Method for preparing continuous carbon fiber reinforced aluminum matrix composite

A technology for strengthening aluminum matrix and composite materials, which is applied in the field of aluminum matrix composite material manufacturing, can solve problems such as complex preparation methods and processes, and achieve the effects of improved mechanical properties, less requirements for process equipment, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

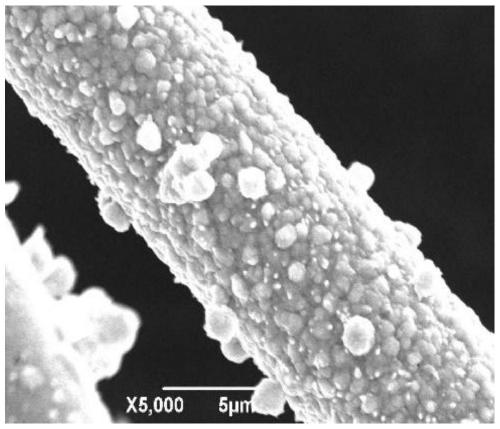

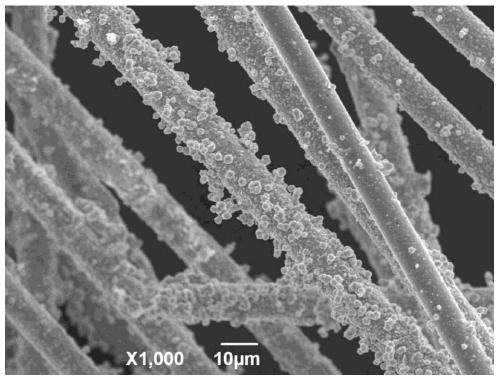

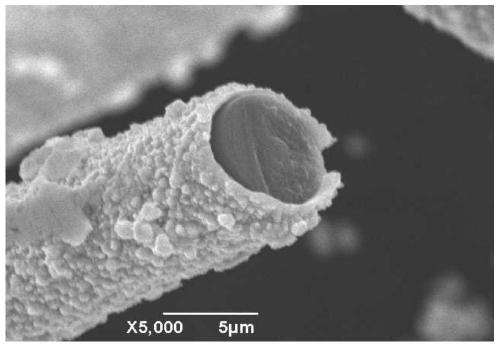

Image

Examples

Embodiment 1

[0050] A method for preparing a continuous carbon fiber reinforced aluminum matrix composite material of the present invention is specifically implemented according to the following steps:

[0051] Step 1, pre-processing

[0052] Put an appropriate amount of bare carbon fiber in a muffle furnace for high-temperature burning treatment to obtain degummed carbon fiber, and place the degummed carbon fiber in HNO with a mass fraction of 20% 3 Stir in the solution evenly, take it out and put it in a NaOH solution with a mass fraction of 10% for neutralization treatment and stir evenly, then perform sensitization and activation treatment on it, and place it in a constant temperature water bath to obtain a carbon fiber solution to be plated;

[0053] Among them, the temperature of high temperature burning treatment is 430°C, and the time is 60min; HNO 3 The volume ratio with NaOH is 1:2.

[0054] The activation process is as follows:

[0055]Put hydrochloric acid with a mass fracti...

Embodiment 2

[0067] The preparation method of the continuous carbon fiber reinforced aluminum matrix composite material is the same as that of Example 1, except that:

[0068] In the pretreatment, the high-temperature burning temperature is 450°C;

[0069] In the plating step, the mass ratio of copper sulfate: formaldehyde: potassium sodium tartrate is 10:2.34:60, and the plating temperature is 60° C.; the pH of the copper-plated carbon fiber solution is 12.0;

[0070] In blank preparation, the mass ratio of copper-plated carbon fiber and aluminum powder is 1:999;

[0071] In step 4, the pressure of the compressor is 600KN, and the holding time is 1min;

[0072] In step 5, the pressure of plasma sintering is 4.0T, and the temperature is 450°C.

Embodiment 3

[0074] The preparation method of the continuous carbon fiber reinforced aluminum matrix composite material is the same as that of Example 1, except that:

[0075] In the pretreatment, the high-temperature burning temperature is 450°C;

[0076] In the plating step, the mass ratio of copper sulfate: formaldehyde: potassium sodium tartrate is 15:2.34:40, and the plating temperature is 65°C; the pH of the copper-plated carbon fiber solution is 12.25;

[0077] In blank preparation, the mass ratio of copper-plated carbon fiber and aluminum powder is 1:499; the binder is glycerin ethanol solution;

[0078] In step 4, the pressure of the compressor is 400KN, and the pressure holding time is 1.5min;

[0079] In step 5, the pressure of plasma sintering is 4.5T, and the temperature is 480°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com