Patents

Literature

30results about How to "Solve the problem that it is difficult to disperse evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

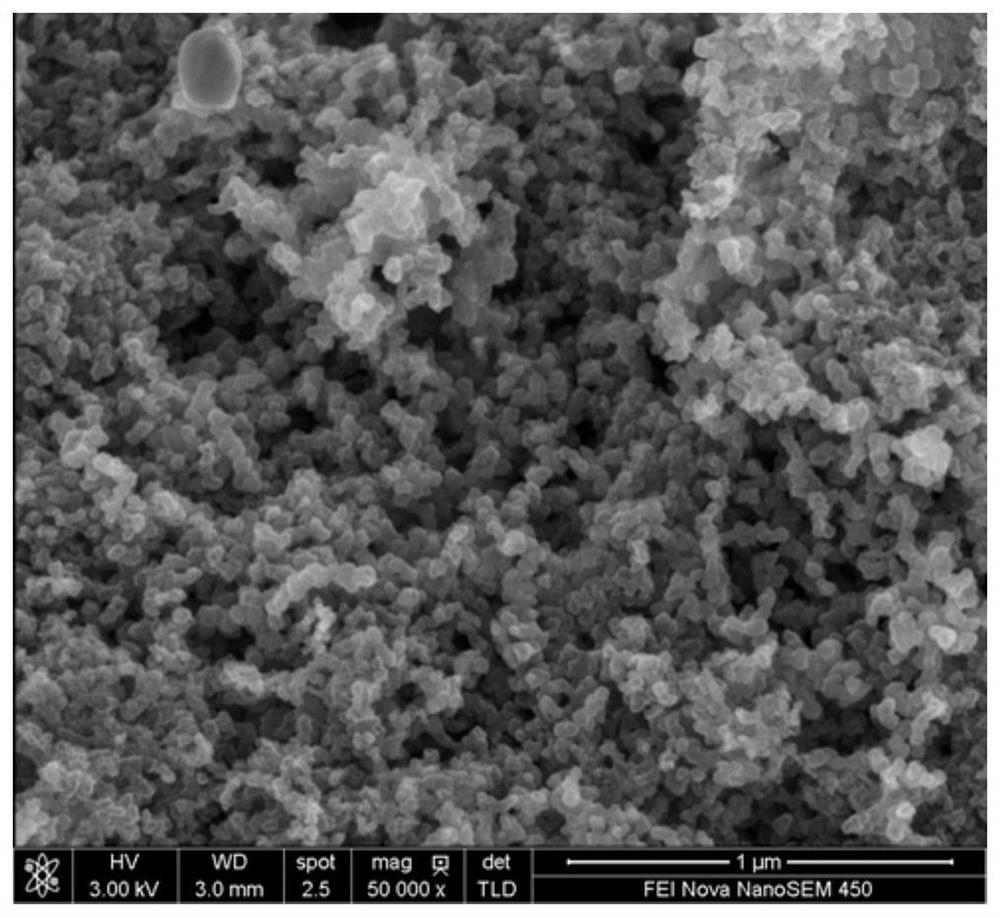

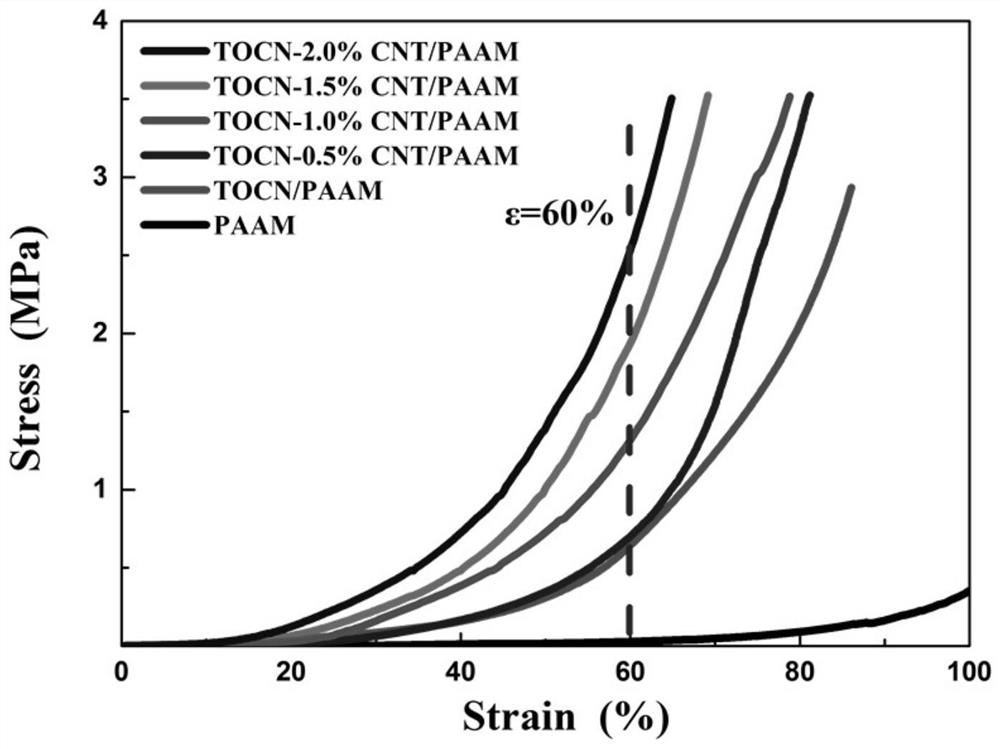

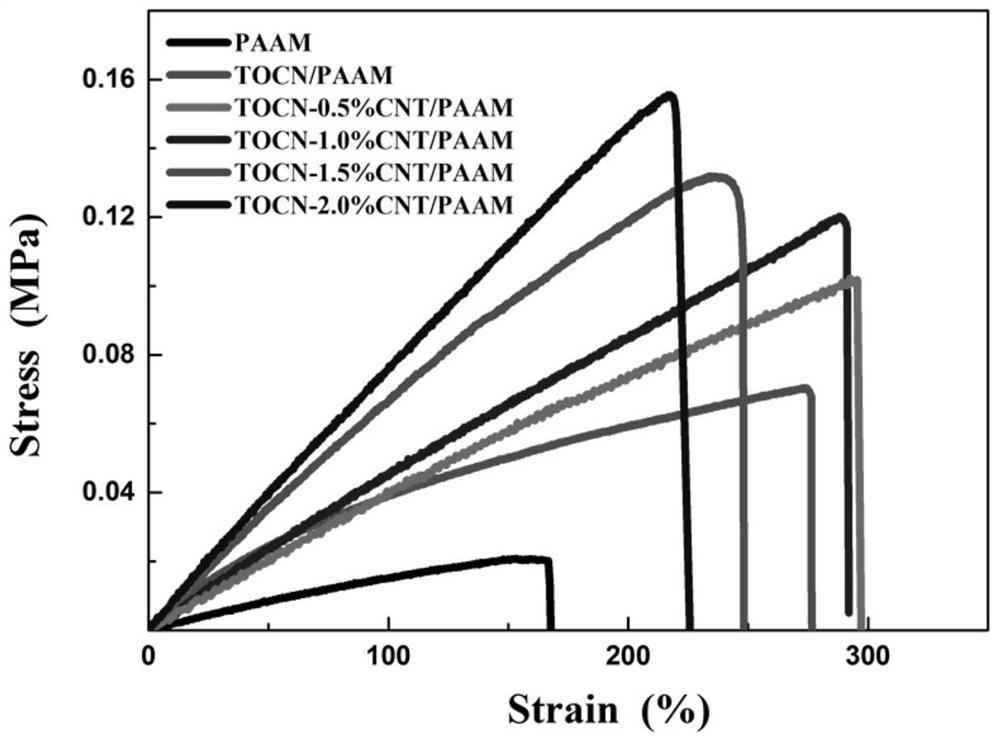

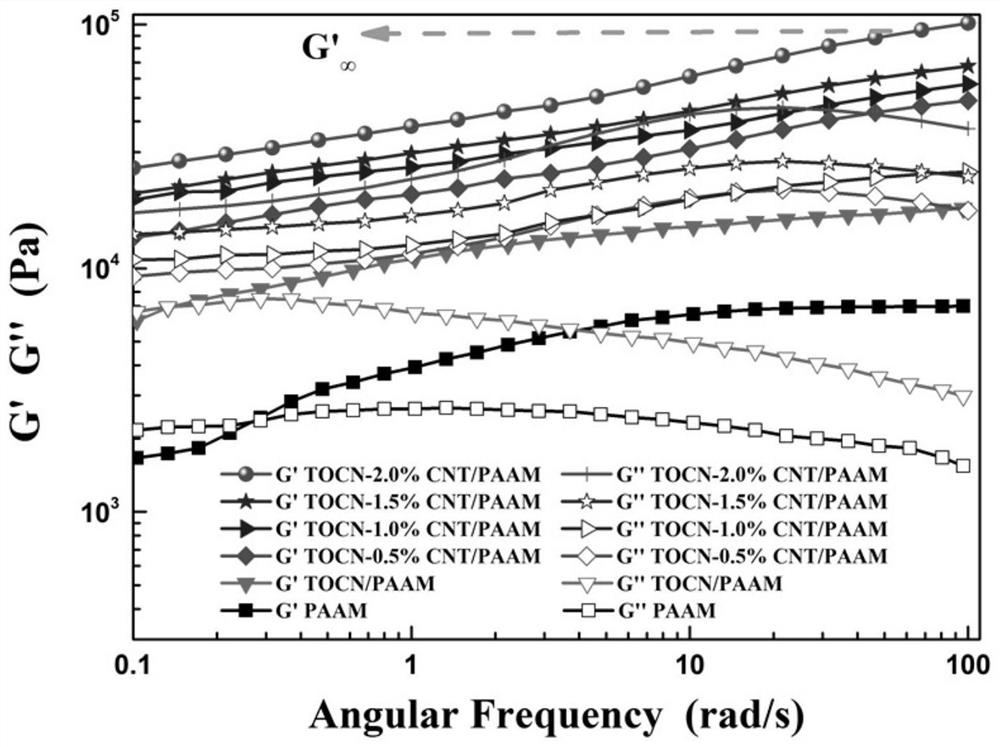

Preparation method of flexible strain sensor based on nanocellulose-carbon nanotube/polyacrylamide conductive hydrogel

ActiveCN110183688AAchieve autonomous self-healingHigh strengthElectrical/magnetic solid deformation measurementCarbon nanotubeCopper electrode

