Lake asphalt/SBS compound modifier and preparation method and application thereof

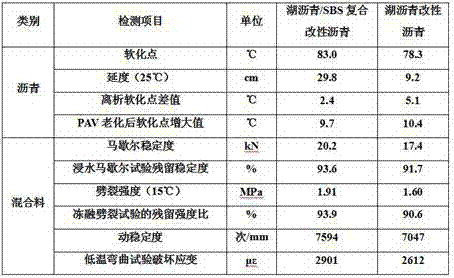

A technology of compound modifier and lake asphalt, which is applied in the field of materials, can solve the problems of low-temperature crack resistance of modified asphalt, high sieve pass rate, and construction machinery failure, etc., to achieve enhanced infiltration and adhesion capabilities, and improved Water damage resistance, improve the effect of high temperature deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 10 parts (parts by mass, the same below) of furfural extracted oil into the heat preservation container of the high-speed shear mixer and heat it to about 170°C; start the high-speed shear mixer, set the speed at 1000rmp, and add 82 parts of properly crushed lake asphalt Then stir for 20 minutes; then increase the temperature to 180°C, increase the speed to 3500rmp, add 8 parts of linear SBS and stir for 1 hour; finally crush the prepared mixture at 5~10°C until the particle size is not greater than 1cm The particles, that is, the lake asphalt / SBS composite modifier pre-dispersion is prepared.

[0032] Add 77.9 parts of petroleum asphalt (penetration of 70dmm at 25°C and softening point of 49.1°C) into the heat preservation container of the high-speed shear mixer and heat it to about 180°C; start the high-speed shear mixer and set the speed to 4000rmp, and Add 22 parts of lake asphalt / SBS composite modifier predispersion and 0.1 part of sulfur into petroleum asphalt...

Embodiment 2

[0038] Put 23 parts of catalytic cracking oil slurry into the heat preservation container of the high-speed shear mixer, and heat it to about 170°C; start the high-speed shear mixer, set the speed at 1500rmp, add 60 parts of appropriately broken lake asphalt, and stir for 30 minutes; then Raise the temperature to 180°C, increase the speed to 4000rmp, add 17 parts of star-shaped SBS and stir for 1.5 hours; finally, crush the prepared mixture at 5-10°C to particles with a particle size of no more than 1cm, which is obtained Lake bitumen / SBS composite modifier predispersion.

[0039] Add 56.5 parts of petroleum asphalt (penetration of 89dmm at 25°C and softening point of 45.8°C) into the heat preservation container of the high-speed shear mixer and heat it to about 180°C; start the high-speed shear mixer and set the speed to 4500rmp, and Add 42 parts of lake asphalt / SBS composite modifier predispersion and 1.5 parts of polyphosphoric acid into petroleum asphalt and stir for 45 mi...

Embodiment 3

[0045] Add 20 parts of epoxidized soybean oil into the high-speed shear mixer insulation container, heat to about 170°C; start the high-speed shear mixer, set the speed at 2000rmp, add 68 parts of appropriately broken lake asphalt and stir for 10 minutes; then Raise the temperature to 180°C, increase the rotation speed to 4500rmp, add 8 parts of linear SBS and 4 parts of star SBS and stir for 1 hour; finally, crush the prepared mixture at 5~10°C until the particle size is not larger than 1cm particles, that is, the lake asphalt / SBS composite modifier pre-dispersion is prepared.

[0046] Add 63 parts of petroleum asphalt (penetration of 78dmm at 25°C and softening point of 46.9°C) into the heat preservation container of the high-speed shear mixer and heat it to about 180°C; start the high-speed shear mixer and set the speed to 3000rmp, and Add 36 parts of lake asphalt / SBS composite modifier predispersion, 0.1 part of sulfur, and 0.9 part of polyphosphoric acid into petroleum as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com