Preparation method of flexible strain sensor based on nanocellulose-carbon nanotube/polyacrylamide conductive hydrogel

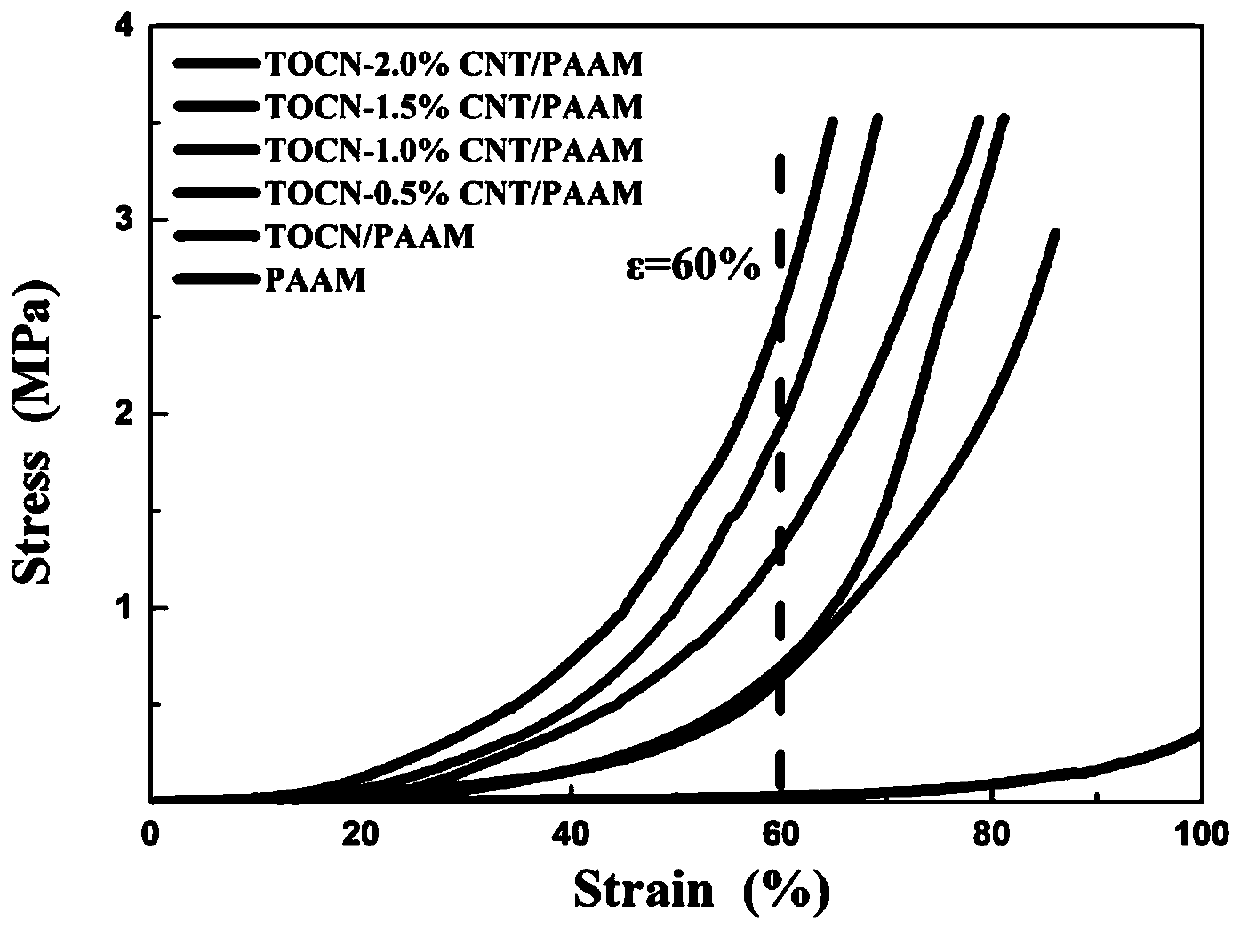

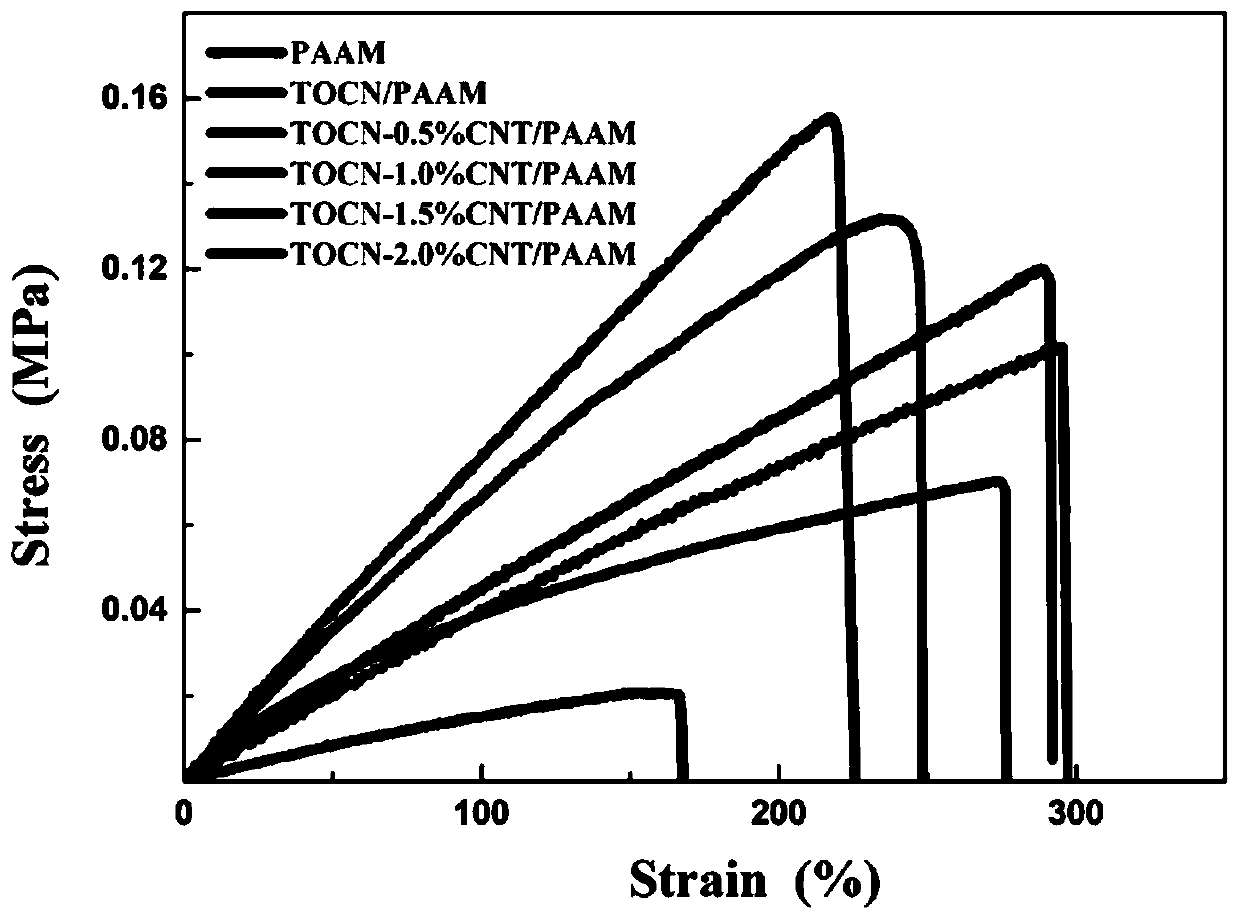

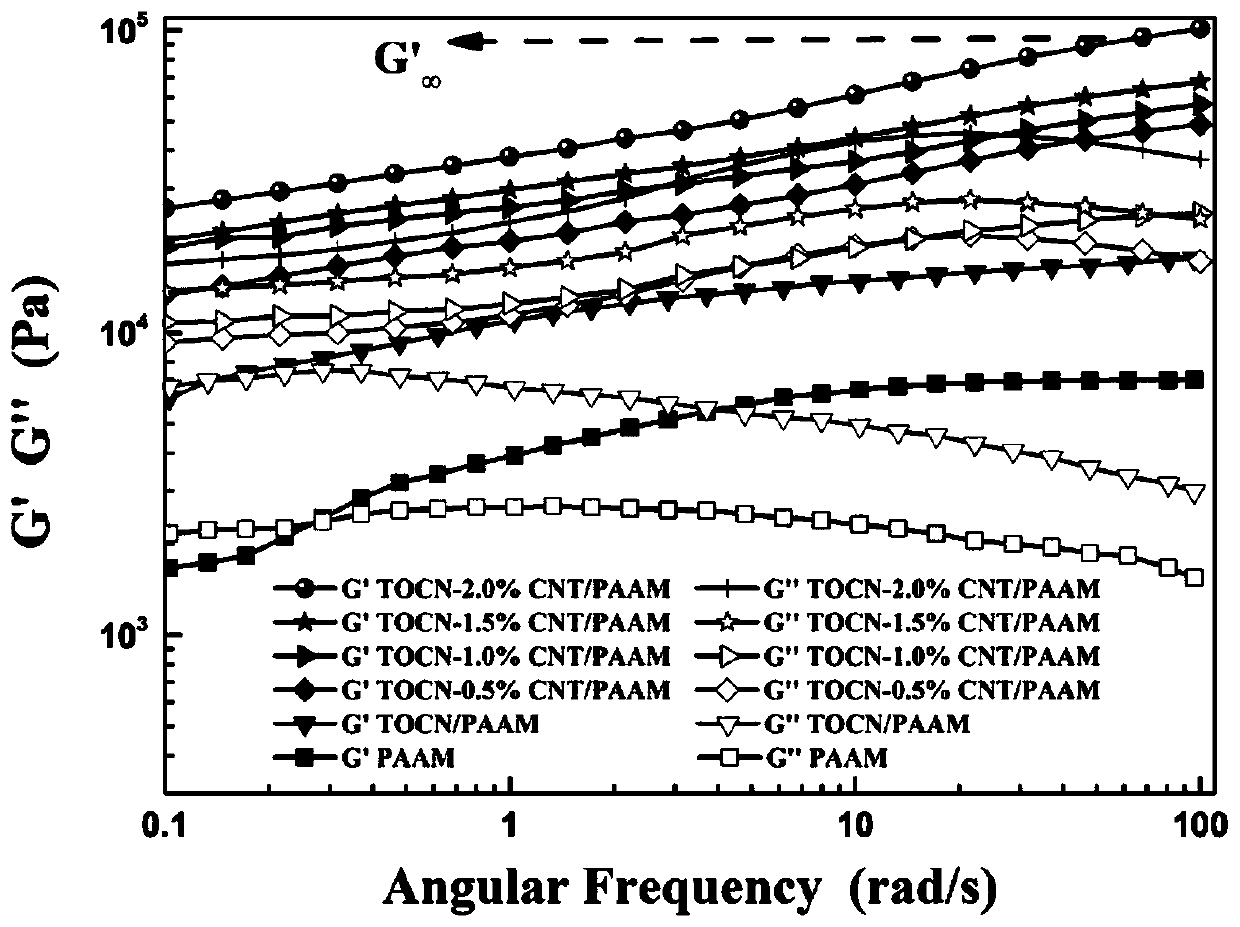

A technology of nano-cellulose and polyacrylamide, which is applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., to achieve high strength, beneficial mechanical properties, and improve electrical conductivity and electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Step 1, the preparation of TEMPO nano-cellulose suspension, its concrete method step comprises:

[0053] (1) Weigh 0.033g of TEMPO and 0.33g of NaBr into 400mL of deionized water in sequence, and stir the above mixture fully with a magnetic stirrer at 10°C. After TEMPO and NaBr are completely dissolved, add 2 g of pulverized bleached wood pulp fiber powder to the reaction system; (2) stir vigorously until the cellulose is evenly dispersed, then add 21 g of NaClO to the system, and add 0.5 mol L -1 NaOH solution to control the pH of the reaction system at about 10; (3) filter the oxidized cellulose after reacting for 6 hours, and wash with deionized water for 3 