Patents

Literature

32results about How to "Improve low temperature cracking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance rubber asphalt pouring sealant and preparation method thereof

InactiveCN103421467AReduce pollutionImprove performanceMineral oil hydrocarbon copolymer adhesivesOther chemical processesCrack resistanceProcess engineering

The invention discloses high-performance rubber asphalt pouring sealant and a preparation method thereof. The high-performance rubber asphalt pouring sealant is made from rubber powder, modifier, petroleum asphalt, tackifier, cosolvent, and stabilizer. The preparation method includes: heating the asphalt to 150-160 DEG C, adding the modifier, stirring to obtain liquid, adding the cosolvent and mixing for 30 minutes, heating to 190-200 DEG C, slowly adding the rubber powder, mixing for 30 minutes, adding the tackifier and the stabilizer, and mixing for 15 minutes to produce high-performance rubber asphalt pouring sealant. The rubber powder of waste tires is utilized, and accordingly product performance is improved, product cost is reduced and environmental pollution is reduced; the modifier, the rubber powder and the asphalt are mixed into stable, even mixture through the cosolvent, so that resin groups, rubber powder groups and asphalt groups can form a stable interlinked structure; through the modifier, route performance of the sealant can be improved, for example, softening point is increased and low temperature cracking resistance is improved; new cracks can be prevented effectively.

Owner:XIYUEFA INT ENVIRONMENTAL PROTECTION NEW MATERIALS CO LTD

High-modulus asphalt mixture additive and preparation method thereof

ActiveCN106633269AHigh temperature sensitivityGood low temperature flexibilityBuilding insulationsEpoxyMolecular sieve

The invention discloses a high-modulus asphalt mixture additive and a preparation method thereof. The additive comprises, by weight, 100 parts of plastic, 10-20 parts of EVA resin, 15-25 parts of butadiene-styrene rubber and / or derivative thereof, 10-20 parts of ethylene tar and 10-20 parts of composite modifier, wherein the composite modifier is composed of a mesoporous molecular sieve coated with epoxy grafted polyethylene wax. The additive has high compatibility with asphalt and a mixture, so that resistance to low-temperature cracking of a high-modulus asphalt mixture is improved remarkably, the additive has excellent resistance to track and water damage, and the mixture is low in blending temperature and high in construction peaceability.

Owner:CHINA PETROLEUM & CHEM CORP +1

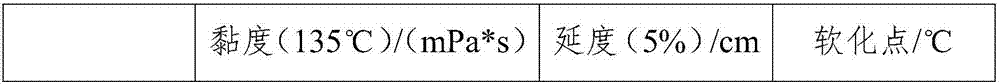

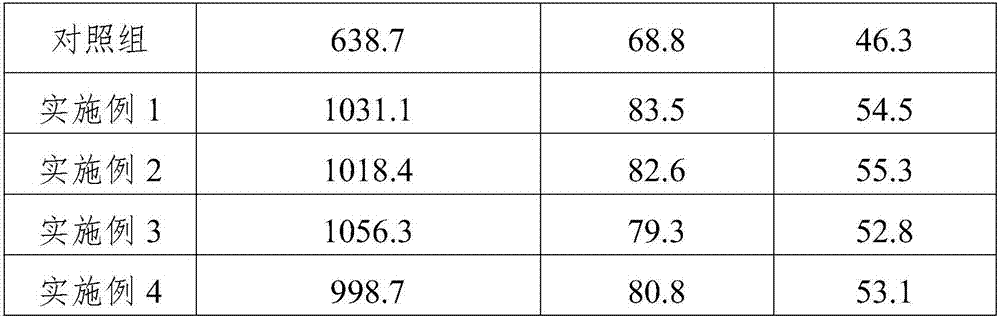

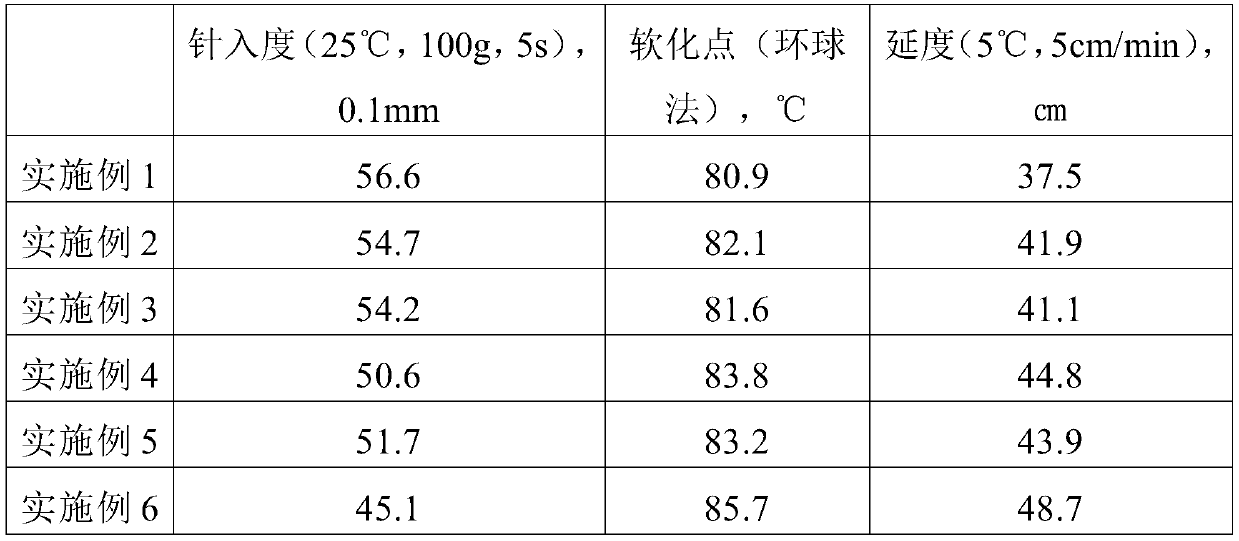

High-ductility modified asphalt and preparation method thereof

InactiveCN105255204AGood compatibilityImprove low temperature performanceBuilding insulationsRoad surfaceAsphalt

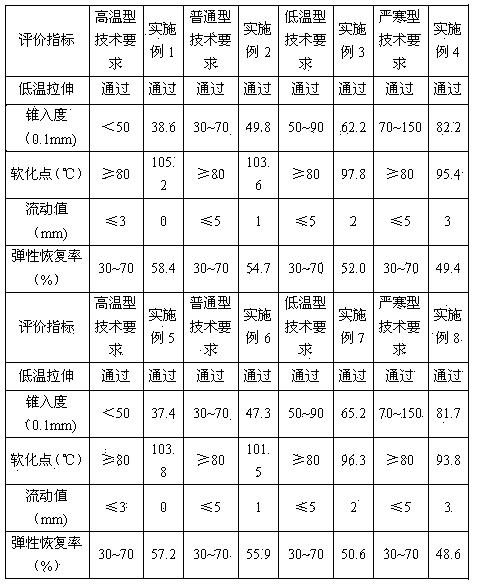

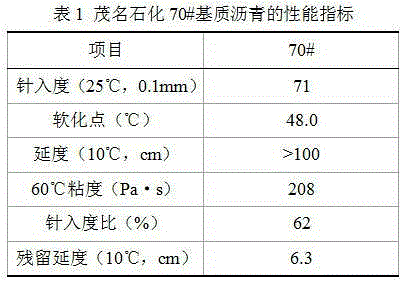

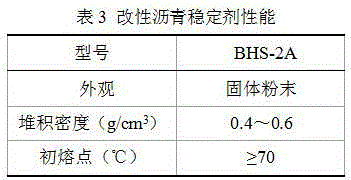

The invention discloses high-ductility modified asphalt. The high-ductility modified asphalt is prepared from, by weight, 92%-96% of matrix asphalt, 3%-6% of linear terminal hydroxylation SBS, 0%-3% of compatilizer and 0.1%-0.4% of stabilizer. The invention further discloses a preparation method of the modified asphalt. The modified asphalt is high in ductility, good in crack resistance, wide in using temperature range, good in storage stability, capable of obviously improving the low-temperature cracking and fatigue resistance of a road surface and widening the application range, and beneficial to industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