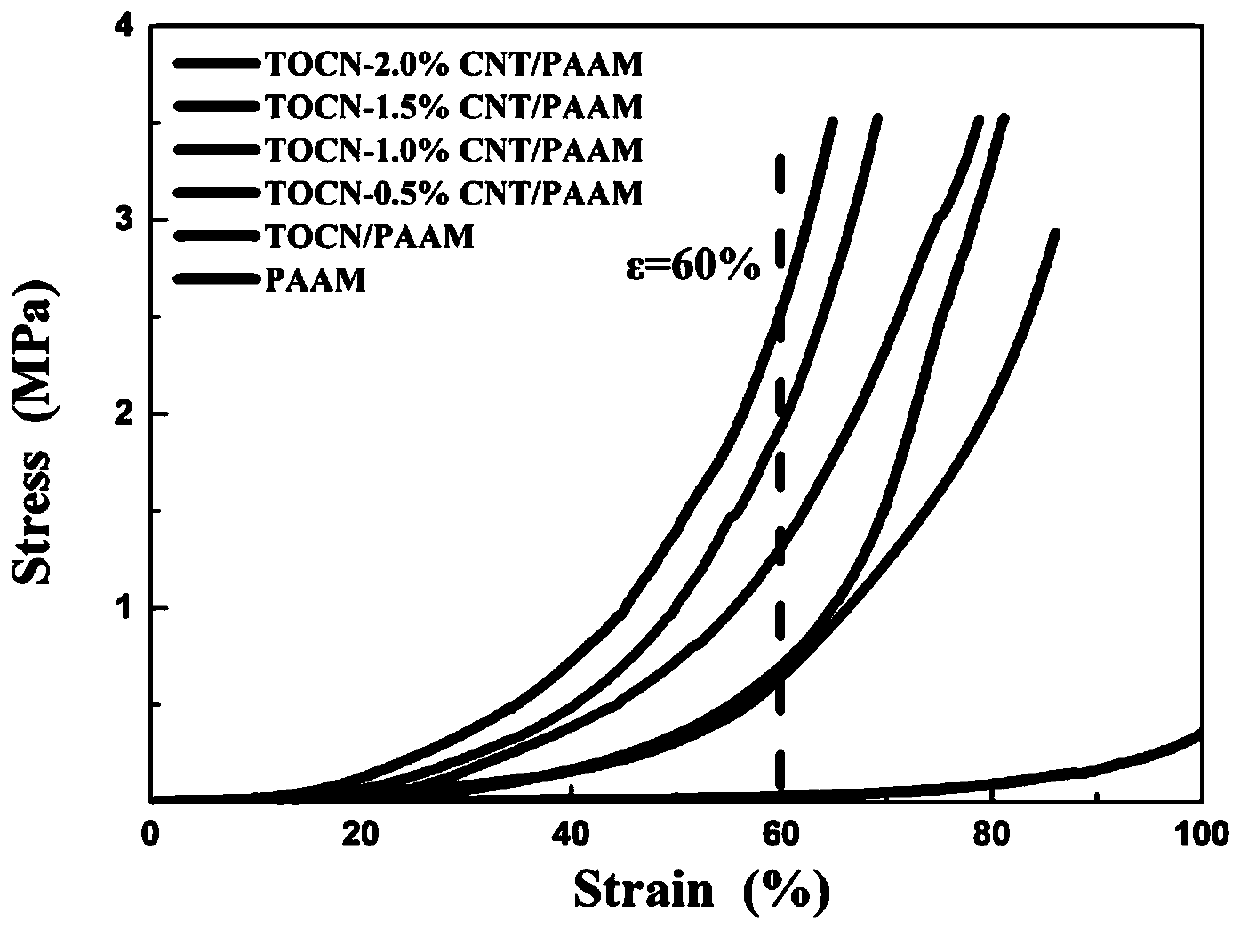

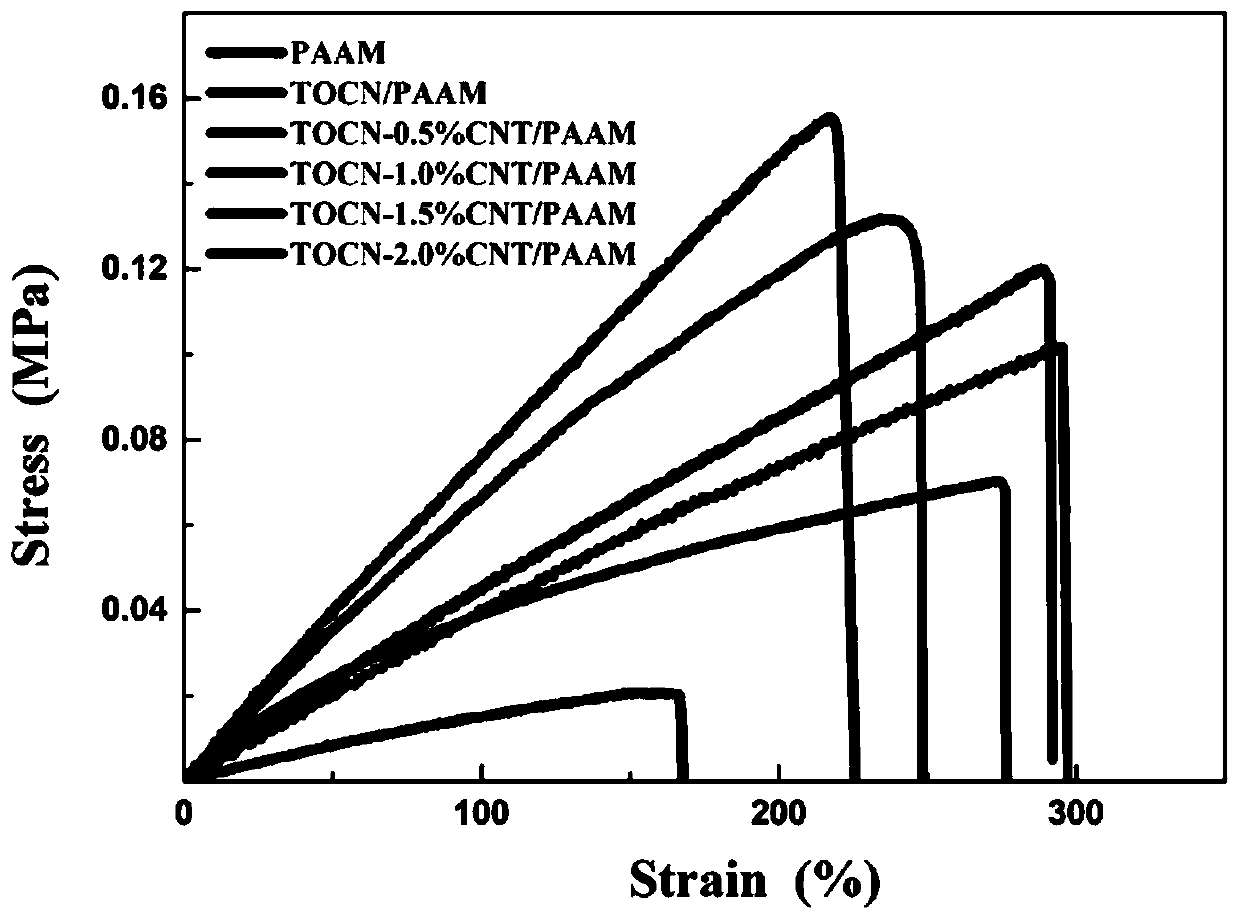

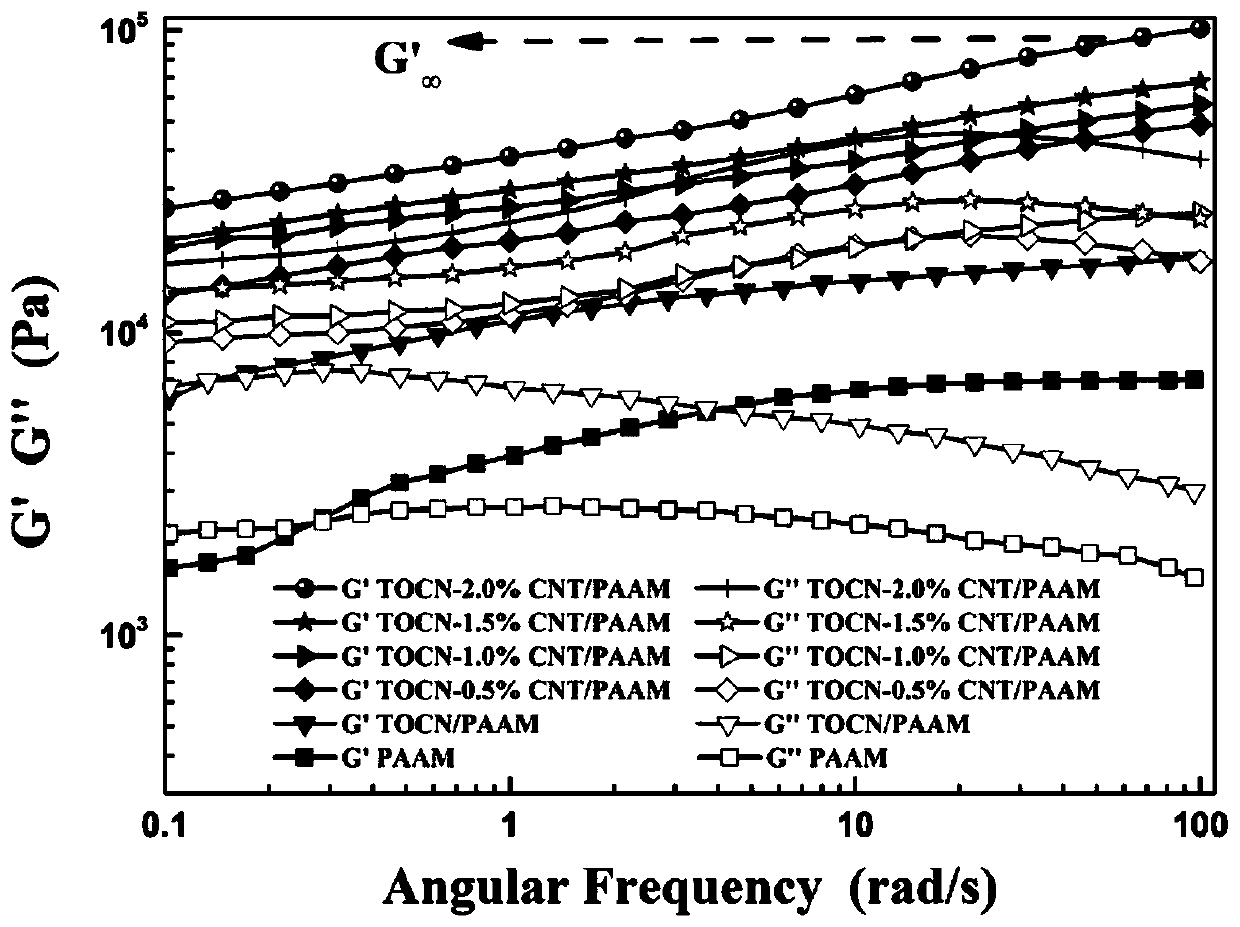

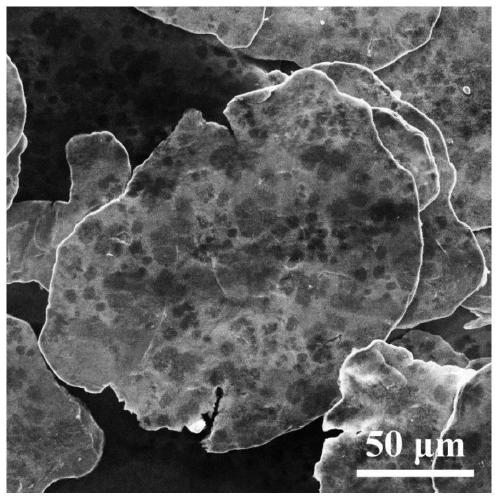

The invention discloses a flexible strain sensor based on nanocellulose-carbon nanotube / polyacrylamide conductive hydrogel. The preparation method of the flexible strain sensor comprises the followingsteps: (1) preparing a TEMPO nanocellulose suspension; (2) preparing a carbon nanotube dispersion; (3) preparing TEMPO nanocellulose-carbon nanotube / polyacrylamide conductive hydrogel; and (4) attaching two separate copper electrodes to both sides of the hydrogel so as to obtain the flexible strain sensor based on the nanocellulose-carbon nanotube / polyacrylamide conductive hydrogel. The sensor has high flexibility, stretchability, high mechanical properties, high electrical conductivity and strain sensitivity.

Owner:NANJING FORESTRY UNIV

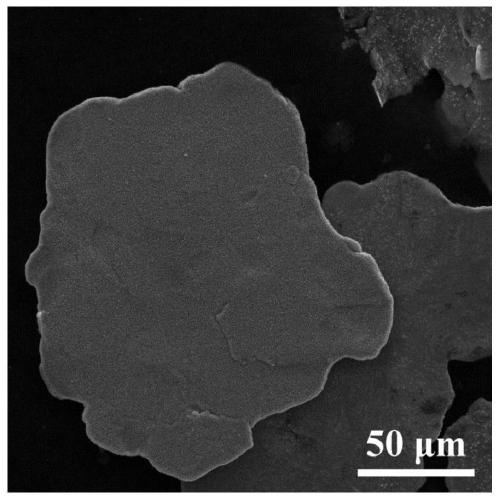

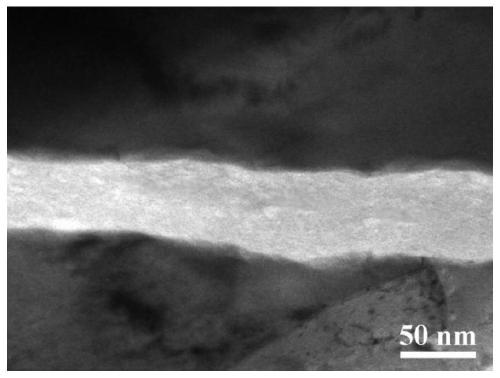

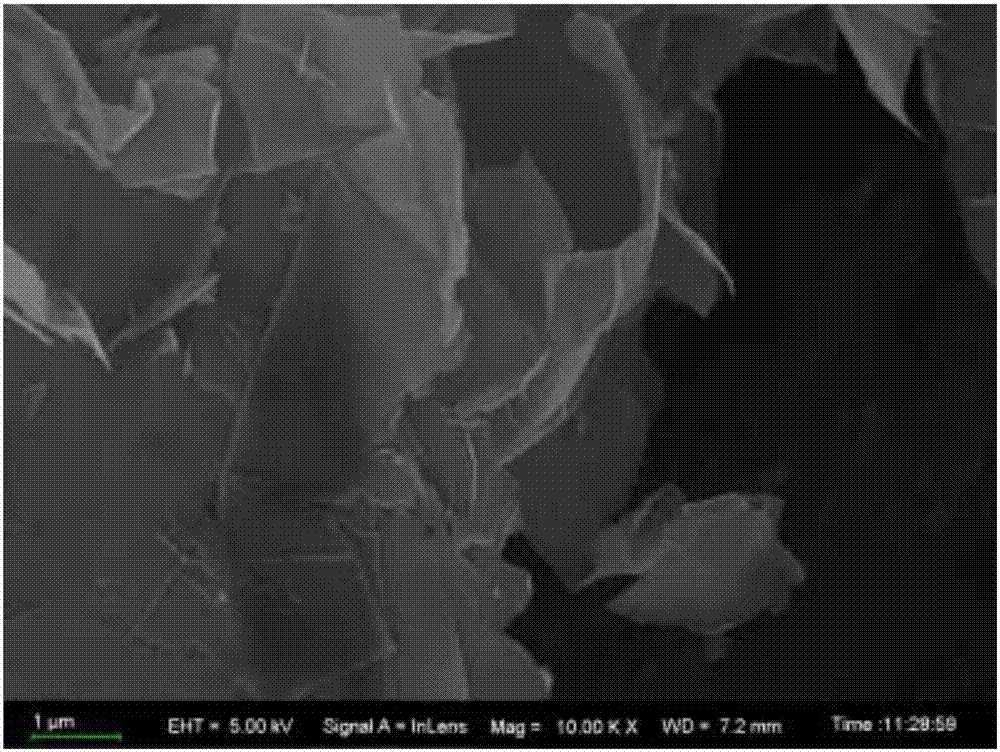

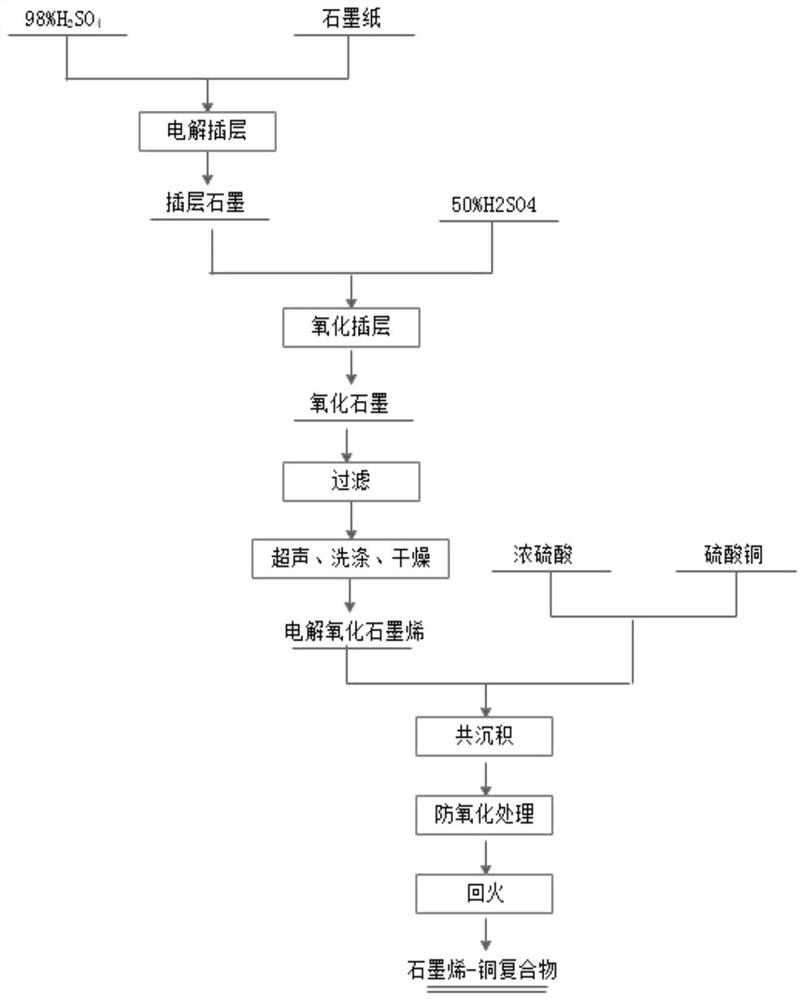

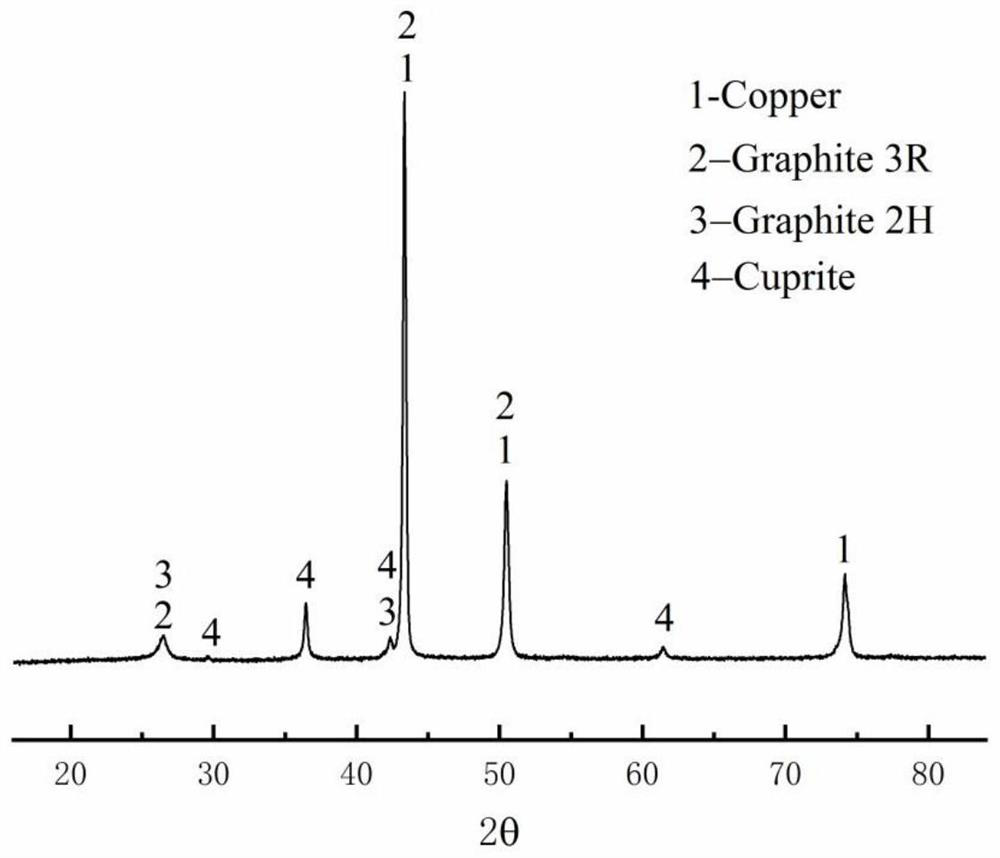

Preparation method of high-strength graphene/copper composite

InactiveCN111560535ASolve the problem that it is difficult to disperse evenlyRaise the potentialLiquid/solution decomposition chemical coatingChemical platingCopper plating

The invention provides a preparation method of a high-strength graphene / copper composite. Firstly, graphene oxide is adsorbed to surfaces of flake copper powder through an electrostatic self-assemblyprocess to prepare graphene oxide / copper compound powder. Then, copper plating is performed on the graphene oxide / copper compound powder through a chemical copper plating process to obtain copper-plated graphene oxide / copper compound powder. Then, heating reduction is performed on the copper-plated graphene oxide / copper compound powder through a tube furnace to obtain copper-plated graphene / coppercompound powder. Finally, the copper-plated graphene / copper compound powder is put into a discharge plasma sintering furnace to be sintered to prepare graphene / copper compound powder. By means of thegraphene / copper composite prepared through the method, uniform dispersing of graphene in a copper base body is realized, an interface bonding property of graphene and copper is improved, and mechanical properties of the composite are remarkably improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

