Patents

Literature

33 results about "Structural regularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

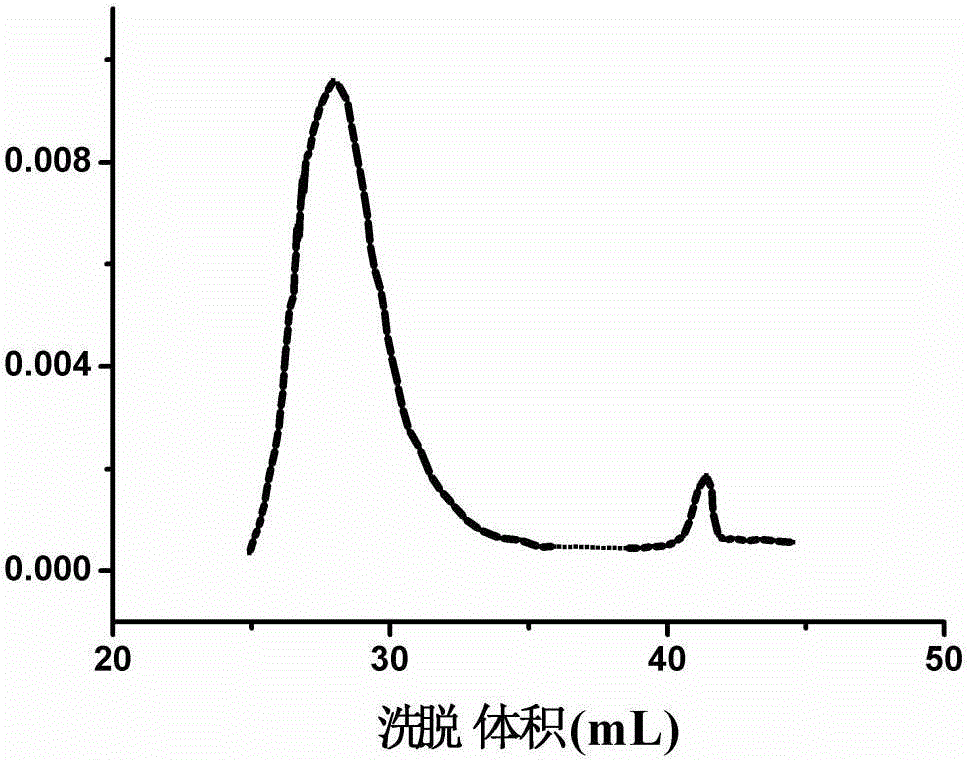

Block poly-carboxylic acid concrete high-efficiency water reducing agent and preparation method thereof

ActiveCN103482897AControl structureControl its molecular weight distributionStructural regularityPolymer science

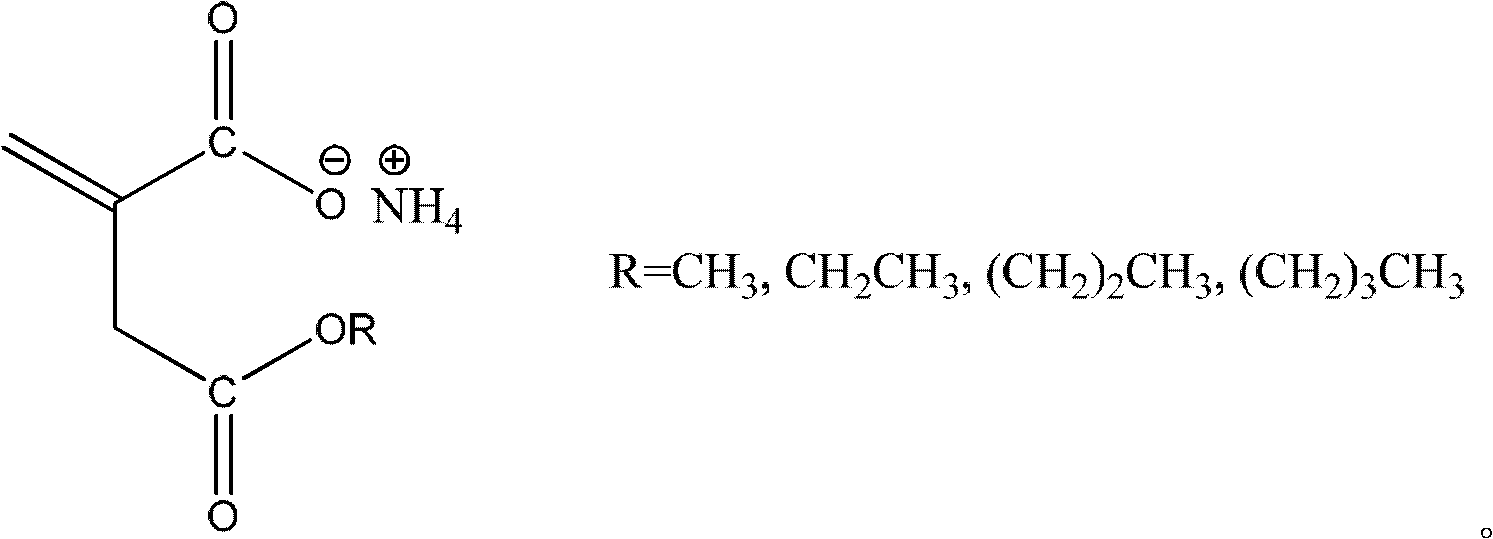

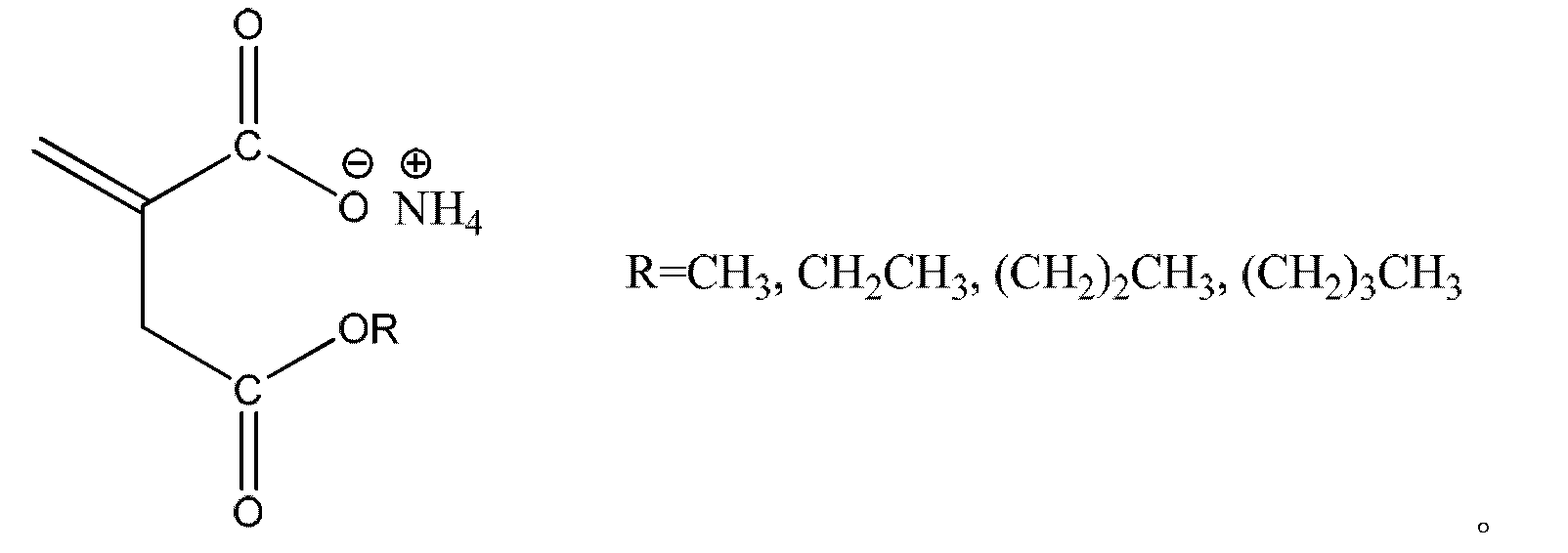

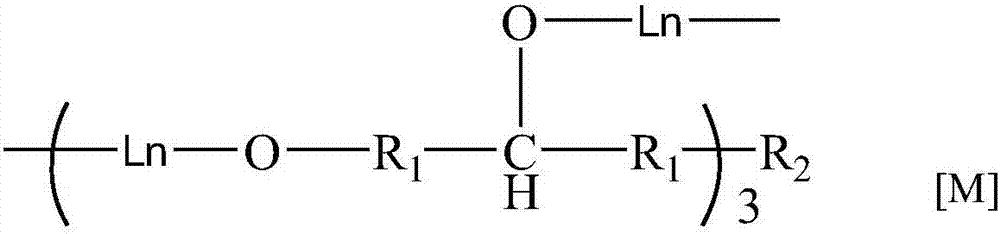

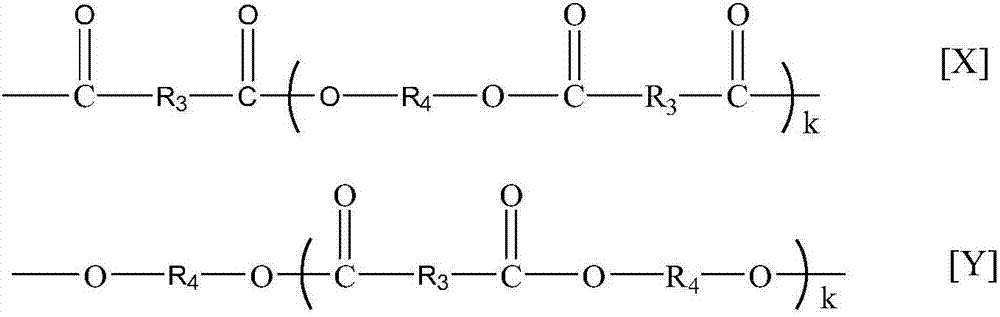

The invention provides a block poly-carboxylic acid concrete high-efficiency water reducing agent with an ordered structure and a preparation method thereof. The block poly-carboxylic acid is prepared by using atom transfer radical polymerization, the structural regularity and the molecular weight distribution of the poly-carboxylic acid are controlled effectively, and the water reducing agent is used in a cement dispersing process. By adoption of the block poly-carboxylic acid concrete high-efficiency water reducing agent and the preparation method thereof, the problems of uncontrollable molecular weight of the poly-carboxylic acid, wider molecular weight distribution, un-designable molecular structure and the like are solved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Organic silicon modified thermoplastic polyurethane elastomer (TPU) and preparation method thereof

ActiveCN105399917AImprove hydrophobicityImprove thermal stabilityChemical structureStructural regularity

The invention belongs to the field of high polymer material research, and provides an organic silicon modified thermoplastic polyurethane elastomer (TPU) in order to overcome the defects of poor temperature resistance and hydrophobic property of the existing TPU. The elastomer consists of the following components in parts by weight: 20-60 parts of macromolecular dihydric alcohol, 2-10 parts of terminal hydroxyalkyl end-blocked polydimethylsiloxane, 10-20 parts of diisocyanate, 2-8 parts of a micromolecular chain extender, 0.1-0.5 part of a catalyst, 0.1-0.5 part of an antioxidant and 0.1-0.5 part of an ultraviolet light absorber. Due to the unique chemical structure and composition, organic silicon has a series of excellent properties, such as high temperature and low temperature resistance and hydrophobic property, which just can make up the defects of the TPU. The invention also provides a preparation method of the elastomer, the preparation method adopts a prepolymer two-step process and is less in side reaction, and the prepared TPU is good in structural regularity.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Ecological multifunctional ternary copolymerization PETG (Polyethylene Terephthalate Glycol) polyester, preparation method of polyester, and method for preparing unidirectional stretching heat-shrinkable film from polyester

ActiveCN102558517ARaw materials are cheapLow pricePolyethylene terephthalate glycolStructural regularity

The invention discloses an ecological multifunctional ternary PETG (Polyethylene Terephthalate Glycol), a preparation method of the polyester, and a method for preparing a unidirectional stretching heat-shrinkable film from the polyester. The ecological multifunctional ternary copolymerization PETG polyester is formed by ternary monomer copolymerization of terephthalic acid, neopentyl glycol and glycol, wherein the molar ratio of terephthalic acid to neopentyl glycol to glycol is 1: (0.1-0.65):(1.2-1.75). The preparation method comprises esterification reaction and polymerization, wherein the temperature of the esterification reaction is 200 DEG C to 255 DEG C, the temperature of the polymerization is 270 DEG C to 280 DEG C, and the vacuum degree of the polymerization is 0.098 MPa to 0.1 MPa. The price of raw materials of the ecological multifunctional ternary copolymerization PETG polyester is low, so that the manufacturing cost is reduced, and the structural regularity of the PETG polyester is good, so that the strength is high. The heat-shrinkable film prepared from the obtained ecological multifunctional ternary copolymerization PETG polyester according to the invention is high in strength, transparency and heat shrinkage.