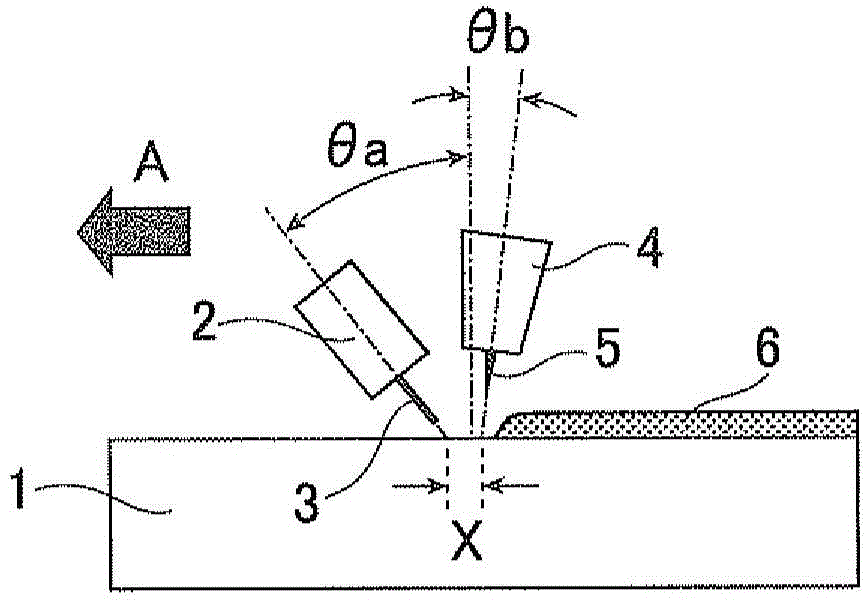

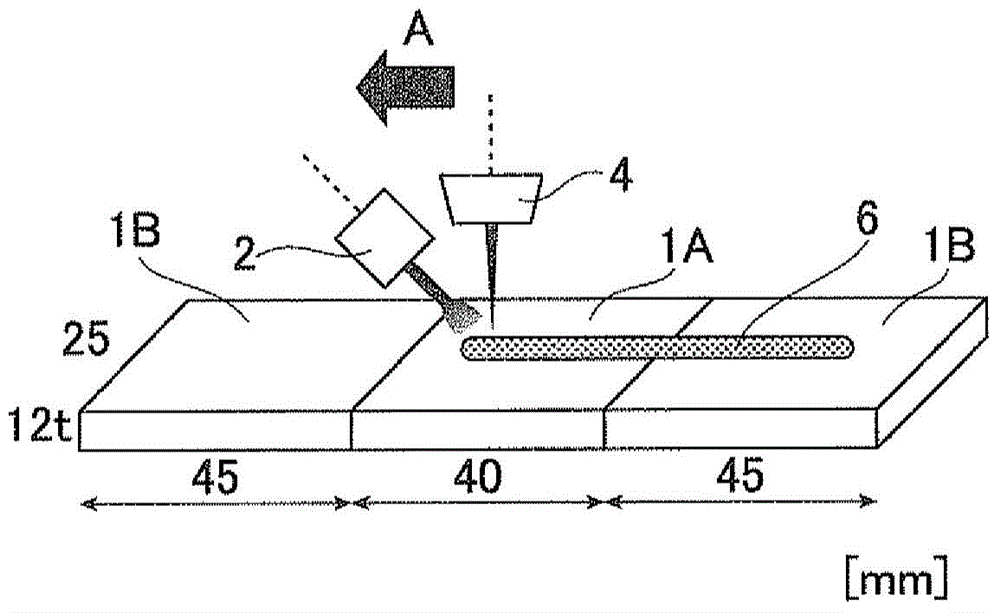

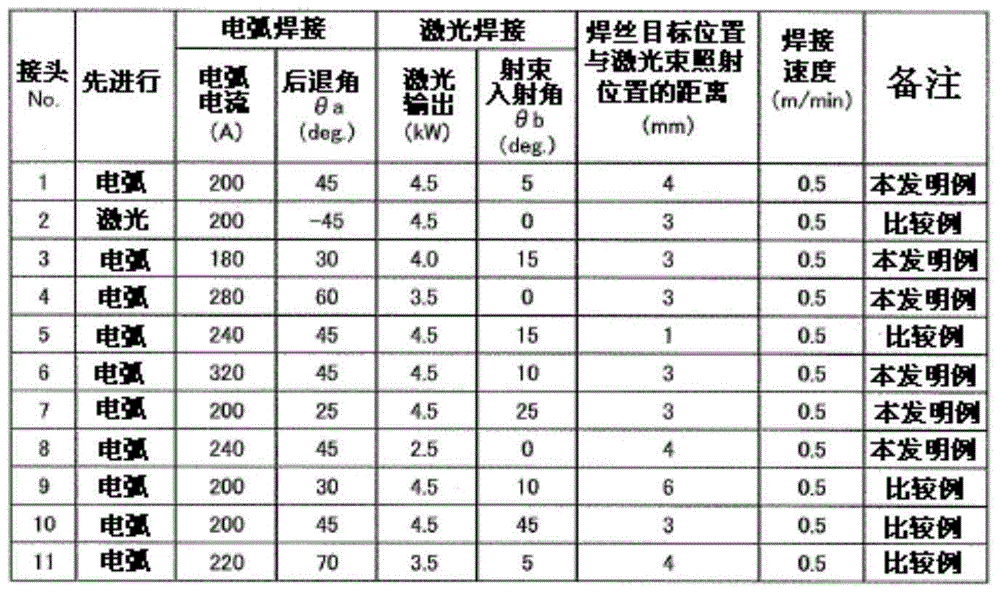

Laser-arc hybrid welding method

InactiveCN104349863AImprove low temperature cracking resistanceReduce the amount of diffusible hydrogenWelding/soldering/cutting articlesLaser beam welding apparatusHigh intensityEngineering

By the present invention, in order to suppress cold cracking, consumable electrode type arc welding is placed at the preceding side and laser welding is placed at the succeeding side with respect to the direction of weld progress, using a high-strength steel sheet having a tensile strength of at least 780 MPa as the welding subject, the distance between the position at which a welding wire for arc welding is aimed and the position of laser beam irradiation is set to a range of 3-5 mm, the electrode angle for arc welding is set to a sweepback angle in the range of 20-60° toward the direction of weld progress, and the incidence angle of the laser beam for laser welding is set to an angle in the range of 0-30° in the direction of weld progress from the vertical direction.

Owner:JFE STEEL CORP

Biological asphalt material for roads and preparation method of biological asphalt material

InactiveCN108424662AImprove toughnessImprove stabilityBuilding insulationsCrack resistanceBituminous materials

The invention discloses a biological asphalt material for roads and belongs to road construction materials. The biological asphalt material is prepared from the following raw materials in parts by weight: 10 to 30 parts of matrix asphalt, 5 to 18 parts of waste polymer material powder, 0.05 to 0.2 part of zinc oxide, 10 to 20 parts of a diluent, 0.5 to 4 parts of a homogenizing agent MS, 0.1 to 0.3 part of stabilizer sulfur, 0.05 to 0.2 part of an additive, wherein the additive is prepared from the following raw materials in parts by weight: 0.02 to 0.1 part of graphene powder and 0.03 to 0.1part of carbon nanotube. The biological asphalt material for the roads, disclosed by the invention, effectively recycles wastes and has the advantages of high toughness, good stability and the like when being used as a road construction material. The biological asphalt material for the roads significantly improves the strength, water stability and low temperature cracking resistance of the asphaltmaterial by adding graphene and the carbon nanotubes.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

