comprises the steps that sensitization and activation treatment is conducted on ZTA particles, surface plating is conducted, the ZTA particles are plated with nickel and chromium to achieve surface metallization by controlling the components andthe proportion of a plating solution, the ZTA particles plated with Cr-Ni layers, Ni-Cr alloy powder and Al powder are put into a graphite mold to be made into a preform which is of a honeycomb structure through vacuum sintering, molten metal is poured by adopting a casting infiltration method, and after cooling is conducted, the reinforced steel based composite material is obtained. According tothe preparation method of the surface-modified ZTA ceramic particle reinforced steel based composite material, the ZTA particles are plated with nickel and chromium to achieve surface metallization bycontrolling the components and the proportion of the plating solution, the wet problem with a metal matrix is solved, and then the mechanical property of the composite material is improved; and meanwhile, the technology is easy to operate, the cost is reduced to a large extent, no toxicity or pollution is generated, the great potential on increasing the economic benefit and the social benefit isachieved, and the good prospect of being applied to the harsh abrasive wear condition is achieved.

Owner:XI AN JIAOTONG UNIV +1

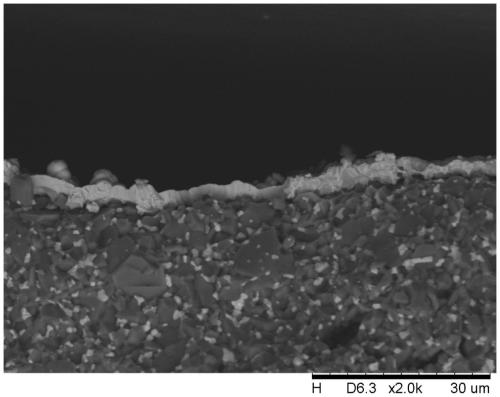

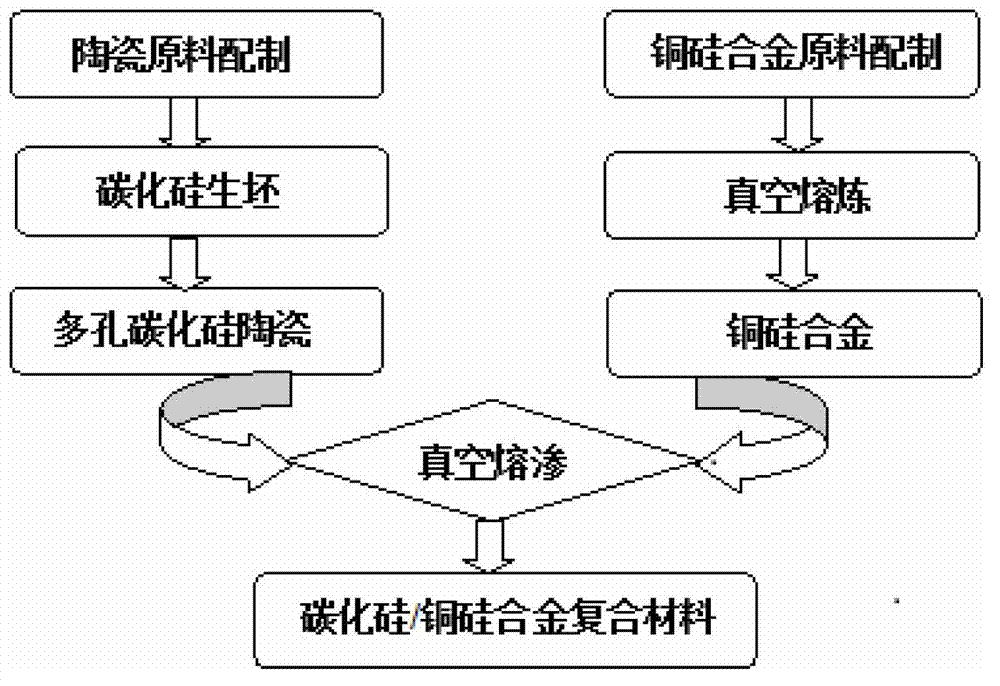

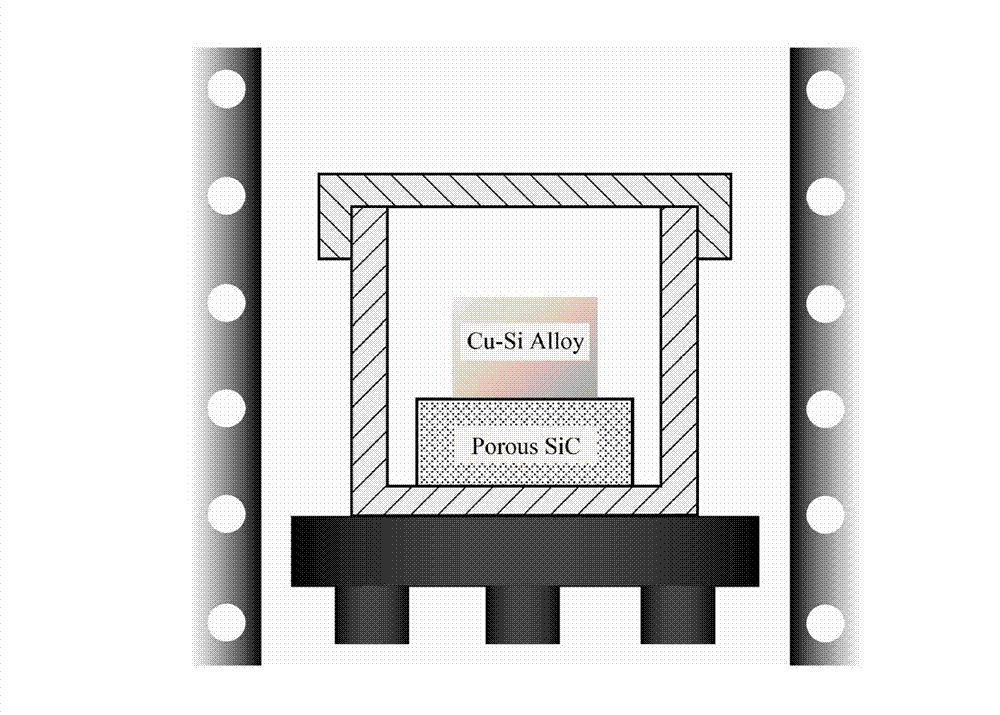

Silicon carbide/copper silicon alloy codual-continuous composite and preparation method thereof

The invention discloses a silicon carbide / copper silicon alloy codual-continuous composite and a preparation method thereof. The composite material comprises the following components in volume fraction: 35-50 percent of porous silicon carbide ceramics and 50-65 percent of copper silicon alloy, wherein the atomic percentage composition of silicon in the copper silicon alloy is 15-40 percent. The preparation method comprises two key processing steps of: preparing the porous silicon carbide ceramics and vacuum infiltrating porous silicon carbide through the copper silicon alloy. Silicon is adopted as an alloying element of copper, so that the problems of wettability and reactivity between copper and silicon carbide are solved simultaneously. In addition, the invention adopts a vacuum infiltrating process as a near net forming preparation process, and specialized die casting equipment and a specific module are not needed, so that the preparation process is simple, has low cost, and can be used for manufacturing various composites with complicated shapes.

