Hydroxyl-containing liquid phosphor-nitrogen fire retardant and preparation method thereof

A flame retardant, diethyl phosphate methylolphenoxy technology, applied in the field of flame retardant, can solve problems such as limited application, and achieve the effects of strong practicability, high content of phosphorus elements, and simple and easy-to-operate preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

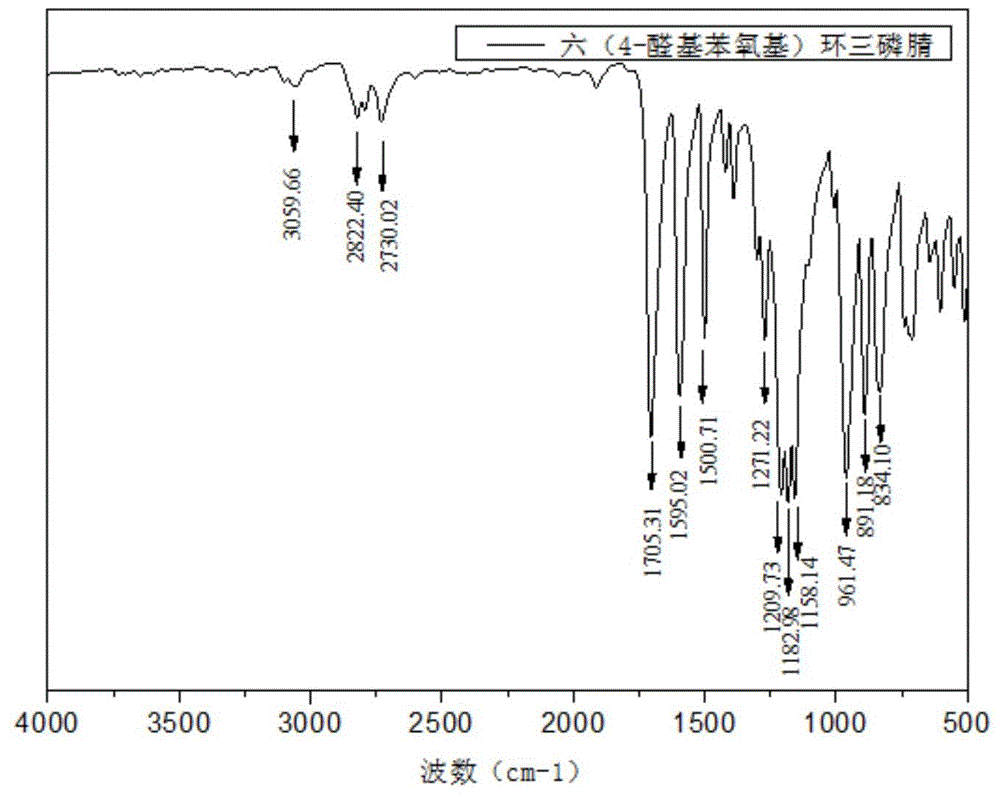

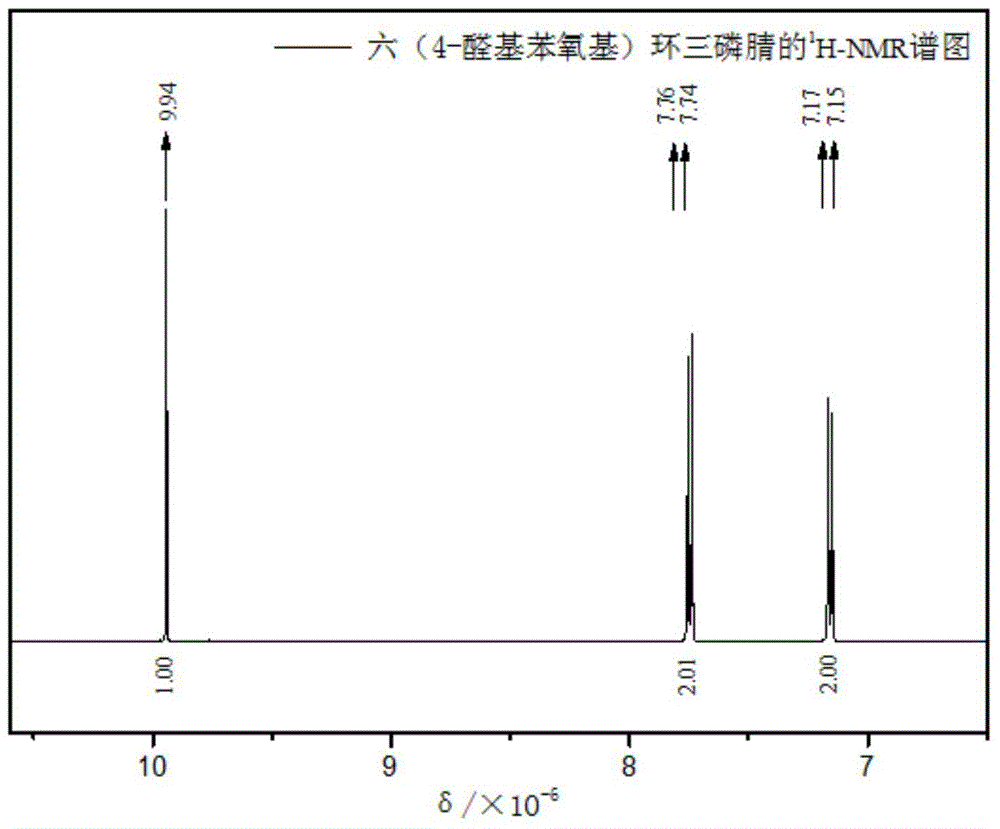

[0022] In a 500mL dry four-necked flask equipped with a mechanical stirrer, a thermometer, a constant pressure dropping funnel, and a condensing reflux device, add 30g of potassium carbonate, 17.6g of p-hydroxybenzaldehyde and 200mL of refined tetrahydrofuran in sequence, and under nitrogen protection, Stir for 1 h to dissolve it; then weigh 8.35 g of hexachlorocyclotriphosphazene (the molar ratio of hexachlorocyclotriphosphazene to p-hydroxybenzaldehyde is 1:6) and dissolve it in 100 mL of refined tetrahydrofuran, and slowly add it dropwise to In the above reaction system, the dropwise addition time is 1 h; after 0.5 h, the temperature is raised to 65° C., refluxed and stirred for 48 h, and the reaction ends. Filtrate, concentrate the filtrate, pour it into a large amount of deionized water, and immediately precipitate a white precipitate; filter again, wash the product repeatedly with deionized water for 3 times; finally recrystallize twice with ethyl acetate, and vacuum dry ...

Embodiment 2

[0029] In a 500mL dry four-necked flask equipped with a mechanical stirrer, a thermometer, a constant pressure dropping funnel, and a condensing reflux device, add 30g of potassium carbonate, 17.6g of p-hydroxybenzaldehyde, and 250mL of refined tetrahydrofuran in sequence. Stir for 1 h to