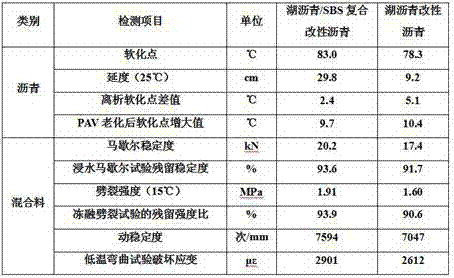

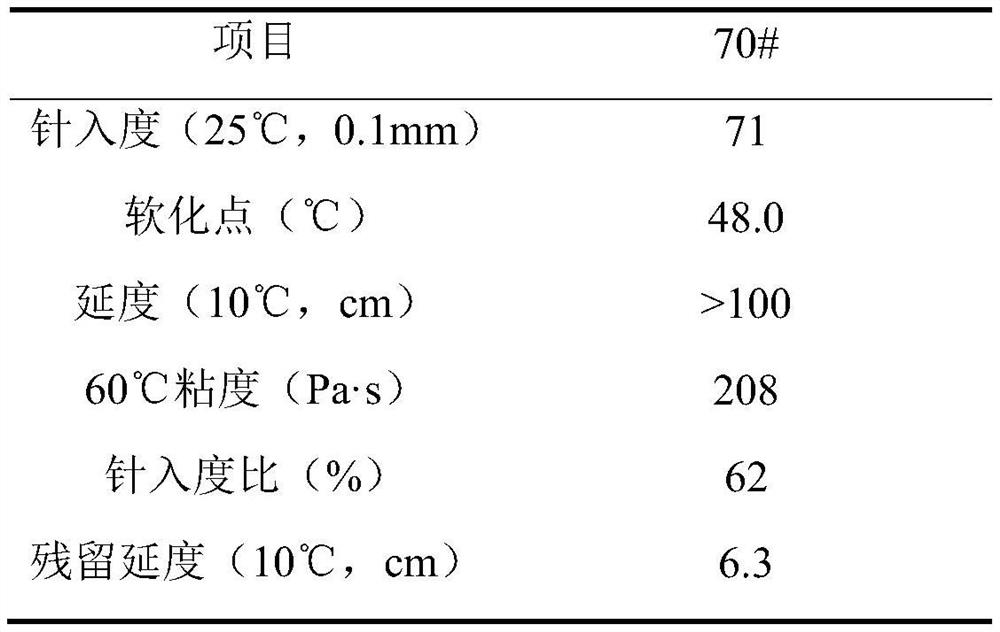

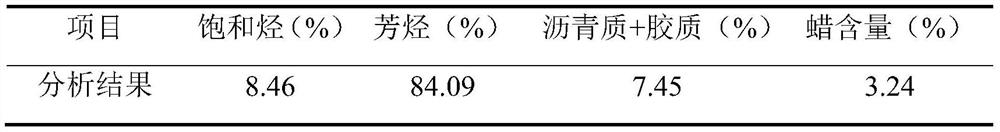

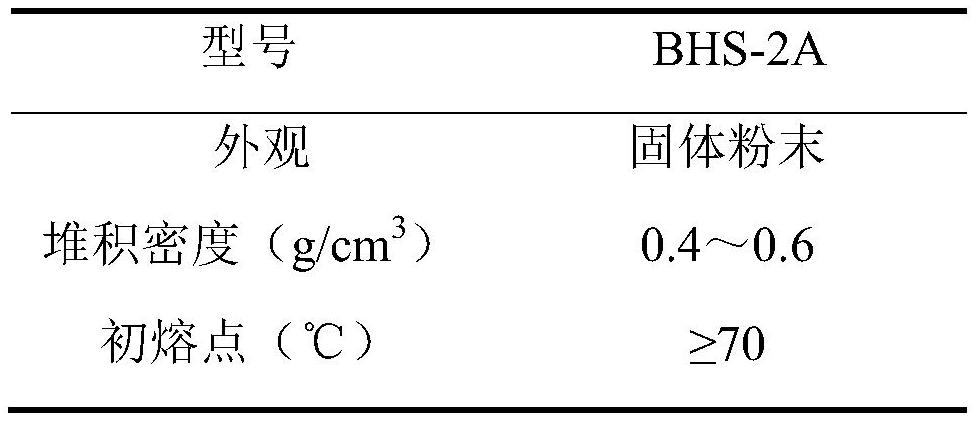

Lake asphalt/SBS compound modifier and preparation method and application thereof

InactiveCN106928731AImproves resistance to water damageImprove low temperature cracking resistanceBuilding insulationsCrack resistanceRoad surface

The invention relates to a lake asphalt / SBS compound modifier and a preparation method and application thereof. The lake asphalt / SBS compound modifier is a pre-dispersant which is prepared by the fusion and blending of lake asphalt, polymer SBS and compatilizers, and modified asphalt can be prepared by fusing and blending the lake asphalt / SBS compound modifier with petroleum asphalt and stabilizers. The obtained lake asphalt / SBS compound modifier is the pre-dispersant which can remarkably improve the high-temperature deformation resistance capability, low-temperature cracking resistance capability and water damage resistance capability of the petroleum asphalt, and by adding the pre-dispersant into the petroleum asphalt and taking use of the advantage of good compatibility between the pre-dispersant and the petroleum asphalt, the lake asphalt / SBS compound modified asphalt is prepared, wherein the modified asphalt is uniform in dispersion, and layered segregation does not occur easily on the modified asphalt. The modified asphalt is used for the construction of heavy-loaded traffic asphalt pavements in high temperature, damp and rainy areas, asphalt pavement diseases can be significantly reduced, the maintenance cost of the pavements is reduced, and the service life of the asphalt pavements is prolonged.

Owner:FUZHOU UNIV

Microstructure analysis method of asphalt and modifier thereof

InactiveCN110455841AIncreased high temperature resistance to ruttingImprove low temperature cracking resistanceMaterial analysis using wave/particle radiationRoad surfaceAnalysis method

The invention relates to a microstructure analysis method of asphalt and a modifier thereof, and belongs to the technical field of microstructure analysis of modified asphalt. The problem that the microstructures of asphalt and the modifier thereof cannot be comprehensively, stereoscopically and clearly analyzed by using only one characterization method at present is solved. According to the microstructure analysis method provided by the invention, neutron small-angle scattering samples of an SBS modifier, matrix asphalt and SBS modified asphalt are prepared at first, a neutron small-angle scattering test is performed on the samples to obtain initial experimental data, and the initial experimental data are processed to obtain an absolute intensity scattering curve, and then different models are fitted through the absolute intensity scattering curves of the samples to quantitatively analyze the microstructures of the SBS modifier, the matrix asphalt and the SBS modified asphalt. Throughthe analysis of the microstructures of the asphalt and the modifier thereof, the modification mechanism of the SBS modified asphalt can be better revealed, and a relationship between the microstructure of the modified asphalt and the macroscopic properties thereof can be established, so that the performance of the SBS modified asphalt, and the service level and the service life of asphalt pavements can be better improved.

Owner:NANJING FORESTRY UNIV

Low-cost, long-reserved time and high-performance modified asphalt and preparation method thereof

ActiveCN105017787AMeet residence time requirementsControl timeBuilding insulationsProcess engineeringPolyethylene glycol

The invention discloses a low-cost, long-reserved time and high-performance modified asphalt and a preparation method thereof. The modified asphalt is an A and B dual-component system, wherein the component A is an epoxy resin and polyethyleneglycol diglycidylether mixture; and the component B comprises an emulsifier, matrix asphalt, a solidification agent and activated waste rubber powder. The preparation method comprises the following steps: adding the activated waste rubber powder into the matrix asphalt, adding the emulsifier and the solidification agent under a high temperature condition, carrying out shearing emulsification to obtain the component B, and fully mixing the component A and the component B of the modified asphalt to obtain the low-cost, long-reserved time and high-performance modified asphalt. Long reserved time is realized through selecting the specific epoxy resin solidification agent and regulating the solidifying rate of an epoxy system in order to meet road pavement and engineering maintenance with long reserved time requirements. The matrix asphalt and the waste rubber powder are used, so the production cost is reduced, and the low-temperature cracking resistance and stability of the modified asphalt are improved.