Owner:XI AN JIAOTONG UNIV

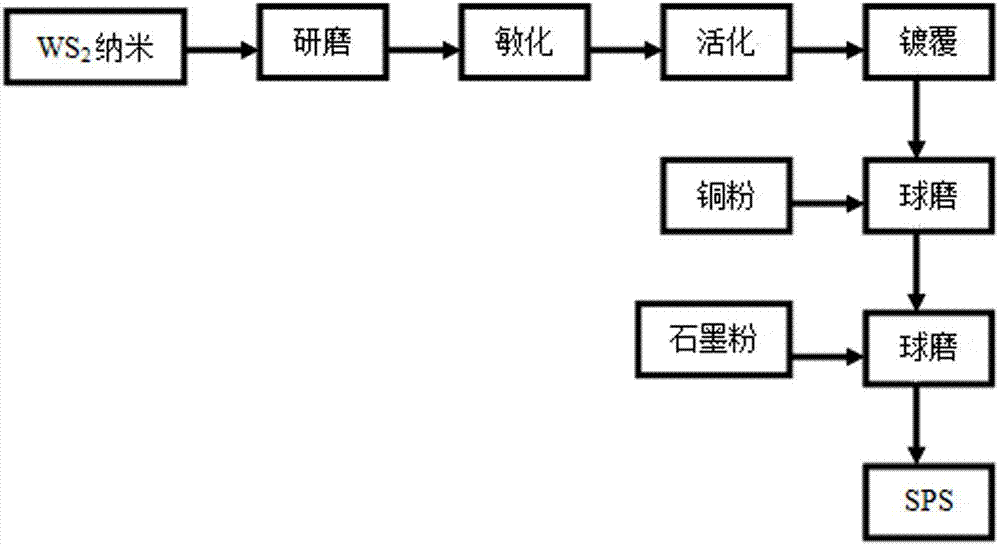

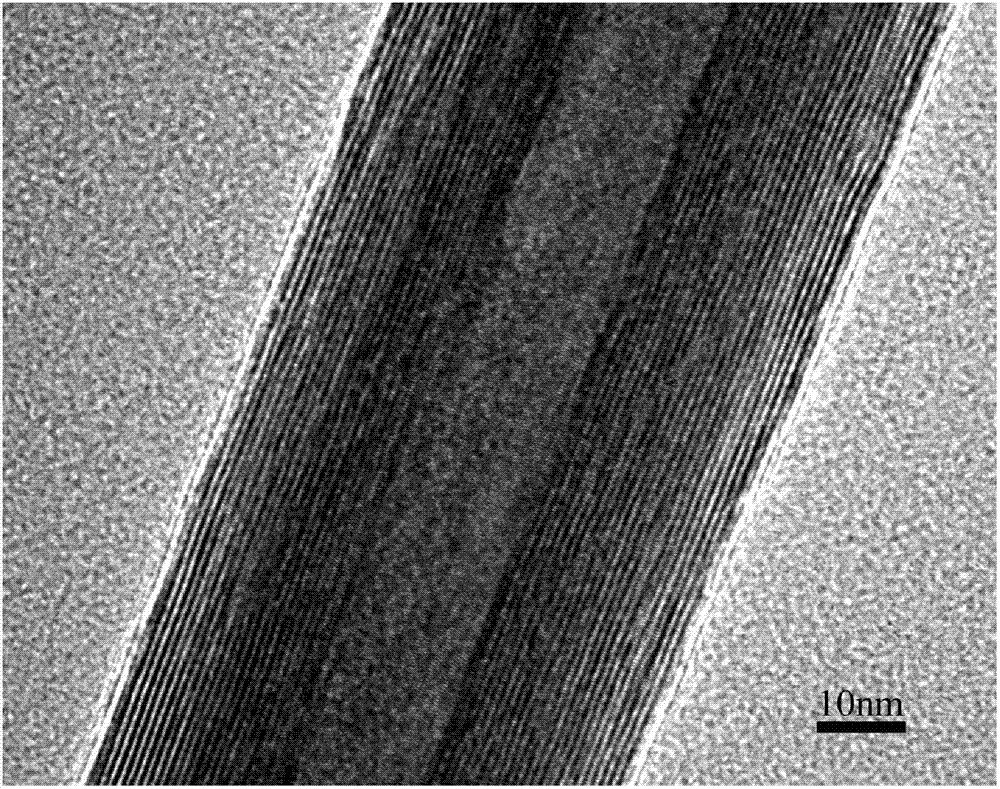

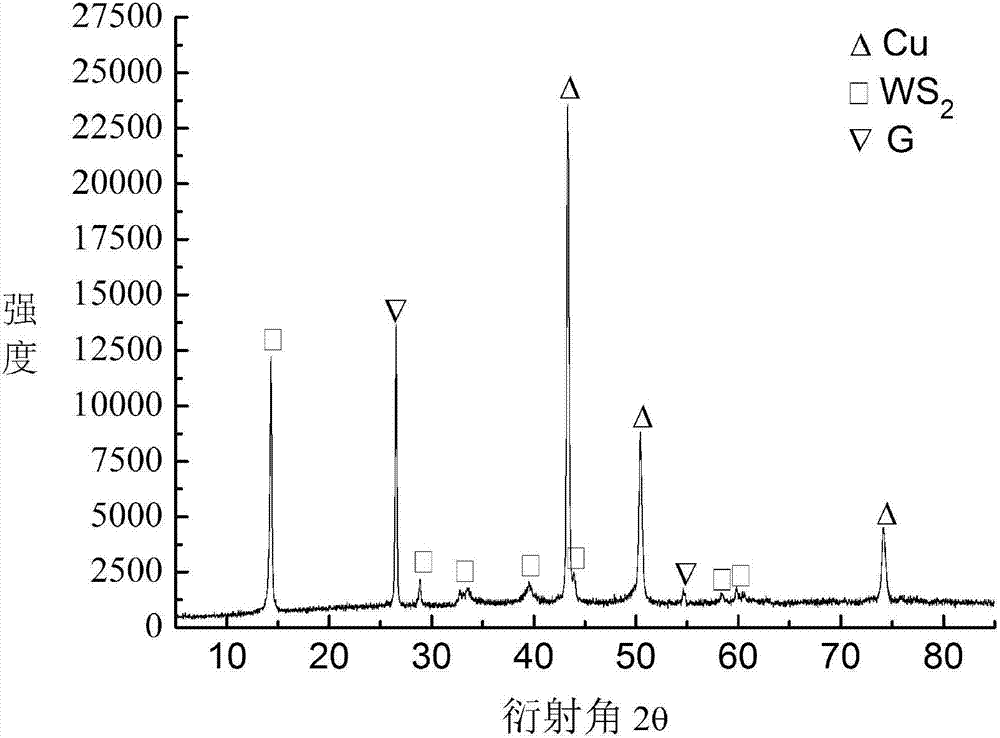

Copper-graphite-tungsten disulfide nanotube self-lubricating composite material and preparation method thereof

ActiveCN103045971AImprove friction and wear propertiesImprove environmental adaptabilityCopper platingElectrolysis

The invention discloses a copper-graphite-tungsten disulfide nanotube self-lubricating composite material and a preparation method thereof, wherein the self-lubricating composite material is prepared by taking copper as a substrate and graphite as well as tungsten disulfide nanotube as solid lubricating additives through a spark plasma sintering process, and consists of the following components in percentage by weight: 80-90% of copper, 7-10% of graphite and 3-10% of tungsten disulfide nanotube. The preparation method comprises the following steps of: grinding, sensitizing, activating and chemically copper-plating the tungsten disulfide nanotube, uniformly mixing with electrolytic copper powder and graphite powder in proportion through a mechanical ball-milling process; and implementing a spark plasma sintering process to the mixing powder, to prepare the tungsten disulfide nanotube and graphite reinforced copper-base self-lubricating composite material. The copper-base self-lubricating composite material prepared by the preparation method disclosed by the invention is high in mechanical intensity, excellent in friction and abrasion resistance and good in environmental suitability.

Owner:HEFEI UNIV OF TECH

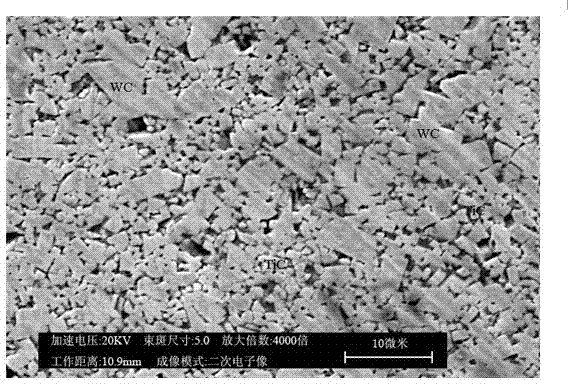

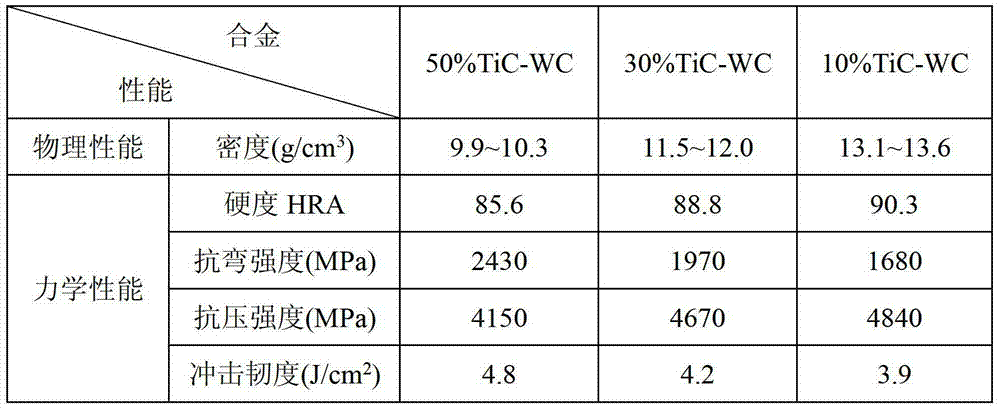

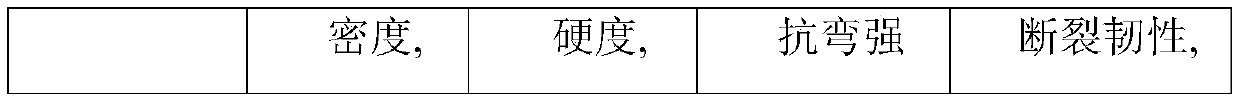

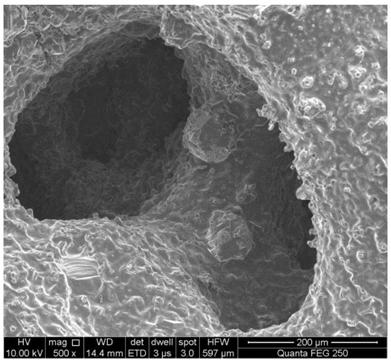

Titanium carbide-tungsten carbide composite hard alloy

The invention discloses a titanium carbide-tungsten carbide composite hard-phase hard alloy. The hard alloy contains a hard-phase titanium carbide-tungsten carbide alloy mixture, an Fe3Al alloy used as a binding phase and Mo, wherein the tungsten carbide alloy accounts for 50-90% by mass percentage of the hard alloy, and is 5-8 microns in granularity; the titanium carbide accounts for 10-50% by mass percentage of the hard alloy, and is 1-3 microns in granularity; the Fe3Al accounts for 5.5-15% by mass percentage of the hard alloy; and the metal Mo accounts for 0.5-1% by mass percentage of the hard alloy. According to the titanium carbide-tungsten carbide composite hard-phase hard alloy disclosed by the invention, the binding phase and the hard phase have an excellent wetting performance, and the prepared hard alloy can provide a structural part which is high in strength, high in density, excellent in corrosion resistance, wearing resistance and other comprehensive performances, and can be mechanically processed, heat-treated and welded; and furthermore, the hard alloy can reduce the preparation cost of like hard alloys.