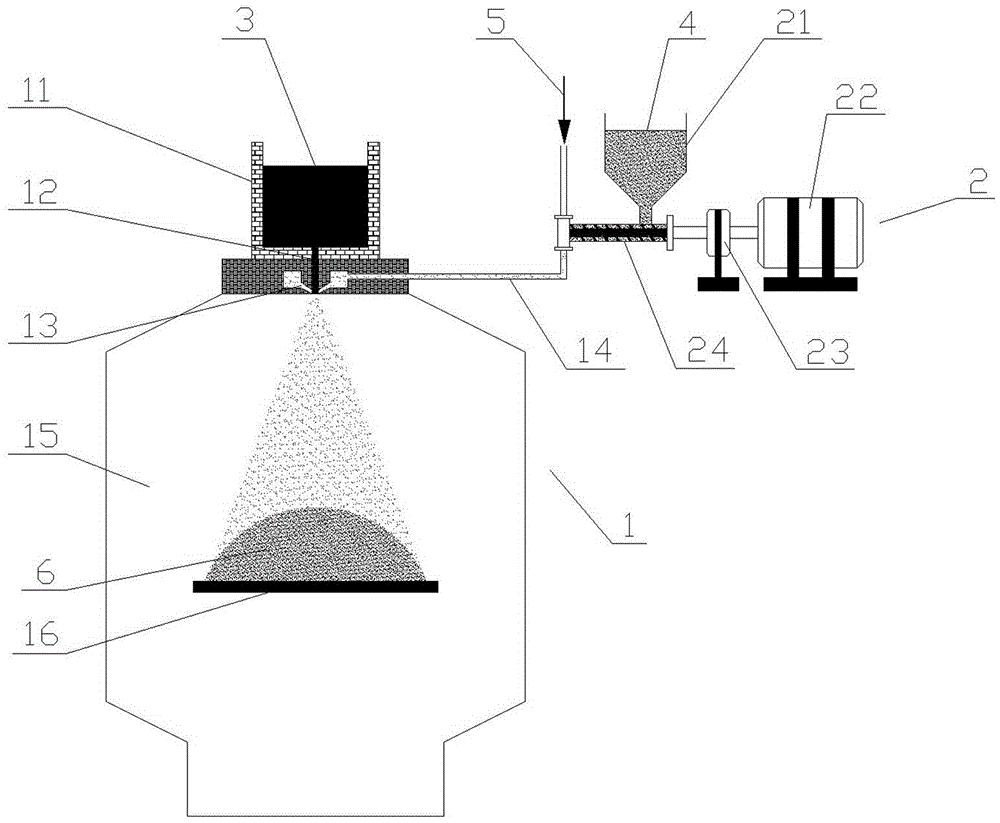

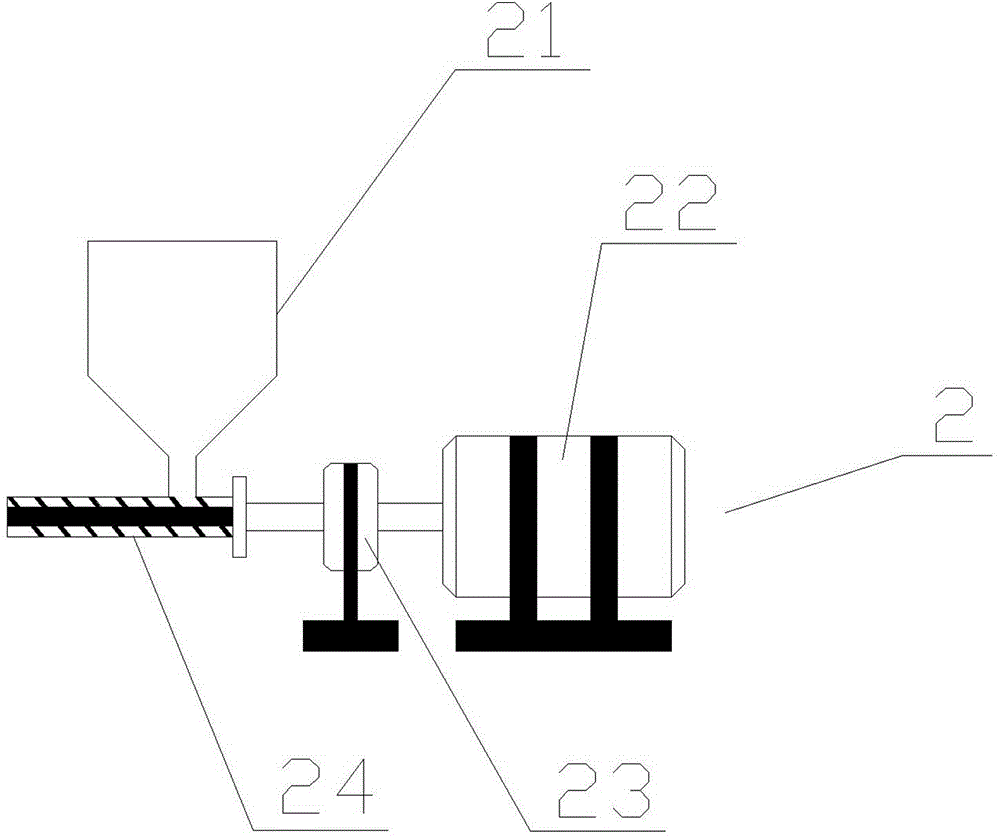

Method and device for preparing tungsten powder reinforced aluminum matrix composite

InactiveCN104878342AAvoid reunionSolve the problem that it is difficult to disperse evenlyMolten spray coatingAluminum matrix compositesAluminium alloy

The invention discloses a method and a device for preparing tungsten powder reinforced aluminum matrix composite. The method comprises the following steps: mounting a quantitative tungsten powder supply device on a high-pressure inert gas input pipe of a device for atomizing, spraying and depositing aluminum or aluminum alloy liquid, taking high-pressure inert gas as a flow carrying medium, spraying the tungsten powder to the surfaces of aluminum or aluminum alloy micro-droplets formed by atomizing, enabling the tungsten powder to disperse and attach onto the surfaces of the aluminum or aluminum alloy micro-droplets, then spraying and depositing the tungsten powder and the aluminum or aluminum alloy micro-droplets to a substrate and solidifying to prepare the tungsten powder reinforced aluminum matrix composite. The device comprises a device for atomizing, spraying and depositing aluminum or aluminum alloy liquid, wherein a quantitative tungsten powder supply device is mounted on a high-pressure inert gas input pipe of the device for atomizing, spraying and depositing aluminum or aluminum alloy liquid. By virtue of the method, the high-pressure inert gas is taken as the flow carrying medium for spraying the tungsten powder and attaching the tungsten powder onto the surfaces of the aluminum or aluminum alloy micro-droplets, then the tungsten powder and the aluminum or aluminum alloy micro-droplets are solidified to prepare the tungsten powder reinforced aluminum matrix composite; the agglomeration of the tungsten powder can be effectively prevented; the tungsten powder reinforced aluminum matrix composite with uniformly distributed tungsten powder is prepared.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

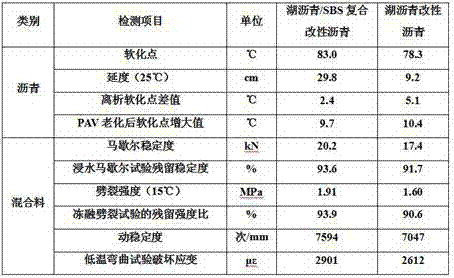

Lake asphalt/SBS compound modifier and preparation method and application thereof

InactiveCN106928731AImproves resistance to water damageImprove low temperature cracking resistanceBuilding insulationsCrack resistanceRoad surface

The invention relates to a lake asphalt / SBS compound modifier and a preparation method and application thereof. The lake asphalt / SBS compound modifier is a pre-dispersant which is prepared by the fusion and blending of lake asphalt, polymer SBS and compatilizers, and modified asphalt can be prepared by fusing and blending the lake asphalt / SBS compound modifier with petroleum asphalt and stabilizers. The obtained lake asphalt / SBS compound modifier is the pre-dispersant which can remarkably improve the high-temperature deformation resistance capability, low-temperature cracking resistance capability and water damage resistance capability of the petroleum asphalt, and by adding the pre-dispersant into the petroleum asphalt and taking use of the advantage of good compatibility between the pre-dispersant and the petroleum asphalt, the lake asphalt / SBS compound modified asphalt is prepared, wherein the modified asphalt is uniform in dispersion, and layered segregation does not occur easily on the modified asphalt. The modified asphalt is used for the construction of heavy-loaded traffic asphalt pavements in high temperature, damp and rainy areas, asphalt pavement diseases can be significantly reduced, the maintenance cost of the pavements is reduced, and the service life of the asphalt pavements is prolonged.

Owner:FUZHOU UNIV

Modified epoxy asphalt and preparation method thereof, and water-based drilling fluid and preparation method thereof

ActiveCN110922771AIncrease stickinessSmall particle sizeDrilling compositionBuilding insulationsPolymer scienceFirming agent

The invention discloses modified epoxy asphalt and a preparation method thereof, and a water-based drilling fluid and a preparation method thereof. The modified epoxy asphalt comprises the following components in parts by weight: 100 parts of matrix asphalt, 1-20 parts of a compatibilizer, 1-10 parts of a toughening agent, 5-20 parts of a curing agent, 1-5 parts of a curing accelerator and 5-30 parts of an epoxy resin, wherein the curing accelerator comprises a product obtained by reacting polyamine, phenol and an aldehyde-containing aqueous solution. According to the water-based drilling fluid, the modified epoxy asphalt liquid is added and is small in particle size and high in softening point, has a certain elastic deformation capacity and is excellent in high-temperature resistance, sothat the drilling fluid has good rheological property and high-temperature and high-pressure filtrate loss reduction effect when used at a high temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Spray-drying and hot-press vulcanization combination-based method for preparing graphene/rubber composite material

The invention provides a spray-drying and hot-press vulcanization combination-based method for preparing a graphene / rubber composite material, and belongs to the technical field of graphene / rubber composite materials, aiming at solving the problems that an existing graphene / rubber composite material cannot use raw graphene without environment stress as filler and cannot be uniformly dispersed into nonpolar rubber by a simple process flow. The method comprises the following steps: 1, preparing a graphene dispersion liquid; 2, preparing graphene-rubber emulsion; 3, preparing graphene / rubber composite material powder by a spray-drying method; and 4, performing hot-press vulcanization with a flat plate to prepare the graphene / rubber composite material. The method can be widely applied to industrial production since pollution-free raw graphene is utilized as the raw material and can be uniformly dispersed into a non-polar rubber substrate.

Owner:HARBIN INST OF TECH

Method for producing C* petroleum resin with chlorine alumine acid ion liquid catalyzed polymerization

ActiveCN101173024AImprove solubilitySolve the problem that it is difficult to disperse evenlyViscous liquidUltra fine

The present invention provides a method for preparing C5 petroleum resin by catalyzed polymerization of chloroaluminate ionic liquid. The method is to add the C5 fraction into a dry airtight or inert gas-protected reactor, raise the temperature to 90-120°C, and add the C5 fraction under stirring. Chloroaluminate ionic liquid with a mass of 0.8-3.0% is polymerized at 120-150°C for 6-10 hours to obtain a viscous liquid; cool the viscous liquid at room temperature to solidify the viscous liquid into a brittle solid and crush it into an ultra-fine powder below 400 meshes, then soaked in 0.5% NaOH solution for 20-24 hours, then washed with distilled water until neutral, filtered to remove most of the water, and vacuum-dried at 80°C and 150°C for 3 hours respectively to obtain Light colored C5 petroleum resin. The invention overcomes the phenomenon that the use of solid AlCl3 as a catalyst easily causes sudden polymerization and kettle overflow, the reaction process is mild, the reaction is easy to control, and the obtained C5 petroleum resin product has stable performance and light color.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

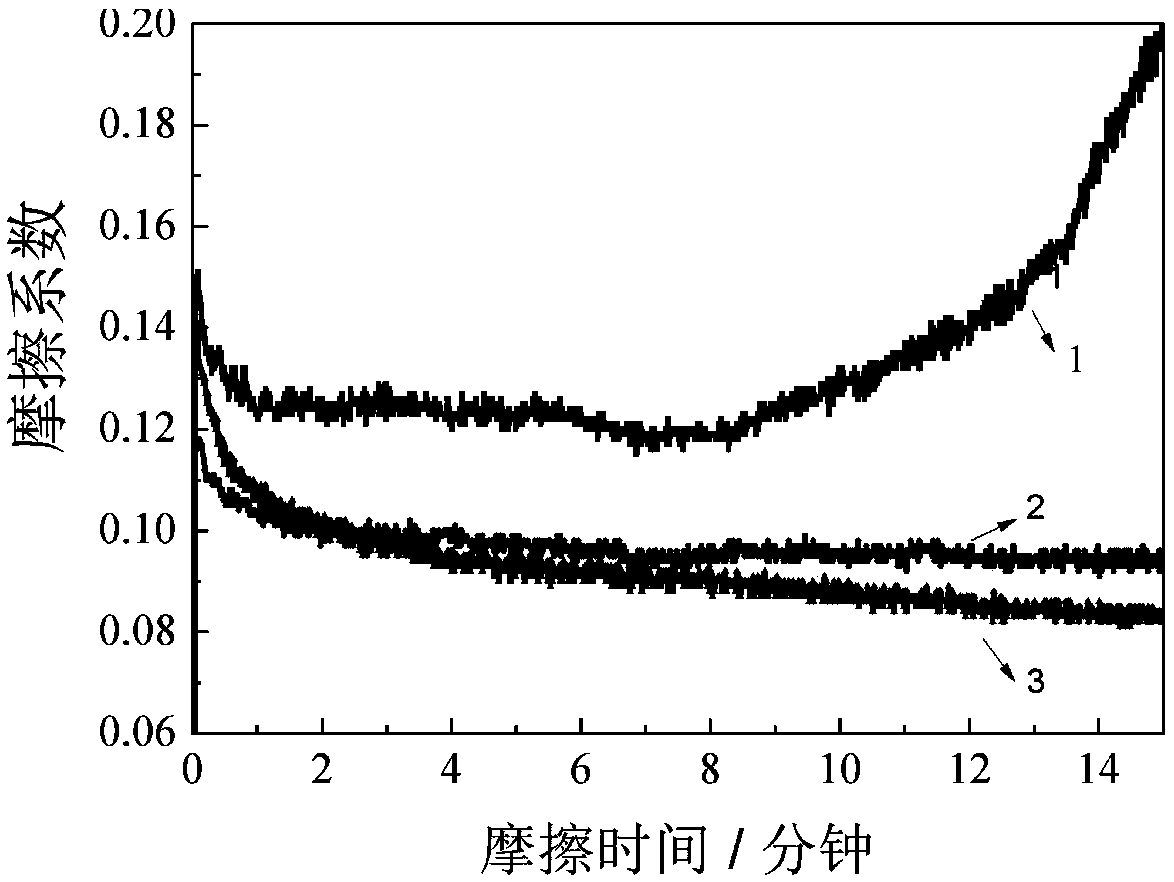

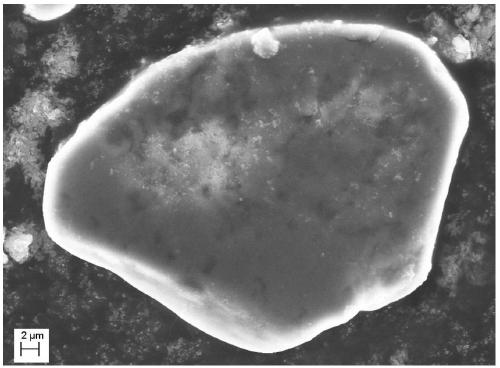

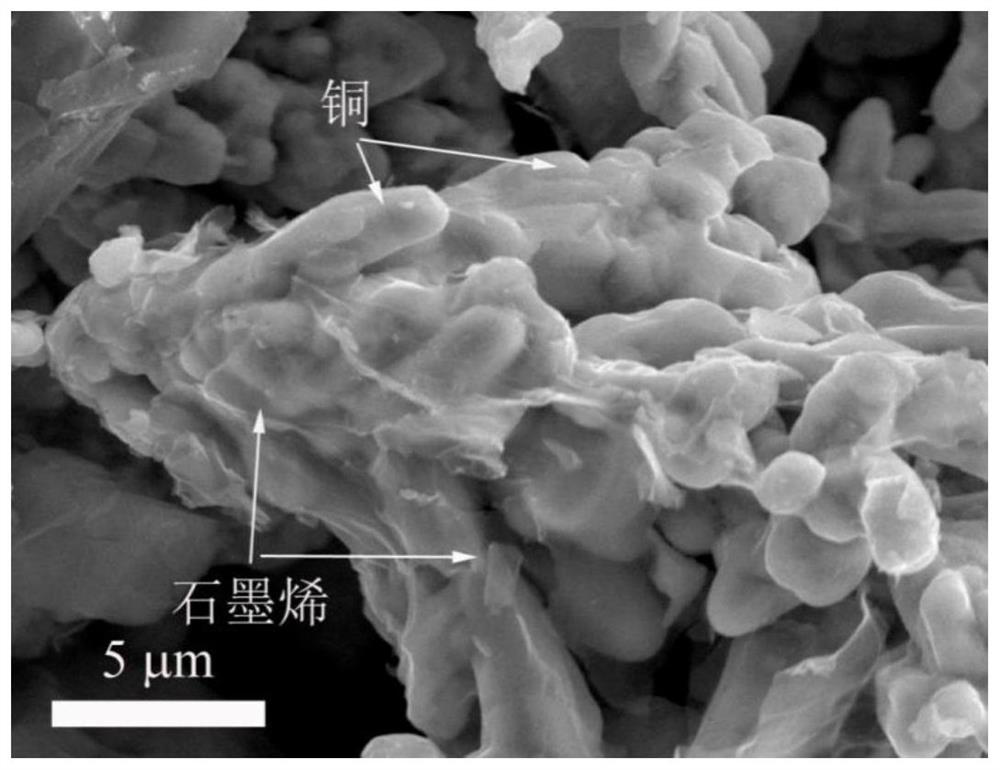

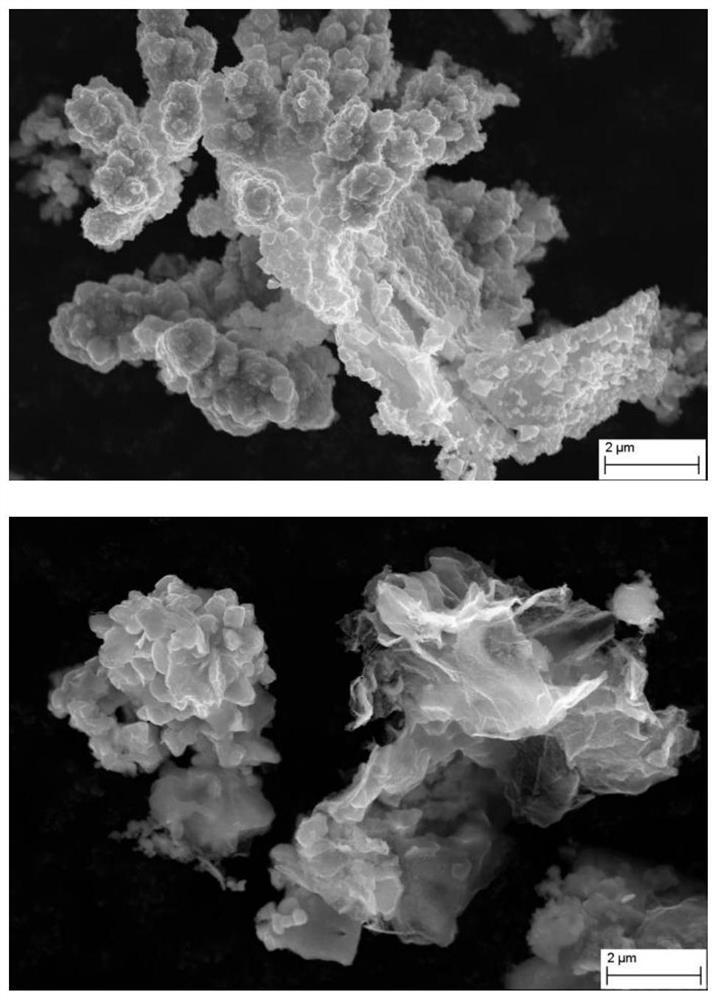

Graphene-reinforced copper based oil-bearing material and preparation method and application thereof

ActiveCN108907181AReduce wearImprove bearing capacityTransportation and packagingMetal-working apparatusPorous grapheneGraphite oxide

The invention belongs to the technical field of oil-bearing materials and discloses a graphene-reinforced copper based oil-bearing material and a preparation method and application thereof. The oil-bearing material is of graphene-coated copper powder obtained by adding copper powder in a water solution of oxidized-graphene colloids by filtering and drying after room temperature stirring reaction;subjecting the graphene-coated copper powder to cold pressing to form a blank body and placing the blank body for sintering in a protective atmosphere to obtain a porous graphene / copper composite material after natural cooling; placing the porous graphene / copper composite material into oil-bearing specialized lubricating oil for soaking till complete infiltration under a certain negative pressureprior to cooling the oil-bearing specialized lubricating oil naturally. The graphene-reinforced copper based oil-bearing material has the advantages of less abrasion, good bearing force, high oil content and stabile lubricating property, the problem that a graphene nano-sheet is difficult to be uniformly dispersed in a copper matrix is effectively solved, and the graphene-reinforced copper based oil-bearing material is applicable to the fields of audio machinery, home appliance machinery, office machinery and transport machinery bearings.

