Patents

Literature

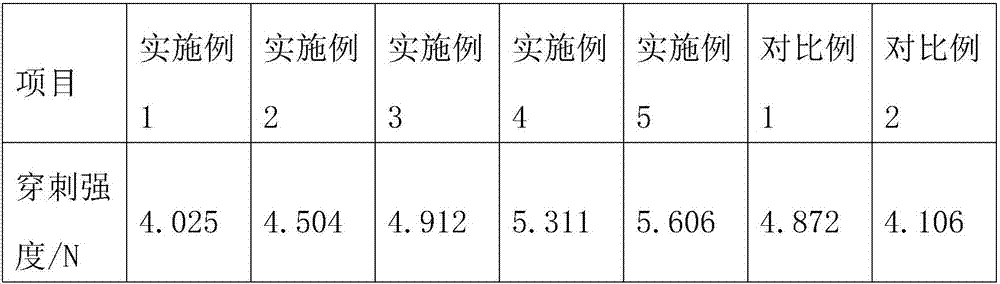

47results about How to "Stable cross-linked structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogel with self-repairing function and preparation method of hydrogel

ActiveCN104892871AImprove hydrophilicityIncrease the number ofOrganic chemistryMethacrylatePolymer science

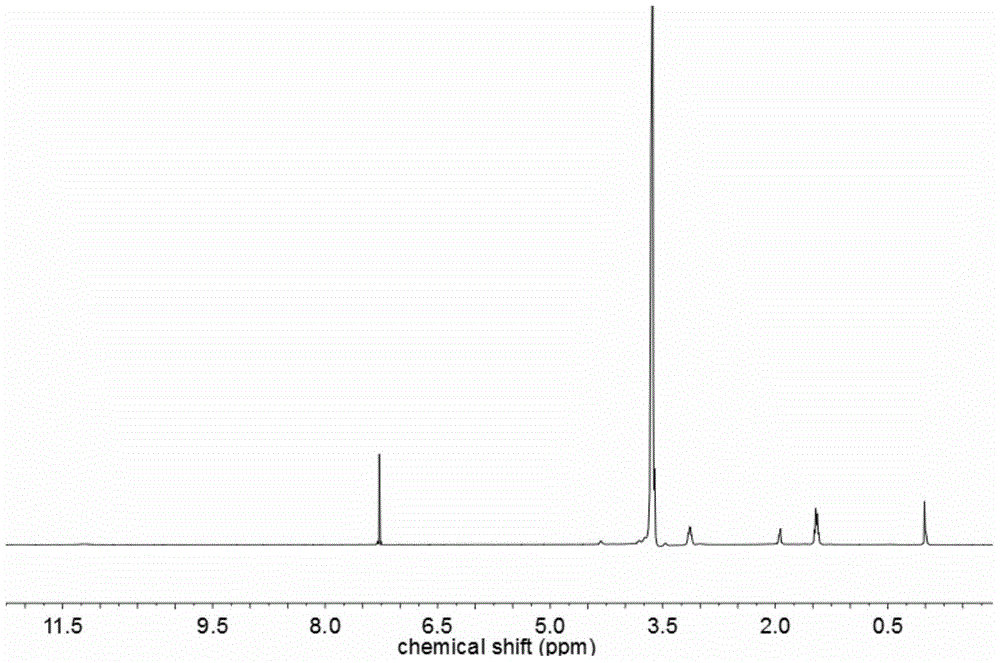

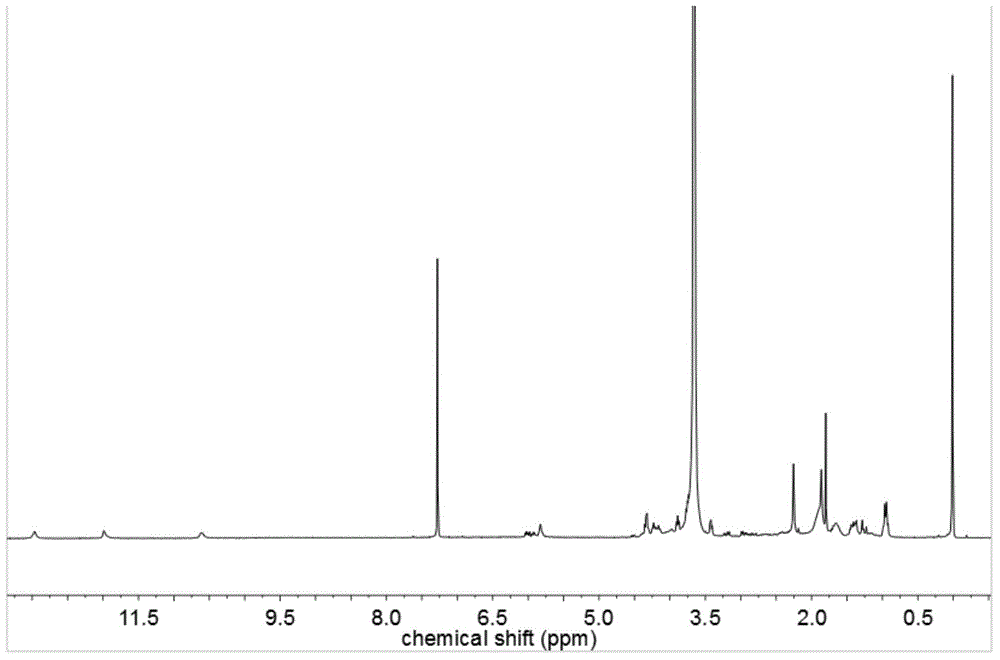

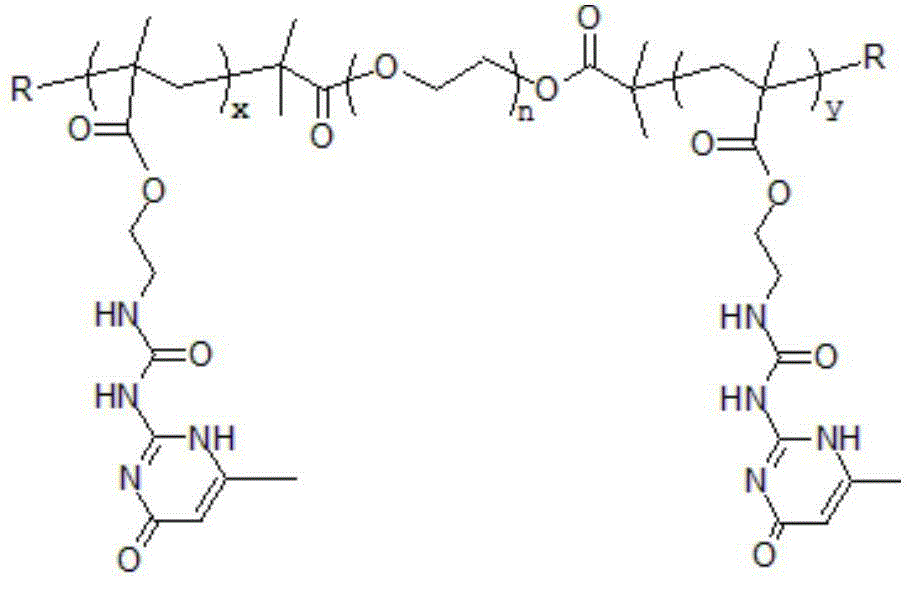

The invention discloses hydrogel with a self-repairing function and a preparation method of the hydrogel. The hydrogel is a hydrophobic unit-UPy (ureido pyrimidinone)-PEG (polyethylene glycol)-UPy-hydrophobic unit polymer. According to the preparation method, firstly, an intermediate Br-PEG-Br and a quadruple hydrogen bonding unit intermediate UPyMA are synthesized and then are copolymerized with hydrophobic units such as butyl acrylate, styrene, methacrylate containing 3-10 carbon and the like, and a target polymer is obtained. The hydrogel has high water-retaining property, varieties of hydrogel with better performance can be prepared by adjusting the proportion of hydrophilic and hydrophobic chain segments in the polymer or changing the variety of a hydrophobic monomer, and the application range is enlarged.

Owner:XIAMEN UNIV

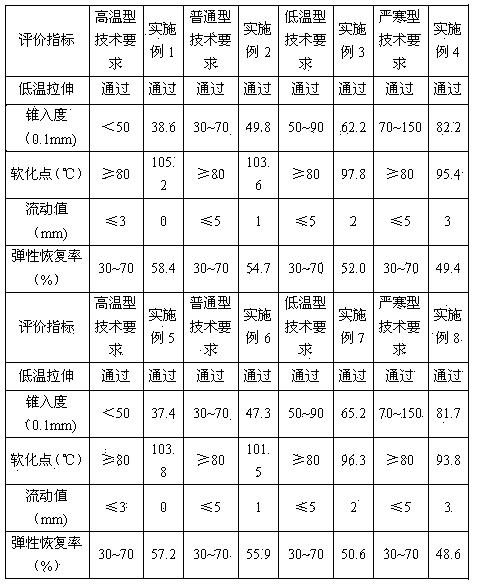

High-performance rubber asphalt pouring sealant and preparation method thereof

InactiveCN103421467AReduce pollutionImprove performanceMineral oil hydrocarbon copolymer adhesivesOther chemical processesCrack resistanceProcess engineering

The invention discloses high-performance rubber asphalt pouring sealant and a preparation method thereof. The high-performance rubber asphalt pouring sealant is made from rubber powder, modifier, petroleum asphalt, tackifier, cosolvent, and stabilizer. The preparation method includes: heating the asphalt to 150-160 DEG C, adding the modifier, stirring to obtain liquid, adding the cosolvent and mixing for 30 minutes, heating to 190-200 DEG C, slowly adding the rubber powder, mixing for 30 minutes, adding the tackifier and the stabilizer, and mixing for 15 minutes to produce high-performance rubber asphalt pouring sealant. The rubber powder of waste tires is utilized, and accordingly product performance is improved, product cost is reduced and environmental pollution is reduced; the modifier, the rubber powder and the asphalt are mixed into stable, even mixture through the cosolvent, so that resin groups, rubber powder groups and asphalt groups can form a stable interlinked structure; through the modifier, route performance of the sealant can be improved, for example, softening point is increased and low temperature cracking resistance is improved; new cracks can be prevented effectively.