Owner:SOUTHEAST UNIV

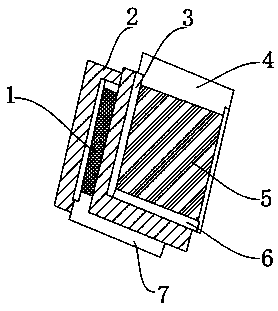

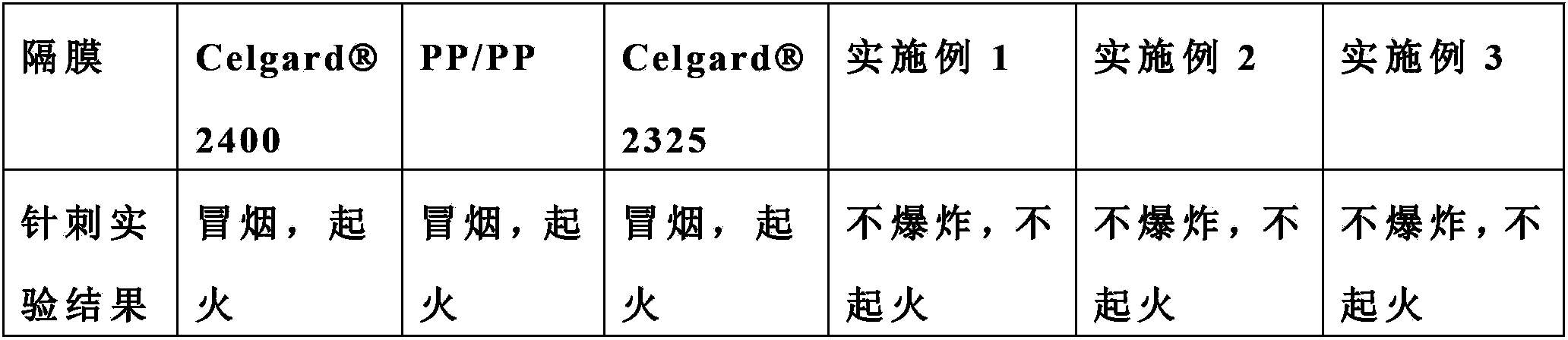

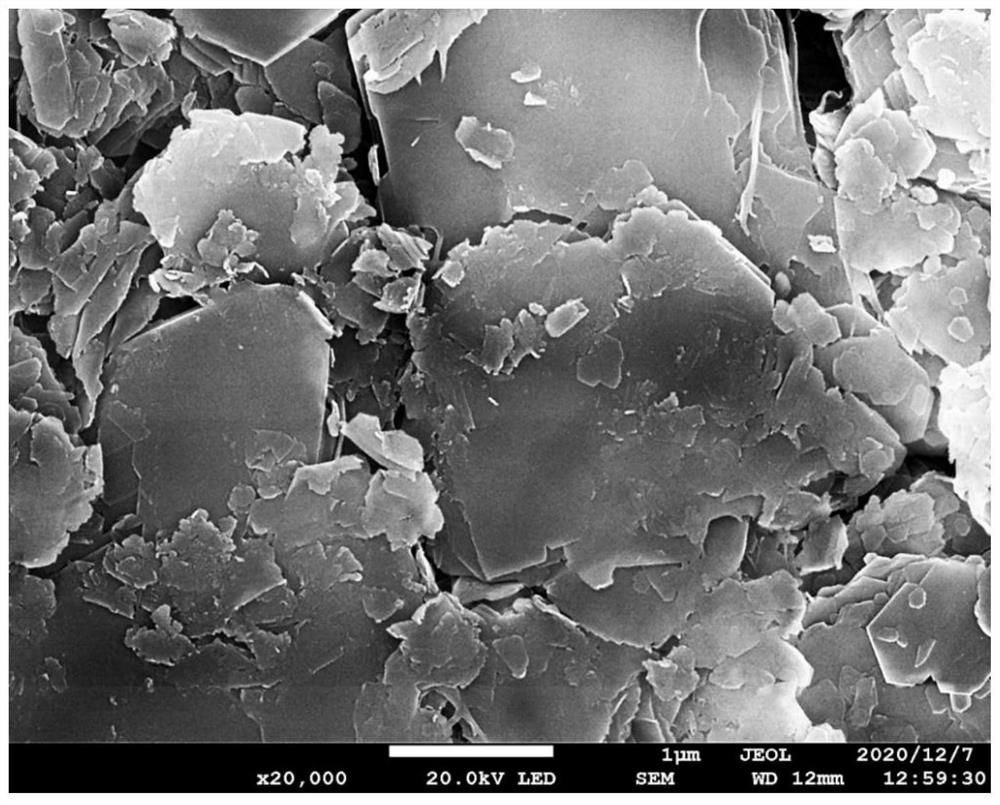

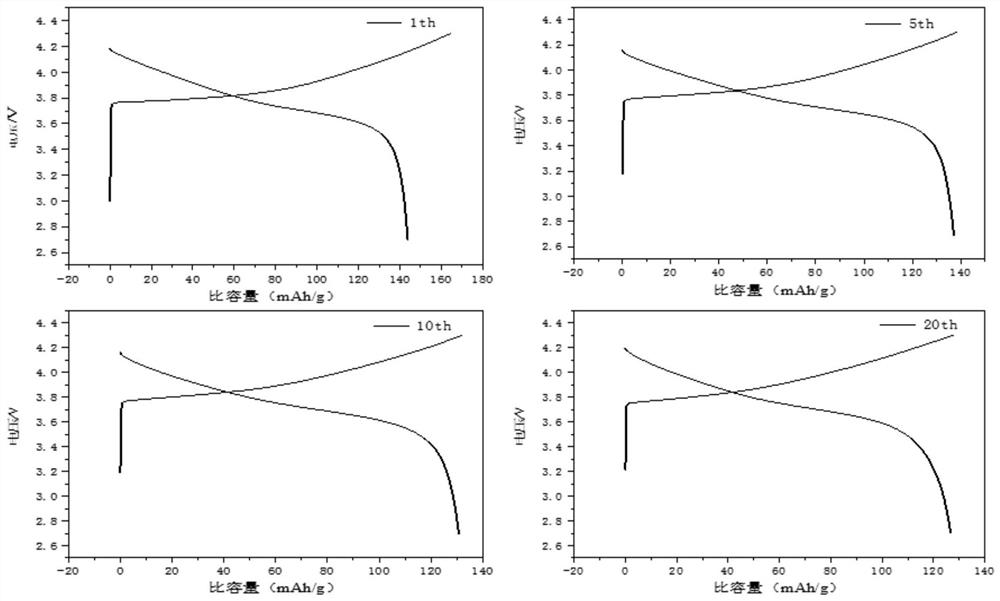

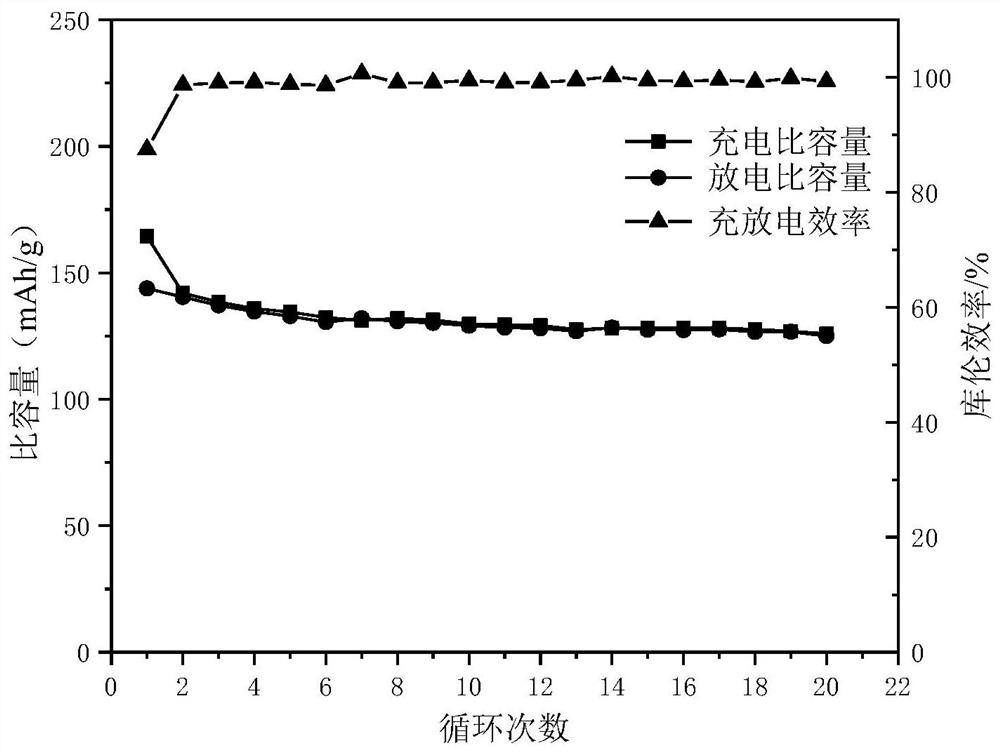

Quick-charging and safe low-temperature lithium ion battery and manufacturing method thereof

InactiveCN111370752AIncrease contact areaEliminate the "partition wall effect"Final product manufactureSecondary cellsInternal resistanceFast charging

The invention discloses a quick-charging and safe low-temperature lithium ion battery and a manufacturing method thereof. The battery is prepared by putting a dry battery cell into a shell, injectingelectrolyte, forming, sealing and grading capacity, and the dry battery cell is formed by winding a positive plate, a ceramic diaphragm, a negative plate and a ceramic diaphragm. The positive / negativeelectrode active substance is secondary micron particles formed by primary nanoparticles, and the nanoscale particles can effectively shorten the migration distance of lithium ions and improve the migration speed of the lithium ions in the charging and discharging process of the battery. Meanwhile, the multiple tabs led out from the positive and negative plates of the dry battery cell are gathered and then are welded with the planar metal sheet current collector to form a full tab. The internal resistance and the temperature rise of the battery in the charging process are effectively reduced,the problem of high-rate quick charging of the battery is solved, the high-current charging and discharging performance of the battery is improved, and the safety stability and the low-temperature electrochemical performance of the battery are also improved.

Owner:LONG POWER SYST NANTONG CO LTD

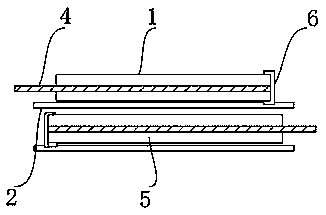

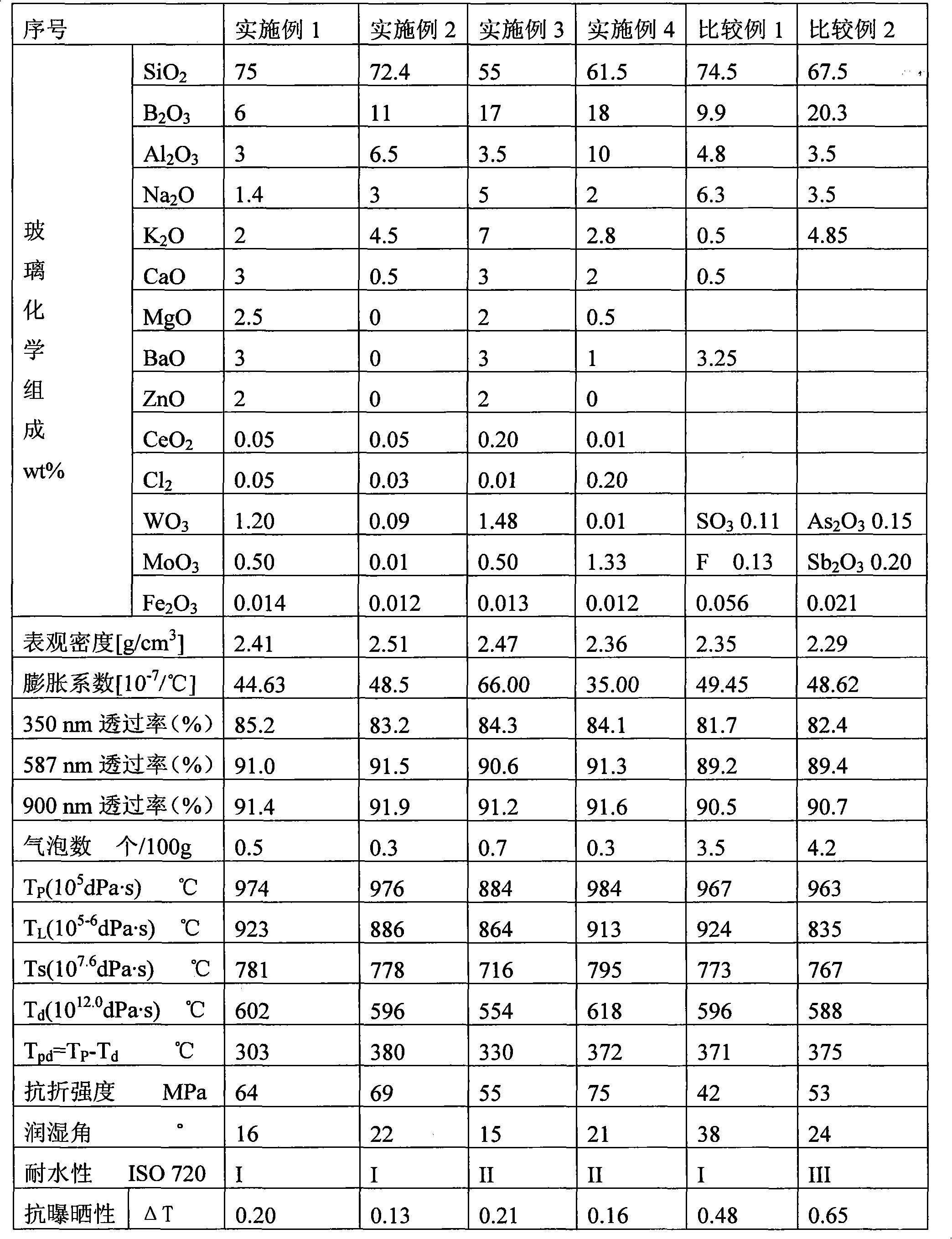

Glass for photo-thermal generation heat-collecting pipe

The invention relates to a glass for a photo-thermal generation heat-collecting pipe. A high precision glass pipe is prepared by a vertical, horizontal or viilo pull-pipe forming technology, thereby meeting the requirements of the glass pipe for a heat-collector which is required by a trench-type photo-thermal generation technique. The glass has high transmissivity of ultraviolet, visible light and near-infrared, high mechanical strength and chemical stability and anti-insolation; and the expansion coefficient of the glass is (36-68)*10-7 / DEG C, thereby meeting the requirements of matched seal and gas tightness of tungsten, molybdenum and kovar alloy. The glass comprises the following components by weight percent: 55-75% of SiO2, 6-18% of B2O3, 3-10% of Al2O3, 0.5-10.5% of MgO+CaO+BaO+ZnO, 3.4-12% of Na2O+K2O, 0.1-2.0% of WO3+MoO3, 0.01-0.20% of Cl2, 0.01-0.20% of CeO2 and no more than 0.015% of Fe2O3. The invention is characterized in that the glass belongs to a borosilicate glass system, satisfies the requirements of the high precise forming technology, does not contain harmful elements such as As2O3, Sb2O3, SO3 and the like, has good melt quality and environmental protection, and can prevent the surface from turning black and the bubble generation when seal processing.