Owner:GUANGDONG UNIV OF TECH

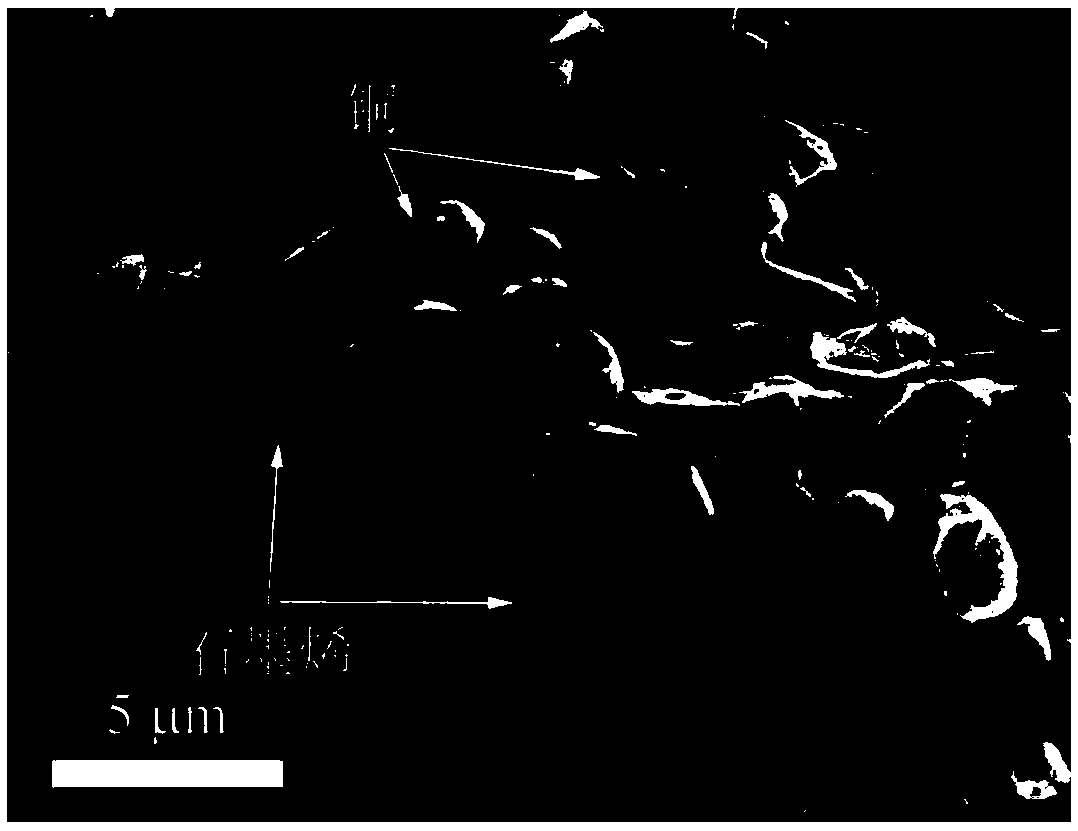

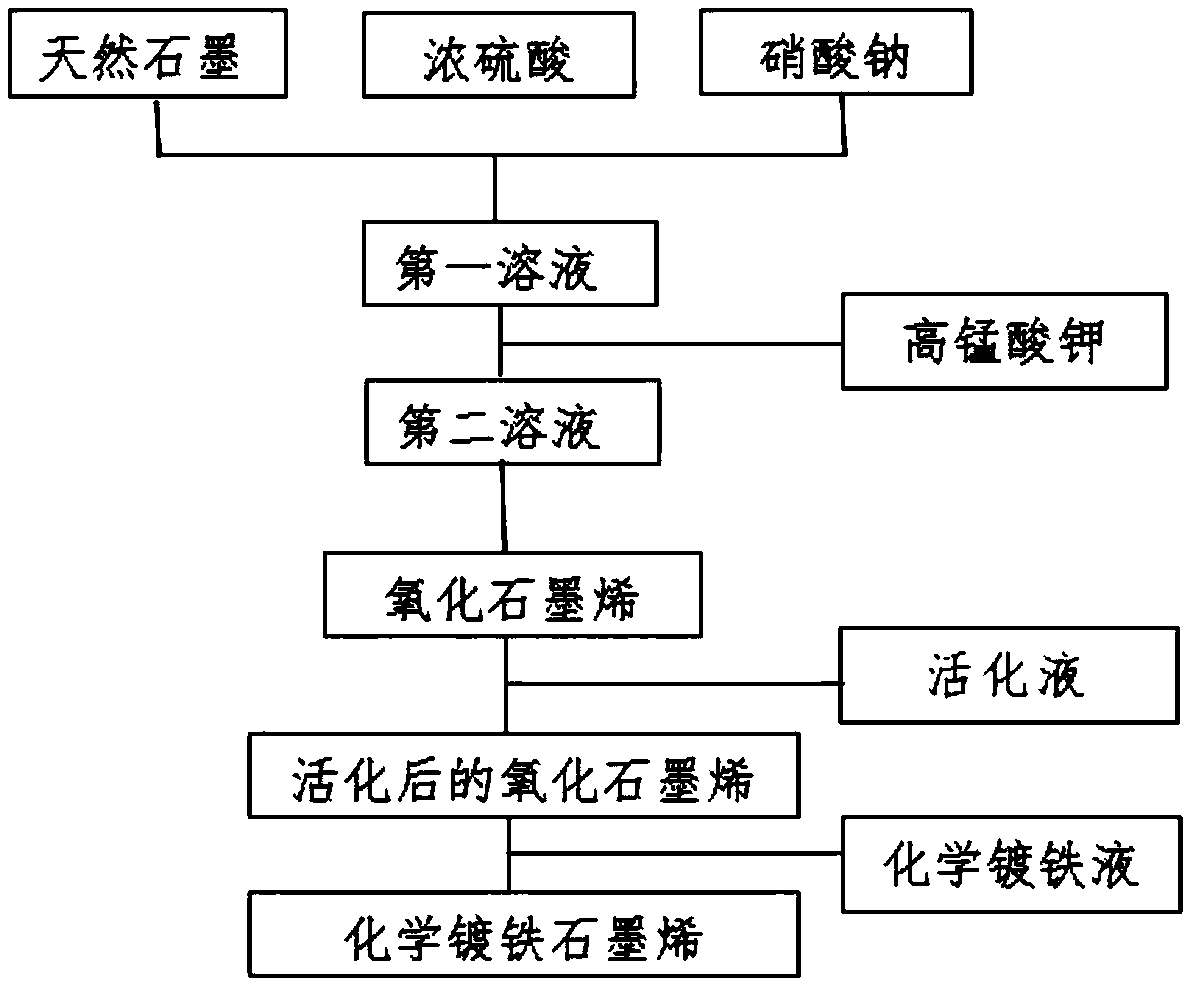

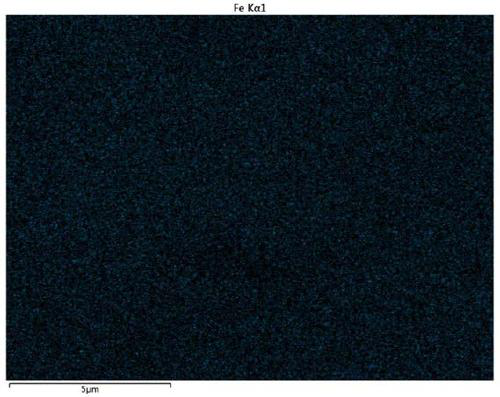

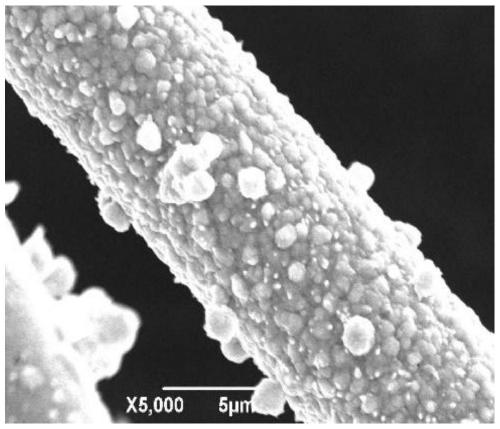

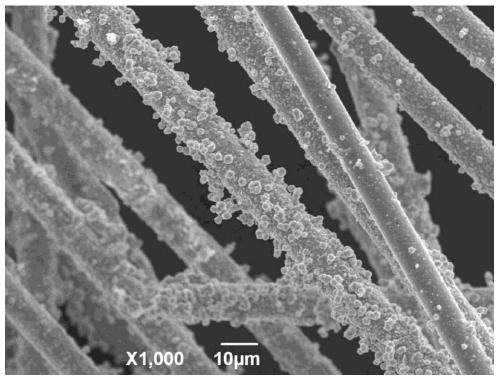

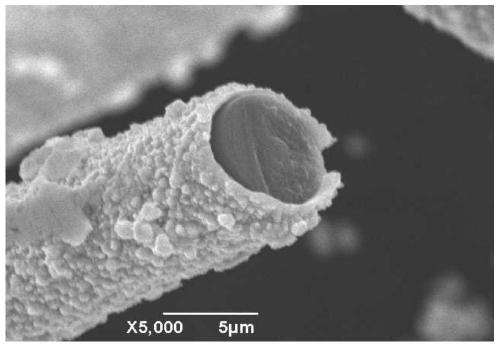

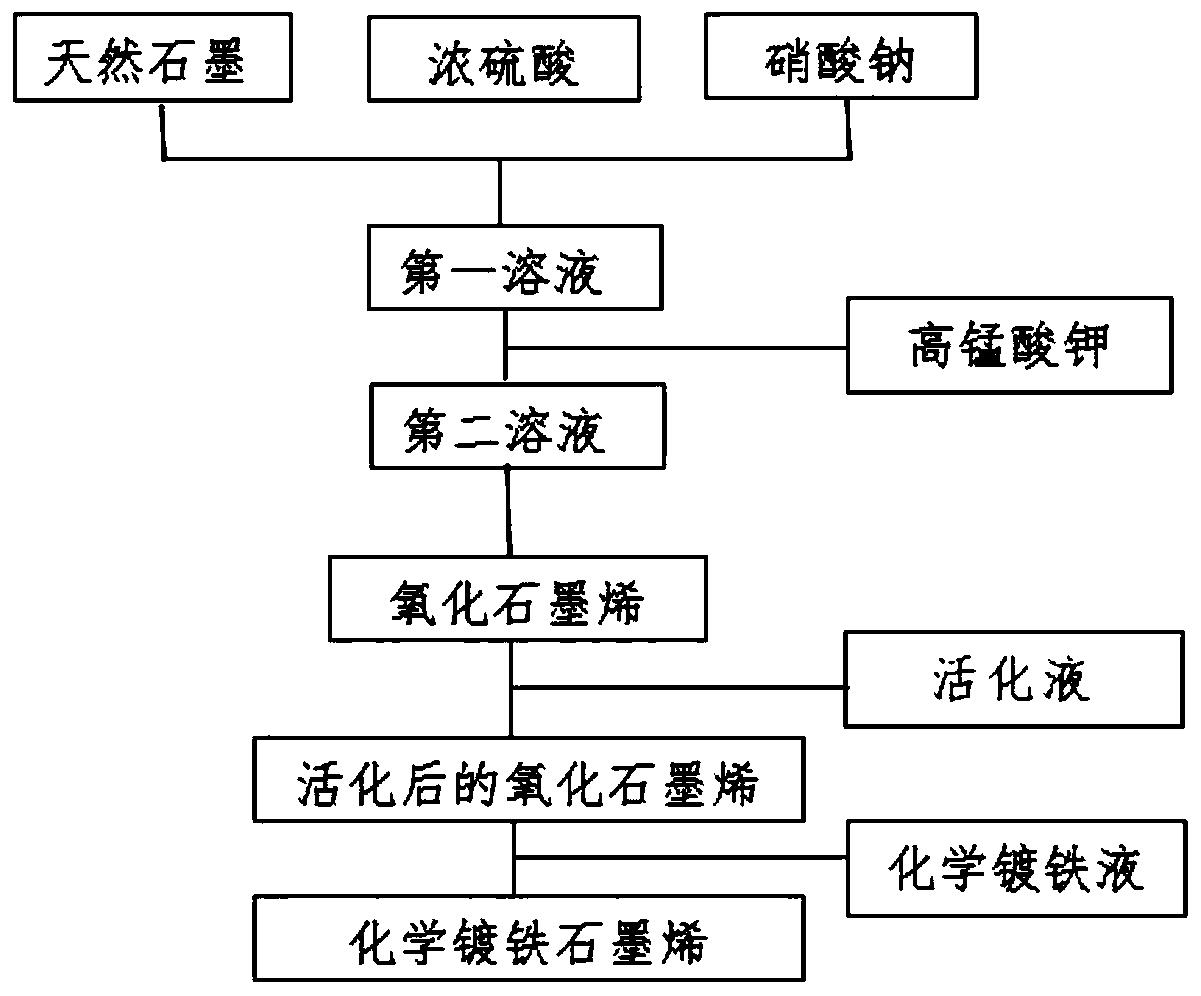

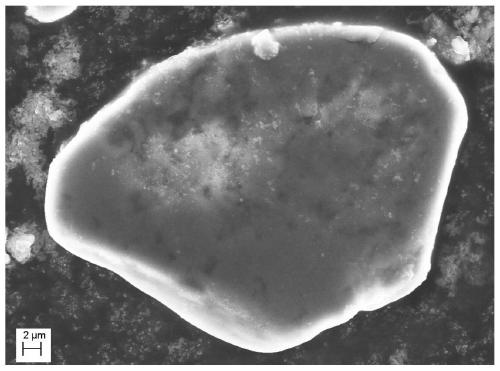

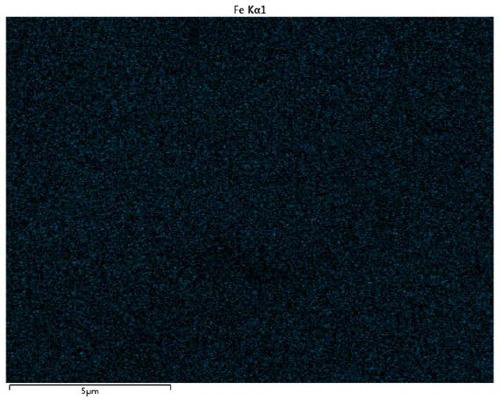

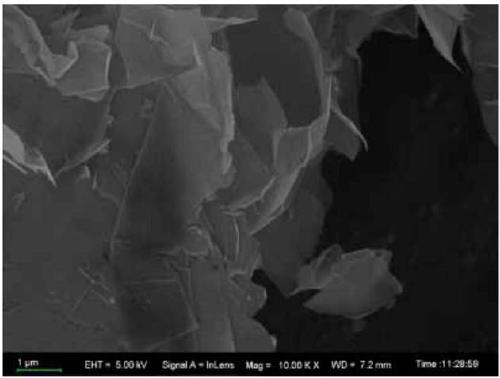

Method for preparing chemical iron-plated graphene through one-step activation method

ActiveCN109055922ASolve the problem that it is difficult to disperse evenlyHigh tensile strengthLiquid/solution decomposition chemical coatingActivation methodCompound (substance)

The invention belongs to the technical field of preparing metal matrix composite reinforcements and particularly relates to a method for preparing chemical iron-plated graphene through a one-step activation method. By means of the method for preparing the chemical iron-plated graphene through the one-step activation method, the oxidized graphene is put in activating liquid, homogenizing operationis conducted, filtering is conducted, filter liquid is reserved, washing is conducted, the graphene is washed to be neutral, and activated oxidized graphene is obtained; the activating liquid is a precious metal salt complex solution; and the activated oxidized graphene is subjected to ultrasonic dispersion, then a chemical iron plating solution is added, mixing is conduced, a reaction is carriedout, and the chemical iron-plated graphene is obtained. By means of the method, wettability between the graphene and a metal matrix is improved, and the problem that the graphene is hardly dispersed evenly in the metal matrix is solved. Meanwhile, a one-step activation technology is adopted, the technical process is simplified, and the production cost is greatly reduced.

