A kind of surface metallized graphene and preparation method thereof

A surface metal, graphene technology, applied in the field of graphene, can solve the problems of poor metal interface wettability, difficult metal matrix composite, agglomeration, etc., to reduce production costs, shorten the process flow, and improve the effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

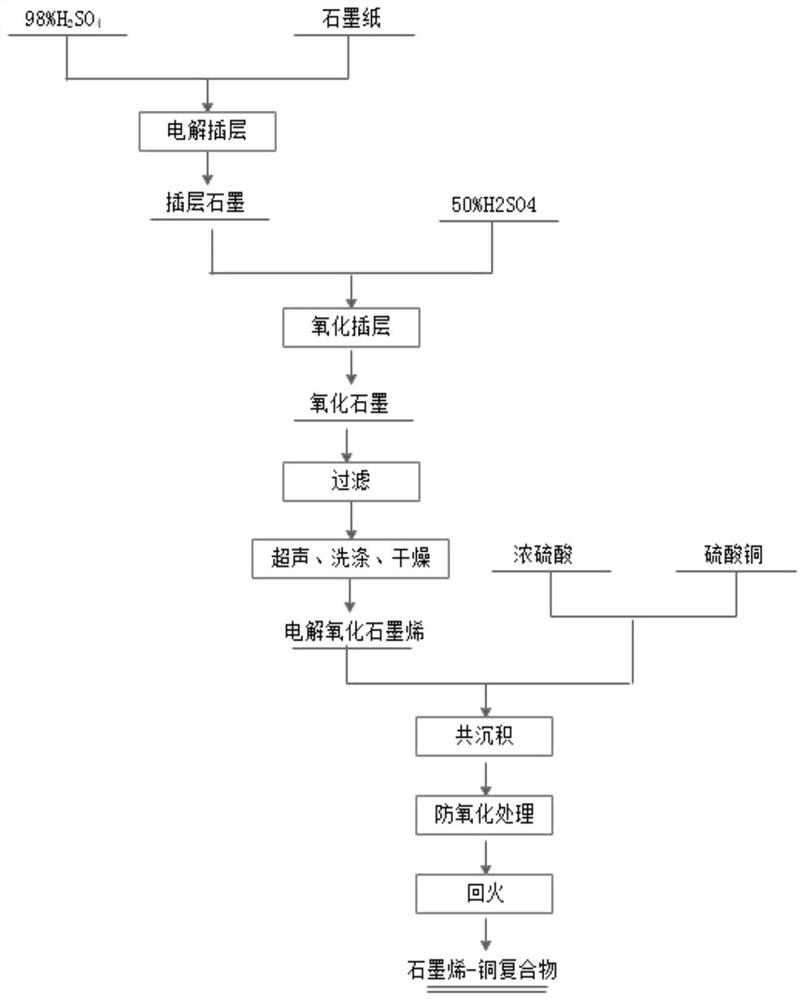

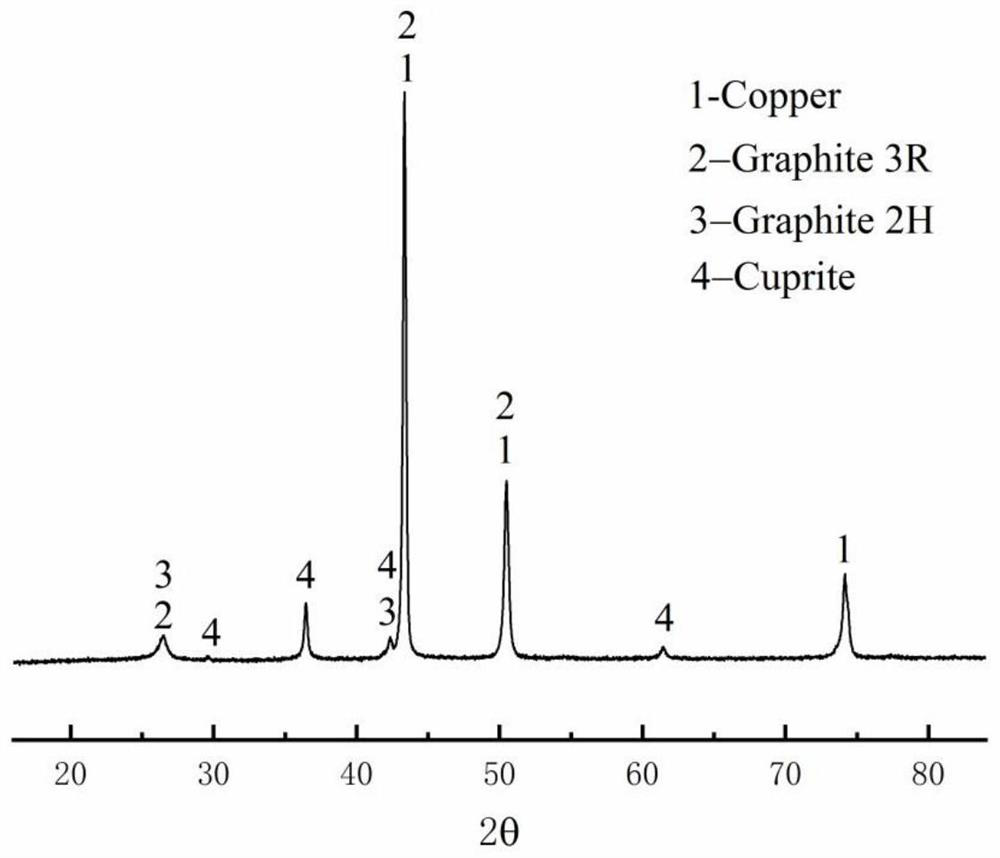

[0026] This embodiment provides a method for preparing surface metallized graphene by electroplating, the process flow is as follows figure 1 As shown, it specifically includes the following steps:

