In-situ micropore-ultraspeed centrifugal adsorption nano combination technique

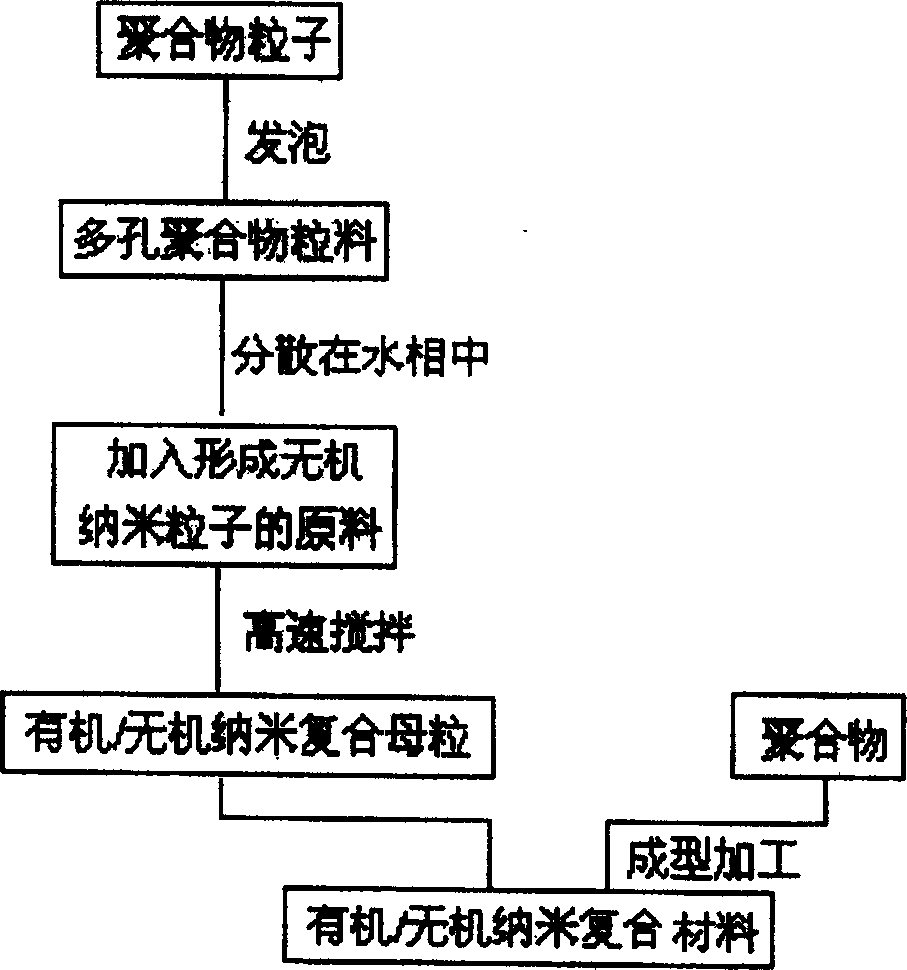

A technology of ultracentrifugation and nano-composite, which is applied in the field of organic/inorganic nano-composite materials, and can solve the problems of surface non-oxidation, non-agglomeration, difficulty in uniform dispersion of inorganic nanoparticles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: first the polyvinyl chloride pellets are foamed to make the polyvinyl chloride pellets form porous particles with interconnected pores, and then the porous polyvinyl chloride pellets are added to the Ca(OH) 2 In the aqueous solution, CO was introduced slowly during high-speed stirring 2 , so that the formation of CaCO 3 Nanoparticles are adsorbed to the large number of micropores and surfaces of porous polyvinyl chloride under the action of centrifugal force to prepare CaCO 3 / PVC nano-composite masterbatch, and then mix and compound the masterbatch with PVC to prepare PVC / CaCO 3 Nanocomposite materials, tested according to the national standard GB / T 1043-93, the tensile strength of PVC products exceeds 80MPa, and the impact strength exceeds 100kJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com