Owner:NORTHEASTERN UNIV

Zirconium doped porous carbon material and preparation method for preparing lithium ion capacitor battery composite positive electrode

InactiveCN110182807AReduce direct contactLess side effectsPigmenting treatmentCarbon fibresLithium-ion capacitorCapacitance

The invention relates to the technical field of lithium ion batteries and supercapacitors, particularly to a zirconium doped porous carbon material and a preparation method for preparing a lithium ioncapacitor battery composite positive electrode, wherein the surface of a porous carbon material is uniformly coated with a layer of nanometer Zr(OH)4 particles through a co-precipitation method, andthen heating and thermal insulation is performed in a protective atmosphere to prepare the zirconium doped porous carbon material. The preparation method for preparing a lithium ion capacitor batterycomposite positive electrode by using the zirconium doped porous carbon material comprises: (1) uniformly mixing a lithium battery positive electrode material, an electric conduction agent and the zirconium doped porous carbon material to obtain a mixed active substance; and (2) coating a current collector with the mixed active substance to obtain the composite positive electrode. According to thepresent invention, with the application of the zirconium doped porous carbon material in the preparation of the lithium ion capacitor battery composite positive electrode, the electrochemical performance and the safety performance of the capacitor battery can be improved.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD +1

Method for preparing continuous carbon fiber reinforced aluminum matrix composite

The invention discloses a method for preparing a continuous carbon fiber reinforced aluminum matrix composite. The method for preparing the continuous carbon fiber reinforced aluminum matrix compositecomprises the steps that after pretreatment and plating application are conducted on bare carbon fiber in sequence, work blanks are then prepared; an appropriate number of work blanks are taken and placed in extrusion dies; a compressor is adopted, the work blanks are formed through extrusion, and prefabricated blocks are acquired; the prefabricated blocks are placed in a plasma sintering furnace, and the continuous carbon fiber reinforced aluminum matrix composite is acquired after sintering. The preparation technology of the continuous carbon fiber reinforced aluminum matrix composite is simple; besides, carbon fiber is uniformly dispersed in the matrix, and material properties are isotropic; and in addition, various kinds of physical properties of the composite are improved, and meanwhile, the mechanical property of the composite is improved conspicuously.

Owner:SHAANXI SCI TECH UNIV

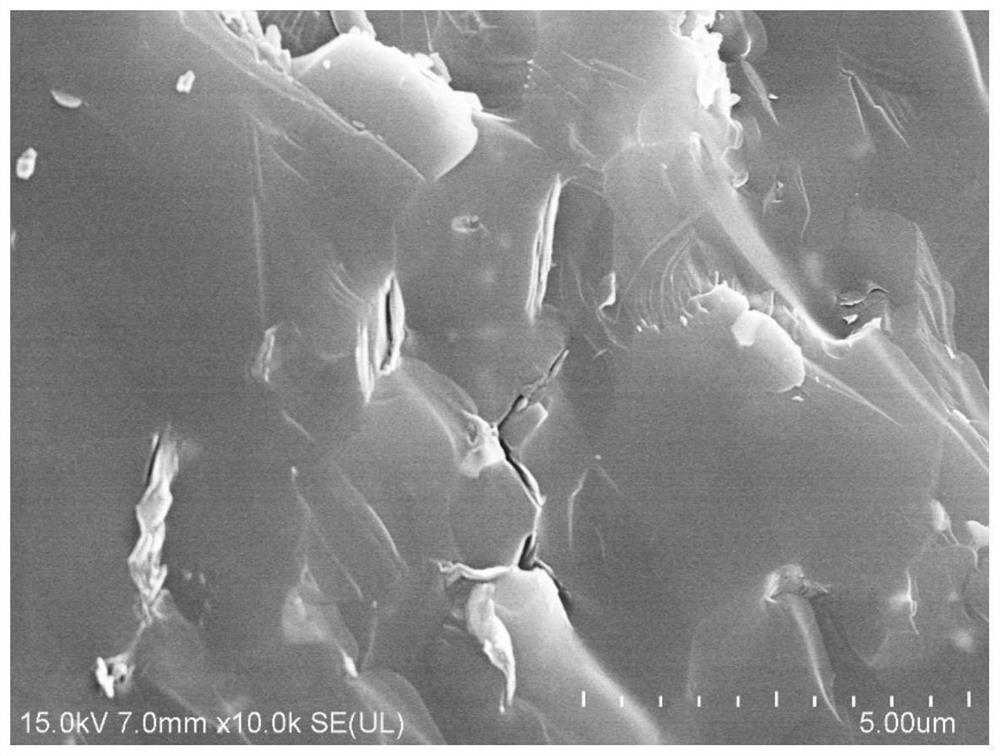

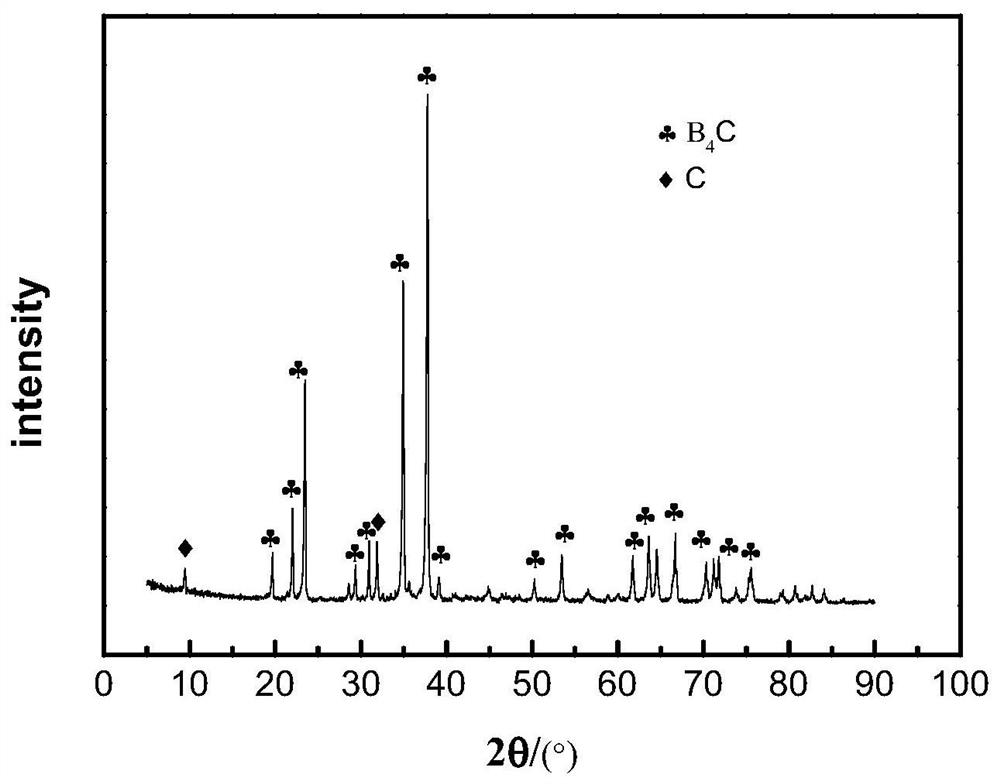

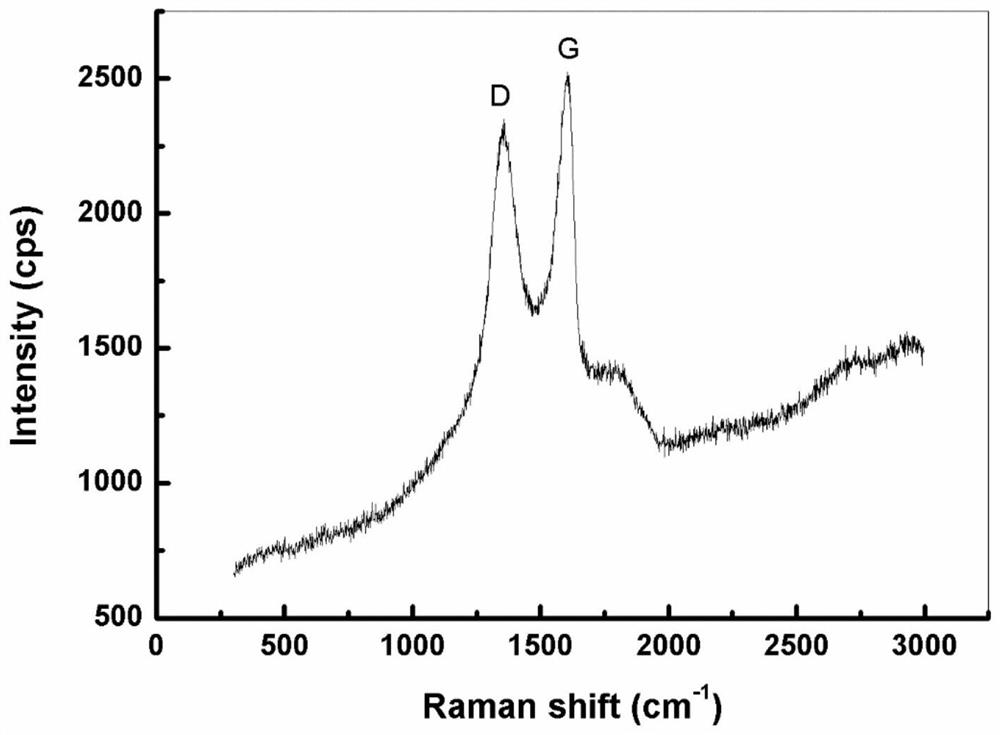

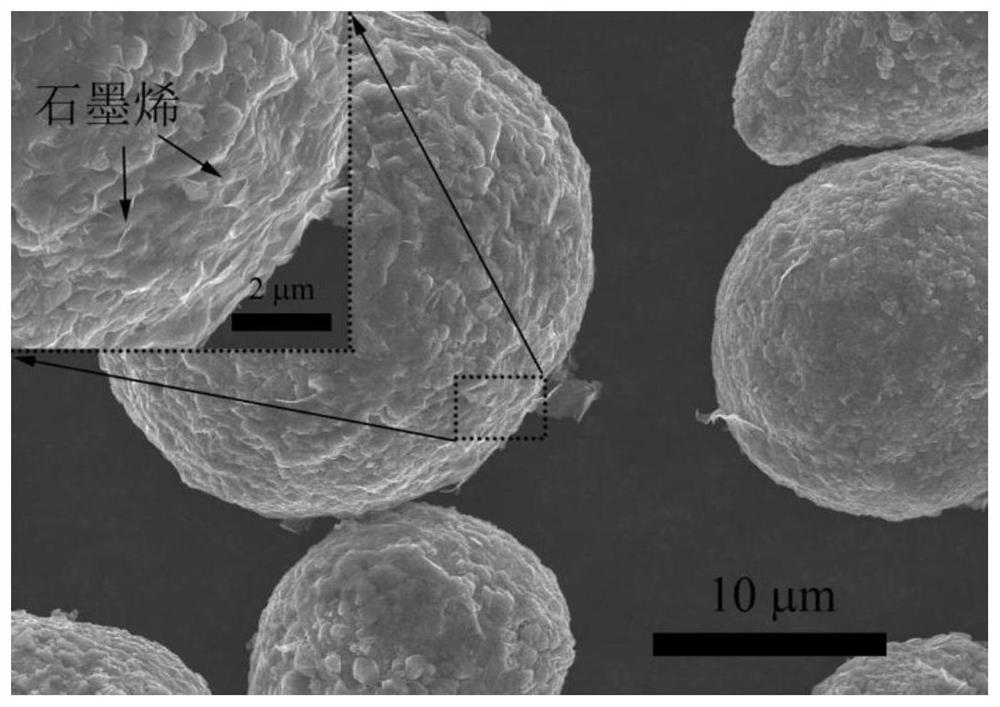

Graphene/boron carbide composite powder for hot pressed sintering, preparation method thereof and preparation method of ceramic product

PendingCN111925214ASolve the problem that it is difficult to disperse evenlyAddress resilienceComposite ceramicWet grinding

The invention discloses graphene / boron carbide composite powder for hot pressed sintering, a preparation method thereof and a preparation method of a ceramic product, and belongs to the field of ceramic materials. Boron carbide powder, graphene oxide and syrup are used as raw materials; atomization granulation and precursor carbonization processes are carried out to obtain the spherical graphene oxide / boron carbide composite powder with uniform component composition; and hot pressed sintering is performed to obtain the graphene / boron carbide composite ceramic with good component structure uniformity. According to the preparation method of the graphene / boron carbide composite powder, all the components of the composite powder are mixed in proportion and subjected to wet grinding to obtain stably-dispersed slurry, spherical composite powder with uniform components is obtained through an atomization granulation process, the obtained atomization granulation powder is subjected to carbonization and hot pressed sintering in a vacuum environment, and a graphene / boron carbide composite ceramic product with uniformly-dispersed graphene is obtained. The problems of large component segregation, difficult process amplification and the like of the graphene / boron carbide composite powder are solved, and the preparation method is suitable for preparing the graphene / boron carbide composite ceramic material with an excellent performance through hot pressed sintering.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

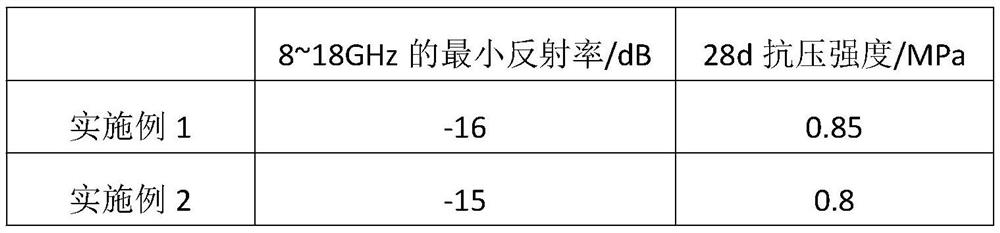

Cement-based conductive composite material and preparation method thereof

InactiveCN112125582AStrong electromagnetic wave absorption functionStrong absorbing abilitySolid waste managementCarbon fibersPolyvinyl alcohol

The invention provides a cement-based conductive composite material, and relates to the technical field of cement materials. The cement-based conductive composite material comprises the following components by weight: 80-100 parts of cement; 110-140 parts of fly ash; 80-100 parts of silica fume; 70-120 parts of water; 1-5 parts of a water reducing agent; 10 to 15 parts of rubber powder; 1-5 partsof steel fibers; 1-3 parts of carbon fiber; 1-3 parts of polyvinyl alcohol fiber; and 30-50 parts of ferrite. The invention also provides a preparation method of the cement-based conductive compositematerial, which comprises the following steps of: uniformly mixing the cement, the fly ash, the silica fume and the rubber powder; adding the water, the steel fibers, the carbon fibers, the polyvinylalcohol fibers, the ferrite and the water reducing agent, and stirring for 5-10 minutes; pouring the mixture into a mold, and vibrating for 1-3 minutes; pressurizing to remove bubbles, strickling thesurface, and maintaining for 24-36 hours; and carrying out demolding maintenance for 28-30 days. The material disclosed by the invention has a relatively strong electromagnetic wave absorption function in a wide frequency range, and has relatively good compressive strength.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

