Method for preparing binary polyacrylonitrile-based carbon fiber protofilament

A polyacrylonitrile-based carbon fiber and acrylonitrile technology, applied in dry spinning, wet spinning, stretch spinning, etc., can solve the problems of high amount of comonomer and difficulty in controlling the regularity of polyacrylonitrile polymer structure. , to achieve the effect of improving structural regularity, small fineness, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

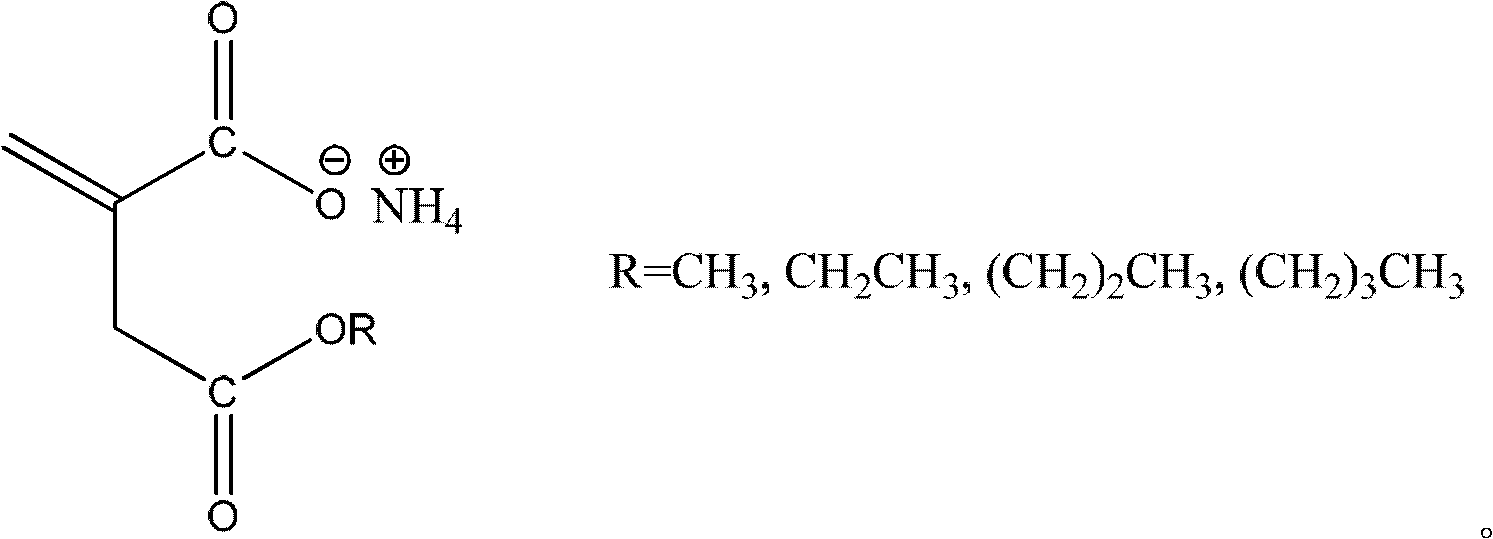

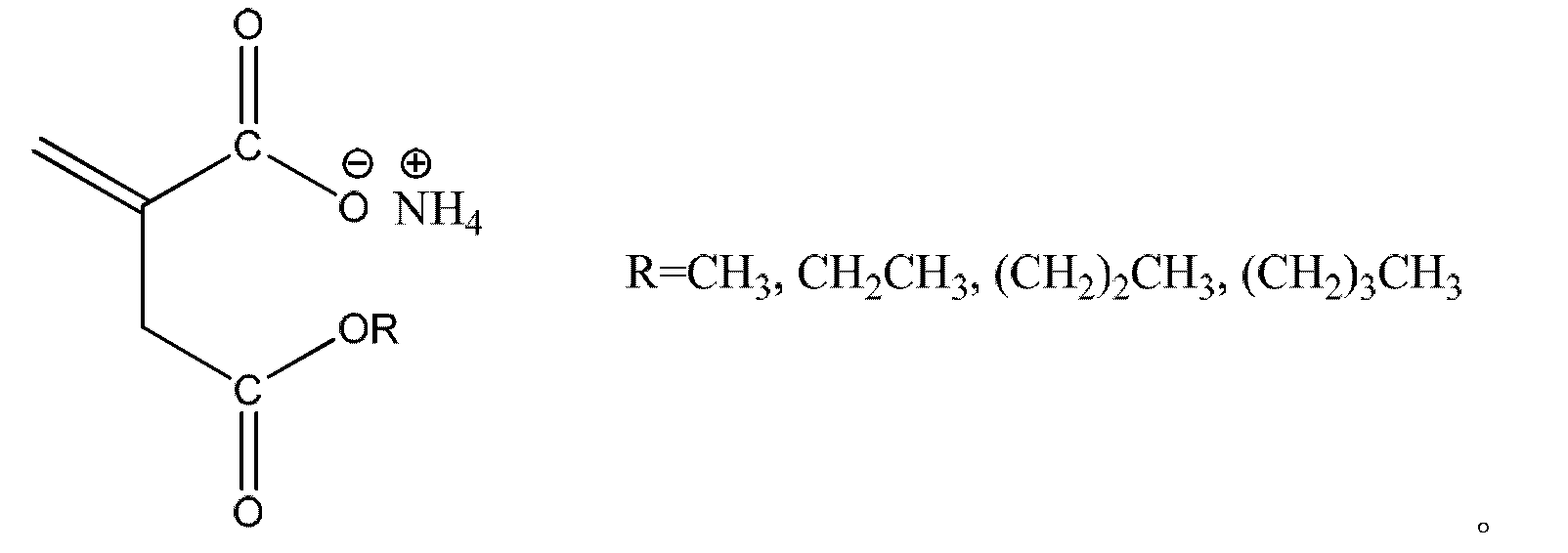

[0026] (1) Acrylonitrile and β-ammonium itaconate are mixed evenly in a mass ratio of 99:1 and then added to the reactor (the total concentration of mixed monomers is 25%), then dimethyl sulfoxide is added, and finally azobis Isobutyronitrile (accounting for 0.4% of the total mass of mixed monomers), reacted for 24 hours at 60 ° C, and the prepared polyacrylonitrile molecular weight was 1.8 × 10 5 g / mol, the molecular weight distribution is 2.64. The above-mentioned polymer solution is filtered through a filter material of 1 μm, singled out, and defoamed to obtain a spinning dope.

[0027] (2) step (1) is obtained spinning dope through dry jet wet spinning, the distance of air section is 10cm, and the temperature of air section is 10 ℃, and relative humidity is 65%, and coagulation bath is dimethyl sulfoxide and Water, wherein the content of dimethyl sulfoxide is 60wt%, the temperature of the coagulation bath is 0 ℃, and the coagulation time is 1min; 2.5 times; oiling; 150°C...

Embodiment 2

