Spray-drying and hot-press vulcanization combination-based method for preparing graphene/rubber composite material

A composite material and graphene technology, applied in the field of preparing graphene/rubber composite materials, can solve problems such as restricting graphene, and achieve the effects of reducing pollution problems, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] A kind of method of preparing graphene / rubber composite material based on the combination of spray drying and hot press vulcanization described in the present embodiment is specifically carried out according to the following steps:

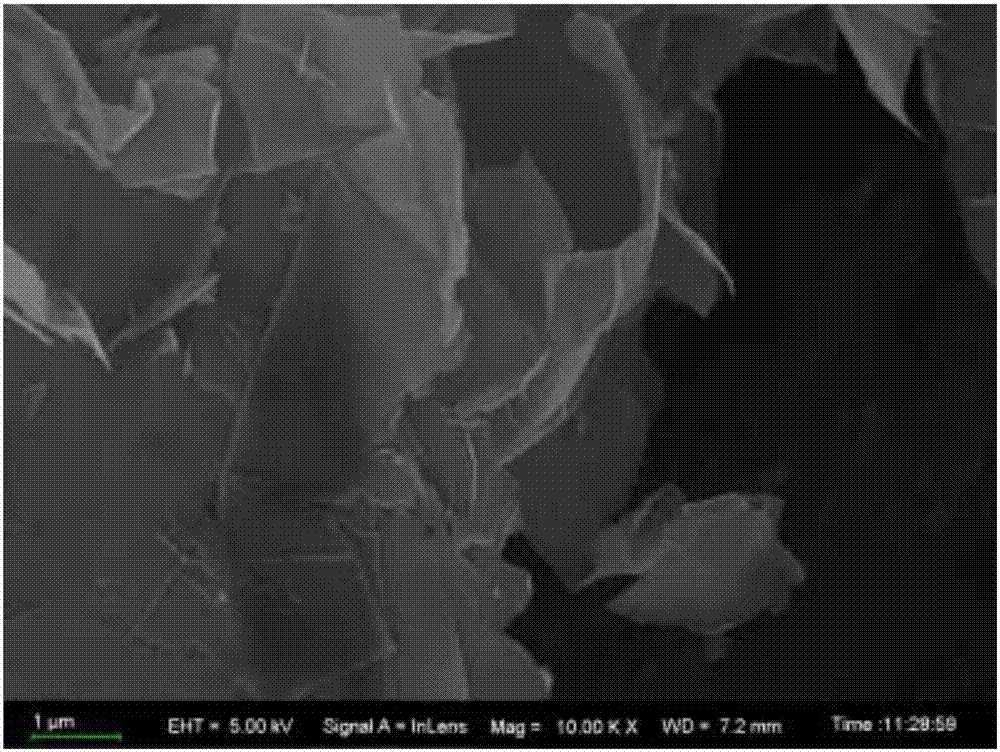

[0027] 1. Preparation of graphene: use natural flake graphite as raw material, take an appropriate amount to sieve, take an appropriate amount of sieve, and then convert it into expanded graphite by microwave treatment for 5 minutes, and then add expanded graphite with a concentration of 10 mg / mL dodecylbenzene In the ethanol solution of sodium sulfonate, the expanded graphite is dissolved in the dispersion liquid by vigorous magnetic stirring at a stirring speed of 400 r / min, and the graphene is obtained by a liquid phase mechanical exfoliation method. The sheets of the original flake graphite are very tightly stacked. After treatment, a large number of holes appear between the sheets of the expanded graphite obtained. At this time, the gra...

specific Embodiment approach 2

[0038] A kind of method of preparing graphene / rubber composite material based on the combination of spray drying and hot press vulcanization described in the present embodiment is specifically carried out according to the following steps:

[0039] 1. Preparation of graphene: use natural flake graphite as raw material, take an appropriate amount to sieve, and after taking an appropriate amount of sieve, convert it into expanded graphite by microwave treatment for 8 minutes, and then add the expanded graphite into dodecylbenzenesulfonate with dispersant In the ethanol solution of sodium bicarbonate, the expanded graphite was dissolved in the dispersion liquid by vigorous magnetic stirring at a stirring speed of 600 r / min, and the graphene was obtained by the liquid phase mechanical exfoliation method. The sheets of the original flake graphite are very tightly stacked. After treatment, a large number of holes appear between the sheets of the expanded graphite obtained. At this tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com