Owner:BEIJING UNIV OF TECH

Suspension curing agent for hardening of phosphate binding agent with water as carrier and preparation method thereof

InactiveCN105945209AEliminate compactionSolve the problem of suspension compactionFoundry mouldsFoundry coresDefoaming AgentsFirming agent

The invention provides a suspension curing agent for hardening of a phosphate binding agent with water as a carrier and a preparation method thereof. The suspension curing agent comprises the following components in percentage by weight: 31-33% of magnesia, 0.06-0.16% of HPMC, 0.7-0.85% of citric acid, 0.09-0.14% of defoaming agent, and 66-69% of water. The magnesia and the HPMC powder are weighed to put in a grinding wheel type mixing grinder for mixing and grinding; the citric acid, and the water and the defoaming agent being 30% of the total water quantity are weighed; the citric acid is dissolved in the water; the defoaming agent is added for uniformly mixing to obtain mixed water solution; the grinding wheel type mixing grinder is started for mixing and grinding the mixed water solution when the mixed water solution is added therein during stirring to obtain paste; the remained water is added in a stirrer; the stirrer is started; and the paste is slowly added in the stirrer for stirring in batches to obtain the suspension curing agent. The prepared suspension curing agent adopts water as the carrier, reaches the suspension rate of 100% by 2 hours, is not caked after more than 6 months of storage, and can be slightly shaken for use.

Owner:HUBEI UNIV OF TECH

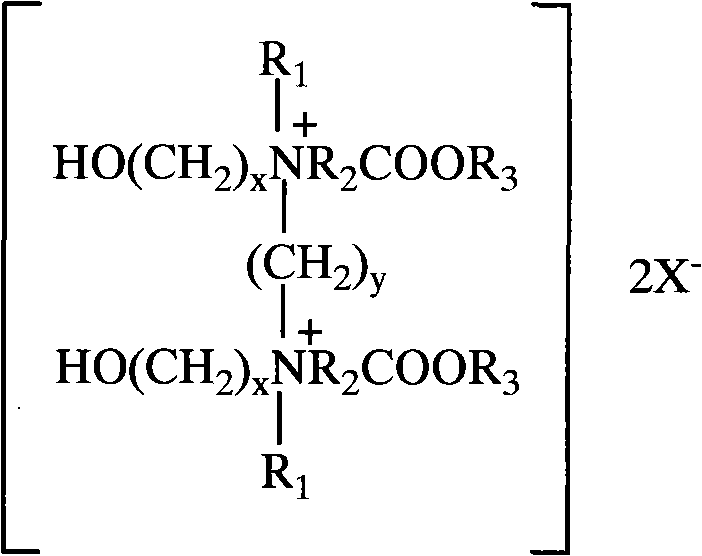

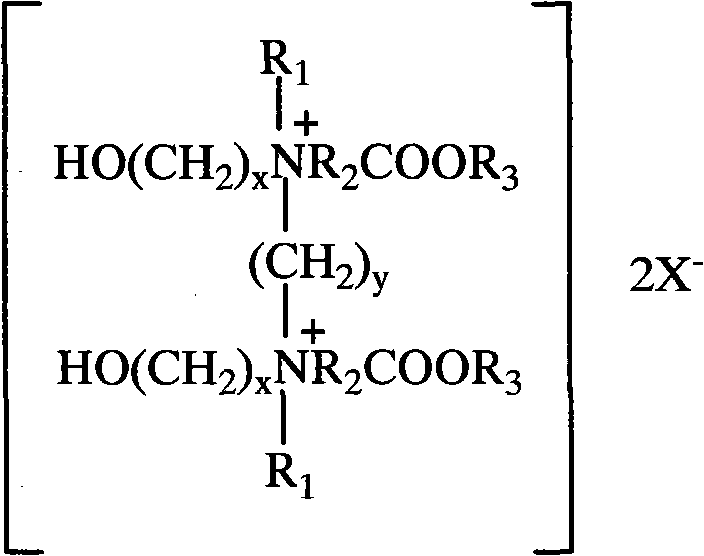

Method for preparing fabric softening agent

InactiveCN102162189AOutstanding advantagesHighlight positive effectsOrganic compound preparationFibre treatmentSolubilityQuaternary ammonium cation

The invention discloses a method for preparing fabric softening agent. The method is characterized in that: long-chain fatty alcohol and unsaturated acid undergo esterification reaction, then the esterification product and alcohol amine undergo addition reaction to form secondary amine, the secondary amine and halogenated hydrocarbon undergo substitution reaction to form tertiary amine, and the tertiary amine and a quaternization reagent are reacted to form the fabric softening agent; and the fabric softening agent has the following structure, wherein R1 is alkyl of C1 to C4 or -CH2CH(OH)CH3, R2 is straight-chain or branch-chain alkyl of C1 to C3, R3 is saturated alkyl with 12 to 22 carbon atoms, x and y are 2 to 6, and X represents negative ions combined with positive ions. The product prepared by the method is a double-ester Gemini quaternary ammonium salt softening agent; by using the Gemini structure and introducing the alcohol ethyl, the problems of poor dissolubility, strong greasy feeling and poor wetting property and air permeability of the conventional softening agent (D1821) are solved; and the softening agent has more excellent softening performance and antistatic performance compared with common ester-based quaternary ammonium salts.

Owner:HENAN TITANING CHEM TECH

Laser-clad side guide plate and machining method thereof

ActiveCN110592580AWear-resistantHigh temperature resistantGuiding/positioning/aligning arrangementsSuperimposed coating processOxidation resistantAlloy

The invention discloses a laser-clad side guide plate and a machining method thereof. A cladding layer with a sandwich structure is machined on a common steel plate matrix through a laser cladding method, and the cladding layer is composed of three layers, that is, a bottom layer, a middle layer and a surface layer. A nickel-based high-temperature alloy system is adopted as an overall material system, the bottom layer has high toughness and is used for realizing an antifatigue function, the middle layer realizes the functions of wear resistance and self-lubricating, and the surface layer realizes the functions of ablation resistance and oxidation resistance. The three-layer structure forms a functionally-graded composite plate, and the composite plate has high-temperature resistance, oxidation resistance, wear resistance and corrosion resistance simultaneously, and has toughness to a certain extent to bear an impact force in a service process, so that the special performance requirements of wear resistance, high-temperature resistance, corrosion resistance, oxidation resistance and impact resistance which are needed in the service process of the side guide plate before the coilingof a production line for a metallurgical hot-rolled coiled plate, are met.

Owner:上海大陆天瑞激光表面工程有限公司

Oiling agent for fluorine-containing polyester FDY fiber and preparation method of oiling agent

The invention relates to an oiling agent for fluorine-containing polyester FDY fiber and a preparation method of the oiling agent. The oiling agent for the fluorine-containing polyester FDY fiber comprises active components in parts by weight: 40-60 parts of mineral oil, 20-35 parts of polyoxyethylene, 5-10 parts of a phosphate ester potassium salt, 8-16 parts of polyethylene glycol fatty acid ester, 1-5 parts of sodium alkyl sulfonate and 1-5 parts of a perfluoroalkyl acrylate. The preparation method comprises: mixing the component and stirring, controlling the temperature at 40-55 DEG C to obtain the FDY oiling agent with good performances. The FDY oiling agent has good comprehensive performance, good compatibility, heat resistance and sizing performance. Due to introduction of the fluorine element, the oiling agent is substantially improved in wettability and permeability, and helps to effectively solve the problemthat conventional oiling agents for fluorine-containing polyester FDY fiber is bad in wettability.

