Preparation method of positive electrode composite material, positive electrode composite material and secondary battery

A technology of composite materials and positive electrode active materials, applied in the field of secondary batteries, can solve problems such as affecting electrochemical performance, affecting material capacity, and difficult to uniformly disperse conductive agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

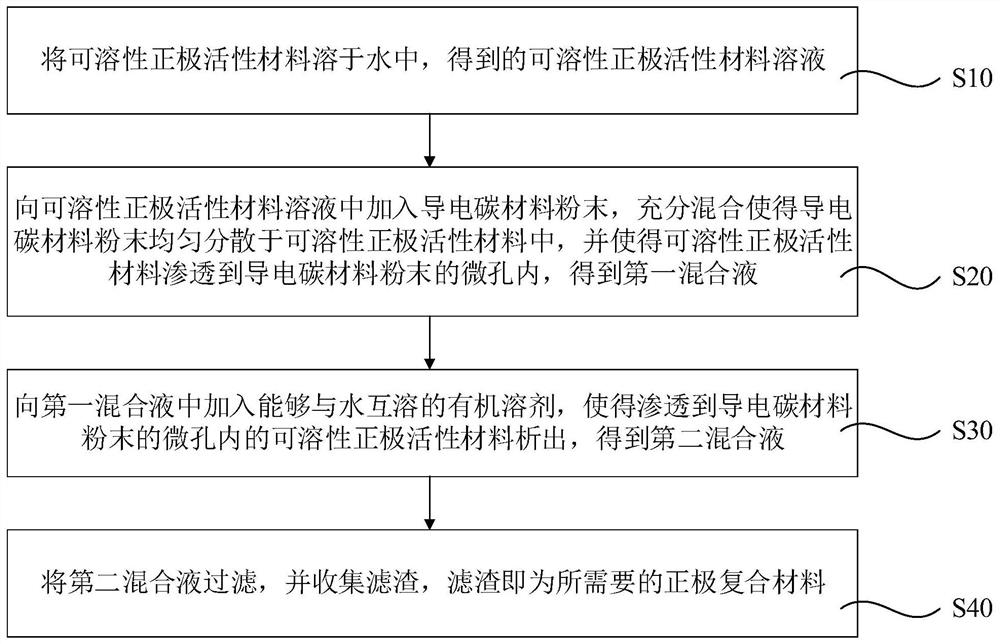

[0024] like figure 1 The preparation method of the positive electrode composite material according to one embodiment includes the following steps.

[0025] S10, dissolving the soluble positive electrode active material in water to obtain a soluble positive electrode active material solution.

[0026] Preferably, the soluble positive electrode active material is a molecular cluster ion compound.

[0027] More preferably, in this embodiment, the molecular cluster ion compound has the general formula A 7 [ZV 13 o 38 ] compound, wherein, A is NH 4 , Li, Na or K, Z=Ni, Co or Mn.

[0028] Has the general formula A 7 [ZV 13 o 38 ] compounds can be prepared by the following operations: to AVO 3 Add HNO to the solution 3 、ZSO 4 and K 2 S 2 o 8 Obtain the mixed solution, after heating and evaporating (preferably at 80° C.) to obtain a compound with general formula A 7 [ZV 13 o 38 ]compound of.

[0029] Preferred, AVO 3 The temperature of the solution is 60°C to 90°C (...

