Halogen-free intumescent flame retardant EVA and preparation method thereof

A technology of intumescent flame retardant and intumescent flame retardant, applied in the field of halogen-free intumescent flame retardant EVA, can solve problems such as unreported, achieve the effects of improving thermal stability and flame retardant performance, reducing adverse effects and overcoming low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

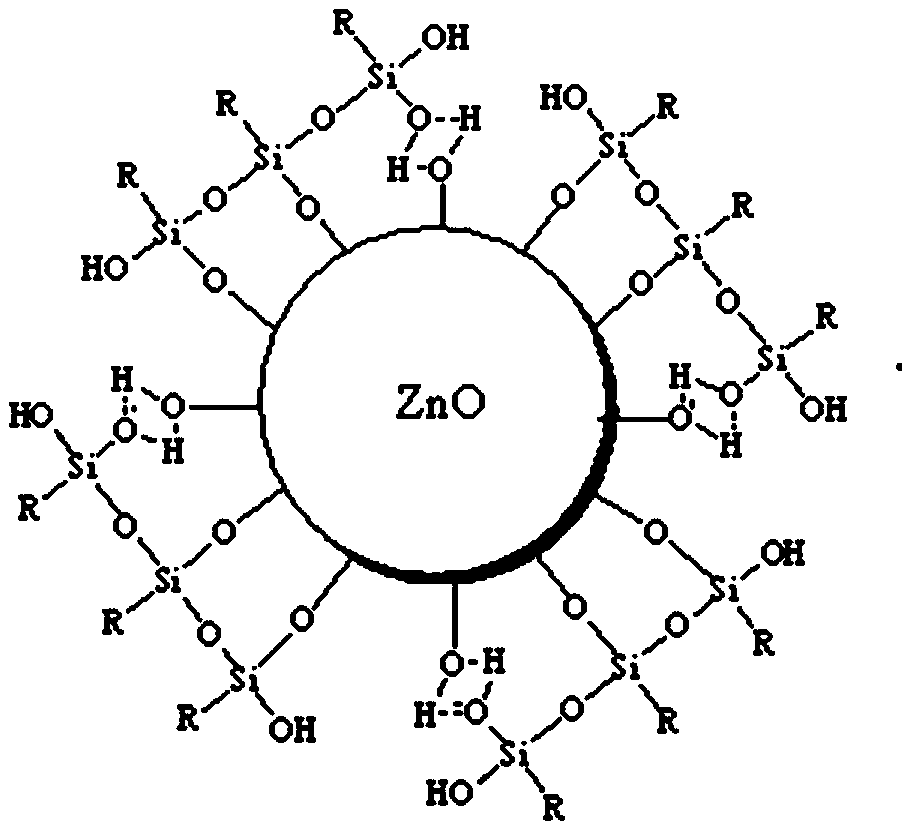

Method used

Image

Examples

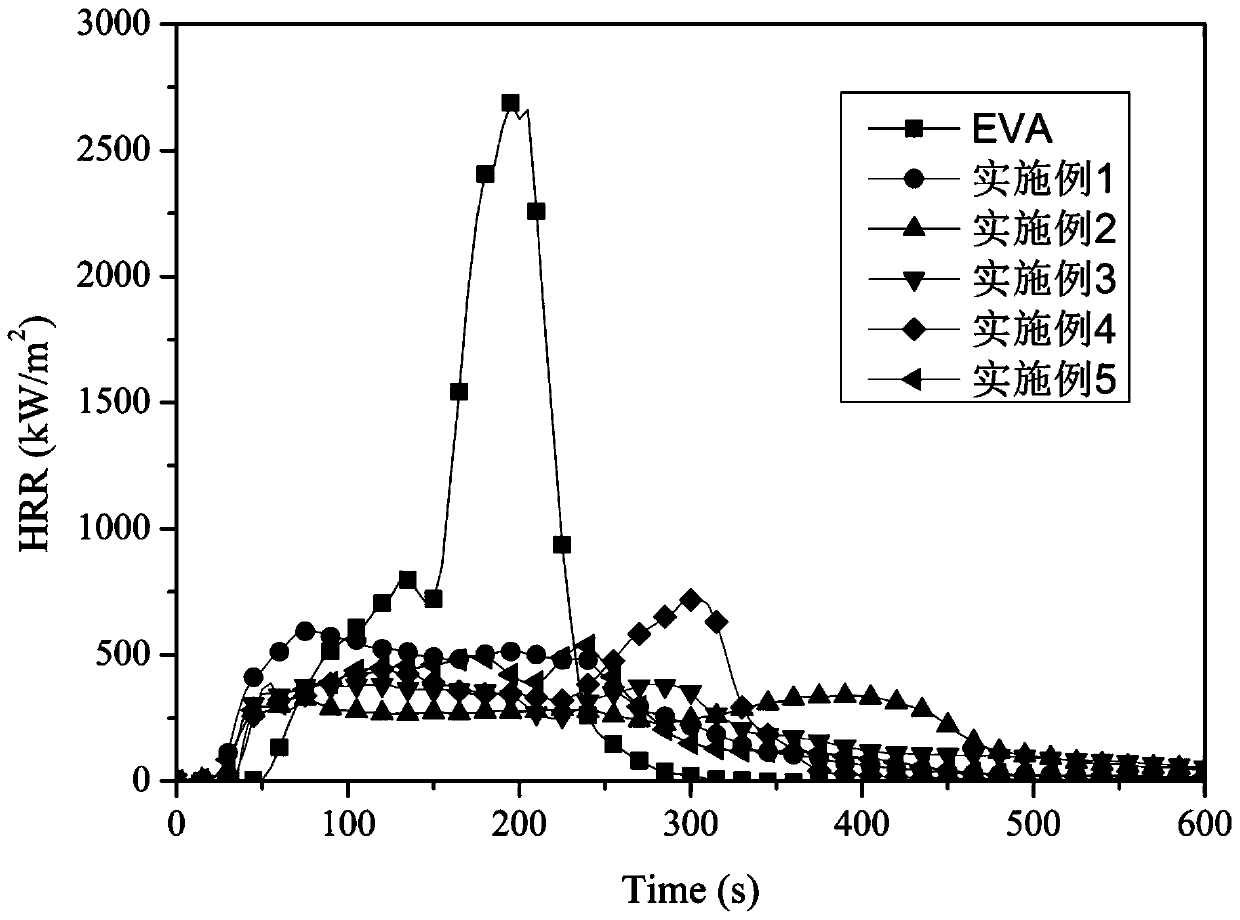

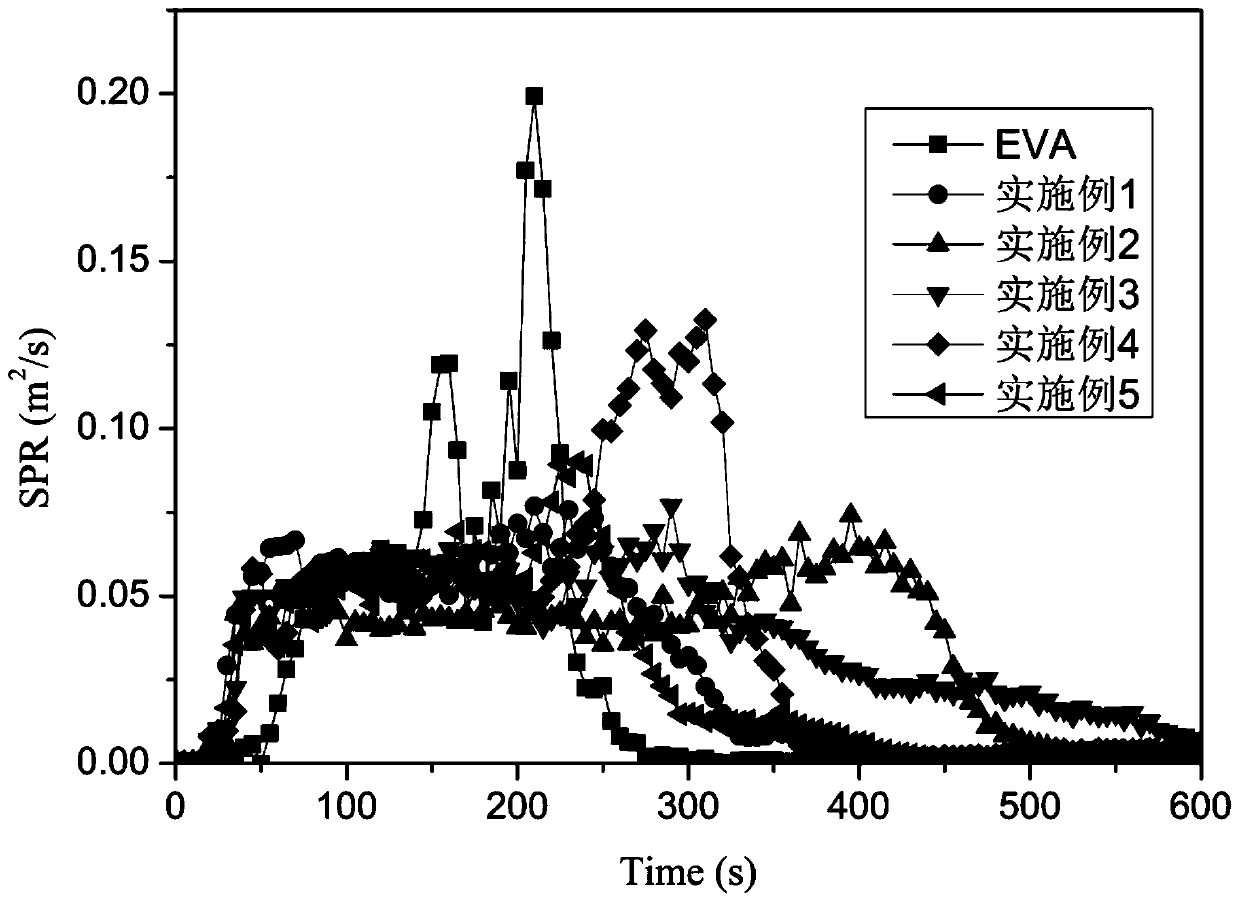

Embodiment 1

[0026] In this example, 25% by weight of halogen-free flame retardant (the mass ratio of APP to SCTCA@ZnO is 1:1) is compounded with 75% of EVA. Melt and mix evenly with a transformer, dry in vacuum at 80°C, pulverize with a pulverizer, melt and extrude in a