Synthetic method of amphoteric polyacrylamide, reinforcing agent for waste paper recovery and papermaking and preparation method of reinforcing agent

A technology of polyacrylamide and synthesis method, which is applied in the field of papermaking additives, can solve the problems of paper strength reduction, paper strength reduction, fiber shortening, etc., and achieve the effect of enhancing paper strength and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

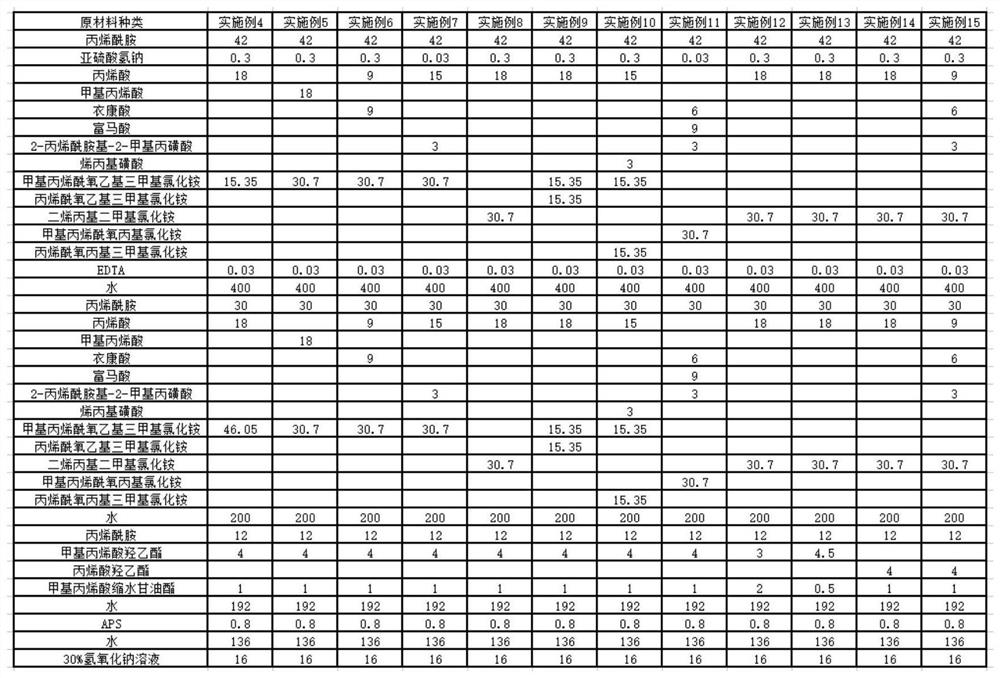

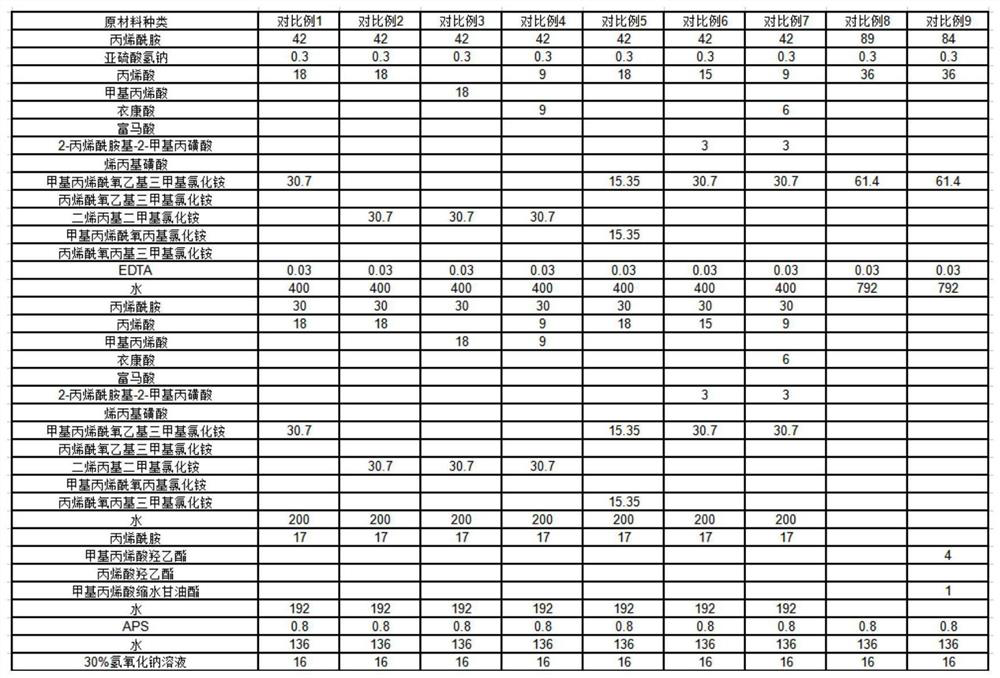

[0050] Embodiment 1 A kind of preparation method of papermaking strengthening agent, comprises the following steps:

[0051] 1, the preparation of amphoteric polyacrylamide (structure such as Figure 7 The compound ②)

[0052] S1. Preparation of substrate

[0053]Add 400g of deionized water to the reactor, then add 42g of acrylamide, 0.3g of sodium bisulfite, stir to dissolve, add 18g of acrylic acid, 30.7g of methacryloyloxyethyltrimethylammonium chloride, stir well, add EDTA 0.03g, stir evenly, heat up to 60°C, obtain the substrate, and set aside;

[0054] S2, the preparation of solution A

[0055] Add 30g of acrylamide to the monomer tank, stir to dissolve, add 18g of acrylic acid, 30.7g of methacryloxyethyltrimethylammonium chloride, 200g of water, stir to dissolve, add 10% sodium hydroxide solution to adjust the pH Value is 3.5, obtain solution A, stand-by;

[0056] S3, preparation of solution B

[0057] Add 12g of acrylamide and 192g of water into the monomer kettl...

Embodiment 2

[0067] A preparation method of a papermaking reinforcing agent, comprising the following steps:

[0068] 1, the preparation of amphoteric polyacrylamide (structure such as Figure 7 The compound ②)

[0069] S1. Preparation of substrate