[0027] s1: Put graphite paper of 4cm*10cm as the anode and platinum wire as the cathode, put it into 98% concentrated sulfuric acid, connect a 1.5-2.5V DC power supply between the anode and the cathode, and react for 15-25min to obtain plug layer graphite;

[0028] Intercalated graphite is used as anode, platinum wire is used as cathode, 40%-60% sulfuric acid is used as electrolyte, connected to 4.5-6.5V DC power supply, and intercalated graphite is slowly put into the electrolyte to obtain graphite oxide;

[0029] After the graphite oxide is filtered and washed by centrifugation, ultrasonic dispersion is carried out for 2-3 hours to obtain a 0.3-0.5 g / L graphene oxide solution.

[0030] s2: Take copper as the anode, titanium as the cathode, copper sulfate solution with a concen...

Embodiment 1

[0034] (1) Take 200ml of 98% concentrated sulfuric acid, put it into a 250ml beaker, take completely dry graphite paper 4cm*10cm as the anode, platinum wire as the cathode, connect it to a 1.5V DC power supply, react for 15min, and take out the intercalated Graphite paper to remove adsorbed sulfuric acid.

[0035] (2) The graphite paper after intercalation is an anode, the platinum wire is a cathode, and 40% sulfuric acid is an electrolyte. Get 200ml of 40% sulfuric acid and put it into a 250ml beaker, insert a 4.5V DC power supply, and put the graphite paper after the intercalation Slowly inserted into the electrolyte, the expanded graphite oxide was collected, filtered several times, washed with deionized water, and then ultrasonically treated.

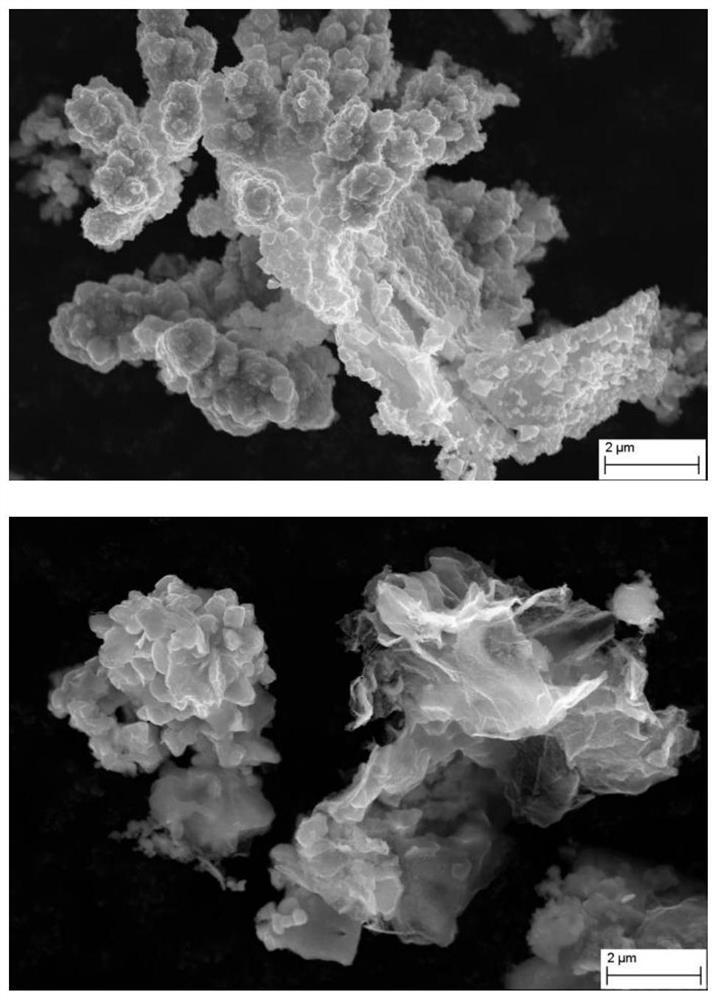

[0036] (3) With titanium and copper as cathode and anode plates respectively, in 40g / L copper sulfate solution, under DC power supply, the current density is 0.015A / cm 2 , the temperature is 15°C, and a 2 μm copper film is pre-plat...

Embodiment 2

[0041] (1) Take 200ml of 98% concentrated sulfuric acid, put it into a 250ml beaker, take completely dry graphite paper 4cm*10cm as the anode, platinum wire as the cathode, connect it to a 2.5V DC power supply, react for 25min, and take out the intercalated Graphite paper removes adsorbed sulfuric acid.

[0042] (2) The graphite paper after intercalation is the anode, the platinum wire is the negative electrode, and 60% sulfuric acid is the electrolyte. The sulfuric acid of 200ml60% is put into a 250ml beaker, connected to a 6.5V DC power supply, and the graphite paper after the intercalation is Slowly inserted into the electrolyte, the expanded graphite oxide was collected, filtered several times, washed with deionized water, and then ultrasonically treated.

[0043] (3) With titanium and copper as cathode and anode plates respectively, in 70g / L copper sulfate solution, under DC power supply, the current density is 0.030A / cm 2 , the temperature is 30°C, and a 2 μm copper fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com