Owner:JURONG NINGWU CHEM

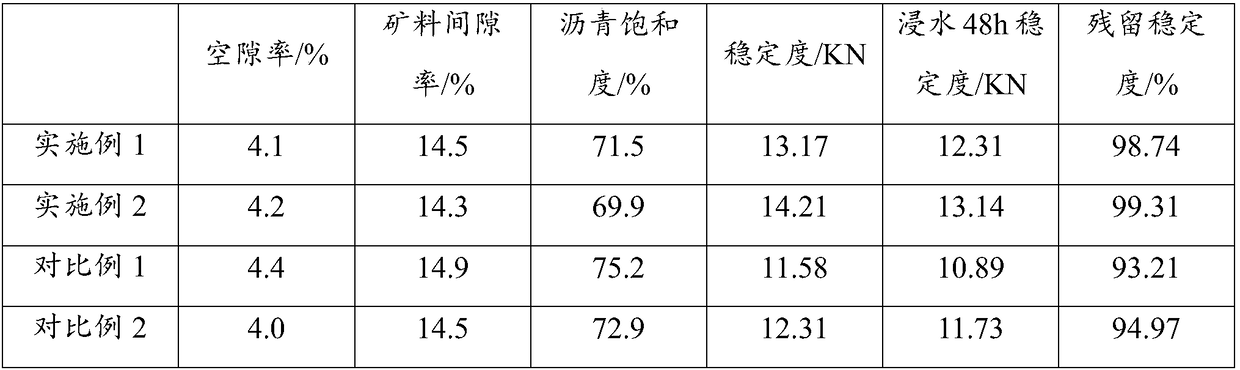

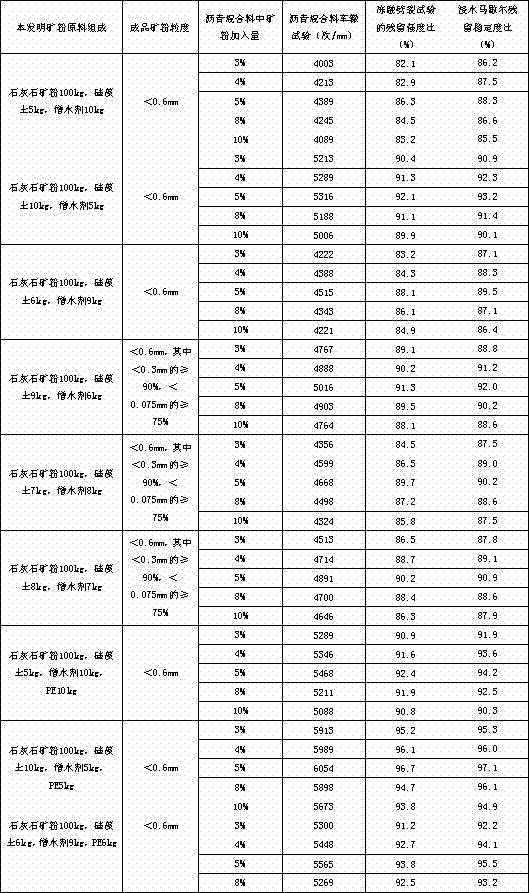

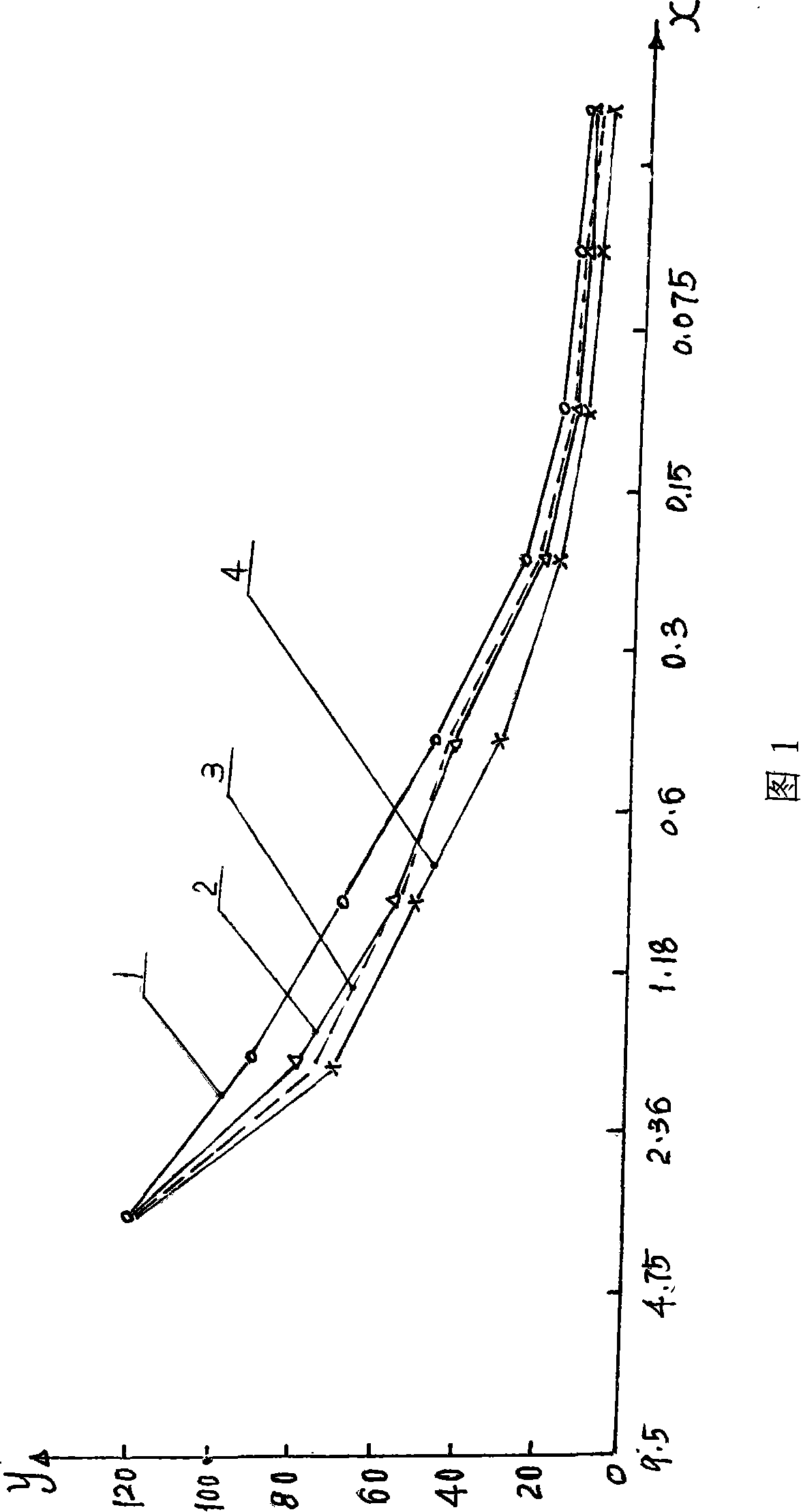

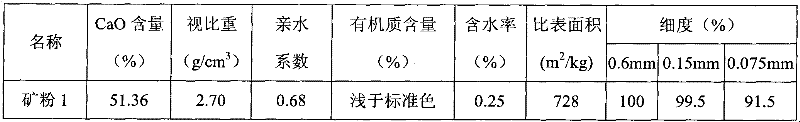

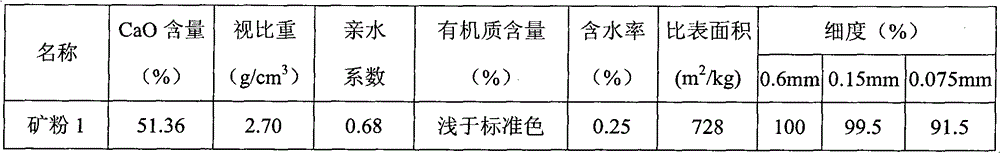

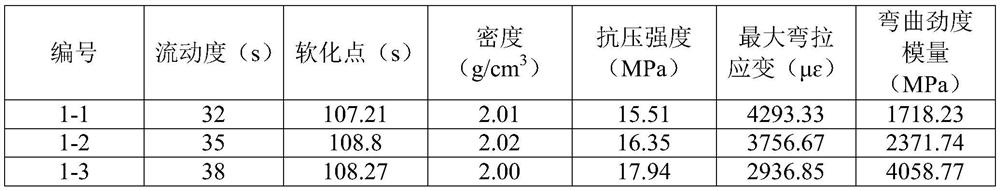

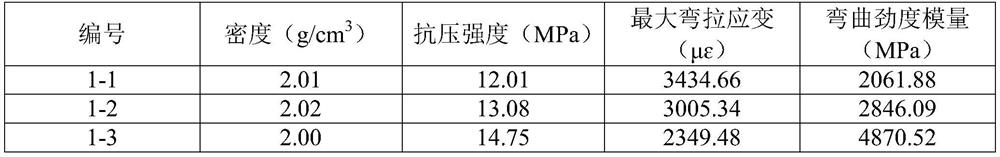

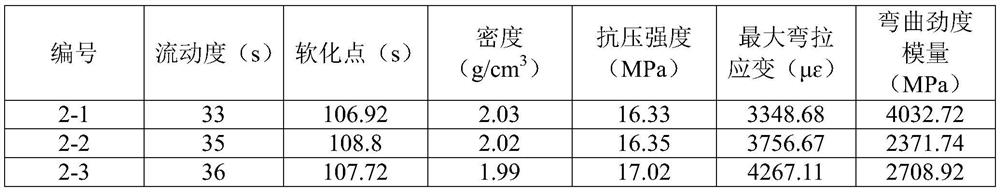

Mineral powder for bituminous mixture and production method thereof

The invention provides mineral powder for a bituminous mixture and a production method of the mineral powder. The mineral powder provided by the invention consists of limestone and an admixture. The admixture comprises a water repellent and diatomaceous earth, and further comprises a modified polymer for modifying a product of the bituminous mixture. The water repellent, the diatomaceous earth and the modified polymer all take up 5-10% of the weight of the limestone. The production method of the mineral powder provided by the invention comprises the steps of: placing and smashing the limestone and the admixture by a smashing device to a certain granularity to obtain finished product of the mineral powder which is same in proportion with raw materials; during production of the bituminous mixture, replacing the mineral powder with current mineral power and a modifier, and adding 3-10% of the mineral powder by weight to the bituminous mixture. The mineral powder is simple in production process and environment-friendly, and the pavement performance is improved and the cost is lowered when the mineral powder is used in the bituminous mixture.

Owner:HUNAN ZHONGDA CONSTR ENG TESTING TECH

Lake asphalt/SBR (styrene butadiene rubber) composite modifier and preparation method and application thereof

InactiveCN106893333AGood compatibilityGood dispersionBuilding insulationsCrack resistanceRoad surface

The invention relates to a lake asphalt / SBR (styrene butadiene rubber) composite modifier and a preparation method and application thereof. The lake asphalt / SBR composite modifier is a pre-dispersed material formed by the lake asphalt, polymer SBR and a compatilizer via melt blending, and the modified asphalt can be obtained by melt blending of petroleum asphalt and a stabilizer. The lake asphalt / SBR composite modifier is the pre-dispersed material capable of remarkably improving capacities of high-temperature deformation, low-temperature cracking resistance and anti-water damage, the pre-dispersed material is then added to the petroleum asphalt, and the lake asphalt / SBR composite modified asphalt uniform in dispersion and less prone to layered segregation by the aid of the advantage of good compatibility of the pre-dispersed material and the petroleum asphalt; the modified asphalt is applied to construction of heavy traffic asphalt pavement of high-temperature, moist and rainy regions, asphalt pavement diseases can be remarkably reduced, pavement maintenance cost is lowered, and service life of the asphalt pavement is prolonged.

Owner:FUZHOU UNIV

Prescription of fibre modified slurry sealing layer and construction method