[0070] Add 400g of deionized water to the reactor, then add 30g of acrylamide, 0.3g of sodium bisulfite, stir to dissolve, add 18g of acrylic acid, 30.7g of methacryloyloxyethyltrimethylammonium chloride, stir well, add EDTA 0.03g, stir evenly, heat up to 50°C, obtain the substrate, and set aside;

[0071] S2, the preparation of solution A

[0072] Add 42g of acrylamide to the monomer tank, stir to dissolve, add 18g of acrylic acid, 30.7g of methacryloyloxyethyltrimethylammonium chloride, 200g of water, stir to dissolve, add 30% sodium hydroxide solution to adjust the pH value For 3, obtain solution A, stand-by;

[0073] S3, preparation of solution B

[0074] Add 12g of acrylamide and 192g of water into the monomer kettle, stir to dissol...

Embodiment 3

[0084] A preparation method of a papermaking reinforcing agent, comprising the following steps:

[0085] 1, the preparation of amphoteric polyacrylamide (structure such as Figure 7 The compound ②)

[0086] S1. Preparation of substrate

[0087] Add 400g of deionized water to the reaction kettle, then add 42g of acrylamide, 0.3g of sodium bisulfite, stir to dissolve, add 9g of acrylic acid, 30.7g of methacryloyloxyethyltrimethylammonium chloride, stir well, add EDTA 0.03g, stir evenly, heat up to 50-70°C, get the substrate, set aside;

[0088] S2, the preparation of solution A

[0089] Add 30g of acrylamide to the monomer tank, stir to dissolve, add 18g of acrylic acid, 30.7g of methacryloyloxyethyltrimethylammonium chloride, 200g of water, stir to dissolve, add an appropriate amount of liquid alkali to adjust the pH to 3- 4. Obtain solution A for use;

[0090] S3, preparation of solution B

[0091] Add 12g of acrylamide and 192g of water into the monomer kettle, stir to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com