Polyester composition as well as preparation method and application thereof

A composition and polymer technology, applied in the field of polyester, can solve problems such as lack of anti-ultraviolet performance, increased carboxyl content, difficulty in uniform dispersion of nanoparticles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Preparation of Catalyst A:

[0065] Add 12.4 grams (0.2 mol) of ethylene glycol in the reactor that stirrer, condenser and thermometer are equipped with, in reactor, slowly drip into tetraisopropyl titanate 28.4 grams (0.1mol), separate out white precipitate, After reacting at 70°C for 2 hours, the product was centrifuged, and the residue was washed with distilled water three times, and the product was vacuum-dried at 70°C to obtain a white powdery substance.

[0066] The dried white powdery substance is placed in a reactor with agitator, condenser and thermometer, 50 grams of ethylene glycol, 32 grams of 25% aqueous sodium hydroxide solution (0.2 mol) in mass fraction, 18 grams of lactic acid (0.2 mol), and reacted for 2 hours at a reaction temperature of 150° C. to obtain a nearly colorless homogeneous liquid, which was Catalyst A.

Embodiment 1

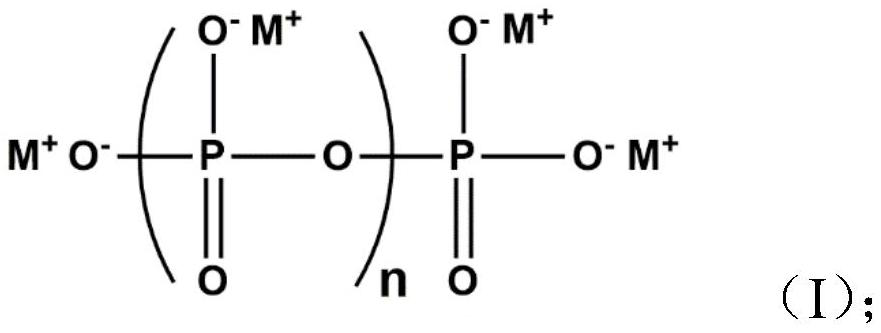

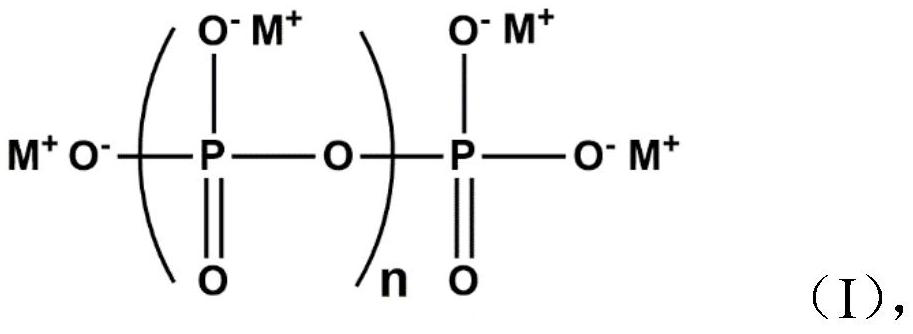

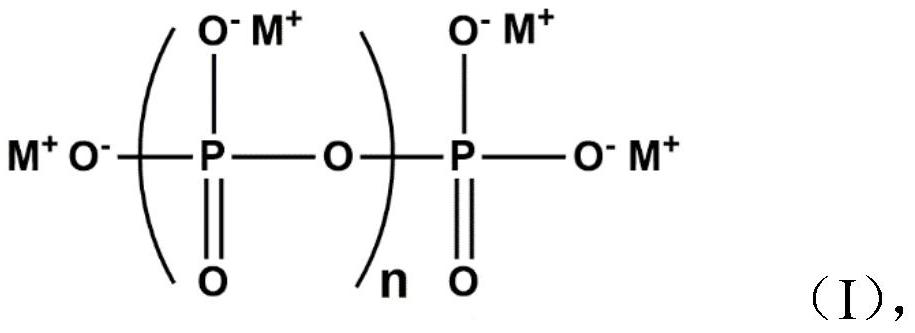

[0068] With 600 grams of terephthalic acid, 300 grams of ethylene glycol, catalyst A (based on the weight of the polyester polymer that finally generates, the weight of titanium atoms is 5 ppm), potassium tripolyphosphate (based on the polyester polymer that finally generates by weight, the weight of phosphorus atoms is 40ppm) and anatase titanium dioxide (average particle diameter 30nm, based on the weight of the polyester polymer that is finally generated, the mass fraction of anatase titanium dioxide is 2%), made into Mix the slurry, add it to the reaction kettle, and carry out the esterification reaction. The esterification temperature is 230-255° C., the pressure is 0.25 MPa, and the water generated by the reaction is discharged through the rectification device. After the esterification is completed, it is reduced to normal pressure and enters the pre-condensation stage. Vacuumize and decompress until the system pressure is maintained at 500 Pa, and the liquid phase temper...

Embodiment 2

[0071] With 600 grams of terephthalic acid, 300 grams of ethylene glycol, catalyst A (based on the weight of the polyester polymer that finally generates, the weight of titanium atoms is 5 ppm), potassium tripolyphosphate (based on the polyester polymer that finally generates by weight, the weight of phosphorus atoms is 40ppm) and anatase titanium dioxide (average particle diameter 30nm, based on the weight of the polyester polymer that is finally generated, the mass fraction of anatase titanium dioxide is 15%), made into Mix the slurry, add it to the reaction kettle, and carry out the esterification reaction. The esterification temperature is 230-255° C., the pressure is 0.25 MPa, and the water generated by the reaction is discharged through the rectification device. After the esterification is completed, it is reduced to normal pressure and enters the pre-condensation stage. Vacuumize and decompress until the system pressure is maintained at 500 Pa, and the liquid phase tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com