Owner:李伟志

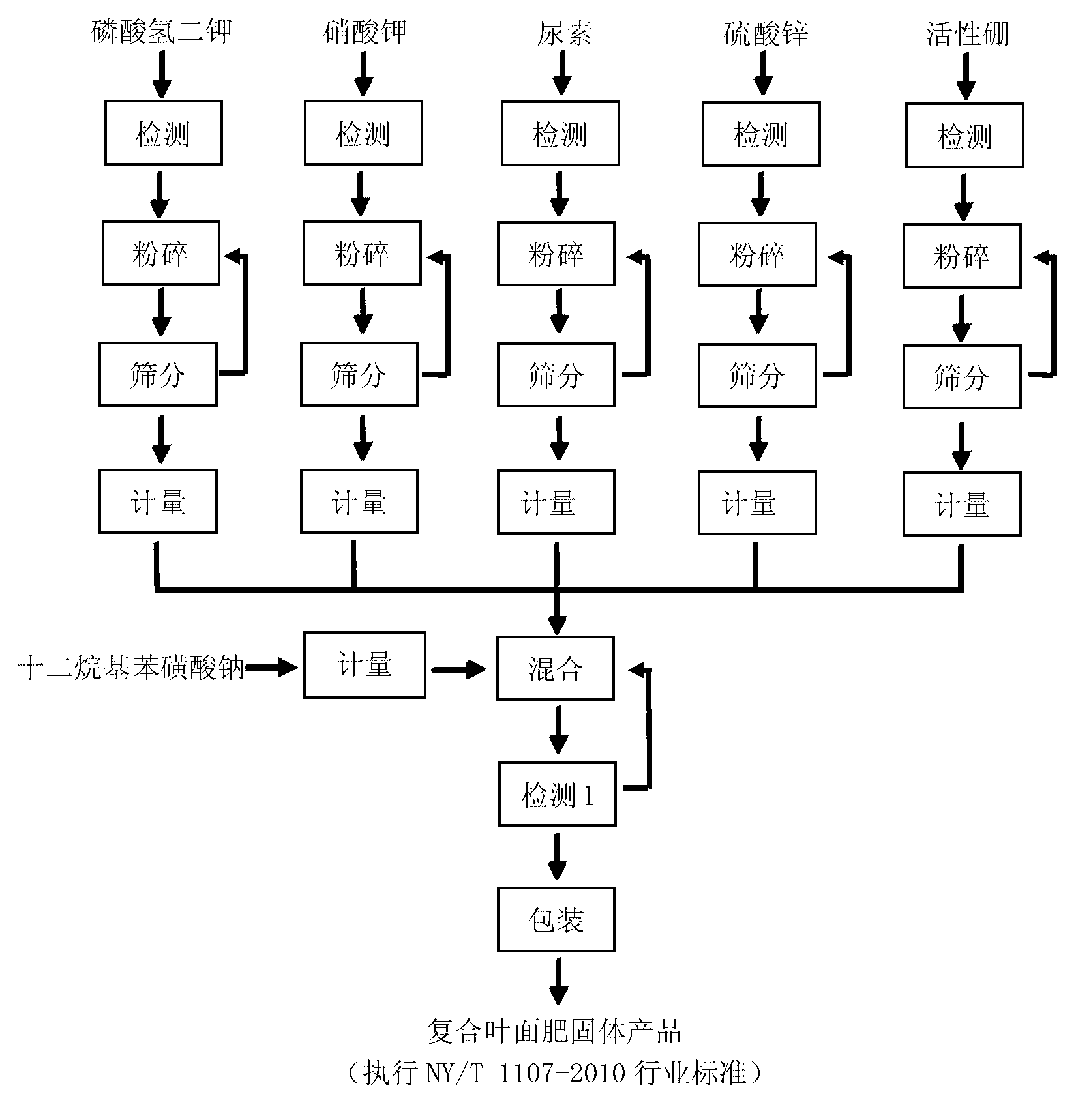

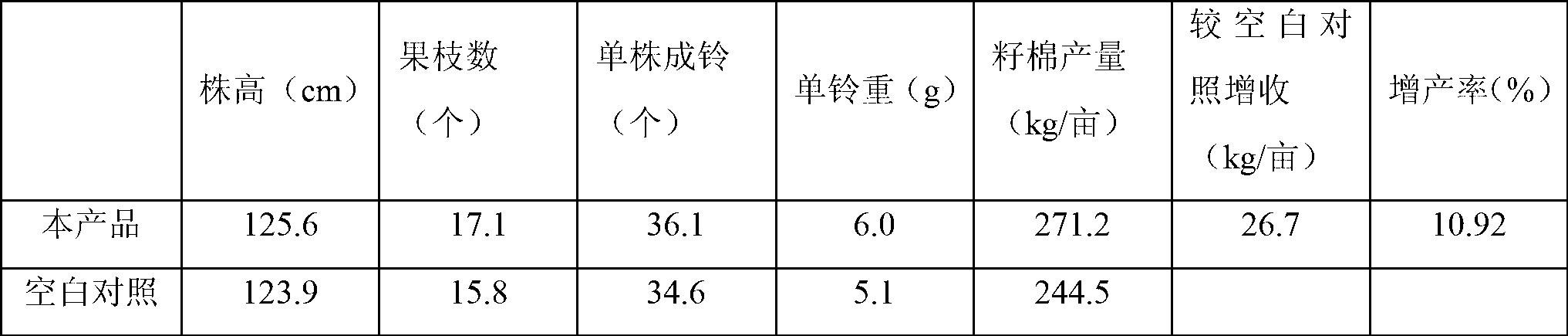

Composite leaf fertilizer for dressing in cotton flower and boll stage

InactiveCN103011977ASolve solubilitySolve Wetting ProblemsFertilizer mixturesAgricultural sciencePotassium

The invention provides a composite leaf fertilizer for dressing in the cotton flower and boll stage. The composite leaf fertilizer is a solid fertilizer containing a lot of nutrient elements and micro nutrient elements. The composite leaf fertilizer is characterized in that the ratio of N to P2O5 to K2O is (1.5 to 2.5): 1: (1.5 to 2.5) based on the mass of nitrogen, phosphorus, potassium, zinc and boron; the sum of N, P2O5 and K2O is not less than 50%; the ratio of Zn to B is (1 to 1.5): 1; the sum of Zn and B is 1 to 3%; and the sodium dodecyl benzene sulfonate is 1 to 2 per mill. When in use, the solid product of the composite leaf fertilizer is diluted 500 times by water, 100kg of diluent is provided for each mu, and the diluent is sprayed to the leaves at the upper part and the intermediate part at 1 to 2 times before the start of autumn times, and particularly sprayed on the rear surfaces of the leaves, and the diluent is sprayed once every 7 to 10 days; and by adopting the composite leaf fertilizer, the average production increase of the seed cotton is over 10%.

Owner:ANHUI JINDIHAO FERTILIZER IND

Galvanizing carbon fiber foamed light metal and preparation method thereof

The invention provides a galvanizing carbon fiber foamed light metal and a preparation method thereof, and relates to foamed light metal technical field. The foamed light metal is composed by galvanizing carbon fiber and light metal. The preparation method comprises the following steps: (1) electroplating carbon fiber in a solution formed by zinc chloride, ammonium chloride, boric acid and dextrin; (2) adding a certain amount of galvanizing short fiber and carboxy methyl amylum ester into saturated salt water and followed by stirring uniformly, and adding a certain amount of salt particle to mix the mixture uniformly and followed by compaction; (3) heating the above mixture and followed by a heat preservation treatment to form a preform; (4) putting the preform into a mould, and filling salt particle to the full around the preform for compaction; (5) heating the preform to a temperature of 300-350 DEG C and followed by a heat preservation treatment, and pouring an overheated light metal solution into the mould to fill gap of the salt particle; (6) washing the salt particle away with water after cooling and solidification to obtain the galvanizing carbon fiber foamed light metal. The galvanizing carbon fiber foamed light metal has the advantages of high strength, high modulus and the like, and has wide and practical application.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

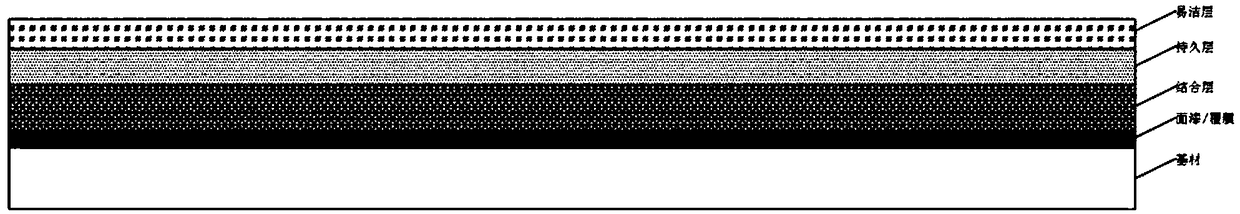

Composition for preparing oil-proof and easy-to-clean paint, related paint, paint preparation method and cupboard board preparation method

ActiveCN109504263AHigh electronegativityStrong bond energyAntifouling/underwater paintsPaints with biocidesPolymer scienceHardness

The invention discloses a composition for preparing oil-proof and easy-to-clean paint, related paint, a paint preparation method and a cupboard board preparation method. The composition for preparingthe oil-proof and easy-to-clean paint is prepared from resin raw materials and a perfluoropolymer system; the resin raw materials include fluorination modified resin and mixed solvents; the perfluoropolymer system includes macromolecular perfluoropolymers with the molecular weight of 30000-100000, medium-molecular perfluoropolymers with the molecular weight of 5000-30000 and micromolecular perfluoropolymers with the molecular weight of 1000-5000. The oil-proof and easy-to-clean paint prepared by the preparation method has the advantages of good hydrophobic and oleophobic effect, high wear resistance, high adhesion to paint layers or coatings on the surfaces of wood boards, high hardness, high wear resistance, and high hydrophobic and oleophobic durability.

Owner:JOMOO KITCHEN & BATHROOM

In-situ self-generated reinforced Ni3Al composite and method for preparing same

The invention relates to origin self- generating Ni3Al compounding material and the method to manufacture. It has four constituents of Ni, B, Ti, and Al. The chemical measuring ratio is that Ni: Al=2.704-3:1, Ti:B=1.04:1, and TiB occupied 3-20% volume of the tally compounding material. The method includes activating Ni-Al-Ti-B system to gain compounding powder and generating TiB / Ni3Al compounding material by discharging plasma sintering origin self generating. The invention has the advantages of fine particle, equally organized, and good mechanical capability.

Owner:HARBIN INST OF TECH

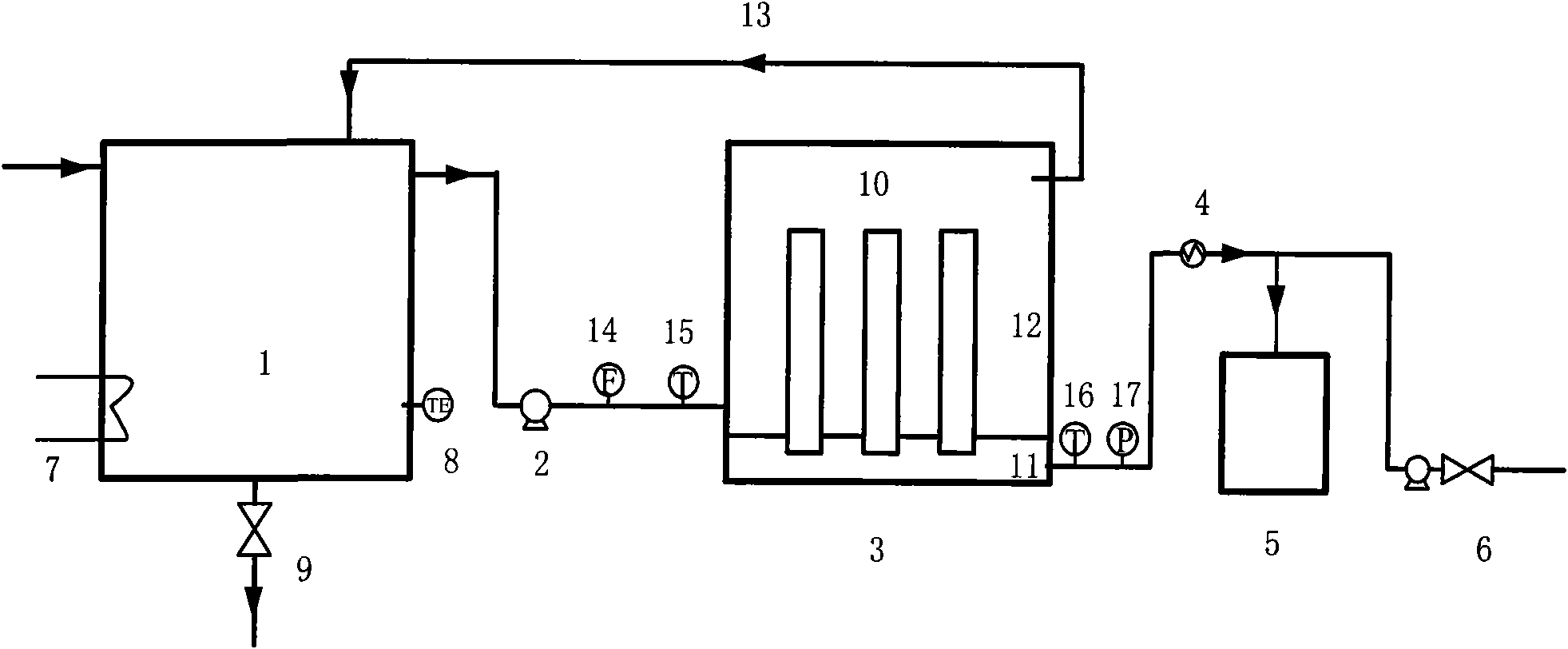

Preparation of TiB2-TiB/Ti gradient composite porous material used for aluminum electrolysis

InactiveCN105088277AExtended service lifeStable cathode reaction interfaceTitanium fluorideElectrolysis

The invention discloses preparation of a TiB2-TiB / Ti gradient composite porous material used for aluminum electrolysis. The composite material reacts with a mixture of borofluoride and titanium fluoride to generate titanium boride and cryolite, and a cathode material with a TiB crystal whisker layer existing between a TiB2 plated layer and matrix titanium is obtained through solid infiltration processing. The bonding strength of a TiB2 deposition layer and a matrix of the cathode material is high. Under the use condition, the TiB2 layer is not prone to falling off from the matrix, and therefore the service life of the cathode material is effectively prolonged, and complete wetting of molten aluminum is achieved through the porous structure of the cathode material. The preparation is simple in method and process, easy to control and low in production cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