Owner:河南银金达新材料股份有限公司

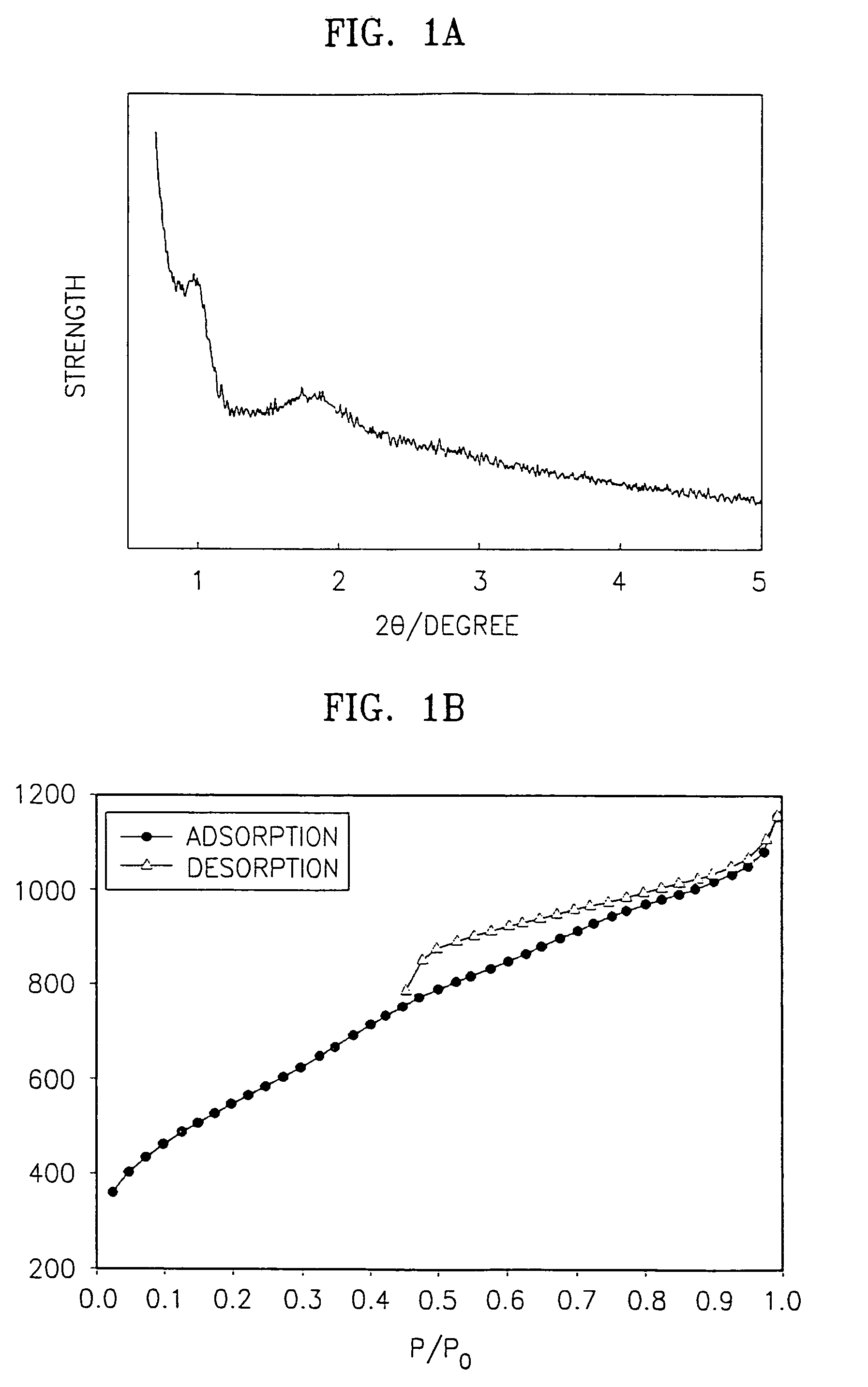

Carbon molecular sieve and method for manufacturing the same

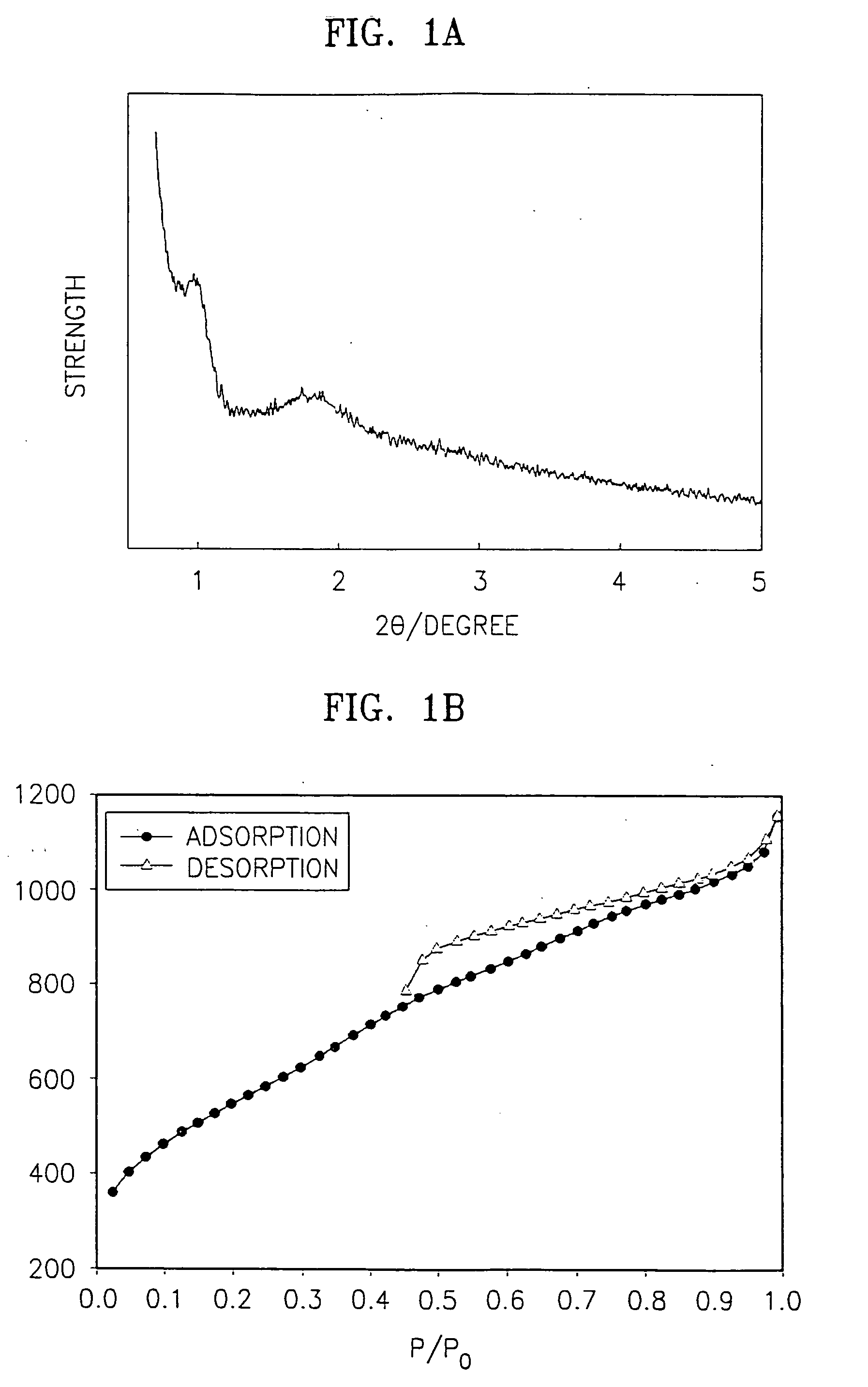

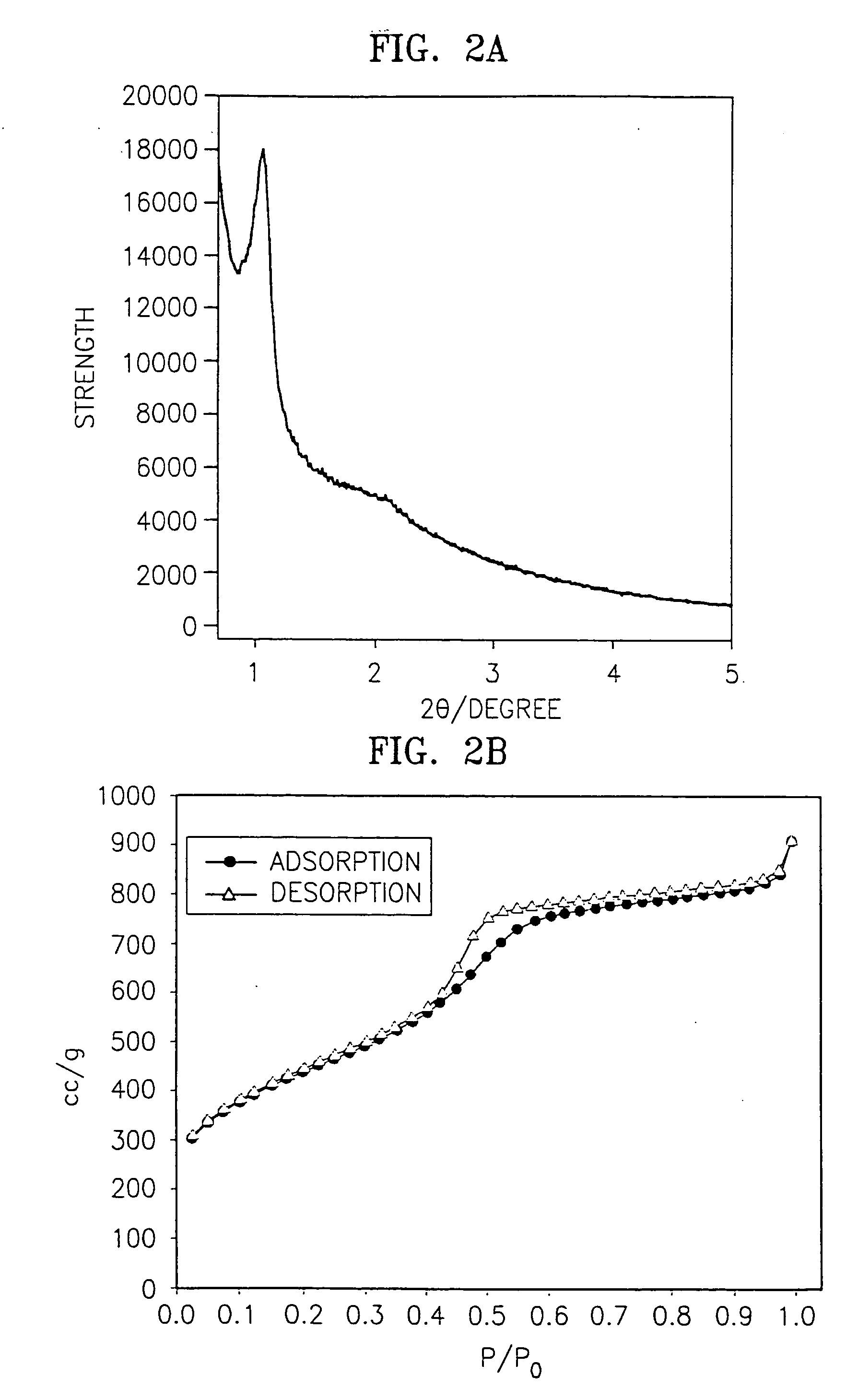

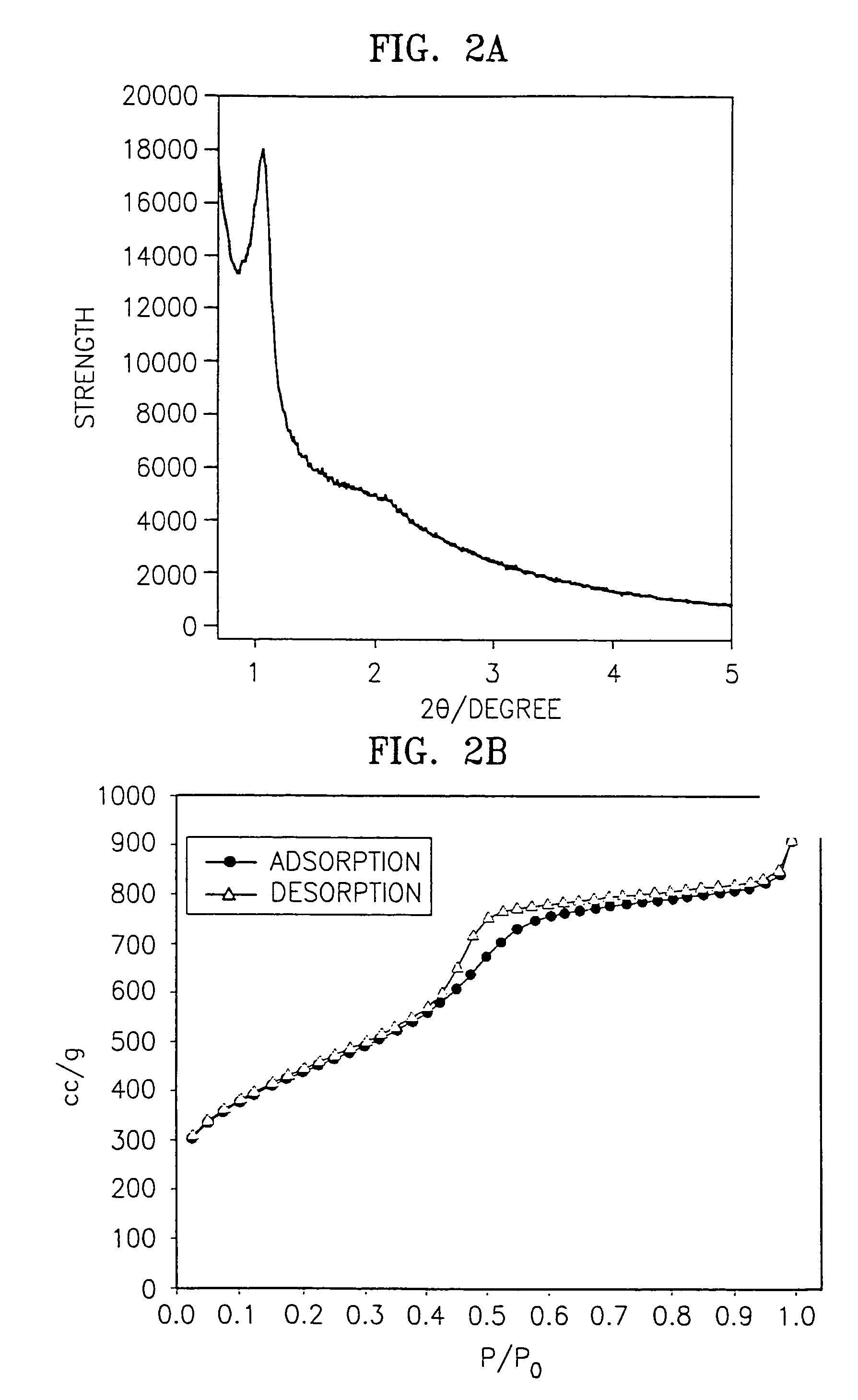

InactiveUS20050036935A1High porosityImprove structural regularityMolecular sieve catalystsOther chemical processesMolecular sieveFuel cells

A method for manufacturing a carbon molecular sieve with increased microporosity; a method for manufacturing a carbon molecular sieve with increased microporosity and improved structural regularity; a carbon molecular sieve with increased microporosity; a carbon molecular sieve with increased microporosity and improved structural regularity; a catalyst for a fuel cell using the carbon molecular sieve; and a fuel cell using the catalyst are provided.

Owner:SAMSUNG SDI CO LTD

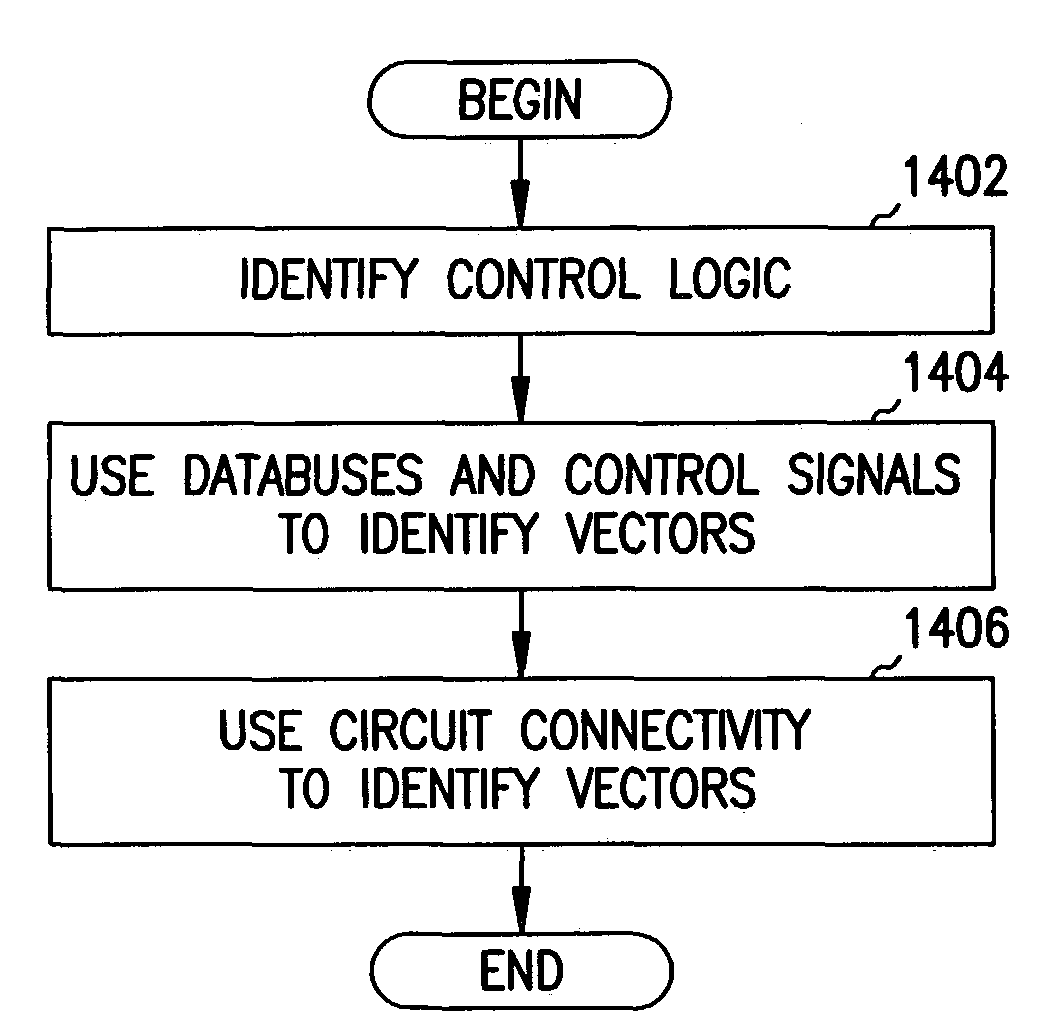

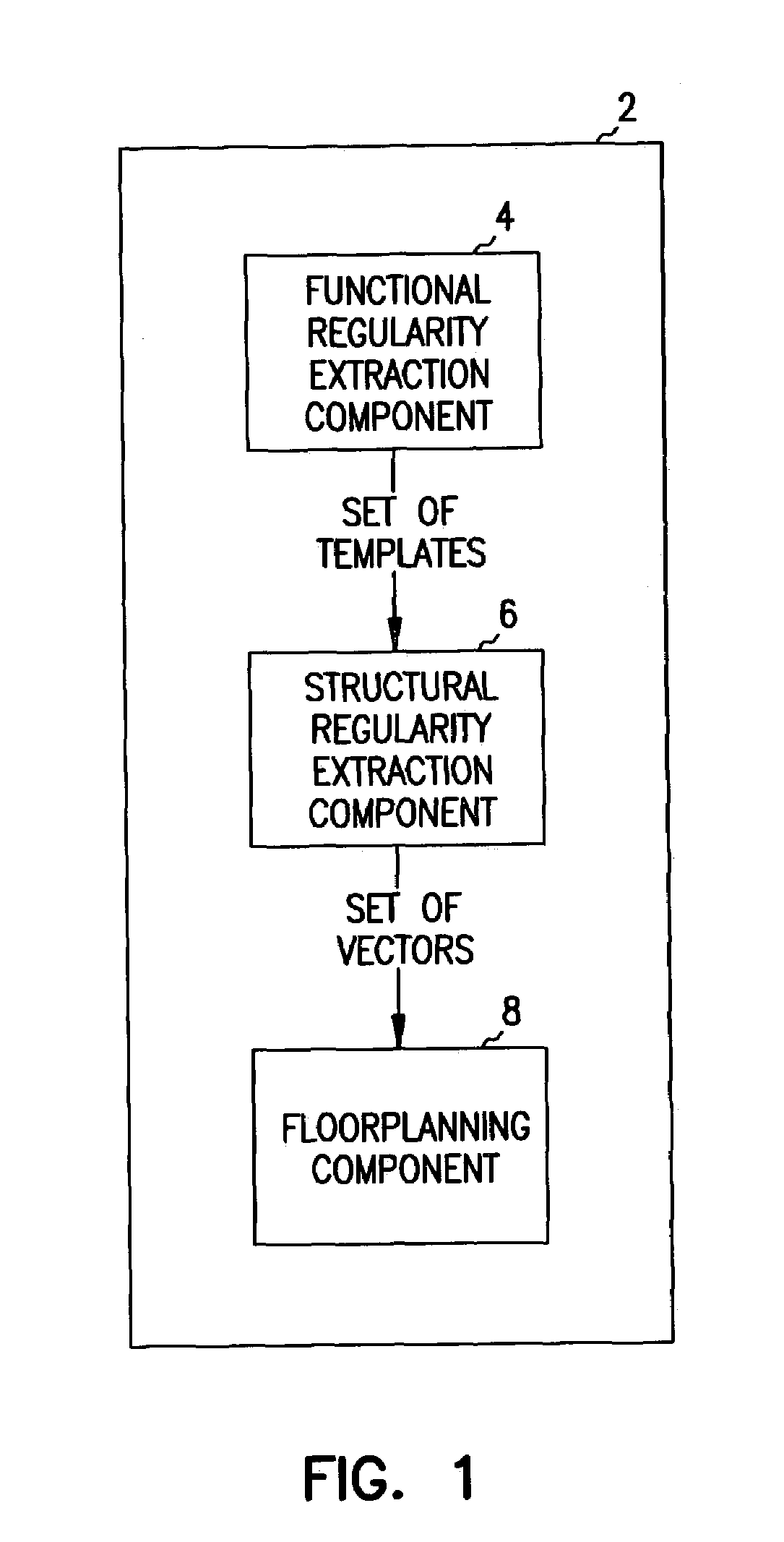

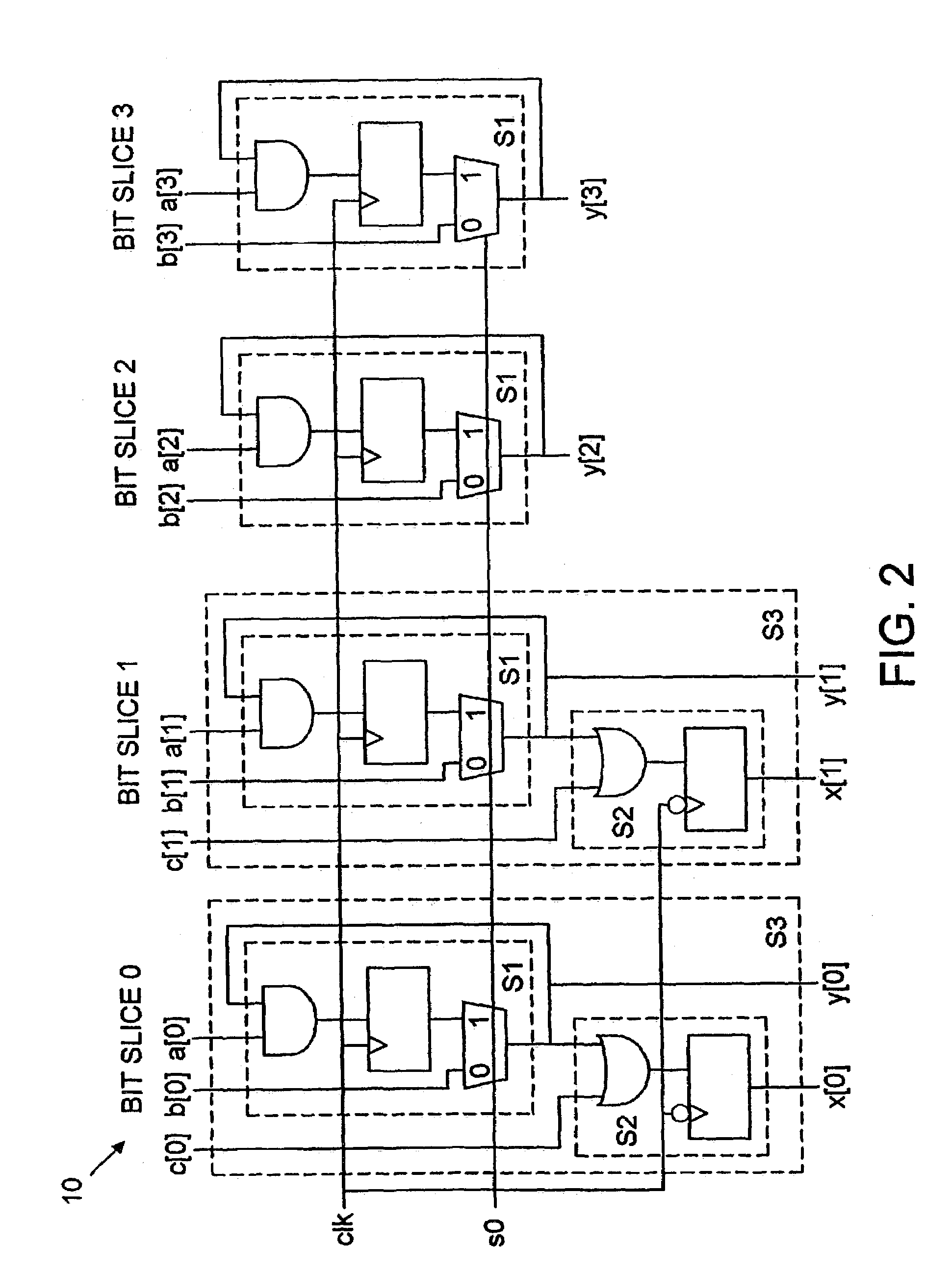

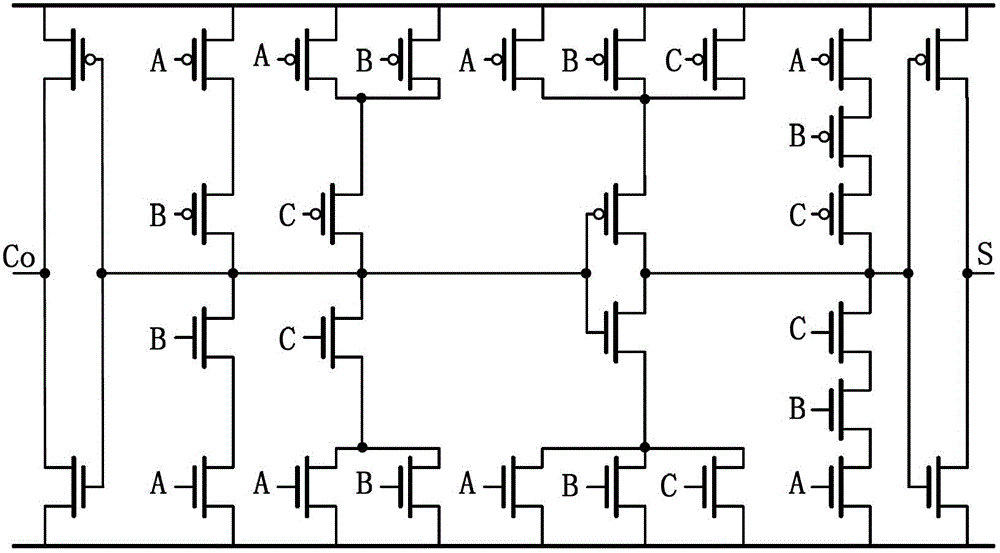

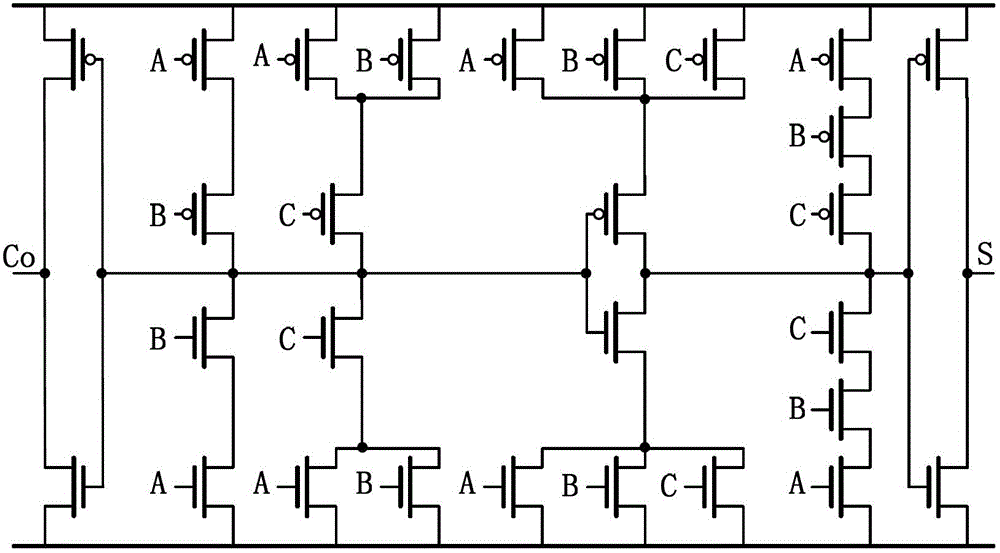

Structural regularity extraction and floorplanning in datapath circuits using vectors

InactiveUS7337418B2CAD circuit designSoftware simulation/interpretation/emulationDatapath circuitsComputer Aided Design

In some embodiments, a computer-aided design system comprises a functional regularity extraction component, a structural regularity extraction component and a floorplanning component. The structural regularity extraction component provides a method to extract regularity for circuits (and in particular datapath circuits) based on the structural characteristics of a logic design. Some embodiments of the structural regularity extraction component automatically generate a set of vectors for the logic design. A vector is a group of template instances that are identical in function and in structure. The vectors generated by the structural regularity extraction component are used by a floorplanning component. The floorplanning component provides a method of generating a circuit layout from the set of vectors. In some embodiments, each vectors corresponds to a row in the circuit layout.

