Rock asphalt fluid fine grinding, modifying and mixing process

A mixing process, rock asphalt technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of asphalt mixtures such as poor high temperature stability and low temperature crack resistance, poor aging resistance and fatigue resistance, and achieve temperature sensitivity The effect of reducing the resistance, enhancing the aging resistance and fatigue resistance, improving the high temperature stability and low temperature crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

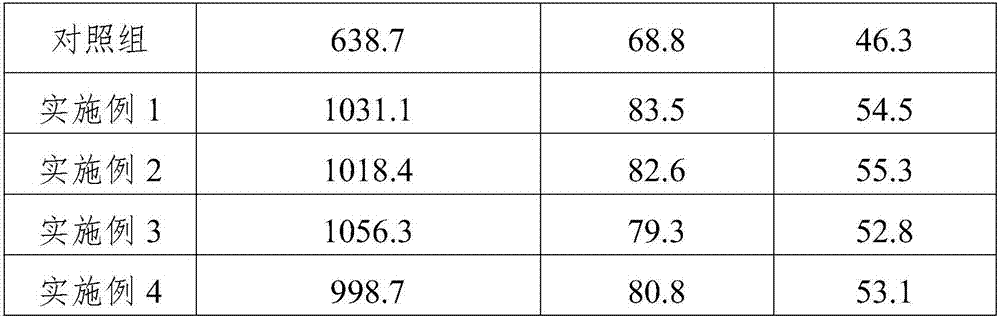

Embodiment 1

[0021] A rock bitumen fluid fine grinding modification mixing process, its components by weight: 38 parts of rock bitumen, 24 parts of base asphalt, 16 parts of diatomite, 15 parts of sodium tetrapolyphosphate, 8 parts of kaolin and 7 parts of surfactant part; its preparation method comprises the following steps:

[0022] a. Mix base asphalt, diatomaceous earth, sodium tetrapolyphosphate, kaolin and surfactant uniformly and pulverize to obtain mixed component A;

[0023] b. Crushing rock asphalt, dehydrating and activating at 120°C, then drying rock asphalt at 100°C until the water content in rock asphalt is less than 2%, and then drying rock asphalt at 162°C, Under the condition of the shearing speed of 2200r / min, the shearing mill is carried out until the fineness is greater than 170 mesh, and the mixed component B is obtained;

[0024] c. Add the mixing component A to the mixing component B, add it to the base asphalt, and stir at a speed of 560r / min, and then glue it at 1...

Embodiment 2

[0026] A rock bitumen fluid fine grinding modification mixing process, its components by weight: 40 parts of rock bitumen, 22 parts of base asphalt, 18 parts of diatomite, 12 parts of sodium tetrapolyphosphate, 11 parts of kaolin and 5 parts of surfactant part; its preparation method comprises the following steps:

[0027] a. Mix base asphalt, diatomaceous earth, sodium tetrapolyphosphate, kaolin and surfactant uniformly and pulverize to obtain mixed component A;

[0028] b. Crushing rock asphalt, dehydrating and activating at 128°C, then drying rock asphalt at 109°C until the water content in rock asphalt is less than 2%, and then drying rock asphalt at 171°C, Under the condition of the shearing speed of 2460r / min, the shearing mill is carried out until the fineness is greater than 170 mesh, and the mixed component B is obtained;

[0029] c. Add the mixing component A to the mixing component B, add it to the base asphalt, and stir at a speed of 560r / min, and then glue it at ...

Embodiment 3

[0031] A rock bitumen fluid fine grinding modification mixing process, its components by weight: 43 parts of rock bitumen, 30 parts of base asphalt, 23 parts of diatomite, 20 parts of sodium tetrapolyphosphate, 13 parts of kaolin and 12 parts of surfactant part; its preparation method comprises the following steps:

[0032] a. Mix base asphalt, diatomaceous earth, sodium tetrapolyphosphate, kaolin and surfactant uniformly and pulverize to obtain mixed component A;

[0033] b. Crushing rock asphalt, dehydrating and activating at 135°C, then drying rock asphalt at 116°C until the water content in rock asphalt is less than 2%, and then drying rock asphalt at 178°C, Under the condition of the shearing speed of 2670r / min, the shearing mill is carried out until the fineness is greater than 170 mesh, and the mixed component B is obtained;

[0034] c. Add the mixing component A to the mixing component B, add it to the base asphalt, and stir at a speed of 560r / min, and then glue it at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com