twin-screw extruder, cool and cut into pellets to obtain a halogen-free intumescent flame-retardant EVA composite material. And measured its limiting oxygen index LOI, vertical burning UL-94 grade and data such as tensile strength and elongation at break, as shown in Table 2.

[0027] Table 1

[0028]

[0029] Table 2

[0030]

[0031]

Embodiment 2

[0033] In this example, the weight fraction is 20% of halogen-free flame retardant (the mass ratio of MP to SCTCA@ZnO is 2:1), 0.1% of anti-slump agent, 0.3% of antioxidant 1076, and 1.1% of lubricant solids Paraffin wax and 78.5% EVA are compounded, the formula is shown in Table 1, then blended uniformly in a high-speed mixer, vacuum-dried at 80°C, melted and extruded in a twin-screw extruder, cooled and pelletized Halogen-free intumescent flame-retardant EVA composite material was obtained. And measured its limiting oxygen index LOI, vertical burning UL-94 grade and data such as tensile strength and elongation at break, as shown in Table 2.

Embodiment 3

[0035] In this example, the weight fraction is 24.5% of halogen-free flame retardant (the mass ratio of MPP to SCTCA@ZnO char forming agent is 4:1), 0.05% of anti-slump agent, 0.15% of antioxidant 1010, 0.3% of The lubricant polyethylene wax is compounded with 75% EVA. The formula is shown in Table 1. Then it is mixed uniformly in a high-speed mixer, dried in vacuum at 80°C, and then melted and extruded in a twin-screw extruder. The halogen-free intumescent flame-retardant EVA composite material was prepared by cooling and pelletizing. And measured its limiting oxygen index LOI, vertical burning UL-94 grade and data such as tensile strength and elongation at break, as shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com