Owner:INTEL CORP

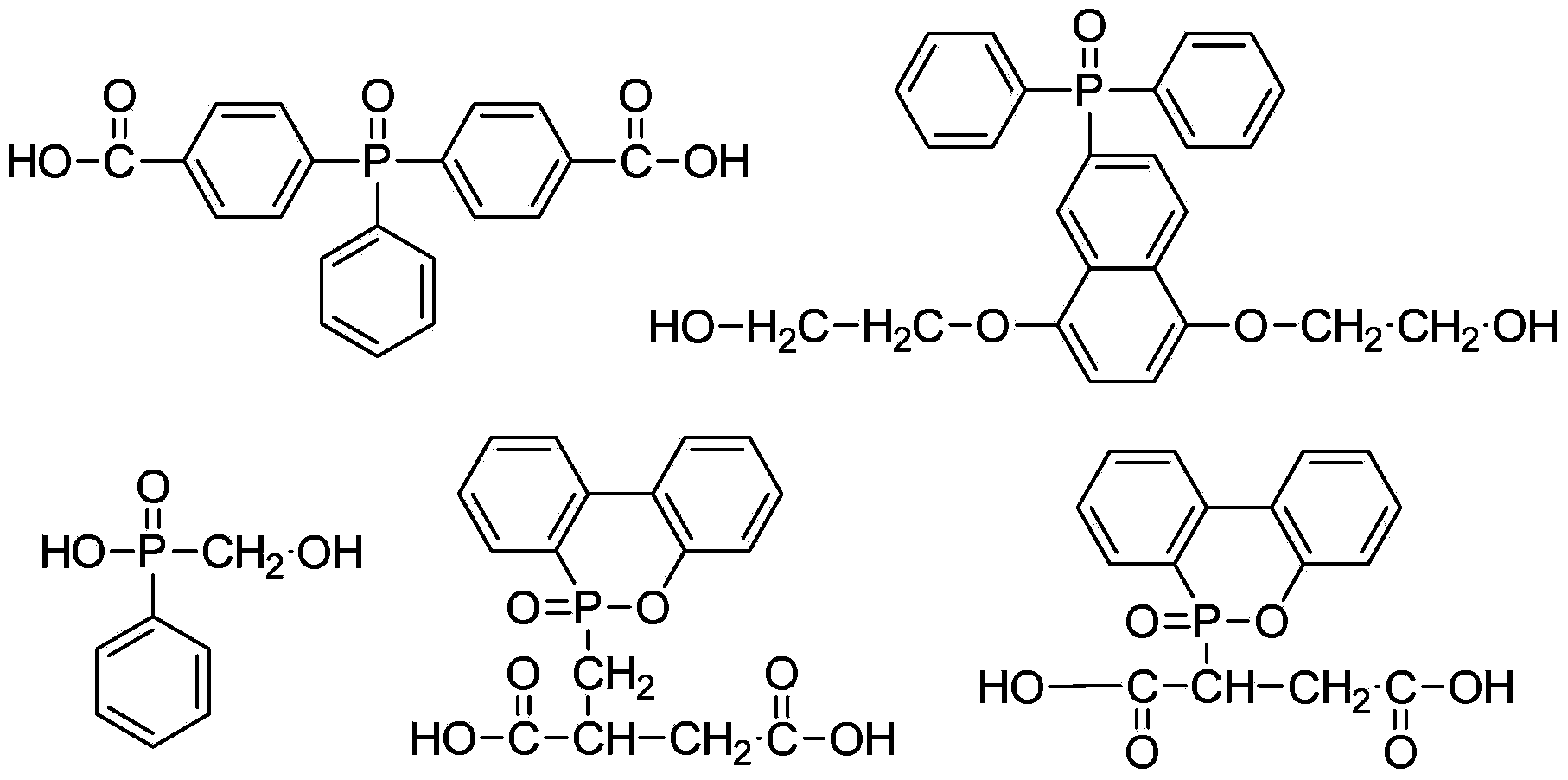

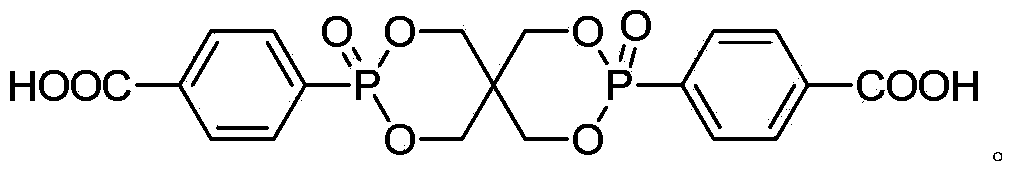

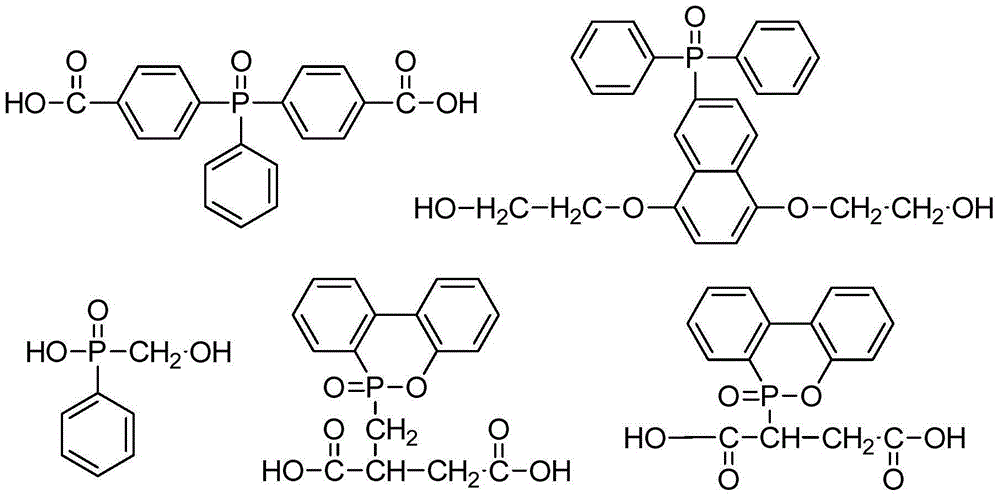

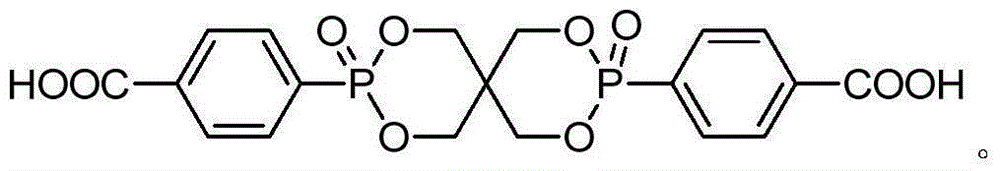

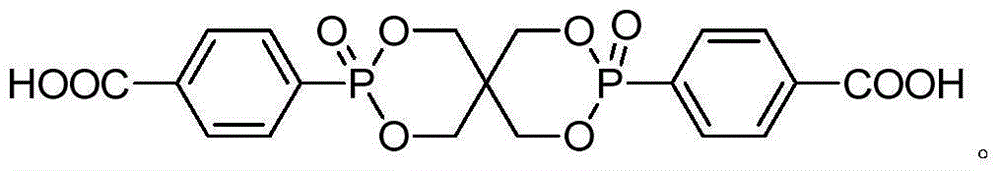

Phosphorus-containing flame retardant monomer, halogen-free flame retardant polyester containing the same and preparation method thereof

ActiveCN103641859AGood effectHigh in phosphorusGroup 5/15 element organic compoundsStructural regularityCrystallinity

The invention relates to a preparation method of halogen-free flame retardant polyester phosphorus containing a phosphorus-containing flame retardant monomer. The preparation method includes: according to a mass ratio, adding 100 parts of terephthalic acid, 3.6-15.2 parts of the phosphorus-containing flame retardant monomer, 46.3-54.7 parts of ethylene glycol, 0.035-0.062 part of a catalyst and 0.008-0.015 part of a heat stabilizer into a synthesis reaction kettle, and carrying out a conventional polyester synthesis process to prepare the halogen-free flame retardant polyester with a phosphorus content of 0.8-1.5wt% and an intrinsic viscosity number of 0.63-0.69dL g<-1>. The halogen-free flame retardant polyester provided by the invention has the characteristics of high structural regularity, high degree of crystallinity, and high melting point.

Owner:JIANGSU YUXING FILM TECH

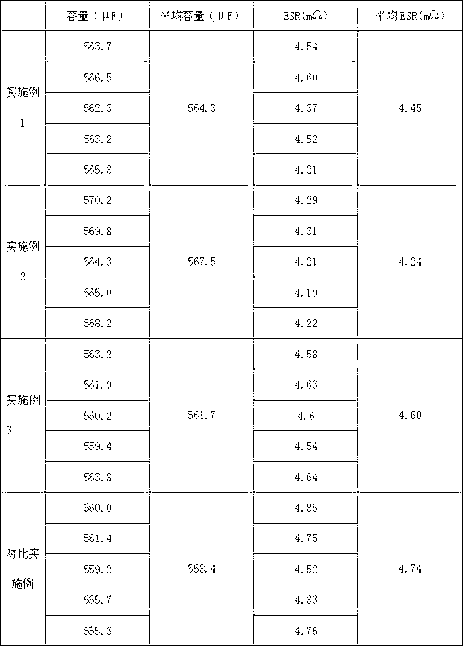

Manufacture method of solid electrolytic capacitor

ActiveCN102856077ALower ESRIncrease capacitySolid electrolytic capacitorsCapacitor electrolytes/absorbentsSolid state electrolyteStructural regularity

A manufacture method of a solid electrolytic capacitor comprises the following steps: inserting an isolation layer between an anode foil which is made of valve metal and provided with an oxidation film on the surface and a cathode foil, and winding into a core packet, winding and fixing the core packet by an adhesive tape; immersing the core packet into chemical fluid, applying voltage to chemically repair, and carrying out carbonizing, cleaning and drying; steeping the formed core packet in oxidant and monomer solution for 1-10 minutes; putting the core packet steeped with the oxidant and the monomer solution into a temperature control device to carry out heating treatment for a certain period of time, and initiating polymerization, wherein the heating treatment is multi-segment polymerization at different temperature ranges, the temperature ranges ascend in a ladder form, and the polymerization temperature range is 20-200 DEG C; packaging the core packet into an aluminum shell, sealing by a rubber stopper, and carrying out segmental aging treatment on the sealed product at 80-180 DEG C. By the adoption of the manufacture method, a generated conductive polymeric material is high in molecular weight, good in structural regularity, and high in conductivity, so that the capacitor has the advantages of low equivalent serial resistance and high capacity.

Owner:SHENZHEN POLYCAP ELECTRONICS TECH

(CO) polymerization process of fluorinated olefinic monomers in aqueous emulsion

InactiveUS6096795AStable end-groupsEasy to controlPhotomechanical apparatusOptical articlesPolymer scienceEmulsion

This invention relates fluorinated polymers having high structural regularity, characterized by a high maximum operating temperature and by improved mechanical and processability properties, prepared by a (co)polymerization process of fluorinated olefinic monomers, optionally in association with non-fluorinated olefins, in aqueous emulsion, in the presence of radical photoinitiators and of ultraviolet-visible radiation.

Owner:AUSIMONT SPA

Method for preparing natural high-molecular material by utilization of rare earth metal ion coordination

InactiveCN106243240AOvercome toxicityOvercome compatibilityProsthesisDiffusion methodsStructural regularity

The invention discloses a method for preparing a natural high-molecular material by the utilization of rare earth metal ion coordination. Through strong coordination between rare earth metal ion and oxygen atom in carboxyl function group, the rare earth metal ion coordinated natural high-molecular material is prepared by an ion permeation and diffusion method. According to the method, carboxyl-modified graphene oxide is introduced into the natural high-molecular material such that mechanical strength of the material is enhanced and structural regularity of the material also can be boosted. By selecting one ingredient from sodium alginate and xanthan gum as the base material, the material can be endowed with good biocompatibility and biodegradability. The method of the invention is simple and feasible. Reaction condition is mild. The prepared natural high-molecular material has good biocompatibility and strong mechanical properties.

