Medium-temperature rubber asphalt mixture modifier and preparation method thereof

A technology of rubber asphalt and modifier, which is applied in the field of medium temperature rubber asphalt mixture modifier and its preparation, which can solve the problems of large influence of mixing equipment, poor construction workability, and difficulty in construction rolling, so as to improve compaction Performance, improve low temperature ductility, ensure the effect of low temperature crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

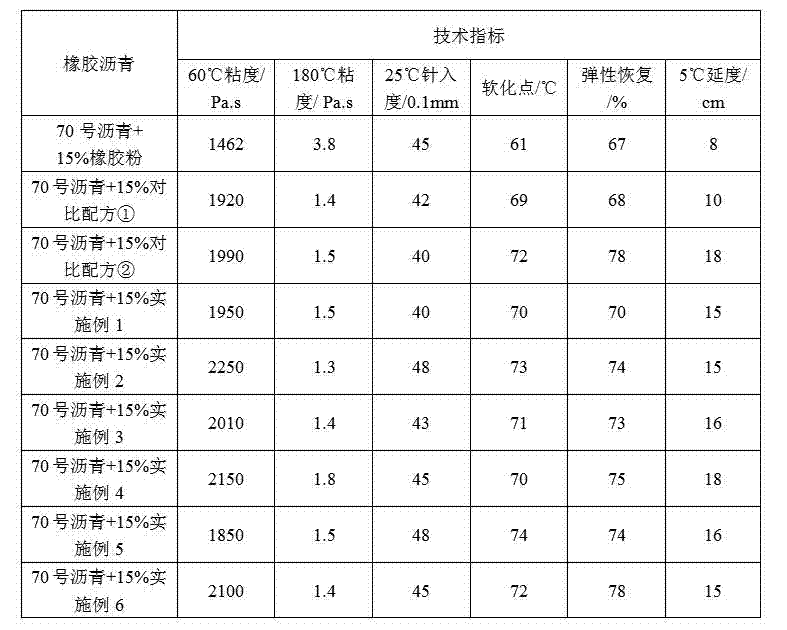

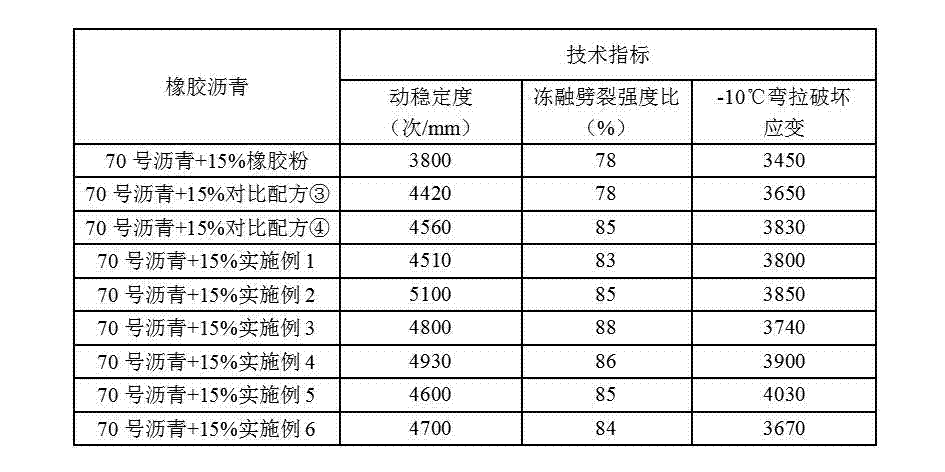

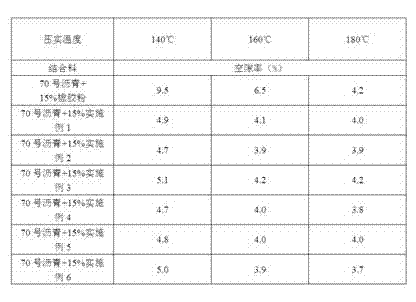

Embodiment 1

[0026] Example 1: This example specifically relates to a medium-temperature rubber asphalt mixture modifier and its preparation method. The weight ratio of the modifier is: 100 parts of 40-mesh rubber powder, 20 parts of polyethylene wax, 5 parts of styrene-butadiene rubber, 4 parts of alkyl trimethyl quaternary ammonium salt, 0.5 part of sulfur.

[0027] The above-mentioned rubber powder is waste tire rubber powder crushed and ground at room temperature, which is a black homogeneous powder of 40 mesh to 60 mesh, with a relative density of 1.10 to 1.30, a water content of less than 0.5%, a metal content of less than 0.05%, and a fiber content of less than 0.5%. The ash content is less than 7%, and the natural rubber content is greater than 25%.

[0028] The above-mentioned polyethylene wax is obtained by catalytic cracking of waste polyethylene plastics. Its melting point is 90-110°C and its average molecular weight is between 1000-3000. It can reduce the viscosity of asphalt ...

Embodiment 2

[0032] Embodiment 2: This embodiment specifically relates to a medium-temperature rubber asphalt mixture modifier. The preferred weight ratio of the modifier is: 100 parts of 40-mesh rubber powder, 15 parts of polyethylene wax, styrene-butadiene rubber 8 parts, imidazoline type ammonium salt 5 parts, sulfur 0.8 part. The preparation method of this modifying agent is the same as that in Example 1.

Embodiment 3

[0033] Embodiment 3: This embodiment specifically relates to a medium-temperature rubber asphalt mixture modifier. The preferred weight ratio of the modifier is: 100 parts of 40-mesh rubber powder, 25 parts of polyethylene wax, styrene-butadiene rubber 6 parts, 6 parts of imidazoline type ammonium salt, 0.5 part of sulfur. The preparation method of this modifying agent is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com