High-performance rubber asphalt pouring sealant and preparation method thereof

A technology for rubberized asphalt and joint-filling glue, which is applied in other directions such as rubber adhesives, asphalt material adhesives, chemical instruments and methods, etc. The effect is not ideal and other problems, to achieve the effect of improving low temperature crack resistance, improving routing performance, and improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

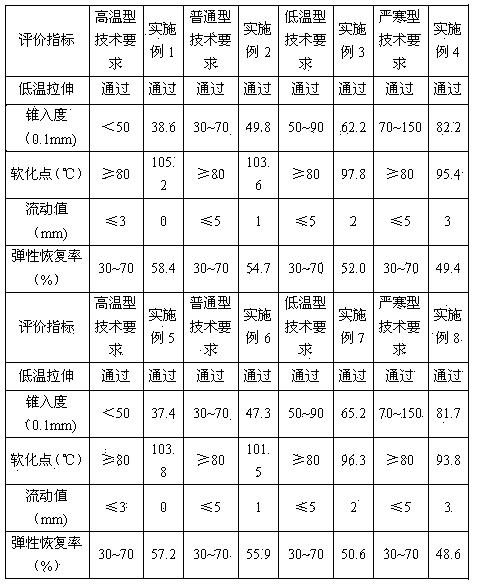

Examples

Embodiment 1

[0028] Taking the production of 100KG of asphalt pavement joint glue of the present invention as an example, the raw materials used and the proportioning ratio are as follows:

[0029] Rubber powder 22.5kg

[0030] Modifier 5.8kg

[0031] Petroleum asphalt 65.5kg

[0032] Tackifier 2.0kg

[0033] Co-solvent 4.0kg

[0034] Stabilizer 0.2kg

[0035] The petroleum asphalt used in this example is grade A grade SK-90 road petroleum asphalt produced in South Korea, with a penetration of 80-100 (calculated as 0.1mm), and the rubber powder is waste tire rubber powder with a fineness of 40 meshes. Produced by Anqiang High Wear-Resistant Rubber Powder Co., Ltd.

[0036] Its preparation method is as follows:

[0037] Heat petroleum asphalt to 150°C; add modifier and stir until liquid, then add co-solvent, stir at 140°C~150°C for 30 minutes; continue to heat up to 190°C and slowly add rubber powder and stir for 30 minutes, Then add tackifier and stabilizer,...

Embodiment 2

[0039] Taking the production of 100KG of asphalt pavement joint glue of the present invention as an example, the raw materials used and the proportioning ratio are as follows:

[0040] Rubber powder 22.5kg

[0041] Modifier 5.8kg

[0042] Petroleum asphalt 63.0kg

[0043] Tackifier 2.0kg

[0044] Co-solvent 6.5kg

[0045] Stabilizer 0.2kg

[0046] The petroleum asphalt used in this example is grade A grade SK-90 road petroleum asphalt produced in South Korea, with a penetration of 80-100 (calculated as 0.1mm), and the rubber powder is waste tire rubber powder with a fineness of 40 meshes. Produced by Anqiang High Wear-Resistant Rubber Powder Co., Ltd.

[0047] Its preparation method is identical with embodiment 1.

Embodiment 3

[0049] Taking the production of 100KG of asphalt pavement joint glue of the present invention as an example, the raw materials used and the proportioning ratio are as follows:

[0050] Rubber powder 19.5kg

[0051] Modifier 7.8kg

[0052] Petroleum asphalt 60.0kg

[0053] Tackifier 3.0kg

[0054] Co-solvent 9.5kg

[0055] Stabilizer 0.2kg

[0056] The petroleum asphalt used in this example is grade A grade SK-90 road petroleum asphalt produced in South Korea, with a penetration of 80-100 (calculated as 0.1mm), and the rubber powder is waste tire rubber powder with a fineness of 60 mesh, which was purchased by Jiangyin City Produced by Anqiang High Wear-Resistant Rubber Powder Co., Ltd.

[0057] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com