dissolve it; then weigh 6.3 hexachlorocyclotriphosphazene (the molar ratio of hexachlorocyclotriphosphazene to p-hydroxybenzaldehyde is 1:8) and dissolve it in 100 mL of refined tetrahydrofuran, and slowly add it dropwise to In the above reaction system, the dropwise addition time is 1h; after 0.5h, the temperature is raised to 65°C, refluxed and stirred for 36h, and the reaction ends. Filtrate, concentrate the filtrate, pour it into a large amount of deionized water, and immediately precipitate a white precipitate; filter again, wash the product repeatedly with deionized water for 3 times; finally recrystallize twice with ethyl acetate, and vacuum dry at 50°C for 12 hours to obtain white Pow...

Embodiment 3

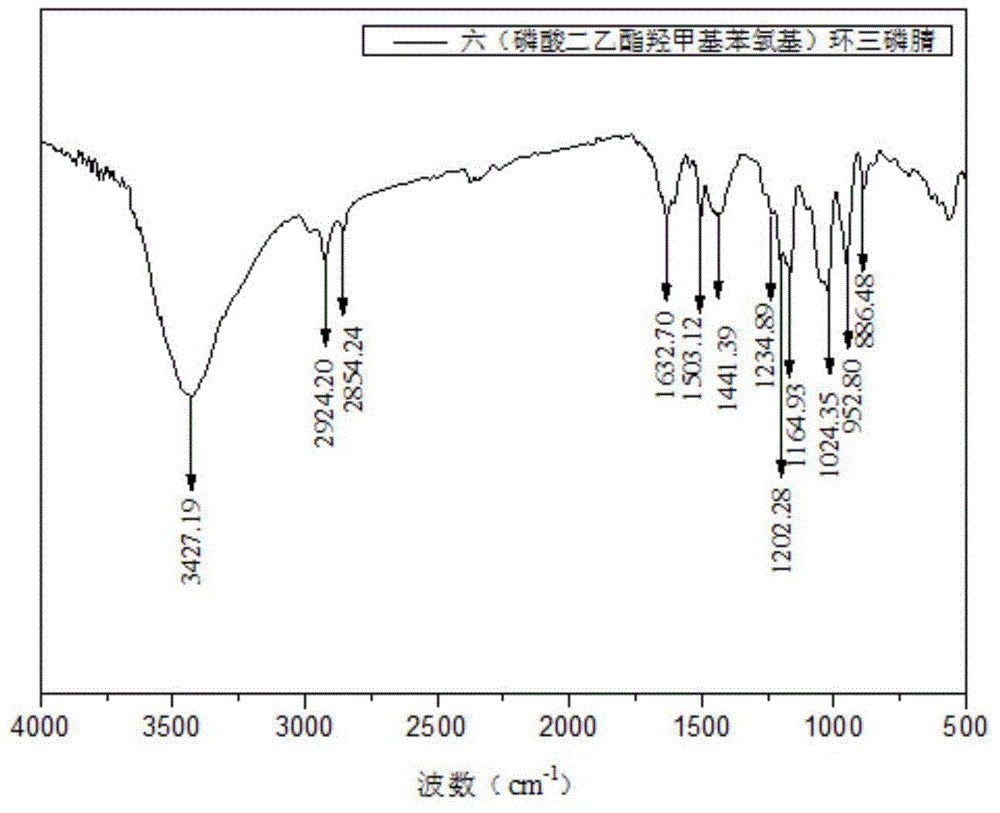

[0032] The first step: in the 500mL dry four-necked flask that mechanical stirrer, thermometer, constant pressure dropping funnel and condensation reflux device are housed, add potassium carbonate 25g, 17.6g p-Hydroxybenzaldehyde and 250mL refining ethyl acetate successively, Stir at room temperature under argon protection for 1 h to dissolve; then weigh 8.35 hexachlorocyclotriphosphazene (the molar ratio of hexachlorocyclotriphosphazene to p-hydroxybenzaldehyde is 1:6) and dissolve it in 100 mL of refined ethyl acetate In the ester, it was slowly added dropwise to the above reaction system, and the dropwise addition time was 1h; after 0.5h, the temperature was raised to 80°C, refluxed and stirred for 24h, and the reaction was completed. Filtrate, concentrate the filtrate, pour it into a large amount of deionized water, and immediately precipitate a white precipitate; filter again, wash the product repeatedly with deionized water for 3 times; finally recrystallize twice with et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com