Owner:XIYUEFA INT ENVIRONMENTAL PROTECTION NEW MATERIALS CO LTD

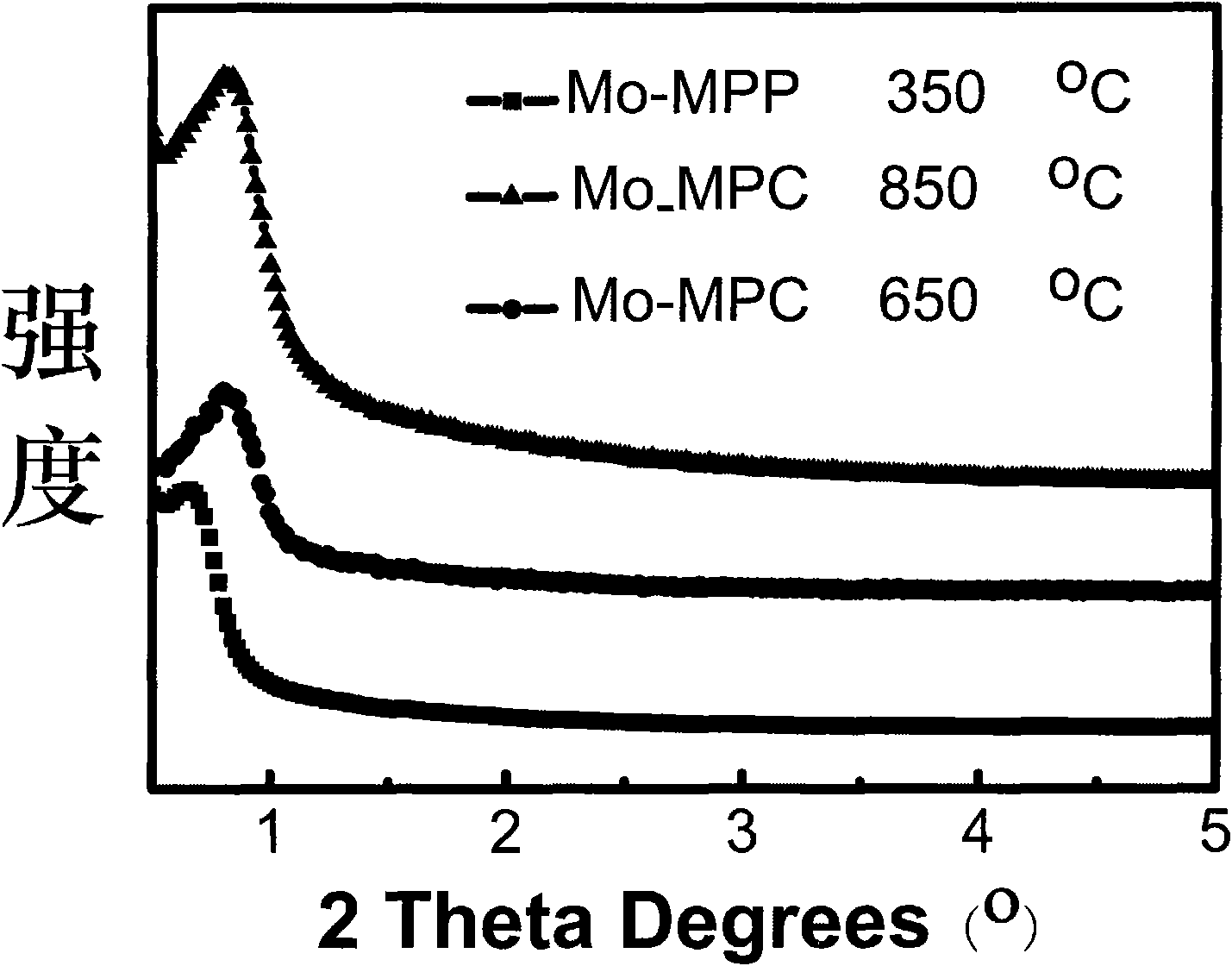

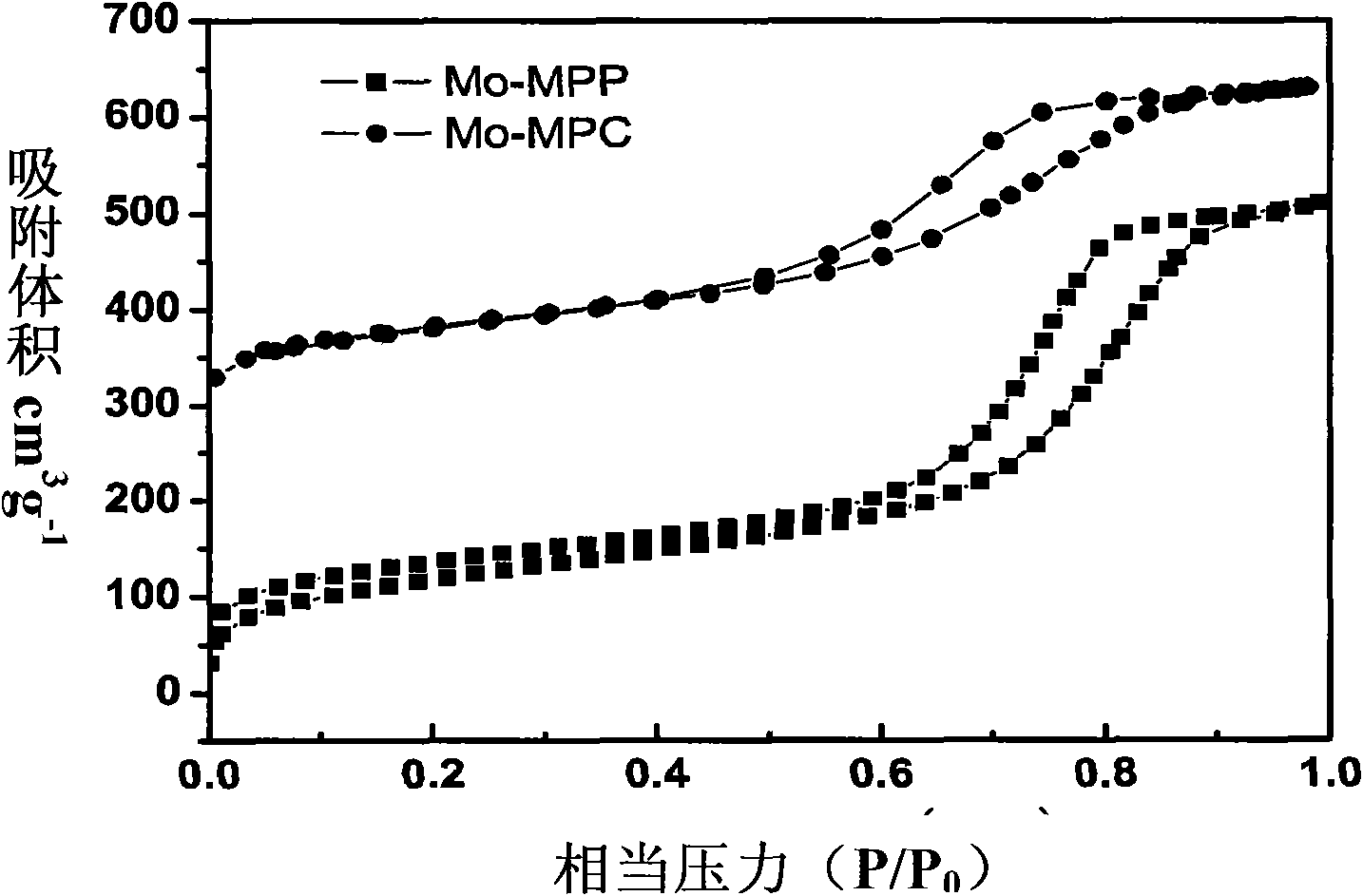

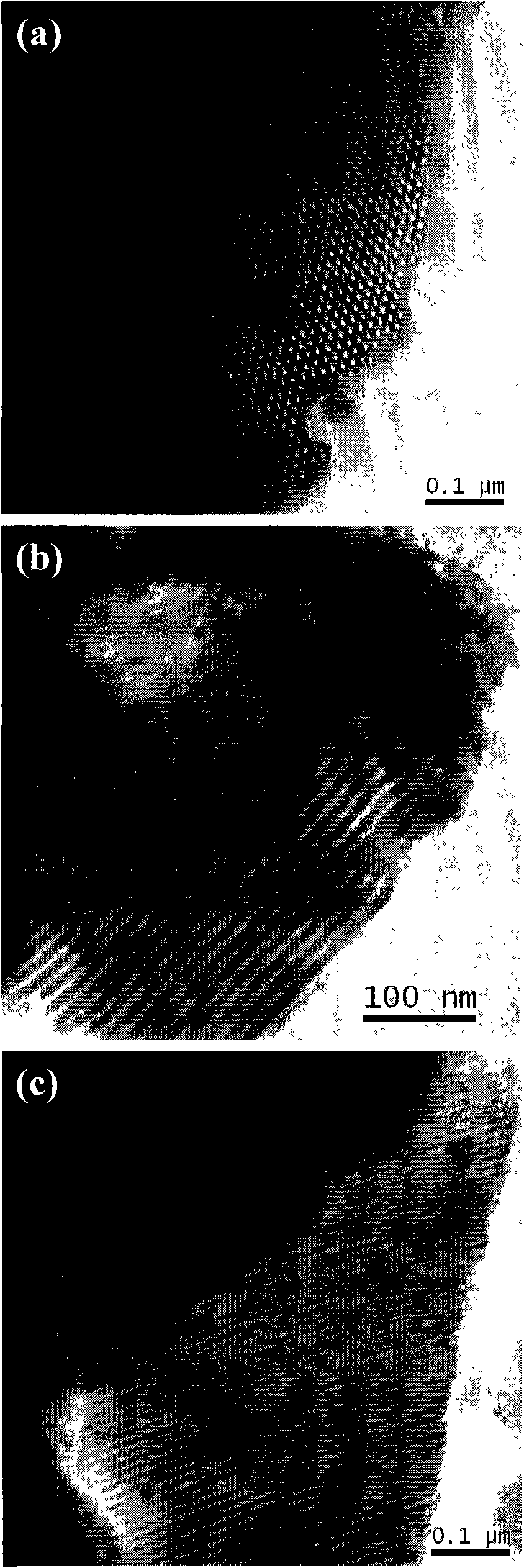

Method for preparing transition metal doped mesoporous carbon material

The invention belongs to a mesoporous carbon material, and particularly relates to a method for preparing a transition metal doped mesoporous carbon material with high specific surface area. The method takes a transition metal doped polymer as a carbonization precursor, takes a block polymer as a pore former, and utilizes a supramolecular self-assembly structure formed by the carbonization precursor and the pore former in a volatile solvent to cure at certain temperature in the existence of a curing agent to form a transition metal doped polymer meso-structure. A transition metal doped mesoporous polymer material can be prepared by roasting to remove the pore former under inert atmosphere. The prepared transition metal doped mesoporous polymer material is subjected to high-temperature carburization in the inert atmosphere to obtain the transition metal doped mesoporous carbon material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

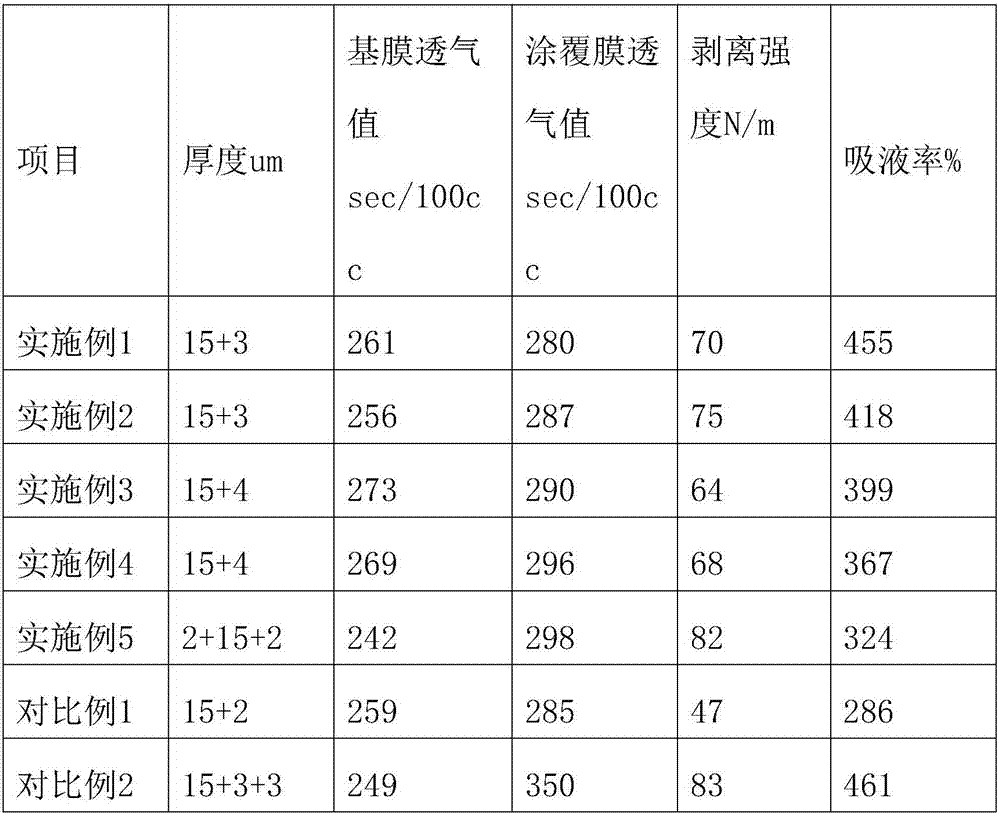

Preparation method for waterborne PMMA composite coating diaphragm

ActiveCN107046116AImprove thermal stabilityImprove mechanical propertiesLi-accumulatorsCell component detailsPolyolefinMixed materials

The invention provides a preparation method for a waterborne PMMA composite coating diaphragm. The coating diaphragm is formed by coating one side or two sides of a polyolefin base membrane with mixed paste of modified PMMA and ceramic in one time; and the modified PMMA is obtained by performing crosslinking and modifying on the PMMA and a copolymer thereof by a crosslinking agent based on a certain proportion. The diaphragm is prepared from the mixed materials of the modified PMMA and the copolymer thereof and ceramic in a coating manner; and the coating layer only needs coating of one time, so that production cost is lowered, ventilation loss caused by thickness of the coating layer also can be lowered, and meanwhile, the thermal stability of the diaphragm is improved.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

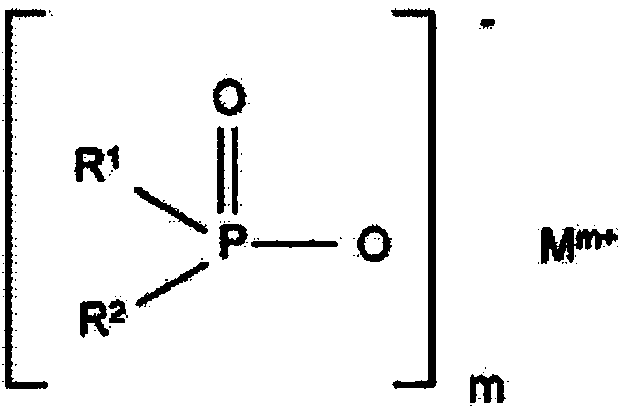

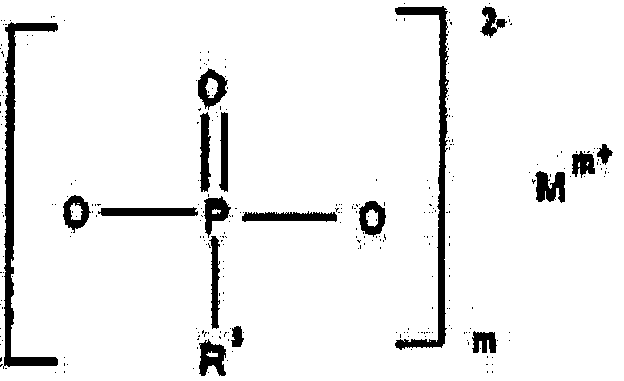

Flame retardant complex system and halogen-free flame-resistant resin-based composite material containing same

The invention belongs to the technical field of flame retardance of high polymer materials, and provides a flame retardant complex system and a halogen-free flame-resistant resin-based composite material containing the same. Reasonable complexing of alkyl hypophosphite, phosphite, alkoxy organosilicon and other low corrosion flame-retardant synergists is used to ensure that the final material is free of the problem of precipitation, the appearance is not influenced, processing equipment generates no precipitation residue, and an air vent is not blocked, the corrosion problem is well improved,adverse effect on the intrinsic beneficial properties is reduced remarkably, injection temperature is normal without serious decomposition, workpieces of various sizes are suitable for injection molding, adding amount is less and cost controllability is high.

Owner:BENSONG ENG PLASTICS HANGZHOU

Conductive polymer aerogel and preparation method thereof

The invention discloses a conductive polymer aerogel and a preparation method thereof. The preparation method comprises the following steps: polymerizing polyaniline in a low-ester pectin water solution, and then inducing to form an aquagel, carrying out solvent washing, and carrying out freeze-drying or supercritical drying. The aerogel is prepared by performing hydrogen bond crosslinking on 20-80 wt% of polyaniline and the balance of low-ester pectin with excellent mechanical properties. The method has the advantages of abundant raw material sources and low price. The obtained aerogel has the advantages of excellent mechanical properties, high conductivity, low density, high specific area and the like, and has favorable application prospects in the fields of energy storage materials, intelligent response, data storage and the like.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