Owner:SOUTHEAST UNIV

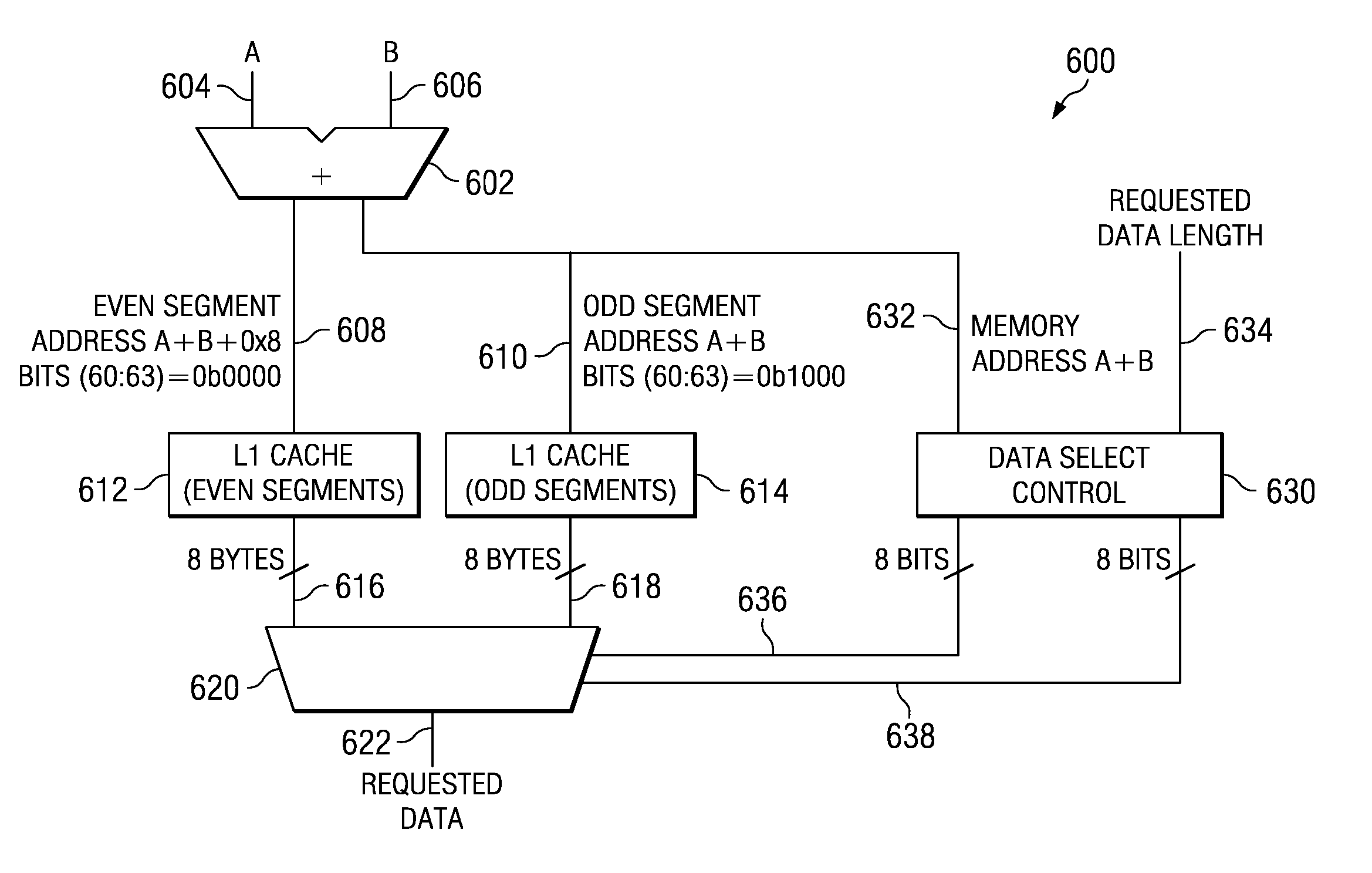

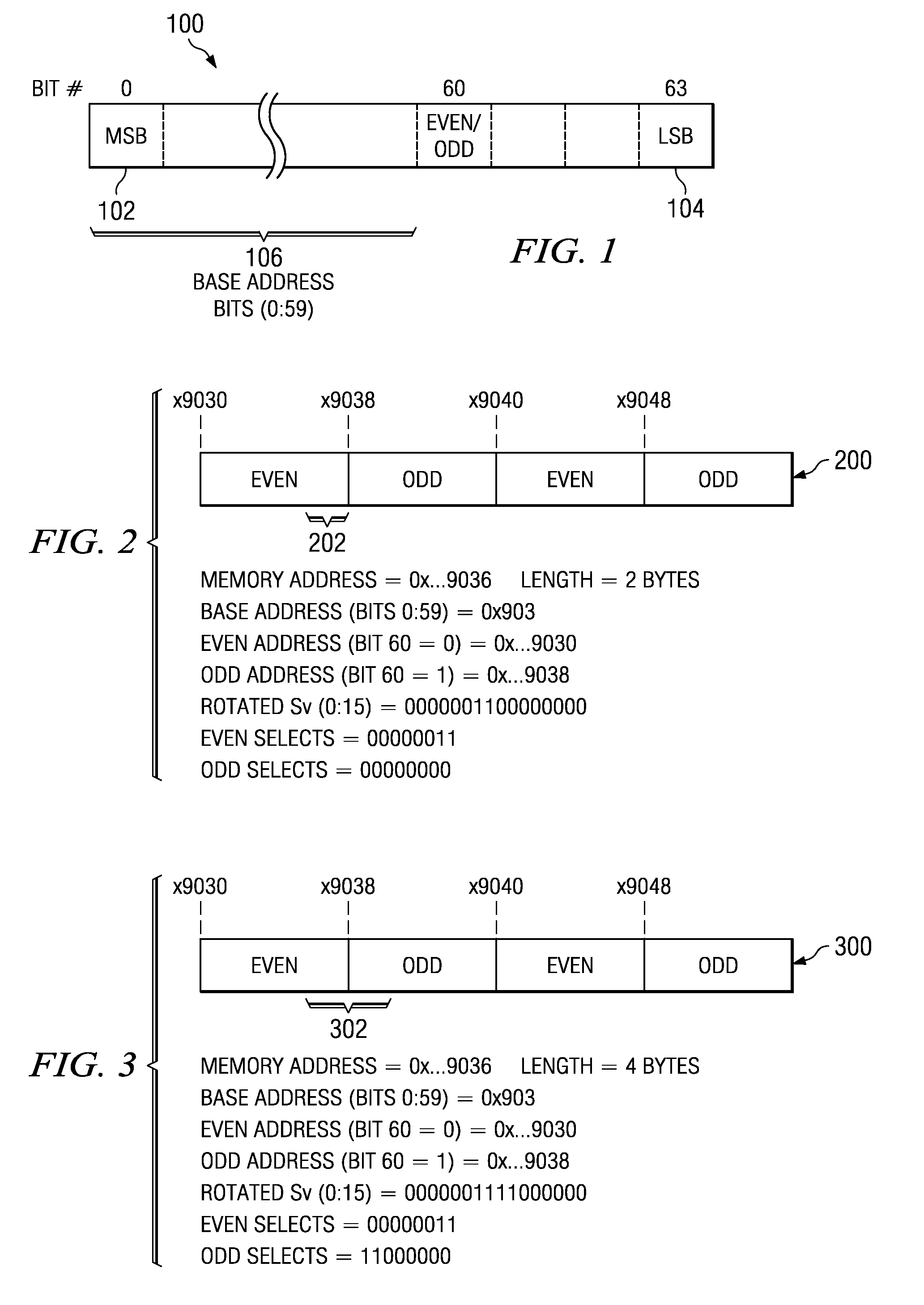

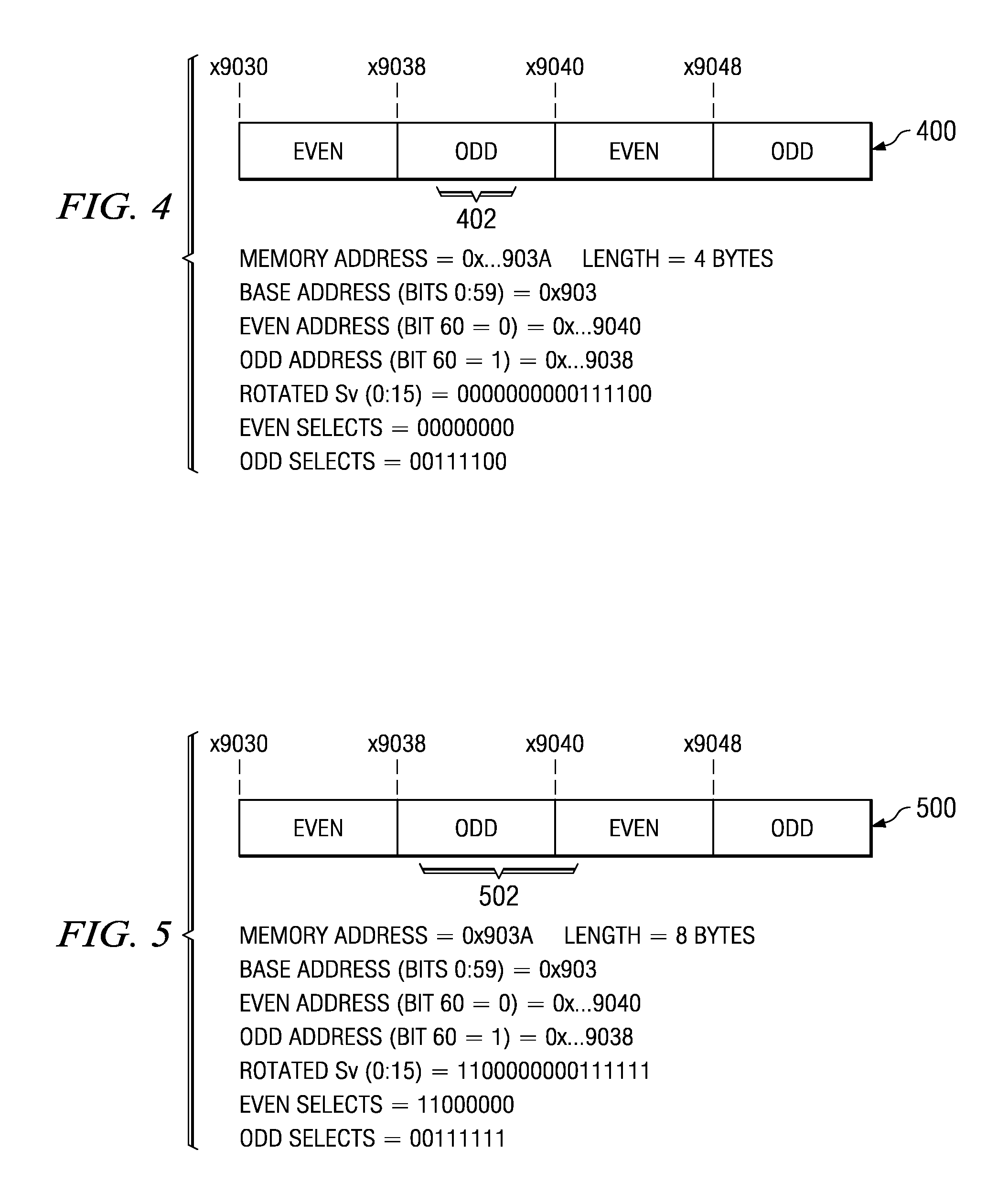

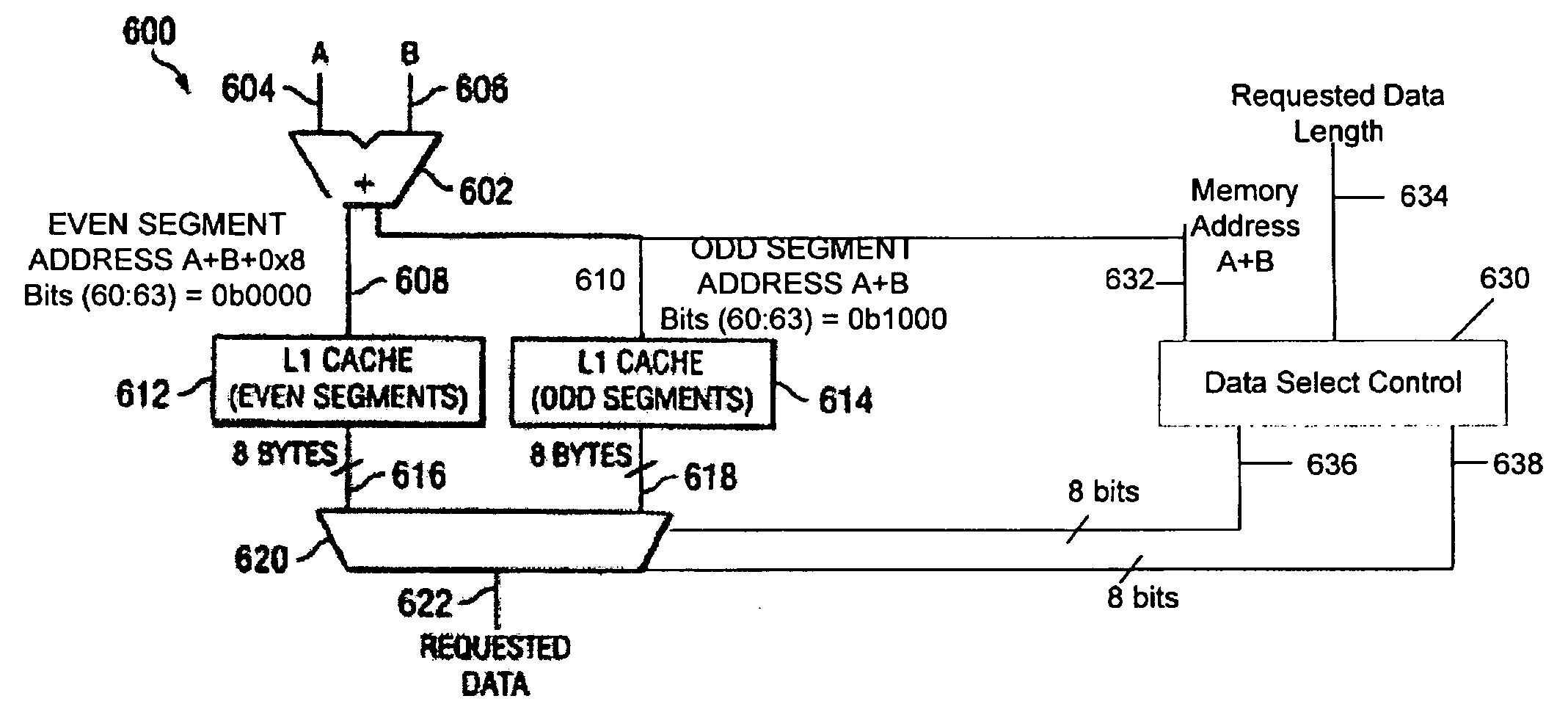

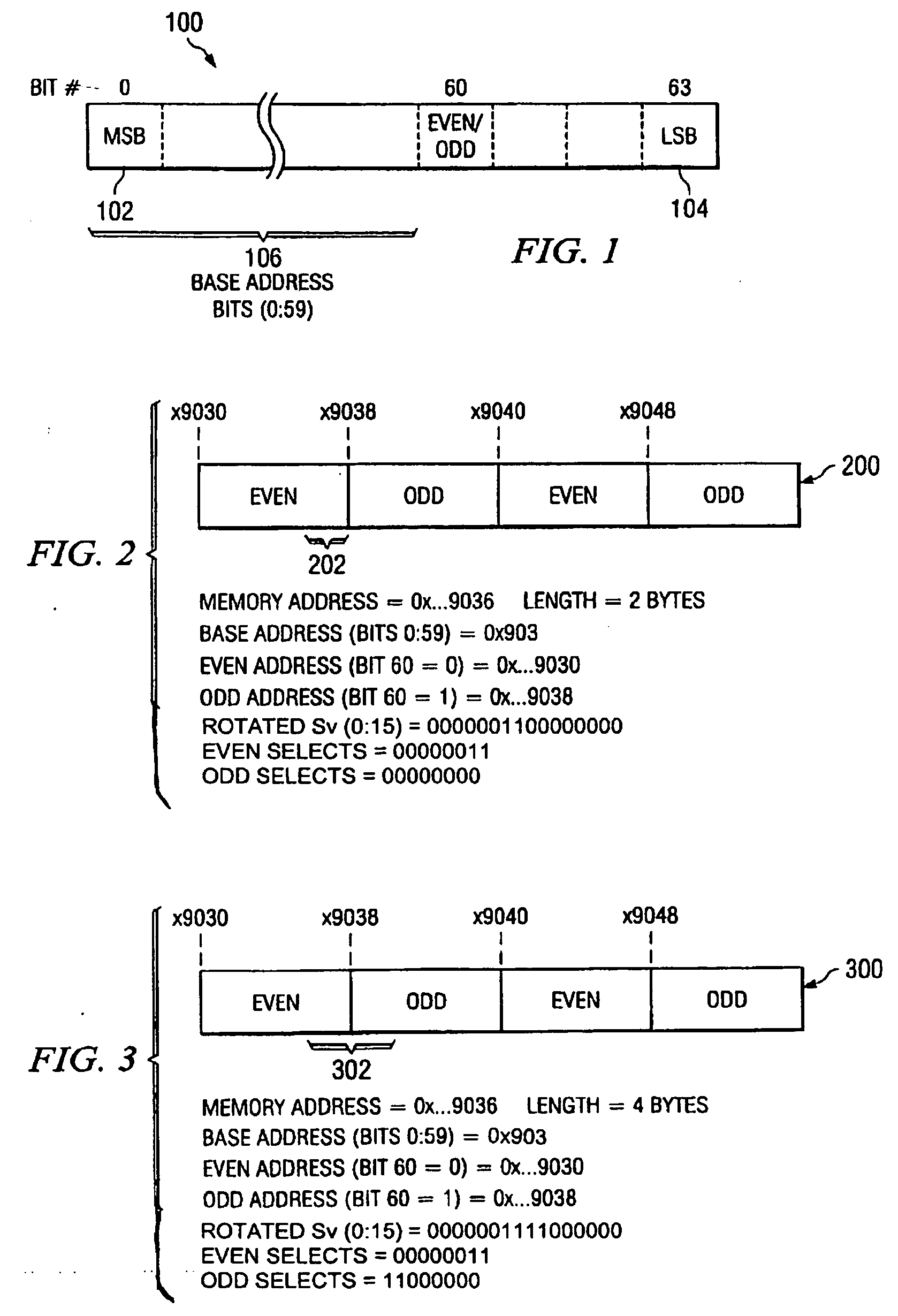

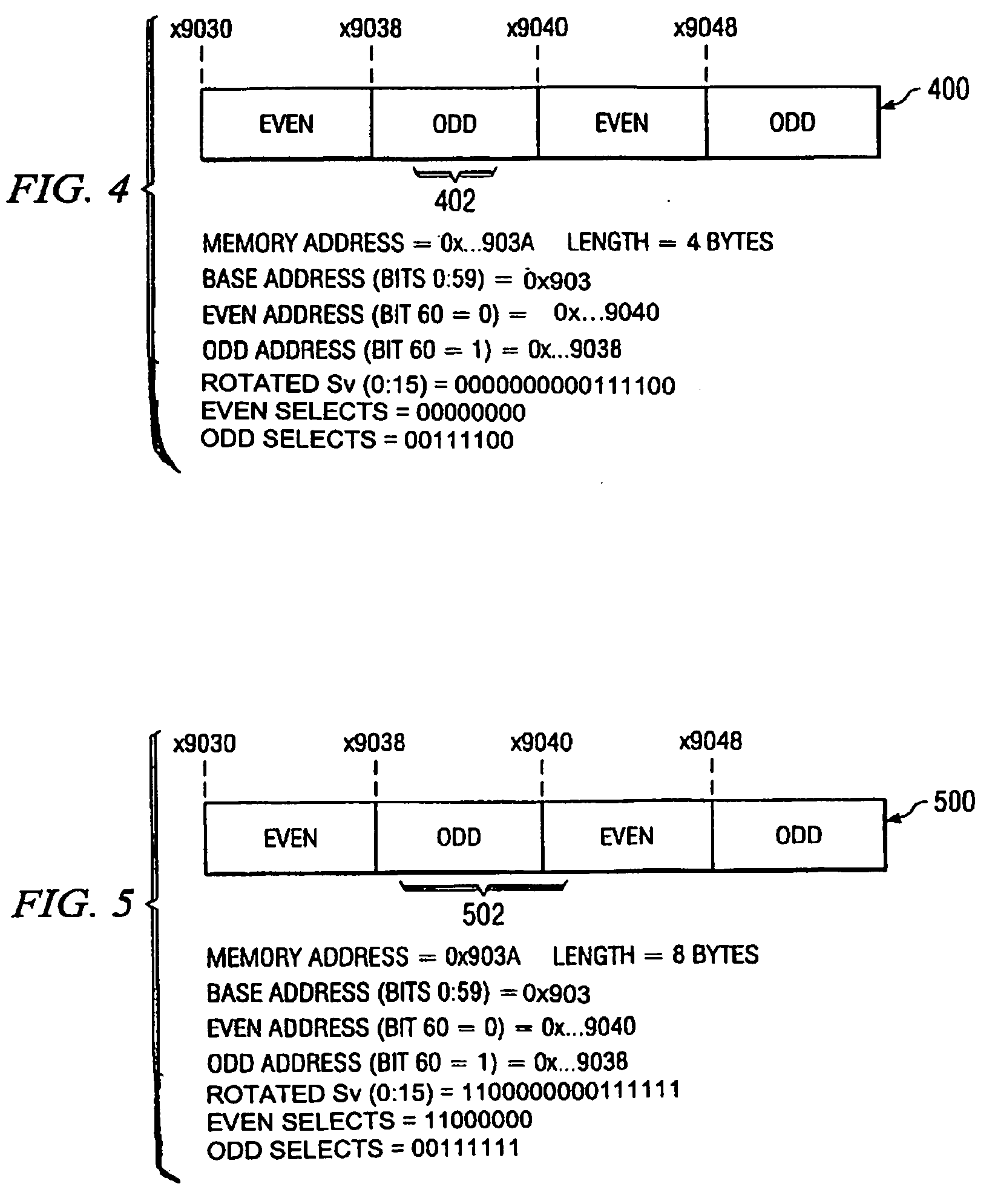

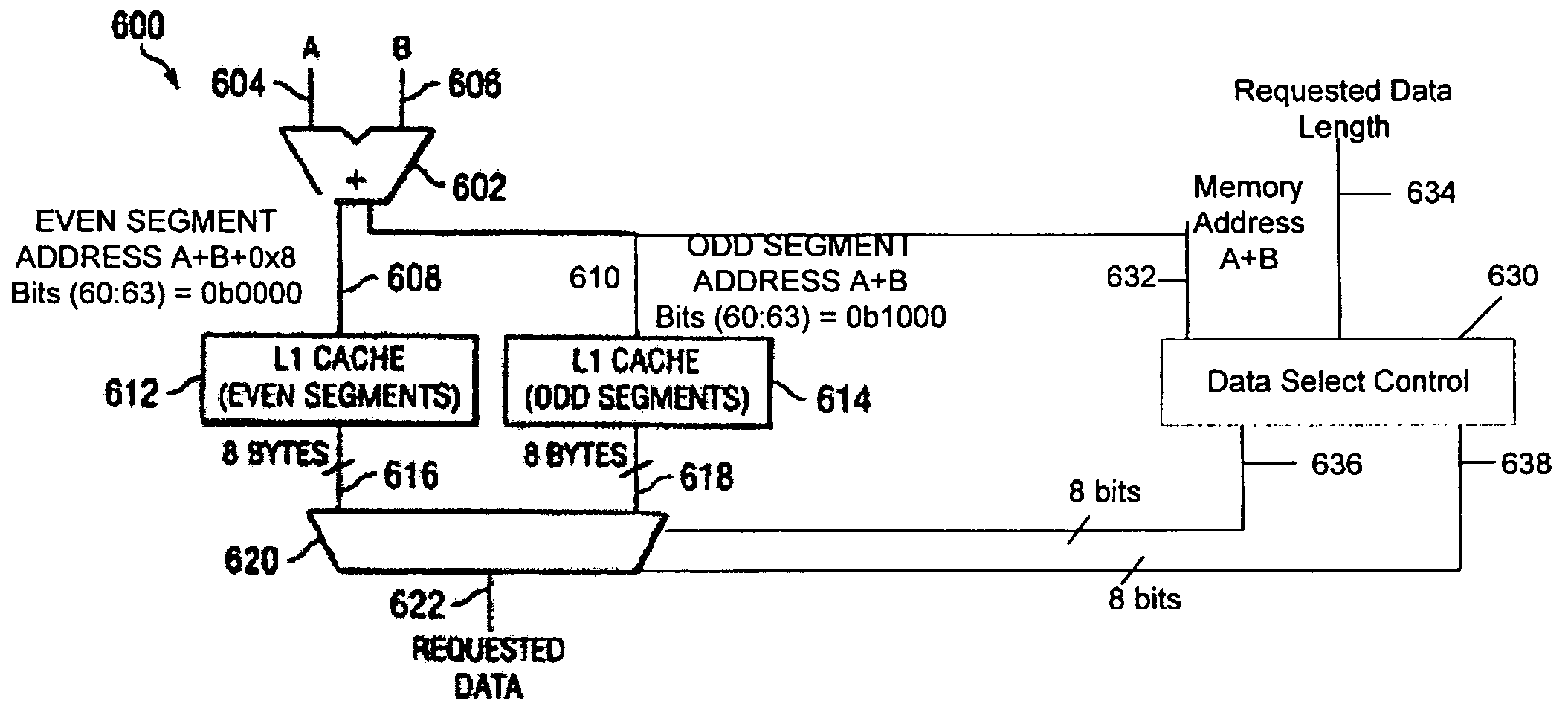

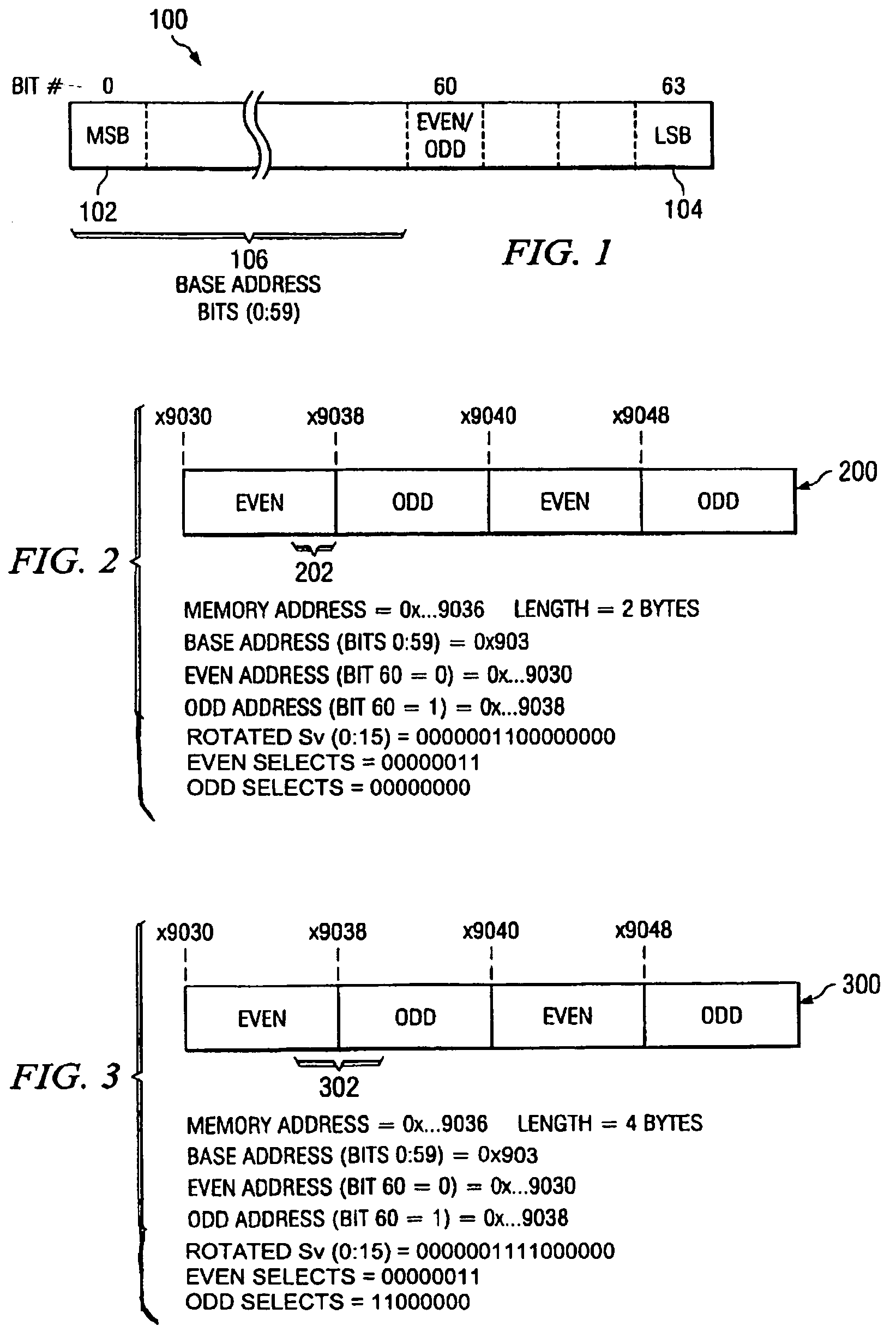

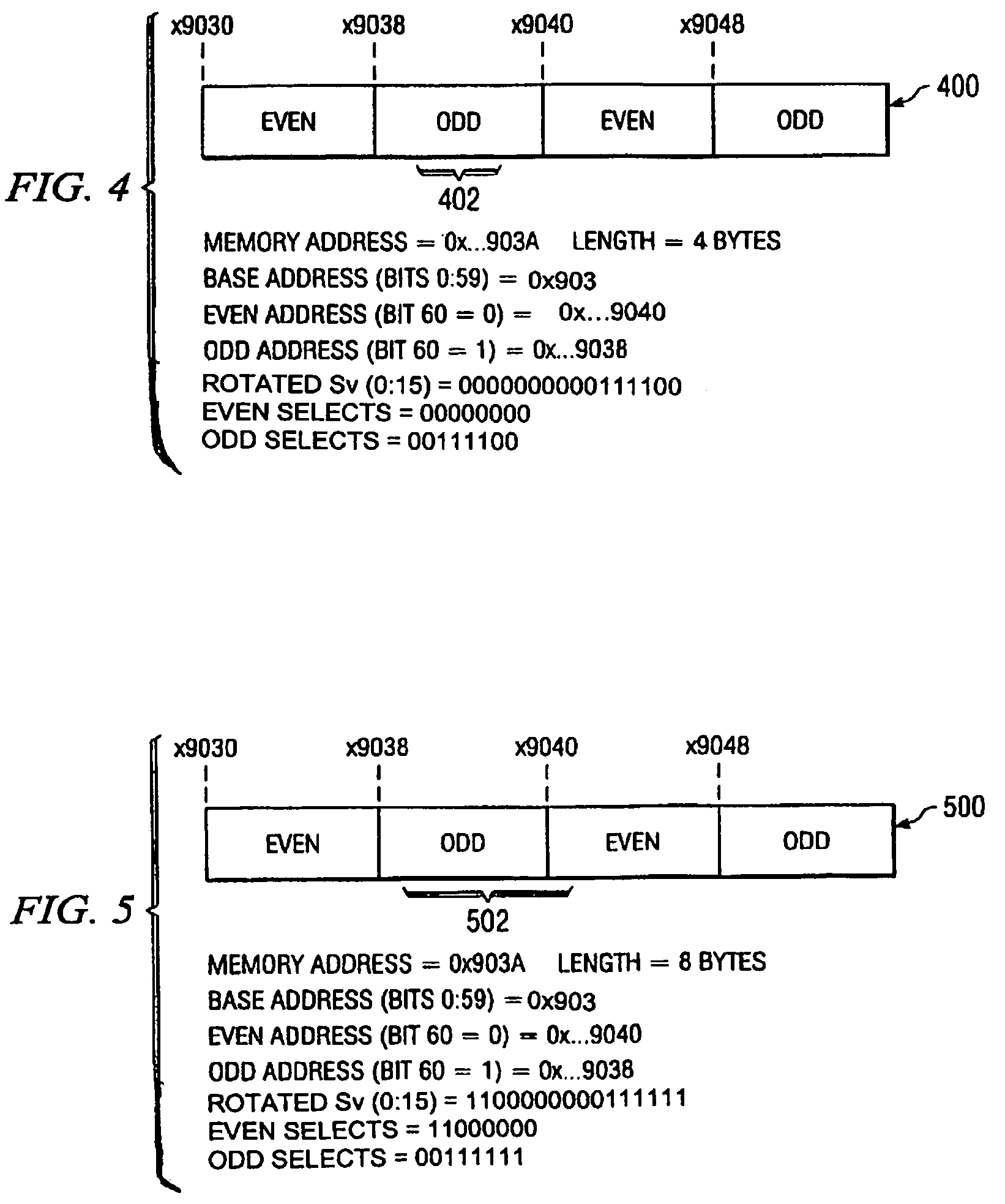

Method and apparatus for efficiently accessing both aligned and unaligned data from a memory

InactiveUS20080010433A1Extension of timeGenerate efficientlyMemory adressing/allocation/relocationMicro-instruction address formationMemory addressStructural regularity

A technique for improving access times when accessing memory, such as when accessing data from cache. By a unique manipulation and usage of a specified memory address in combination with the cache's internal organization, the address range required by the requested data can be covered by one odd and one even segment of the cache, where the odd segment is always at the base address created by the summation of the source operands and set to the odd segment, and the even address is created by summation of the source operands plus an offset value equivalent to the size of the cache line. This structural regularity is used to efficiently generate both the even and odd addresses in parallel to retrieve the desired data.

Owner:LINKEDIN

Method and apparatus for efficiently accessing both aligned and unaligned data from a memory

InactiveUS20060184734A1Extension of timeGenerate efficientlyMemory adressing/allocation/relocationMicro-instruction address formationMemory addressStructural regularity

A technique for improving access times when accessing memory, such as when accessing data from cache. By a unique manipulation and usage of a specified memory address in combination with the cache's internal organization, the address range required by the requested data can be covered by one odd and one even segment of the cache, where the odd segment is always at the base address created by the summation of the source operands and set to the odd segment, and the even address is created by summation of the source operands plus an offset value equivalent to the size of the cache line. This structural regularity is used to efficiently generate both the even and odd addresses in parallel to retrieve the desired data.