Embodiment 1

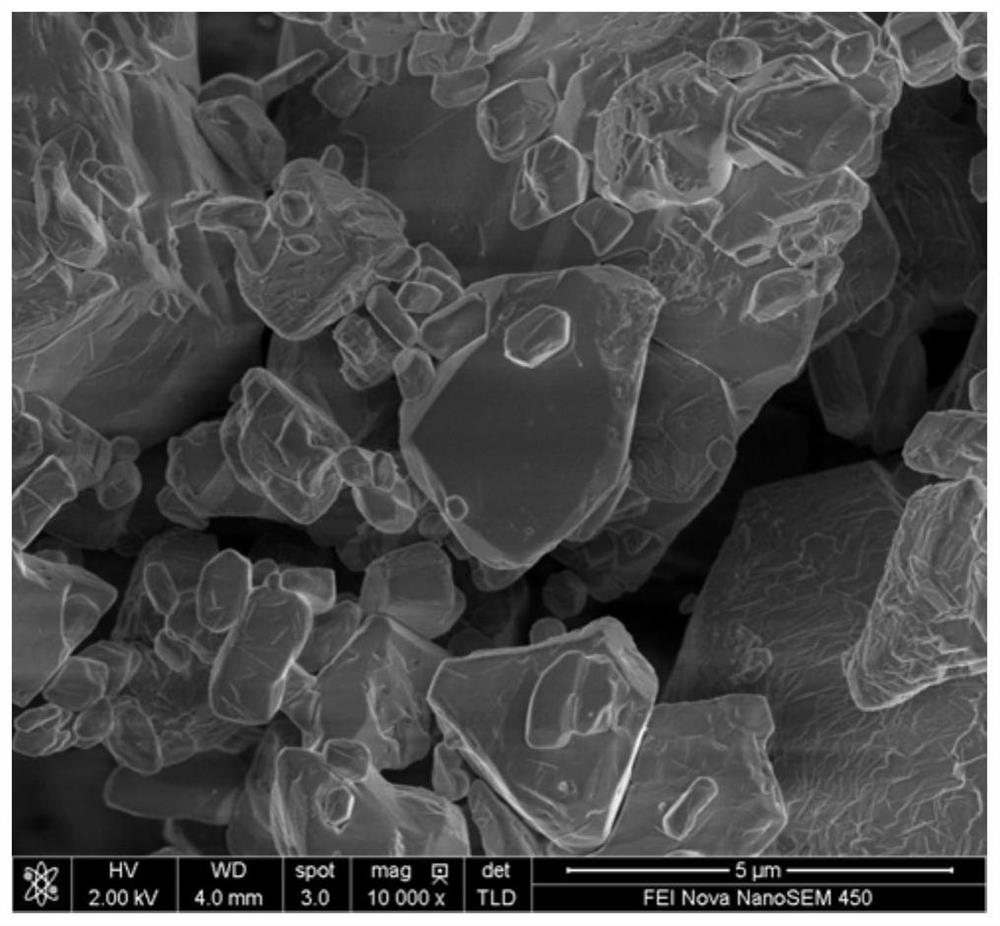

[0058] 7.18g KVO 3 Dissolve in 180mL deionized water at 80°C, add 4mL 1mol / L HNO 3 , 4mL1mol / L of MnSO 4 and 2.16g of K 2 S 2 o 8 , the mixed solution was stirred at a temperature of 80° C. until the solvent evaporated, and a solid crystal was obtained. The solid crystal has the molecular formula K 7 [MnV 13 o 38 ]compound of. figure 2 K obtained for Example 1 7 [NiV 13 o 38 ] Scanning electron microscope image.

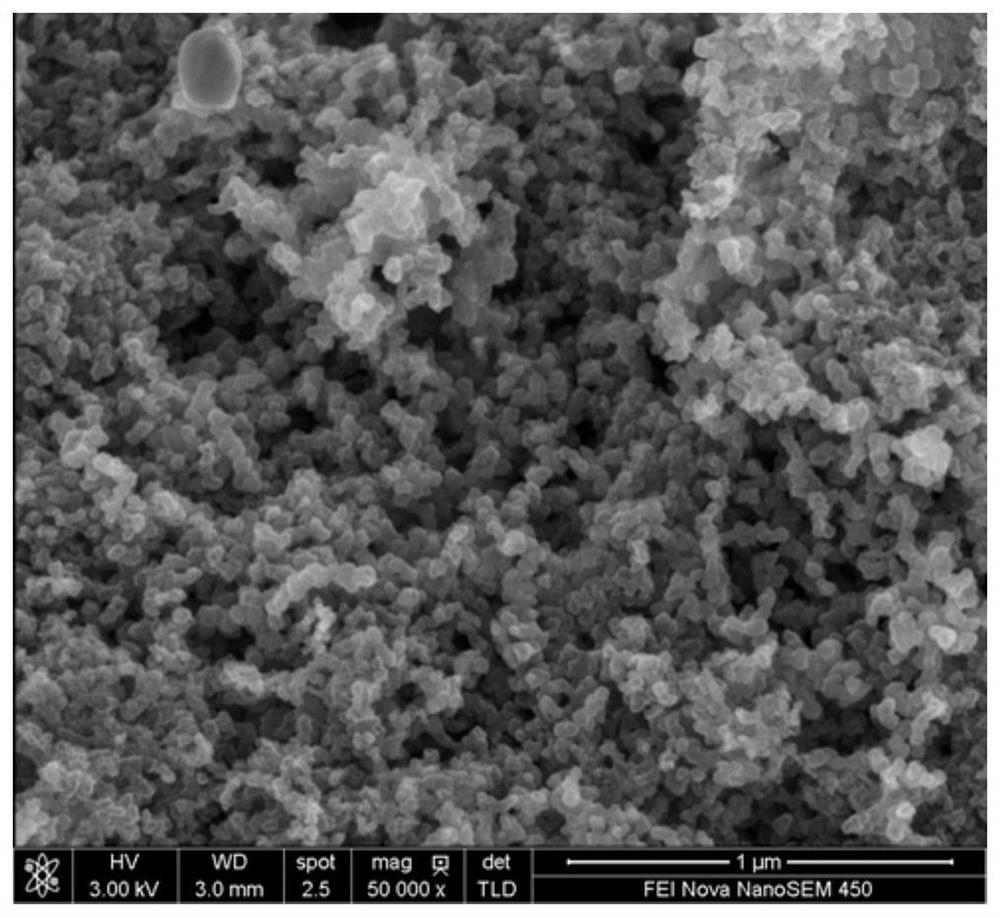

[0059] With the K that 2g embodiment 1 makes 7 [NiV 13 o 38 ] was dissolved in 30mL deionized water, and then 2g of dried powdered carbon black Carbon ECP 600JD was added in a small amount in batches, and the solution was stirred at high speed while adding until all the powdered carbon black was evenly dispersed in the aqueous solution. Then add 60mL of absolute ethanol, and stir the solution, so that the free K that penetrates into the micropores of carbon black + with [NiV 13 o 38 ] 7- It was separated out by reprecipitation. Finally, the solut...

Embodiment 2

[0065] With the K that 2g embodiment 1 makes 7 [NiV 13 o 38 ] was dissolved in 20mL of deionized water, and then 2g of dried powdered carbon black Carbon ECP 600JD was added in a small amount in batches, and the solution was stirred at high speed while adding, until all the powdered carbon black was evenly dispersed in the aqueous solution. Then add 80mL of anhydrous methanol, and stir the solution, so that the free K that penetrates into the micropores of carbon black + with [NiV 13 o 38 ] 7- It was separated out by reprecipitation. Finally, the solution was filtered to obtain the cathode composite material.

[0066] Slurry preparation, coating, drying, rolling, and sheet cutting were performed on the prepared positive electrode composite material and PTFE binder at a mass ratio of 96%:4%, to obtain positive electrode sheets. EC: DMC = 1: 1 (volume ratio) + 1mol / L LiPF 6 It is the electrolyte, and the metal lithium sheet is the negative electrode, which is assembled i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com