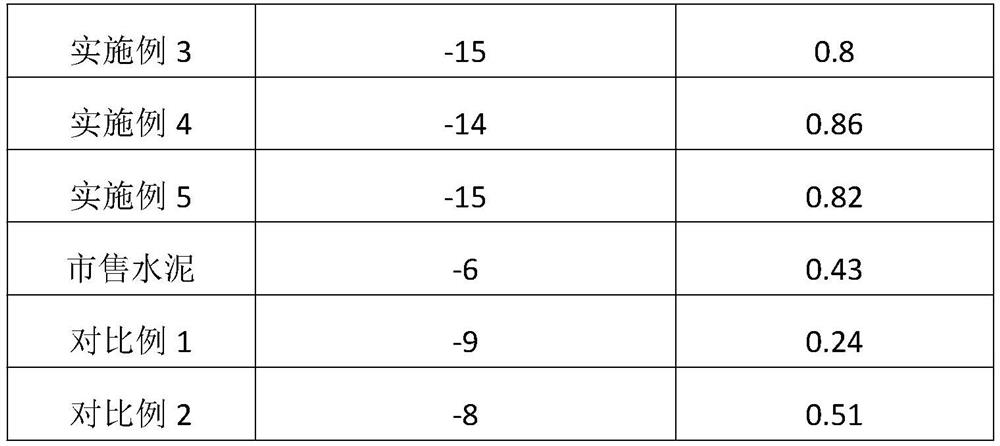

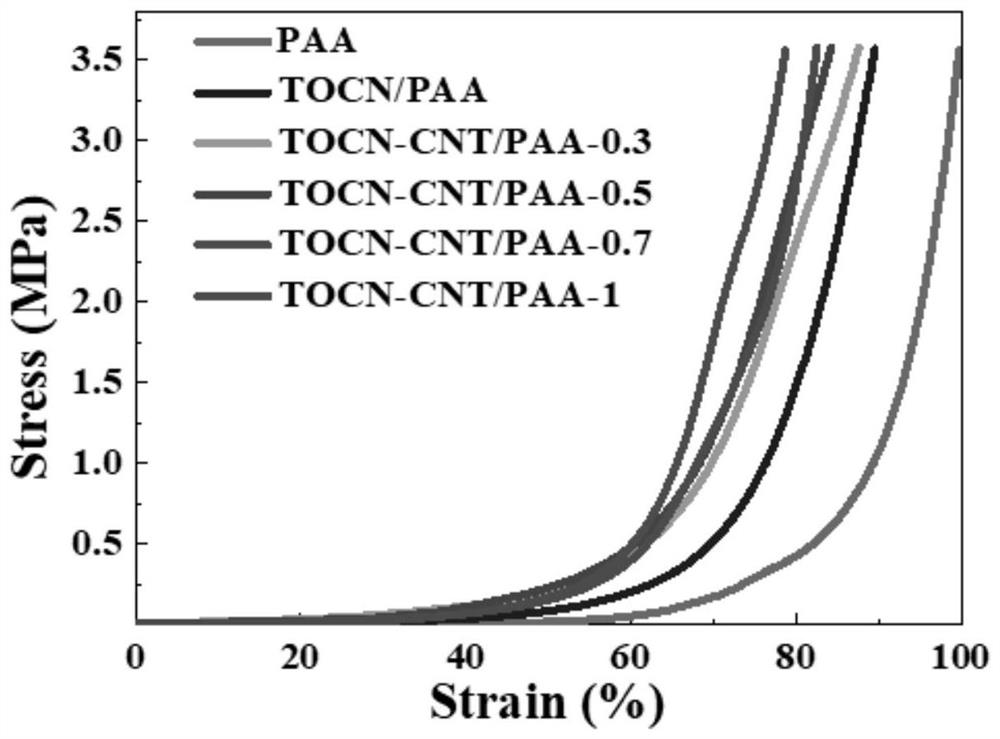

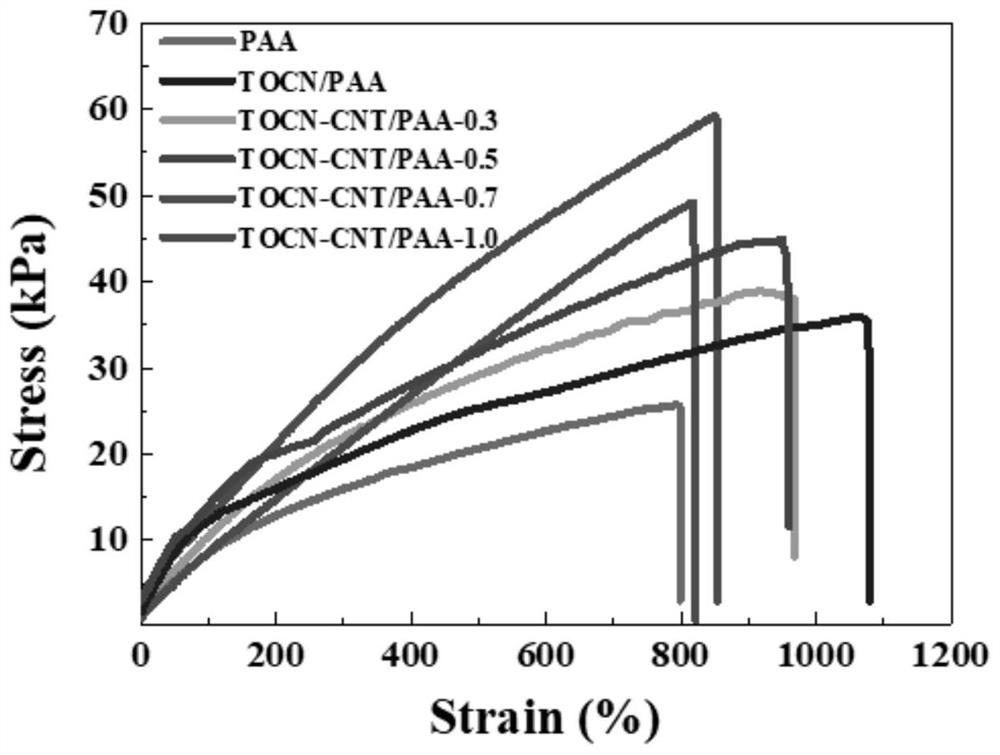

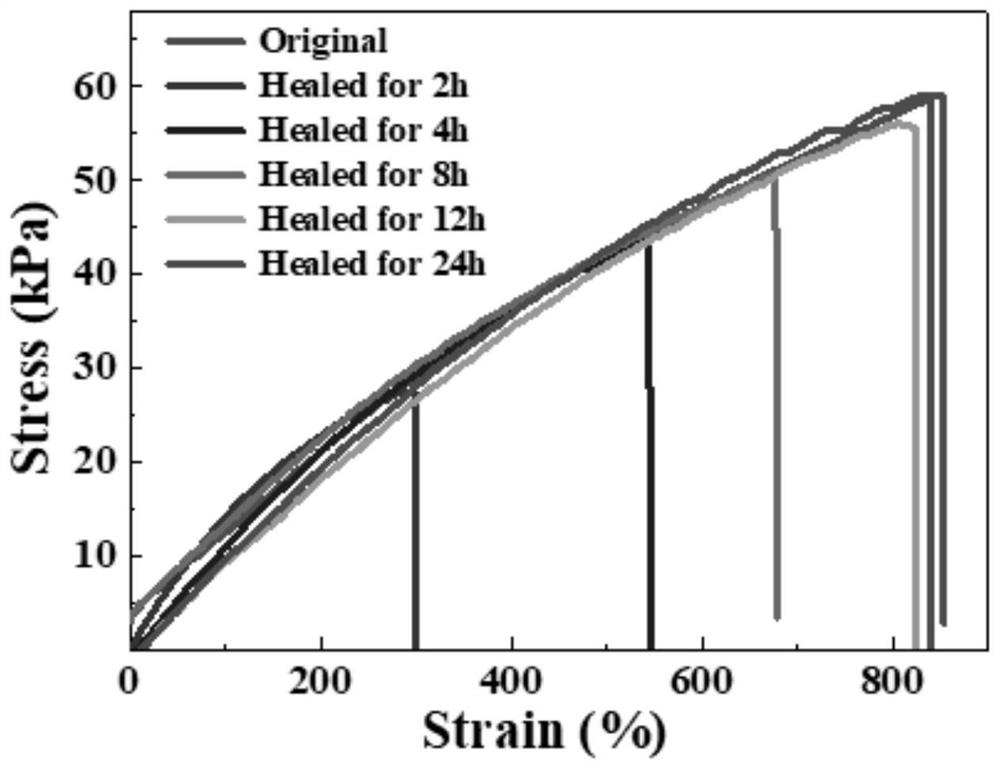

Preparation method and application method of tempo nano cellulose-polyacrylic acid gel

The invention discloses a preparation method and application method of TEMPO nanocellulose-polyacrylic acid gel. The preparation method comprises the following steps: a. preparing TEMPO nanocellulose suspension; b. preparing carbon nanomaterial dispersion; c. TEMPO The nanocellulose suspension is mixed with the carbon nanomaterial dispersion, added to the polyacrylic acid aqueous solution, added with a crosslinking agent, and stirred until a gel is formed to obtain a carbon nanotube-TEMPO nanocellulose-polyacrylic acid gel. The present invention introduces the concept of biology into polymer materials to form an intelligent material with self-healing properties, prolongs the service life of the material, and restores and retains its original characteristics. And in some applications, it can avoid damage caused by the accumulation of cracks and improve the safety of materials.