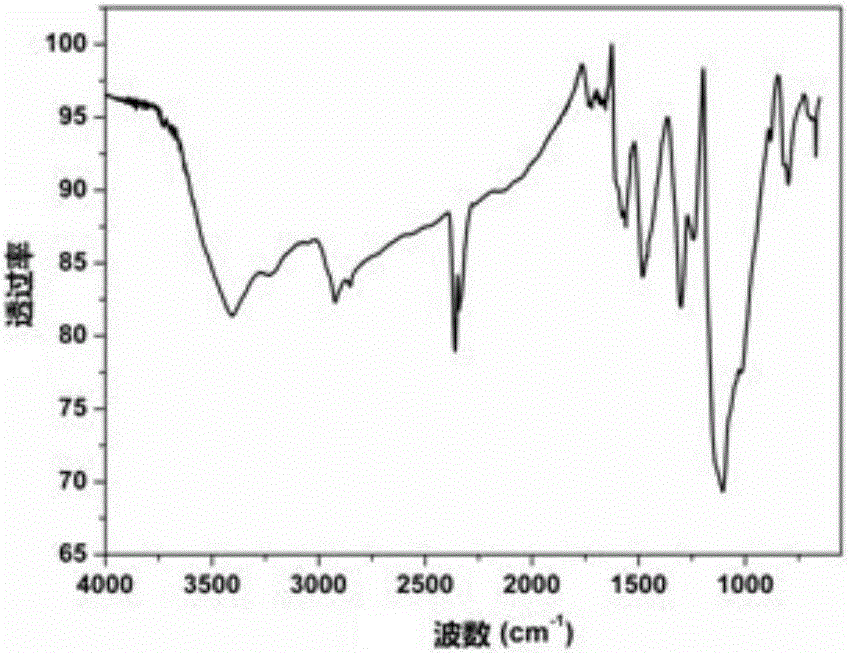

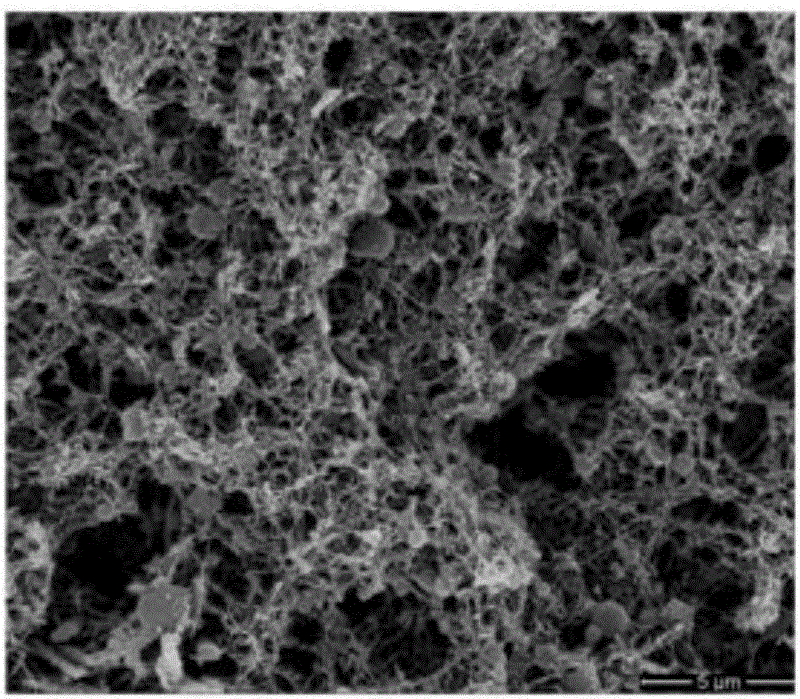

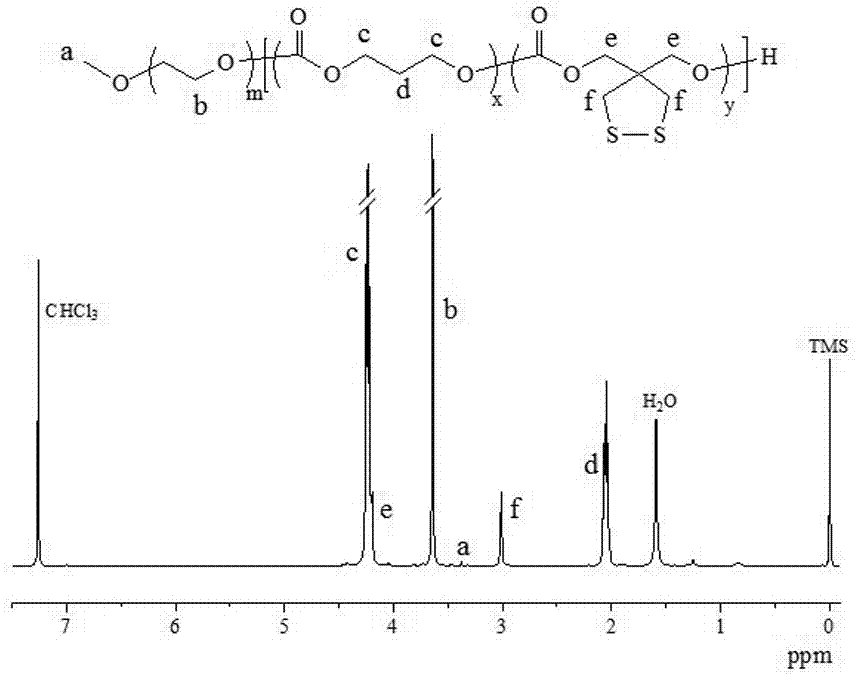

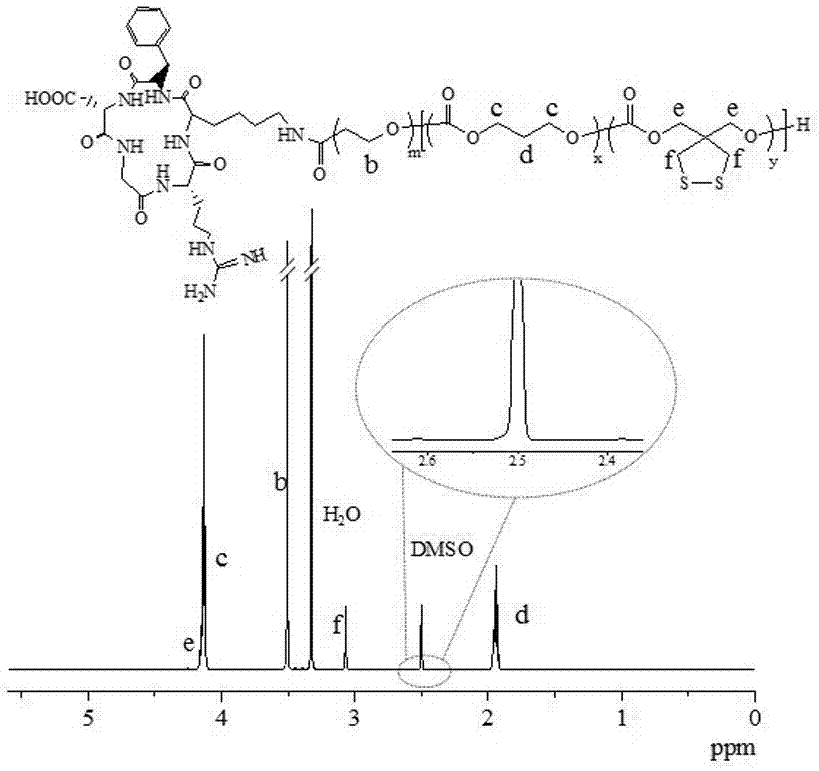

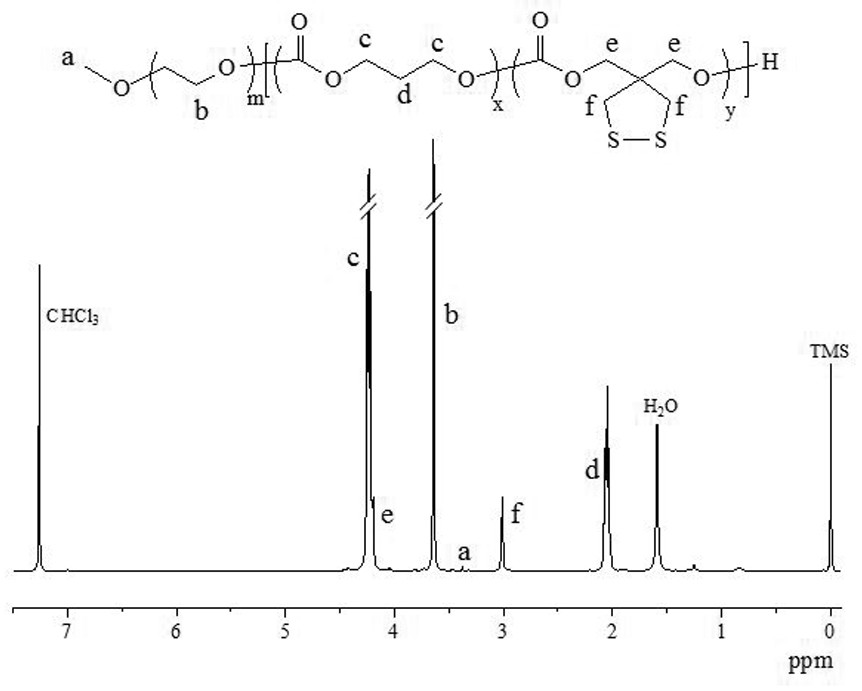

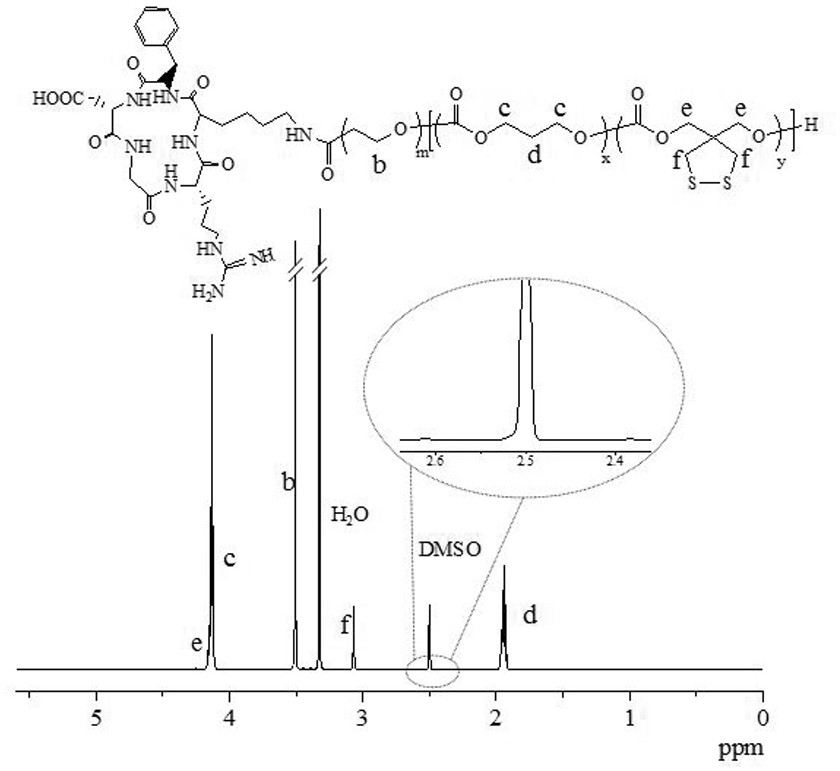

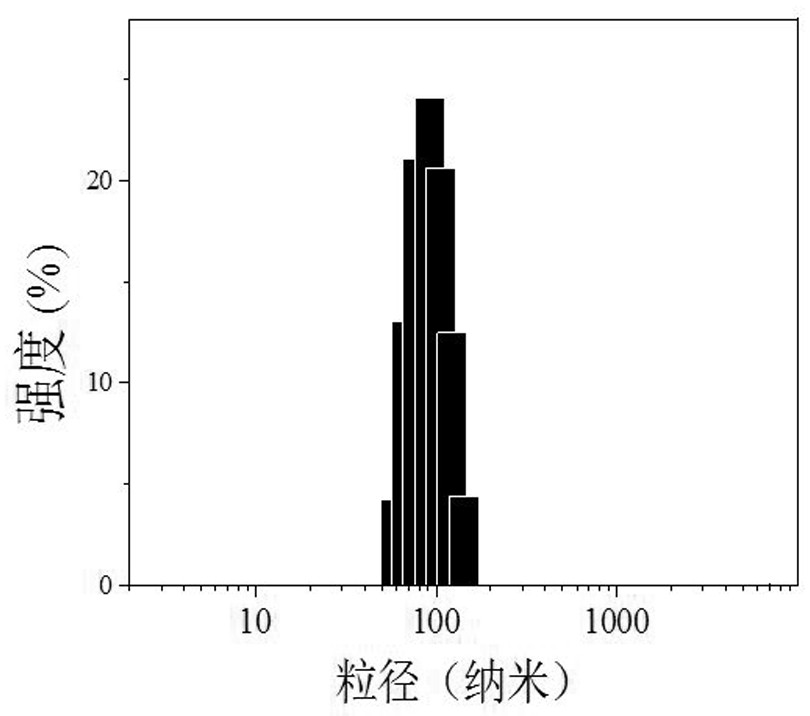

Preparation method of crosslinked nanodrug based on active reaction type one-step method

ActiveCN107096038AStable cross-linked structureLow toxicityOrganic active ingredientsPharmaceutical non-active ingredientsSide chainCancer chemotherapy

The invention discloses a preparation method of a crosslinked nanodrug based on an active reaction type one-step method. The preparation method specifically comprises the following step: adding a polymer and a drug with sulfydryl into a solution to be mixed to dialyze to obtain a crosslinked nanodrug, wherein the side chain of the polymer contains a dithiolane structure. The circularly stable nanodrug can be obtained by simple preparation, so that the defects that in the prior art, a chemically bonded nanodrug is complex to prepare and needs a catalyst and the like are overcome. The product prepared by the invention has a stable crosslinking structure and avoids the problem that an existing chemically bonded nanodrug is not crosslinked; and on a B16F10 melanoma-loading model, the nanodrug shows a good curative effect, and the tumor inhibition rate exceeds 90%. The active targeted crosslinked nanodrug has a huge potential application in the field of cancer chemotherapy.

Owner:SUZHOU UNIV

Organic-inorganic composite type high-temperature proton exchange membrane used for fuel cell and preparation method for proton exchange membrane

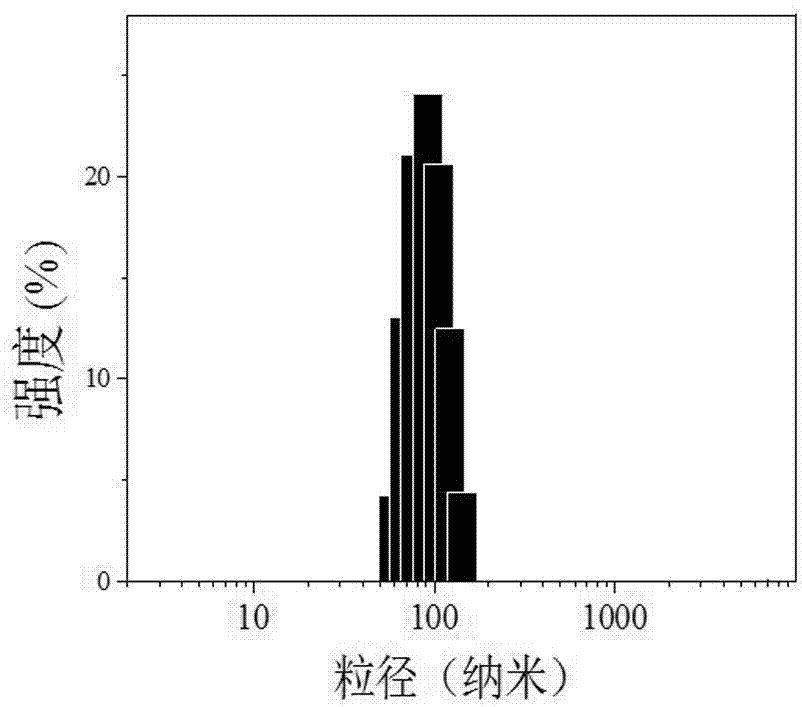

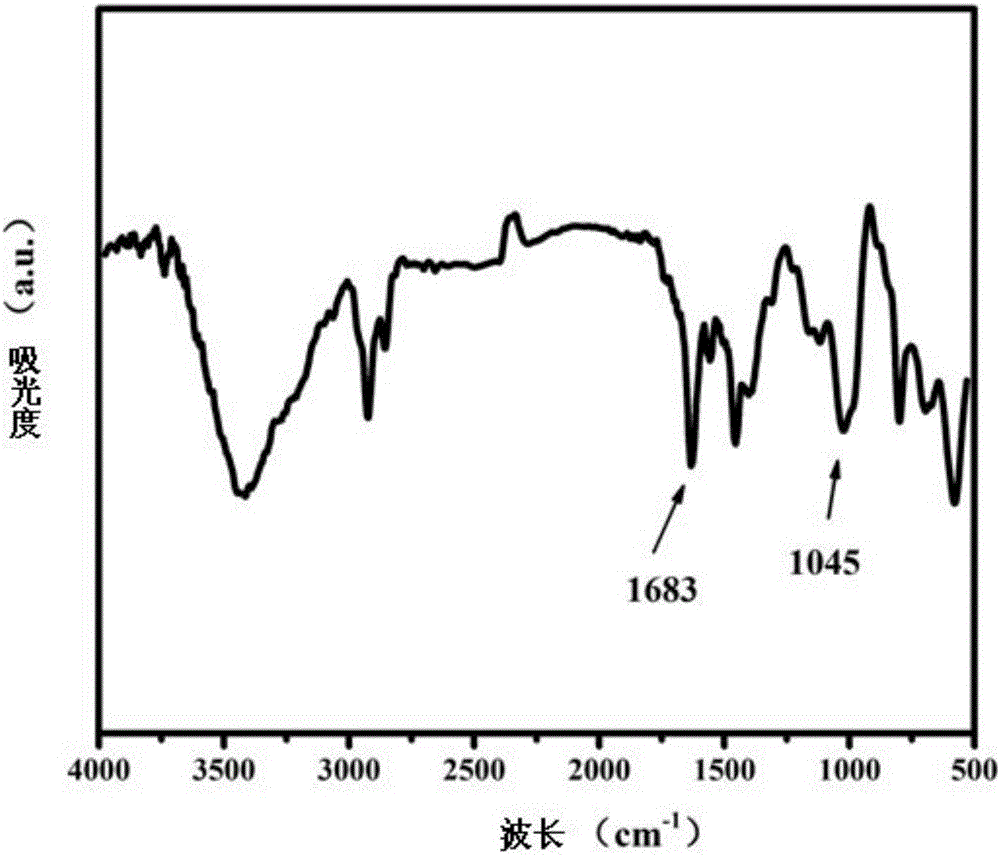

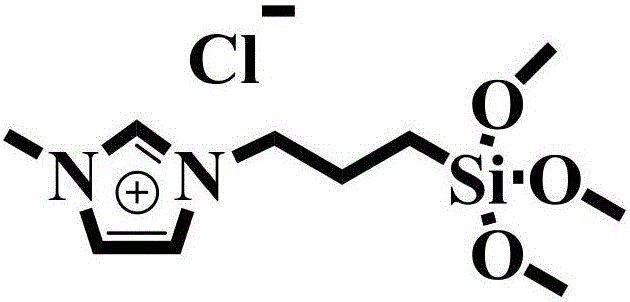

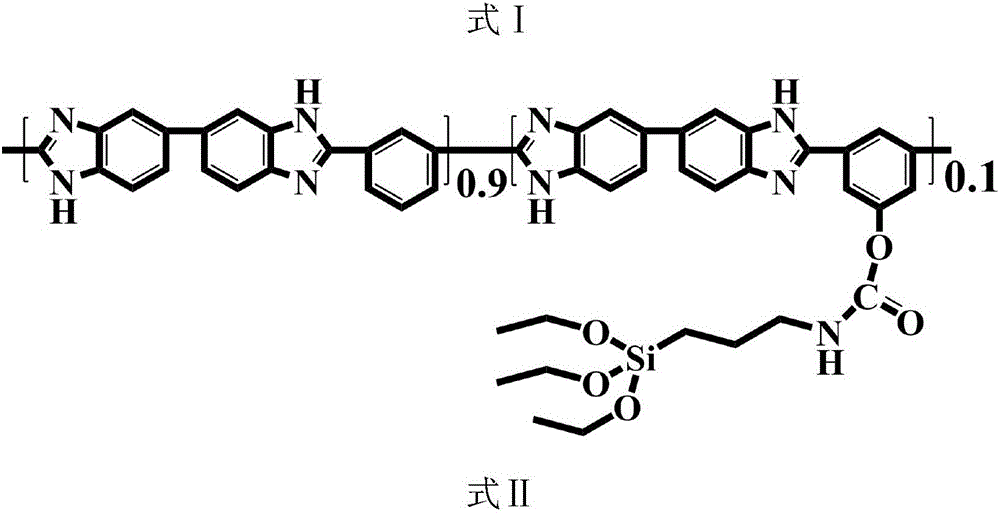

ActiveCN106684414AImprove proton conductivityImprove intake capacityFuel cellsStructural formulaProton exchange membrane fuel cell

The invention provides an organic-inorganic composite type high-temperature proton exchange membrane used for a fuel cell and a preparation method for the proton exchange membrane, and belongs to the field of high polymer chemistry and high-temperature proton exchange membrane fuel cells. The proton exchange membrane is prepared from the following components based on weight percentages: 3-12% of ionic liquid functionalized silicon dioxide precursor and 88-97% of siloxane side base-containing polybenzimidazole; and the structural formulas of the ionic liquid functionalized silicon dioxide precursor and the siloxane side base-containing polybenzimidazole are as shown in the formulas I and II as follows respectively. The invention also provides the preparation method for the organic-inorganic composite type high-temperature proton exchange membrane used for the fuel cell. The proton conductivity of the organic-inorganic composite type high-temperature proton exchange membrane at a temperature of 170 DEG C is 0.050-0.075S / cm; and the thickness of the organic-inorganic composite type high-temperature proton exchange membrane is 30-50[mu[m.

Owner:CHANGCHUN UNIV OF TECH

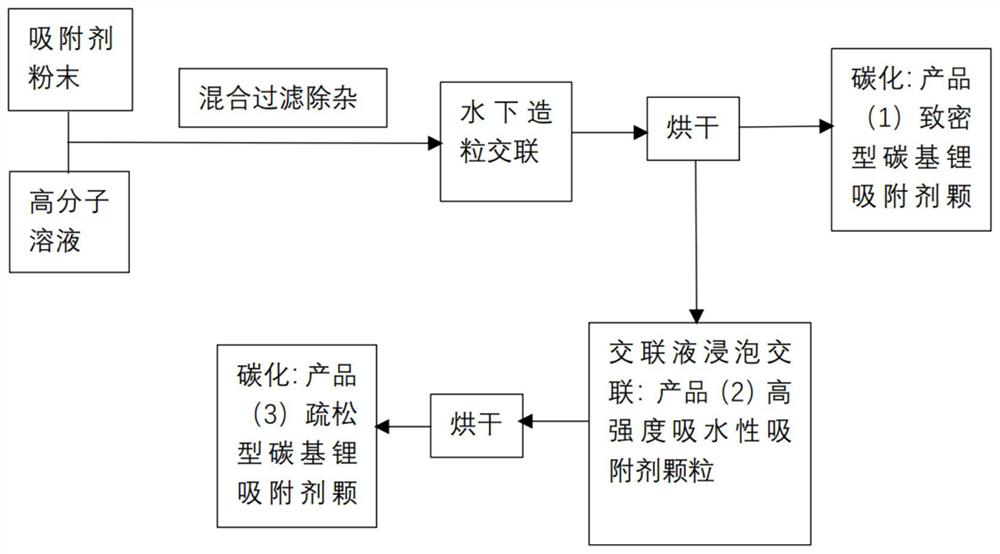

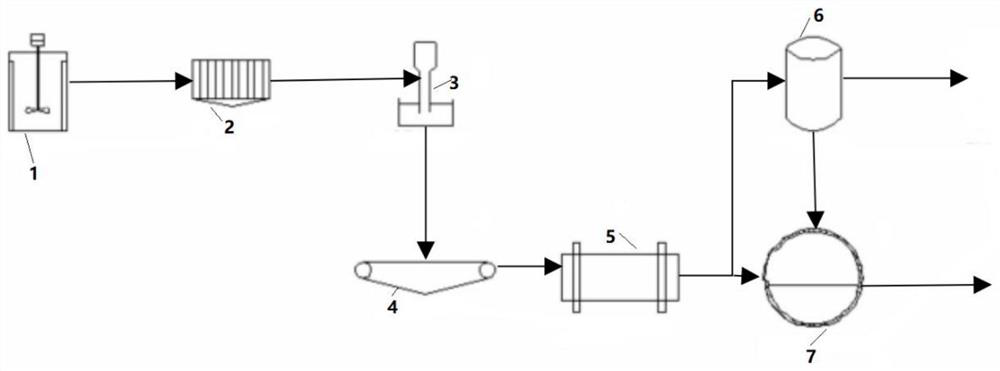

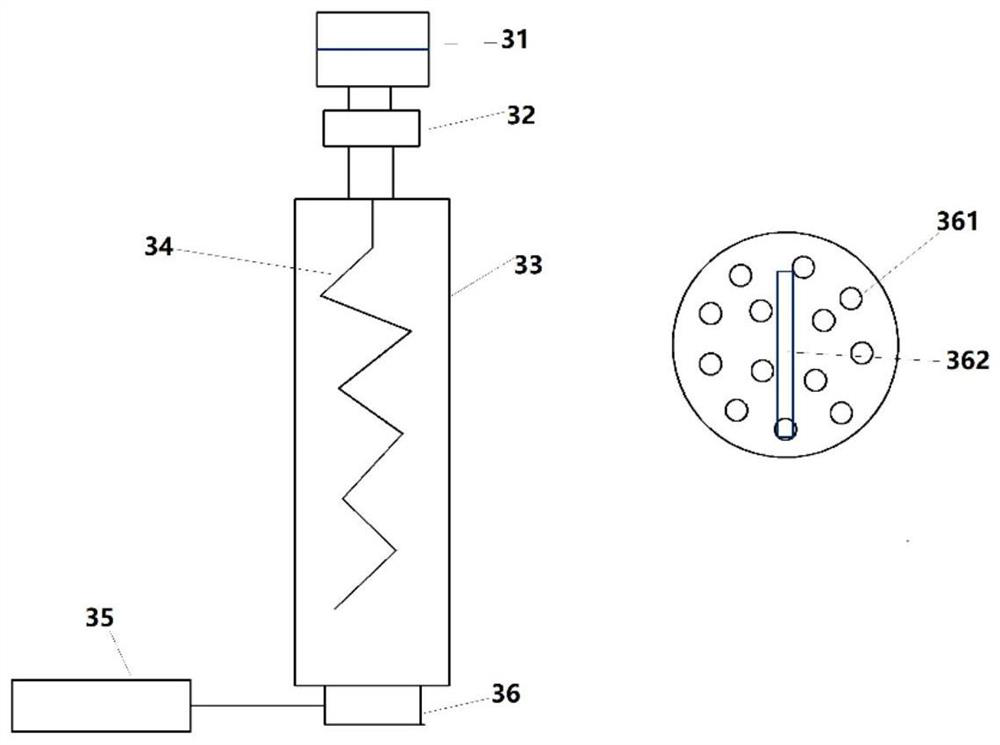

Carbon-based adsorbent particle for liquid lithium resource extraction, preparation method and preparation device