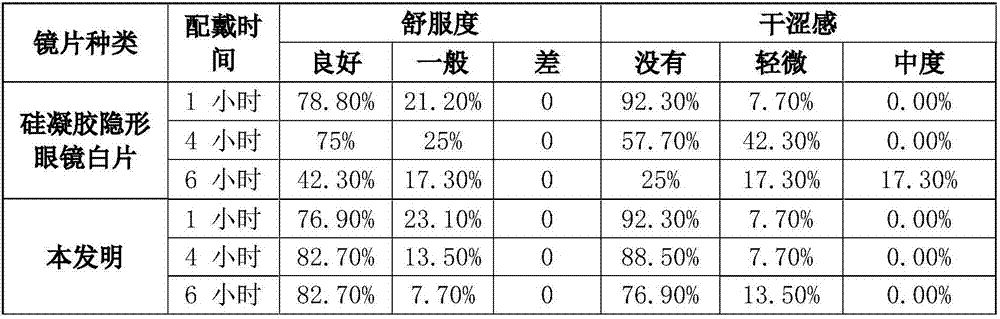

Silica gel contact lenses surface modification method and preparation method of colorful contact lenses

The invention provides a silica gel contact lenses surface modification method and a preparation method of colorful contact lenses. The modification method comprises the following steps: coating the surface of silica gel contact lenses with a coating of a network pattern structure with a gradient water content, wherein the water content of the coating is higher than that of the substrate of the silica gel contact lenses, the coating is colorful or colorless, the coating is made of a biopolymer, and the silica gel contact lenses are made of a silicon-containing prepolymer or a mixture of monomers with the silicon-containing prepolymer in a polymerization manner. The surface properties of the silica gel contact lenses are improved by using the coating of the network structure with the gradient water content, the wearing effect is improved, the wearing dryness of colorful contact lenses is effectively reduced, and meanwhile the wearing comfort is also improved. The appropriate coating water content ensures exchange of a water liquid with ocular humor is ensured, meanwhile the oxygen permeability of contact lenses, appropriate moisture volatilization and moistening of the surface of the coating are ensured, and proteins can be prevented from deposition on the surface of the coating.

Owner:江苏彩康隐形眼镜有限公司

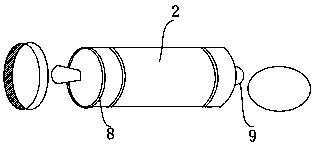

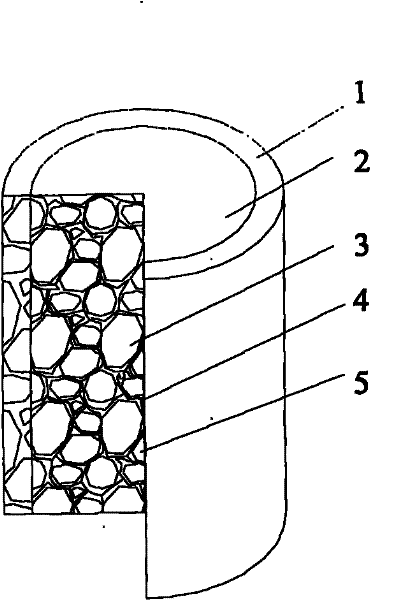

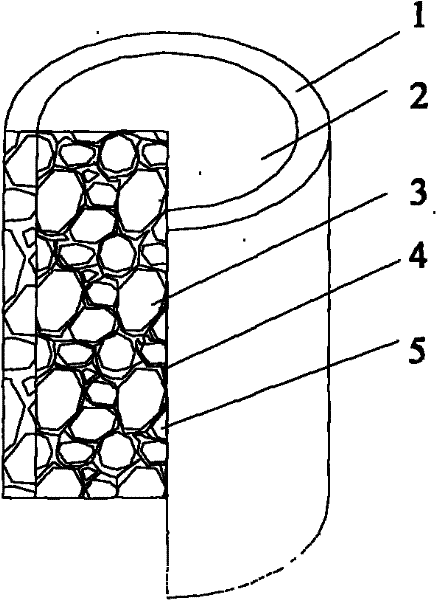

Intervention catheter surface treatment method and intervention catheter

InactiveCN104130438AReduce frictionTo achieve the purpose of covalent linkageCatheterCoatingsHydrophilic coatingCoating system

The invention provides an intervention catheter surface treatment method and an intervention catheter. The method comprises the steps of pre-treatment, grafting and modification treatment, coating application, and post-treatment. With the method, problems of inadequate intervention catheter surface paint wetness and inadequate hydrophilic coating firmness are effectively solved. According to the invention, approaches such as plasma treatment, grafting, coating system application, and the like are combined, such that covalent bond connection between the coating and a catheter substrate is realized. With the treatment, friction force on the intervention catheter in a water environment is reduced by more than 90%.

Owner:BEIJING DEMAX MEDICAL TECH

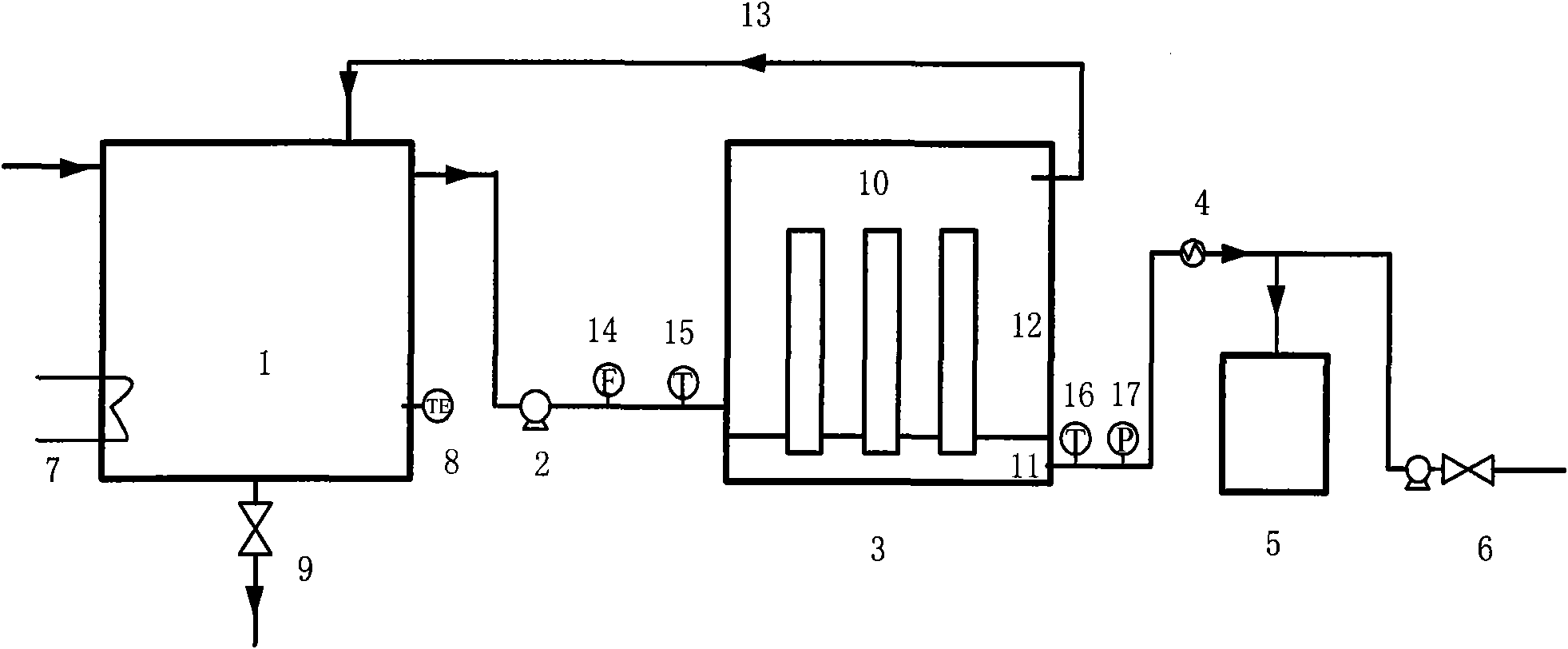

Method and device for treating high-salt content water by hydro-power molecular membrane

InactiveCN102398961AGood removal effectExtended service lifeWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by heatingWater productionWater quality

The invention discloses a method and a device for treating high-salt content water by a hydro-power molecular membrane. The device orderly comprises a material liquid tank, a water circulating pump, a membrane tank, a condenser, a product water tank and a vacuum pump. The material liquid tank is provided with an electric heating system and a temperature sensor. The device and the method adopt a core technology of a hydro-power molecular membrane, realize excellent and stable product water quality and a high salt rejection rate reaching 99.99%, have good COD and color removal effects, reduce energy consumption, wherein power consumption is in a range of 3 to 6KWh / m<3>, prolong a hydro-power molecular membrane service life, greatly resist pollution, realize a high water production flux of 10 to 100L / m<2>*h, solve the problems of hydrophobic membrane aperture wetting and wire fracture in membrane distillation, and adopt heat sources such as industrial waste heat, underground heat, solar energy and the like so that high-efficiency and energy-saving high-salt content water treatment is realized.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

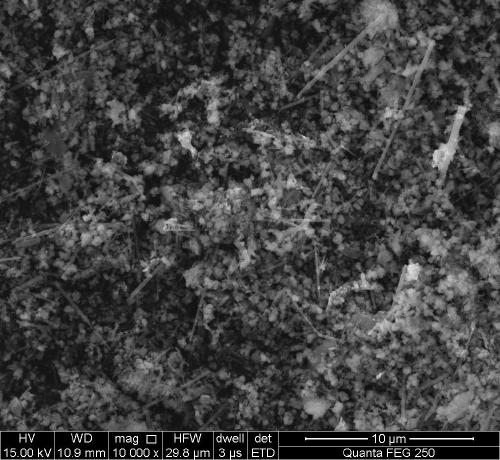

Coating nanometer silicon carbide whisker toughened Ti(C,N) based metal ceramic material and preparing method thereof

ActiveCN109807327AHigh hardnessImprove flexural strengthLiquid/solution decomposition chemical coatingChemical platingWhiskers

The invention discloses a coating nanometer silicon carbide whisker toughened Ti(C,N) based metal ceramic material and a preparing method thereof. The coating nanometer silicon carbide whisker toughened Ti(C,N) based metal ceramic material is composed, by mass percent, 0.5 to 5wt% of coating nanometer silicon carbide, and 95 to 99.5wt% of Ti(C,N) based metal ceramic powder. The chemical plating method is adopted, the coating is formed on the surface of the silicon carbide, the coating nanometer silicon carbide is introduced into the traditional Ti(C,N) based metal ceramic material, dispersionbetween silicon carbide particles can be enhanced, the wettability of the silicon carbide whisker toughened Ti(C,N) based metal ceramic material can be obviously improved, and finally, the propertiesof hardness, bending resistance and the like of the toughened Ti(C,N) based metal ceramic material can be improved; and the comprehensive property is excellent, and the material can meet the use needsof the particular occasion.