Owner:NANJING FORESTRY UNIV

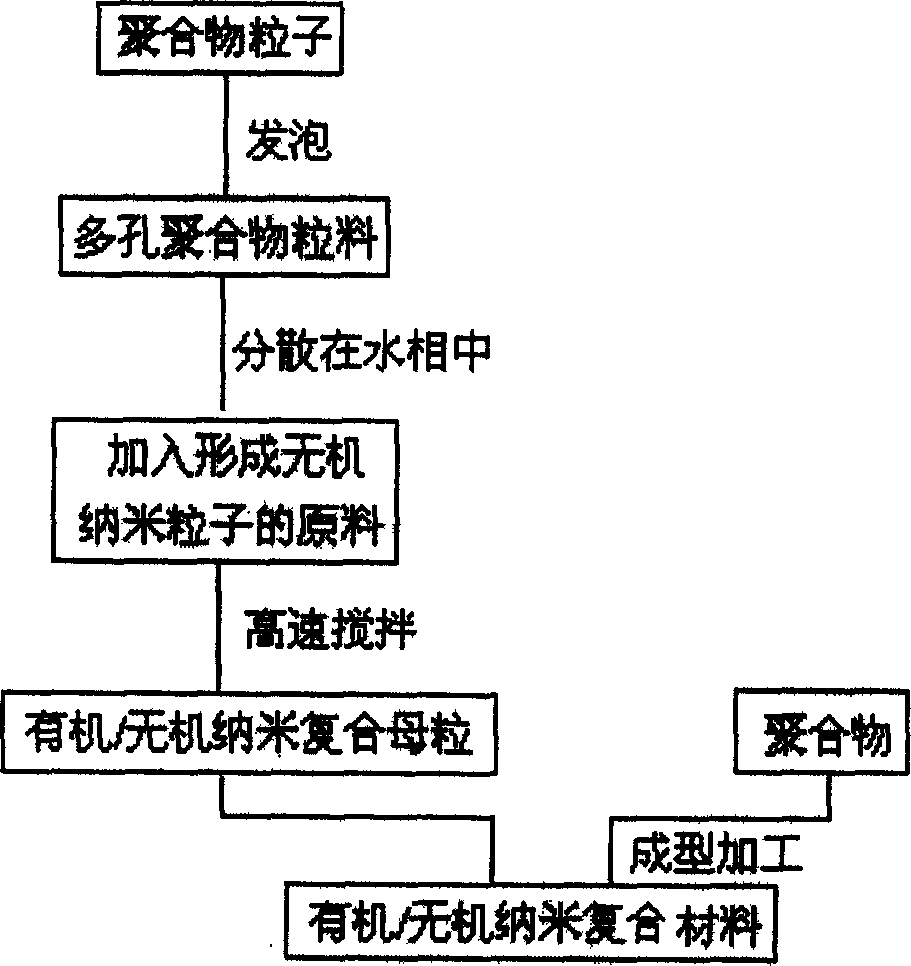

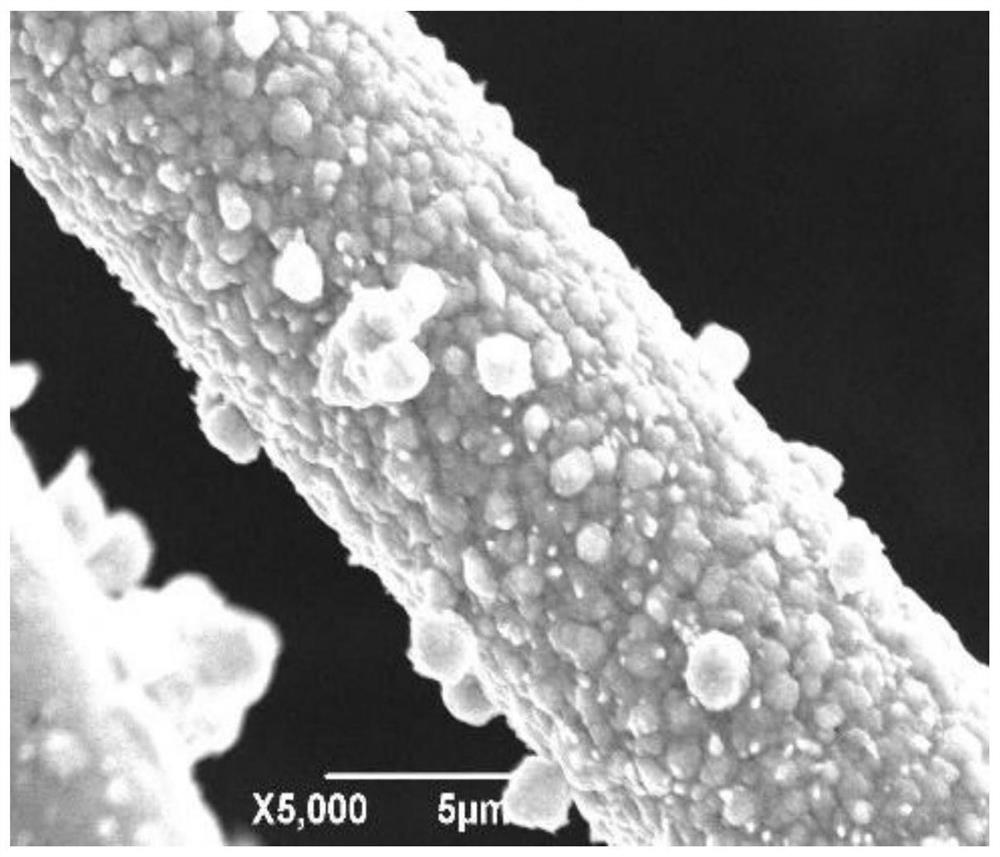

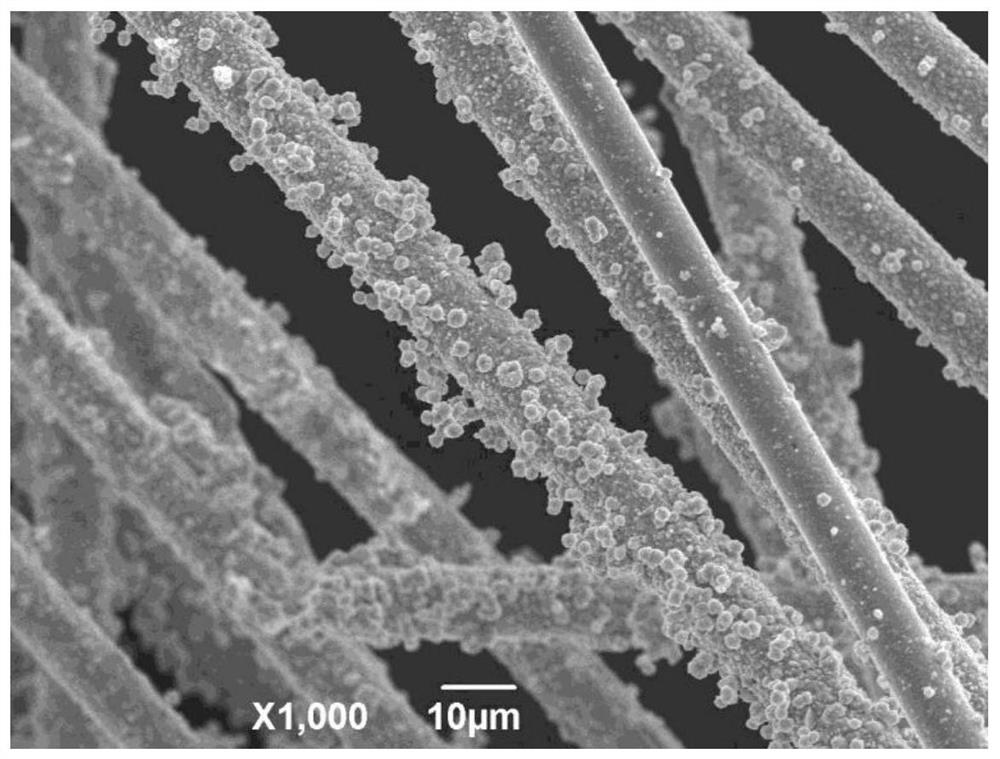

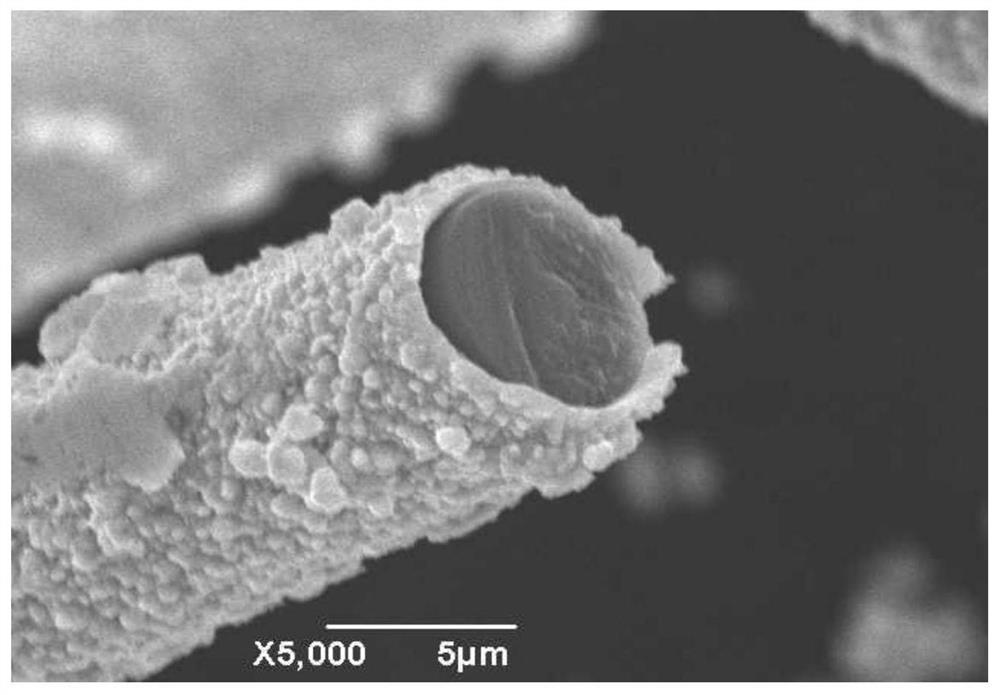

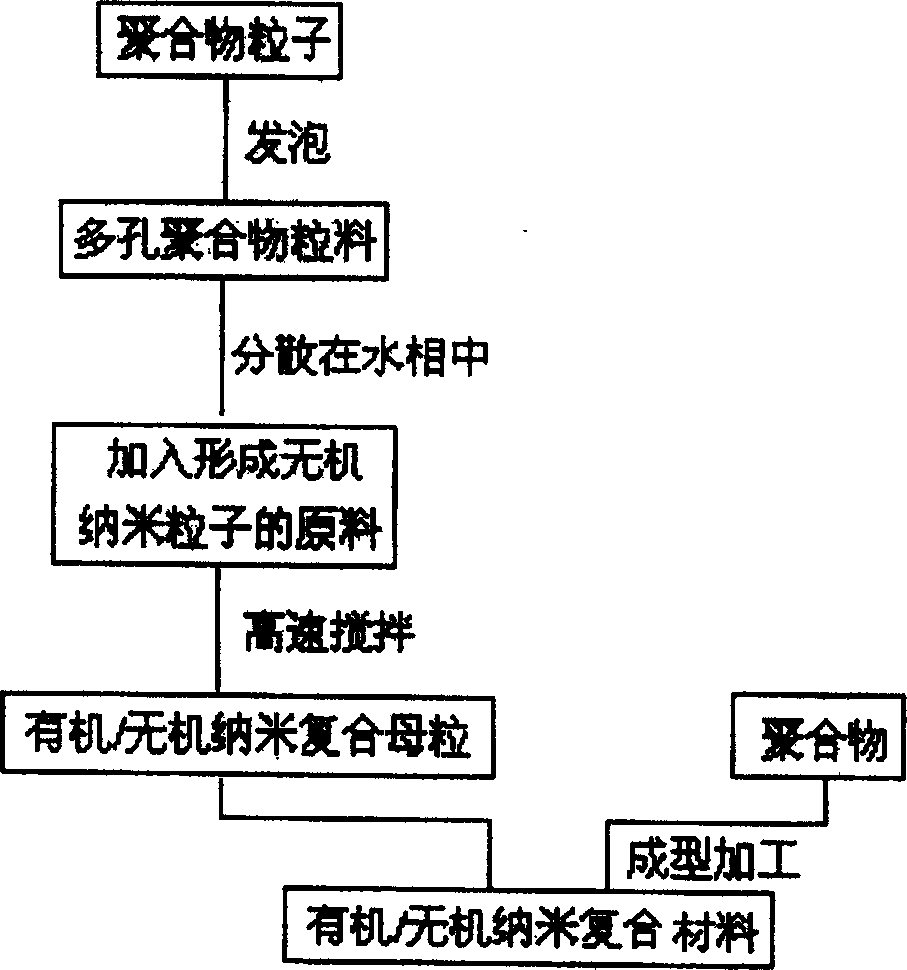

In-situ micropore-ultraspeed centrifugal adsorption nano combination technique

Firstly, adopting conventional foaming process to make polymer particles be foamed to obtain porous polymer granules material with through hole, then dispersing said porous polymer granules into water phase, adding raw material capable of forming inorganic nano particles in the water phase, stirring at high speed and making the inorganic nano particles be adsorbed in the lots of micropores of the polymer and on the surface of them to obtain the organic / inorganic nano composite mother granules, after the composite mother granules and conventional polymer are uniformly mixed, using conventional forming processing technology to prepare the invented nano composide material.

Owner:WUHAN UNIV OF TECH

A kind of preparation method of continuous carbon fiber reinforced aluminum matrix composite material

The invention discloses a method for preparing a continuous carbon fiber reinforced aluminum matrix composite. The method for preparing the continuous carbon fiber reinforced aluminum matrix compositecomprises the steps that after pretreatment and plating application are conducted on bare carbon fiber in sequence, work blanks are then prepared; an appropriate number of work blanks are taken and placed in extrusion dies; a compressor is adopted, the work blanks are formed through extrusion, and prefabricated blocks are acquired; the prefabricated blocks are placed in a plasma sintering furnace, and the continuous carbon fiber reinforced aluminum matrix composite is acquired after sintering. The preparation technology of the continuous carbon fiber reinforced aluminum matrix composite is simple; besides, carbon fiber is uniformly dispersed in the matrix, and material properties are isotropic; and in addition, various kinds of physical properties of the composite are improved, and meanwhile, the mechanical property of the composite is improved conspicuously.

Owner:SHAANXI SCI TECH UNIV

A kind of one-step activation method prepares the method for electroless iron-plated graphene

ActiveCN109055922BSolve the problem that it is difficult to disperse evenlyHigh tensile strengthLiquid/solution decomposition chemical coatingActivation methodBiological activation

The invention belongs to the technical field of preparing metal matrix composite material reinforcements, and particularly relates to a method for preparing electroless iron-plated graphene by a one-step activation method. In this method, graphene oxide is placed in an activation solution and homogenized, the filtrate is filtered and retained, and washed until neutral to obtain activated graphene oxide; the activation solution is a precious metal salt complex solution; The activated graphene oxide is ultrasonically dispersed, and then added to an electroless iron plating liquid to mix and react to obtain electroless iron plating graphene. The method of the invention improves the wettability between graphene and the metal matrix, and solves the problem of difficulty in uniform dispersion of graphene in the metal matrix. At the same time, the one-step activation process is adopted to simplify the process and significantly reduce production costs.

Owner:NORTHEASTERN UNIV LIAONING

A method for preparing graphene/rubber composites based on the combination of spray drying and hot press vulcanization

ActiveCN107129613BSolve the problem that it is difficult to disperse evenlySimple processEmulsionVulcanization

Owner:HARBIN INST OF TECH

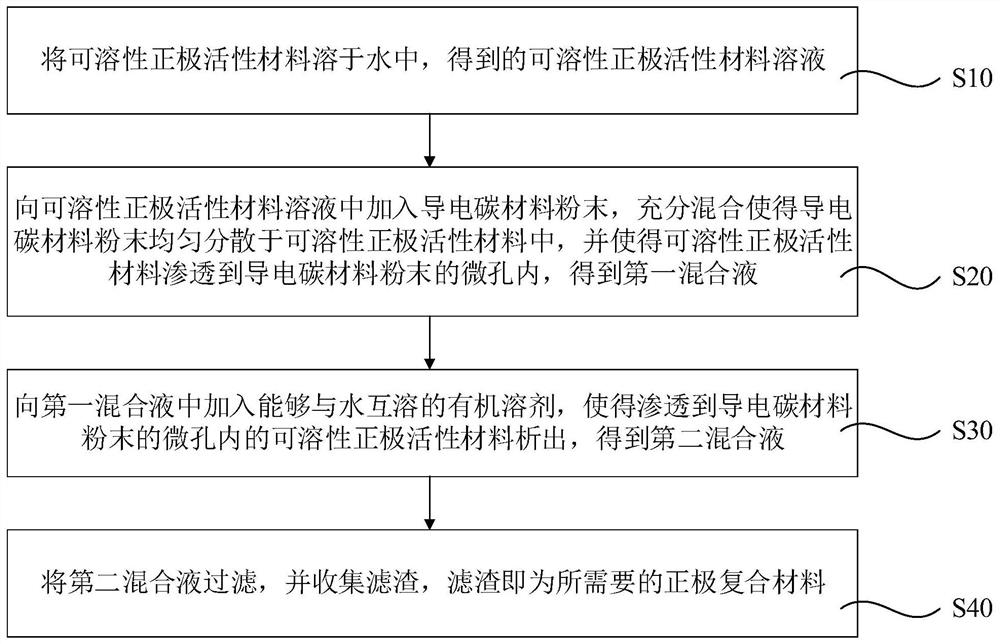

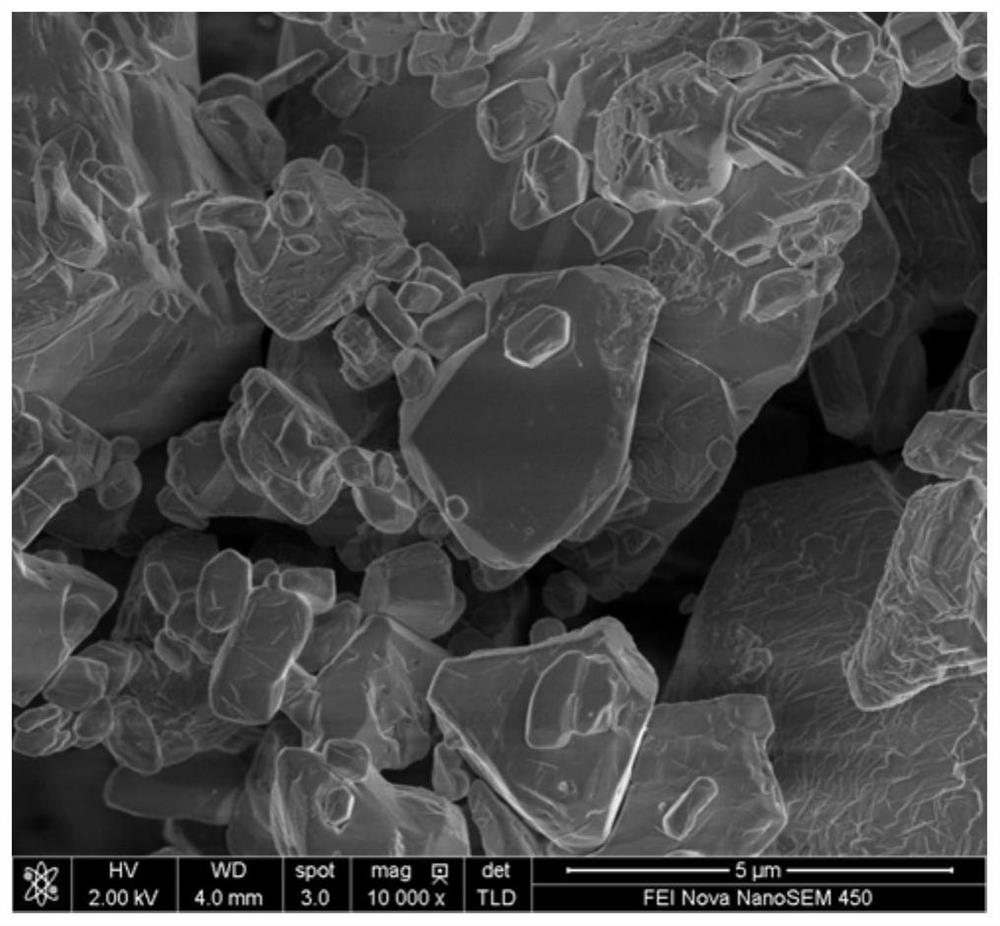

Preparation method of positive electrode composite material, positive electrode composite material and secondary battery

ActiveCN113517431ASolve the problem that it is difficult to disperse evenlySecondary cellsPositive electrodesOrganic solventElectrical battery

The invention discloses a preparation method of a positive electrode composite material, the positive electrode composite material and a secondary battery. The preparation method of the positive electrode composite material comprises the following steps of: adding conductive carbon material powder into a soluble positive electrode active material solution, and fully mixing to obtain a first mixed solution; adding an organic solvent which is mutually soluble with water into the first mixed solution to obtain a second mixed solution; and filtering the second mixed solution, and collecting filter residues which are the needed positive electrode composite material. According to the preparation method of the positive electrode composite material, the soluble positive electrode active material is adsorbed by the conductive carbon material powder, and then the soluble positive electrode active material permeating into micropores of the conductive carbon material powder is separated out through the organic solvent which is mutually soluble with water, and therefore, the soluble positive electrode active material forms small particles which are uniformly attached to the conductive carbon material powder, and the positive electrode composite material is obtained.

Owner:深圳市博理科技有限公司

Preparation method of flexible strain sensor based on nanocellulose-carbon nanotube/polyacrylamide conductive hydrogel

ActiveCN110183688BAchieve autonomous self-healingHigh strengthElectrical/magnetic solid deformation measurementCopper electrodeStrain sensor

The invention discloses a flexible strain sensor based on nanocellulose-carbon nanotube / polyacrylamide conductive hydrogel. The preparation method comprises the following steps: a. preparing TEMPO nanocellulose suspension; b. preparing carbon nanotube dispersion c. Prepare TEMPO nanocellulose-carbon nanotubes / polyacrylamide conductive hydrogel; d. Connect two separate copper electrodes to both sides of the hydrogel, that is, nanocellulose-carbon nanotube-based / Flexible strain sensor of polyacrylamide conductive hydrogel. The sensor provided by the present invention combines high flexibility, stretchability, high mechanical properties, high electrical conductivity and strain sensitivity.

Owner:NANJING FORESTRY UNIV

A kind of graphene-reinforced copper-based oil bearing material and its preparation method and application

ActiveCN108907181BReduce wearImprove bearing capacityTransportation and packagingMetal-working apparatusPorous grapheneBase oil

The invention belongs to the technical field of oil-impregnated bearing materials, and discloses a graphene-reinforced copper-based oil-impregnated bearing material, a preparation method and an application thereof. The oil-containing bearing material is obtained by adding copper powder into graphene oxide colloidal aqueous solution, stirring and reacting at room temperature, filtering and drying to obtain graphene-coated copper powder; cold-pressing the graphene-coated copper powder to obtain an embryo body, The green body is sintered in a protective atmosphere, and after natural cooling, a porous graphene / copper composite material is obtained; the porous graphene / copper-based composite material is placed in a special lubricating oil for oil-impregnated bearings, and soaked under a certain negative pressure until completely Soaked and naturally cooled. The graphene-reinforced copper-based oil-bearing bearing material prepared by the invention has the advantages of less wear, good bearing capacity, high oil content and stable lubrication performance, and effectively solves the problem that graphene nanosheets are difficult to uniformly disperse in the copper matrix. It is used in the fields of audio machinery, household electrical appliances, office machinery and transportation machinery bearings.

Owner:GUANGDONG UNIV OF TECH

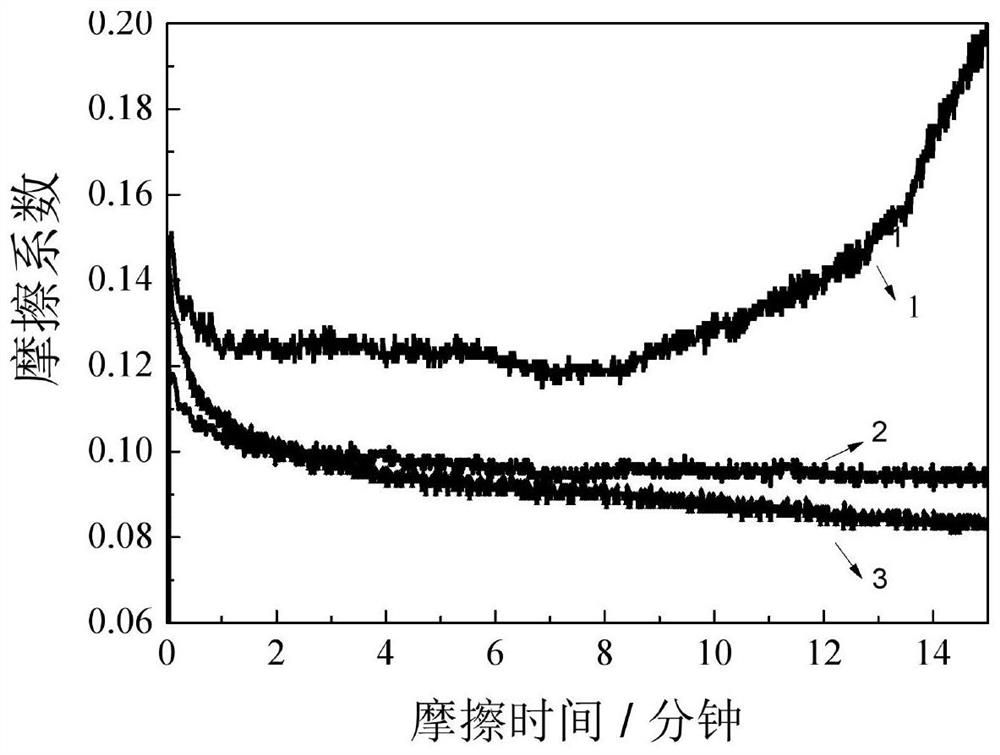

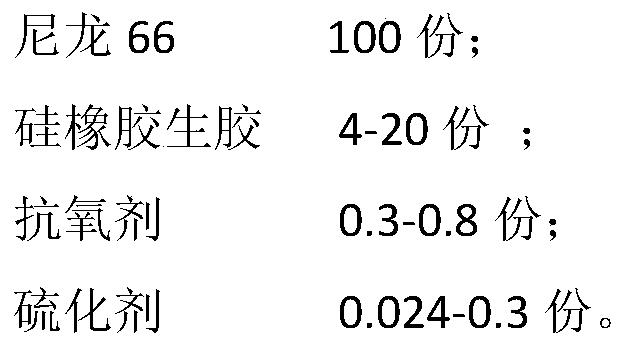

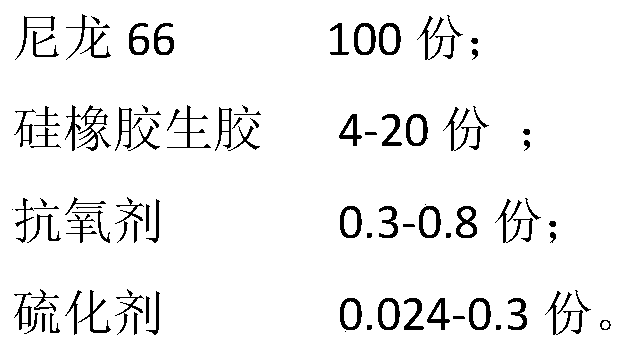

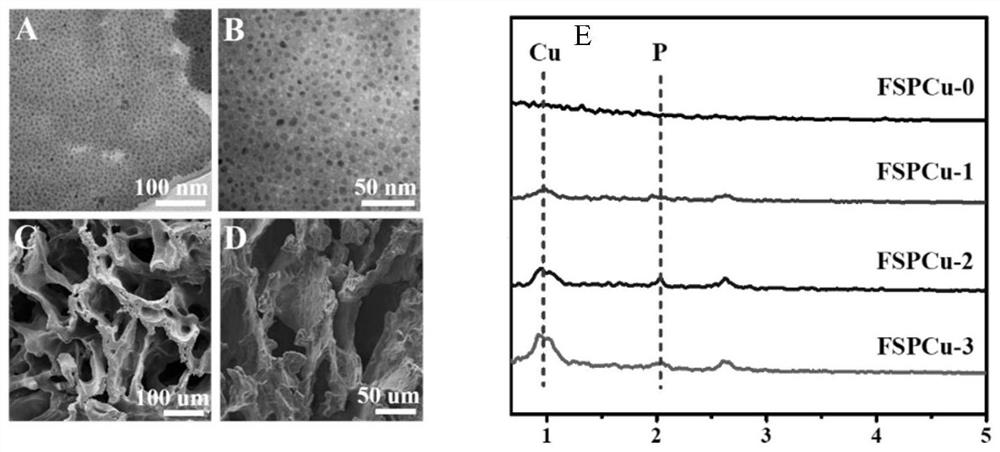

Toughened nylon 66 material and its preparation method and application

ActiveCN105331102BSolve the problem that it is difficult to disperse evenlyGood toughening effectNylon materialPolymer science