ActiveCN113842877APrepare large loadsHigh strengthOther chemical processesProcess efficiency improvementAdhesiveSorbent

The invention discloses a carbon-based lithium adsorbent particle for liquid lithium resource extraction. No adhesive needs to be added in the forming process of the adsorbent particles, and carbon has a fixing effect on adsorbent powder; the size is stable, and swelling is avoided in long-term use in strong acid, strong alkali and water; strong acid resistance and strong alkali resistance are achieved, and lithium adsorption under the alkaline condition and desorption operation under the acidic condition can be met; the carbon-based particles have pore structures and can exchange with a solution in the adsorption and desorption process, so that the efficiency is improved. Another purpose of the invention is to provide a preparation method of carbon-based adsorbent particles extracted from liquid lithium resources, and the preparation method comprises the following steps: carrying out extrusion granulation on water-absorbent resin, preparing high-strength water-absorbent particles by using a secondary cross-linking process, and carbonizing the high-strength water-absorbent particles to prepare carbon-based adsorbent particles; the invention also aims to provide a preparation device of the carbon-based adsorbent particles for extracting the liquid lithium resource. The preparation device has the advantages that one set of equipment can be used for producing various products, continuous production can be realized, and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

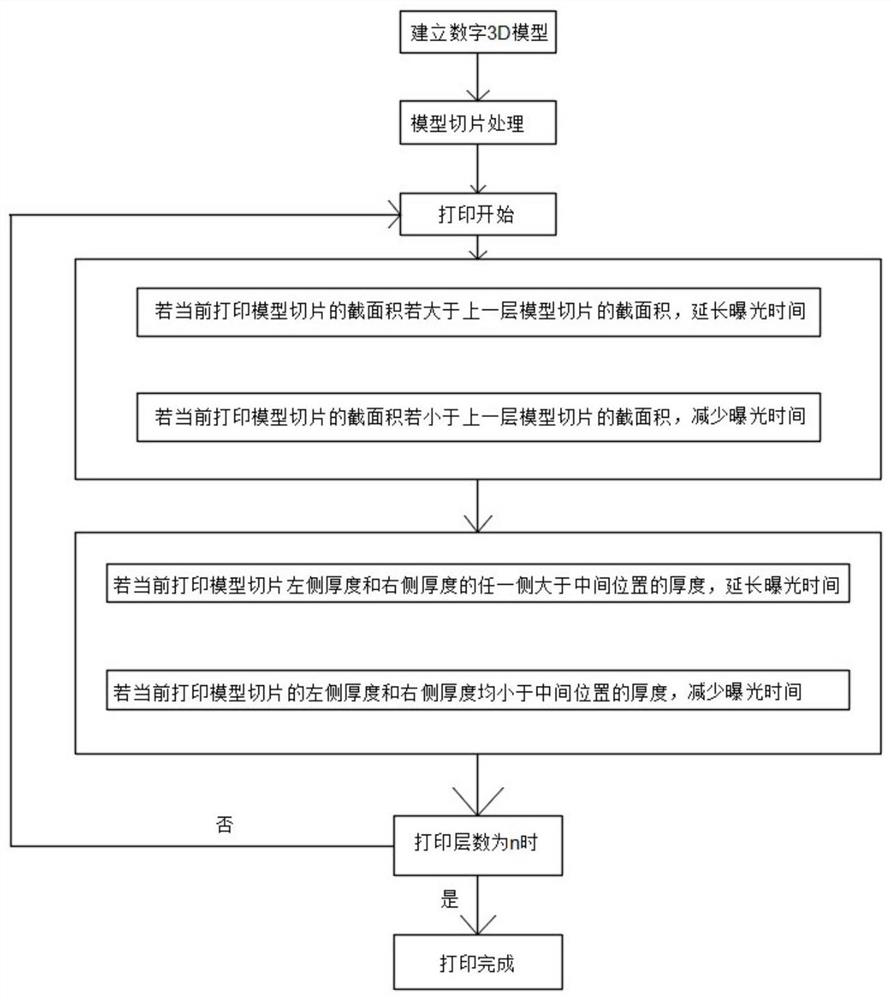

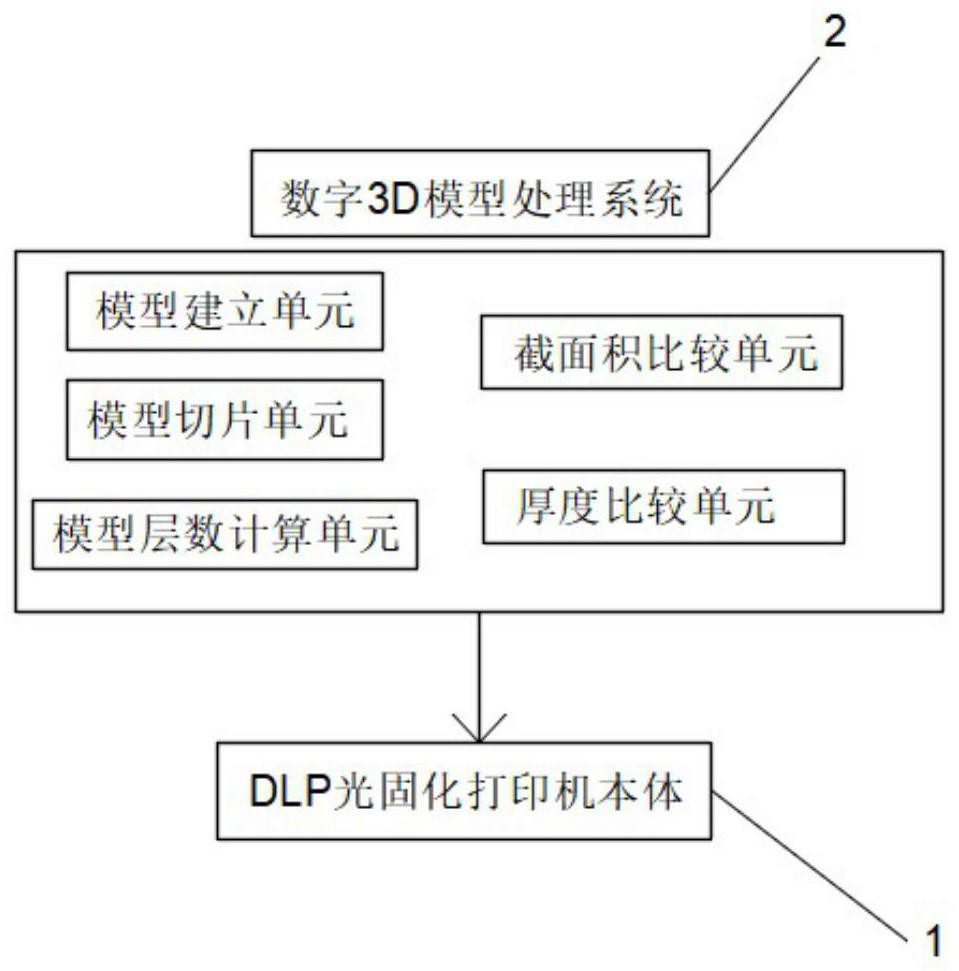

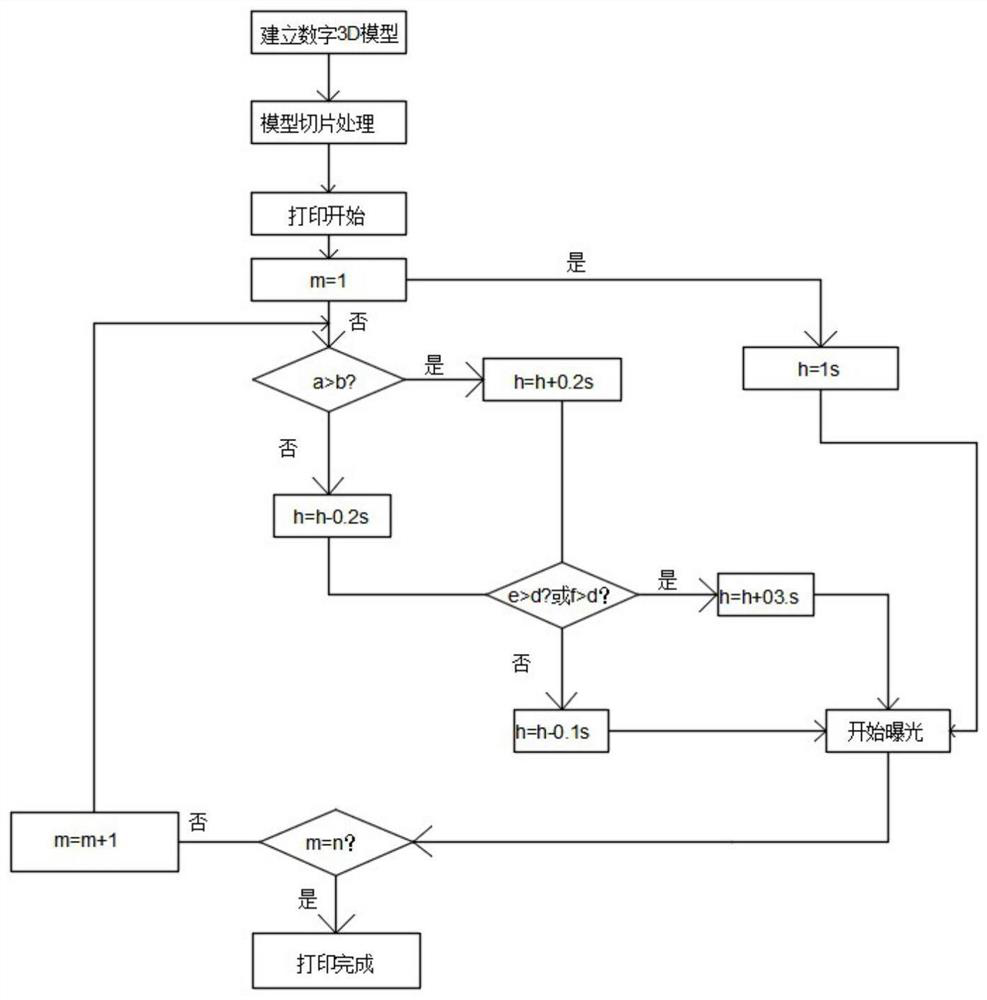

Printing method and system of DLP photocuring printer

InactiveCN112440471AShorten exposure timeReduce printing timeAdditive manufacturing apparatus3D object support structuresSlicingEngineering

The invention discloses a printing method of a DLP photocuring printer. The printing method comprises the following steps that 1, a digital 3D model of a to-be-printed object is established; 2, the digital 3D model is subjected to slicing treatment, and multiple layers of model slices are obtained, wherein the number of the model slices is n; and 3, printing is started from the bottom end to the top end of the digital 3D model from the first layer according to the model slices, wherein the number of the current printing layers is m, the exposure time is h, and h is 1s. According to the printing method, through a digital 3D model processing system, during specific using, the sectional area of the current printing model slice and the sectional area of the upper layer of model slice can be compared through a sectional area comparison unit in the digital 3D model processing system, if the sectional area of the current printing model slice is smaller than the sectional area of the upper layer of model slice, the cross-linked structure of the two layers of slices is relatively stable, thus, the exposure time can be properly shortened, the printing time of a complex model is greatly shortened, and the printing efficiency is improved.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

A kind of preparation method of shape memory polyurethane

Owner:SHENZHEN UNIV

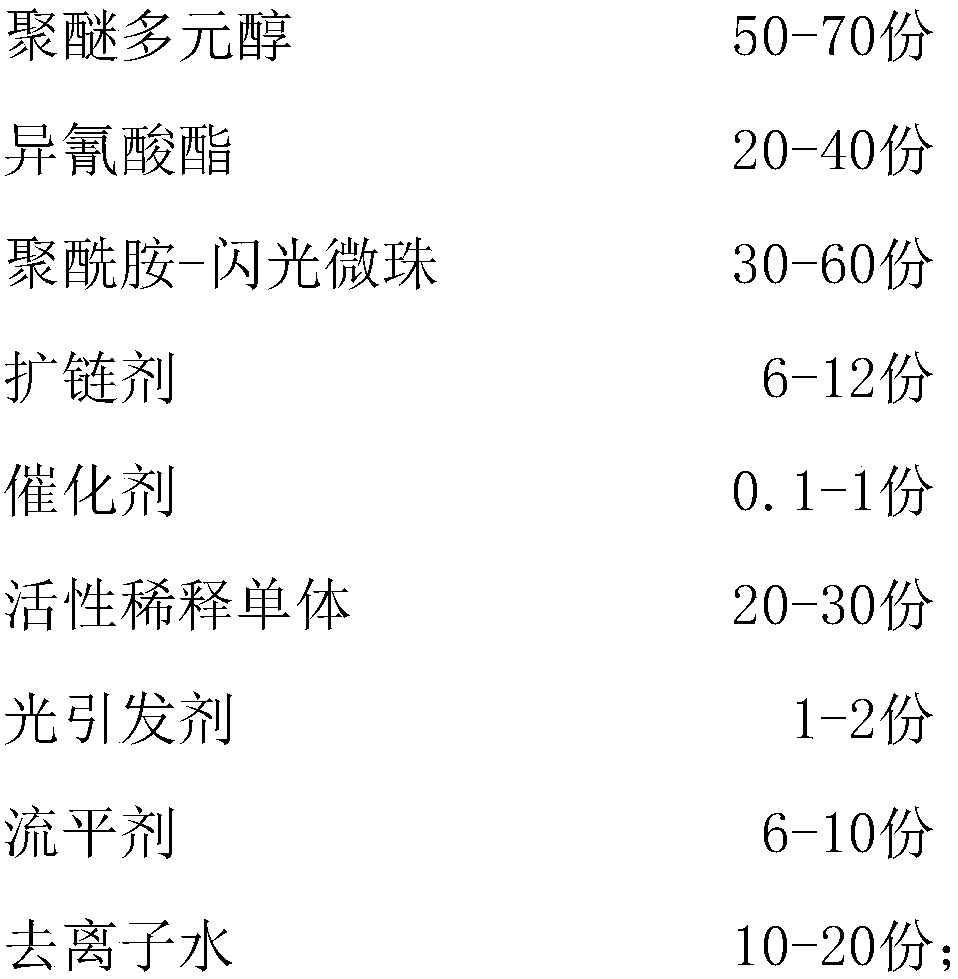

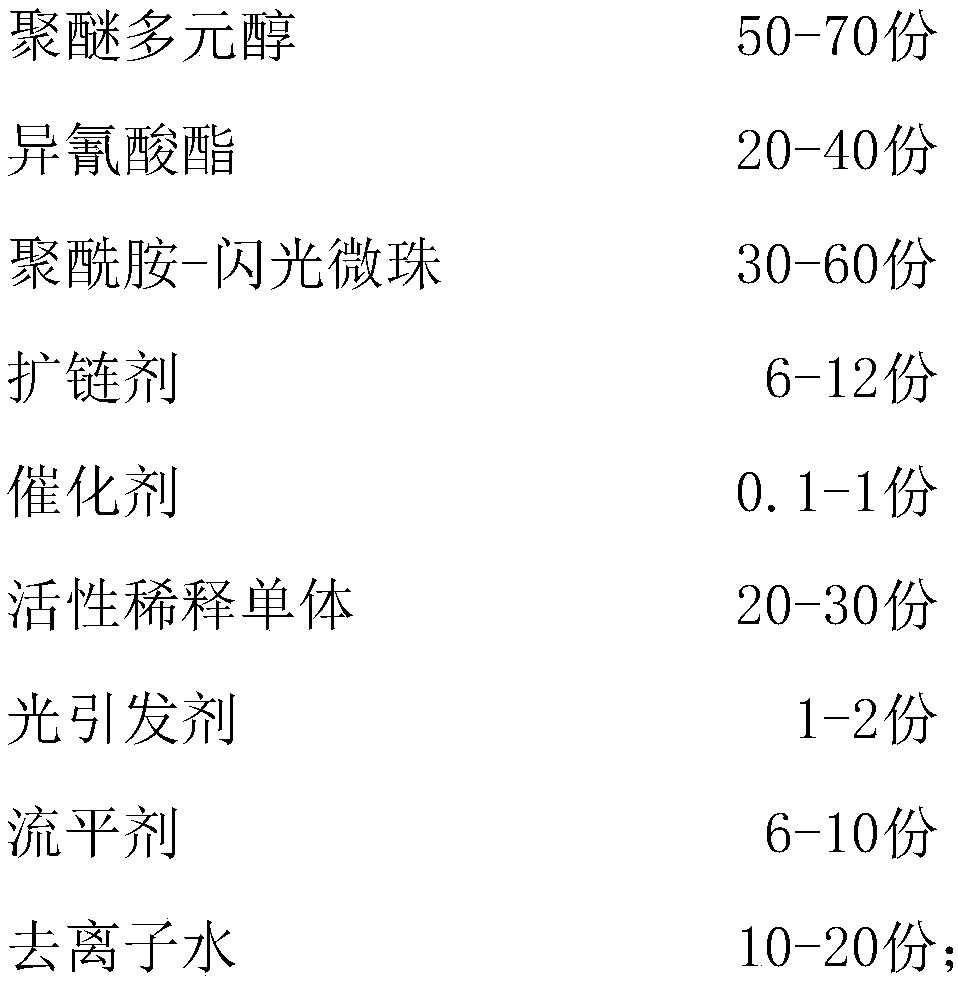

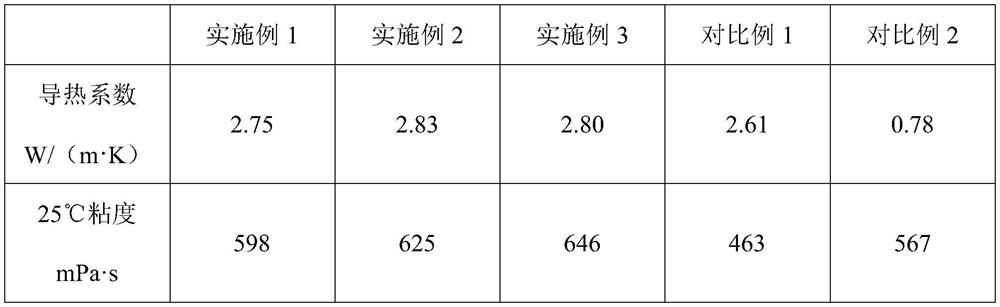

Polyurethane flash waterproof paint for zippers and preparation method of polyurethane flash waterproof paint

ActiveCN108977040ALow impact of flash effectImprove suspension stabilityPolyurea/polyurethane coatingsPolyamide coatingsCross-linkPolyamide

The invention relates to the technical field of waterproof paint for zippers and in particular relates to polyurethane flash waterproof paint for zippers and a preparation method of the polyurethane flash waterproof paint. The waterproof paint comprises polyether polyol, isocyanate, polyamide-flash beads, a chain extender, a catalyst, an active diluent monomer, a photoinitiator, a flatting agent and deionized water, wherein the polyamide-flash beads are composed of flash beads and a polyamide layer coating the flash beads. According to the waterproof paint disclosed by the invention, the flashbeads are coated by adopting the polyamide, so that the flash beads are uniformly dispersed in deionized water. The polyamide layer has many hydroxide radicals and can perform cross-linking polymerization with isocyanate, carbon-carbon double bonds in the polyamide layer can also carry out a polymerization reaction with the active diluent monomer, so that the stability of the polyamide-flash beads in the paint is improved. The coating can achieve excellent waterproof property and mechanical property, and the ornamental value is high.

