A kind of preparation method of continuous carbon fiber reinforced aluminum matrix composite material

A technology for strengthening aluminum-based and composite materials, applied in the field of aluminum-based composite material manufacturing, can solve the problems of complex preparation methods and processes, and achieve the effects of improving mechanical properties, improving production efficiency, and requiring less process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing a continuous carbon fiber reinforced aluminum matrix composite material of the present invention is specifically implemented according to the following steps:

[0051] Step 1, pre-processing

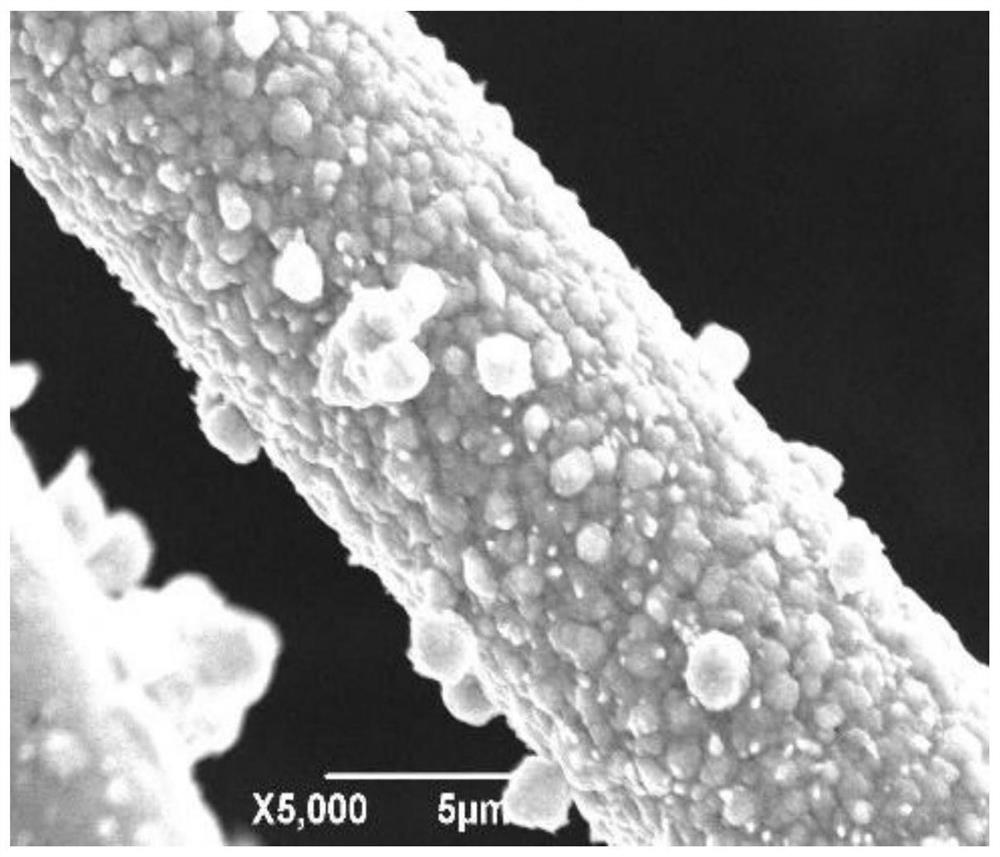

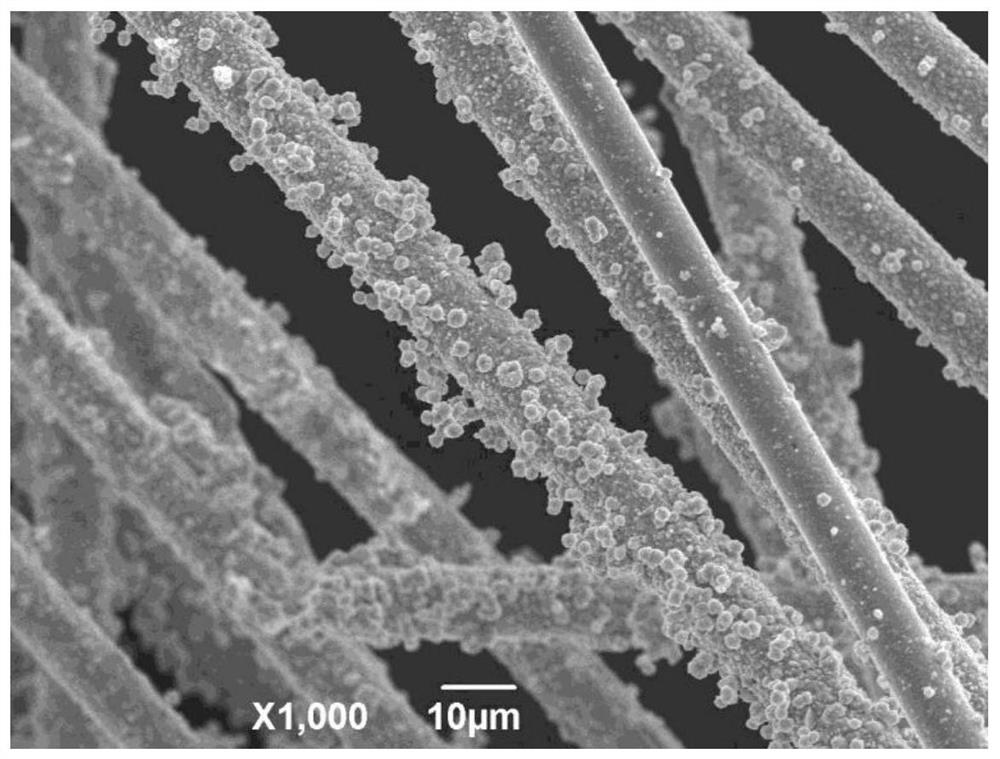

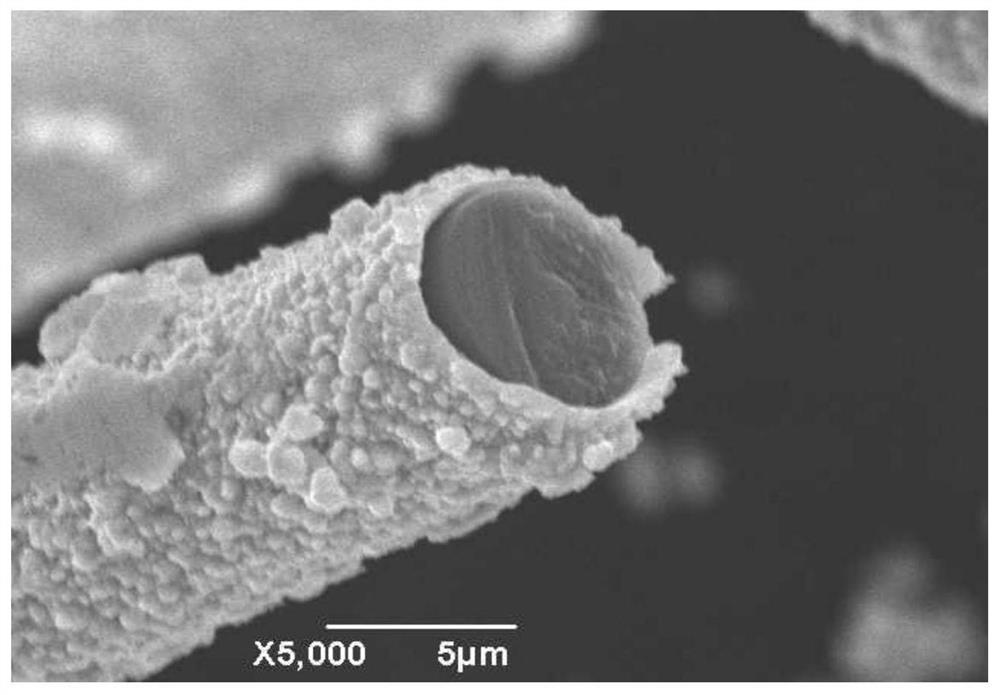

[0052] Put an appropriate amount of bare carbon fiber in a muffle furnace for high-temperature burning treatment to obtain degummed carbon fiber, and place the degummed carbon fiber in HNO with a mass fraction of 20% 3 Stir in the solution evenly, take it out and put it in a NaOH solution with a mass fraction of 10% for neutralization treatment and stir evenly, then perform sensitization and activation treatment on it, and place it in a constant temperature water bath to obtain a carbon fiber solution to be plated;

[0053] Among them, the temperature of high temperature burning treatment is 430°C, and the time is 60min; HNO 3 The volume ratio with NaOH is 1:2.

[0054] The activation process is as follows:

[0055]Put hydrochloric acid with a mass fracti...

Embodiment 2