The invention relates to a material prescription for road maintenance and the construction method thereof, in particular to the prescription and the construction method of a fibre modified slurry seal layer which consists of the following materials (calculated by weight): grade compound of 82.11 parts, modified emulsification bitumen of 9.44 parts, spraying twistless roving of 0.24 parts and water of 8.21 parts. The construction method comprises the steps as follows: firstly, disposing the damage of maintaining road; secondly, choosing a pneumatic cutting machine and a slurry seal layer vehicle which are capable of adding spraying twistless roving measurement; thirdly, mixing the materials, adopting the prescription and the construction method of the fibre modified slurry seal layer disclosed in the invention to improve the anti-tracking performance of the maintenance road by 60 percent, the anti-cutting performance by 35 percent, the bonding performance and the waterproof damage property by 33 percent, the material collecting anti-dispersion performance by 30 percent, the anti low temperature crazing performance by 15 percent and the anti-fatigue performance by 15.6 percent.

Owner:王晓伟

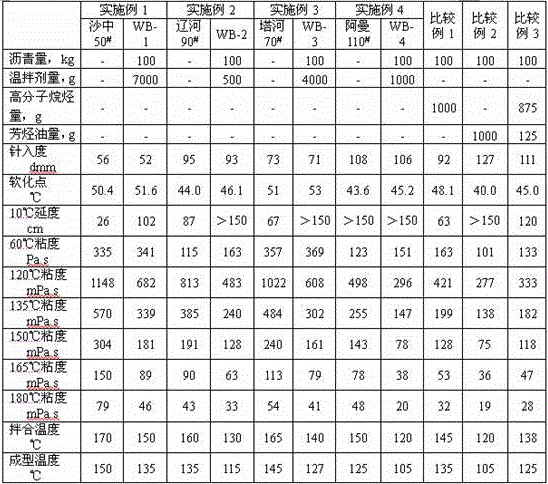

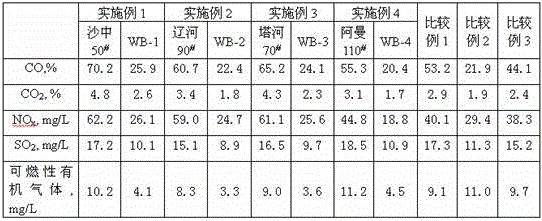

Warm mix asphalt and preparation method thereof

ActiveCN106147250ALower mixing temperatureReduce high temperature viscositySludge treatment by pyrolysisClimate change adaptationActive agentOil sludge

The invention discloses warm mix asphalt and a preparation method thereof. A formula of the warm mix asphalt comprises a powdered solid material, a branched high-molecular polymer, an oleophylic surfactant, stearic acid and matrix asphalt, wherein the powdered solid material is a separated solid product obtained by conducting oily sludge hot extraction and dewatering technology treatment on oily sludge. According to the warm mix asphalt, all components act synergistically, the effect of additive synergism can be achieved, mixing temperature and forming temperature of a warm mix asphalt mixture prepared form the warm mix asphalt are both lower than 135 DEG C, the warm mix asphalt mixture has the advantages of obviously decreasing the mixing temperature and forming temperature, and various properties of the warm mix asphalt mixture are equivalent to those of hot mix asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

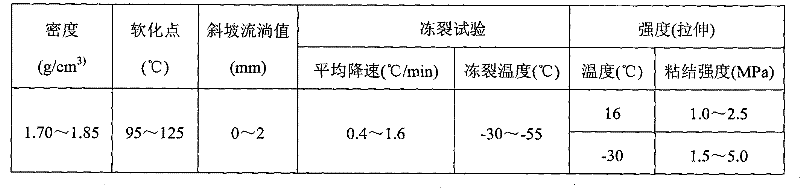

Modified asphalt mastic resin used for panel sealing layer, and preparation and application methods thereof

The invention discloses a modified asphalt mastic resin applied in the field of water conservancy and hydropower project, and provides a preparation method and an application method of the modified asphalt mastic resin. The modified asphalt mastic resin comprises modified asphalt used as a matrix and ground alkaline rock mineral powder as filler, and the addition amount of the filler is 40-70%. The modified asphalt mastic resin is prepared by separately heating the modified asphalt matrix and the mineral powder and then uniformly mixing. When in use, the modified asphalt mastic resin is heated to 180-200 DEG C, simultaneously the surface of asphalt concrete for construction is cleaned, and then the modified asphalt mastic is brushed on the surface. The modified asphalt mastic resin has greatly improved anti-aging and anti-high-temperature slope flowing capabilities and low-temperature cracking resistance, and good adhesion with impermeable asphalt concrete under frost action. According to the construction method provided by the invention, the modified asphalt mastic resin can be brushed easily and evenly with few bubbles, convexes, needle holes and other defects.