Owner:东莞市瑞翔新型材料科技有限公司

Waste molasses-based high-strength environment-friendly formaldehyde-free adhesive as well as preparation method and application thereof

ActiveCN114133913AHigh bonding strengthImprove thermal stabilityNon-macromolecular adhesive additivesProtein adhesivesFiberAdhesive

The invention discloses a waste molasses-based high-strength environment-friendly formaldehyde-free adhesive as well as a preparation method and application thereof. The waste molasses / wheat gluten protein composite material is prepared from the following raw materials in parts by weight: 80 to 100 parts of waste molasses, 40 to 60 parts of wheat gluten protein, 4 to 5 parts of carbon nanotubes, 10 to 15 parts of graphene fibers, 5 to 10 parts of silicon dioxide microspheres, 5 to 10 parts of a KH560 silane coupling agent, 3 to 4 parts of sodium sulfite, 2 to 3 parts of polyacrylamide, 0.05 to 2 parts of phosphoric acid and 40 to 50 parts of water. A hydrolysis product reacts with wheat gluten protein under the action of a KH560 silane coupling agent to generate a high-molecular polymer, so that a cross-linked structure is more compact and stable, an adhesive formed after curing has good bonding strength and thermal stability, and carbon nanotubes and graphene fibers are added into the adhesive, so that the adhesive has good bonding strength and thermal stability. The defect of poor heat conductivity of a traditional adhesive is overcome, the thermocuring rate is increased, and the bonding strength is further improved.

Owner:NANJING FORESTRY UNIV

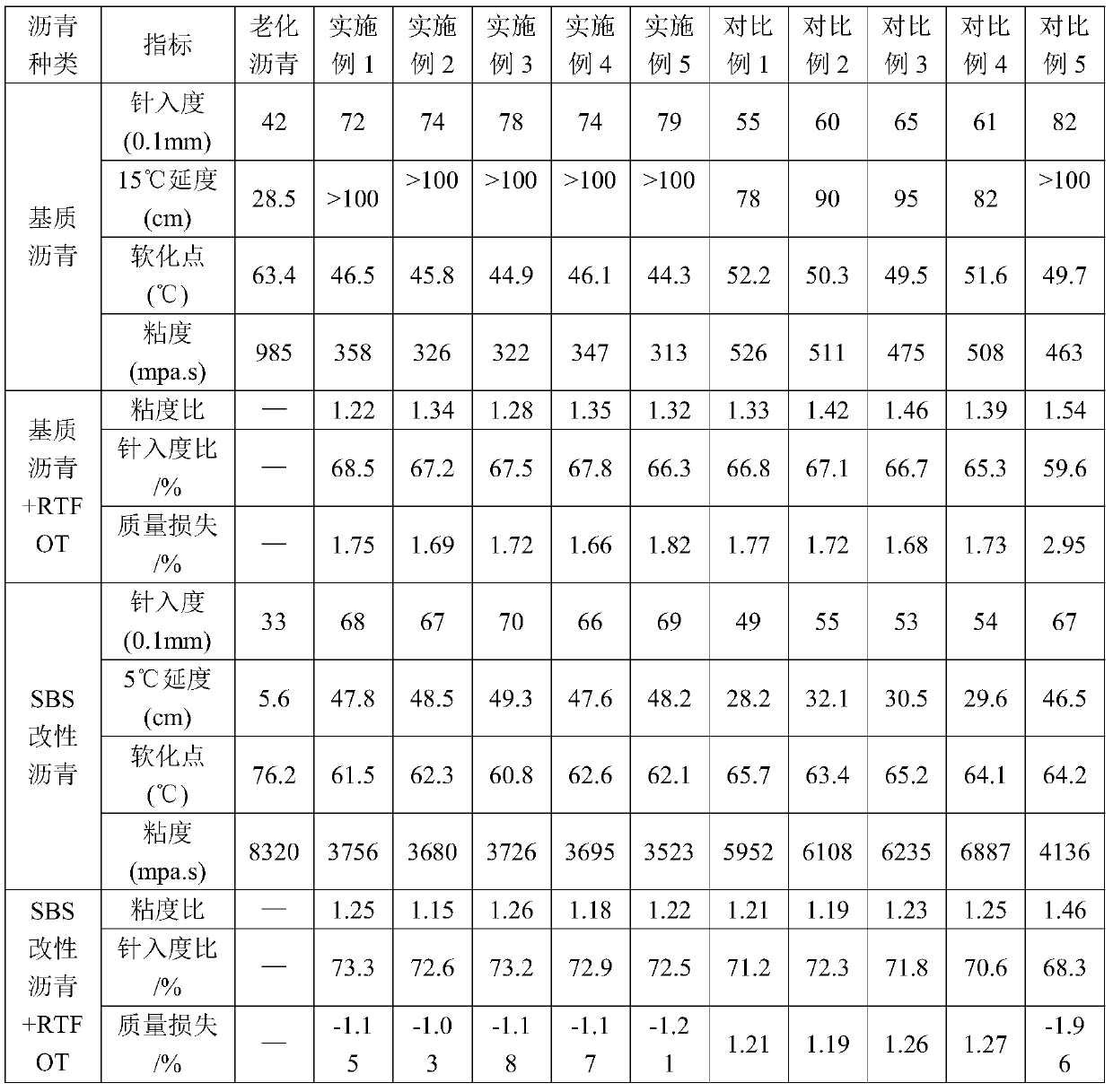

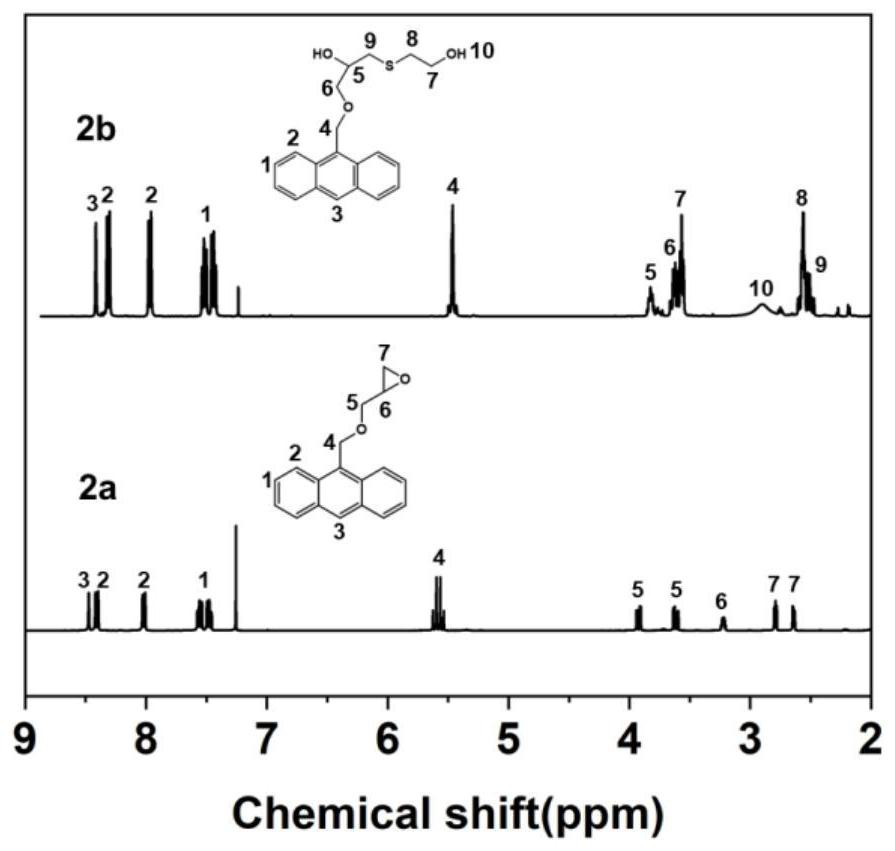

High-performance asphalt pavement regenerant and preparation method thereof

ActiveCN111410848AImproved thermal stabilityImprove long-term aging performanceBuilding insulationsChemistryProcess engineering

The invention provides a high-performance asphalt pavement regenerant and a preparation method thereof. The high-performance asphalt pavement regenerant is prepared from, by weight, 60-70 parts of anactivating component, 5-10 parts of a permeating component, 10-15 parts of a plasticizing component, 8-15 parts of a modifying component and 3-6 parts of an anti-aging component, and the sum of the weight parts of the raw materials is 100 parts. According to the invention, the synergistic combination of thermal stability substances is used as an activating component to replace the traditional aromatic hydrocarbon oil activating component, so that the thermal stability of the regenerant can be greatly improved, and the long-term aging performance of the regenerated mixture can be improved. Theselected surfactant enables the asphaltene association structure to be deassociated, and dissolution and dispersion of asphaltene are promoted. The preparation process is simple, raw materials are wide in source, starting from the asphalt aging mechanism, activation and performance blending of aging components are considered, and the prepared regenerant is excellent in pavement performance and wide in application prospect.

Owner:山西省高速公路集团有限责任公司

Toughened epoxy adhesive capable of being reprocessed and recycled and curing method

ActiveCN110982464AAchieve fixRealize reprocessing recyclingMacromolecular adhesive additivesEpoxy resin adhesivesEndcappingPolymer science

The invention relates to a toughened epoxy adhesive capable of being reprocessed and recycled and a curing method. The toughened epoxy adhesive capable of being reprocessed and recycled comprises thefollowing raw material components in parts by mass: 100 parts of epoxy resin, 15-35 parts of diaminodiphenyl disulfide serving as a curing agent and 20-70 parts of aromatic amino-terminated polysulfide resin serving as a toughening agent, wherein the raw material of the toughening agent aromatic amino terminated polysulfide resin comprises the following components in parts by mass: 100 parts of sulfydryl terminated liquid polysulfide resin, 6-25 parts of diaminodiphenyl disulfide, 0.1 part of tertiary amine, 5 parts of hydrogen peroxide and 150 parts of methane dioxide as a solvent; the curingagent and the toughening agent both contain the same reversible covalent bond, so that the dynamic reversibility of the whole cross-linked structure is realized, the screenwork rearrangement is initiated to enable the epoxy adhesive to have reprocessability and recoverability, and the main performance retention rate after three cycles exceeds 90%; and the problems of environmental pollution and resource waste caused by waste high polymer materials can be effectively relieved.

