Phosphorus-containing flame retardant monomer, halogen-free flame retardant polyester containing the same and preparation method thereof

A flame-retardant monomer and flame-retardant polyester technology, which is applied in the field of flame-retardant polyester manufacturing, can solve the problems of applications that cannot meet the strict requirements of crystallization performance, large molecular weight drop, and symmetrical structure destruction, so as to ensure the esterification reaction The effect of activity, high crystallization performance, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

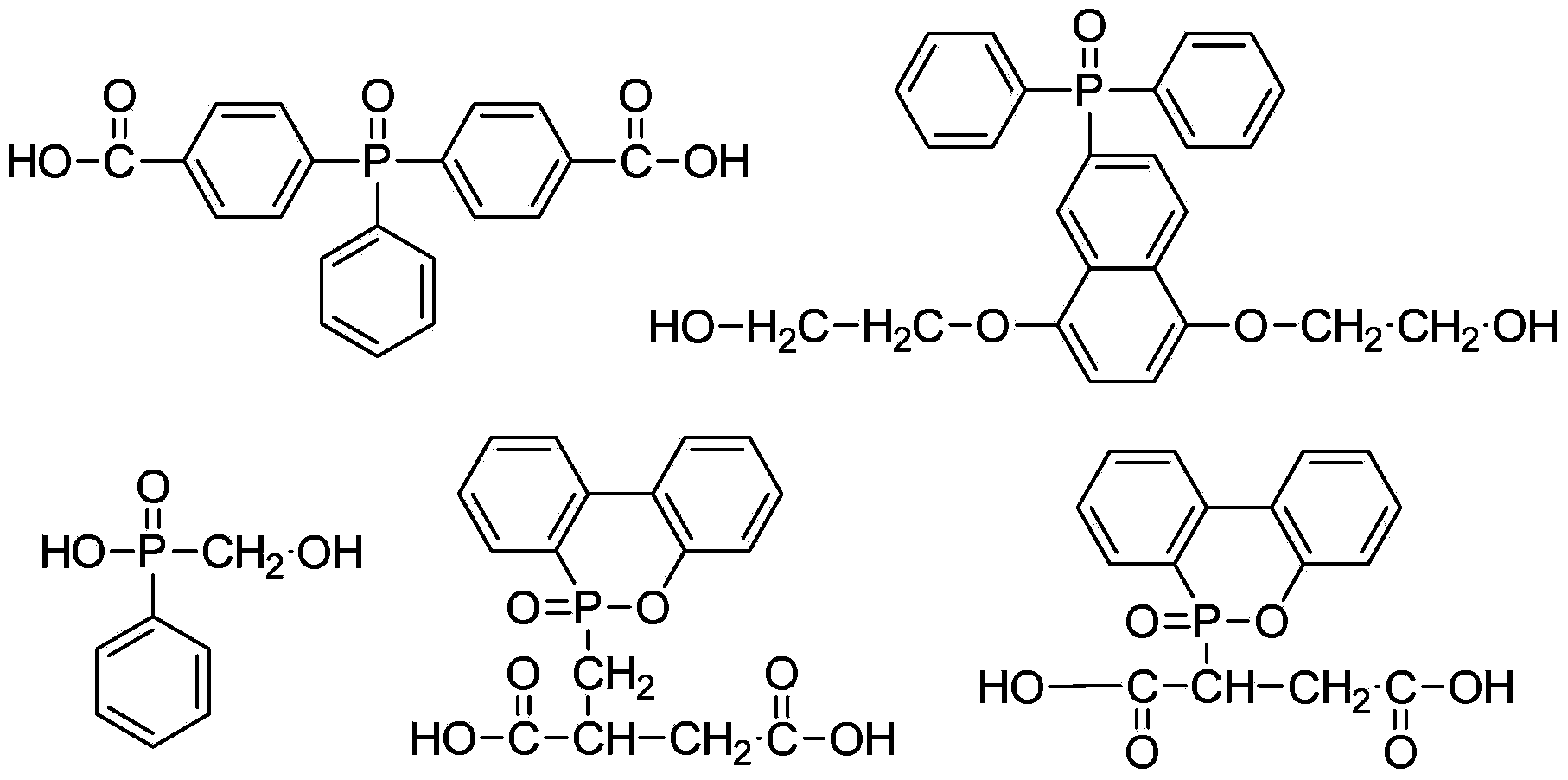

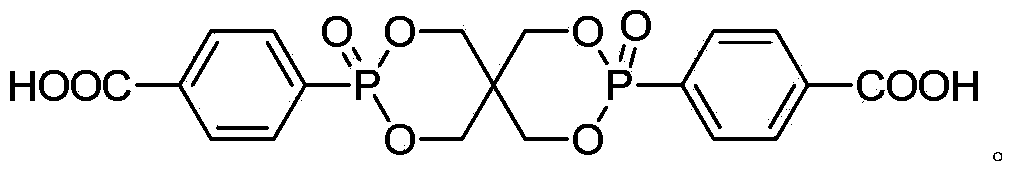

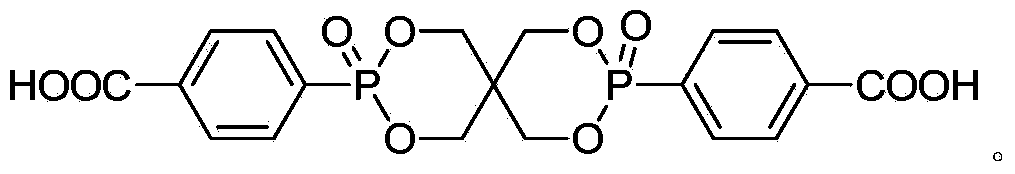

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of phosphorus-containing flame-retardant monomer of the present invention, carries out according to the following steps:

[0027] (1) Add 272ml of phosphorus oxychloride and 68g of pentaerythritol into the reactor. The reactor can be heated to 60°C with a mechanical stirrer, condenser, thermometer, and tail gas absorption device, reacted for 1 hour, and then heated Reflux until no HCl gas is released, filter after cooling to room temperature, wash and dry the resulting filter cake to obtain white solid pentaerythritol diphosphate diphosphoryl chloride, the present invention can wash the filter cake twice with toluene, and then use Washing with distilled water three times, and drying in vacuum to obtain pentaerythritol diphosphate diphosphoryl chloride, the yield can reach 83.4%.

[0028] ⑵, the pentaerythritol diphosphate diphosphoryl chloride of 297g, the toluene of 368g and the aluminum chloride AlCl of 293.7g 3 Add to the reactor, excess tolue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com