Owner:IBM CORP

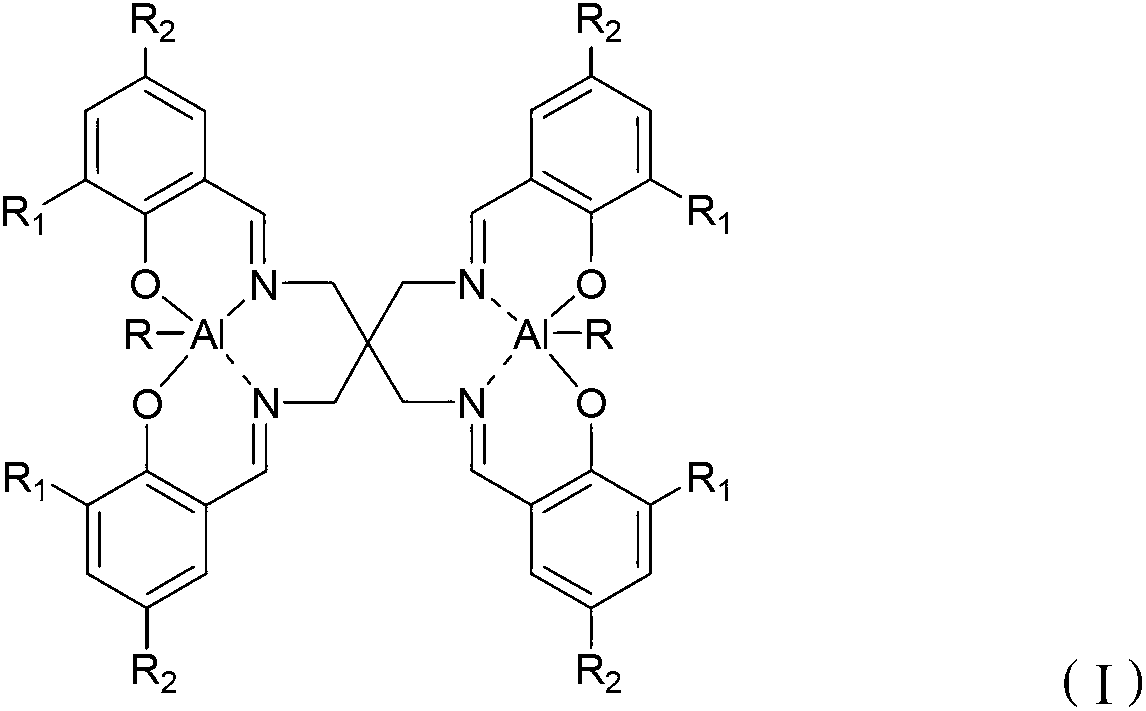

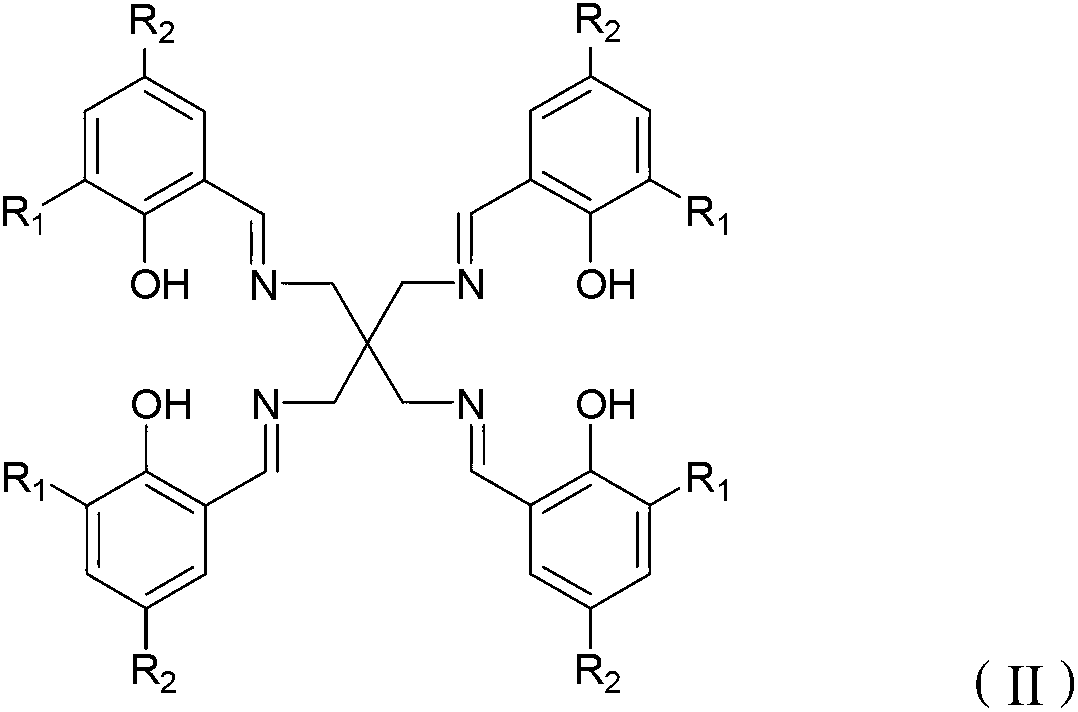

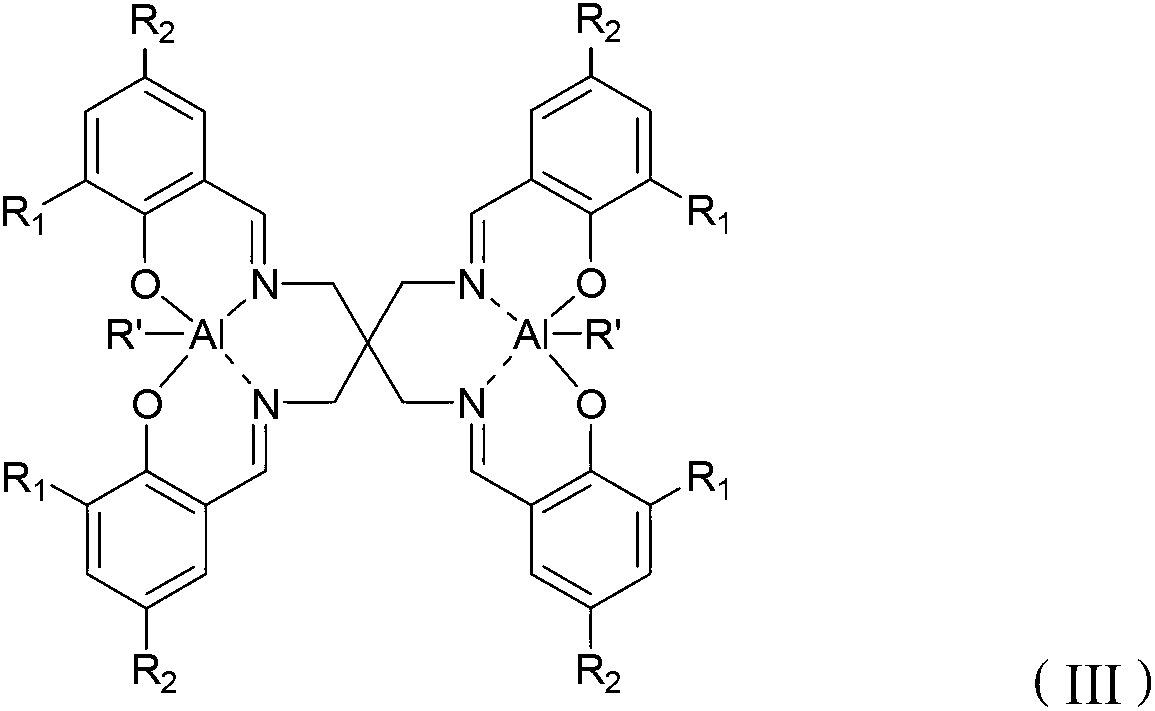

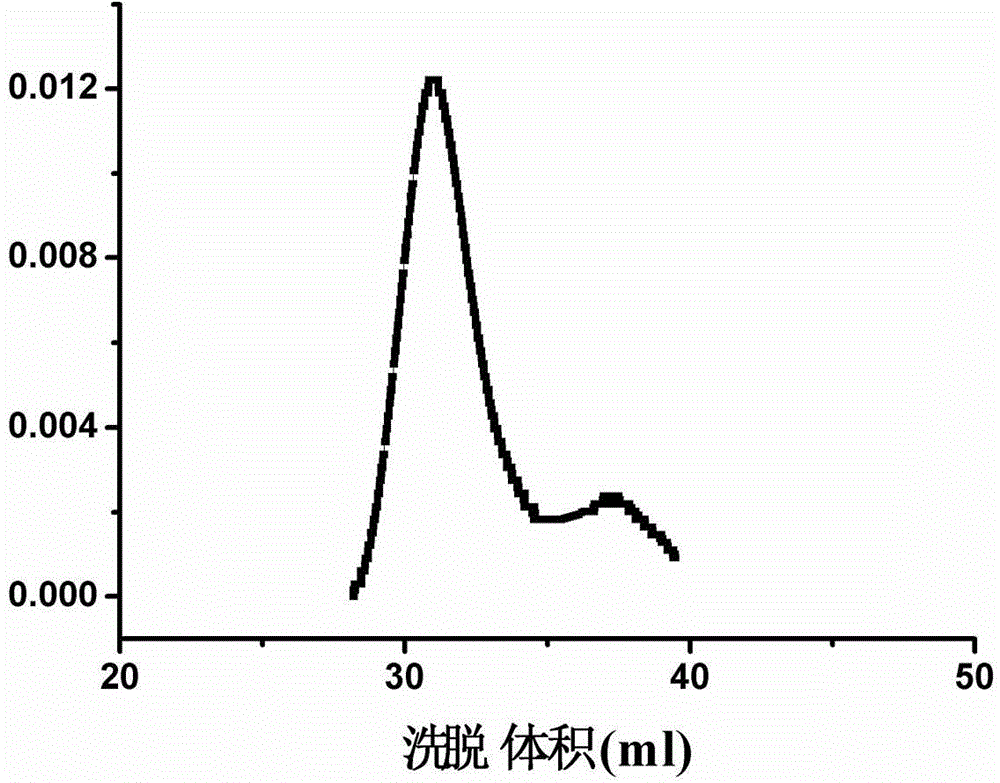

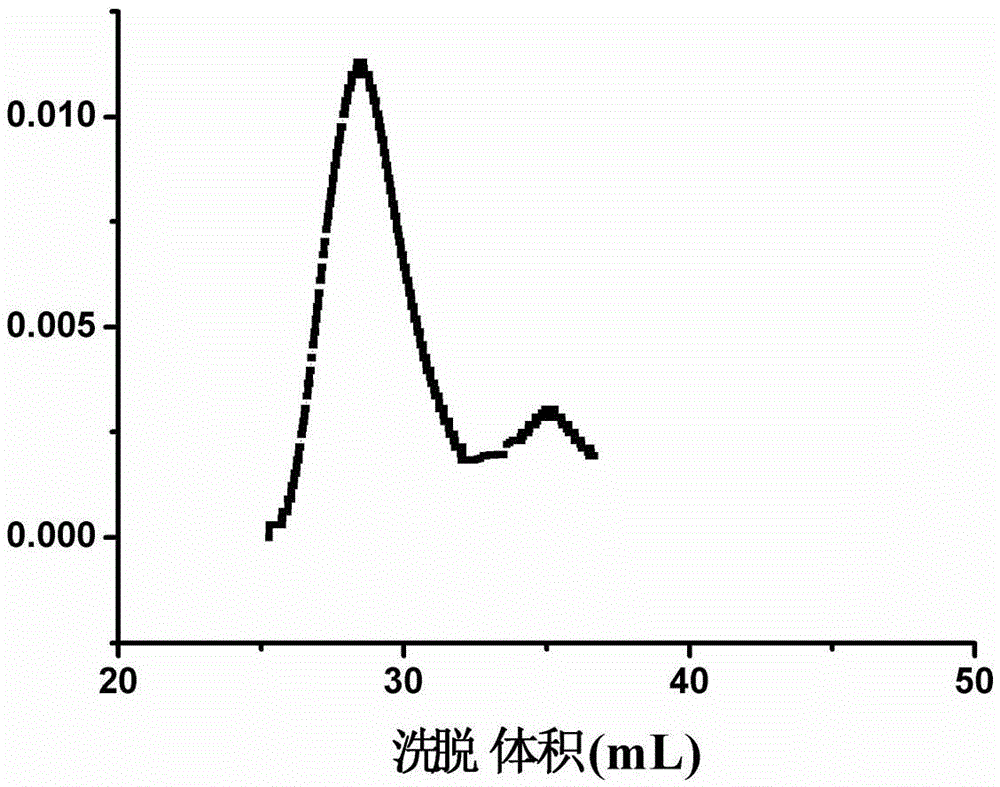

Schiff base aluminum compound, preparation method thereof and preparation method of polylactic acid

The invention provides a Schiff base aluminum compound, a preparation method thereof and a preparation method of polylactic acid. The formula (I) of the Schiff base aluminum compound is shown in the description. Compared with the metal-centered Schiff base in the prior art, tetramine compounds are used to connect four C=N functional groups, so that two metal active center binding sites are provided to form the double-metal-centered Schiff base. The double-metal-centered Schiff base has larger molecular space and larger steric hindrance, so that selectivity of lactide ring opening polymerization of the double-metal-centered Schiff base is improved, and spacially structural regularity of polymerizate is improved; reaction activity of the catalyst is improved by introducing the double metal centers, and activity of polymerization reaction is improved.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Preparation method of binary polyacrylonitrile carbon fiber precursor

InactiveCN103614800AReduce dosageImprove structural regularityFibre typesArtificial filament heat treatmentStructural regularityCarbon fibers

The invention relates to a preparation method of a binary polyacrylonitrile carbon fiber precursor. The method comprises the following steps: mixing acrylonitrile, a second comonomer beta-itaconic acid ester amide and a solvent in the presence of nitrogen, and adding an initiator; reacting for 22-38 hours under the condition of 35-75 DEG C, so as to obtain an acrylonitrile polymer; then filtering, taking off and defoaming, so as to prepare a spinning solution; spinning the spinning solution by virtue of a dry-jet wet process, stretching, oiling, drying, densifying, drawing by hot steam, and thermoforming, so as to obtain the binary polyacrylonitrile carbon fiber precursor. By adopting the preparation method, double functional group beta-itaconic acid ester amide is adopted as a comonomer, and a polyacrylonitrile macromolecule for the carbon fiber precursor is prepared by binary copolymerization and substituted ternary copolymerization. Thus, the dosage of the comonomer is reduced, meanwhile, the structural regularity of the polyacrylonitrile macromolecule is improved, and the prepared carbon fiber precursor is even in structure, small in fineness and high in strength.

Owner:DONGHUA UNIV

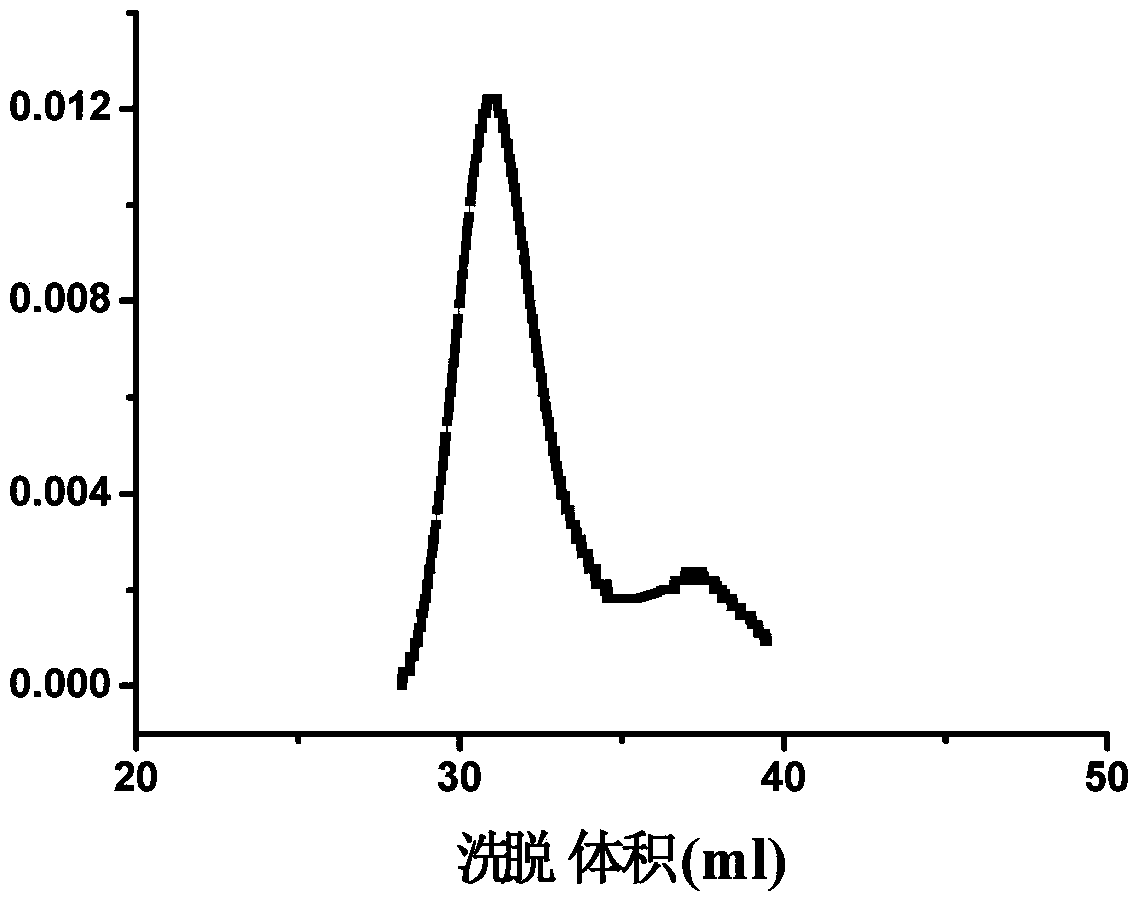

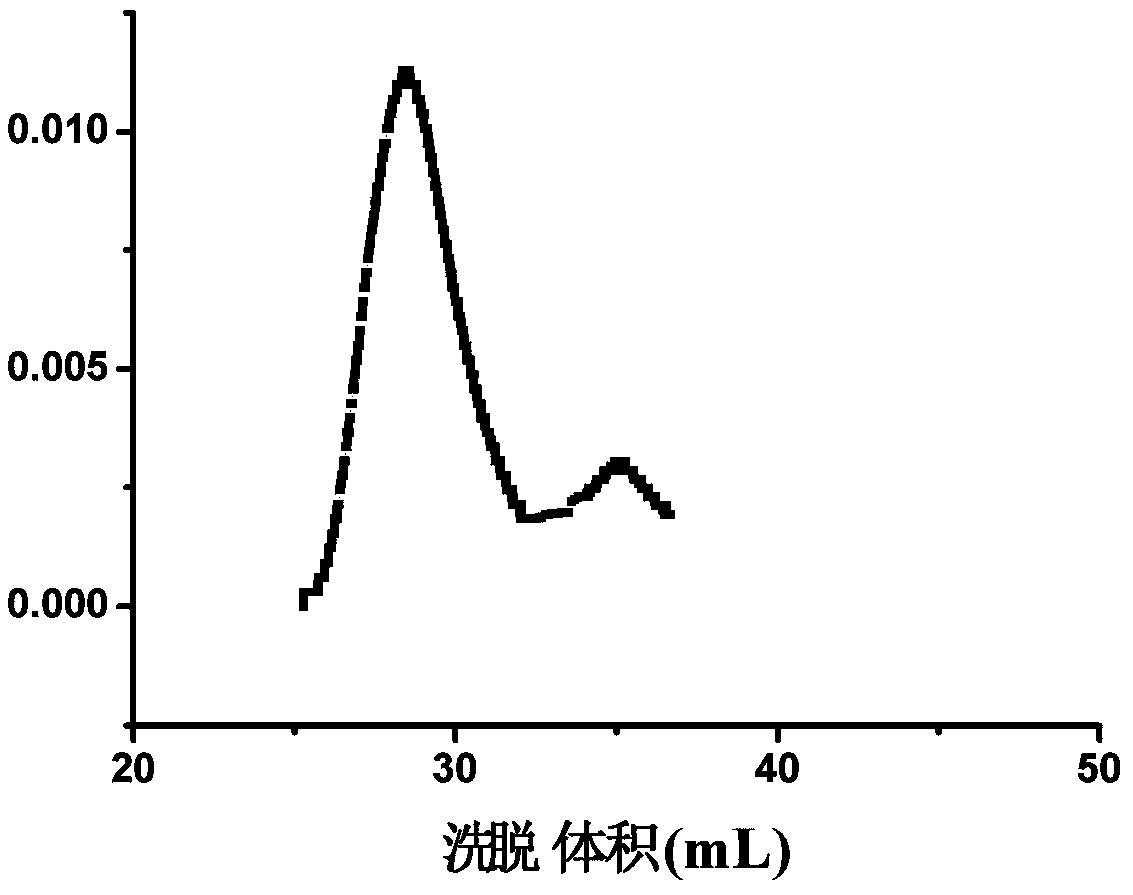

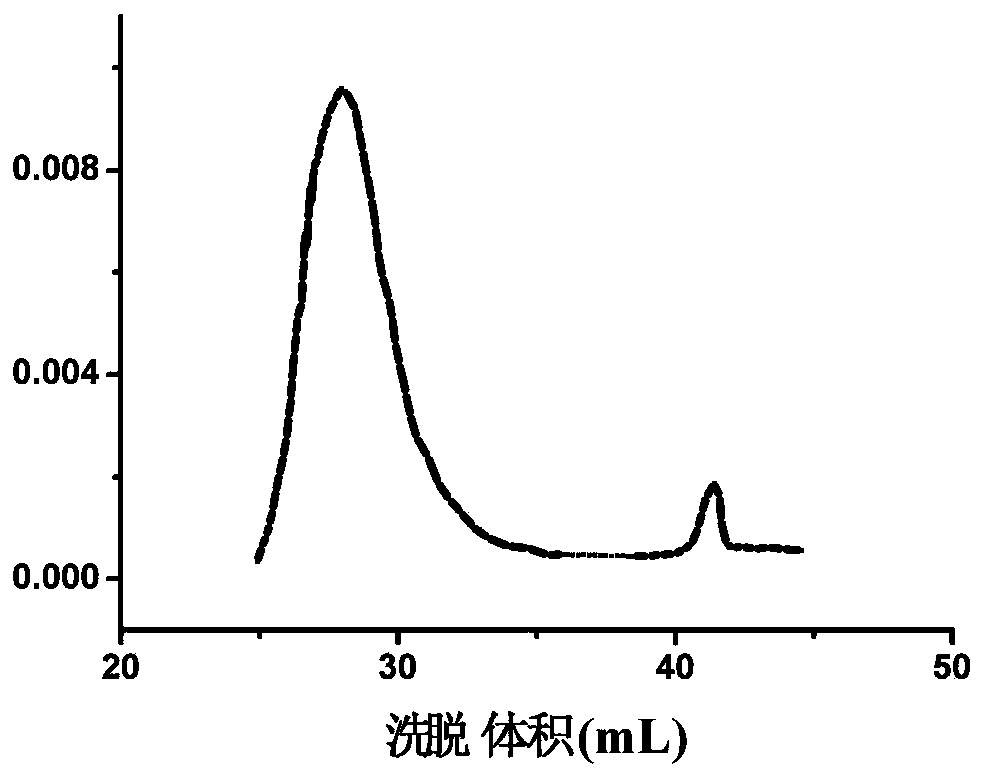

A high-efficiency water reducer for block polycarboxylate concrete and its preparation method