Owner:NANJING INST OF TECH

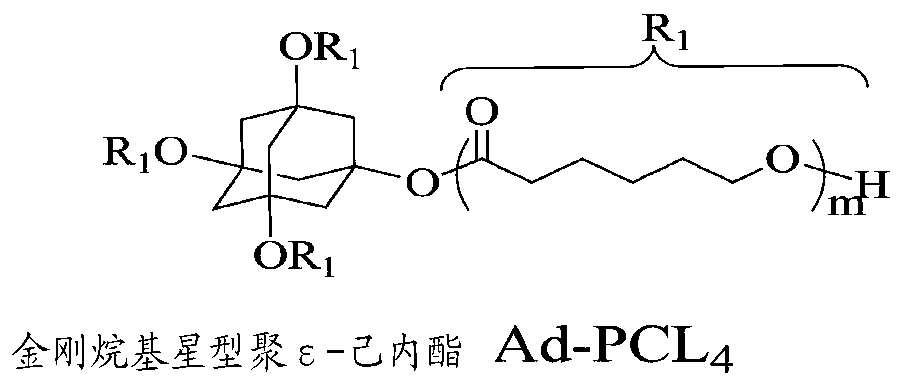

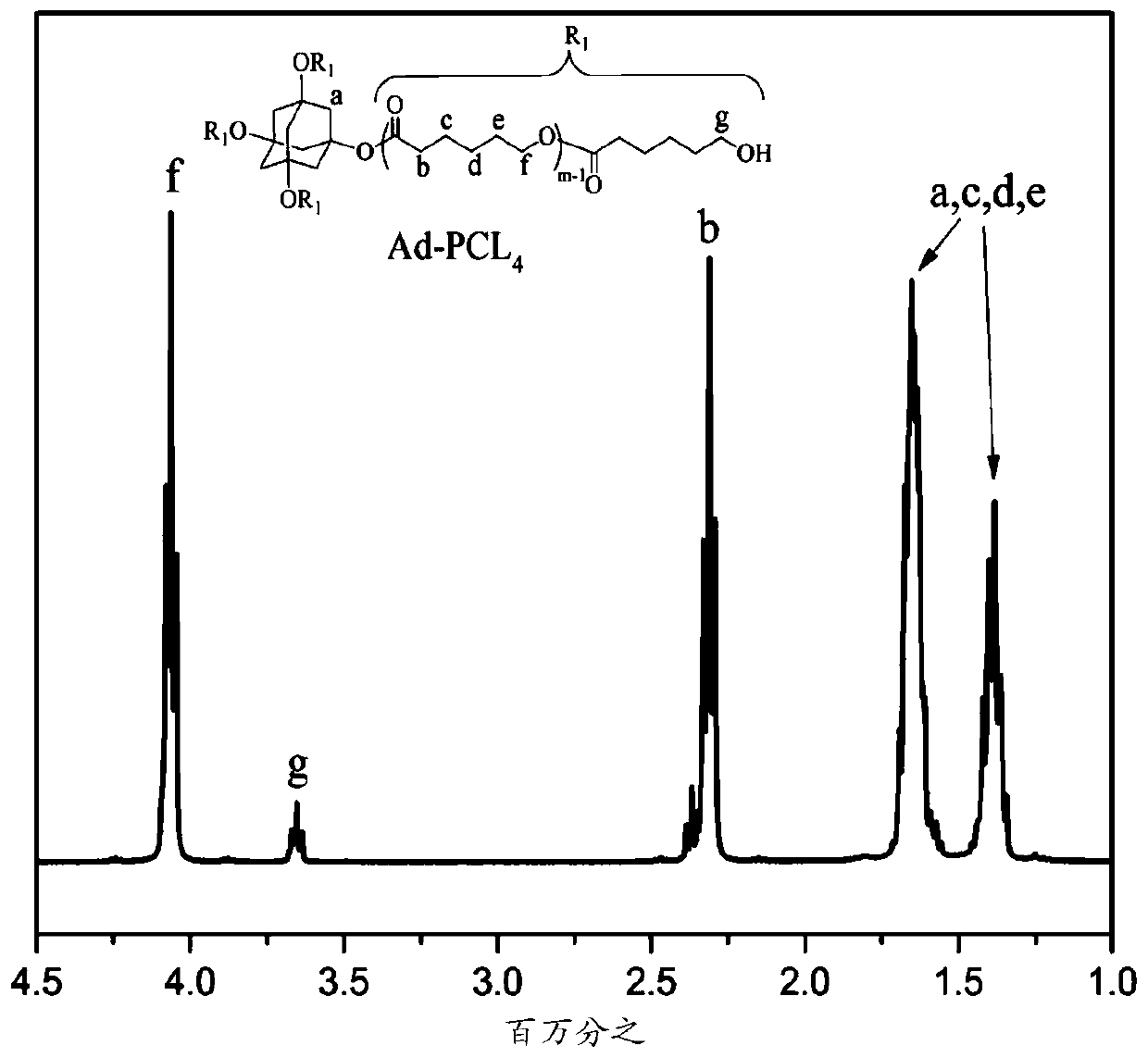

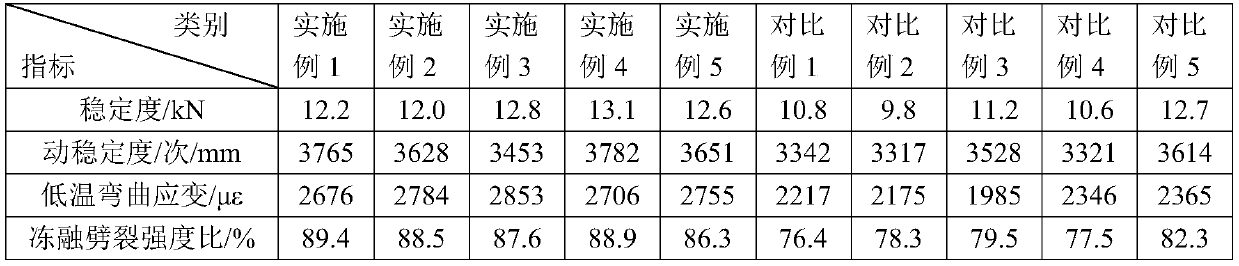

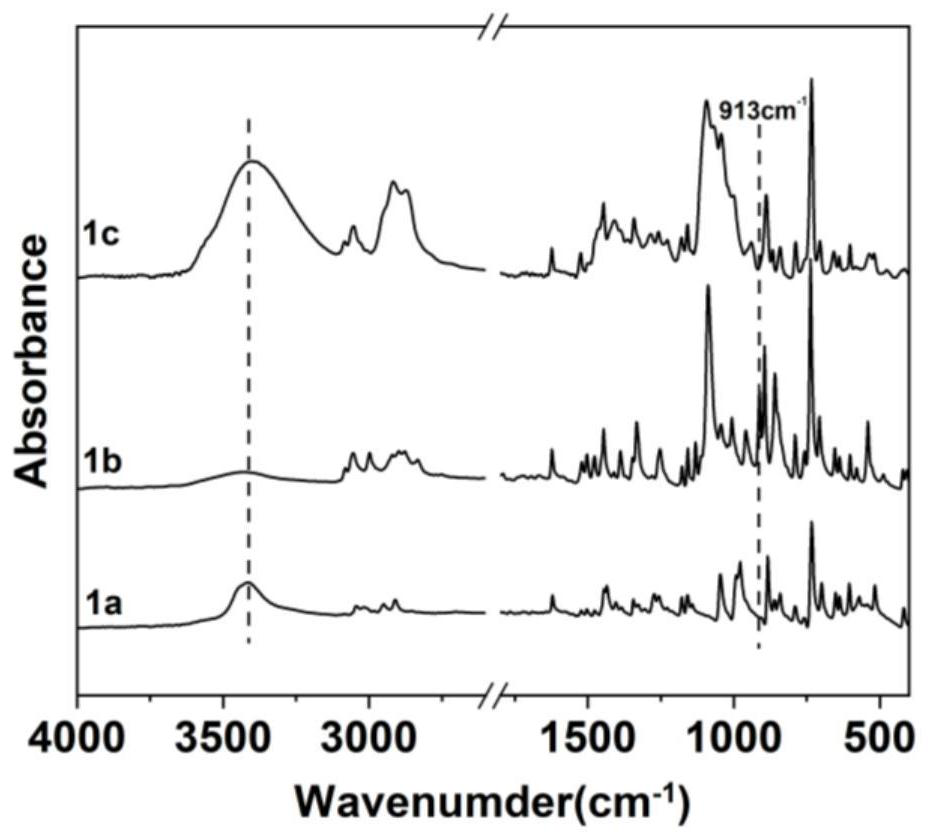

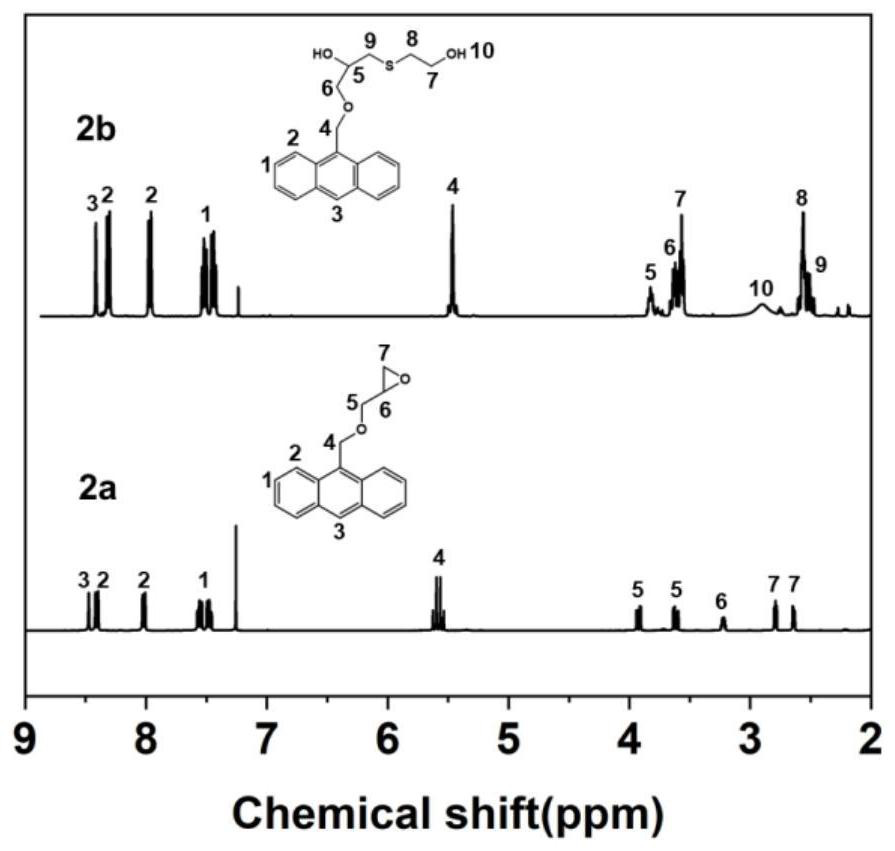

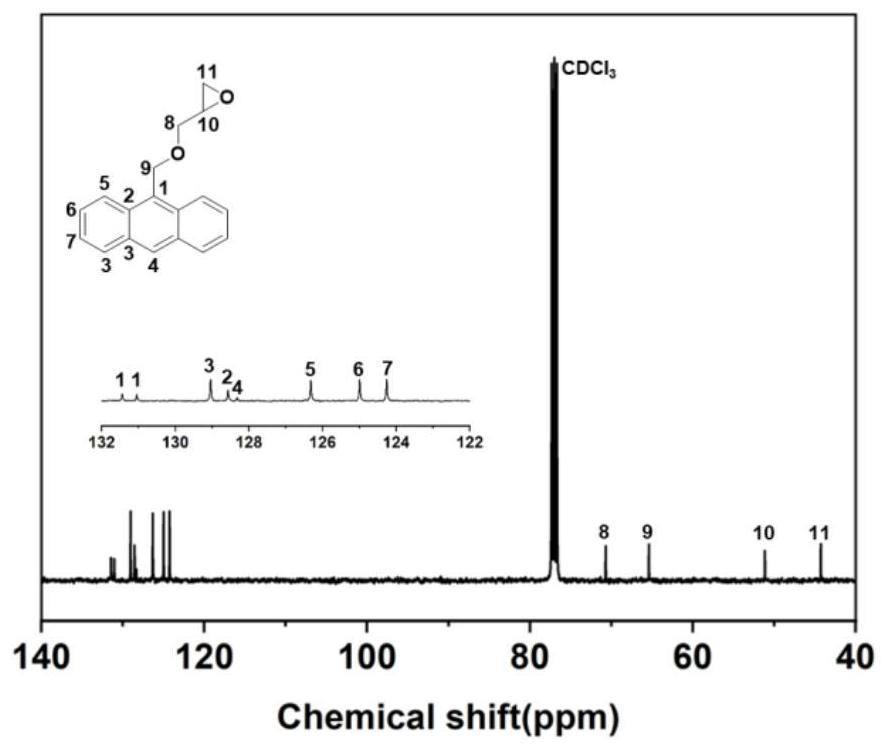

High-strength photoreversible adhesive, and preparation method and application thereof

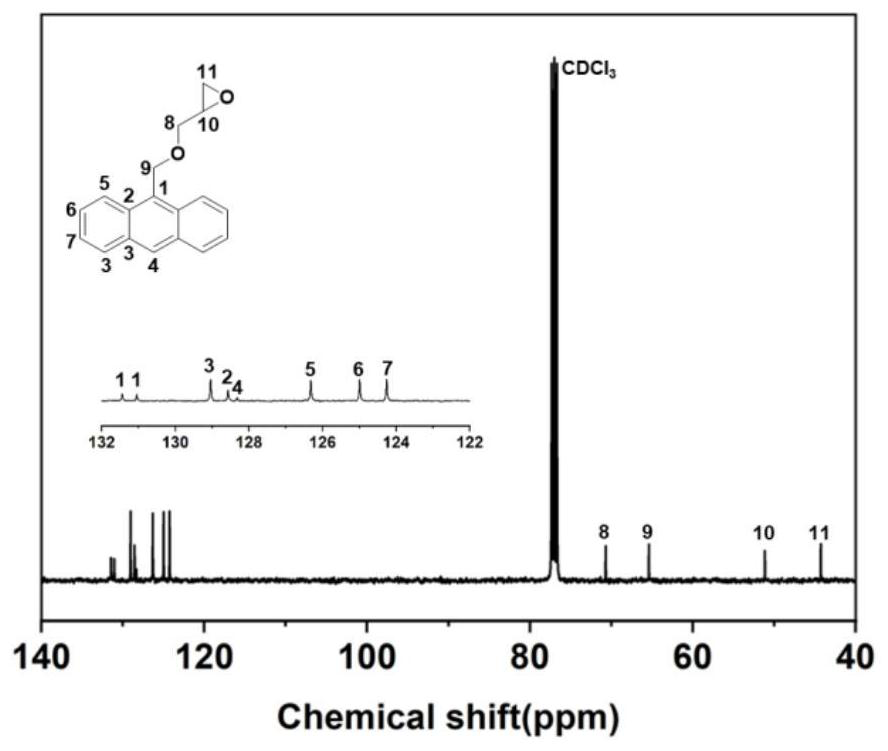

ActiveCN113337238AHigh reactivityEasy to operatePolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention discloses a high-strength photoreversible adhesive, and a preparation method and application thereof. The preparation method comprises the following steps: epoxidizing an anthryl-containing compound raw material to prepare an anthracene-containing epoxidized product, mixing the anthracene-containing epoxidized product with a mercapto-terminated alcohol compound and an accelerant, and carrying out ring opening at room temperature to prepare a double-end hydroxyl compound containing an anthryl side chain; adopting a double-end isocyanate group compound and double-end hydroxyl polycaprolactone, adding an organic tin catalyst, and carrying out a chain extension reaction to form a chain-extended double-end isocyanate group compound with relatively large molecular weight; and finally, reacting the chain-extended double-end isocyanate group compound with the double-end hydroxyl compound containing the anthryl side chain and a double-end hydroxyl compound without an anthryl side chain, and adding the organic tin catalyst for catalytic reaction to obtain the high-strength photoreversible adhesive. The adhesive disclosed by the invention is subjected to [4+4] cycloaddition reaction under irradiation of 350-405 nm ultraviolet light, and is cured; and the adhesive is decrosslinked under the irradiation of ultraviolet light with the wavelength of less than 300 nm.

Owner:BEIJING UNIV OF CHEM TECH

Mildew-proof wear-resistant environment-friendly PVC artificial leather and preparation method thereof

PendingCN112721364AEnhanced scratch resistanceImprove flame retardant performanceSynthetic resin layered productsFlat articlesElastomerPolymer science

The invention relates to mildew-proof wear-resistant environment-friendly PVC artificial leather and a preparation method thereof. The PVC artificial leather comprises a base cloth layer and a PVC surface layer attached to the base cloth layer. The PVC surface layer is prepared from the following raw materials in parts by weight: 100 parts of PVC resin, 20-30 parts of a functional elastomer, 50-70 parts of a plasticizer, 12-20 parts of coconut shell powder modified vermiculite powder, 4-12 parts of a cross-linking agent, 1-5 parts of a heat stabilizer, 1-3 parts of an antibacterial agent and 0.2-4 parts of a foaming agent. Compared with the prior art, the PVC artificial leather disclosed by the invention does not contain any volatile solvent, is good in environmental protection property, smooth in hand feeling, strong in stereoscopic impression and high in glossiness quality, has excellent mould-proof, antibacterial and wear-resistant scratching properties, is plump in hand feeling like real leather, has physical properties reaching test standards, and is long in service life; the problems that existing PVC leather is prone to aging, mildewing, peeling and the like can be effectively solved, and high economic practicability is achieved.

Owner:嘉兴市博尔新材料股份有限公司

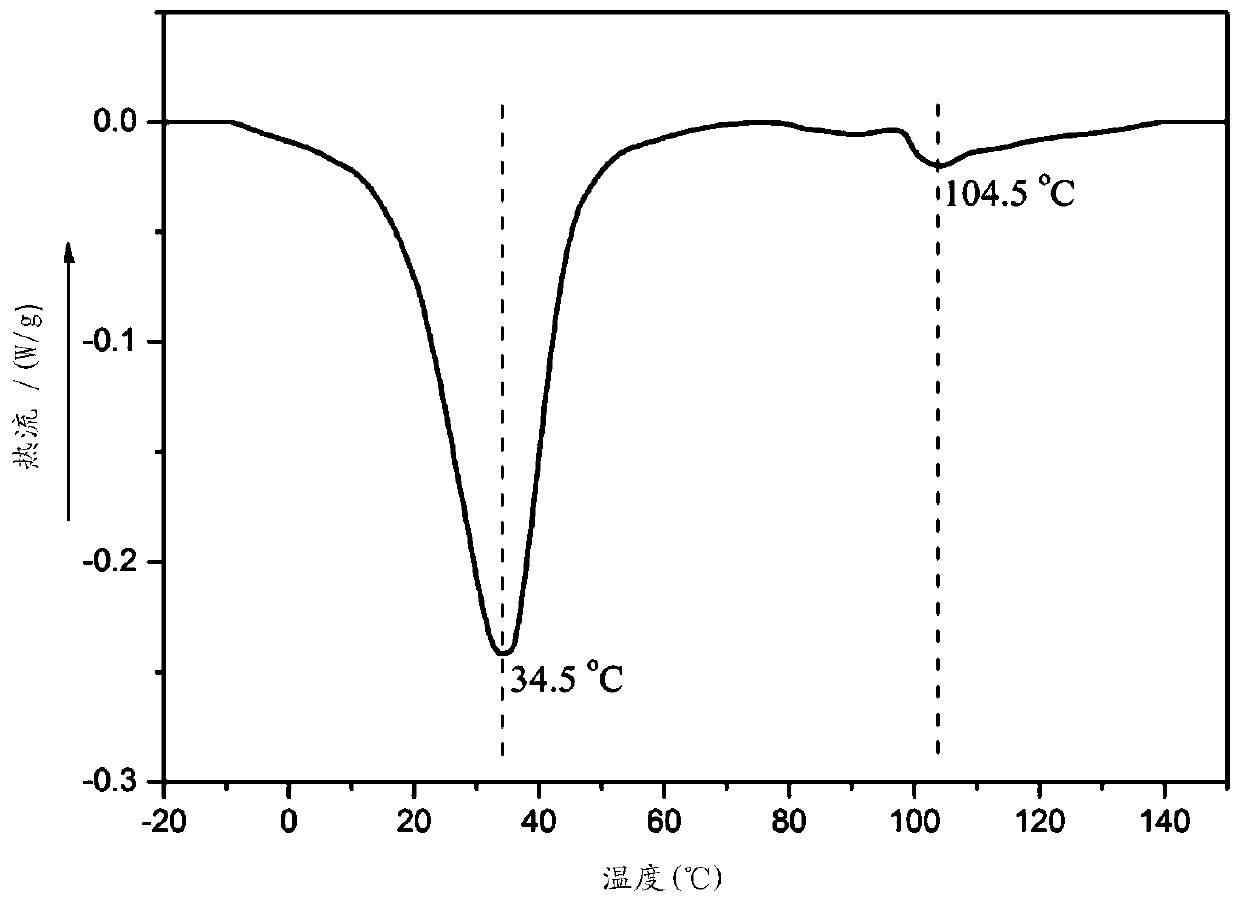

Preparation method of fibroin/temperature-sensitive cellulose fabric

ActiveCN112482034AHas a warming effectStable cross-linked structureFibre typesPolymer scienceOxidised cellulose

The invention provides a preparation method of fibroin / temperature-sensitive cellulose fabric. The preparation method comprises the following steps: S1, preparing oxidized cellulose; S2, preparing a fibroin aqueous solution; S3, preparing fibroin / cellulose composite porous microspheres; S4, preparing a phase change material; S5, preparing a composite phase change material; and S6, preparing the temperature-sensitive fabric. According to the fibroin / temperature-sensitive cellulose fabric provided by the invention, fibroin / cellulose microspheres loaded with a phase-change material are finished on the fabric, so that the temperature of the fabric is intelligently controlled under a certain temperature condition.

