Phenolic foam heat insulation board and production method thereof

A phenolic foam and thermal insulation board technology is applied in the field of thermal insulation materials, which can solve the problems of poor toughness and high acidity of thermal insulation boards, and achieve the effects of good dispersion, improved thermal stability and flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

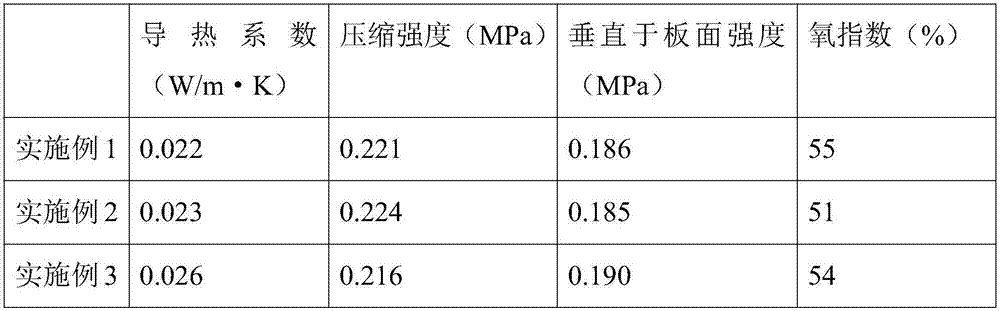

Examples

Embodiment 1

[0024] A phenolic foam insulation board, calculated in parts by weight, comprises the following raw materials:

[0025] 75 parts of phenolic resin, 7 parts of modified nano silicon dioxide, 6 parts of toughening agent, 5 parts of Tween 80, 12 parts of phosphoric acid and 6 parts of cyclopentane.

[0026] The modified nano-silica is prepared by the following method: dissolve nano-silica in ethyl acetate, heat it in a water bath to 50°C, then adjust the pH to 8.5 with ammonia water, add KH560 for reaction, the reaction time is 20h, and then centrifuge Washing to obtain modified nano silicon dioxide. The molar ratio of KH560 to nano silica is 5:1.

[0027] The toughening agent is a mixture of polyethylene glycol and acrylic styrene copolymer emulsion, wherein the mass percentage of the acrylic styrene copolymer emulsion is 30%, and the percentage content of polyethylene glycol is 70%.

[0028] Preparation:

[0029] 1) Preparation of modified nano-silica: Dissolve nano-silica i...

Embodiment 2

[0033] A phenolic foam insulation board, calculated in parts by weight, comprises the following raw materials:

[0034] 70 parts of phenolic resin, 5 parts of modified nano silicon dioxide, 4 parts of toughening agent, 806 parts of Tween, 10 parts of p-toluenesulfonic acid and 4 parts of n-pentane.

[0035] The modified nano-silica is prepared by the following method: dissolve nano-silica in ethyl acetate, heat it in a water bath to 40°C, then adjust the pH to 8 with ammonia water, add KH550 for reaction, the reaction time is 18h, and then centrifuge Washing to obtain modified nano silicon dioxide. The molar ratio of KH550 to nano silica is 6:1.

[0036] The toughening agent is a mixture of polyethylene glycol and acrylic styrene copolymer emulsion, wherein the mass percentage of the acrylic styrene copolymer emulsion is 40%, and the percentage content of polyethylene glycol is 60%.

[0037] Preparation:

[0038] 1) Preparation of modified nano-silica: Dissolve nano-silica ...

Embodiment 3

[0042] A phenolic foam insulation board, calculated in parts by weight, comprises the following raw materials:

[0043] 80 parts of phenolic resin, 10 parts of modified nano silicon dioxide, 8 parts of toughening agent, 803 parts of Tween, 15 parts of hydrochloric acid and 8 parts of n-pentane.

[0044] The modified nano-silica is prepared by the following method: dissolve nano-silica in ethyl acetate, heat it in a water bath to 60°C, then adjust the pH to 9 with ammonia water, add KH560 for reaction, the reaction time is 24h, and then centrifuge Washing to obtain modified nano silicon dioxide. The molar ratio of KH560 to nano silica is 4:1.

[0045] The toughening agent is a mixture of polyethylene glycol and acrylic styrene copolymer emulsion, wherein the mass percentage of the acrylic styrene copolymer emulsion is 35%, and the percentage content of polyethylene glycol is 65%.

[0046] Preparation:

[0047] 1) Preparation of modified nano-silica: Dissolve nano-silica in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com