Owner:POWERCHINA BEIJING ENG

Warm-mix asphalt additive and preparation method thereof

ActiveCN106147251AReduce the temperatureEmission reductionClimate change adaptationSludge treatment by pyrolysisEthylene bisAsphalt

The invention discloses a warm-mix asphalt additive and a preparation method thereof. The warm-mix asphalt additive is prepared from powdery solid, Fischer-tropsch wax, a branched high-molecular polymer and N,N'-ethylenebisstearamide, wherein the powdery solid is a solid product separated after oily sludge is treated by adopting an oil sludge heat extraction and dehydration technology. The components in the warm-mix asphalt additive have a synergistic effect, an additive synergism effect can be played, the mixing and forming temperature of a warm-mix asphalt mixed material prepared by applying the warm-mix asphalt additive is lower than 135 DEG C, the warm-mix asphalt additive has the advantage of obviously reducing the mixing and forming temperature, and the properties of the mixed material are equivalent to the properties of warm-mix asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rock asphalt fluid fine grinding, modifying and mixing process

InactiveCN107383903AIncrease stickinessImprove high temperature performanceBuilding insulationsCrack resistanceRoad surface

The invention relates to the technical field of pavement construction, and concretely relates to a rock asphalt fluid fine grinding, modifying and mixing process. A rock asphalt fluid is prepared from the following components: 38 to 43 parts of rock asphalt, 22 to 30 parts of matrix asphalt, 16 to 23 parts of kieselguhr, 12 to 20 parts of sodium tetrapolyphosphate, 8 to 15 parts of kaolin, and 5 to 12 parts of surface active agent. According to the rock asphalt fluid fine grinding, modifying and mixing process provided by the invention, the sodium tetrapolyphosphate, the kaolin and the matrix asphalt are used as raw materials for preparing the rock asphalt, and the oil content in the rock asphalt is gradually oxidized and transformed into asphaltene, so that the viscosity of the rock asphalt is increased, and meanwhile, a high temperature performance of the rock asphalt is also improved; through the mixed use of the kieselguhr and the kaolin, the high-temperature stability and the low-temperature cracking resistance of the rock asphalt can be improved, so that a viscoelasticity range of the rock asphalt is increased, the temperature sensibility is reduced, and meanwhile, the ageing resistance and the fatigue resistance of the rock asphalt are improved.

Owner:安徽和轩岩沥青科技有限公司

Asphalt reinforcing agent and application of asphalt reinforcing agent in modified heavy traffic asphalt

ActiveCN109810523AImprove high temperature stabilityImprove low temperature cracking resistanceBuilding insulationsBasalt fiberAsphalt

The invention discloses an asphalt reinforcing agent and application of the asphalt reinforcing agent in modified heavy traffic asphalt. The asphalt reinforcing agent is prepared from raw materials: functional mineral powder and modified basalt fiber; and the functional mineral powder is modified serpentine and / or modified vermiculite. Compared with the prior art, the asphalt reinforcing agent isapplied to asphalt modification and can significantly improve the high-temperature stability and low-temperature anti-cracking property of asphalt, the modified heavy traffic asphalt can meet requirements of the use property of the road, and the service life of the road is prolonged.

Owner:上海同沥新材料科技有限公司

A kind of waste rubber powder activated modified epoxy asphalt functional material and preparation method thereof

ActiveCN104592775BHigh surface activation treatment efficiencyImprove processing efficiencyWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsEpoxyPolymer science

The invention discloses a waste rubber powder activated and modified epoxy asphalt functional material and a preparation method thereof. The functional material comprises an epoxy asphalt component A and an epoxy asphalt component B, wherein the epoxy asphalt component A is the mixture of epoxy resin and terminal-group epoxy modified silicone oil; the epoxy asphalt component B is a polymer dispersant, a matrix asphalt, a curing agent and a waste rubber powder activation product. The preparation method comprises the following steps: activating waste rubber powder to obtain activated waste rubber powder with surface activity; adding the obtained activated waste rubber powder into the matrix asphalt to obtain the epoxy asphalt component B, adequately mixing the epoxy asphalt component A with the epoxy asphalt component B to obtain the waste rubber powder activated and modified epoxy asphalt functional material. The preparation method disclosed by the invention can be used for comprehensively improving the compatibility between the matrix asphalt and the rubber powder, and improving the low-temperature crack resistance, fatigue resistance and stability of the epoxy asphalt functional material.

Owner:JURONG NINGWU CHEM

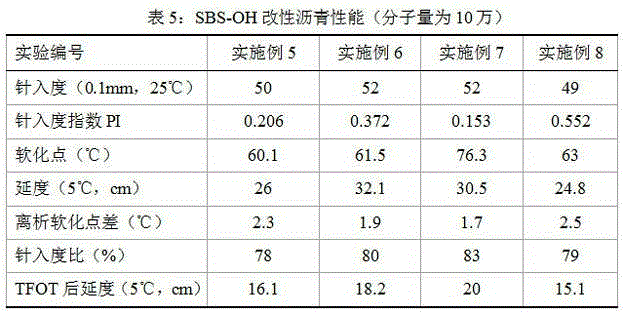

Hydroxylated SBS/graphene composite modified asphalt and preparation method thereof

InactiveCN112745692AGood compatibilityImprove low temperature performanceBuilding insulationsGrapheneAsphalt

The invention discloses hydroxy-terminated SBS / graphene composite modified asphalt and a preparation method thereof, linear hydroxy-terminated SBS(SBS-OH) is used as a modifier to modify asphalt, the SBS-OH has certain polarity, improves the compatibility with matrix asphalt, fully embodies the performance of SBS, improves the low-temperature ductility and fatigue resistance of the modified asphalt, and meanwhile, the graphene has high strength, and the high-temperature performance of the modified asphalt can be improved.

Owner:CHINA PETROLEUM & CHEM CORP

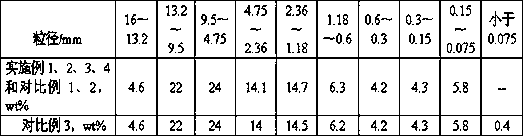

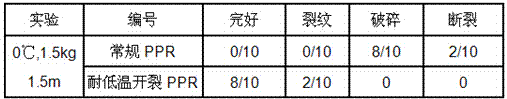

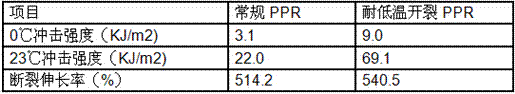

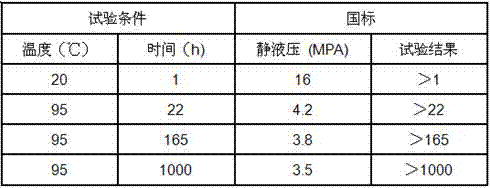

PPR pipe material resistant to low-temperature cracking, preparation method thereof and PPR pipe product prepared from PPR pipe material