ActiveCN103482897BMicrostructural regulationComposition is easy to controlPolymer scienceStructural regularity

The invention provides a block poly-carboxylic acid concrete high-efficiency water reducing agent with an ordered structure and a preparation method thereof. The block poly-carboxylic acid is prepared by using atom transfer radical polymerization, the structural regularity and the molecular weight distribution of the poly-carboxylic acid are controlled effectively, and the water reducing agent is used in a cement dispersing process. By adoption of the block poly-carboxylic acid concrete high-efficiency water reducing agent and the preparation method thereof, the problems of uncontrollable molecular weight of the poly-carboxylic acid, wider molecular weight distribution, un-designable molecular structure and the like are solved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

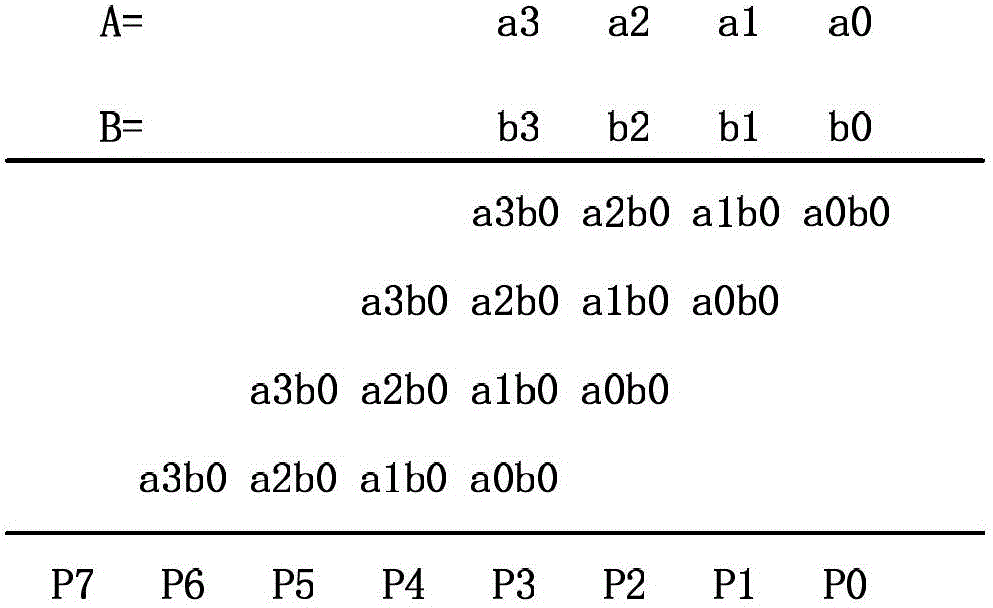

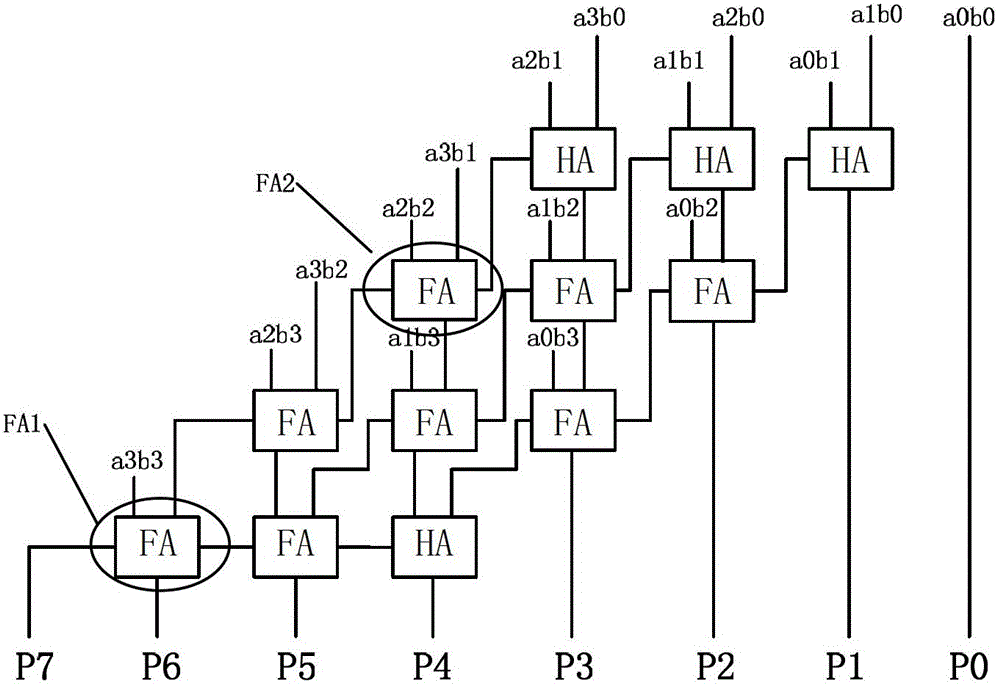

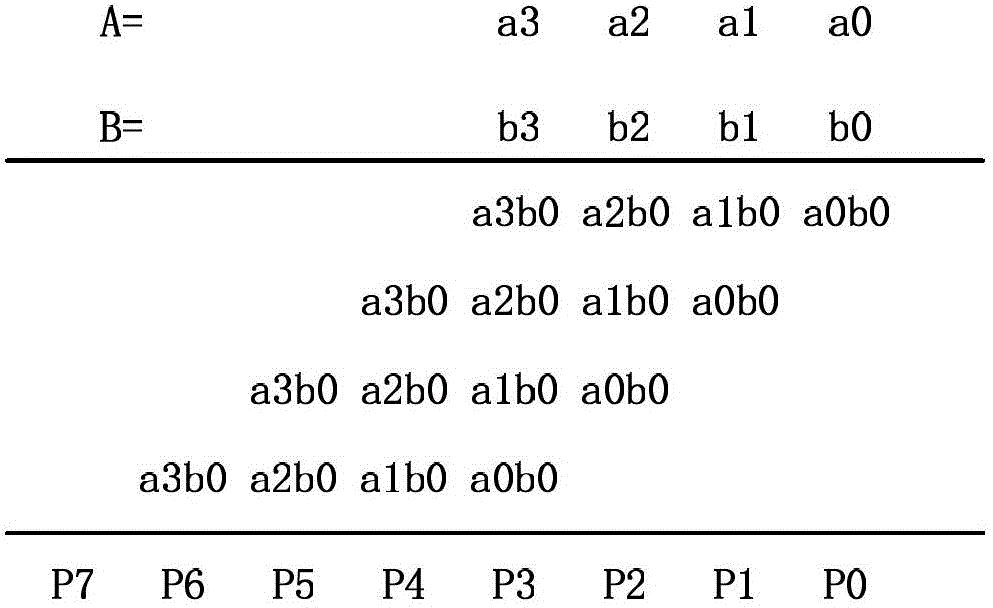

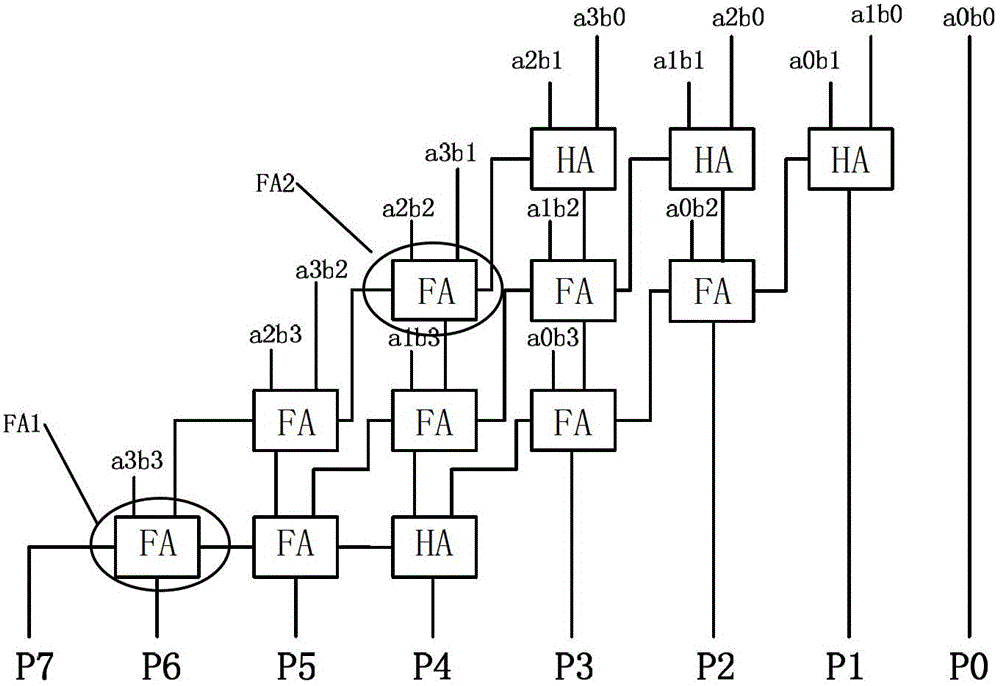

Carry-saving multiplier

InactiveCN102722351AReduce areaReduce in quantityComputation using non-contact making devicesStructural regularityGate array

The invention discloses a carry-saving multiplier, relating to the technical field of integrated circuit. Through analysis on the conventional carry-saving multiplier, full adders at two special positions in an array can be logically simplified, so that the speed and the power consumption are optimized on the premise of reducing the area of the multiplier; and furthermore, in an AND gate array for generating a partial product, each row of AND gates has a common signal, so that the number of transistors is reduced by sharing a downwardly drawn NMOS (N-channel Mental-oxide-semiconductor) tube; therefore, in combination of the two ways, a novel simplified carry-saving multiplier is constructed. A simulating result shows that compared with the conventional carry-saving multiplier, the carry-saving multiplier disclosed by the invention can reduce a power consumption delay product as high as 12.41 percent; the improved carry-saving multiplier still has the advantage of structural regularity of all array multiplier, so that the improved carry-saving multiplier is still applicable to design of a large-scale integrated circuit; and meanwhile, due to advantages in the speed and the power consumption of the improved carry-saving multiplier, performance of a circuit system can be further improved.

Owner:PEKING UNIV

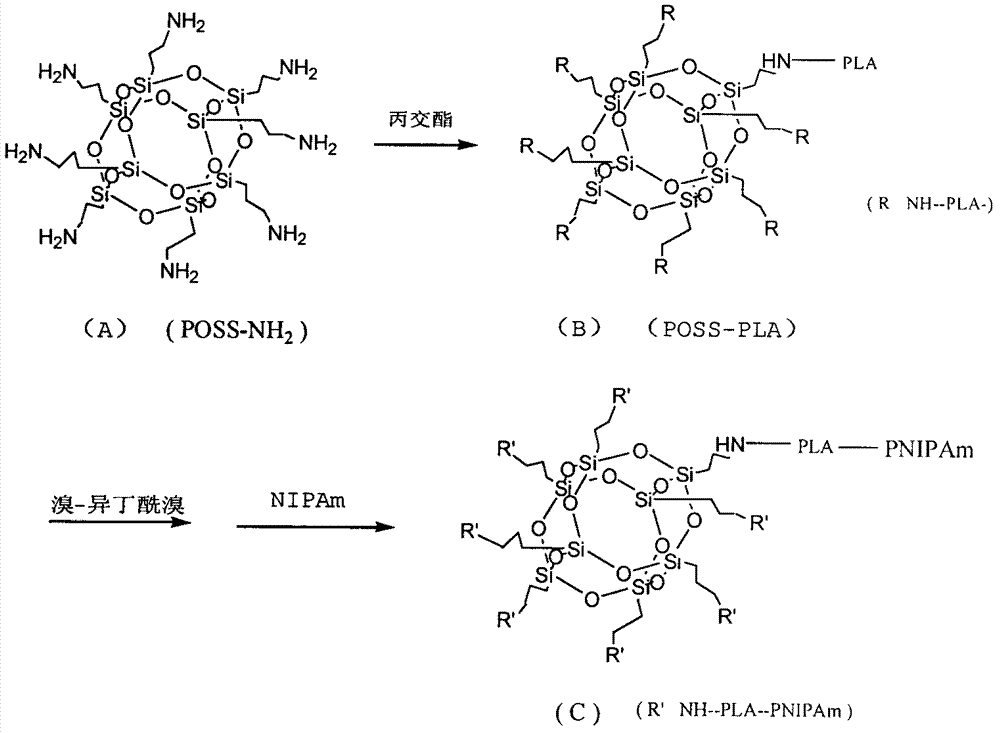

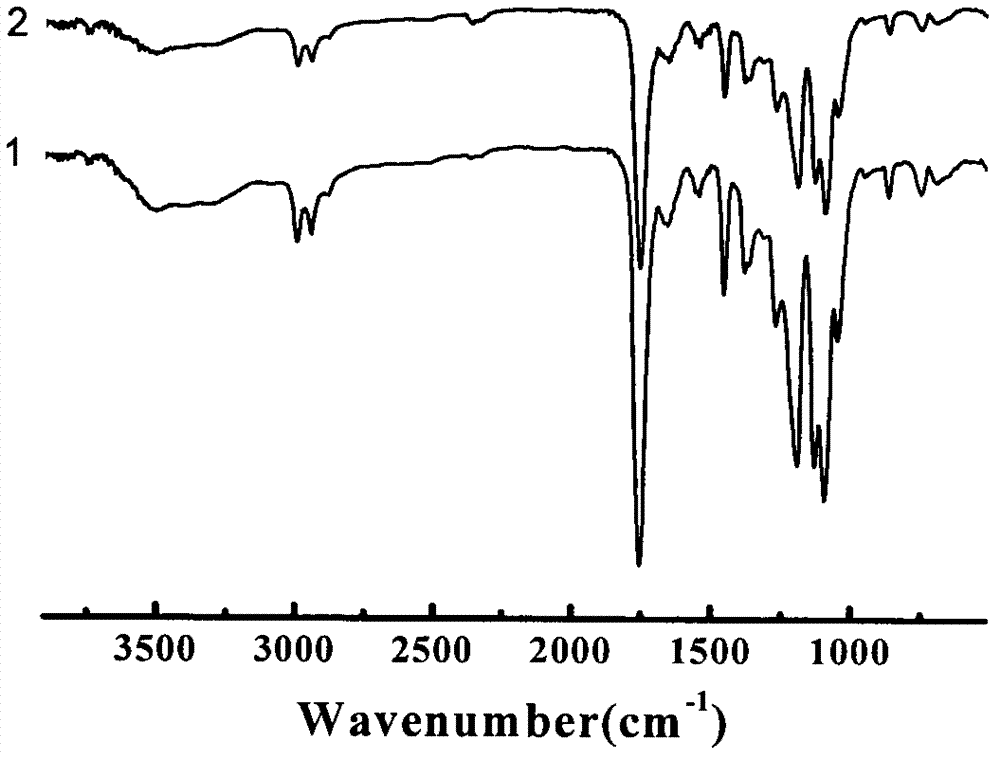

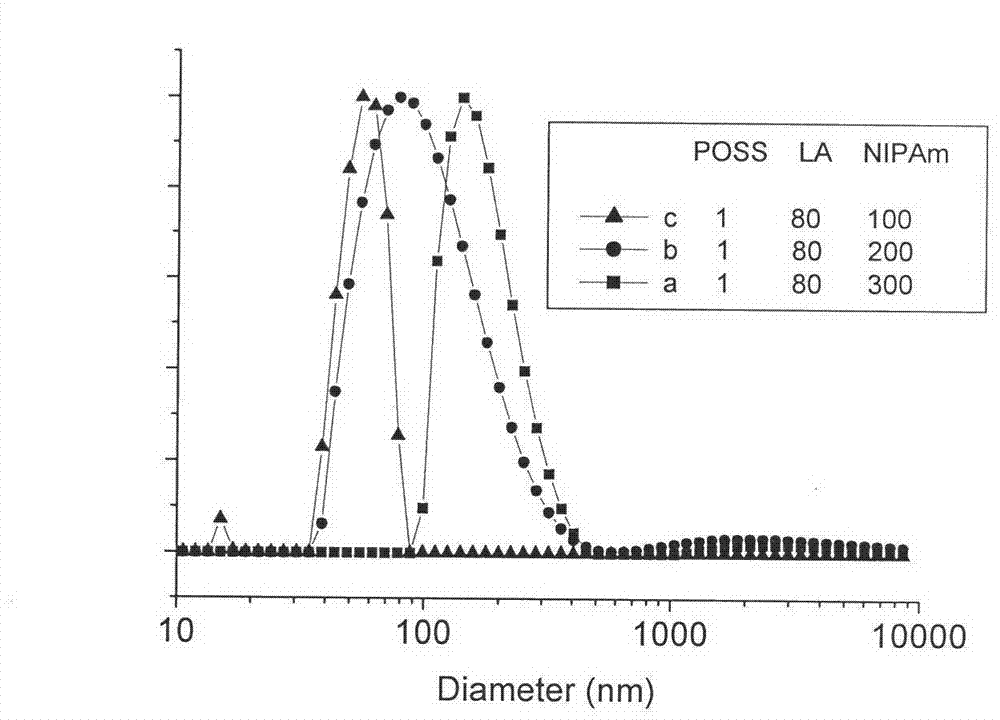

POSS/poly lactic acid and poly(n-isopropyl acrylamide) star block copolymer preparation

InactiveCN103087277AStable structureRegular shapeOrganic active ingredientsSolution deliveryPolymer scienceStructural regularity

According to the present invention, cage octa-aminopropyl silsesquioxane (POSS-NH2) is adopted as a starting molecule, an initiation effect of the surface amino in the POSS-NH2 is adopted to make the POSS containing a plurality of amino initiate active loop opening polymerization of D,L-lactide under catalysis of stannous octanoate to obtain a star polymer POSS-PLA having structural regularity, the terminal hydroxyl group of the star polymer is converted into a macromolecule initiator capable of initiating atom transfer radical polymerization (ATRP) to carry out an ATRP reaction of N-isopropyl acrylamide (NIPAAm) to synthesize a star block copolymer adopting the POSS as a center, adopting poly lactic acid as a core, and adopting poly(N-isopropyl acrylamide) as a shell, the star block copolymer is dissolved in DMF, the obtained solution is added to water in a dropwise manner to prepare micelles, a scanning electron microscopy (SEM) is adopted to observe a shape and a size of the micelle, and dynamic light scattering (DLS) is adopted to determine a particle size and distribution of the micelles and confirm structural regularity of the micelles, wherein a diameter of the micelles is about 170 nm, and the nanometer micelles have functions of drug loading and temperature control release.

Owner:NANTONG ZHENGDA AGROCHEM

Carbon molecular sieve and method for manufacturing the same

InactiveUS7718570B2High porosityImprove structural regularityMolecular sieve catalystsOther chemical processesMolecular sieveStructural regularity

A method for manufacturing a carbon molecular sieve with increased microporosity; a method for manufacturing a carbon molecular sieve with increased microporosity and improved structural regularity; a carbon molecular sieve with increased microporosity; a carbon molecular sieve with increased microporosity and improved structural regularity; a catalyst for a fuel cell using the carbon molecular sieve; and a fuel cell using the catalyst are provided.