Owner:吴江市腾旭纺织厂

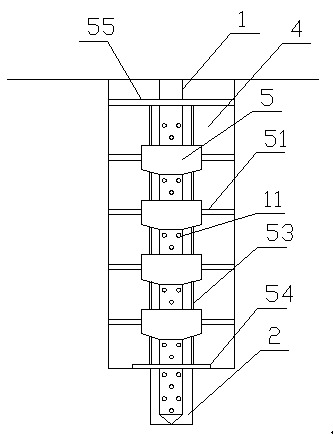

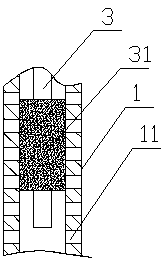

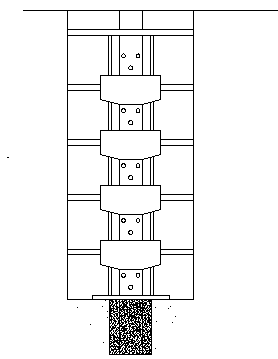

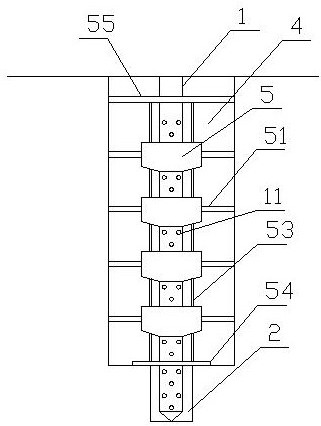

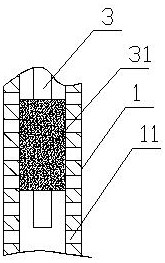

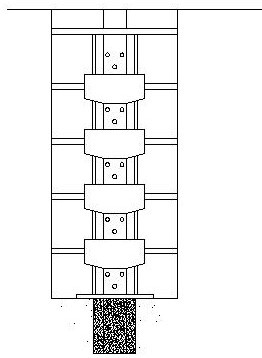

Foundation strengthening method

ActiveCN110904955AHigh strengthIncreased diffusion radiusBulkheads/pilesArchitectural engineeringStructural engineering

The invention relates to a foundation strengthening method. The foundation strengthening method comprises the following steps that firstly, foundation hole drilling is conducted, the lower end of a floral tube is inserted in a foundation hole, and the lower section of the foundation hole is filled with coarse sand to be compacted, wherein a plurality of holes are evenly distributed in the tube wall of the floral tube; secondly, a water glass solution and cement paste are injected into the bottom of the floral tube through a first inner casing pipe, and the bottom end of the floral tube is cured in the foundation hole; thirdly, chambering is conducted on the upper portion of the foundation hole, an expanding hole is formed, and then grouting discs sequentially sleeve the part, located at the expanding hole, of the floral tube at equal intervals; fourthly, the expanding hole is filled with coarse sand; fifthly, a second inner casing pipe is used for sequentially pumping the high-pressurewater glass solution into various grouting discs, the water glass solution is outwards scoured and diffused through a grouting pipe, and then the second inner casing pipe is pulled out; and sixthly,the cement paste is injected into the floral tube, part of the cement paste is outwards diffused through the grouting pipe and makes contact with the water glass solution, the other part directly enters the coarse sand in the expanding hole through the holes in the floral tube, and work is finished after cement paste liquid curing.

Owner:淮安市建筑设计研究院有限公司

A ground reinforcement method

ActiveCN110904955BHigh strengthIncreased diffusion radiusBulkheads/pilesArchitectural engineeringStructural engineering

The invention relates to a foundation reinforcement method, comprising the following steps: (1) Drilling a foundation hole, inserting the lower end of a flower tube with several holes evenly distributed on the pipe wall into the foundation hole, filling the lower part of the foundation hole with coarse sand and then compacting it; (2) ) Inject water glass solution and cement slurry into the bottom of the flower tube through the first inner sleeve, and wait for the bottom of the flower tube to solidify in the foundation hole; (3) Ream the upper part of the foundation hole to form an enlarged hole, and then inject The grout discs are set equidistantly and sequentially on the part of the flower tube located in the enlarged hole; (4) Fill the enlarged hole with coarse sand; (5) Pump the high-pressure water glass solution into each grouting disc sequentially through the second inner casing , the water glass solution scours and diffuses outward through the grouting pipe, and then pulls out the second inner sleeve; (6) Inject cement slurry into the floral tube, part of the cement slurry diffuses outward through the grouting pipe to contact the water glass solution, and the other part Directly enter the coarse sand in the enlarged hole through the hole on the flower tube, and the work is completed after the cement slurry solidifies.

Owner:淮安市建筑设计研究院有限公司

Preparation method of crosslinked nanomedicine based on active reaction one-step method

ActiveCN107096038BEasy to makeAvoid the problem of non-crosslinkingOrganic active ingredientsPharmaceutical non-active ingredientsStage melanomaPtru catalyst

The invention discloses a method for preparing a cross-linked nano-medicine based on an active-response one-step method, which specifically includes the following steps: after adding a polymer and a drug with a sulfhydryl group into a solution and mixing them, dialyzing to obtain a cross-linked nano-medicine; the polymer The side chain contains a dithiolane structure. The present invention can obtain nano-medicines with stable circulation through simple preparation, which solves the defects of complex preparation of chemically bonded nano-medicines and the need for catalysts in the prior art; moreover, the products prepared by the present invention have a stable cross-linked structure, avoiding the existing chemical bond The problem of non-crosslinking of composite nanodrugs; on the B16F10 melanoma-bearing model, it showed good therapeutic effect, and the tumor inhibition rate exceeded 90%, indicating that the active targeting crosslinking nanodrug has great potential application in cancer chemotherapy .

Owner:SUZHOU UNIV

Method for preparing weak excitation photochromism WO3 powder by utilizing n-propanol hybridization

InactiveCN100587023CStable cross-linked structureEasy compoundTenebresent compositionsLuminescent compositionsFast blueUltraviolet

The process of hybridizing n-propanol to prepare weak excitant photochromic WO3 powder includes the following steps: 1. preparing tungstate solution; 2. regulating pH of the reactant solution to 0.8-2.0; 3. adding n-propanol to the solution and homogenizing the reactant system through stirring for 2-6 hr; 4. setting the reaction system in a hydrothermal kettle for hydrothermal reaction to obtain WO3 portions; 5. washing the powder; and 6. vacuum drying in a vacuum drying oven to obtain the weak excitant photochromic WO3 powder. The hybridized powder has raised photochromic reaction activity, fast bluing under the excitation of sunlight or low power ultraviolet ray, fast discoloring in no light condition and relaxed requirement on the light source for color change.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

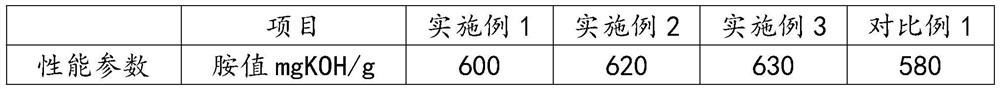

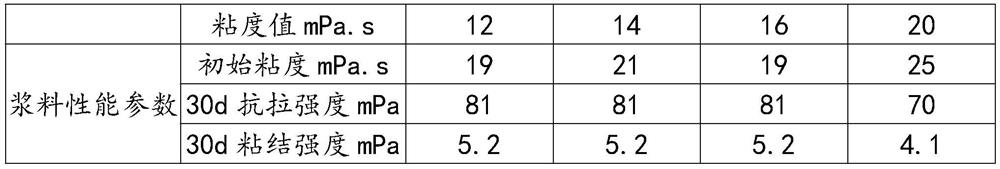

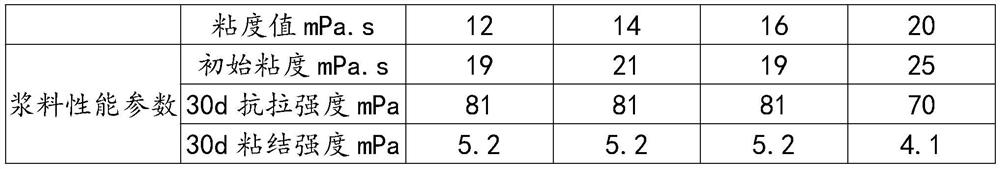

High-strength high-molecular curing agent for grouting and preparation process thereof

The invention discloses a high-strength polymer grouting curing agent and a preparation process thereof. The high-strength polymer grouting curing agent comprises the following raw materials in parts by weight: 20-30 parts of a first component, 23-25 parts of a second component, 30-40 parts of formaldehyde, 30-50 parts of melamine, 50-60 parts of deionized water and 0.1-0.3 part of span 20. The preparation process comprises the following steps: 1, preparing the first component and the second component; 2, uniformly mixing formaldehyde, melamine and deionized water to obtain a mixed solution, adjusting the pH value of the mixed solution, setting the temperature at 70-80 DEG C, and stirring for 50-60 minutes to obtain a prepolymer solution for later use; and 3, stirring the first component, the second component and Span 20 at room temperature for 5-10 minutes, adding the prepolymer solution prepared in the step 2, setting the temperature to be 60 DEG C, adjusting the pH value of the reaction solution, stirring for 2 hours, and adjusting the pH value of the system after stirring to obtain the high-strength high-molecular grouting curing agent.

Owner:潘巧珍

Macromolecular thermosensitive resistor and method for making same

InactiveCN100437840CPrevent movementSimple preparation processNon-conductive material with dispersed conductive materialPositive temperature coefficient thermistorsProcedure AgentsInsulation layer

This invention discloses a macromolecule heat sensitive resistance and its process method, whose base slice element and weight percentage as the following: polymer 30-65; conductive stuff 30-60; inorganic stuff10-40; processed assistant agent 0.2-5, wherein, the conductive stuff is nickel powder, copper powder or carbon and the inorganic stuff is metal oxidation and the processed assistant agent comprises anti-oxidant agent and the couple agent mixture with the weight proportion as 1: 1.5-2.5, wherein, the couple agent is titanium acid ester or silicon alkyl compound composed of base slice and slice electrode and the lead wire electrode welded on the electrode surface and the insulation layer covered on the outer surface.

Owner:深圳市长园维安电子有限公司

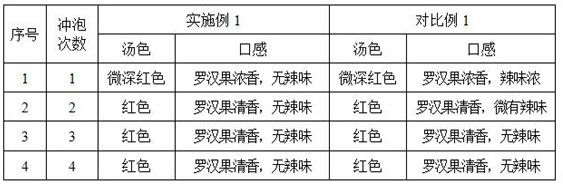

Sweet tea suitable for diabetics to drink

PendingCN111990513ADoes not affect the tasteSustained hypolipidemic effectTea substituesBiotechnologyGlycemic

The invention discloses sweet tea suitable for diabetics to drink. The sweet tea is prepared by the following steps: S1, taking siraitia grosvenorii seeds, and punching a plurality of blind holes in the siraitia grosvenorii seeds by using a first punching needle; and S2, taking a second punching needle, wherein the diameter of the second punching needle is smaller than that of the first punching needle, an air hole is formed in the side portion of the second punching needle, an elastic film bag is arranged on the side portion of the second punching needle in a sleeved mode, the second punchingneedle is soaked in slow-release gel containing gingerol first and then inserted into the blind holes of fructus momordicae seeds, ventilation is performed, gas are exhausted from the air hole, the volume of the film bag is enlarged to be attached to the edges of the blind holes, and ventilation is stopped, and then the second punching needle and the film bag are taken out. The sweet tea preparedby the method disclosed by the invention can meet the requirements of diabetics for eating desserts, and also can help to control blood sugar to a certain extent.

Owner:桂林丰润莱生物科技股份有限公司

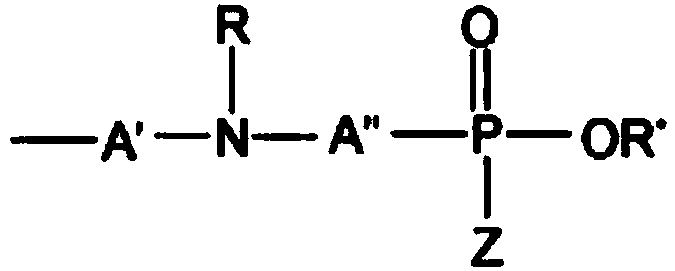

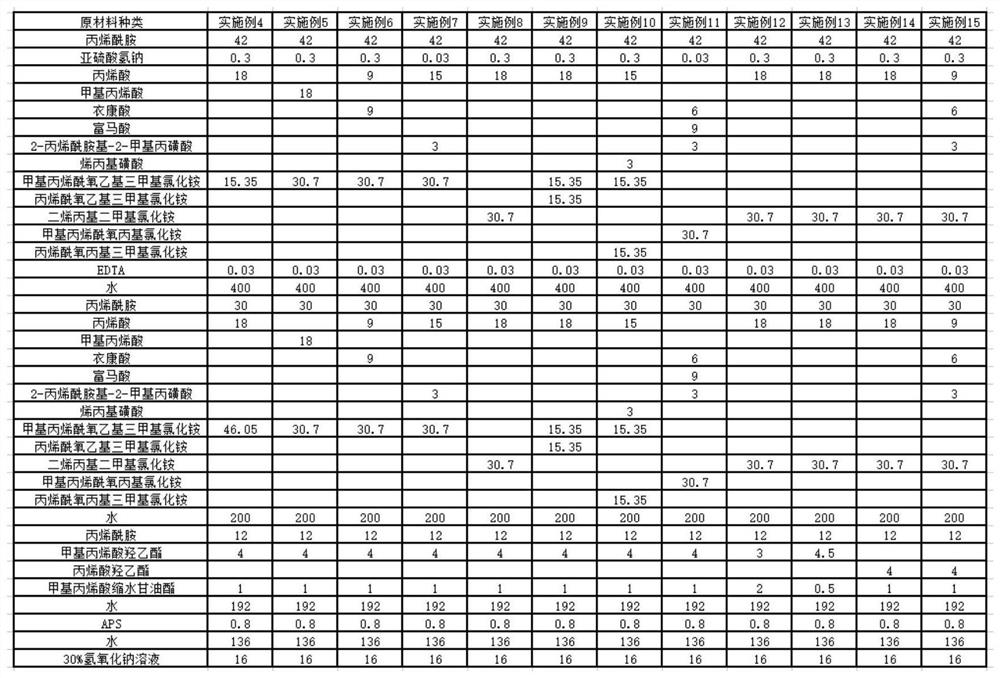

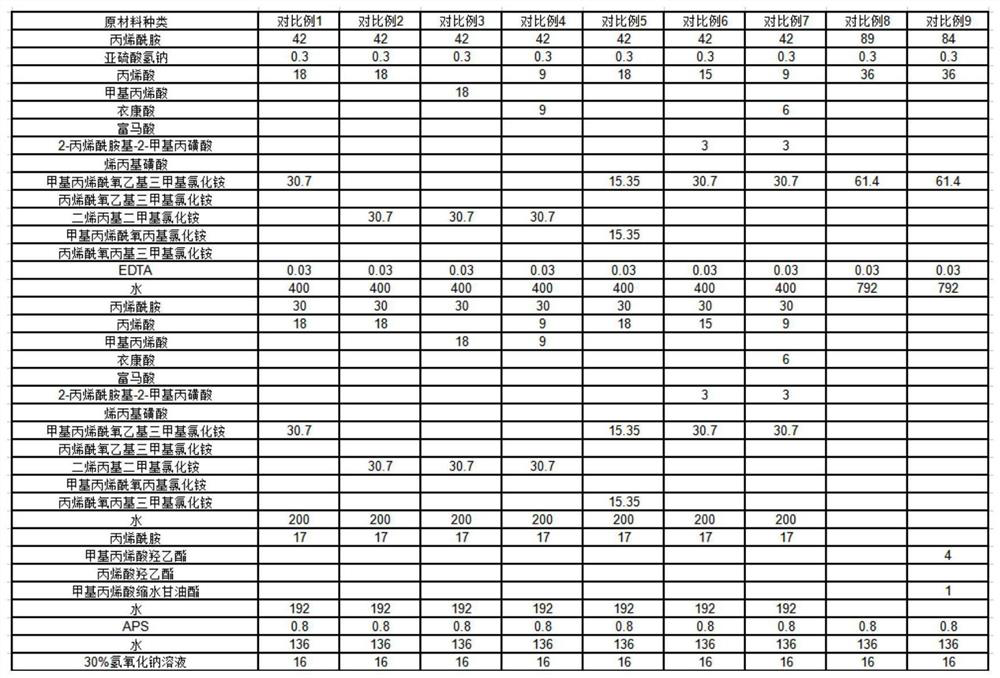

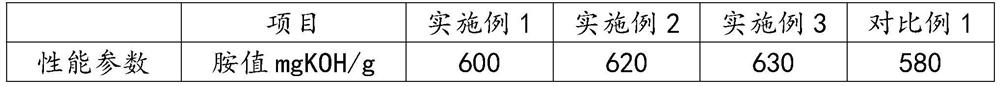

Synthetic method of amphoteric polyacrylamide, reinforcing agent for waste paper recovery and papermaking and preparation method of reinforcing agent

PendingCN113943409AStable cross-linked structureHigh strengthReinforcing agents additionPaper/cardboardPaper sheetAcrydite

The invention discloses a synthetic method of amphoteric polyacrylamide, a reinforcing agent for waste paper recovery and papermaking and a preparation method of the reinforcing agent. The amphoteric polyacrylamide is obtained through an initiation reaction on the basis of acrylamide. The reinforcing agent for waste paper recovery and papermaking comprises the amphoteric polyacrylamide and a glyoxal urea polymer in a weight ratio of 1: (1-3). The reinforcing agent provided by the invention can obviously improve the strength of paper.

Owner:深圳市瑞洲实业股份有限公司

Curing agent for high-strength polymer grouting and preparation process thereof

The invention discloses a curing agent for high-strength polymer grouting and a preparation process of the curing agent. The curing agent comprises the following raw materials in parts by weight: 20-30 parts of a first component, 23-25 parts of a second component, 30-40 parts of formaldehyde, 30-50 parts of melamine, 50-60 parts of deionized water and 0.1-0.3 part of span 20. The preparation process comprises the following steps: 1, preparing the first component and the second component; 2, uniformly mixing formaldehyde, melamine and deionized water to obtain a mixed solution, adjusting the pH value of the mixed solution, setting the temperature to be 70-80 DEG C, and carrying out stirring for 50-60 minutes to obtain a prepolymer solution for later use; and 3, stirring the first component, the second component and span 20 at room temperature for 5-10 minutes, adding the prepolymer solution prepared in the step 2, setting the temperature to be 60 DEG C, regulating the pH value of the reaction solution, stirring for 2 hours, and regulating the pH value of the system after stirring is finished, thereby obtaining the curing agent for high-strength polymer grouting.

