A kind of graphene-reinforced copper-based oil bearing material and its preparation method and application

A bearing material and graphene technology, which is applied in transportation and packaging, metal processing equipment, etc., can solve the problems of weakening the mechanical properties of the metal matrix of oil-bearing bearings, increasing the amount of graphene, and increasing the production cost, so as to improve the supply/suction efficiency, Improve oil content and good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

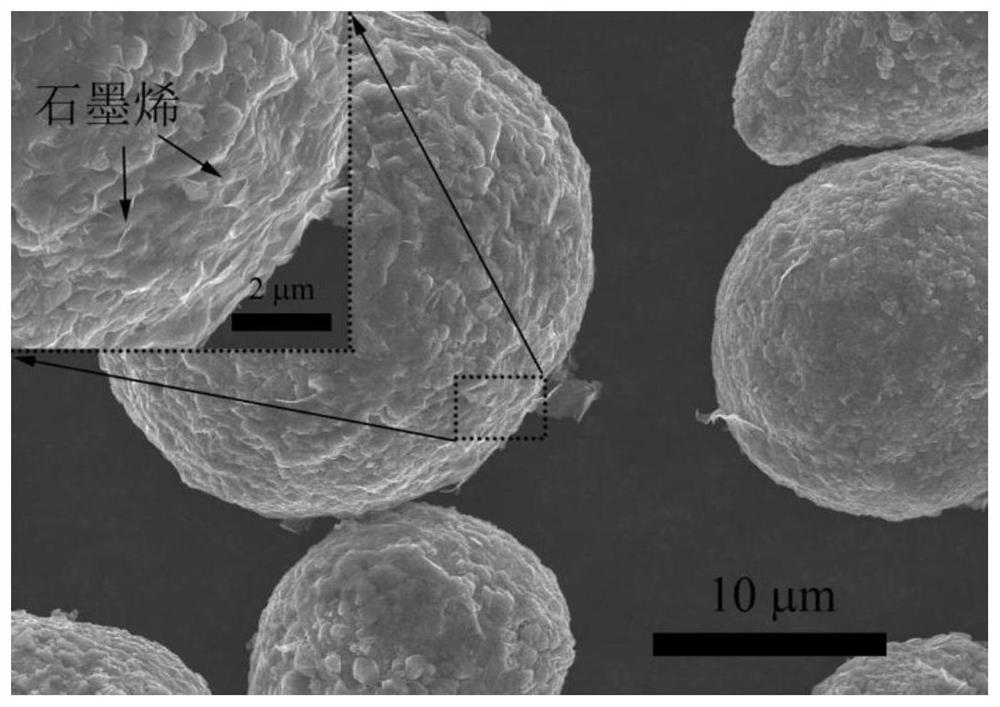

[0030] Add 20g of copper powder (particle size: 20±10μm) into 2L of graphene oxide colloidal aqueous solution (concentration: 0.1mg / mL), stir and react at room temperature for 0.5h, filter and dry the product at 80°C under vacuum to obtain graphene-coated Copper-clad powder, wherein the content of graphene is 0.5wt.% of the graphene-coated copper powder. figure 1 For the surface topography SEM photo of the graphene-coated copper powder of gained, from figure 1 It can be seen that graphene nanosheets are uniformly deposited along the surface of copper powder.

Embodiment 2

[0032] The difference from Example 1 is that the graphene oxide concentration in the graphene oxide colloidal aqueous solution is 0.2 mg / mL, the stirring reaction time is 1 h, and the graphene content in the graphene-coated copper powder is 1.0 wt.%.

Embodiment 3

[0034] The difference from Example 1 is that the particle size of the copper powder is 30±10 μm, the concentration of the graphene oxide colloidal aqueous solution is 0.05 mg / mL, and the volume is 4 L. figure 2 For the surface topography SEM photo of the graphene-coated copper powder of gained, from figure 2 It can be seen that graphene nanosheets are uniformly deposited along the surface of copper powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com