Owner:SAMSUNG SDI CO LTD

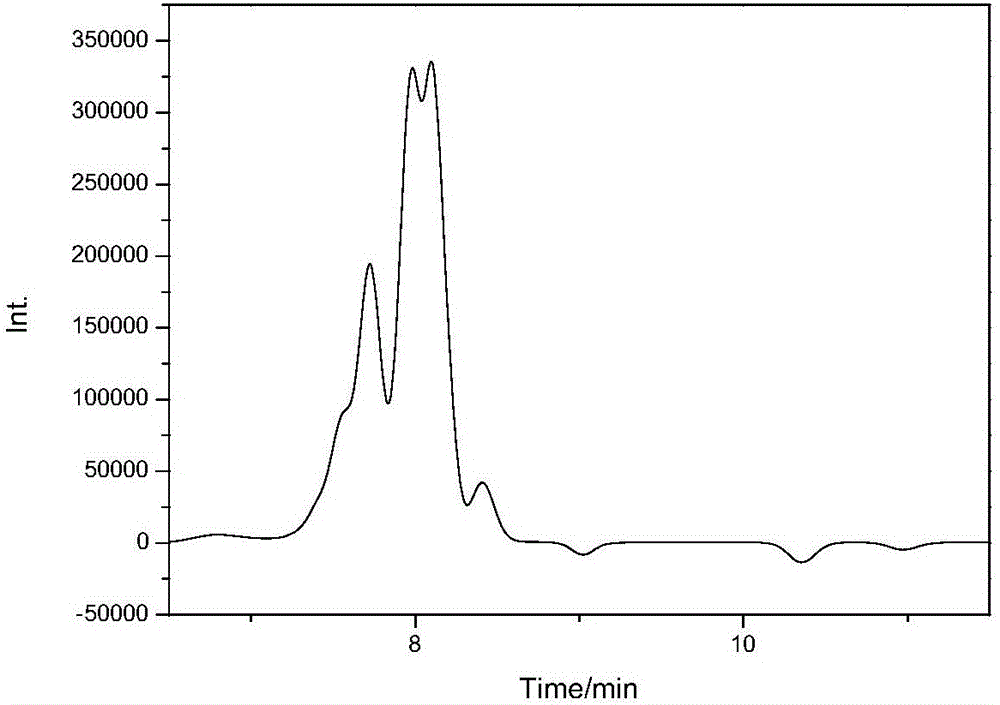

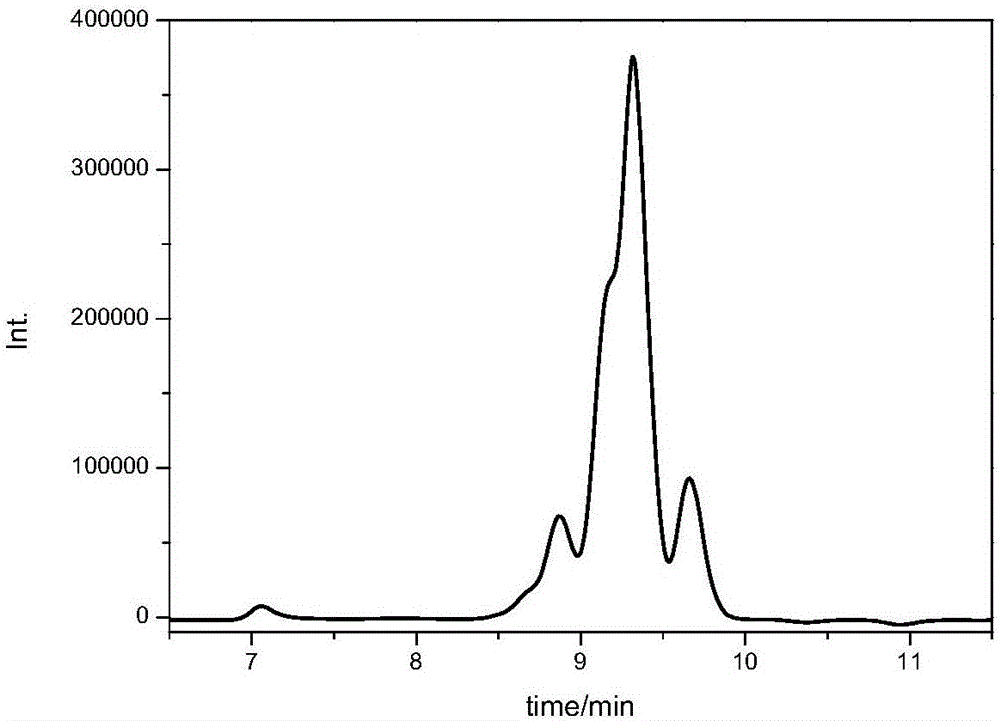

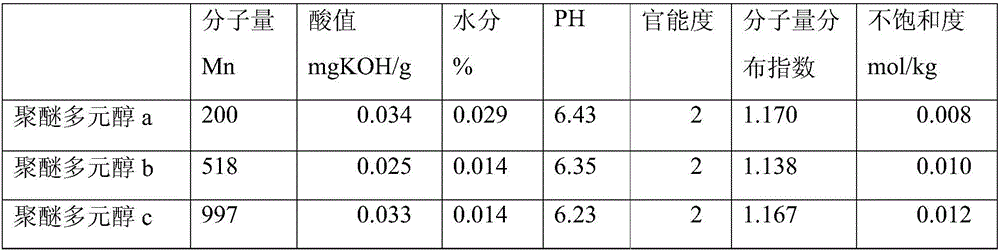

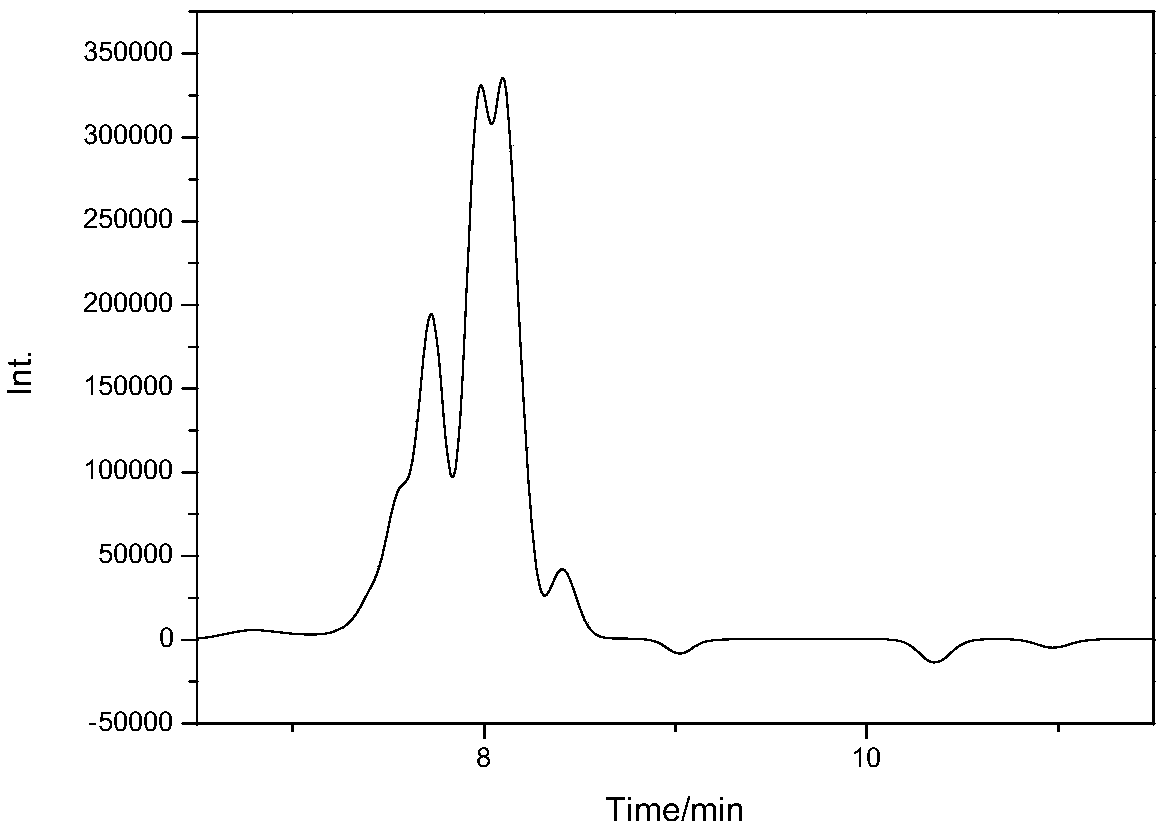

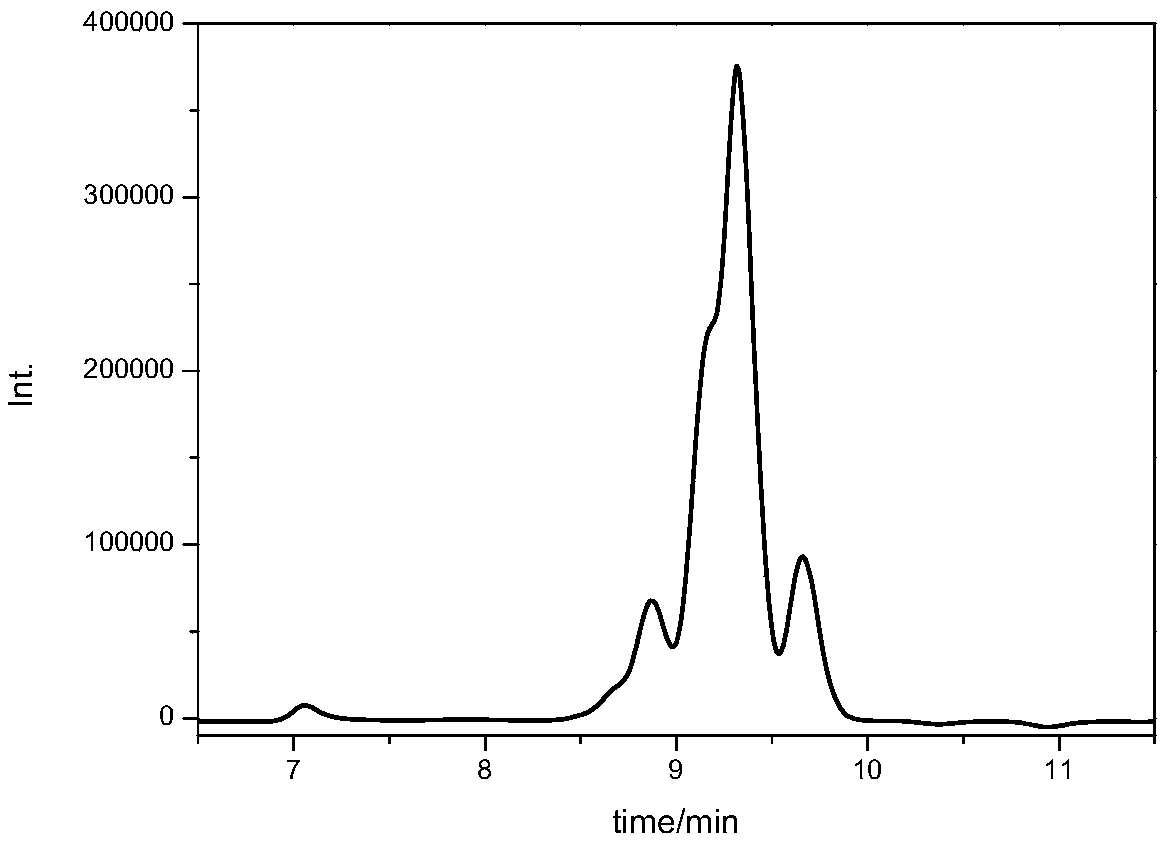

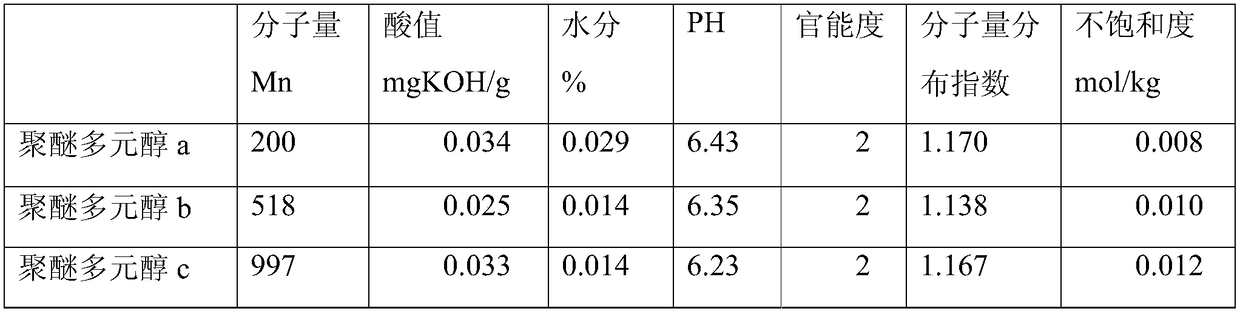

Preparation method preparation method of low-molecular-weight polyether polyol for polyetheramine

ActiveCN106242954AHigh viscosityLow melting pointEther preparation from oxiranesStructural regularityPolyol synthesis

The invention belongs to the technical field of polyether polyol synthesis and specifically relates to a preparation method of low-molecular-weight polyether polyol for polyetheramine. According to the preparation method, 2-methyl-1,3-propylene glycol, which is used as a starting agent, reacts with epoxide in the presence of an alkali metal catalyst at low temperature; and then, the reaction product is end-capped with epoxypropane at high temperature so as to obtain low-molecular-weight polyether polyol for polyetheramine. During the polymerization, 2-methyl-1,3-propylene glycol is used as the starting agent. Due to structural regularity and symmetry of 2-methyl-1,3-propylene glycol, activities at two ends are identical. During polymerization between 2-methyl-1,3-propylene glycol and the epoxide, polyether structure is more regular. During amino-capping, activities at two ends are consistent. The product has characteristics of amorphism, strong weatherability, tension resistance, strong bending resistance and the like. By the structure, polyetheramine can be endowed with characteristics of low melting point, low viscosity and good intersolubility with auxiliaries.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Method for preparing binary polyacrylonitrile-based carbon fiber protofilament

InactiveCN102605476AReduce dosageImprove structural regularityArtificial filament washing/dryingArtificial filament heat treatmentStructural regularityCarbon fibers

The invention relates to a method for preparing a binary polyacrylonitrile-based carbon fiber protofilament. The method comprises the following steps of: (1) performing copolymerization reaction on acrylonitrile and beta-ammonium itaconate for 10 to 30 hours at the temperature of between 50 and 70 DEG C by using dimethyl sulfoxide as a solvent and using azodiisobutyronitrile as an initiator, filtering, removing residual monomers, and defoaming to obtain a spinning solution; and (2) sequentially performing dry-spray wet spinning, drawing, oiling, drying densification, hot steam drawing and heat setting on the spinning solution, and thus obtaining the carbon fiber protofilament. By the method, the consumption of copolymerization monomers is reduced, and the structural regularity of polyacrylonitrile macromolecules is improved; and the prepared carbon fiber protofilament is uniform in structure, low in fineness and high in strength, and is suitable for preparing high-performance carbon fibers.

Owner:DONGHUA UNIV

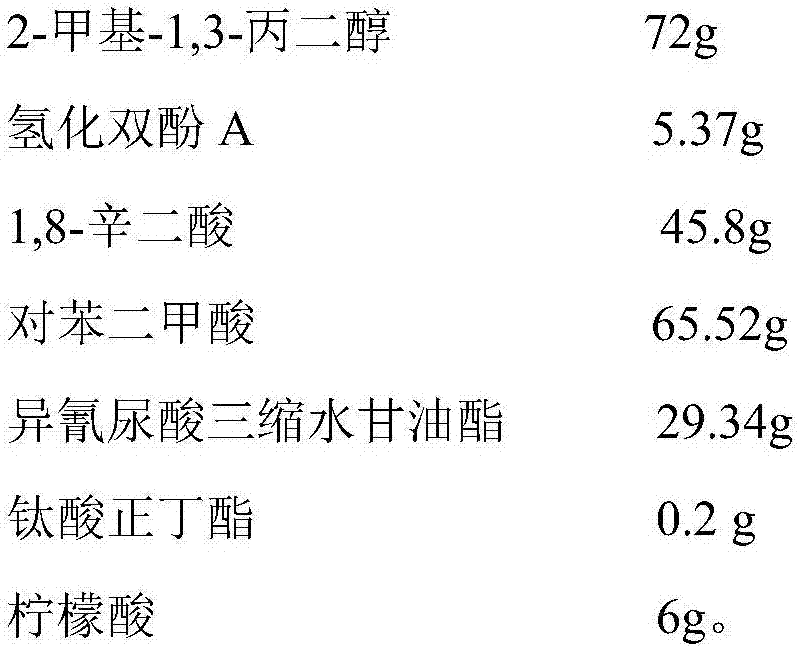

Heterocycle modified flexible hydrolysis-resistant polyester and preparation method thereof

ActiveCN107973905AReduced flexibilityFlexibility SurprisePolyester coatingsPolyesterStructural regularity

The invention discloses a heterocycle modified flexible hydrolysis-resistant polyester. The heterocycle modified flexible hydrolysis-resistant polyester has a number-average molecular weight of 3500 to 12000, a glass transition temperature of minus 5 to 45 DEG C, a melt viscosity of 2000 to 8000 mPa*s at 200 DEG C, an acid value of 10 to 40 mgKOH / g, and a hydroxyl value of 20 to 250 mgKOH / g. The heterocycle modified flexible hydrolysis-resistant polyester is prepared mainly through the following method: selecting a component A, a component B and a branching component C, carrying out an esterification condensation polymerization reaction in the presence of a catalyst, then adding a component D in the later period of the reaction, and carrying out a reaction so as to obtain a flexible hydrolysis-resistant polyester with a six-member branched island structure. The flexible hydrolysis-resistant polyester provided by the invention has a six-member branched island structure and unique structural regularity, can achieve excellent flexibility and hydrolysis resistance, and comprehensively improves comprehensive performances like solvent resistance, heat resistance, water boiling resistanceand scratch resistance. The invention also discloses a preparation method for the above-mentioned heterocycle modified flexible hydrolysis-resistant polyester.

Owner:GUANGZHOU KINTE IND

Ecological multifunctional ternary copolymerization PETG (Polyethylene Terephthalate Glycol) polyester, preparation method of polyester, and method for preparing unidirectional stretching heat-shrinkable film from polyester

ActiveCN102558517BRaw materials are cheapLow priceStructural regularityPolyethylene terephthalate glycol

The invention discloses an ecological multifunctional ternary PETG (Polyethylene Terephthalate Glycol), a preparation method of the polyester, and a method for preparing a unidirectional stretching heat-shrinkable film from the polyester. The ecological multifunctional ternary copolymerization PETG polyester is formed by ternary monomer copolymerization of terephthalic acid, neopentyl glycol and glycol, wherein the molar ratio of terephthalic acid to neopentyl glycol to glycol is 1: (0.1-0.65):(1.2-1.75). The preparation method comprises esterification reaction and polymerization, wherein the temperature of the esterification reaction is 200 DEG C to 255 DEG C, the temperature of the polymerization is 270 DEG C to 280 DEG C, and the vacuum degree of the polymerization is 0.098 MPa to 0.1 MPa. The price of raw materials of the ecological multifunctional ternary copolymerization PETG polyester is low, so that the manufacturing cost is reduced, and the structural regularity of the PETG polyester is good, so that the strength is high. The heat-shrinkable film prepared from the obtained ecological multifunctional ternary copolymerization PETG polyester according to the invention is high in strength, transparency and heat shrinkage.

Owner:河南银金达新材料股份有限公司

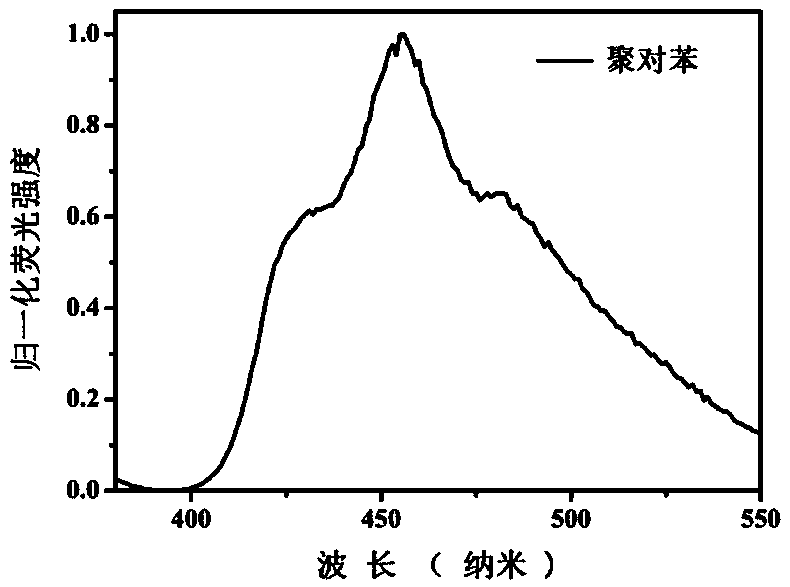

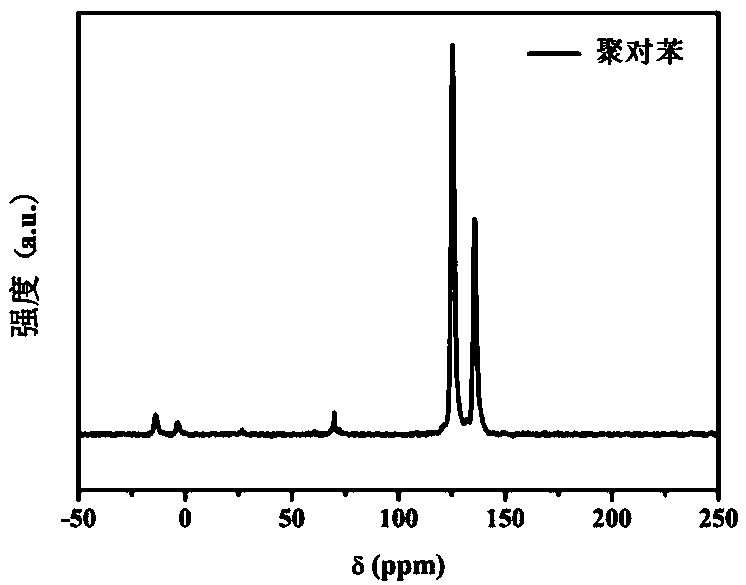

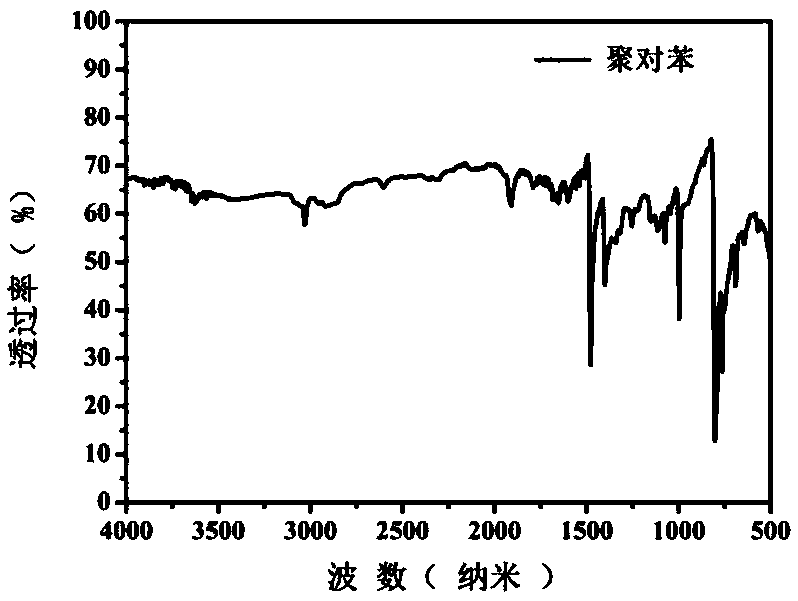

Organic conjugated polymer fluorescent material and synthesis method thereof

ActiveCN109608625ALow priceRegular structureLuminescent compositionsPolymer scienceStructural regularity

The invention relates to the technical field of organic light-emitting materials, in particular to an organic conjugated polymer fluorescent material and a synthetic method thereof. The organic conjugated polymer of the invention is at least one selected from the group consisting of polymers represented by a general formula I, and has the advantages of structural regularity, high thermal stability, high fluorescence efficiency and adjustable light-emitting range. The invention also provides an aqueous phase synthesis method for the conjugated polymer, and the method is simple, efficient, mildin conditions and inexpensive. By adjusting the ratio of different monomer components, the intramolecular and intermolecular interactions of the conjugated polymer are adjusted, or the offset and transmission of pi electrons in the polymer conjugated structure are adjusted, and thus the luminescent properties of the conjugated polymer fluorescent material is adjusted. The organic conjugated polymer fluorescent material and the synthetic method thereof have certain application prospects in the field of organic electroluminescence.