Owner:武汉市晶博特科技有限公司

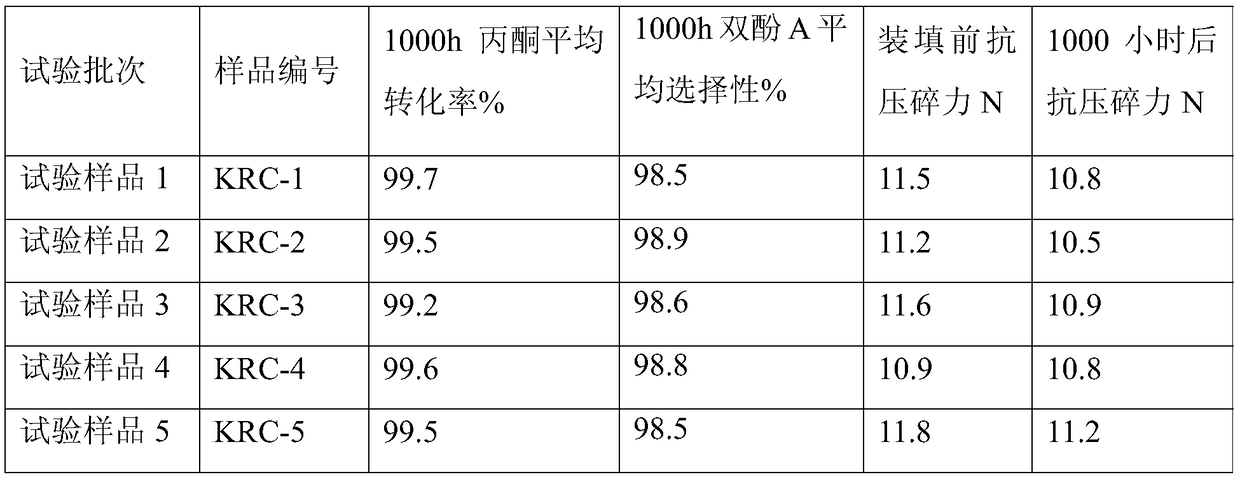

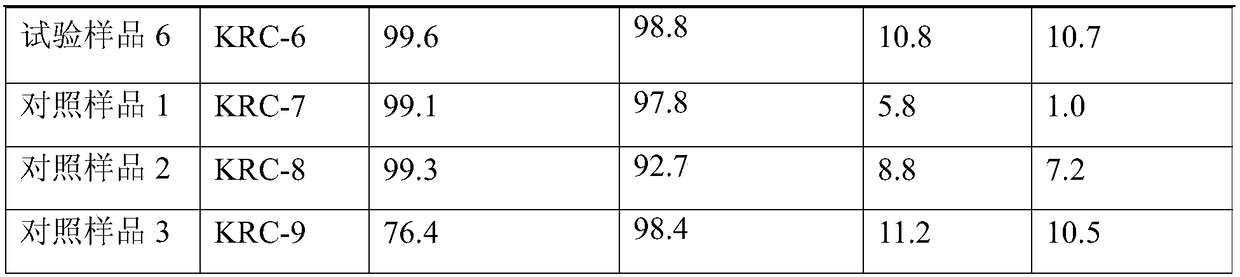

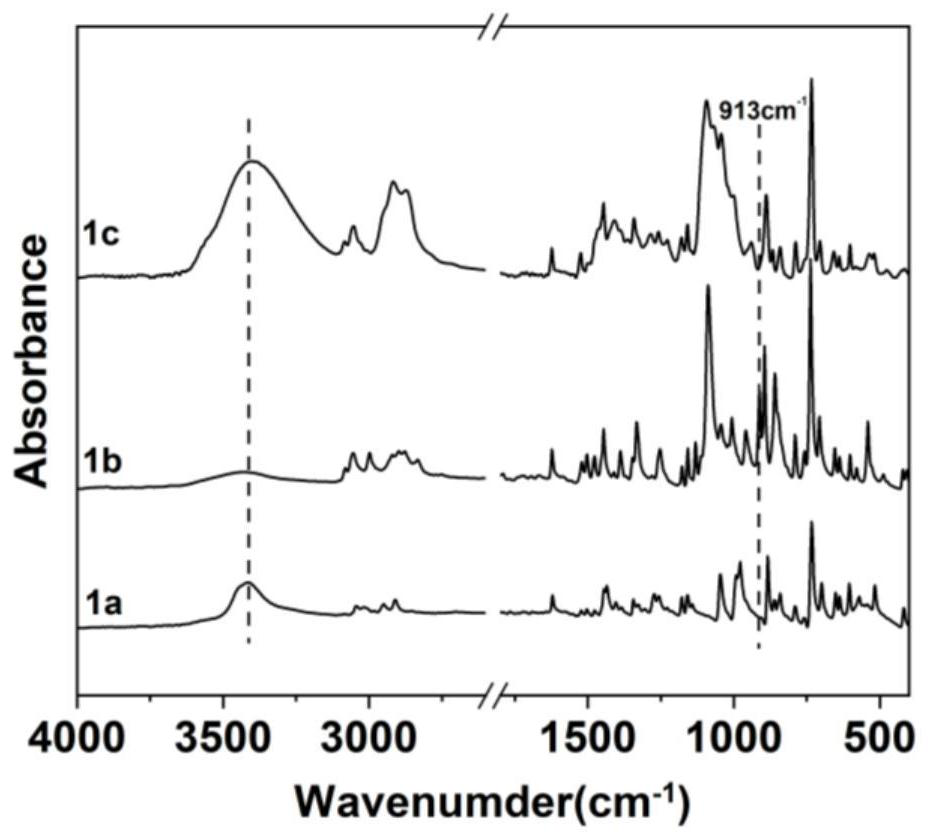

A kind of bisphenol A synthetic resin catalyst and preparation method thereof

ActiveCN106563502BReduce differential pressurePass unobstructedOrganic chemistryOrganic compound preparationStrong acidsDouble bond

The invention provides a bisphenol A synthetic resin catalyst and a preparation method thereof. It is a media with a pore size of 1-20 nm obtained by copolymerizing a third monomer with an unsaturated double bond and introducing a cross-linking degree of 2 to 8%. Porous white balls are used as the matrix, and then a mild sulfonation process is used for sulfonation. Finally, the resin is modified to obtain a high-strength strong acid mesoporous cationic resin catalyst with a pore size of 2-10nm. The mesopores on the catalyst in the present invention reduce the pressure difference between the material and the catalyst; the mesopores are conducive to the generation of bisphenol A and have less by-products; after the third monomer diallyl bisphenol A is added to the catalyst during polymerization, the inside of the resin The cross-linked structure is more stable, the compressive strength is increased, the affinity of the resin to phenol is increased, the swelling of the resin by phenol, acetone and other materials is reduced, and the destructiveness of the material to the resin is reduced. The catalyst of the present invention plays the role of a cocatalyst through the addition of a modifier, and improves the conversion rate of reaction raw materials phenol and acetone.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

A kind of high-intensity photoreversible adhesive, preparation method and application

ActiveCN113337238BHigh reactivityEasy to operatePolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention discloses a high-intensity photoreversible adhesive, a preparation method and an application. The present invention firstly epoxidizes anthracenyl-containing compound raw materials to prepare anthracene-containing epoxidized products, then mixes them with terminal mercapto alcohol compounds and accelerators, and performs ring opening at room temperature to prepare anthracenyl-containing side chains. Double terminal hydroxyl compound. A double-terminal isocyanate compound and double-terminal hydroxyl polycaprolactone are used, and an organic tin catalyst is added to carry out a chain extension reaction to form a larger molecular weight chain-extended double-terminal isocyanate compound. Finally, the chain-extended double-terminal isocyanate compound is reacted with the double-terminal hydroxyl compound containing anthracenyl side chain and the double-terminal hydroxyl compound not containing anthracenyl side chain, and an organotin catalyst is added to catalyze the reaction to obtain the high-intensity photoreversible adhesive. The adhesive of the invention undergoes [4+4] cycloaddition reaction under the irradiation of ultraviolet light of 350-405nm, and is cured; it is decrosslinked under the irradiation of ultraviolet light of less than 300nm.

Owner:BEIJING UNIV OF CHEM TECH

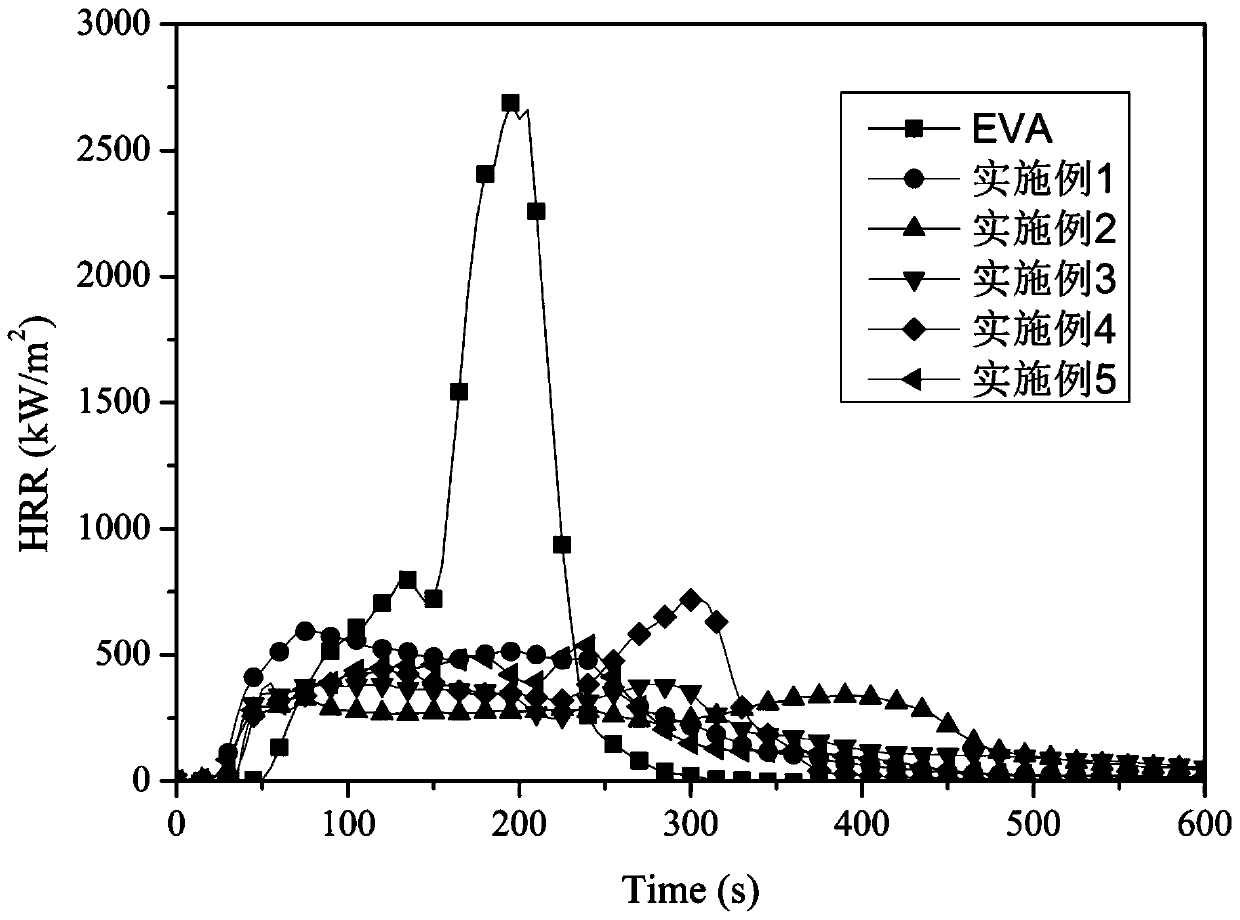

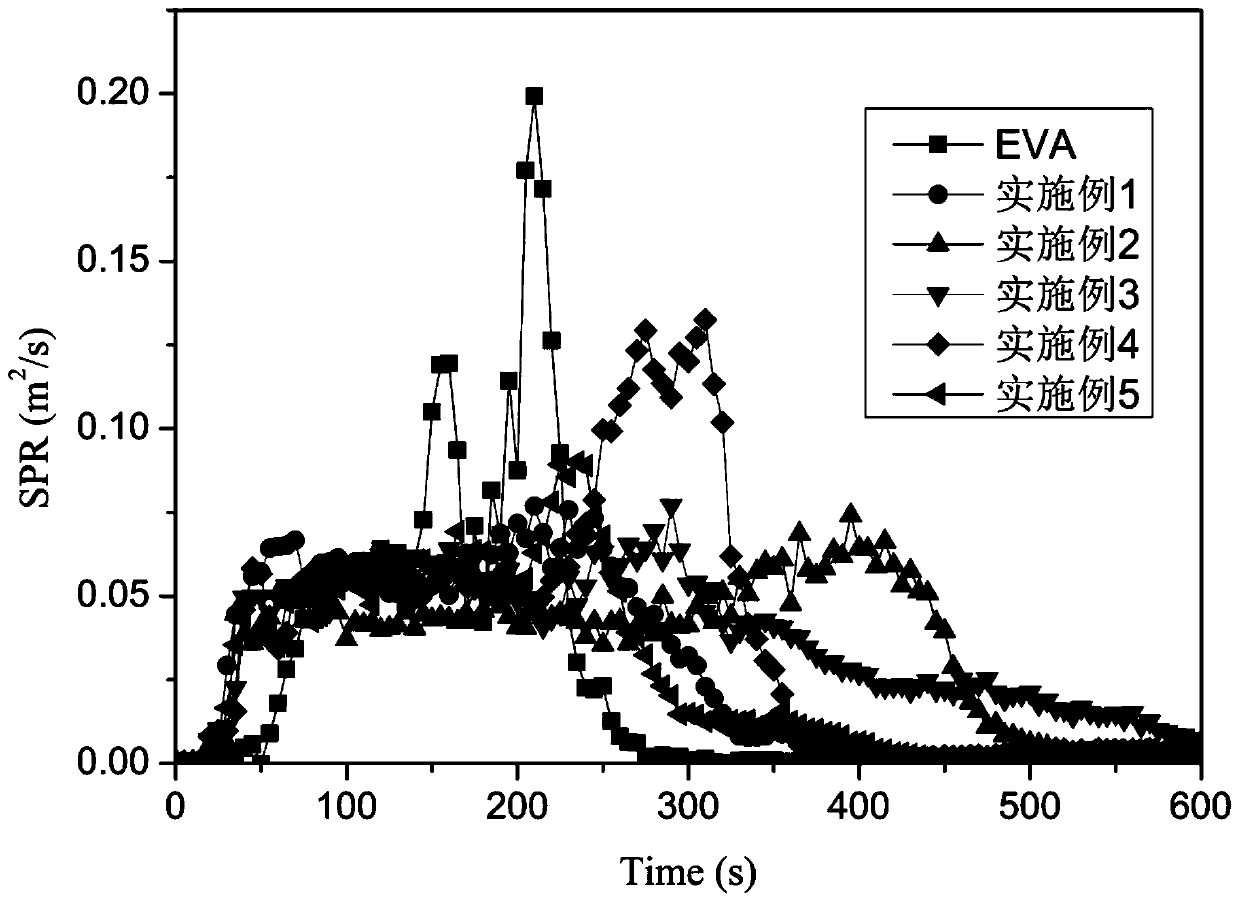

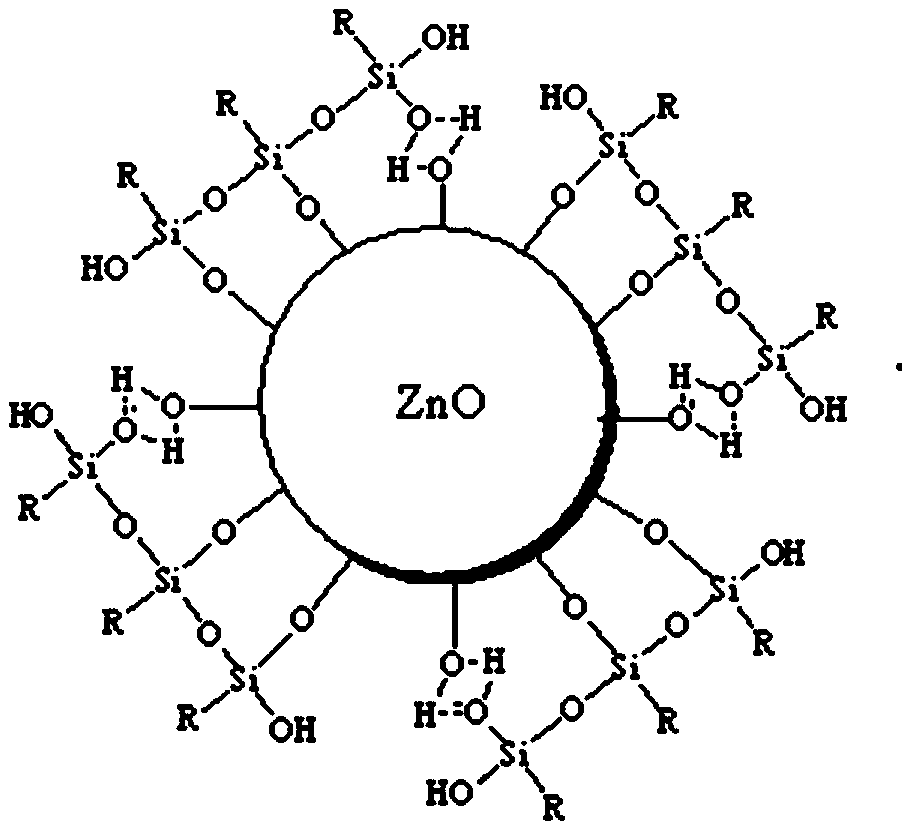

Halogen-free intumescent flame retardant EVA and preparation method thereof

InactiveCN109851903AImprove synergistic catalytic char formationImproved thermal stability and flame retardancyCarbon sourceAdverse effect

The invention relates to a halogen-free intumescent flame retardant EVA and a preparation method thereof. The material comprises in mass percent: 50%-80% of an EVA base material, 15%-30% of a halogen-free intumescent flame retardant, 0%-0.2% of an anti-dropping agent, 0-0.5% of an antioxidant, and 0-2% of a lubricant. The halogen-free intumescent flame retardant consists of an organic-metal triazine hybrid SCTCA@ZnO as a carbon source and a gas source, and an acid source, and the mass ratio of a char forming agent to the acid source is 1:1-4:1. The halogen-free intumescent flame retardant is especially suitable for the halogen-free flame retardant of polyolefin materials, shortcomings that low flame retardant efficiency, large additive amount and the like of existing intumescent flame retardants are overcome, the adverse effects of the flame retardant on the mechanical properties of the matrix are reduced, and the production and use are very convenient. The halogen-free intumescent flame retardant EVA composite material has high flame retardant efficiency, no halogen, low smoke and low toxicity, and has excellent processing properties, so that the material can be widely used in many fields such as electronics and electronic appliances, automotive components and parts and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com