Toughened nylon 66 material and its preparation method and application

A nylon and toughening technology, which is applied in the field of nylon materials and its preparation, can solve the problems of affecting heat resistance, poor compatibility, and affecting the tensile strength and bending strength of nylon 66 composite materials, so as to improve the elastic modulus and strength The effect of reduction, good heat resistance, good dimensional stability and strength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]

[0039] A kind of preparation method of toughening nylon 66 material, it comprises the steps:

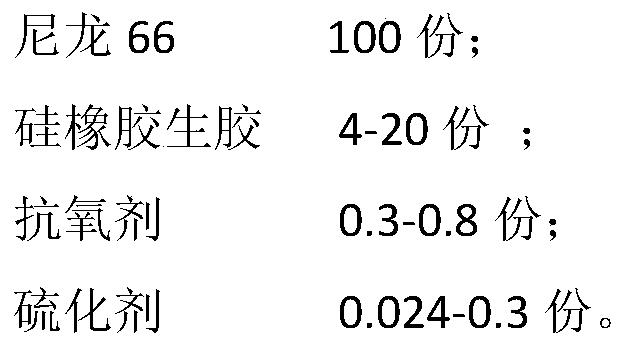

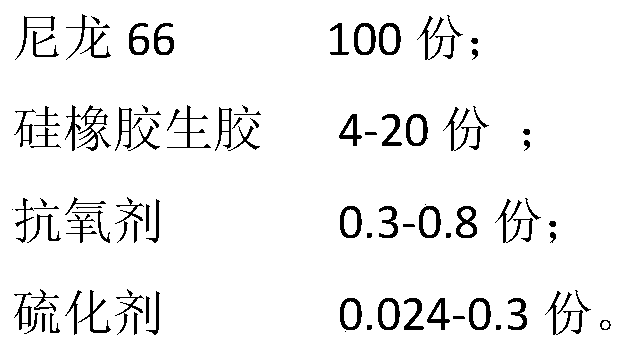

[0040] (1), 100 parts of dry nylon 66, 4-20 parts of silicone rubber raw rubber, 0.3-0.8 parts of antioxidant and 0.024-0.3 parts of vulcanizing agent are mixed uniformly to obtain a premix;

[0041] (2) Add the premixed material to a twin-screw extruder for melt blending, and obtain a toughened nylon 66 material after cooling, drawing and pelletizing.

[0042] Wherein, in step (1), the dried nylon 66 is obtained by drying nylon 66 in a dryer at 100° C. for 12 hours.

[0043] In step (1), mixing is carried out in a high-speed mixer, and the mixing time can be 3-5min.

[0044] In step (1), the weight portion of silicone rubber raw rubber can also be preferably 8-12 parts; And / or, the weight portion of antioxidant can also be preferably 0.5-0.6 part; And / or, the weight of vulcanizing agent Parts can also preferably be 0.065-0.14 parts.

[0045] In step (2), the temperatur...

Embodiment 1

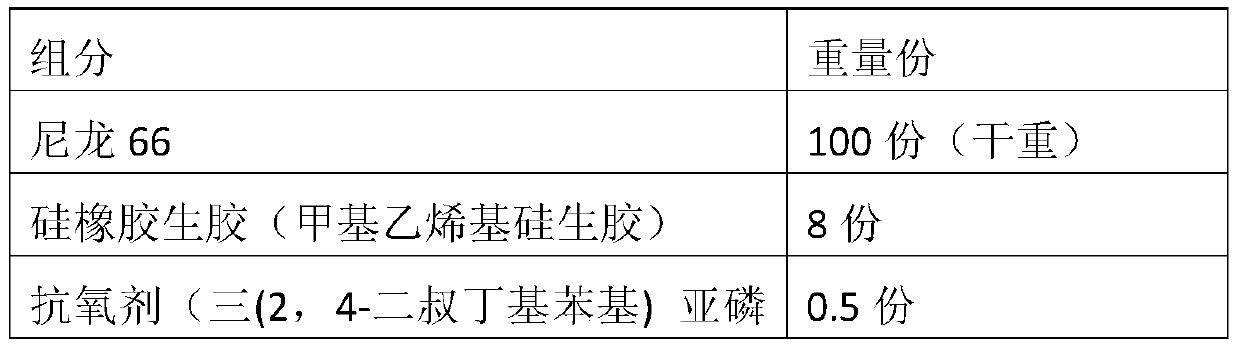

[0058] The content of each component of the toughened nylon 66 material in this embodiment is shown in Table 1 below.

[0059] Table 1 Component content table of the toughened nylon 66 material in Example 1

[0060]

[0061]

[0062] In Table 1, the weight part of nylon 66 is the weight after drying (dry weight), the same below.

[0063] The preparation method of the toughened nylon 66 material in the present embodiment comprises the steps:

[0064] (1) Dry nylon 66 in a dryer at 100°C for 12 hours to obtain dried nylon 66;

[0065] (2), take dry nylon 66, silicon rubber raw rubber, antioxidant, vulcanizing agent according to the weight part of table 1 and mix 5min in high-speed mixer, obtain premix;

[0066] (3) The premixed material is added to a twin-screw extruder for melt blending, and the toughened nylon 66 material is obtained after cooling, drawing and pelletizing.

[0067] Wherein, in step (3), the temperature of each zone of the twin-screw extruder is: the t...

Embodiment 2

[0069] The content of each component of the toughened nylon 66 material in this embodiment is shown in Table 2 below.

[0070] Table 2 Component content table of the toughened nylon 66 material of Example 2

[0071]

[0072] The preparation method of the toughened nylon 66 material in the present embodiment comprises the steps:

[0073] (1) Dry nylon 66 in a dryer at 100°C for 12 hours to obtain dried nylon 66;

[0074] (2), according to the parts by weight of Table 2, take dry nylon 66, silicone rubber raw rubber, antioxidant, vulcanizing agent and mix 5min in high-speed mixer, obtain premix;

[0075] (3) The premixed material is added to a twin-screw extruder for melt blending, and the toughened nylon 66 material is obtained after cooling, drawing and pelletizing.

[0076] Wherein, in step (3), the temperature of each zone of the twin-screw extruder is: the temperature of the first zone is 230°C, the temperature of the second zone is 235°C, the temperature of the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com