[0067] The preparation method of the continuous carbon fiber reinforced aluminum matrix composite material is the same as that of Example 1, except that:

[0068] In the pretreatment, the high-temperature burning temperature is 450°C;

[0069] In the plating step, the mass ratio of copper sulfate: formaldehyde: potassium sodium tartrate is 10:2.34:60, and the plating temperature is 60° C.; the pH of the copper-plated carbon fiber solution is 12.0;

[0070] In blank preparation, the mass ratio of copper-plated carbon fiber and aluminum powder is 1:999;

[0071] In step 4, the pressure of the compressor is 600KN, and the holding time is 1min;

[0072] In step 5, the pressure of plasma sintering is 4.0T, and the temperature is 450°C.

Embodiment 3

[0074] The preparation method of the continuous carbon fiber reinforced aluminum matrix composite material is the same as that of Example 1, except that:

[0075] In the pretreatment, the high-temperature burning temperature is 450°C;

[0076] In the plating step, the mass ratio of copper sulfate: formaldehyde: potassium sodium tartrate is 15:2.34:40, and the plating temperature is 65°C; the pH of the copper-plated carbon fiber solution is 12.25;

[0077] In blank preparation, the mass ratio of copper-plated carbon fiber and aluminum powder is 1:499; the binder is glycerin ethanol solution;

[0078] In step 4, the pressure of the compressor is 400KN, and the pressure holding time is 1.5min;

[0079] In step 5, the pressure of plasma sintering is 4.5T, and the temperature is 480°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com