Graphene/boron carbide composite powder for hot pressed sintering, preparation method thereof and preparation method of ceramic product

A technology for hot-pressing sintering and composite powder, which is applied in the fields of graphene/boron carbide composite powder for hot-pressing sintering and its preparation and the preparation of ceramic products, and can solve the problem of difficulty in uniform dispersion, difficult processing, and low toughness of hot-pressed boron carbide ceramics. and other problems, to achieve the effect of improving sintering density, improving sintering activity, improving fracture toughness and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

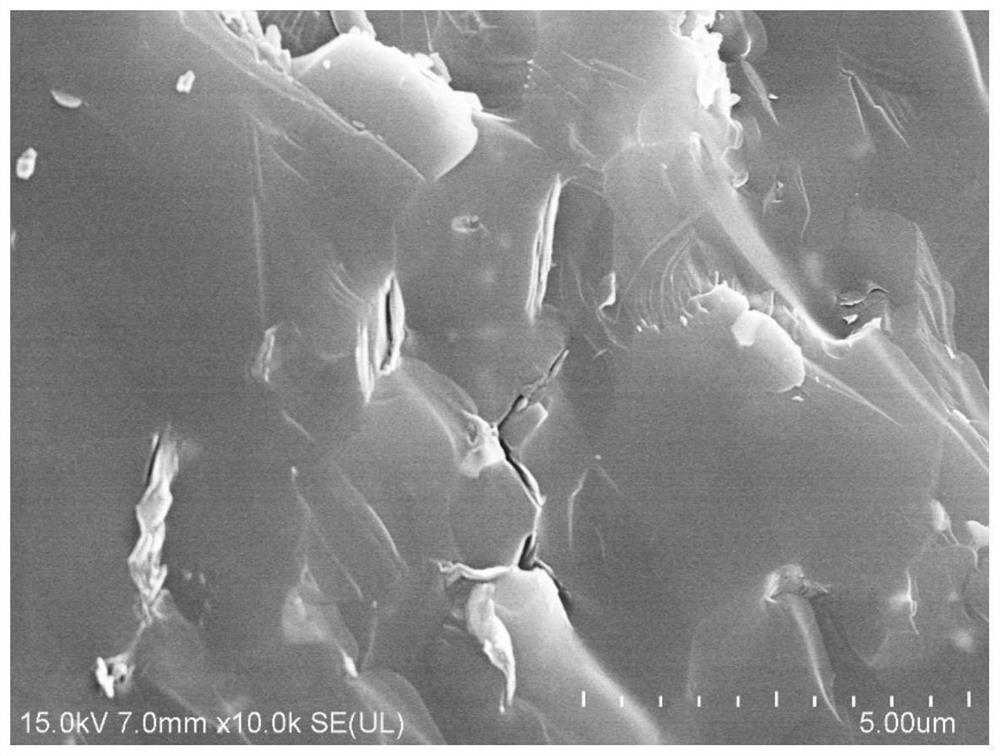

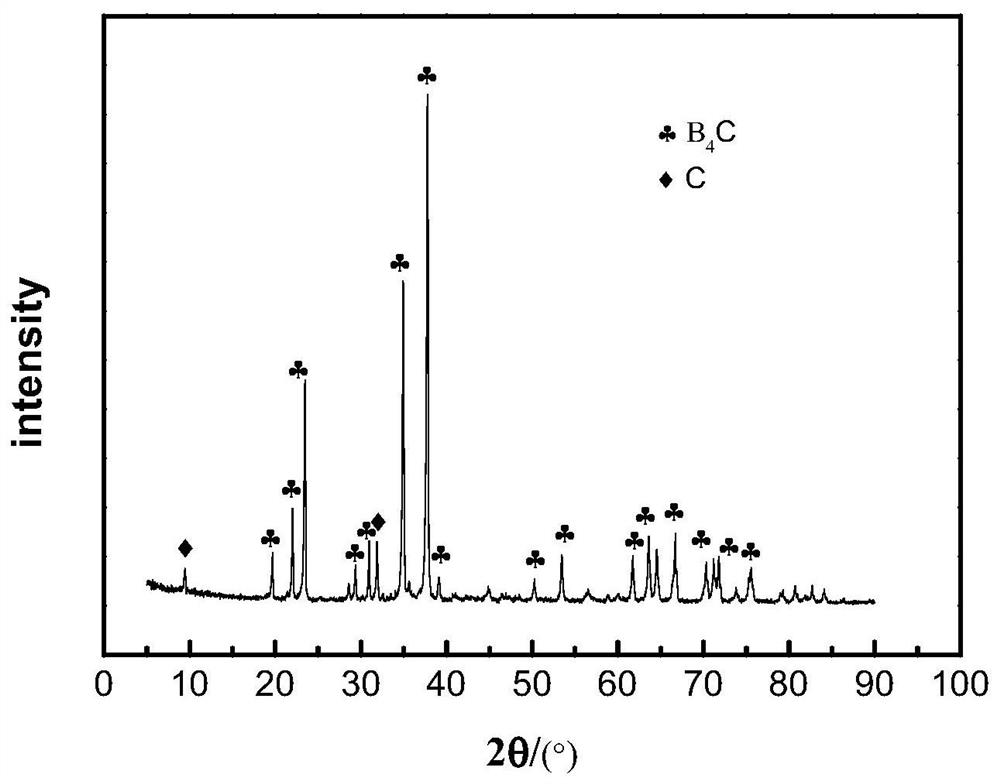

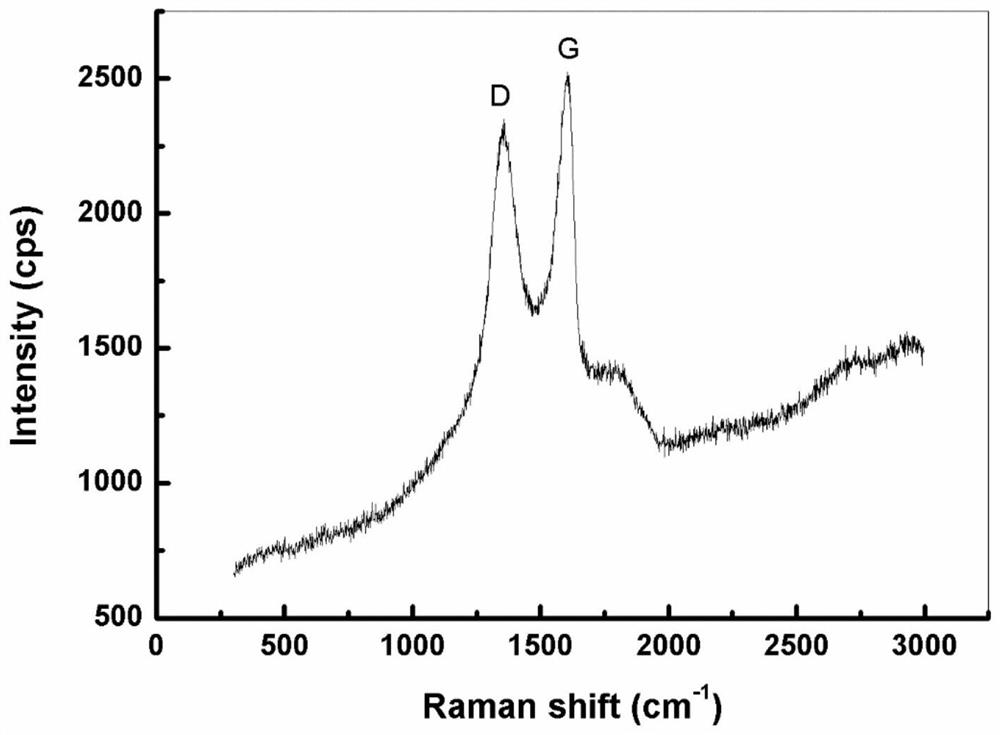

Image

Examples

Embodiment 1

[0033] Embodiment 1, a hot-pressed sintered graphene / boron carbide spherical composite powder, boron carbide powder, graphene oxide powder, and syrup constitute the main material of the raw material powder, and its composition mass percentages are respectively: boron carbide powder: 80%, oxidized Graphene powder: 12%: syrup: 8%;

[0034] A method for preparing hot-pressed sintered graphene / boron carbide spherical composite powder and ceramic products, the specific steps are as follows:

[0035] Step 1) Mixing, mixing boron carbide powder, graphene oxide and syrup according to the above ratio, adding deionized water, adjusting the solid content to 50%, wet grinding in a ball mill for 60 minutes; then adding the dispersant PVP to the slurry, adding The amount is 4.5g per kilogram of slurry, and then continue ball milling for 24h; finally add defoamer n-octanol, the addition is 0.3ml per kilogram of slurry, eliminate the bubbles in the stirring process, and obtain mixed slurry; t...

Embodiment 2