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

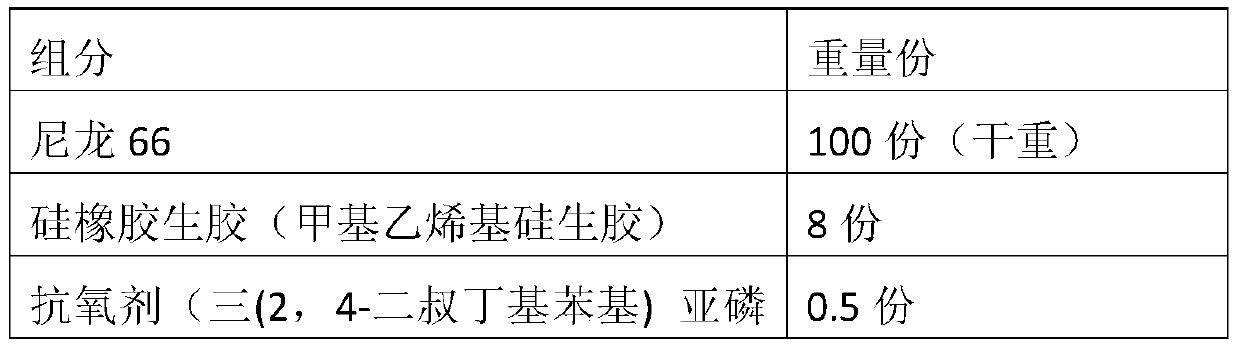

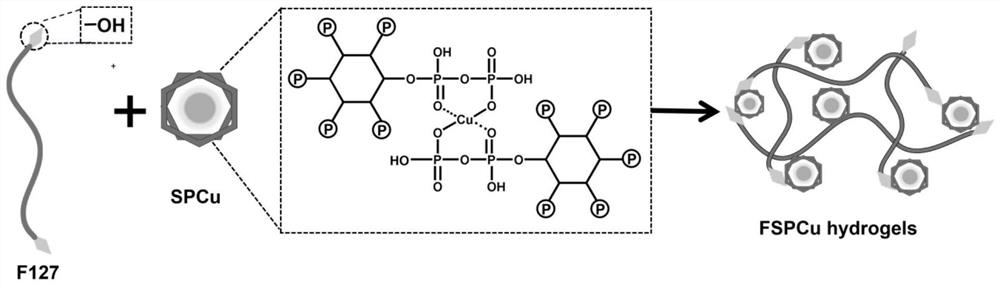

A kind of nanocomposite hydrogel dressing and its preparation method and application

ActiveCN114225101BExcellent antioxidant and antibacterial propertiesSolve the problem that it is difficult to disperse evenlyBandagesPhosphateDrug biological activity

The invention discloses a nanocomposite hydrogel dressing and its preparation method and application. In the method, polyether F127 polymer aqueous solution is used as a reaction medium, and sodium phytate and copper chloride are added in a certain proportion; in an ice-water bath environment, Through the coordination assembly strategy of phosphate and copper ions, copper phytate gradually nucleates and grows, and is uniformly dispersed in the F127 aqueous solution; finally, the pH of the reaction system is adjusted to neutral, and the reaction solution is gradually transformed into a coagulated form by heating in a water bath. gel state, that is, the nanocomposite hydrogel is prepared. The preparation method of the nanocomposite hydrogel dressing proposed in the present invention is green and environment-friendly, the raw materials are safe, and the cost is low. The hydrogel dressing prepared by the method has excellent mechanical properties and biological activity. The excellent temperature sensitivity, injectability and self-healing properties of the nanocomposite hydrogel ensure that it can be applied in complex wound environments.

Owner:XI AN JIAOTONG UNIV

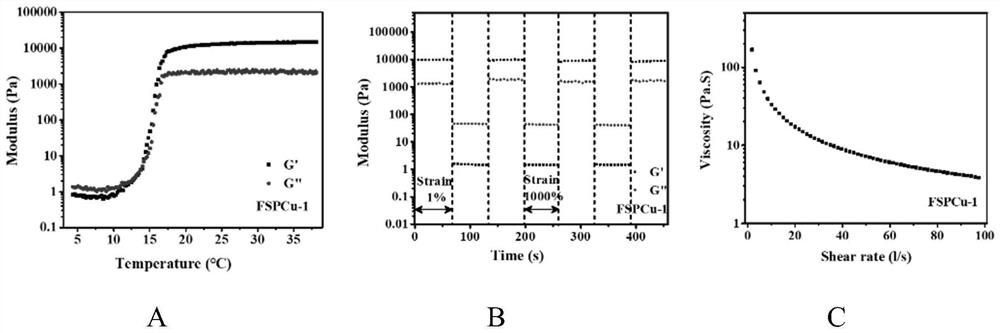

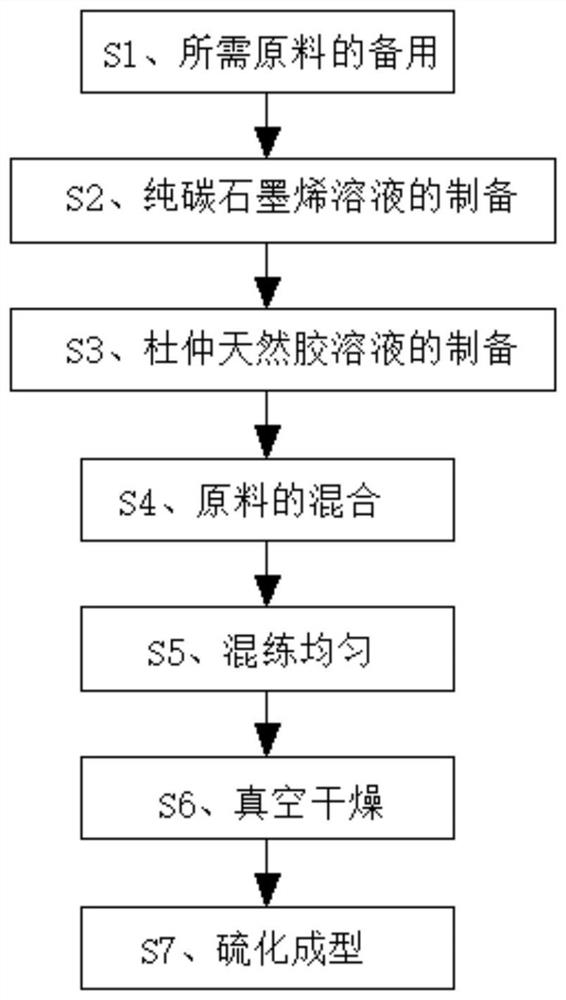

Method for preparing rubber composite material based on blending of pure carbon graphene and eucommia ulmoides natural rubber

InactiveCN111961264AContributes to mechanical propertiesContribute to electrical performanceRubber materialPolymer science

The invention discloses a method for preparing a rubber composite material based on blending of pure carbon graphene and eucommia ulmoides natural rubber, and relates to the technical field of rubbercomposite materials. The preparation method comprises: mixing and dispersing graphene and eucommia ulmoides natural rubber, adding a dispersing agent, a silane coupling agent, an accelerant and a vulcanizing agent, so that the pure carbon graphene and eucommia ulmoides natural rubber blended rubber is prepared, preparing a pure carbon graphene and eucommia ulmoides natural rubber blended rubber composite material through rubber mixing and vulcanization, and uniformly dispersing graphene in the rubber material in the preparation process. The comprehensive properties such as the mechanical property, the electrical property and the thermal conductivity of the rubber composite material are facilitated, the method is simple in process, low in cost, high in production efficiency and good in controllability, the composite material with high filling amount can be prepared, the requirements of different projects can be met, and the problems that in the past, the filling amount is too large, andgraphene is difficult to disperse uniformly are solved.

A kind of modified epoxy asphalt, water-based drilling fluid and preparation method thereof

ActiveCN110922774BHigh softening pointImprove stabilityDrilling compositionBuilding insulationsPolymer scienceFirming agent

The invention discloses a modified epoxy asphalt, a water-based drilling fluid and a preparation method thereof. The components of the modified epoxy asphalt include modified asphalt, epoxy resin and curing agent, wherein the components of the modified asphalt include base asphalt, organic acid anhydride, SBS and crosslinking agent. The water-based drilling fluid includes base slurry and modified epoxy asphalt fluid, and the modified epoxy asphalt fluid includes modified epoxy asphalt and water. The modified epoxy asphalt of the invention not only has small particle size, high softening point, certain elastic deformation ability, but also excellent high temperature resistance. The drilling fluid has good rheological properties and high temperature and high pressure fluid loss reduction effect when used at high temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

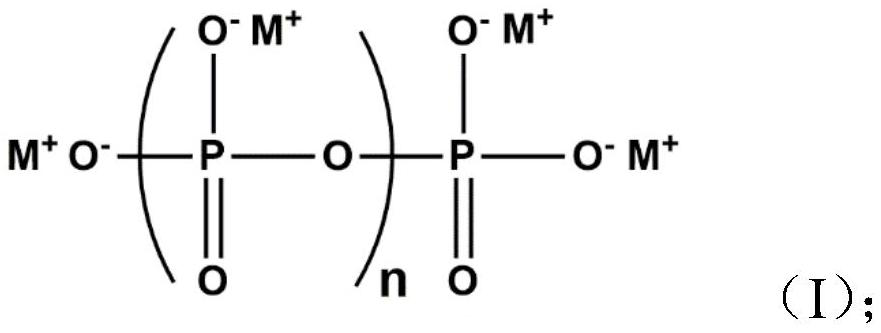

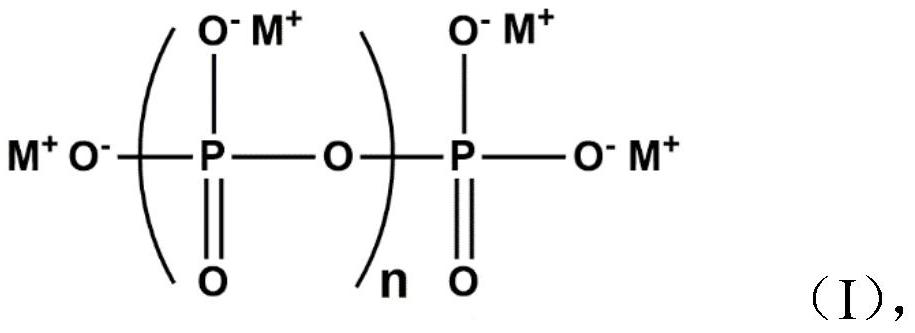

Polyester composition as well as preparation method and application thereof

ActiveCN112679914AStable heat resistanceStable hydrolysis resistancePhotovoltaic energy generationSemiconductor devicesPolyesterPolymer science

The invention discloses a polyester composition as well as a preparation method and application thereof. The polyester composition comprises 4 to 50 ppm of a titanium element, 0.1 to 100 ppm of a phosphorus element and 1.5 to 30% of a nano white filler. The phosphorus element is derived from an alkali metal salt of polyphosphoric acid contained in the polyester composition, and the nano-white filler is selected from a nano-white pigment having a refractive index being greater than 1.50 at 20 DEG C. The preparation method comprises the step of carrying out esterification and condensation polymerization on components including dicarboxylic acid, alkylene glycol, a titanium source, a phosphorus source and a white filler to obtain the polyester composition. The polyester composition can be used for producing film materials such as photovoltaic backboards. The polyester composition is low in terminal carboxyl group content, meets the technical requirement of hydrolysis resistance, and achieves better ultraviolet resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

In-situ micropore-ultraspeed centrifugal adsorption nano combination technique

Firstly, adopting conventional foaming process to make polymer particles be foamed to obtain porous polymer granules material with through hole, then dispersing said porous polymer granules into water phase, adding raw material capable of forming inorganic nano particles in the water phase, stirring at high speed and making the inorganic nano particles be adsorbed in the lots of micropores of the polymer and on the surface of them to obtain the organic / inorganic nano composite mother granules, after the composite mother granules and conventional polymer are uniformly mixed, using conventional forming processing technology to prepare the invented nano composide material.

Owner:WUHAN UNIV OF TECH

Method for producing C5 petroleum resin with chlorine alumine acid ion liquid catalyzed polymerization

ActiveCN101173024BImprove solubilitySolve the problem that it is difficult to disperse evenlyPtru catalystPetroleum resin

The invention relates to a method for using chlorine aluminic acid ion liquid to prepare C5 petroleum resin by catalyzing and polymerizing. C5 fraction is added into a dry and closed container or a container which has inactive gas protection , the temperature of 90 to 120 DEG C can be improved, and then the chlorine aluminic acid ion liquid with 0.8 to 3.0 percent of the C5 fraction quality is added under the mixing condition to polymerizing and reacting for 6 to 10 hours to get slumpability liquid; the gotten slumpability liquid is cooled at room temperature to be coagulated into brittle solid, and then crushed to superfines below 400 meshes, and soaked and processed by 0.5 percent of NaOH solution for 20 to 24 hours, and then washed by distilled water until neutrality, dried for 3 hours respectively in the vacuum of 80 DEG C and 150 DEG C after filtrating and eliminating most of water, and finally light colored C5 petroleum resin can be obtained. The invention overcomes flash polymerization and overflowing kettle phenomenon caused by using solid AlCl3 as a catalyst. The reaction process is gentle, and the reaction is easy to be controlled. The obtained petroleum resin product has stable performance and light color.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

Modified epoxy asphalt, water-based drilling fluid and preparation method thereof

ActiveCN110922771BIncrease stickinessSmall particle sizeDrilling compositionBuilding insulationsPolymer scienceFirming agent

The invention discloses a modified epoxy asphalt, a water-based drilling fluid and a preparation method thereof. The modified epoxy asphalt, in parts by weight, includes: 100 parts of base asphalt, 1-20 parts of compatibilizer, 1-10 parts of toughening agent, 5-20 parts of curing agent, 1-5 parts of curing accelerator parts, 5 to 30 parts of epoxy resin; wherein, the curing accelerator includes polyamines, phenols and products obtained by reacting aldehyde-containing aqueous solutions. The modified epoxy asphalt fluid is added to the water-based drilling fluid of the present invention. The modified epoxy asphalt not only has a small particle size, a high softening point, and a certain elastic deformation ability, but also has excellent high temperature resistance. The drilling fluid When used at high temperature, it has good rheological properties and high temperature and high pressure drop fluid loss effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of surface metallized graphene and preparation method thereof

InactiveCN110158123BImprove wettabilitySolve the problem that it is difficult to disperse evenlyJewelleryActive agentComposite plate

The invention relates to the technical field of metal matrix composite reinforcements, and in particular to a surface metallized graphene and a preparation method thereof. Mix the graphene oxide dispersion and activator in the electroplating solution, use titanium as the cathode and copper as the anode plate to connect to direct current for electroplating, so that graphene oxide is deposited on the surface of the surface that has been plated with a layer of copper film during the electroplating process. On the titanium plate, a composite coating containing copper and graphene oxide is formed on the titanium plate. The composite coating is collected to obtain surface metallized graphene. The surface metalized graphene includes a metal film wrapped on the surface of graphene oxide. The metal film is metal Copper film. The invention does not need to introduce a connecting medium, greatly shortens the process flow and reduces production costs. At the same time, the preparation raw materials can be recycled, no waste liquid is generated, and is environmentally friendly. It also improves the wettability between graphene and the metal matrix and solves the problem of graphite. The problem of uniform dispersion of alkenes in metal matrix.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com