Owner:株洲卓然新材料有限公司

Silver tungsten carbide-molybdenum composite electrical contact material as well as skeleton powder and preparation method thereof

InactiveCN111001801AImprove adverse effectsImprove wettability relationshipElectric switchesLow voltageMolybdenum trioxide

The invention discloses a silver tungsten carbide-molybdenum composite electrical contact material as well as skeleton powder and a preparation method thereof. According to the technical scheme, the preparation method comprises the steps of ball-milling and mixing ultrafine tungsten carbide powder and nano molybdenum trioxide powder; enabling molybdenum trioxide to react with free carbon in tungsten carbide in a high-temperature inert atmosphere to form molybdenum dioxide, discharging carbon dioxide, mixing tungsten carbide, molybdenum trioxide and molybdenum dioxide mixed powder with a certain amount of pure silver powder, and sintering the mixture in a high-temperature reducing atmosphere to convert molybdenum dioxide and molybdenum trioxide powder into molybdenum powder; and then obtaining the compact ultrafine silver tungsten carbide-molybdenum composite material by adopting conventional pressing, sintering and infiltration processes. Compared with traditional silver tungsten carbide, the ultrafine silver tungsten carbide-molybdenum composite electrical contact material eliminates negative effects caused by free carbon, is higher in product compactness and strength, has very good wear resistance and burning loss resistance, and has a longer electrical life when used in a low-voltage electrical appliance.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

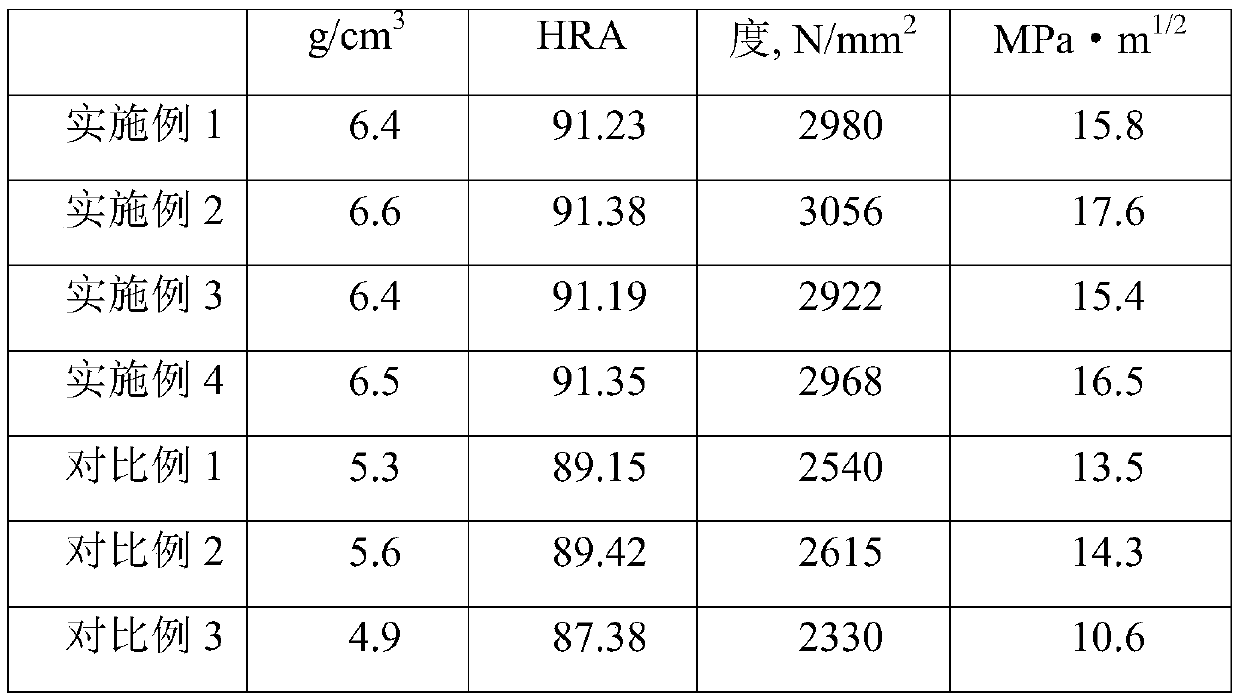

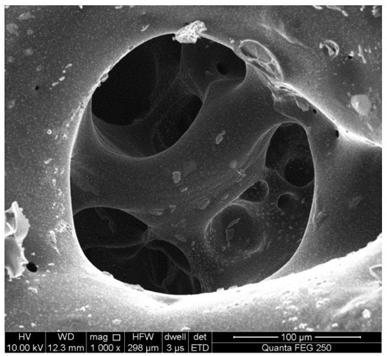

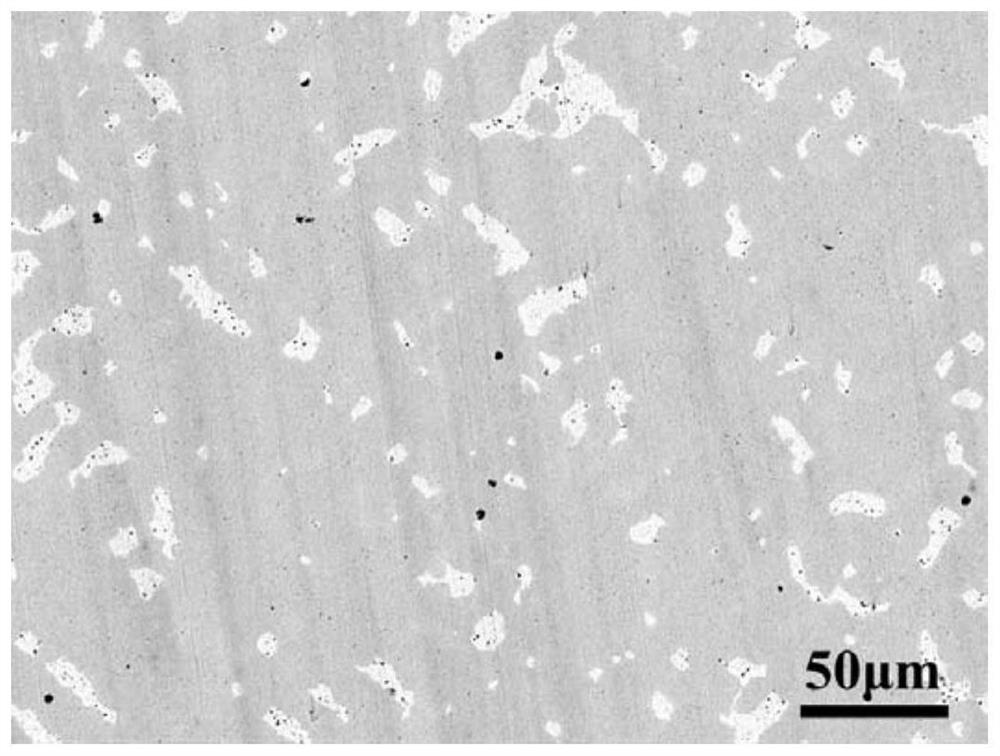

Three-dimensional network silicon carbide enhanced metal-based composite material and preparation method thereof

ActiveCN109536768APore uniformity is highHigh hardnessCarbon preparation/purificationFiberCarbon fibers

The invention relates to a three-dimensional network silicon carbide enhanced metal-based composite material and a preparation method thereof. The composite material comprises a metal matrix and a three-dimensional network silicon carbide ceramic enhanced phase. The three-dimensional network silicon carbide ceramic enhanced phase is obtained by siliconizing the surface of the three-dimensional carbon. The preparation method comprises the following steps: foaming and carbonizing a mixture of wood flour and short carbon fibers to prepare three-dimensional network carbon; and siliconizing the surface of the three-dimensional network carbon at a high temperature to prepare the three-dimensional network silicon carbide ceramic enhanced phase and carrying out cast-infiltration to the metal matrix to obtain the three-dimensional network silicon carbide enhanced metal-based composite material. In the composite material prepared by the method, the three-dimensional network silicon carbide ceramic is great in porosity and small in pore diameter, and the three-dimensional network silicon carbide is continuous in a three-dimensional space and forms metallurgical bonding with the metal matrix.Compared with a conventional silicon carbide particle enhanced metal matrix, the composite material has a better integral structure, and not only can play high hardness, high wear resistance and highheat resistance of the silicon carbide ceramic in the three-dimensional direction, but also can keep good toughness and heat and electricity conducting performance of the metal matrix. The prepared composite material shows excellent shock-resistant, impact-resistant and wear-resistant performance in various severe working conditions.

Owner:CENT SOUTH UNIV

Method for reinforcing aluminum-based composite material by high-strength silicon carbide particles and composite material of method

ActiveCN111889686ASolve Wetting ProblemsSolve the problem of difficult reserved holesTransportation and packagingMetal-working apparatusWaxAluminum matrix composites

The invention discloses a method for reinforcing an aluminum-based composite material by high-strength silicon carbide particles and the composite material of the method. The method comprises the following steps of S1, uniformly ball-milling silicon carbide particles with different particle sizes and aluminum powder according to a certain mass ratio; S2, adding an adhesive, emulsion wax and aluminum dihydrogen phosphate, and performing uniform stirring and sieving for later use; S3, putting a sieved material into a mold, and performing demolding to obtain a silicon carbide aluminum pre-sintered body; and S4, sintering, crushing and ball-milling shaping the pre-sintered body, and performing sieving to obtain silicon carbide aluminum particles and the like. After modifying the silicon carbide particles with small particle size, a silicon carbide aluminum prefabricated form can be manufactured, and then differential-pressure impregnation on molten aluminum is carried out to obtain the high-strength silicon carbide reinforced aluminum composite material. The defects that submicron or nanoscale silicon carbide aluminum (the particle size is smaller than 1 <mu>m) is easy to agglomerate and difficult to impregnate are solved, and the defects in existing pressure casting and stirring casting are overcome.

Owner:陕西迈特瑞科技有限公司

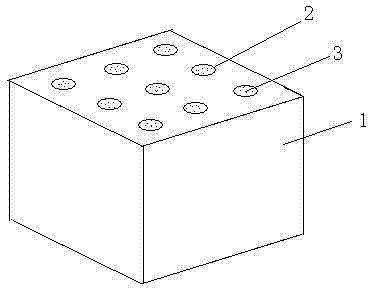

TiB2-C composite cathode for aluminum electrolysis and preparation method thereof

The invention provides a TiB2-C composite cathode for aluminum electrolysis and a preparation method thereof. The TiB2-C composite cathode comprises a full-graphite carbon block or a graphitized cathode carbon block for aluminum electrolysis, wherein holes are formed in a conductive face of the carbon block, and TiB2-C composite cathode materials are arranged in the holes. A plurality of TiB2-C composite materials penetrating through the interior of a base body have good wetting properties with aluminum liquid, then, during electrolysis, aluminum liquid films are firstly formed at conductive poles of the wettable TiB2-C composite material, then, a continuous aluminum liquid film face is formed by a plurality of points, a whole cathode conductive face is covered, and then, a layer of uniform and firm aluminum liquid film is formed on a whole cathode surface, so that the problem of the wetting of the aluminum liquid and a cathode material is solved thoroughly, the condition that an inert wettable cathode can have a stable cathodic reaction interface in various novel aluminum electrolysis tanks is ensured, the real wetting of the aluminum liquid and the cathode is realized, conditions for realizing the low-polar-distance production of aluminum electrolysis are provided, and meanwhile, the problems that a TiB2 composite coating cathode is short in technical service life and easy in falling off are solved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

High-entropy alloy system high-temperature brazing filler metal

PendingCN113245747ARelief of residual stressGood stabilityWelding/cutting media/materialsSoldering mediaHigh entropy alloysTemperature resistance

The invention discloses high-entropy alloy system high-temperature brazing filler metal, and relates to high-temperature brazing filler metal. The problems that a ceramic brazed joint brazed by traditional brazing filler metal has too large residual stress and poor high temperature resistance is solved. The chemical formula of the high-entropy alloy system high-temperature brazing filler metal is CoCrFeNiCuxTiy, the value range of x is 0.5-2, the value range of y is 0.1-0.5, and the molar ratio of Co to Cr to Fe to Ni to Cu to Ti is 1: 1: 1: 1: (0.5-2): (0.1-0.5). A method comprises the following steps of 1, weighing raw materials; and 2, vacuum arc melting. The prepared high-entropy alloy system high-temperature brazing filler metal is used for brazing ceramics and ceramic-based composite materials, the number of fcc solid solution phases in an obtained brazing seam structure is larger, and the residual stress can be effectively relieved through plastic deformation. According to the method, the high-entropy alloy system high-temperature brazing filler metal can be obtained.