[0039] Embodiment 2, a hot-pressed sintered graphene / boron carbide spherical composite powder, boron carbide powder, graphene oxide powder, and syrup constitute the main material of the raw material powder, and its composition mass percentages are respectively: boron carbide powder: 85%, oxidized Graphene powder: 10%: syrup: 5%;

[0040] A method for preparing hot-pressed sintered graphene / boron carbide spherical composite powder and ceramic products, the specific steps are as follows:

[0041] Step 1) mixing, mixing boron carbide powder, graphene oxide and syrup according to the above ratio, adding deionized water, adjusting the solid content to 50%, and wet grinding in a ball mill for 60 minutes; then N-methylpyrrolidone (NMP) Add the slurry in an amount of 5 g per kilogram of slurry, and then continue ball milling for 24 hours; finally add the defoamer n-octanol in an amount of 0.4 ml per kilogram of slurry to eliminate air bubbles during the stirring process to obtain a mi...

Embodiment 3

[0045] Embodiment three, a hot-pressed sintered graphene / boron carbide spherical composite powder, boron carbide powder, graphene oxide powder, and syrup constitute the main material of the raw material powder, and its composition mass percentages are respectively: boron carbide powder: 75%, oxidized Graphene powder: 15%: syrup: 10%;

[0046] A method for preparing hot-pressed sintered graphene / boron carbide spherical composite powder and ceramic products, the specific steps are as follows:

[0047] Step 1) Mixing, mixing boron carbide powder, graphene oxide and syrup according to the above ratio, adding deionized water, adjusting the solid content to 50%, wet grinding in a ball mill for 60 minutes; then adding the dispersant PVP to the slurry, adding The amount is 5g per kilogram of slurry, and then continue ball milling for 24h; finally add defoamer n-octanol, the addition is 0.4ml per kilogram of slurry, to eliminate the bubbles in the stirring process, to obtain mixed slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com