Owner:UNIV OF SCI & TECH OF CHINA

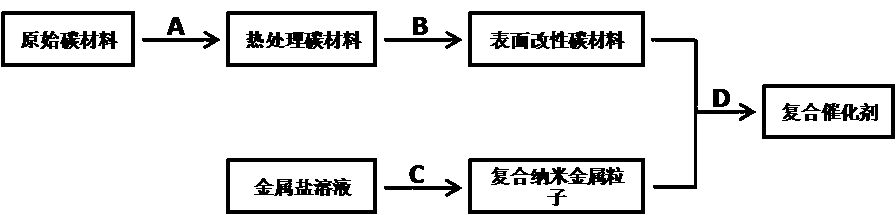

Preparation method of water treatment advanced oxidation catalyst

InactiveCN108620088AExtended service lifeImprove regularityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsStructural regularityWastewater

The invention relates to the field of wastewater treatment and discloses a preparation method of a loaded water treatment advanced oxidation catalyst. The preparation method mainly includes followingfour steps: step 1, subjecting an original carbon material to high-temperature thermal treatment to improve structural regularity thereof so as to improve integral strength and running stability of acatalyst; step 2, putting the carbon material after going through high-temperature thermal treatment into a chitosan solution with certain concentration for surface modification; step 3, applying a chemical reducing method to prepare composite metal nanoparticles; step 4, well mixing the carbon material with the composite metal nanoparticles to obtain the novel water treatment advanced oxidation catalyst, wherein the carbon material which is electronegative on the surface and the metal nanoparticles are closely combined through high molecular chitosan which is electropositive on the surface.

Owner:BEIJING NEWBIOLINK TECH DEV

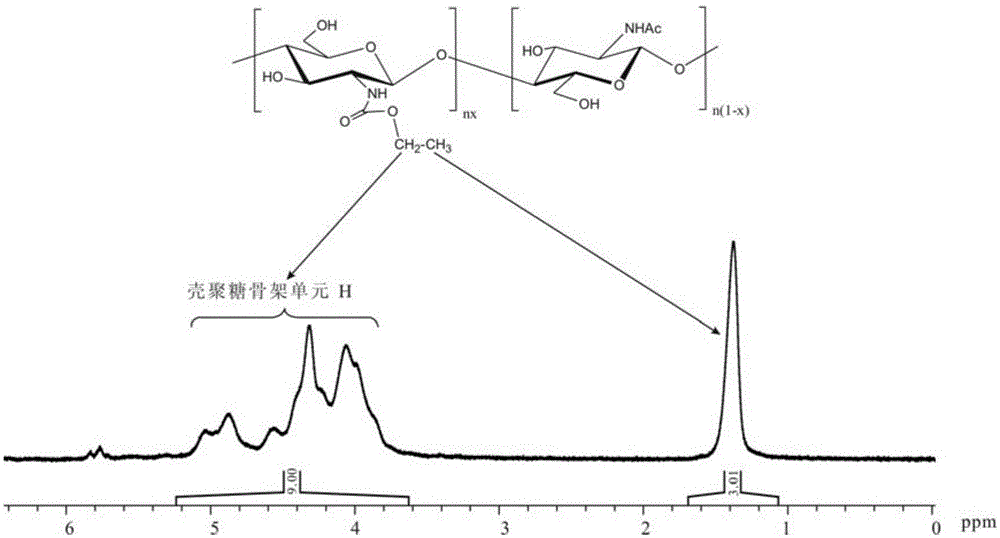

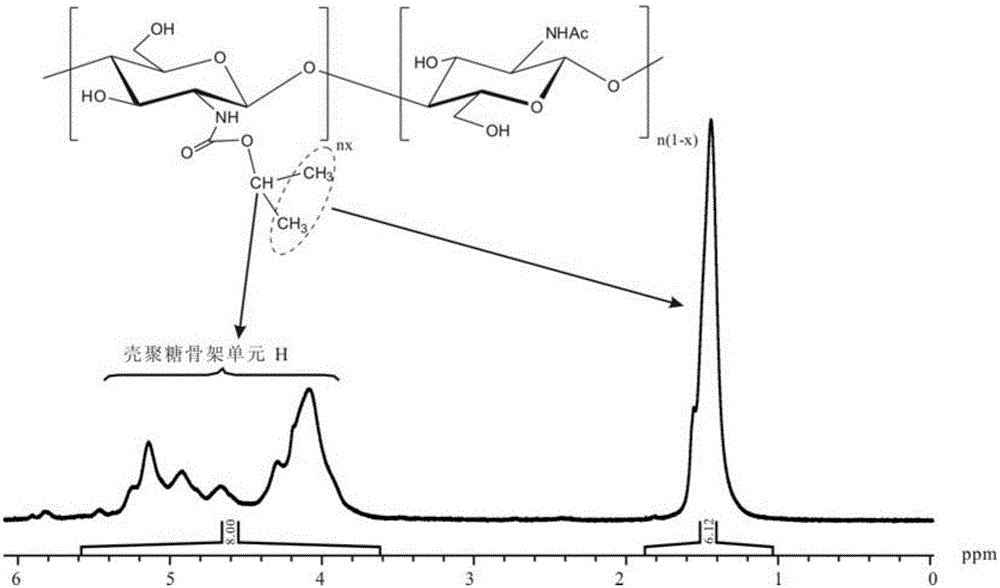

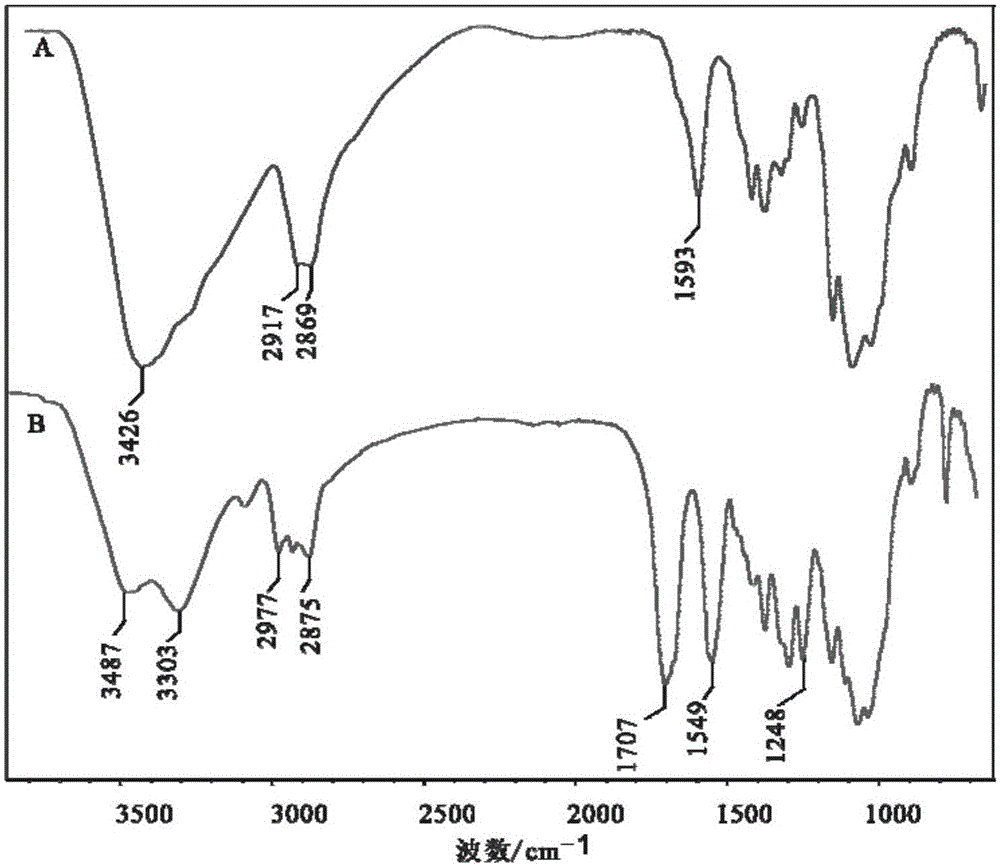

Chitosan-alkoxy formamide and preparation method thereof

InactiveCN105153327AImprove structural regularityGood chemical propertiesStructural regularityLithium chloride

The invention relates to a chitosan-alkoxy formamide and a preparation method thereof. The preparation method comprises the following steps: 1) dissolving chitosan with the deacetylation degree of 98% or above in a dilute hydrochloric acid water solution, adding excessive chloroformate and a right amount of methanol into the obtained solution, regulating the pH value of the reaction system by using tertiary amine as an acid-binding agent, and reacting to obtain partially N-acylated chitosan; and 2) dissolving the partially N-acylated chitosan in a lithium chloride N,N-dimethylacetamide solution, adding excessive chloroformate and a proper amount of methanol, regulating the pH value of the reaction system by using tertiary amine as an acid-binding agent, and reacting to generate the completely N-acylated chitosan-alkoxy formamide. The prepared material has the advantages of high structural regularity and favorable chemical or physical characteristics; and the prepared chitosan-alkoxy formamide has regular structure, and can be used as a raw material for synthesizing materials with requirements for high regularity, such as chiral parting materials and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

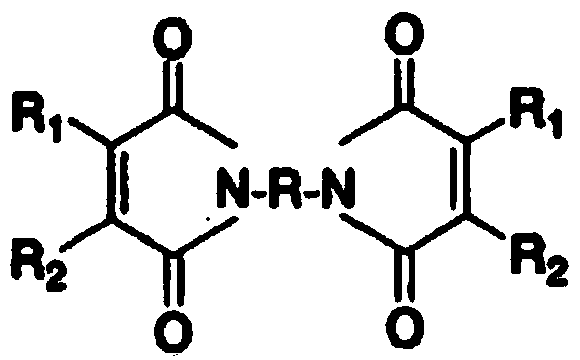

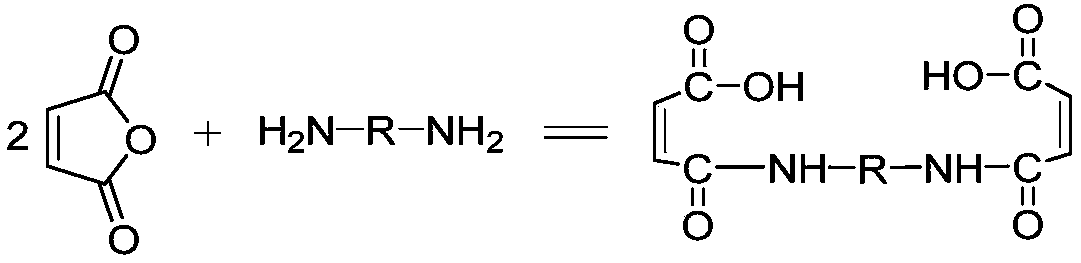

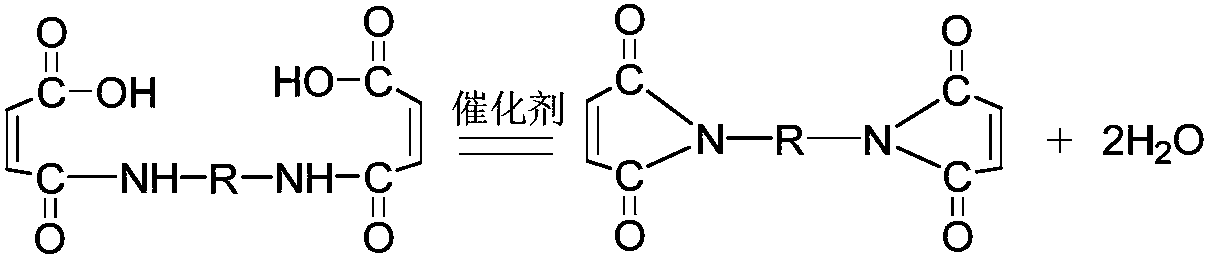

Bismaleimide eutectic mixture, preparation method and bismaleimide resin prepolymer

The invention relates to a bismaleimide eutectic mixture, a preparation method and a bismaleimide resin prepolymer. The bismaleimide eutectic mixture is prepared from maleic anhydride and diamine mixture by synthetic reaction, wherein the diamine mixture comprises two or more diamine compounds which at least comprise one aromatic diamine. Molecular structures of the diamine compounds are different, and the diamine compounds further comprise aliphatic diamine and alicyclic diamine. The melting point of the prepared bismaleimide eutectic mixture is lower than that of pure compounds, the structural regularity of the formed eutectic mixture is reduced, and the solubility of the eutectic mixture in the bismaleimide resin prepolymer is increased. The prepared bismaleimide resin prepolymer is free from precipitation along with standing time, and the service life of the bismaleimide resin prepolymer is prolonged.

Owner:陕西硕博电子材料有限公司

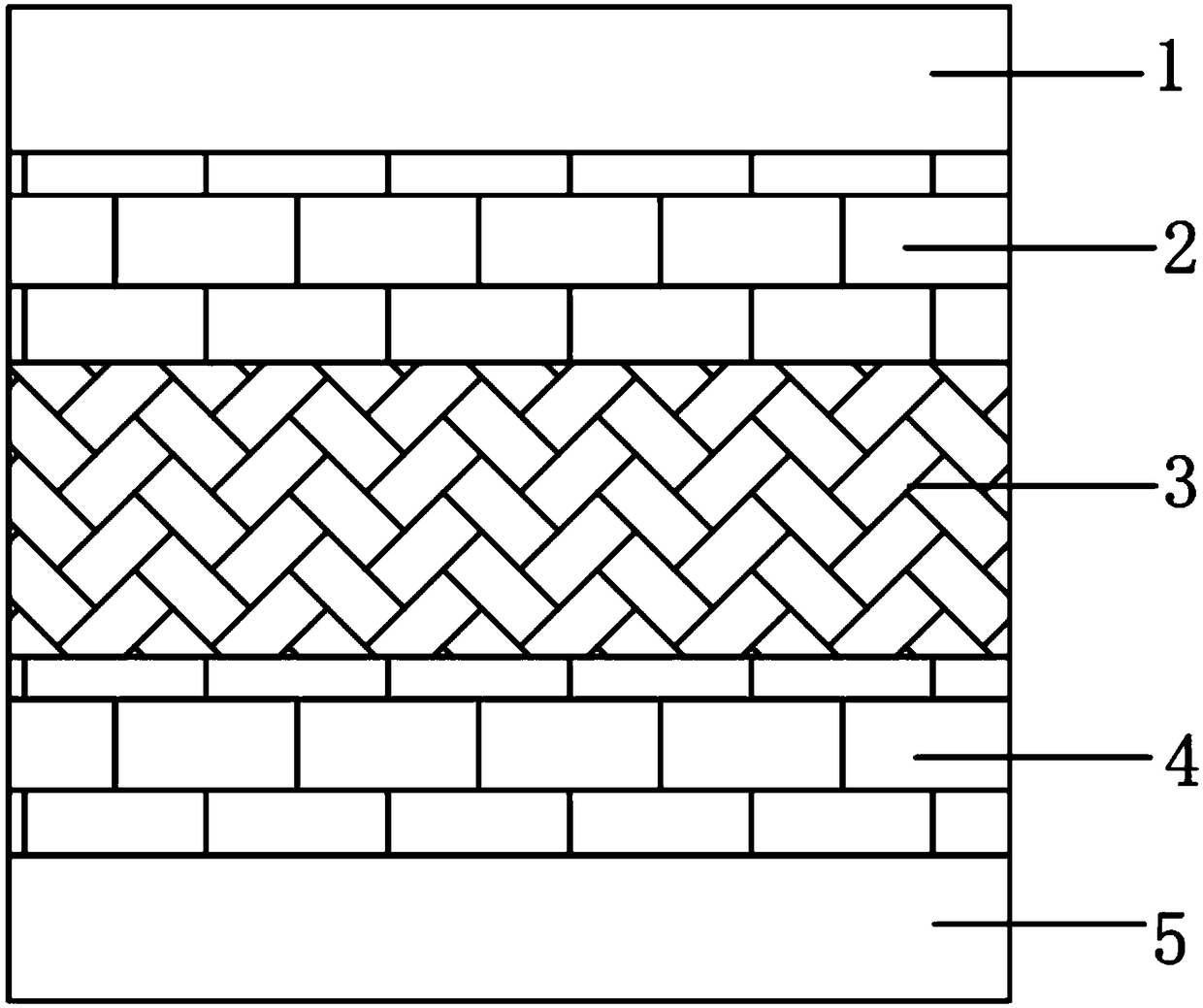

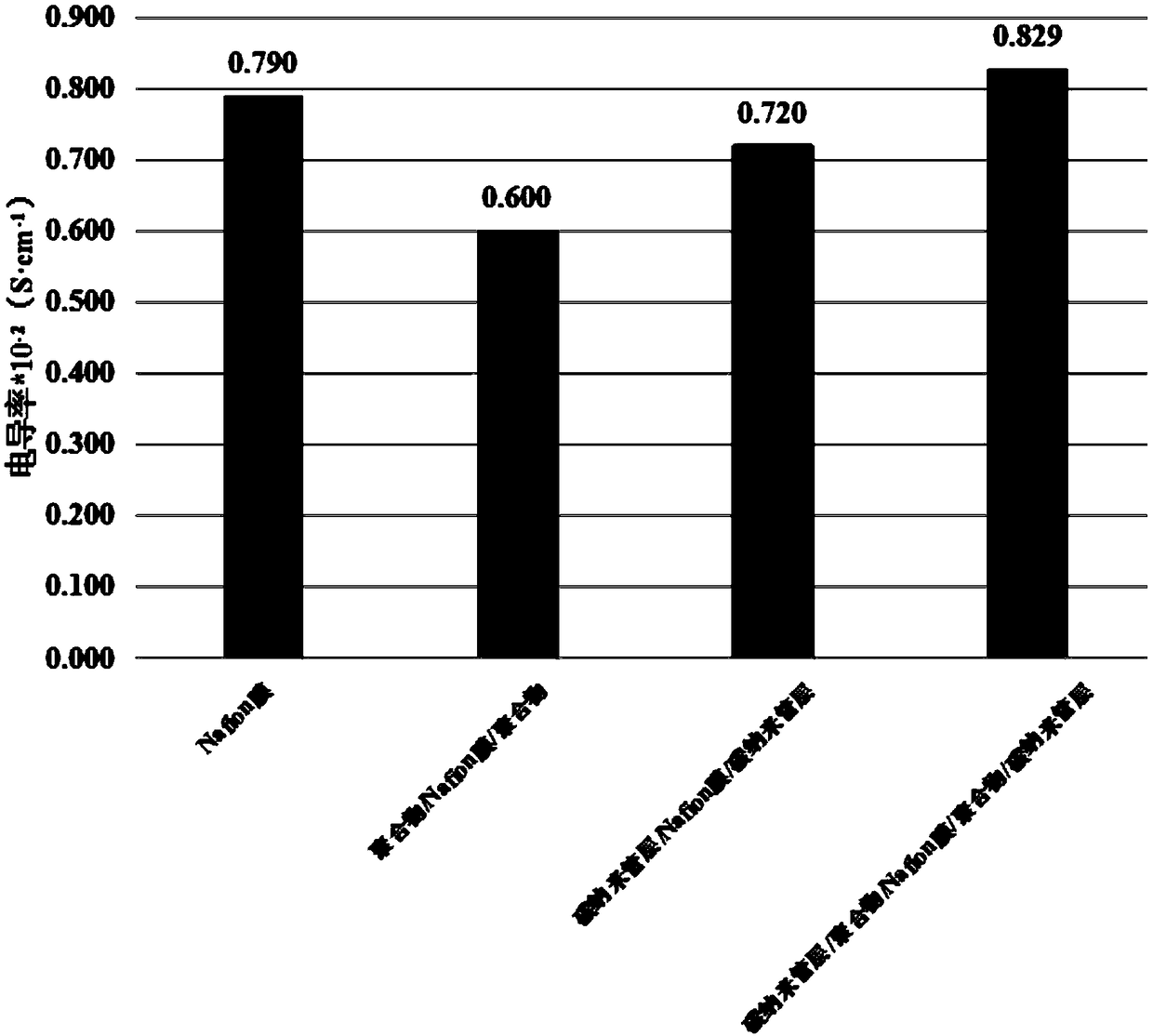

A composite proton exchange membrane for hydrogen fuel cell and a preparation method thereof

InactiveCN109193012AImprove structural regularityDimensionally stableFinal product manufactureFuel cellsStructural regularityCarbon nanotube

The invention discloses a composite proton exchange membrane for hydrogen fuel cell and a preparation method thereof. The film material is prepared by a layer-by-layer self-assembly method, wherein the Nafion film is first immersed in a polymer solution, and then immersed in a carbon nanotube dispersion solution, and a hamburger structure film of the carbon nanotube film / polymer / Nafion / polymer / carbon nanotube film is obtained by the method. The invention discloses a composite proton exchange membrane for hydrogen fuel cell and a preparation method thereof, which has high manufacturing processprecision and can be used for preparing a high-performance composite proton exchange membrane for hydrogen fuel cell, and the obtained membrane material not only has high structural regularity and good dimensional stability, but also has improved proton conductivity of the membrane.

Owner:杭州润涞科技服务有限公司

Method and apparatus for efficiently accessing both aligned and unaligned data from a memory

InactiveUS7302525B2Extension of timeGenerate efficientlyMemory adressing/allocation/relocationMicro-instruction address formationMemory addressStructural regularity

A technique for improving access times when accessing memory, such as when accessing data from cache. By a unique manipulation and usage of a specified memory address in combination with the cache's internal organization, the address range required by the requested data can be covered by one odd and one even segment of the cache, where the odd segment is always at the base address created by the summation of the source operands and set to the odd segment, and the even address is created by summation of the source operands plus an offset value equivalent to the size of the cache line. This structural regularity is used to efficiently generate both the even and odd addresses in parallel to retrieve the desired data.

Owner:INT BUSINESS MASCH CORP

Preparation method of low molecular weight polyether polyol for polyether amine

ActiveCN106242954BHigh viscosityLow melting pointEther preparation from oxiranesPolyol synthesisStructural regularity

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Phosphorus-containing flame-retardant monomer, halogen-free flame-retardant polyester containing the monomer and preparation method thereof

ActiveCN103641859BHigh in phosphorusMeet flame retardant requirementsGroup 5/15 element organic compoundsPolymer scienceStructural regularity

The invention relates to a preparation method of halogen-free flame retardant polyester phosphorus containing a phosphorus-containing flame retardant monomer. The preparation method includes: according to a mass ratio, adding 100 parts of terephthalic acid, 3.6-15.2 parts of the phosphorus-containing flame retardant monomer, 46.3-54.7 parts of ethylene glycol, 0.035-0.062 part of a catalyst and 0.008-0.015 part of a heat stabilizer into a synthesis reaction kettle, and carrying out a conventional polyester synthesis process to prepare the halogen-free flame retardant polyester with a phosphorus content of 0.8-1.5wt% and an intrinsic viscosity number of 0.63-0.69dL g<-1>. The halogen-free flame retardant polyester provided by the invention has the characteristics of high structural regularity, high degree of crystallinity, and high melting point.

Owner:JIANGSU YUXING FILM TECH

Carry-saving multiplier

InactiveCN102722351BReduce areaReduce in quantityComputation using non-contact making devicesStructural regularityGate array

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com