to 5 times to obtain oxidized cellulose; (4) use deionized water to filter the oxidized cellulose Supplemented into 2mg ml -1 In an ice-water bath, oxidized cellulose was peeled off into cellulose nanofibers by ultrasonication at 300W power for 5 minutes, and the prepared fiber nanofiber suspension was stored in ...

Embodiment 2

[0061] Step 1, the preparation of TEMPO nano-cellulose suspension, its concrete method step comprises:

[0062] (1) Weigh 0.033g of TEMPO and 0.33g of NaBr into 400mL of deionized water in sequence, and stir the above mixture fully with a magnetic stirrer at 10°C. After TEMPO and NaBr are completely dissolved, add 2 g of pulverized bleached wood pulp fiber powder to the reaction system; (2) stir vigorously until the cellulose is evenly dispersed, then add 21 g of NaClO to the system, and add 0.5 mol L -1 NaOH solution to control the pH of the reaction system at about 10; (3) filter the oxidized cellulose after reacting for 6 hours, and wash with deionized water for 3 to 5 times to obtain oxidized cellulose; (4) use deionized water to filter the oxidized cellulose Supplemented into 2mg ml -1 In an ice-water bath, oxidized cellulose was peeled off into cellulose nanofibers by ultrasonication at 300W power for 5 minutes, and the prepared fiber nanofiber suspension was stored in ...

Embodiment 3

[0070] Step 1, the preparation of TEMPO nano-cellulose suspension, its concrete method step comprises:

[0071] (1) Weigh 0.033g of TEMPO and 0.33g of NaBr into 400mL of deionized water in sequence, and stir the above mixture fully with a magnetic stirrer at 10°C. After TEMPO and NaBr are completely dissolved, add 2 g of pulverized bleached wood pulp fiber powder to the reaction system; (2) stir vigorously until the cellulose is evenly dispersed, then add 21 g of NaClO to the system, and add 0.5 mol L -1 NaOH solution to control the pH of the reaction system at about 10; (3) filter the oxidized cellulose after reacting for 6 hours, and wash with deionized water for 3 to 5 times to obtain oxidized cellulose; (4) use deionized water to filter the oxidized cellulose Supplemented into 2mg ml -1 In an ice-water bath, oxidized cellulose was peeled off into cellulose nanofibers by ultrasonication at 300W power for 5 minutes, and the prepared fiber nanofiber suspension was stored in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com