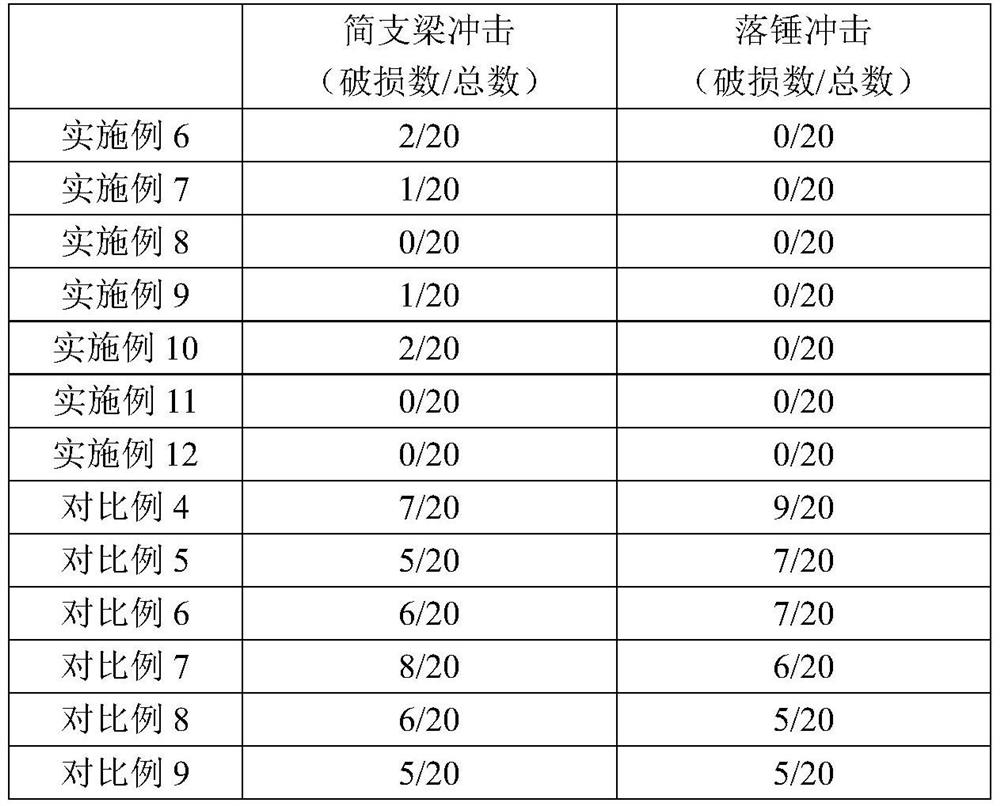

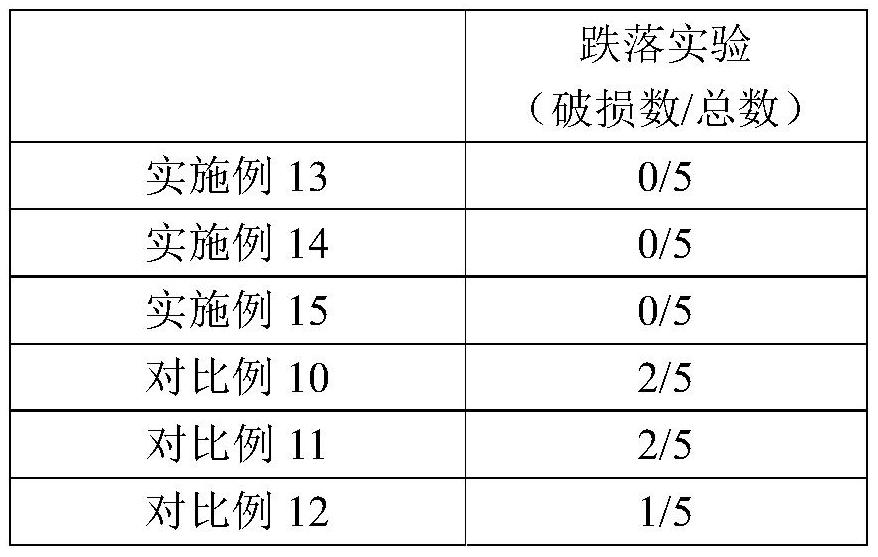

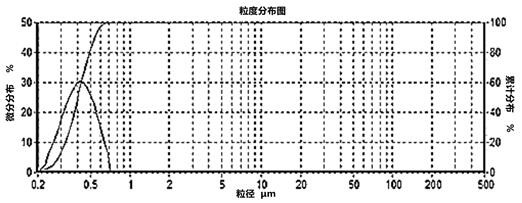

ActiveCN113061304AImprove brittlenessExcellent resistance to low temperature crackingLinear low-density polyethyleneCrystal structure

The invention discloses a PPR pipe material resistant to low-temperature cracking, a preparation method of the PPR pipe material and a PPR pipe product prepared from the PPR pipe material. The PPR pipe material resistant to low temperature cracking is prepared from the following components in parts by weight: 100 parts of PPR, 10 parts of PPB, 0.05 to 0.1 part of beta nucleating agent, 3 to 5 parts of LLDPE (Linear Low Density Polyethylene) and 3 to 5 parts of color master batch, wherein the PPR pipe product is prepared from the PPR pipe material, and the preparation method of the PPR pipe product comprises the steps of forming, cooling and curing treatment. The PPB, the beta nucleating agent and the LLDPE are added for synergistic interaction, so that the problem of brittleness of PPR at low temperature is effectively improved, and the PPR pipe material with excellent low-temperature cracking resistance is obtained. By utilizing the PPR pipe material, through long-time curing treatment at a relatively low temperature, the intermolecular tension of each component in the PPR pipe material is effectively reduced, the stability of a crystal structure is enhanced, and the low-temperature cracking resistance of a PPR pipe product is further improved.

Owner:长春联塑实业有限公司

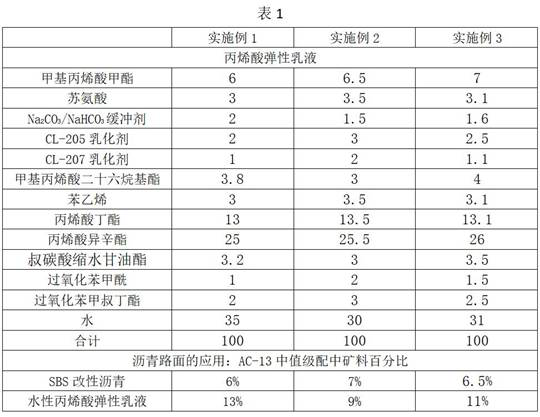

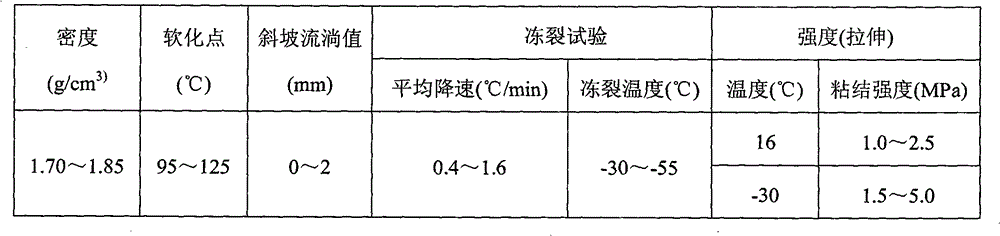

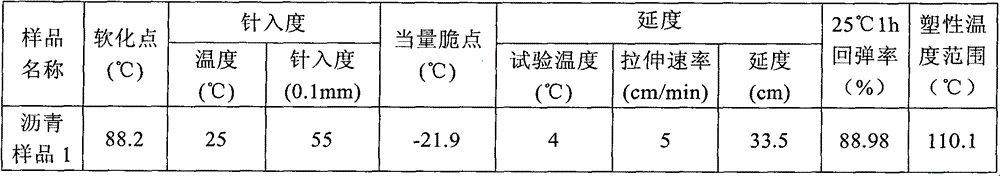

A kind of water-based acrylic elastic emulsion and its preparation method and its application on asphalt pavement

Owner:甘肃省公路交通建设集团有限公司 +1

Modified asphalt mastic resin used for panel sealing layer, and preparation and application methods thereof

The invention discloses a modified asphalt mastic resin applied in the field of water conservancy and hydropower project, and provides a preparation method and an application method of the modified asphalt mastic resin. The modified asphalt mastic resin comprises modified asphalt used as a matrix and ground alkaline rock mineral powder as filler, and the addition amount of the filler is 40-70%. The modified asphalt mastic resin is prepared by separately heating the modified asphalt matrix and the mineral powder and then uniformly mixing. When in use, the modified asphalt mastic resin is heated to 180-200 DEG C, simultaneously the surface of asphalt concrete for construction is cleaned, and then the modified asphalt mastic is brushed on the surface. The modified asphalt mastic resin has greatly improved anti-aging and anti-high-temperature slope flowing capabilities and low-temperature cracking resistance, and good adhesion with impermeable asphalt concrete under frost action. According to the construction method provided by the invention, the modified asphalt mastic resin can be brushed easily and evenly with few bubbles, convexes, needle holes and other defects.

