Method for preparing rubber composite material based on blending of pure carbon graphene and eucommia ulmoides natural rubber

A composite material and natural rubber technology, which is applied in the field of rubber composite materials based on the blending of pure carbon graphene and Eucommia natural rubber, can solve the problem of affecting the strength of rubber composite materials, it is difficult to ensure the dispersion effect of graphene, and graphene is prone to occurrence Reunion and other problems, to achieve the effect of suitable for large-scale production, reasonable preparation method and steps, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

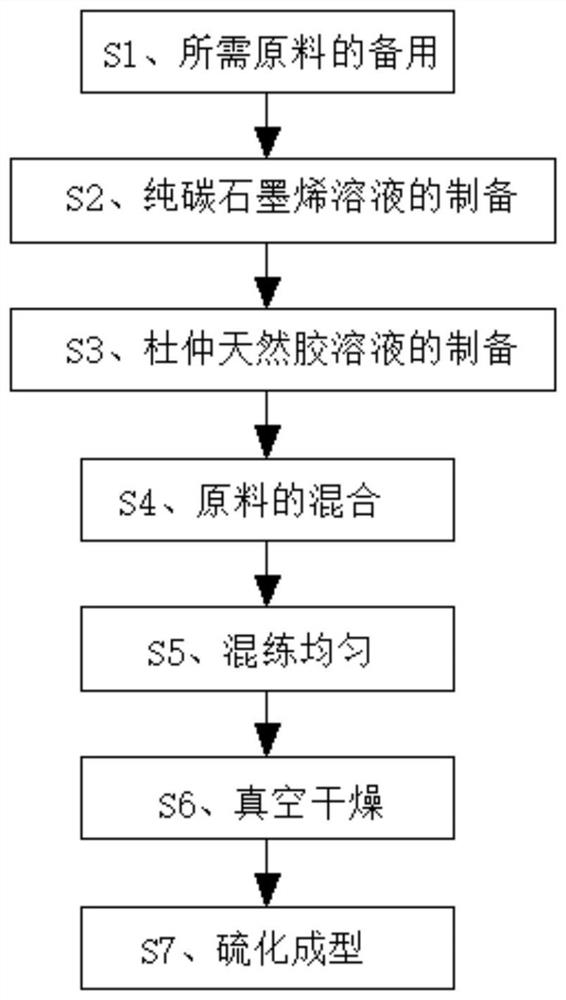

[0026] Example 1: Please refer to figure 1 , the invention discloses a method based on pure carbon graphene and eucommia natural rubber blended rubber composite material, comprising the following steps:

[0027] S1. Spare materials required: 70-80 parts of pure carbon graphene, 30-40 parts of white carbon black, 60-80 parts of eucommia natural gum, 20-25 parts of tetrahydrofuran, 10-20 parts of dispersant, silane coupling agent 10-20 parts, 100 parts of deionized water, 15-25 parts of anti-scorch agent, 30-40 parts of accelerator and 35-40 parts of vulcanizing agent.

[0028] S2, preparation of pure carbon graphene solution: put the pure carbon graphene, white carbon black, distilled water and dispersant in the step S1 into the inside of the ultrasonic disperser in turn, carry out high-speed stirring treatment, and prepare uniformly dispersed pure carbon graphite ethylene solution, the ultrasonic power of the ultrasonic disperser is 50W, the ultrasonic time is 30min, and the ...

Embodiment 2

[0034] Example 2: Please refer to figure 1 , the invention discloses a method based on pure carbon graphene and eucommia natural rubber blended rubber composite material, comprising the following steps:

[0035] S1, spare parts of required raw materials: 75 parts of pure carbon graphene, 35 parts of white carbon black, 70 parts of eucommia natural gum, 23 parts of tetrahydrofuran, 15 parts of dispersant, 15 parts of silane coupling agent, 100 parts of deionized water, 20 parts of coke agent, 35 parts of accelerator and 38 parts of vulcanizing agent.

[0036] S2, preparation of pure carbon graphene solution: put the pure carbon graphene, white carbon black, distilled water and dispersant in the step S1 into the inside of the ultrasonic disperser in turn, carry out high-speed stirring treatment, and prepare uniformly dispersed pure carbon graphite ethylene solution, the ultrasonic power of the ultrasonic disperser is 60W, the ultrasonic time is 40min, and the dispersing agent i...

Embodiment 3

[0042] Example 3: Please refer to figure 1 , the invention discloses a method based on pure carbon graphene and eucommia natural rubber blended rubber composite material, comprising the following steps:

[0043] S1, spare parts of required raw materials: 80 parts of pure carbon graphene, 40 parts of white carbon black, 80 parts of eucommia natural gum, 25 parts of tetrahydrofuran, 20 parts of dispersant, 20 parts of silane coupling agent, 100 parts of deionized water, 25 parts of coke agent, 40 parts of accelerator and 40 parts of vulcanizing agent.

[0044] S2, preparation of pure carbon graphene solution: put the pure carbon graphene, white carbon black, distilled water and dispersant in the step S1 into the inside of the ultrasonic disperser in turn, carry out high-speed stirring treatment, and prepare uniformly dispersed pure carbon graphite ethylene solution, the ultrasonic power of the ultrasonic disperser is 80W, the ultrasonic time is 50min, and the dispersant is sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com