High-temperature-resistant metal plate adopting inorganic coating and preparation method thereof

An inorganic coating and high temperature resistant technology, applied in coatings, fireproof coatings, etc., can solve problems that affect the safe operation of equipment, poor corrosion resistance, weather resistance, and inability to maintain product functions for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

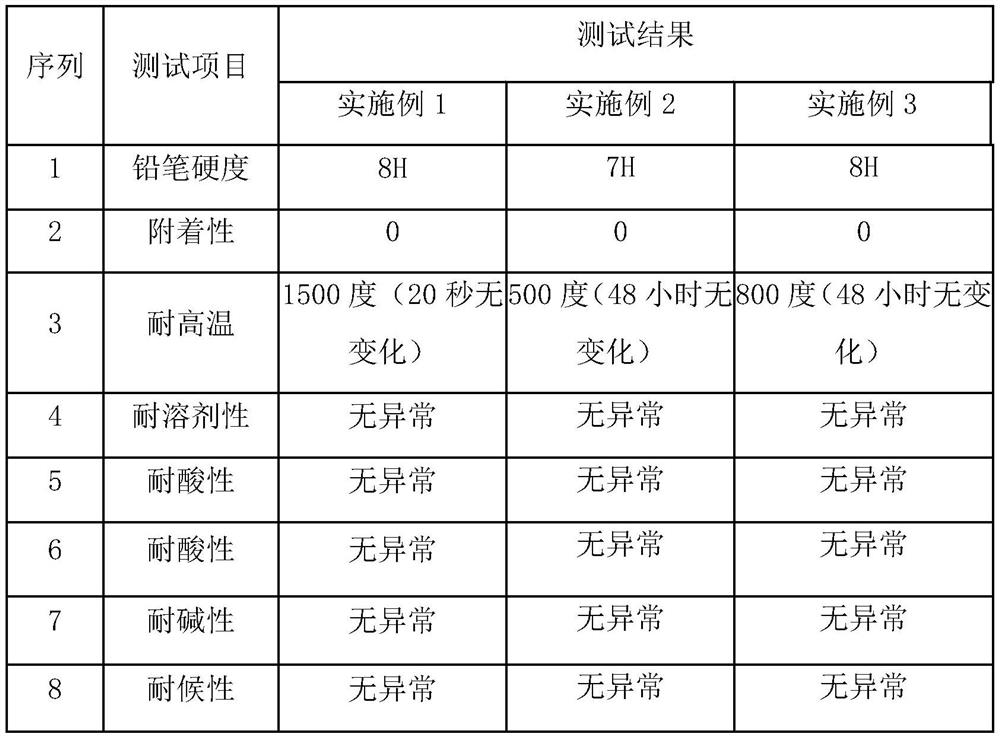

Examples

Embodiment 1

[0024] A high-temperature-resistant metal plate with an inorganic coating, comprising a metal substrate and an inorganic coating coated on the substrate, the metal substrate is a carbon steel plate, and the thickness of the inorganic coating is 32 μm, wherein the inorganic coating includes The following components in parts by mass: 39 parts of nano-silica sol, 45 parts of organosilane, 8 parts of functional filler, 12 parts of water, 20 parts of inorganic pigment, 2.1 parts of functional additive, and 1.2 parts of thickener.

[0025] In the above formula, the organosilane is methyltrimethoxysilane. The thickener is fumed silica with a particle size of less than 1 μm. The functional filler is a mixture of boron nitride, silicon nitride, potassium titanate and alumina. The inorganic pigment is a mixture of titanium dioxide and iron oxide red. Functional additives include leveling agent, defoamer and organosilane, wherein the leveling agent is selected from polyether-modified d...

Embodiment 2

[0036] A high temperature resistant metal plate with an inorganic coating, comprising a metal substrate and an inorganic coating coated on the substrate, the metal substrate is an aluminum plate material, and the thickness of the inorganic coating is 45 μm, wherein the inorganic coating includes The following components in parts by mass: 25 parts of nano-silica sol, 36 parts of organosilane, 5 parts of functional filler, 5 parts of water, 10 parts of inorganic pigment, 0.1 part of functional additive, and 0.1 part of thickener.

[0037] In the above formula, the organosilane is ethyltriethoxysilane. The thickener is fumed silica with a particle size of less than 1 μm. The functional filler is a mixture of alumina, potassium titanate and silicon carbide. The inorganic pigments are titanium dioxide and copper chrome black. Functional additives include leveling agent, defoamer and organosilane, wherein the leveling agent is polyester-modified dimethylpolysiloxane copolymer, and...

Embodiment 3

[0045] A high-temperature-resistant metal plate with an inorganic coating, comprising a metal substrate and an inorganic coating coated on the substrate, the metal substrate is a cold-rolled steel plate material, and the thickness of the inorganic coating is 20 μm, wherein the inorganic coating The layer includes the following components in parts by mass: 45 parts of nano-silica sol, 25 parts of organosilane, 10 parts of functional filler, 15 parts of water, 15 parts of inorganic pigment, 3 parts of functional additive, and 2 parts of thickener .

[0046] In the above formula, the organosilane is tetraethoxysilane. The thickener is fumed silica with a particle size of less than 1 μm. The functional filler is a mixture of potassium titanate, boron nitride and alumina. The inorganic pigment is cobalt blue. Functional additives include leveling agent, defoamer and organosilane, wherein the leveling agent is selected from polyether-modified methyl alkylpolysiloxane copolymer, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com