Owner:POWERCHINA BEIJING ENG

A kind of warm mix asphalt additive and preparation method thereof

ActiveCN106147251BSolve the problem of poor road performanceReduce the interaction forceClimate change adaptationSludge treatment by pyrolysisWaxPolymer science

The invention discloses a warm-mix asphalt additive and a preparation method thereof. The warm-mix asphalt additive is prepared from powdery solid, Fischer-tropsch wax, a branched high-molecular polymer and N,N'-ethylenebisstearamide, wherein the powdery solid is a solid product separated after oily sludge is treated by adopting an oil sludge heat extraction and dehydration technology. The components in the warm-mix asphalt additive have a synergistic effect, an additive synergism effect can be played, the mixing and forming temperature of a warm-mix asphalt mixed material prepared by applying the warm-mix asphalt additive is lower than 135 DEG C, the warm-mix asphalt additive has the advantage of obviously reducing the mixing and forming temperature, and the properties of the mixed material are equivalent to the properties of warm-mix asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of warm mix asphalt and preparation method thereof

ActiveCN106147250BLower mixing temperatureReduce high temperature viscosityClimate change adaptationSludge treatment by pyrolysisSludgeStearic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

A low-cost long-residence time high-performance modified asphalt and its preparation method

The invention discloses a low-cost, long-reserved time and high-performance modified asphalt and a preparation method thereof. The modified asphalt is an A and B dual-component system, wherein the component A is an epoxy resin and polyethyleneglycol diglycidylether mixture; and the component B comprises an emulsifier, matrix asphalt, a solidification agent and activated waste rubber powder. The preparation method comprises the following steps: adding the activated waste rubber powder into the matrix asphalt, adding the emulsifier and the solidification agent under a high temperature condition, carrying out shearing emulsification to obtain the component B, and fully mixing the component A and the component B of the modified asphalt to obtain the low-cost, long-reserved time and high-performance modified asphalt. Long reserved time is realized through selecting the specific epoxy resin solidification agent and regulating the solidifying rate of an epoxy system in order to meet road pavement and engineering maintenance with long reserved time requirements. The matrix asphalt and the waste rubber powder are used, so the production cost is reduced, and the low-temperature cracking resistance and stability of the modified asphalt are improved.

Owner:JURONG NINGWU CHEM

Cooling type high-performance road marking hot melt coating for high-altitude area and preparation method thereof

PendingCN114806320AMaintain and effectively improve good road performanceImproves UV resistanceReflecting/signal paintsHot melt coatingPlasticizer

The invention provides a cooling type high-performance road marking hot melt coating for high-altitude areas and a preparation method thereof, and relates to the technical field of road marking materials. The cooling type high-performance road marking hot-melt coating for the high-altitude area comprises the following components in percentage by mass: 10-18% of a cementing material, 40-60% of a filler, 3-8% of a pigment, 15-23% of a reflective material, 0.5-3% of a plasticizer, 4-12% of an elasticizer, 1-4% of a rheological agent, 0.5-3% of a warm mixing agent and 0.5-2% of a light screening agent. According to the obtained cooling type high-performance road marking coating for the high-altitude areas, the ultraviolet resistance and the low-temperature cracking resistance can be remarkably improved on the premise that the good pavement performance of the road marking coating is maintained and effectively improved, and the cooling type high-performance road marking coating has important application and popularization significance in the high-altitude areas.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

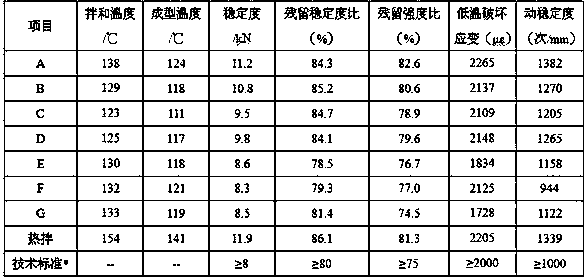

Warm asphalt mixture and preparation method thereof

ActiveCN104591605BEasy to makeLow molding temperatureClimate change adaptationOrganic chemistryAsphalt

The invention discloses a warm-mix asphalt mixture. The warm-mix asphalt mixture comprises the following components in percentage by mass: 4.0-6.0% of warm-mix asphalt, 1.0-3.0% of mineral powder and 91.0-95.0% of aggregate; the warm-mix asphalt is prepared by the warm-mix agent. The warm-mix agent is prepared by the high polymer alkane, halogen, aromatic oil and catalyst. The dosage of the halogen is 0.3-0.5 times of the mole number of the high polymer alkane. The weight ratio of the high polymer alkane and the aromatic oil is (1-7):(7-1). The dosage of the catalyst is 0.3-0.9% of the content of the arene in the aromatic oil. The mixing and forming temperature can be reduced for the warm-mix asphalt mixture, the harmful gas generation amount is reduced, the warm-mix asphalt mixture is friendly to the environment, and the high and low temperature performance of the asphalt mixture can be improved.

Owner:辽宁兆利高新路面材料有限公司

Modified emulsified asphalt concrete

ActiveCN112794677AImproves resistance to water damageImprove heat aging resistanceSolid waste managementBitumen emulsionStructural engineering

The invention provides modified emulsified asphalt concrete, and belongs to the technical field of road pavement construction. The modified emulsified asphalt concrete comprises the following components in percentage by mass: 4%-5% of asphalt, 5%-7% of slag powder, 40%-50% of fine aggregate, 40%-50% of coarse aggregate and 0.2%-0.8% of an anti-stripping agent, the asphalt is SBRII-A type modified asphalt, the fine aggregate is 0-4.75 mm machine-made sand, the coarse aggregate is 4.75-9.5 mm broken stone and 9.5-16 mm broken stone, and the doping amount of the 4.75-9.5 mm broken stone is higher than that of the 9.5-16 mm broken stone. The HY-1 type anti-stripping agent is added into the modified emulsified asphalt concrete, so that the adhesive force between asphalt and aggregate can be increased, the water damage resistance and thermal aging resistance of the asphalt concrete are improved, the possibility of forming oil flooding and pitted surfaces on a pavement is reduced, and the service life of the pavement is prolonged; by using the SBRII-A type modified asphalt, the influence of plateau day and night temperature difference on the asphalt pavement can be reduced, the low-temperature cracking resistance and the high-temperature rutting resistance are improved, and shrinkage cracks formed on the asphalt pavement are reduced or avoided.

Owner:CONSTR COMPANY OF CHINA RAILWAY NO 8 ENGNEERING GRP +1

Warm mix additive for asphalt mixture and preparation method thereof

ActiveCN106147248BIn line with the concept of environmental protectionReduce manufacturing costClimate change adaptationBuilding insulationsSludgeStearate

The invention discloses a bituminous mixture warm mixing additive and a preparation method thereof. The bituminous mixture warm mixing additive is prepared from, by weight, 44%-92.5% of powdery solids, 1%-10% of branched polymers, 0.5%-6% of lubrication components, 2%-15% of abietic acid and 4%-25% of stearate. The preparation method comprises the following steps that the powdery solids, the branched polymers, the lubrication components, abietic acid and stearate are put into a screw extruder in proportion and mixed to be uniform, a finished product is extruded and pelleted, and the bituminous mixture warm mixing additive is obtained. According to the bituminous mixture warm mixing additive, the powdery solids generated after extraction treatment of oily sludge are fully recycled and can be used for producing a bituminous mixture by replacing mineral powder, cost is reduced, environmental pollution is reduced, a use method is simple, the application range is wide, and the economization and environmental protection idea is met.

Owner:CHINA PETROLEUM & CHEM CORP +1

SBS modified asphalt and preparation method thereof

Owner:河南现代交通道路科技有限责任公司

A low-temperature cracking-resistant PPR pipe with controllable crystal form and preparation method thereof

Owner:ZHEJIANG WEIXING NEW BUILDING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com