Owner:LINYI UNIVERSITY

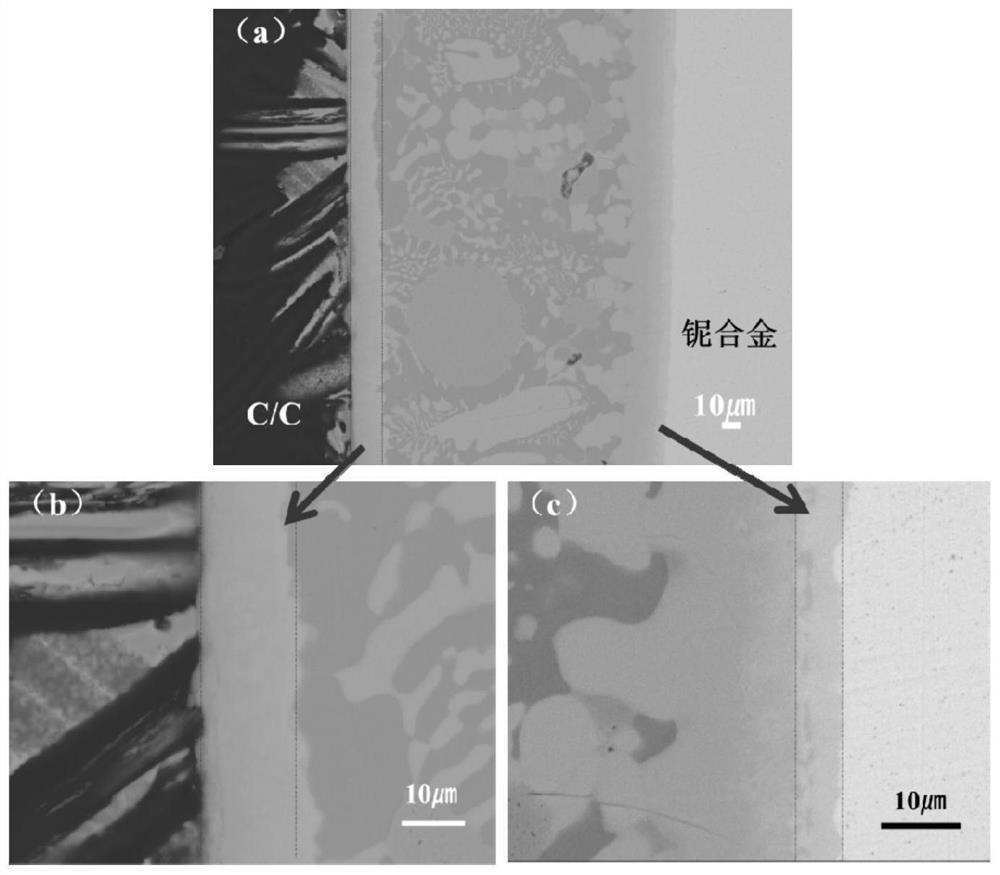

Method for preparing continuous carbon fiber reinforced aluminum matrix composite

The invention discloses a method for preparing a continuous carbon fiber reinforced aluminum matrix composite. The method for preparing the continuous carbon fiber reinforced aluminum matrix compositecomprises the steps that after pretreatment and plating application are conducted on bare carbon fiber in sequence, work blanks are then prepared; an appropriate number of work blanks are taken and placed in extrusion dies; a compressor is adopted, the work blanks are formed through extrusion, and prefabricated blocks are acquired; the prefabricated blocks are placed in a plasma sintering furnace, and the continuous carbon fiber reinforced aluminum matrix composite is acquired after sintering. The preparation technology of the continuous carbon fiber reinforced aluminum matrix composite is simple; besides, carbon fiber is uniformly dispersed in the matrix, and material properties are isotropic; and in addition, various kinds of physical properties of the composite are improved, and meanwhile, the mechanical property of the composite is improved conspicuously.

Owner:SHAANXI SCI TECH UNIV

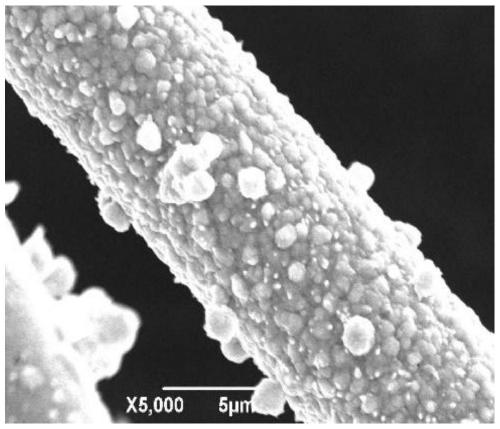

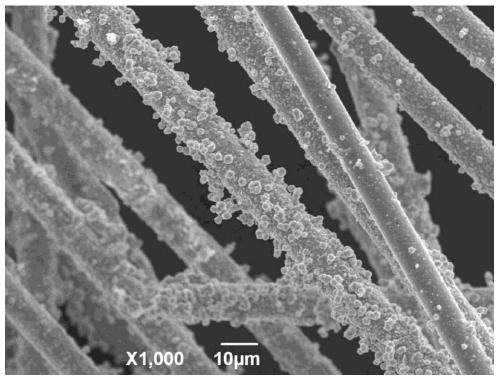

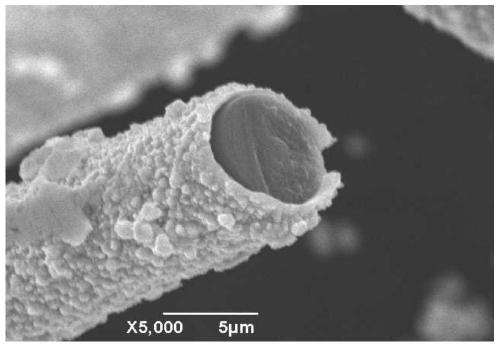

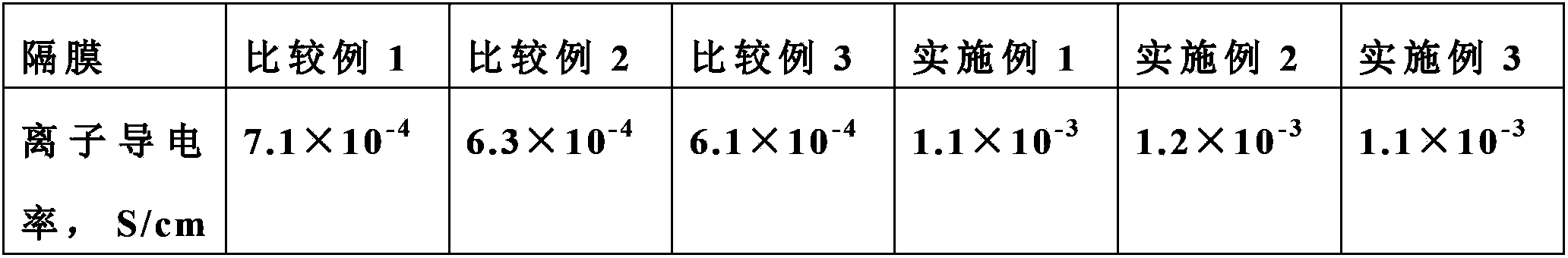

Method for preparing multilayer composite membrane for secondary battery by using electrostatic spinning coating method

ActiveCN102779964BImprove securityEnsure safetySynthetic resin layered productsCell component detailsComposite filmElectrospinning

The invention discloses preparation of a multilayer composite membrane for a secondary battery by using an electrostatic spinning coating technology combined with a pore-forming technology, a manufacturing method of the multilayer composite membrane and the secondary battery prepared by using the membrane. The method is characterized by comprising the following steps of: (1) dissolving a high-molecular organic matter into a solvent to form a high-molecular solution; (2) adding a small-molecular organic matter and / or an inorganic nanometer material into the high-molecular solution to ensure that the small-molecular organic matter is dissolved into the high-molecular solution; dispersing an inorganic nanometer material into the high-molecular solution to form an organic / inorganic mixed solution; (3) uniformly coating the formed organic / inorganic mixed solution on at least one side of a film matrix by using the electrostatic spinning coating technology to form a composite film, and drying the composite film; and (4) extracting the small-molecular organic matter from the dried composite film to continuously dry and form the multilayer composite membrane for the secondary battery. By using the method, an inorganic complex of inorganic membranes is realized quickly and conveniently, the ionic conductivity of the lithium ion battery membrane can be improved, and the heat stability and the security of the battery are guaranteed; and the method has the advantages of being simple in operation and convenient for industrialization.

Owner:LONG POWER SYST SUZHOU

Lithium battery composite diaphragm and preparation method thereof

PendingCN113013547AAdvantages of preparation methodImprove the delivery effectMaterial nanotechnologyCell component detailsPhysical chemistryMontmorillonite

The invention provides a lithium battery composite diaphragm and a preparation method thereof, and the preparation method comprises the following steps: S1, dispersing pretreated montmorillonite in a solvent, and uniformly stirring and dispersing to obtain a montmorillonite dispersion liquid; S2, taking upper turbid liquid of the montmorillonite dispersion liquid, putting the upper turbid liquid into a centrifugal tube for centrifugal treatment to obtain montmorillonite nanosheets, putting the montmorillonite nanosheets into an alkaline solution for infiltration, then performing ice-bath ultrasonic treatment to prepare montmorillonite emulsion, and finally performing solid-liquid separation and drying to obtain montmorillonite powder; S3, uniformly mixing the montmorillonite powder with an oil-based binder to form an oil-based coating slurry; and S4, coating the surface of the lithium battery diaphragm with the oil coating slurry, and drying to obtain the lithium battery composite diaphragm. According to the lithium battery composite diaphragm provided by the invention, rapid transmission of lithium ions on the diaphragm is facilitated, the cycle performance and the ionic conductivity of the diaphragm are improved, the preparation process is simple and feasible, the product purity is high, the preparation cost is low, and the lithium battery composite diaphragm is suitable for large-scale industrial production.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com