[0029] (1) Acrylonitrile and β-ammonium itaconate are mixed evenly in a mass ratio of 99:1 and then added to the reactor (the total concentration of mixed monomers is 25%), then dimethyl sulfoxide is added, and finally azobis Isobutyronitrile (accounting for 0.2% of the total mass of mixed monomers), reacted for 24 hours at 60°C, and the prepared polyacrylonitrile molecular weight was 2.1×10 5 g / mol, the molecular weight distribution is 2.78. Filter the above-mentioned polymer solution through a 0.5 μm filter material, remove the single, and defoam to obtain the spinning stock solution.

[0030] (2) step (1) is obtained spinning dope through dry jet wet spinning, the distance of air section is 5cm, and the temperature of air section is 30 ℃, and relative humidity is 50%, and coagulation bath is dimethyl sulfoxide and Water, wherein the content of dimethyl sulfoxide is 45wt%, the temperature of the coagulation bath is 15 ℃, and the coagulation time is 0.5min; Stretching 2 tim...

Embodiment 3

[0032] (1) Acrylonitrile and β-ammonium itaconate are mixed evenly in a mass ratio of 98:2 and then added to the reactor (the total concentration of mixed monomers is 25%), then dimethyl sulfoxide is added, and finally azobis Isobutyronitrile (accounting for 0.2% of the total mass of mixed monomers), reacted for 24 hours at 55°C, and the prepared polyacrylonitrile molecular weight was 1.7×105 g / mol, the molecular weight distribution is 2.84. The above-mentioned polymer solution is filtered through a filter material of 2 μm, singled out, and defoamed to obtain a spinning dope.

[0033] (2) step (1) is obtained spinning dope through dry jet wet spinning, the distance of air section is 15cm, and the temperature of air section is 20 ℃, and relative humidity is 75%, and coagulation bath is dimethyl sulfoxide and Water, wherein the content of dimethyl sulfoxide is 60wt%, the temperature of the coagulation bath is 0 ℃, and the coagulation time is 1min; Stretching 4 times; oiling; dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com